Master Sourcing Top-Quality White Leather Shoes for Global

Guide to White Leather Shoes

- Introduction: Navigating the Global Market for white leather shoes

- Understanding white leather shoes Types and Variations

- Key Industrial Applications of white leather shoes

- Strategic Material Selection Guide for white leather shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for white leather shoes

- Comprehensive Cost and Pricing Analysis for white leather shoes Sourcing

- Spotlight on Potential white leather shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for white leather shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the white leather shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of white leather shoes

- Strategic Sourcing Conclusion and Outlook for white leather shoes

Introduction: Navigating the Global Market for white leather shoes

Understanding the global significance of white leather shoes is essential for any B2B buyer aiming to succeed in today’s competitive marketplace. These footwear products are not only a fashion staple across diverse markets but also symbolize quality, versatility, and style—attributes highly valued by consumers worldwide. For buyers from Africa, South America, the Middle East, and Europe, sourcing the right white leather shoes can unlock new growth opportunities, enhance brand reputation, and meet rising consumer demands for premium, durable footwear.

This comprehensive guide is designed to equip international buyers with critical insights into every facet of the white leather shoe supply chain. From exploring various types—such as formal, casual, and luxury designs—to understanding key materials like full-grain, top-grain, and bonded leather, readers will gain clarity on what differentiates quality products. It also covers manufacturing and quality control best practices, helping buyers identify reliable suppliers and ensure consistent standards.

Additionally, the guide provides actionable intelligence on sourcing strategies, cost considerations, and market trends, tailored specifically for regions like Saudi Arabia, Thailand, and other key markets. Whether you are evaluating suppliers, negotiating prices, or navigating import regulations, this resource empowers you to make informed, strategic decisions. By leveraging this knowledge, B2B buyers can optimize their supply chains, mitigate risks, and capitalize on the growing demand for white leather footwear globally.

Understanding white leather shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Oxford | Closed lacing system, sleek design, minimal embellishments | Formal wear, corporate uniforms | Pros: Elegant, timeless appeal; Cons: Higher manufacturing costs |

| Derby (Blucher) | Open lacing system, more versatile and relaxed look | Business casual, retail, hospitality | Pros: Easier to fit, versatile; Cons: Slightly less formal than Oxfords |

| Loafer (Penny, Leather Slip-On) | Slip-on style, often with minimal stitching, decorative features | Casual business settings, retail, hospitality | Pros: Easy to wear, comfortable; Cons: Less formal, limited style variety |

| Brogue & Wingtip | Decorative perforations, wingtip design, often with contrasting details | Fashion-forward, semi-formal occasions | Pros: Stylish, distinctive; Cons: Less formal, may be less versatile |

| Chelsea Boots | Elastic side panels, ankle-high, sleek silhouette | Formal events, fashion retail, corporate uniforms | Pros: Stylish, easy to slip on; Cons: Limited ventilation, less breathable |

Classic Oxford

The Classic Oxford is characterized by its closed lacing system, giving it a smooth, streamlined appearance. Typically crafted from high-quality white leather, these shoes are ideal for formal settings and corporate uniforms. B2B buyers should prioritize sourcing Oxfords with durable leather and sturdy soles to withstand daily wear, especially in regions with varied climates. They are often priced higher due to craftsmanship but offer a premium look. For buyers, ensuring consistent leather quality and reliable supply chains is critical for maintaining inventory levels and meeting client expectations.

Derby (Blucher)

Derby shoes feature an open lacing system, making them more adaptable to different foot shapes and offering enhanced comfort. Their versatile design suits both formal and casual business environments, making them a popular choice across sectors like retail and hospitality. B2B buyers should focus on sourcing from manufacturers that provide consistent leather grades and flexible sizing options. Cost considerations are important, as Derby shoes can be produced with varying levels of detailing, affecting pricing. Their adaptability makes them suitable for diverse markets, including regions with fluctuating fashion trends.

Loafer (Penny, Leather Slip-On)

Loafers are slip-on shoes distinguished by minimal stitching and often decorative elements like penny straps. They are favored for their comfort and ease of wear, making them suitable for casual business settings and retail environments. For international buyers, especially in regions like the Middle East and Southeast Asia, sourcing loafers with high-quality, breathable leather is essential to meet customer expectations for comfort and durability. Cost-effective manufacturing and versatile styling options can enhance market appeal, but buyers should verify leather authenticity and finishing quality to avoid quality issues.

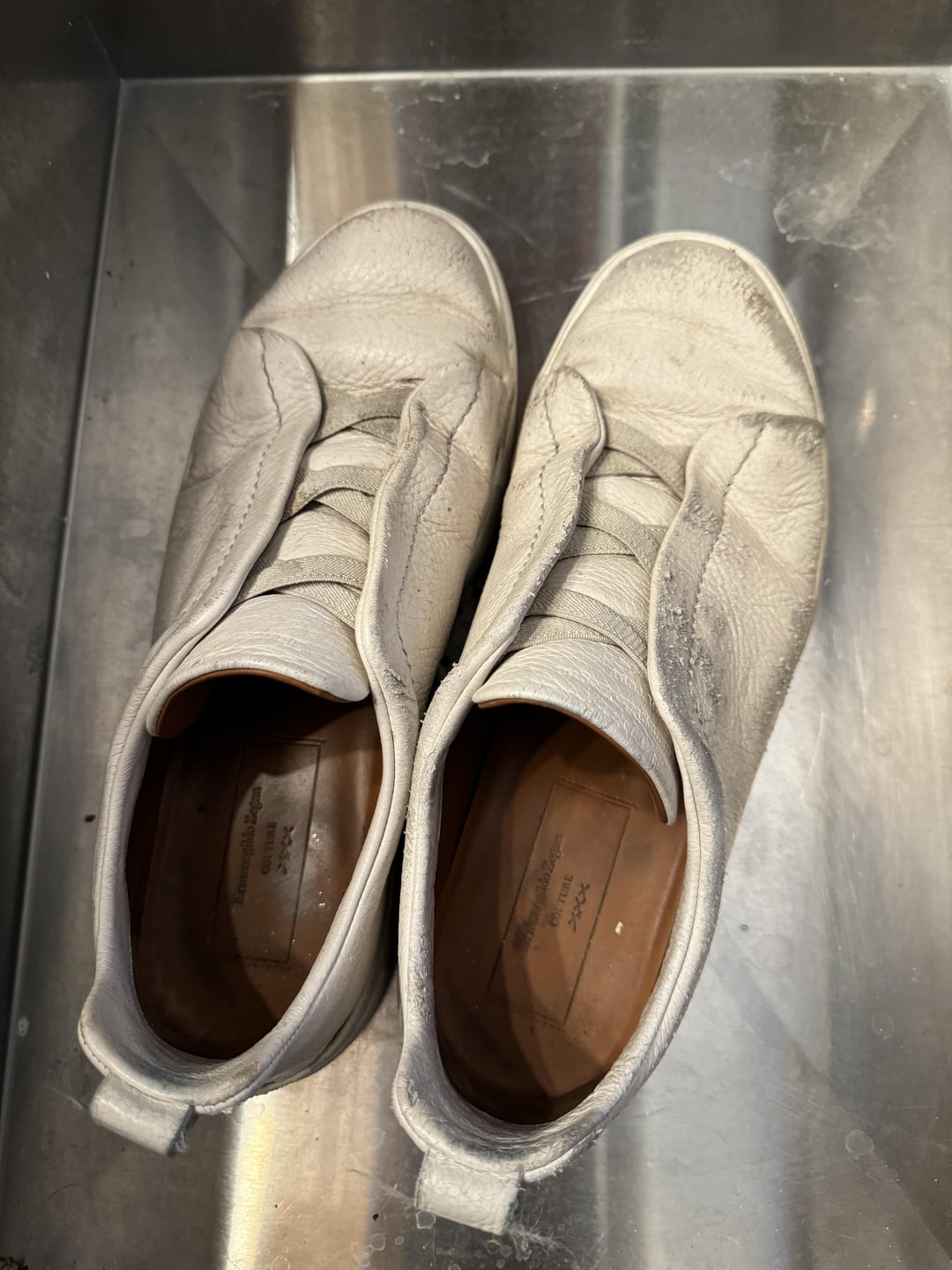

Illustrative Image (Source: Google Search)

Brogue & Wingtip

Brogues and Wingtips are noted for their decorative perforations and contrasting leather details, offering a stylish, semi-formal aesthetic. These shoes appeal to fashion-conscious markets and are suitable for semi-formal occasions. B2B buyers should consider sourcing from suppliers who can provide consistent perforation quality and leather finishing. While they tend to be slightly more expensive, their distinctive look can command premium pricing in fashion-forward regions like Europe and South America. Ensuring authenticity and detailed craftsmanship is key to maintaining product value.

Chelsea Boots

Chelsea boots feature elastic side panels, a sleek silhouette, and ankle-high design, making them both stylish and functional. They are increasingly popular in formal and fashion retail sectors across Europe and the Middle East. For buyers, sourcing from manufacturers with reliable elastic and leather quality ensures durability and comfort. They are easy to slip on, reducing labor costs for fitting, but buyers should evaluate leather thickness and sole construction to guarantee longevity, especially in markets with rougher terrain or climate variations.

This detailed overview of white leather shoe types provides B2B buyers with critical insights into product characteristics, market suitability, and purchasing considerations. Understanding these variations enables strategic sourcing aligned with regional preferences, price points, and end-user demands.

Key Industrial Applications of white leather shoes

| Industry/Sector | Specific Application of white leather shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare & Medical | Medical staff footwear, including nurses and doctors’ shoes | Ensures hygiene, easy cleaning, and professional appearance; reduces contamination risk | Must meet hygiene standards, antimicrobial properties, and comfort requirements |

| Hospitality & Service | Uniform footwear for hotel staff, waiters, and service personnel | Projects a clean, professional image; enhances customer trust and satisfaction | Durability, slip resistance, and ease of maintenance are critical factors |

| Corporate & Business | Formal office wear for executives and employees | Conveys professionalism and brand consistency; supports corporate identity | High-quality leather, consistent color, and comfort for long wear are essential |

| Fashion & Retail | Wholesale distribution to fashion brands and retail outlets | Offers versatile, trendy footwear options; supports seasonal collections | Consistency in color, finish, and supply chain reliability are key considerations |

| Industrial & Light Manufacturing | Uniforms for workers in light manufacturing environments | Provides a neat appearance, safety, and comfort; easy to clean and maintain | Material durability, safety standards, and cost-effectiveness are priorities |

Healthcare & Medical

White leather shoes are extensively used in healthcare settings, especially by medical staff such as nurses, doctors, and technicians. These shoes provide a hygienic barrier, are easy to disinfect, and help maintain a sterile environment, which is crucial for patient safety. International B2B buyers from regions like the Middle East and Africa should prioritize sourcing shoes with antimicrobial treatments and compliance with medical safety standards (e.g., ASTM or ISO certifications). The shoes must also offer comfort for long shifts, slip resistance, and durability to withstand frequent cleaning.

Hospitality & Service

In the hospitality industry, white leather shoes are a staple for hotel staff, waiters, and service personnel. They project a clean, professional image that enhances guest confidence and satisfaction. For buyers from Europe or Southeast Asia, sourcing shoes with slip-resistant soles, high-quality leather finishes, and easy maintenance is vital. These features ensure longevity and safety in high-traffic environments. Additionally, sourcing from suppliers who can provide consistent quality and supply chain reliability helps maintain operational standards.

Corporate & Business

White leather shoes serve as a key component of formal business attire across many regions, including South America and Europe. They support brand image and professionalism, especially in sectors like finance, consulting, and corporate services. B2B buyers should focus on sourcing premium-grade leather that offers a polished appearance, comfort for prolonged wear, and consistent color matching. Suppliers capable of providing customization options and bulk discounts can enhance value and streamline procurement processes.

Fashion & Retail

The fashion industry relies heavily on white leather shoes for seasonal collections and wholesale distribution. These shoes are versatile, aligning with current trends, and appeal to a broad consumer base. International buyers from Thailand, Europe, and Latin America should seek suppliers with strong quality control, consistent color and finish, and the ability to meet large volume demands. Reliable sourcing ensures timely delivery, supporting seasonal launches and retail inventory needs.

Industrial & Light Manufacturing

White leather shoes are increasingly used as uniforms for workers in light manufacturing and assembly lines, especially in regions like Africa and the Middle East. These shoes offer a neat appearance, safety, and comfort, making them suitable for environments where workers need to move freely and maintain hygiene standards. Buyers should prioritize sourcing durable, cost-effective shoes that meet safety standards (e.g., slip resistance, puncture resistance) and can withstand frequent cleaning, ensuring operational efficiency and worker safety.

Strategic Material Selection Guide for white leather shoes

Material Analysis for White Leather Shoes

Selecting the appropriate materials for white leather shoes is crucial for ensuring product quality, durability, and compliance with international standards. Different materials offer distinct advantages and limitations that influence manufacturing processes, costs, and end-user satisfaction. Below is a detailed analysis of three commonly used materials: genuine leather, synthetic leather, and coated fabrics, with specific insights relevant to international B2B buyers from Africa, South America, the Middle East, and Europe.

Genuine Leather

Key Properties:

Genuine leather, typically derived from bovine, sheep, or goat hides, offers excellent breathability, flexibility, and a premium aesthetic. It naturally conforms to foot shape over time and is highly durable if properly maintained. Leather’s resistance to temperature fluctuations makes it suitable for diverse climates.

Pros & Cons:

– Pros: High durability, premium look and feel, excellent aging characteristics, and good breathability.

– Cons: Higher manufacturing complexity, cost, and susceptibility to water damage if untreated. Leather production also involves environmental considerations, which may impact compliance with certain standards.

Impact on Application:

Leather’s natural properties make it suitable for high-end fashion shoes, but it requires proper finishing to resist moisture and stains, especially in humid or rainy environments common in tropical regions.

International Considerations:

Buyers from Africa and South America should verify that leather suppliers comply with local and international environmental standards (e.g., REACH, LWG certification). In Europe and the Middle East, adherence to strict chemical use regulations (e.g., EU REACH) is essential. Additionally, sourcing from countries with sustainable practices can enhance brand reputation.

Synthetic Leather (Polyurethane or PVC)

Key Properties:

Synthetic leather mimics the appearance of genuine leather but is manufactured using polymer coatings on fabric or plastic bases. It offers consistent color and texture, with lower production costs and easier manufacturing processes.

Pros & Cons:

– Pros: Cost-effective, lightweight, water-resistant, and easy to clean. It also allows for a wide range of colors and finishes.

– Cons: Generally less durable than genuine leather, prone to cracking and peeling over time, and less breathable, which can affect comfort.

Impact on Application:

Ideal for mass-produced, affordable white shoes, especially in markets where cost is a primary concern. However, in humid or hot climates (e.g., Middle East, Southeast Asia), breathability issues may impact comfort.

International Considerations:

Buyers should ensure that synthetic materials meet safety standards (e.g., ASTM D4236 for toxicity). In regions with strict import regulations, suppliers should provide certifications confirming the absence of harmful chemicals. Additionally, some markets prefer eco-friendly or biodegradable synthetics, which can be a competitive advantage.

Coated Fabrics (e.g., Canvas with PU Coating)

Key Properties:

Coated fabrics combine textile base materials with polymer coatings to improve water resistance and durability. They are often used in casual or fashion-oriented white shoes.

Pros & Cons:

– Pros: Lightweight, flexible, and relatively low-cost. Coatings provide water and stain resistance, suitable for outdoor use.

– Cons: Less abrasion-resistant than leather, can be prone to cracking or peeling if the coating deteriorates, and may lack the premium feel of genuine leather.

Impact on Application:

Suitable for casual or fashion-oriented white shoes in markets where affordability and weather resistance are priorities. Not ideal for heavy-duty or long-term use.

International Considerations:

Buyers should confirm coating safety and compliance with local chemical regulations. In markets like Europe, adherence to REACH standards is vital. For regions with high humidity, selecting coated fabrics with durable coatings can extend product lifespan.

Summary Table

| Material | Typical Use Case for white leather shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | Premium dress shoes, formal footwear | High durability, natural breathability, premium aesthetic | Higher cost, manufacturing complexity, environmental concerns | High |

| Synthetic Leather | Mass-market casual shoes, affordable fashion footwear | Cost-effective, water-resistant, lightweight | Less durable, less breathable, potential cracking over time | Low |

| Coated Fabrics | Casual and outdoor shoes, fashion sneakers | Lightweight, water-resistant, flexible | Less abrasion-resistant, coating deterioration possible | Low to Med |

This comprehensive analysis helps B2B buyers from diverse regions understand the trade-offs involved in material selection. Considering climate, regulatory compliance, cost sensitivity, and end-use application ensures optimal material choices aligned with market demands and sustainability goals.

In-depth Look: Manufacturing Processes and Quality Assurance for white leather shoes

Manufacturing Processes for White Leather Shoes

The production of white leather shoes involves a series of meticulously coordinated stages, each critical to ensuring high quality, durability, and aesthetic appeal. For international B2B buyers, understanding these processes enables better supplier evaluation and quality assurance.

Material Preparation

The journey begins with sourcing premium leather, typically full-grain or corrected-grain, selected for its softness, strength, and ability to accept finishes. Suppliers often process raw hides through tanning, which can be chrome or vegetable-based, depending on environmental standards and market demands. The leather is then cut into patterns, often using automated cutting machines to ensure precision and reduce waste. White leather shoes demand careful handling during this phase to prevent staining or discoloration, especially since the color accentuates any imperfections.

Forming and Component Manufacturing

The cut leather pieces undergo shaping through lasting and molding techniques. For uppers, stitching and bonding are performed, often utilizing advanced sewing machines that ensure consistent seam strength and appearance. Components such as insoles, outsoles, and linings are manufactured separately, with attention to bonding strength and material compatibility. Adhesives used must meet international safety standards to prevent off-gassing or VOC emissions, especially for markets with strict environmental regulations.

Assembly

During assembly, the upper parts are attached to the sole unit via cementing, stitching, or a combination of both. This phase requires precision to maintain symmetry and avoid misalignments, which could compromise comfort or aesthetics. Modern assembly lines employ automated machinery for stitching and bonding, but skilled craftsmanship remains vital for finishing details. For white shoes, particular attention is paid to avoid color transfer or staining during assembly, necessitating strict process controls.

Finishing

The final stage involves polishing, coloring, and applying protective coatings. White leather shoes often undergo multiple finishing steps: surface cleaning, applying a white dye or paint, and sealing with water-resistant coatings. Surface uniformity is critical, so quality checks are performed to detect discolorations, blemishes, or surface irregularities. The shoes are then subjected to quality inspections before packaging, ensuring they meet aesthetic and functional standards.

Quality Assurance and Industry Standards

Robust quality assurance (QA) protocols are fundamental to producing consistent, high-quality white leather shoes. International B2B buyers should prioritize suppliers that adhere to recognized standards and implement comprehensive QC procedures.

International Standards and Certifications

- ISO 9001: The cornerstone of quality management, ISO 9001 certification indicates a supplier’s commitment to consistent process quality, customer satisfaction, and continuous improvement.

- ISO 14001: Environmental management standard, particularly relevant for suppliers using environmentally friendly tanning and finishing processes.

- CE Marking: For shoes sold within the European Economic Area, indicating compliance with safety, health, and environmental requirements.

- Other Industry Certifications: API (American Petroleum Institute) standards may be relevant for components like adhesives or coatings used in manufacturing.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Raw materials like leather, adhesives, and components are inspected upon arrival for defects, color consistency, and compliance with specifications.

- In-Process Quality Control (IPQC): During manufacturing, checkpoints ensure each stage (cutting, stitching, bonding, finishing) meets quality criteria. Techniques include dimensional checks, seam strength testing, and surface inspections.

- Final Quality Control (FQC): Completed shoes undergo rigorous testing for visual defects, fit, and durability. This includes visual inspections, color uniformity checks, and functional tests such as bend and wear tests.

Illustrative Image (Source: Google Search)

Testing Methods

- Visual Inspection: Detects surface blemishes, discolorations, and stitching defects.

- Color Fastness Tests: Ensures that white leather maintains its color despite exposure to light, moisture, or friction.

- Durability Tests: Includes flexing, abrasion, and sole adhesion tests to simulate real-world wear.

- Chemical Tests: Checks for residual chemicals, VOC emissions, and compliance with environmental standards.

How B2B Buyers Can Verify Supplier QC

Effective verification methods are vital for international buyers to mitigate risks and ensure supplier reliability.

- Supplier Audits: Conduct on-site audits focusing on manufacturing processes, QC procedures, and environmental compliance. Buyers from Africa, South America, and the Middle East should prioritize suppliers with proven track records and certifications relevant to their markets.

- Inspection Reports: Request detailed third-party inspection reports, ideally from accredited agencies like SGS, Intertek, or Bureau Veritas. These reports should cover raw material quality, process compliance, and final product testing.

- Sample Testing: Before bulk orders, perform independent testing on samples to verify material properties, colorfastness, and durability against specified standards.

- Certifications and Documentation: Verify authenticity of ISO certifications and compliance certificates. Cross-check supplier declarations with test reports for consistency.

- Ongoing Quality Monitoring: Establish a periodic review system, including spot checks and third-party audits, especially when engaging new suppliers or expanding product ranges.

Special Considerations for International B2B Buyers

Different regions impose varying standards and expectations. Buyers from Europe, such as Saudi Arabia and Thailand, often require strict adherence to environmental and safety standards, including REACH compliance and eco-labels. Suppliers targeting these markets should have relevant certifications and transparent documentation.

Buyers from Africa and South America should focus on suppliers with proven capacity to meet volume demands and demonstrate flexibility in customization. For the Middle East, durability and heat resistance are critical, so verifying testing related to thermal stability and surface finish longevity is essential.

In all cases, establishing clear quality specifications, requesting comprehensive documentation, and maintaining open communication channels are key to building reliable supply chains. Collaborating with suppliers who demonstrate transparency, possess relevant certifications, and participate in continuous improvement initiatives will ensure high-quality white leather shoes tailored to diverse market needs.

Comprehensive Cost and Pricing Analysis for white leather shoes Sourcing

Cost Structure Breakdown for White Leather Shoes

Understanding the comprehensive cost structure is essential for making informed sourcing decisions. The primary components include:

- Materials: High-quality genuine leather, especially full-grain or top-grain, constitutes the bulk of material costs. Leather prices can fluctuate based on quality, source region, and grade. Additional materials like soles, laces, and linings add to the total material expenses.

- Labor: Manufacturing labor costs vary significantly by region. Countries like Vietnam, China, and India typically offer lower labor rates, whereas European suppliers may charge premium wages due to stricter labor laws and higher living costs.

- Manufacturing Overhead: Factory expenses such as machinery, utilities, and maintenance influence overall costs. Advanced production facilities with automation tend to have higher upfront costs but can reduce per-unit expenses over large volumes.

- Tooling & Equipment: Initial investment in molds, cutting dies, and specialized machinery can be substantial but are amortized over large production runs. Customization or design complexity increases tooling costs.

- Quality Control (QC): Rigorous QC processes are vital for consistent product quality. Costs include inspection personnel, testing equipment, and certification processes, especially if aiming for certifications like ISO or REACH.

- Logistics & Shipping: Freight costs depend on shipment volume, destination, and mode (sea, air, land). For Africa, South America, and the Middle East, sea freight is generally more economical but slower, whereas air freight provides quicker delivery at a premium.

- Margins & Markup: Suppliers add margins to cover risks, currency fluctuations, and profit. Typical margins range from 10% to 30%, depending on the supplier’s market position and negotiation outcomes.

Key Factors Influencing Pricing

Several variables directly impact the final price:

- Order Volume & MOQ: Larger orders usually lead to lower unit costs due to economies of scale. Minimum order quantities (MOQs) can range from 500 to 5,000 pairs, influencing overall pricing.

- Specifications & Customization: Customized designs, colors, and branding increase production complexity and cost. Standard white leather shoes with minimal customization tend to be more cost-effective.

- Material Quality & Certifications: Higher-grade leather and eco-friendly certifications (e.g., vegetable-tanned leather, cruelty-free) often command premium prices.

- Supplier Location & Capabilities: European manufacturers may charge more but often offer higher quality assurance and compliance standards. Asian suppliers typically provide competitive pricing with flexible production capabilities.

- Incoterms & Logistics Terms: The choice of Incoterms (FOB, CIF, DDP) affects who bears shipping and insurance costs, impacting the total landed cost for the buyer.

Strategic Tips for International B2B Buyers

- Negotiate for Volume Discounts: Leverage your order size to negotiate better unit prices, especially when committing to long-term or large-volume contracts.

- Focus on Total Cost of Ownership (TCO): Consider all costs—material, manufacturing, shipping, duties, and post-sales support—rather than just unit price.

- Understand Pricing Nuances: Be aware that suppliers may offer attractive FOB prices but load costs into freight or customs duties, impacting total landed costs.

- Leverage Multiple Suppliers: Diversify sourcing to mitigate risks related to supply chain disruptions, currency fluctuations, or quality issues.

- Factor in Customs & Duties: Import taxes vary by country; for example, European Union countries often have higher tariffs compared to Southeast Asian markets. Engage customs brokers early to estimate these costs accurately.

- Evaluate Lead Times & Flexibility: Suppliers with shorter lead times and flexible production can reduce inventory costs and respond swiftly to market changes.

Price Indicators & Disclaimers

Indicative FOB prices for standard white leather shoes can range from $8 to $15 per pair, depending on volume, quality, and sourcing region. For premium or customized options, prices may increase to $20 or more per pair. These figures serve as a baseline—actual prices fluctuate with market dynamics, exchange rates, and supplier negotiations.

Disclaimer: Prices are indicative and subject to change based on market conditions, currency fluctuations, and specific order requirements. Buyers should conduct thorough due diligence and request detailed quotes tailored to their exact specifications before committing.

Spotlight on Potential white leather shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for white leather shoes.)*

Essential Technical Properties and Trade Terminology for white leather shoes

Critical Technical Properties

1. Material Grade and Leather Quality

The quality of leather used in white shoes directly impacts durability, appearance, and customer satisfaction. High-grade full-grain leather is preferred for premium products, offering superior strength and aesthetic appeal. B2B buyers should specify the leather’s origin, tanning process, and certification (e.g., ISO, REACH compliance) to ensure consistent quality across batches.

2. Tolerance Levels and Dimensional Accuracy

Tolerance refers to the permissible variation in measurements such as length, width, and height of shoe components. Tight tolerances (e.g., ±1mm) ensure consistency in sizing, reducing returns and customer complaints. For large orders, clear specifications on tolerances are essential for quality control and minimizing discrepancies during manufacturing.

3. Stitching and Finish Quality

The seam strength and overall finish influence durability and aesthetic appeal. Industry standards specify double-stitched seams and smooth finishing for premium shoes. Suppliers should provide sample standards and inspection reports to verify that stitching meets durability and visual quality expectations.

4. Sole Compatibility and Attachment

The method of attaching the sole—whether cemented, stitched, or molded—affects longevity and comfort. Compatibility with various sole materials (rubber, leather, synthetic) should be confirmed, especially for products intended for different climates or usage scenarios. Clear technical specifications aid in evaluating supplier capability.

5. Colorfastness and Surface Treatment

White leather shoes must maintain their appearance over time, resistant to yellowing, dirt, and water stains. Specifications for surface treatments, such as protective coatings or dye fastness standards, help ensure the product remains pristine, especially important for markets with high humidity or dust.

6. Compliance with Industry Standards

Adherence to regional safety and environmental standards (e.g., EU REACH, US CPSIA) is critical. Certifications demonstrate that the product meets legal requirements, facilitating smoother import processes and market acceptance.

Common Trade Terms

1. OEM (Original Equipment Manufacturer)

Refers to manufacturing products based on the buyer’s specifications and branding. Understanding OEM terms helps buyers negotiate custom designs, branding rights, and exclusive production rights, which are vital for differentiating in competitive markets.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce or sell per order. Knowing MOQ helps buyers plan inventory and negotiate better terms, especially in markets with fluctuating demand or when testing new suppliers.

3. RFQ (Request for Quotation)

A formal process where buyers solicit price and delivery details from suppliers. A well-structured RFQ accelerates procurement, ensures competitive pricing, and clarifies technical requirements upfront.

4. Incoterms (International Commercial Terms)

Standardized trade terms (e.g., FOB, CIF, DDP) defining responsibilities for shipping, insurance, and customs. Familiarity with Incoterms enables buyers to optimize logistics costs and mitigate risks during international shipment.

5. Lead Time

The period from order placement to delivery. Awareness of supplier lead times aids in planning inventory and aligning production schedules, especially critical for seasonal or fashion-sensitive footwear.

6. Quality Assurance (QA) & Inspection Terms

Terms such as pre-shipment inspection, third-party audits, and compliance checks ensure product quality before shipment. Incorporating these processes reduces the risk of non-conforming products reaching end markets.

This technical and terminological foundation empowers international B2B buyers to communicate effectively with suppliers, negotiate confidently, and ensure the procurement of high-quality white leather shoes suited to diverse markets across Africa, South America, the Middle East, and Europe.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the white leather shoes Sector

Market Overview & Key Trends

The global white leather shoes market is driven by evolving consumer preferences, fashion trends, and expanding middle-class populations across emerging markets. In regions such as Africa, South America, the Middle East, and parts of Europe, demand is increasingly influenced by a desire for premium, stylish footwear that balances aesthetics with comfort. B2B buyers from these regions should monitor shifts toward customization and branded collaborations, which add value and differentiate offerings in competitive markets.

Technological advancements are transforming sourcing and manufacturing processes. Innovations like 3D printing, AI-driven supply chain management, and digital sampling enable faster turnaround times and reduced costs. Moreover, sourcing trends now favor near-shoring and regional manufacturing hubs to mitigate supply chain disruptions, especially post-pandemic. For instance, Southeast Asian countries like Thailand are becoming key players due to their skilled craftsmanship and strategic proximity to major markets.

International buyers should also capitalize on e-commerce platforms and B2B marketplaces that streamline procurement, offering greater transparency and access to a diverse supplier base. Sustainable logistics and just-in-time inventory management are increasingly vital to meet fast-changing market demands. As the market becomes more competitive, emphasis on quality control, branding, and rapid delivery will be crucial for success.

Furthermore, regional preferences influence design and material choices. Middle Eastern markets often favor luxurious finishes and premium materials, while African and South American buyers look for cost-effective yet durable options. Staying attuned to these regional nuances, coupled with leveraging data analytics for market insights, will enable B2B buyers to optimize sourcing strategies and stay ahead of emerging trends.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone of strategic sourcing in the white leather shoes sector, driven by increasing consumer awareness and stricter regulations. Environmental impacts of leather production—such as water consumption, chemical use, and greenhouse gas emissions—pose significant challenges. B2B buyers should prioritize sourcing from suppliers who adhere to environmentally responsible practices, including the use of eco-friendly tanning methods and water-efficient processes.

Certifications like Leather Working Group (LWG), Global Organic Textile Standard (GOTS), and Forest Stewardship Council (FSC) are valuable benchmarks for verifying sustainable practices. Incorporating these standards into procurement criteria not only enhances brand reputation but also reduces long-term operational risks associated with regulatory non-compliance.

Ethical sourcing extends beyond environmental concerns to encompass labor rights and fair wages. Transparency in the supply chain is essential, with buyers encouraged to engage with suppliers who demonstrate strong commitments to ethical labor practices and social responsibility. Conducting regular audits and leveraging blockchain technology can improve traceability and accountability.

In addition, the adoption of ‘green’ materials—such as vegetable-tanned leather, recycled synthetics, or bio-based alternatives—can significantly reduce environmental footprints. For B2B buyers, fostering partnerships with suppliers committed to sustainability can lead to innovation, cost savings, and access to premium market segments that value ethically produced footwear.

Brief Evolution/History (Optional)

The white leather shoes market has evolved from traditional handcrafted footwear to a highly automated, fashion-driven industry. Historically, craftsmanship and material quality defined the sector, but today’s B2B landscape emphasizes speed, scalability, and sustainability. The rise of fast fashion and e-commerce has accelerated the demand for white leather shoes, prompting manufacturers to adopt new technologies and sourcing strategies.

This evolution reflects broader industry shifts toward ethical production and environmental consciousness. As consumers globally become more aware of the social and ecological impacts of their purchases, B2B buyers are increasingly seeking suppliers that align with these values. Understanding this historical transition helps buyers appreciate the importance of integrating innovation with tradition to meet modern market expectations effectively.

Illustrative Image (Source: Google Search)

Frequently Asked Questions (FAQs) for B2B Buyers of white leather shoes

-

How can I effectively vet and select reliable suppliers of white leather shoes internationally?

To ensure supplier reliability, start with comprehensive due diligence: verify business licenses, check for industry certifications (e.g., ISO, Leather Working Group), and review customer testimonials or references. Request samples to assess quality firsthand. Utilize trade platforms like Alibaba, Global Sources, or industry-specific directories, and consider visiting manufacturing facilities when feasible. Building strong communication channels and requesting detailed product specifications, production capacity, and lead times will help gauge supplier transparency and professionalism. Establishing clear contractual terms upfront minimizes risks and fosters long-term, trustworthy partnerships. -

What customization options are typically available, and how do they impact order processes and costs?

Manufacturers often offer customization in design, sizing, packaging, and branding (e.g., logos or labels). Custom features may include specific stitching, finishes, or color shades to match your brand identity. Customization generally increases lead times and may require higher minimum order quantities (MOQs). Discuss your needs early to obtain accurate quotations and timelines. Clear communication of specifications reduces errors and rework costs. Keep in mind that complex customizations might also affect unit pricing—balancing your branding goals with cost efficiency is essential for scalable sourcing. -

What are typical MOQs, lead times, and payment terms for bulk orders of white leather shoes?

Most suppliers have MOQs ranging from 500 to 2,000 pairs, depending on the manufacturer’s capacity and the level of customization. Lead times generally span 4 to 12 weeks, influenced by order volume, complexity, and production schedules. Common payment terms include 30% upfront deposit with the remaining balance payable before shipment, or letters of credit for larger transactions. Negotiating flexible payment options and early order placements can help manage cash flow and ensure timely delivery, especially when dealing with overseas suppliers. -

What quality assurance standards and certifications should I look for when importing white leather shoes?

Look for suppliers with certifications such as ISO 9001 (quality management), Leather Working Group (sustainable leather sourcing), and social compliance certifications like SA8000. These standards indicate adherence to quality, environmental, and ethical practices. Request detailed QA protocols, including sampling procedures, inspection reports, and testing results (e.g., colorfastness, sole durability). Conduct third-party inspections during production or pre-shipment to verify quality. Working with certified suppliers reduces risks of product defects, non-compliance, and reputational damage in your target markets. -

What logistics considerations should I account for when importing white leather shoes internationally?

Coordinate with suppliers to select optimal shipping methods—air freight offers faster delivery but at higher costs, while sea freight is more economical for large volumes. Clarify Incoterms (e.g., FOB, CIF) to define responsibilities and cost allocations. Factor in customs clearance procedures, import duties, and taxes applicable in your country (e.g., Saudi Arabia, Brazil, Thailand). Engage experienced freight forwarders familiar with your target markets to streamline logistics, ensure timely delivery, and minimize delays. Establish clear communication channels with suppliers and logistics providers for tracking and resolving issues swiftly. -

How can I handle disputes or quality issues effectively with international suppliers?

Establish clear contractual agreements outlining quality standards, inspection procedures, and dispute resolution mechanisms before placing orders. Maintain detailed records of communications, inspections, and product samples. If issues arise, promptly communicate with the supplier, providing evidence and referencing contractual terms. Negotiating amicable solutions such as replacements or partial refunds is preferable; however, if unresolved, consider arbitration or legal channels compliant with the contract. Building strong relationships and transparent communication from the outset reduces misunderstandings and facilitates quicker resolutions. -

What are the key factors to consider for sustainable and ethical sourcing of white leather shoes?

Prioritize suppliers with certifications related to environmental sustainability and ethical labor practices, such as Leather Working Group, Fair Labor Association, or SA8000. Verify the traceability of leather sourcing to ensure environmentally responsible tanneries and ethical labor conditions. Consider suppliers’ commitments to reducing waste, water usage, and emissions. Incorporate sustainability clauses into your contracts and request transparency reports. Sourcing ethically not only aligns with global standards but also enhances brand reputation and appeals to increasingly conscious consumers across Africa, South America, the Middle East, and Europe. -

What are best practices for building long-term relationships with international white leather shoe suppliers?

Focus on consistent communication, timely payments, and mutual respect to foster trust. Regularly visit supplier facilities if possible, or conduct virtual audits to ensure ongoing compliance. Provide constructive feedback and collaborate on product improvements. Establish shared goals around quality, lead times, and sustainability. Maintaining flexibility and understanding cultural differences can strengthen partnerships. Long-term relationships often lead to better pricing, priority production slots, and customized solutions, providing a competitive edge in your target markets.

Strategic Sourcing Conclusion and Outlook for white leather shoes

Conclusion and Future Outlook

Effective strategic sourcing for white leather shoes requires a nuanced understanding of global supply chains, quality standards, and cost dynamics. By prioritizing reliable suppliers, leveraging regional manufacturing hubs, and fostering strong supplier relationships, B2B buyers can secure superior products while optimizing costs. Diversification of sourcing channels, especially from emerging markets in Africa, South America, and the Middle East, can mitigate risks and enhance supply chain resilience.

Looking ahead, technological advancements such as digital procurement platforms and supply chain transparency tools will play a critical role in streamlining sourcing processes. Sustainability considerations, including ethical sourcing and eco-friendly production practices, are increasingly influencing purchasing decisions and brand reputation.

International buyers from regions like Saudi Arabia, Thailand, and Africa are encouraged to adopt a proactive, data-driven approach to sourcing. Emphasizing quality, reliability, and sustainability will be key to gaining competitive advantage. By staying informed of market trends and fostering strategic partnerships, buyers can navigate future challenges and capitalize on emerging opportunities in the white leather footwear sector.