Master Global Sourcing of G Unit Shoes: A Complete B2B

Guide to G Unit Shoes

- Introduction: Navigating the Global Market for g unit shoes

- Understanding g unit shoes Types and Variations

- Key Industrial Applications of g unit shoes

- Strategic Material Selection Guide for g unit shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for g unit shoes

- Comprehensive Cost and Pricing Analysis for g unit shoes Sourcing

- Spotlight on Potential g unit shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for g unit shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the g unit shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of g unit shoes

- Strategic Sourcing Conclusion and Outlook for g unit shoes

Introduction: Navigating the Global Market for g unit shoes

Understanding the global demand for g unit shoes is essential for B2B buyers seeking to capitalize on this dynamic market. As a prominent brand recognized for its streetwear appeal and cultural influence, g unit shoes have become a staple in the footwear industry, attracting diverse consumer bases worldwide. For international buyers—particularly from regions such as Africa, South America, the Middle East, and Europe—accessing reliable sources, competitive pricing, and quality assurance is critical to establishing a successful supply chain.

This comprehensive guide offers actionable insights into the entire lifecycle of g unit shoes, from understanding different product types and materials to navigating manufacturing, quality control, and supplier networks. It also addresses key considerations around costs, market trends, and regulatory compliance, empowering buyers to make informed sourcing decisions. Whether sourcing for retail, wholesale, or private label distribution, this resource aims to streamline your procurement process, mitigate risks, and optimize your market entry strategies.

By equipping you with industry expertise and practical strategies, this guide supports B2B buyers across diverse regions in tapping into the lucrative and evolving g unit shoes market. Whether you are exploring new supplier partnerships or expanding existing channels, our insights are designed to help you navigate complexities and capitalize on emerging opportunities in the global footwear landscape.

Understanding g unit shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic G Unit Sneakers | Low-top design, iconic branding, durable rubber sole | Fashion retail, streetwear brands | Pros: Widely recognized, versatile; Cons: High competition, price sensitivity |

| High-Top G Unit Sneakers | Elevated ankle support, reinforced materials, bold aesthetics | Sportswear, premium streetwear | Pros: Appeal to niche markets, high margin potential; Cons: Higher manufacturing costs |

| Limited Edition G Units | Unique colorways, collaborations, exclusive releases | Collector markets, premium boutiques | Pros: High resale value, brand prestige; Cons: Limited supply, higher MOQ |

| Customizable G Units | Modular components, personalized design options | Custom retail, corporate branding | Pros: Differentiation, increased customer engagement; Cons: Increased complexity and lead times |

| Eco-Friendly G Units | Sustainable materials, eco-conscious manufacturing processes | Green retail, international markets with eco-focus | Pros: Growing consumer demand, brand differentiation; Cons: Potentially higher costs, supply chain complexity |

Classic G Unit Sneakers

This variation embodies the original G Unit sneaker design—low-top, durable construction with recognizable branding elements. They are suitable for mass-market retail, streetwear outlets, and casual fashion sectors. B2B buyers should consider factors like consistent supply chain, brand authenticity, and price points to meet retail demands. Their widespread popularity makes them a reliable product, though high competition and price sensitivity among buyers require strategic sourcing and volume negotiations.

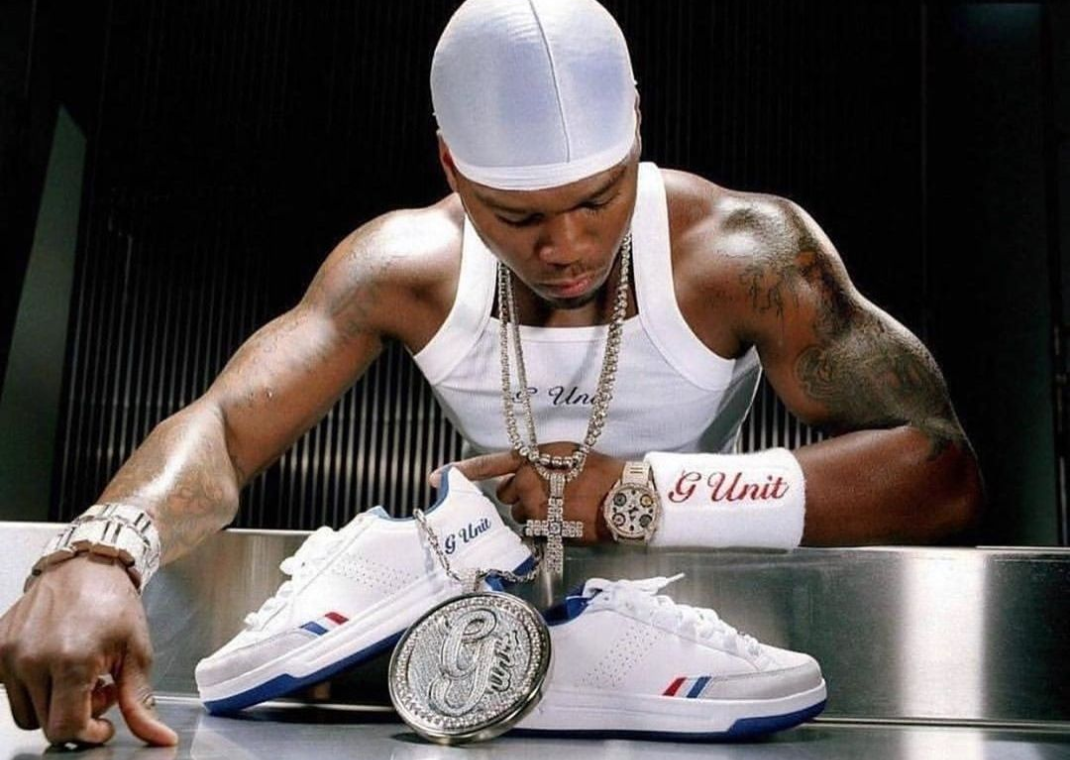

Illustrative Image (Source: Google Search)

High-Top G Unit Sneakers

Featuring elevated ankle support and reinforced materials, high-tops appeal to consumers seeking both style and functional durability. They are well-suited for sportswear brands and premium streetwear markets. B2B buyers need to evaluate manufacturing costs associated with higher material usage and the potential for higher retail margins. These models often command a premium price, making them attractive for brands targeting niche segments willing to pay more for exclusivity and durability.

Limited Edition G Units

Limited edition releases leverage collaborations, exclusive colorways, or unique design elements to create scarcity and drive demand. They are ideal for premium boutiques, collectors, and brands aiming to enhance their exclusivity. For B2B buyers, understanding the supply chain constraints, managing minimum order quantities, and timing releases are crucial. These products often have high resale value, but their limited nature demands careful planning and inventory management.

Customizable G Units

Offering modular components and personalization options, customizable G Units allow brands and retailers to differentiate their offerings. They are particularly appealing in markets where consumer engagement and brand loyalty are vital. B2B buyers should assess the complexity of manufacturing, lead times, and costs associated with customization. This variation can command higher margins but requires robust supplier partnerships to ensure quality and timely delivery.

Eco-Friendly G Units

Manufactured with sustainable materials and environmentally conscious processes, eco-friendly G Units cater to the growing demand for green products. They are suitable for brands targeting eco-aware consumers across international markets, including Europe and parts of South America and Africa. B2B buyers should evaluate supply chain transparency, certification standards, and cost implications. While potentially higher in production costs, these shoes can strengthen brand reputation and meet regulatory standards in various regions.

Key Industrial Applications of g unit shoes

| Industry/Sector | Specific Application of g unit shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Wellhead and valve sealing | Ensures secure, leak-proof seals under high pressure and temperature | Material compatibility with hydrocarbons, API/ISO certifications, durability in harsh environments |

| Power Generation | Turbine and generator component isolation | Provides reliable insulation and vibration damping in critical machinery | Resistance to thermal cycling, high mechanical strength, compliance with industry standards |

| Chemical Processing | Reactor and piping insulation and sealing | Prevents chemical leaks, withstands corrosive media | Chemical resistance, compliance with safety standards, ease of installation |

| Mining & Heavy Industry | Heavy machinery mounting and vibration control | Absorbs shocks, reduces equipment wear, enhances operational lifespan | High load capacity, resilience to abrasive environments, consistent performance |

| Water & Wastewater | Pump and pipeline sealing | Ensures leak-tight operation, prevents contamination | Compatibility with water treatment chemicals, long service life, ease of maintenance |

Oil & Gas

G unit shoes are extensively used in oil and gas operations, particularly for wellhead and valve sealing. They provide a reliable, high-pressure seal that withstands extreme temperatures and corrosive substances common in hydrocarbon extraction. For international B2B buyers from Africa, South America, the Middle East, and Europe, sourcing g unit shoes that meet API and ISO standards ensures safety and operational integrity. Their robustness minimizes downtime and prevents costly leaks, making them essential for maintaining operational efficiency in challenging environments.

Power Generation

In power plants, g unit shoes serve as critical components in turbines and generators, offering insulation and vibration damping. They help maintain optimal performance by absorbing mechanical shocks and reducing wear on sensitive equipment. Buyers from regions with diverse energy infrastructures—such as Egypt’s thermal plants or European renewable facilities—must prioritize high thermal resistance and compliance with industry standards. Proper sourcing ensures longevity, reduces maintenance costs, and enhances overall plant reliability.

Chemical Processing

Chemical industries rely on g unit shoes for sealing reactors and piping systems, especially where aggressive chemicals are involved. These components prevent leaks and contain hazardous media, ensuring safety and environmental compliance. International buyers should focus on sourcing g unit shoes with proven chemical resistance and certifications aligned with safety standards like ATEX or IECEx. This guarantees that the seals perform reliably under corrosive conditions, safeguarding personnel and assets.

Mining & Heavy Industry

Heavy machinery in mining and industrial sectors use g unit shoes for mounting and vibration control. They absorb shocks from heavy loads and rough terrains, protecting equipment from premature failure and reducing maintenance costs. For buyers in Africa or South America, selecting g unit shoes with high load capacities and resilience to abrasive environments is vital. Proper sourcing ensures sustained operational efficiency and safety in demanding conditions.

Water & Wastewater

In water treatment plants, g unit shoes are used for pump and pipeline sealing, preventing leaks and contamination. Their chemical compatibility with water treatment chemicals and long service life are crucial for maintaining environmental standards. Buyers should seek g unit shoes that are easy to install and maintain, ensuring leak-proof performance over extended periods. This reduces operational disruptions and supports sustainable water management practices.

This detailed overview provides international B2B buyers with actionable insights into selecting the right g unit shoes for their specific industrial needs, emphasizing quality, standards compliance, and operational benefits.

Strategic Material Selection Guide for g unit shoes

Analysis of Common Materials for g unit Shoes from a B2B Perspective

1. Leather (Genuine and Synthetic)

Leather remains a traditional choice for g unit shoes, valued for its aesthetic appeal and comfort. Genuine leather offers excellent durability, breathability, and a premium look, making it suitable for high-end or fashion-oriented models. Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), provides a more cost-effective alternative with easier manufacturing processes.

Key Properties:

– Genuine leather: High tensile strength, excellent aging resistance, good flexibility.

– Synthetic leather: Moderate durability, water-resistant, lighter weight.

– Both types are generally resistant to moderate temperature fluctuations but can degrade under extreme heat or prolonged exposure to moisture.

Pros & Cons:

– Genuine leather: Pros include longevity and premium feel; cons involve higher cost and complex manufacturing.

– Synthetic leather: Pros include lower cost and ease of manufacturing; cons involve lower breathability and potential environmental concerns.

Impact on Application:

– Leather performs well in media with moderate moisture but can be compromised in highly humid or wet environments unless treated.

– Synthetic variants are more resistant to water but may not age as gracefully.

International Considerations:

– Buyers from Africa and South America should verify local import regulations regarding animal products and synthetic materials.

– European and Middle Eastern markets often demand compliance with environmental standards like REACH or OEKO-TEX, influencing material choice.

– Leather sourcing should consider sustainability certifications to meet consumer expectations and regulatory standards.

2. Thermoplastic Elastomers (TPE)

TPE materials are increasingly popular in g unit shoes for their flexibility, resilience, and ease of processing. They combine the characteristics of rubber and plastic, offering excellent shock absorption and weather resistance.

Key Properties:

– High elasticity, good abrasion resistance, and moderate temperature tolerance.

– Typically resistant to oils, chemicals, and UV exposure.

– Can be formulated to meet specific performance standards.

Pros & Cons:

– Pros include lightweight construction, cost-effectiveness, and ease of molding.

– Cons involve potential limitations in high-temperature environments and lower long-term wear resistance compared to rubber or leather.

Impact on Application:

– Suitable for outsole components, mid-soles, or decorative elements requiring flexibility and durability.

– Performs well in diverse climates, making it ideal for international markets with varying weather conditions.

International Considerations:

– TPE formulations must comply with regional standards such as ASTM in the US, DIN in Europe, or JIS in Japan.

– Buyers should verify chemical safety certifications, especially for markets with strict regulations like the EU.

– Cost considerations are favorable for emerging markets, but quality consistency is crucial for brand reputation.

3. Rubber (Natural and Synthetic)

Rubber remains a staple in the outsole and midsole components of g unit shoes due to its excellent grip, shock absorption, and durability. Both natural and synthetic rubbers are used depending on the application and regional availability.

Key Properties:

– Natural rubber offers high elasticity and resilience but can be susceptible to environmental degradation.

– Synthetic rubbers like SBR (styrene-butadiene rubber) or EPDM provide better weather resistance and chemical stability.

– Both types withstand a wide temperature range but can become brittle under prolonged UV exposure if not treated.

Pros & Cons:

– Pros include superior slip resistance, durability, and impact absorption.

– Cons involve environmental concerns related to vulcanization processes and higher costs for high-quality grades.

Impact on Application:

– Ideal for outsoles exposed to rough terrains or high wear conditions.

– Compatibility with various media (e.g., oils, chemicals) depends on specific rubber formulations.

International Considerations:

– Buyers from regions with high humidity or temperature fluctuations, such as Egypt or Argentina, should select rubber grades with enhanced weather resistance.

– Compliance with environmental standards like REACH or RoHS is essential, especially for synthetic rubbers.

– Cost and availability may vary; synthetic options often provide more consistent supply chains in regions with limited natural rubber sources.

Summary Table

| Material | Typical Use Case for g unit shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather (Genuine & Synthetic) | Upper, overlays, premium models | Durability, aesthetic appeal, comfort | Higher cost, environmental concerns, manufacturing complexity | High |

| Thermoplastic Elastomers (TPE) | Outsoles, mid-soles, flexible decorative elements | Flexibility, weather resistance, ease of molding | Limited high-temp resistance, lower long-term wear | Med |

| Rubber (Natural & Synthetic) | Outsoles, shock absorption layers | Slip resistance, durability, impact absorption | Environmental concerns, cost variability | Med to High |

This comprehensive analysis aims to guide international B2B buyers in selecting the most appropriate materials for g unit shoes, considering regional standards, environmental factors, and cost implications. Proper material choice ensures product performance, compliance, and market competitiveness across diverse global markets.

Illustrative Image (Source: Google Search)

In-depth Look: Manufacturing Processes and Quality Assurance for g unit shoes

Manufacturing Processes for g unit Shoes

The production of g unit shoes involves a series of meticulously coordinated stages, each critical to ensuring product quality, durability, and compliance with international standards. Understanding these stages allows B2B buyers to evaluate supplier capabilities effectively.

1. Material Preparation

Material preparation is foundational to the manufacturing process. Suppliers source high-quality raw materials such as genuine or synthetic leather, textiles, rubber, and foam insoles. For consistent quality, they often work with certified suppliers adhering to ISO 9001 standards. Critical considerations include:

- Material Certification: Ensure suppliers provide Certificates of Compliance (CoC) verifying material origin and adherence to safety standards.

- Sample Testing: Conduct initial batch testing for tensile strength, colorfastness, and moisture resistance.

- Storage & Handling: Proper storage conditions prevent material degradation, which is vital for maintaining consistency.

2. Forming and Cutting

In this stage, materials are cut into patterns matching shoe designs. Techniques include:

- Automated Cutting Machines: Use CNC or laser cutters for precision, reducing waste and ensuring uniformity.

- Pattern Optimization: Efficient pattern layout minimizes material waste and reduces costs.

- Quality Checks: Visual inspection of cut pieces for defects or inconsistencies before assembly.

3. Assembly and Stitching

Assembly involves stitching and attaching components:

- Stitching Techniques: High-frequency sewing machines, often with reinforced stitching, ensure durability.

- Adhesive Bonding: Use of industry-grade adhesives for parts like soles and overlays, complying with safety standards.

- Component Integration: Attaching eyelets, laces, insoles, and soles, often using automated or semi-automated processes to ensure uniformity.

4. Finishing and Quality Control

Finishing includes surface treatments and final inspections:

- Surface Treatments: Polishing, dyeing, and coating to achieve desired aesthetics and water resistance.

- Final Assembly Checks: Confirming proper fit, alignment, and finishing details.

- Packaging: Ensuring that shoes are packed according to international shipping standards to prevent damage during transit.

Quality Assurance Protocols for g unit Shoes

Robust quality assurance (QA) is essential for maintaining product integrity and meeting international compliance standards. B2B buyers should understand the typical QA checkpoints and how to verify supplier adherence.

1. International Standards and Certifications

- ISO 9001: Most reputable manufacturers operate under ISO 9001, ensuring a quality management system that emphasizes continuous improvement and customer satisfaction.

- CE Marking: For European markets, compliance with CE standards indicates conformity with health, safety, and environmental protection requirements.

- Other Industry Certifications: Depending on the destination market, certifications like ASTM, REACH (for chemicals), or API (for specific industrial applications) may be relevant.

2. QC Checkpoints

- Incoming Quality Control (IQC): Inspection of raw materials before production begins, including material testing and supplier documentation review.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing, focusing on stitching quality, dimensional accuracy, and adherence to design specifications.

- Final Quality Control (FQC): Comprehensive assessment of finished shoes, including visual inspections, functional tests, and packaging verification.

3. Testing Methods

- Visual Inspection: Checking for defects such as scuffs, uneven stitching, or color inconsistencies.

- Dimensional Measurement: Confirming size and shape accuracy using calipers and templates.

- Durability Testing: Conducted through flex tests, abrasion resistance, and adhesion tests, often following ASTM or ISO standards.

- Environmental Testing: Assessing resistance to water, UV exposure, and temperature variations, particularly important for shoes destined for diverse climates.

4. Supplier Verification for B2B Buyers

- Audits and Inspections: Regular on-site audits or third-party inspections verify compliance with quality standards and production capacity.

- Quality Reports and Documentation: Request detailed QC reports, test certificates, and production records to ensure transparency.

- Third-party Inspection Services: Engage independent agencies like SGS, Bureau Veritas, or Intertek to conduct unbiased assessments, especially when sourcing from regions with variable quality standards.

Nuances for International B2B Buyers from Africa, South America, the Middle East, and Europe

Different regions present unique challenges and opportunities regarding manufacturing and quality assurance:

- Africa: Often characterized by emerging manufacturing sectors, buyers should prioritize suppliers with ISO 9001 certification and proven export experience. Auditing local facilities can uncover gaps in process control or compliance with international standards.

- South America: Countries like Argentina have a growing footwear industry with a focus on quality. Buyers should verify certifications, especially CE and ISO, and consider local third-party inspections to mitigate risks related to quality inconsistencies.

- Middle East: Suppliers may have advanced manufacturing capabilities, but buyers should scrutinize compliance with chemical safety standards like REACH or US chemical regulations, particularly for footwear imported into Europe or North America.

- Europe: European manufacturers often adhere strictly to EU standards, including CE marking and REACH compliance. Due diligence should include reviewing detailed test reports and certifications, as well as conducting periodic audits to ensure ongoing compliance.

Practical Steps for B2B Buyers to Ensure Quality

- Develop Clear Specifications: Provide detailed technical specifications and quality expectations upfront.

- Establish Regular Communication: Maintain ongoing dialogue with suppliers to address potential issues proactively.

- Visit Manufacturing Sites: When feasible, conduct on-site audits or engage local representatives for inspections.

- Leverage Third-party Certification: Rely on established inspection agencies for independent verification.

- Implement Continuous Improvement Programs: Encourage suppliers to adopt Kaizen or similar methodologies to enhance quality over time.

By understanding the intricacies of manufacturing and QA processes, B2B buyers from diverse regions can make informed sourcing decisions, reduce risks, and build long-term partnerships with reputable g unit shoe manufacturers.

Comprehensive Cost and Pricing Analysis for g unit shoes Sourcing

Cost Structure Breakdown for g unit Shoes

Understanding the comprehensive cost structure is essential for international buyers aiming to optimize their procurement strategies. The primary components include:

- Materials: The choice of materials—synthetic leather, rubber, textiles, or eco-friendly options—significantly impacts cost. Material costs vary by quality and origin, with imported or specialty materials often commanding higher prices.

- Labor: Wages differ markedly across regions. For instance, manufacturers in Egypt or certain South American countries may offer competitive labor costs compared to European producers. Skilled labor and automation levels also influence expenses.

- Manufacturing Overheads: These encompass factory utilities, machinery maintenance, and factory management costs. Overheads are generally higher in developed regions but can be optimized through efficient operations or bulk production.

- Tooling and Setup: Initial tooling costs are incurred for molds, dies, and prototypes. These are typically one-time expenses but can add to upfront costs, especially for customized designs.

- Quality Control (QC): Ensuring product quality involves inspection and testing, which can add to costs depending on certification requirements (e.g., ISO, environmental standards). Higher QC standards may increase per-unit costs but reduce downstream returns.

- Logistics and Shipping: Freight costs depend on shipment volume, mode (air, sea, land), and destination. For Africa and South America, sea freight is common but can be slower; for urgent needs, air freight is more costly.

- Margins: Markup varies based on buyer-supplier relationships, order volume, and competitive positioning. Larger orders typically benefit from lower per-unit costs due to economies of scale.

Price Influencers and Variability

Several factors shape the final unit price:

- Order Volume & MOQ: Higher volumes reduce per-unit costs through economies of scale. Many suppliers offer discounts for larger orders or when meeting specific MOQ thresholds.

- Specifications & Customization: Customized designs, branding, or specialized features increase costs, especially if tooling or unique materials are involved.

- Material Choices: Premium or imported materials elevate costs. Conversely, locally sourced or standard materials help contain expenses.

- Quality Certifications & Standards: Meeting international standards (e.g., ISO, fair labor) can add costs but also enhance marketability, particularly in Europe and North America.

- Supplier Factors: Experience, reputation, and proximity influence pricing. Suppliers closer to the buyer or with established export channels may offer more competitive rates.

- Incoterms & Shipping Terms: FOB (Free on Board), CIF (Cost, Insurance, Freight), or DDP (Delivered Duty Paid) terms affect who bears shipping and customs costs, influencing the overall landed cost.

Strategic Tips for International B2B Buyers

- Negotiate for Volume Discounts: Engage suppliers early about tiered pricing, especially for large or recurring orders. Emphasize long-term partnership potential to secure better rates.

- Focus on Total Cost of Ownership (TCO): Consider not just unit price but also shipping, customs, taxes, and after-sales support. Sometimes, paying a premium for faster or more reliable logistics reduces overall costs.

- Leverage Local Sourcing Opportunities: For buyers in Africa and South America, sourcing from regional manufacturers can reduce shipping time and costs, while also supporting local economies.

- Understand Pricing Nuances: Be aware of hidden costs such as tariffs, import duties, and compliance costs, especially when importing into Europe or the Middle East.

- Customize Specifications Judiciously: Balance customization needs with cost implications; standard models often offer substantial savings.

Price Range Estimates (Indicative Only)

For a standard g unit shoe produced in regions like Egypt or Argentina, unit prices might range between $8 to $15 per pair at larger volumes (e.g., 10,000+ units). Premium or customized options can push prices above $20, especially when factoring in higher-quality materials or certification requirements. Smaller orders or specialized designs tend to have higher per-unit costs due to setup and logistics.

Disclaimer: These prices are indicative and can vary significantly based on market conditions, supplier negotiations, and specific project requirements. It is advisable to conduct detailed quotes and audits for precise budgeting.

By understanding these cost components and influencing factors, international buyers can better negotiate, optimize procurement, and ensure cost-effective sourcing of g unit shoes tailored to their market needs.

Spotlight on Potential g unit shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for g unit shoes.)*

Essential Technical Properties and Trade Terminology for g unit shoes

Critical Technical Properties for g unit Shoes

1. Material Grade and Composition

The quality and durability of g unit shoes heavily depend on the material grade used in their manufacturing. High-grade materials such as premium leather, specialized synthetic fabrics, or reinforced rubber contribute to longevity, comfort, and aesthetic appeal. For international buyers, ensuring the supplier uses certified, standardized materials reduces the risk of defects and returns. Clear specifications on material grades (e.g., ASTM or ISO standards) are essential for quality assurance.

2. Tolerance Levels

Tolerance refers to the permissible variation in dimensions and construction during manufacturing. Precise tolerances (e.g., ±0.5mm) ensure that shoes fit consistently across batches, which is critical for brand reputation and customer satisfaction. Buyers should specify tolerance levels for key components like sole thickness, upper dimensions, and stitching quality to prevent issues like misalignment or sizing inconsistencies.

3. Weight and Flexibility

The weight of g unit shoes affects comfort and usability, especially for active wear. Lightweight shoes made with advanced materials can enhance performance, while overly heavy models may deter end-users. Flexibility, evaluated through bending tests, indicates how well the shoe adapts to foot movement, impacting comfort during prolonged wear. These properties are vital for athletes or casual consumers and should meet industry standards for performance footwear.

4. Manufacturing Certifications and Compliance

Certifications such as ISO 9001 (quality management) or environmental standards like OEKO-TEX (for non-toxic materials) are indicators of reliable production processes. Compliance with international safety and environmental regulations (e.g., REACH in Europe, local standards in Africa and South America) minimizes legal risks and enhances market acceptance. B2B buyers must verify supplier certifications before entering long-term agreements.

5. Durability and Wear Resistance

Properties like abrasion resistance, sole adhesion strength, and colorfastness determine how well the shoes withstand daily use and environmental conditions. Testing reports demonstrating these properties help buyers assess the product’s longevity, especially for markets with varying climates and usage patterns.

Essential Trade Terms for g unit Shoes

1. OEM (Original Equipment Manufacturer)

Refers to manufacturers that produce shoes branded by another company. Understanding OEM relationships helps buyers negotiate customization, quality control, and intellectual property rights. It’s crucial for buyers seeking private label or bespoke designs for different markets.

2. MOQ (Minimum Order Quantity)

The smallest number of units a supplier agrees to produce or sell in one order. MOQs influence inventory planning and pricing. Buyers from regions like Africa and South America should negotiate flexible MOQs to balance cost and demand, especially when entering new markets.

3. RFQ (Request for Quotation)

A formal process where buyers solicit price and lead time estimates from suppliers. An RFQ ensures transparency and competitive pricing. It is especially useful for international buyers to compare multiple suppliers and ensure compliance with local import regulations.

4. Incoterms (International Commercial Terms)

Standardized trade terms (e.g., FOB, CIF, DDP) defining responsibilities for shipping, insurance, and customs clearance. Understanding Incoterms helps buyers manage costs and logistics risks effectively, particularly when importing to regions with complex customs procedures like Egypt or Argentina.

5. Lead Time

The period from order placement to product delivery. Accurate knowledge of lead times is vital for inventory management and meeting seasonal demand. Buyers should specify acceptable lead times and include penalties for delays in contractual agreements.

6. Quality Assurance (QA) & Inspection Terms

Terms like pre-shipment inspection, third-party audits, or factory audits ensure product compliance with specifications. Implementing strict QA protocols reduces the risk of receiving substandard goods, which is essential for maintaining brand integrity across diverse markets.

Understanding these technical properties and trade terms empowers international B2B buyers to make informed decisions, negotiate effectively, and establish long-term, reliable supply relationships for g unit shoes. Proper attention to specifications and terminology minimizes risks and optimizes supply chain efficiency across Africa, South America, the Middle East, and Europe.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the g unit shoes Sector

Market Overview & Key Trends

The global market for g unit shoes is experiencing significant transformation driven by shifts in consumer preferences, technological advancements, and supply chain innovations. As a staple in urban streetwear and athletic footwear, g unit shoes appeal to a diverse demographic, making them attractive for international B2B buyers seeking versatile products.

Emerging sourcing trends include increased adoption of digital platforms for procurement, such as online B2B marketplaces and supply chain management tools, which streamline sourcing processes and enhance transparency. Suppliers are leveraging automation, 3D printing, and AI-driven design to reduce costs and accelerate product development cycles.

For buyers from Africa, South America, the Middle East, and Europe, understanding regional dynamics is critical. Markets like Egypt and Argentina are emerging as manufacturing hubs due to lower labor costs and improving infrastructure, while European buyers benefit from proximity to innovation centers and stricter sustainability standards. In South America, Brazil’s established footwear manufacturing ecosystem offers opportunities for cost-effective sourcing.

Current market drivers include the rising demand for customized, limited-edition releases, and the increasing importance of fast turnaround times. Supply chain resilience has become a priority, prompting many buyers to diversify sourcing regions and establish closer relationships with manufacturers. Keeping abreast of trade policies, tariffs, and regional trade agreements is essential to optimize procurement costs and mitigate risks.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal factor in the g unit shoes supply chain. International buyers are increasingly prioritizing suppliers with strong environmental credentials, recognizing that eco-conscious sourcing can enhance brand reputation and meet regulatory requirements.

Environmental impact reduction involves sourcing materials like recycled rubber, organic cotton, and biodegradable adhesives. Certification standards such as Global Organic Textile Standard (GOTS), Forest Stewardship Council (FSC), and Leather Working Group (LWG) are valuable indicators of ethical practices and environmental responsibility. Suppliers with these certifications demonstrate compliance with high environmental and social standards.

Ethical sourcing also encompasses fair labor practices, safe working conditions, and transparency across the supply chain. Buyers should seek suppliers who adhere to international labor laws and participate in social audits. Establishing long-term partnerships with certified factories not only ensures product quality but also promotes sustainable development in manufacturing regions.

Illustrative Image (Source: Google Search)

Investing in ‘green’ innovations—such as waterless dyeing processes, low-impact tanning, and renewable energy use—can further reduce environmental footprints. Incorporating sustainability criteria into procurement policies aligns with global trends and enhances market competitiveness for buyers targeting eco-conscious consumers.

Brief Evolution/History (Optional)

The g unit shoes sector has evolved from basic athletic footwear into a symbol of urban culture and streetwear fashion. Originally popularized in the early 2000s, the brand has expanded its product lines and manufacturing capabilities worldwide. For B2B buyers, understanding this evolution highlights the importance of brand authenticity and quality consistency in sourcing.

Over time, the industry has shifted towards more sustainable practices, driven by consumer demand and regulatory pressures. Manufacturers have adopted eco-friendly materials and transparent supply chains, aligning production with global sustainability standards. This evolution underscores the importance for international buyers to partner with suppliers committed to innovation and responsible manufacturing, ensuring long-term viability in a competitive market.

Frequently Asked Questions (FAQs) for B2B Buyers of g unit shoes

-

How can I verify the credibility and reliability of G Unit shoe suppliers?

To ensure supplier credibility, conduct thorough due diligence by reviewing their business licenses, certifications, and references. Request samples to assess product quality firsthand. Check for supplier accreditation from recognized industry bodies and verify their production capacity and compliance with international standards (e.g., ISO, CE). Engaging with verified sourcing platforms or trade associations can also help identify reputable suppliers. Establish clear communication channels and consider visiting manufacturing facilities if possible. Reliable suppliers will be transparent about their processes and willing to provide documentation to build trust and mitigate risks. -

What customization options are available for G Unit shoes, and how do they impact lead times and costs?

Most suppliers offer customization in areas such as branding (logos, labels), colorways, materials, and packaging. Advanced customization, like design modifications or exclusive styles, may require longer lead times and incur additional costs. Clearly communicate your specifications early to receive accurate quotes. Custom orders typically add 2-6 weeks to standard production timelines, depending on complexity. Negotiate minimum order quantities (MOQs) that align with your budget and timeline. Ensure all customization details are documented in contracts to prevent misunderstandings and ensure timely delivery. -

What are typical MOQs, lead times, and payment terms for bulk G Unit shoe orders?

MOQ varies depending on the supplier, generally ranging from 500 to 5,000 pairs for B2B orders. Lead times typically span 4-8 weeks after order confirmation, influenced by order size and customization requirements. Payment terms often include a 30% deposit upfront with the balance payable before shipment or upon delivery. Some suppliers may offer flexible terms for large or repeat orders, such as letter of credit or escrow payments. Establish clear agreements on these terms early to avoid delays and ensure smooth cash flow management. -

What quality assurance measures and certifications should I expect from G Unit shoe suppliers?

Reputable suppliers should adhere to international quality standards such as ISO 9001 or ISO 14001. They should provide test reports for durability, colorfastness, and safety (e.g., non-toxic materials). Certifications like CE, SGS, or REACH demonstrate compliance with regional safety and environmental regulations. Request detailed QA protocols, including factory audits, sample testing, and inspection reports before shipment. Implementing third-party inspection services at the production site can further ensure product quality aligns with your specifications, reducing the risk of defective goods reaching your market. -

What logistics options are available for importing G Unit shoes to Africa, South America, the Middle East, and Europe?

Suppliers typically ship via sea, air, or land freight, with sea freight being most cost-effective for large volumes. For urgent needs, air freight offers faster delivery but at a higher cost. Choose reliable freight forwarders with experience in your target regions to navigate customs, tariffs, and import regulations smoothly. FOB (Free On Board) or CIF (Cost, Insurance, Freight) terms are common; clarify which is included in your agreement. Establish clear logistics timelines and contingency plans for delays, especially considering regional customs procedures and transportation infrastructure. -

How should I handle disputes or quality issues with G Unit shoe suppliers?

Establish a detailed contract outlining quality standards, inspection procedures, and dispute resolution mechanisms before placing orders. Maintain comprehensive documentation of communications, invoices, and inspection reports. In case of disputes, consider mediation or arbitration clauses within the contract to resolve issues efficiently. Conduct pre-shipment inspections or third-party audits to detect problems early. Building strong, transparent relationships with suppliers fosters better communication and quicker resolution of issues. Always keep a record of defect reports and negotiate fair remedies such as replacements, refunds, or discounts. -

What are the key considerations for ensuring compliance with regional import regulations?

Research regional import tariffs, customs procedures, and product-specific restrictions in your target market (e.g., Argentina, Egypt, or European countries). Ensure G Unit shoes meet local safety, labeling, and environmental standards—such as REACH in Europe or local certification requirements in South America. Work with customs brokers familiar with regional regulations to streamline clearance processes. Proper documentation, including invoices, certificates of origin, and compliance certificates, is essential for smooth customs clearance. Staying informed about policy updates helps prevent delays or penalties and ensures ongoing compliance. -

What are the best practices for building a long-term partnership with G Unit shoe suppliers?

Develop open, transparent communication channels and provide clear, detailed purchase agreements. Regularly review supplier performance based on quality, lead times, and responsiveness. Consider establishing long-term contracts or volume-based agreements to secure better pricing and priority service. Invest in relationship-building through visits, consistent feedback, and prompt payments. Collaborate on product development or innovation initiatives to deepen engagement. A strong partnership reduces supply chain risks, enhances product quality, and facilitates mutual growth, especially important when expanding into new markets with specific demands.

Strategic Sourcing Conclusion and Outlook for g unit shoes

Strategic Sourcing Outlook for g unit shoes

Effective strategic sourcing is pivotal for international B2B buyers seeking to capitalize on the growing demand for g unit shoes. By diversifying supply chains, leveraging regional manufacturing hubs, and establishing robust supplier relationships, buyers can enhance product quality, reduce costs, and mitigate risks associated with geopolitical and logistical disruptions.

For buyers in Africa, South America, the Middle East, and Europe, understanding regional manufacturing capabilities and trade dynamics offers a competitive edge. Engaging with suppliers who prioritize sustainable practices and compliance not only aligns with global standards but also bolsters brand reputation. Additionally, embracing digital procurement tools can streamline sourcing processes, ensuring timely deliveries and transparent communication.

Looking ahead, the future of sourcing g unit shoes lies in building resilient, adaptable supply chains that can respond to market shifts and consumer preferences. International buyers should prioritize strategic partnerships, continuous supplier evaluation, and technological integration to stay ahead. Proactively exploring new sourcing regions and fostering innovation will be key to maintaining a competitive advantage in this dynamic industry. Now is the time for strategic action—capitalize on emerging opportunities to secure a sustainable, profitable supply chain.