Master Sourcing High-Quality Lime Green Shoes for Global

Guide to Lime Green Shoes

- Introduction: Navigating the Global Market for lime green shoes

- Understanding lime green shoes Types and Variations

- Key Industrial Applications of lime green shoes

- Strategic Material Selection Guide for lime green shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for lime green shoes

- Comprehensive Cost and Pricing Analysis for lime green shoes Sourcing

- Spotlight on Potential lime green shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for lime green shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the lime green shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of lime green shoes

- Strategic Sourcing Conclusion and Outlook for lime green shoes

Introduction: Navigating the Global Market for lime green shoes

In today’s highly competitive global footwear market, lime green shoes have emerged as a bold, trendsetting choice that captures consumer attention and drives brand differentiation. For B2B buyers across Africa, South America, the Middle East, and Europe—such as Egypt and Germany—understanding the strategic importance of sourcing quality lime green footwear is essential for capitalizing on this vibrant niche. These shoes are not only a fashion statement but also a versatile product with applications spanning athletic wear, casual fashion, and promotional merchandise, making them a valuable addition to diverse product portfolios.

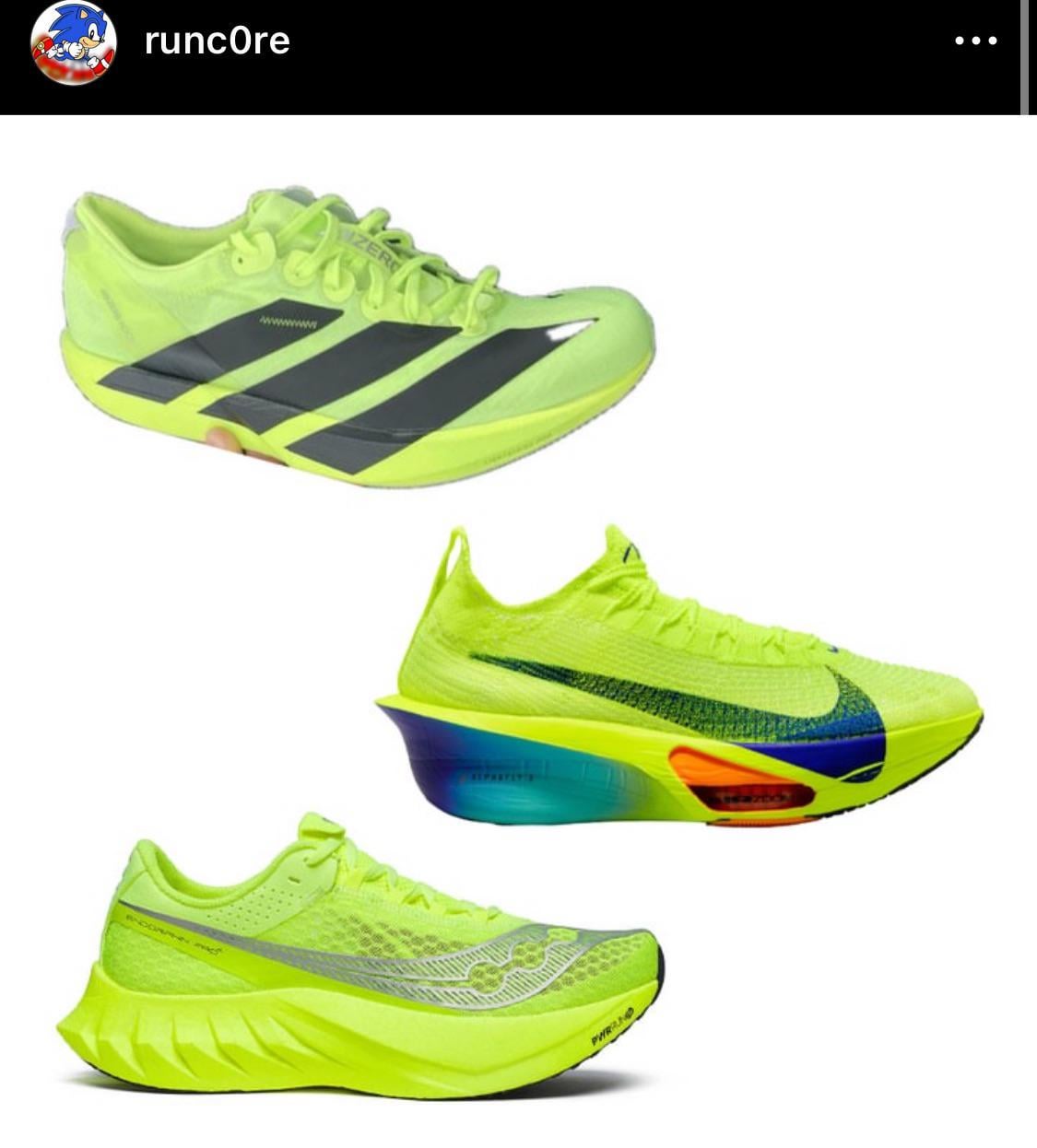

Illustrative Image (Source: Google Search)

This comprehensive guide is designed to equip international buyers with critical insights needed for successful sourcing. It covers a broad spectrum, including the different types of lime green shoes, materials used, manufacturing processes, quality control standards, and reliable supplier networks. Additionally, it addresses cost considerations, market trends, and common FAQs to clarify complex sourcing dynamics.

By providing actionable intelligence, this guide aims to empower B2B buyers to make informed decisions—whether negotiating prices, selecting suppliers, or ensuring compliance with quality standards. In a marketplace where color and innovation can significantly influence consumer preference, mastering the nuances of sourcing lime green shoes offers a competitive advantage. Ultimately, this resource will help you navigate the complexities of international trade, optimize your supply chain, and unlock new growth opportunities in this eye-catching footwear segment.

Understanding lime green shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Athletic/Running Shoes | Lightweight, breathable mesh upper, cushioned sole, vibrant lime green color | Sportswear brands, fitness centers, retail chains | Pros: High demand in activewear markets, visually striking. Cons: Seasonal demand fluctuations, high competition. |

| Formal/Business Shoes | Sleek design, leather or synthetic material, subtle lime green accents | Corporate gifting, fashion boutiques | Pros: Niche market, premium pricing potential. Cons: Limited styles, requires quality control. |

| Casual Sneakers | Versatile, trendy designs, rubber soles, bold lime green accents | Youth fashion outlets, online retailers | Pros: Wide consumer appeal, high turnover. Cons: Price sensitivity, trend dependency. |

| Safety/Work Shoes | Durable, reinforced toe caps, slip-resistant soles, lime green for visibility | Construction, manufacturing, logistics | Pros: High safety standards, consistent demand. Cons: Strict compliance requirements, heavier products. |

| Eco-friendly Shoes | Made from sustainable or recycled materials, natural dyes, lime green accents | Green product markets, eco-conscious brands | Pros: Growing market segment, brand differentiation. Cons: Higher production costs, supply chain complexity. |

Athletic/Running Shoes

This category features shoes designed for high performance, characterized by lightweight materials, breathable mesh uppers, and cushioned soles. The vivid lime green color enhances visibility and brand recognition, making them highly attractive in sports and fitness markets. These shoes are suitable for sports brands, fitness centers, and retail chains targeting active consumers. B2B buyers should consider the seasonal demand for athletic footwear and evaluate supplier consistency in quality and color fastness, as vibrant hues can fade if not manufactured properly.

Formal/Business Shoes

Lime green formal shoes are a niche but distinctive product, combining sleek, professional designs with subtle lime green accents or linings. Typically crafted from leather or synthetic materials, they appeal to fashion boutiques and corporate gifting segments seeking unique, standout items. These shoes command higher price points due to their premium quality and design. B2B buyers should focus on reliable suppliers with a proven track record in producing high-quality formal footwear, ensuring color consistency and durability, especially when sourcing for luxury markets.

Casual Sneakers

Casual lime green sneakers are versatile and trendy, often featuring bold designs, rubber soles, and eye-catching accents. They are popular among youth and fashion-forward consumers, making them ideal for online retailers, youth fashion outlets, and general retail chains. The main considerations for buyers include keeping pace with fast-changing trends and managing inventory turnover. Supplier flexibility in design and timely delivery are critical to capitalize on the high demand for stylish, affordable footwear.

Safety/Work Shoes

Designed for industrial environments, lime green safety shoes prioritize durability, visibility, and safety compliance. Reinforced toe caps, slip-resistant soles, and high-visibility color schemes make them essential in construction, manufacturing, and logistics sectors. B2B buyers should verify suppliers’ adherence to safety standards and certifications, as well as their capacity to produce consistent, durable products. These shoes tend to have steady demand, but buyers must be attentive to evolving safety regulations and material costs.

Eco-friendly Shoes

This segment emphasizes sustainability, often made from recycled or natural materials with eco-conscious dyes, including lime green accents. They appeal to environmentally aware brands and markets focusing on green products. B2B buyers should evaluate suppliers’ sustainability certifications, material sourcing transparency, and production costs, which tend to be higher than conventional footwear. These shoes offer differentiation and align with growing consumer demand for eco-friendly products, but require careful supply chain management to ensure authenticity and quality.

Key Industrial Applications of lime green shoes

| Industry/Sector | Specific Application of lime green shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Emergency shutoff and safety footwear in drilling sites | Enhanced visibility reduces accident risk, quick response in emergencies | Flame-resistant materials, durability in harsh environments, high-visibility standards |

| Mining | Protective footwear for underground mining operations | Increased worker safety through high visibility, corrosion resistance | Robust construction, slip resistance, compliance with mining safety standards |

| Construction | Site safety shoes for construction workers | Improved worker visibility, compliance with safety regulations | Comfort for extended wear, slip-resistant soles, weather resistance |

| Agriculture | Fieldwork footwear for large-scale farming operations | Better visibility in sprawling fields, protection from environmental hazards | Weatherproof features, durability, lightweight design for mobility |

| Healthcare & Sanitation | Specialized footwear for sanitation workers and healthcare staff | Visibility in high-traffic or hazardous zones, hygiene compliance | Easy to clean materials, antimicrobial properties, high-visibility features |

Oil & Gas

In the oil and gas industry, lime green shoes are primarily used as emergency shutoff and safety footwear on drilling and extraction sites. Their high-visibility color ensures workers are easily spotted, especially in low-light or hazardous conditions, facilitating rapid response during emergencies. These shoes must meet stringent safety standards, including flame resistance and durability against chemicals and high temperatures. For international buyers from regions like Egypt or Germany, sourcing reliable, certified PPE footwear that complies with local safety regulations is critical to ensure worker safety and regulatory adherence.

Mining

Mining operations, especially underground, demand footwear that combines safety with high visibility. Lime green shoes serve as protective gear that enhances worker safety by making personnel more visible in dimly lit environments. They are designed to withstand harsh conditions, including moisture, dust, and mechanical impacts. Sourcing considerations include ensuring shoes meet industry-specific certifications, such as ASTM or ISO standards, and are constructed with corrosion-resistant and slip-resistant materials. This is vital for mining companies in South America or Africa aiming to reduce accidents and improve operational safety.

Construction

Construction sites require safety footwear that balances protection, comfort, and visibility. Lime green shoes are ideal for workers operating in busy, dynamic environments, reducing the risk of accidents caused by poor visibility. These shoes often feature slip-resistant soles, reinforced toe caps, and weather-resistant materials to withstand outdoor conditions. International buyers from Europe or the Middle East should prioritize sourcing shoes with certifications like CE or OSHA compliance, ensuring they meet regional safety standards for construction safety footwear.

Agriculture

Large-scale farming operations benefit from lime green shoes by improving worker visibility across expansive fields, especially during early mornings or late evenings. These shoes also provide environmental protection against mud, water, and agricultural chemicals. Durability and lightweight construction are essential for mobility and comfort during long hours of work. Buyers in South America or Africa should consider sourcing shoes with weatherproof features and antimicrobial properties to maintain hygiene and extend product lifespan in rugged conditions.

Healthcare & Sanitation

In healthcare and sanitation sectors, lime green shoes enhance safety by increasing visibility in crowded or hazardous environments. They are often used by sanitation workers, hospital staff, and cleaning crews who operate in zones with high traffic or potential chemical exposure. Easy-to-clean, antimicrobial materials are crucial to maintain hygiene standards. International buyers should seek shoes that meet local health and safety regulations, ensuring they are both effective and compliant for use in sensitive environments like hospitals or waste management facilities.

Strategic Material Selection Guide for lime green shoes

Material Analysis for Lime Green Shoes

Selecting the appropriate materials for lime green shoes involves balancing performance, cost, manufacturing complexity, and compliance with international standards. Here, we analyze four common materials—leather, synthetic polymers, rubber, and thermoplastics—highlighting their key properties, advantages, limitations, and considerations for global B2B buyers from regions such as Africa, South America, the Middle East, and Europe.

Leather

Key Properties:

Leather is a natural material renowned for its durability, breathability, and aesthetic appeal. It offers good flexibility and aging characteristics, making it suitable for high-quality footwear. Leather’s resistance to abrasion and mechanical stress enhances its longevity.

Pros & Cons:

Leather’s primary advantage is its premium feel and durability, which appeals to consumers seeking luxury or long-lasting products. However, it involves complex tanning processes, making manufacturing more costly and time-consuming. Leather also requires proper maintenance and is sensitive to moisture and environmental conditions.

Impact on Application:

Leather performs well in various climates, but in humid or rainy regions—common in parts of Africa and South America—it may require additional water-resistant treatments. Its natural origin means it can meet many international standards (e.g., ISO 9001, REACH compliance), but buyers must verify sourcing and tanning practices for ethical and environmental standards.

International Buyer Considerations:

European buyers often favor vegetable-tanned or eco-friendly leather, aligning with strict environmental regulations. Buyers from the Middle East and Africa should consider sourcing leather that complies with local import regulations and standards, and ensure traceability to avoid legal or ethical issues.

Synthetic Polymers (e.g., PU, PVC)

Key Properties:

Polyurethane (PU) and polyvinyl chloride (PVC) are synthetic materials widely used in footwear. They offer excellent flexibility, water resistance, and color vibrancy, making them ideal for bright lime green finishes.

Pros & Cons:

These materials are generally more affordable than leather and allow for rapid manufacturing with consistent quality. They are lightweight and resistant to moisture and chemicals. However, synthetic polymers may lack breathability, potentially affecting comfort, and some types (especially PVC) raise environmental concerns due to their production and disposal.

Impact on Application:

Synthetic materials are suitable for mass production and can be engineered to meet specific media resistance requirements, such as resistance to oils or UV exposure. They are often compliant with international standards like ASTM D4236 for labeling and safety, but environmental standards (e.g., REACH) should be verified.

International Buyer Considerations:

Buyers from Europe and the Middle East should prioritize eco-friendly formulations and certifications, as regulations tighten around plastic use and disposal. African and South American buyers should evaluate local import standards and ensure suppliers adhere to quality certifications to avoid legal issues.

Rubber (Natural and Synthetic)

Key Properties:

Rubber offers excellent elasticity, shock absorption, and water resistance. Natural rubber provides superior flexibility and resilience, while synthetic variants (e.g., SBR, neoprene) can be tailored for specific media and environmental conditions.

Pros & Cons:

Rubber’s durability and slip resistance make it ideal for outsoles and protective components. It is also relatively cost-effective and easy to process. However, natural rubber can be sensitive to ozone and temperature variations, and synthetic rubbers may involve complex manufacturing processes.

Impact on Application:

Rubber performs well in outdoor and rugged environments, suitable for work or casual shoes. It can meet various international standards for safety and environmental impact, but buyers should verify the specific rubber grade used, especially for chemical or oil resistance.

International Buyer Considerations:

European markets favor environmentally certified natural rubber (e.g., FSC, Fair Rubber), while buyers in Africa and South America should ensure supply chain transparency. Middle Eastern buyers should consider compatibility with local climate conditions, such as high temperatures and humidity.

Thermoplastics (e.g., TPU, TPE)

Key Properties:

Thermoplastics like Thermoplastic Polyurethane (TPU) and Thermoplastic Elastomers (TPE) combine flexibility, toughness, and ease of processing. They are highly customizable in terms of color, texture, and performance characteristics.

Pros & Cons:

These materials enable innovative design features and are often lightweight. They also offer excellent resistance to abrasion, chemicals, and UV exposure. However, their cost can be higher than basic synthetic polymers, and some grades may require specialized manufacturing equipment.

Impact on Application:

Thermoplastics are suitable for decorative elements, midsoles, and flexible components. They typically comply with international standards such as ASTM F963 for safety and environmental standards, but buyers should specify grade requirements to ensure performance.

International Buyer Considerations:

European and Middle Eastern buyers often seek high-performance grades with eco-labels or certifications. Buyers from Africa and South America should verify supplier compliance with local standards and ensure that materials meet durability and safety expectations for their target markets.

Summary Table

| Material | Typical Use Case for lime green shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Premium casual and formal footwear | Durable, breathable, high-end aesthetic | Costly, sensitive to moisture, complex tanning process | High |

| Synthetic Polymers (PU, PVC) | Fashion sneakers, casual shoes, vibrant color finishes | Affordable, versatile, water-resistant | Less breathable, environmental concerns | Medium |

| Rubber (Natural & Synthetic) | Outsoles, rugged outdoor footwear | Shock absorption, slip resistance, durable | Sensitive to ozone and temperature, environmental impact | Low to Medium |

| Thermoplastics (TPU, TPE) | Decorative elements, flexible midsoles | Lightweight, customizable, high resistance to wear | Higher cost, specialized processing needs | Medium to High |

This detailed analysis enables international B2B buyers to make informed decisions, balancing performance requirements with regional standards, environmental considerations, and cost constraints. Proper material selection tailored to specific application needs and compliance standards will optimize product quality and market success.

In-depth Look: Manufacturing Processes and Quality Assurance for lime green shoes

Manufacturing Processes for Lime Green Shoes

The production of lime green shoes involves a series of meticulously coordinated stages, each critical to achieving the desired color vibrancy, durability, and overall quality. For B2B buyers, understanding these processes enables better supplier evaluation and quality control alignment.

Material Preparation

The manufacturing process begins with sourcing high-quality raw materials such as leather, synthetic fabrics, or microfiber uppers, along with mid-soles and outsoles made from rubber, EVA, or polyurethane. For lime green shoes, dyeing or pigmentation is integral early on, requiring specialized color formulation techniques to ensure consistent vibrancy. Suppliers often utilize pigment dispersions or dye baths, with strict adherence to color matching standards like Pantone to guarantee uniformity across batches.

Key considerations for buyers:

– Confirm that raw materials meet industry standards (e.g., REACH compliance for chemicals).

– Request documentation on dye formulations, especially for vibrant colors prone to fading.

Forming and Assembly

The upper components are cut, stitched, and assembled using automated or semi-automated machinery, ensuring precision in seams and shape. The assembly stage includes attaching the upper to the sole, which may involve gluing, stitching, or a combination of both. For lime green shoes, special attention is given to color consistency during assembly, with some manufacturers applying color sealants or protective coatings to enhance vibrancy and fade resistance.

Key techniques:

– Use of computerized cutting machines for pattern precision.

– Ultrasonic or heat welding in synthetic shoe components.

– Application of colorfast adhesives compatible with vibrant dyes.

Finishing

The final stage involves quality-enhancing treatments such as polishing, buffing, and applying protective coatings. For lime green shoes, UV-resistant and water-repellent coatings are often added to maintain brightness and durability in various environmental conditions. Additionally, the shoes are inspected for color uniformity, structural integrity, and finishing quality.

Finishing touches include:

– Embossing or branding applications.

– Final cleaning and packaging with protective inserts to preserve shape and color.

Quality Assurance (QA) and Control Practices

Robust quality assurance protocols are essential to ensure lime green shoes meet international standards, especially for B2B buyers from diverse markets such as Egypt, Germany, or South America.

International Standards and Certifications

- ISO 9001: Most reputable manufacturers adhere to ISO 9001 standards, emphasizing a quality management system that ensures consistent product quality and continuous improvement.

- CE Marking: For shoes sold within the European Economic Area, CE certification confirms compliance with safety, health, and environmental protection requirements.

- Other Industry Certifications: Depending on target markets, certifications like ASTM (North America), Satra (UK), or specific chemical safety standards (e.g., OEKO-TEX) may be relevant.

Implication for buyers: Ensure suppliers provide valid certification documents and are compliant with the standards relevant to your market.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Raw materials and components are inspected upon receipt, focusing on color consistency, material defects, and chemical safety compliance.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing includes dimensional checks, stitching quality, and color fidelity. For lime green shoes, spectral analysis or colorimeters are used to verify precise color matches.

- Final Quality Control (FQC): Completed shoes undergo comprehensive inspection for defects, color uniformity, sole adhesion, and finishing quality. Random sampling and statistical process controls (SPC) are common methods.

Testing methods:

– Colorfastness tests under light exposure and rubbing.

– Mechanical tests such as tensile strength, flexibility, and abrasion resistance.

– Chemical safety testing, including VOC emissions and chemical residues.

Verifying Supplier Quality Control

B2B buyers should adopt rigorous verification strategies to ensure suppliers maintain high QC standards:

- Supplier Audits: Conduct on-site audits focusing on production processes, QC documentation, and employee training. For international buyers, engaging third-party inspection firms (e.g., SGS, Bureau Veritas) can provide unbiased evaluations.

- Inspection Reports: Request detailed inspection reports, including test results, defect rates, and corrective action documentation.

- Sample Testing: Obtain product samples for independent testing in certified laboratories, especially for colorfastness, chemical safety, and mechanical properties.

- Third-party Certifications: Verify authenticity and scope of certifications through issuing bodies or via databases.

Special Considerations for International B2B Buyers

Buyers from Africa, South America, the Middle East, and Europe face unique challenges and should consider:

- Market-specific compliance: For example, European buyers must prioritize CE certification and chemical safety standards, while Middle Eastern markets may require specific chemical disclosures or halal certifications.

- Cultural and environmental factors: Ensure that manufacturing practices align with local environmental regulations and social compliance standards.

- Logistics and lead times: Choose suppliers with reliable quality documentation and inspection protocols to mitigate risks associated with longer shipping durations and customs procedures.

Conclusion

A comprehensive understanding of manufacturing processes and rigorous quality assurance practices are vital for B2B buyers sourcing lime green shoes internationally. By focusing on detailed material control, precise assembly techniques, and strict QC checkpoints aligned with international standards, buyers can secure products that meet their quality expectations and market requirements. Moreover, leveraging third-party audits, certifications, and independent testing enhances confidence in supplier capabilities, ensuring a successful and compliant supply chain across diverse markets.

Illustrative Image (Source: Google Search)

Comprehensive Cost and Pricing Analysis for lime green shoes Sourcing

Cost Components in Lime Green Shoes Sourcing

Understanding the comprehensive cost structure is crucial for effective sourcing of lime green shoes. The primary components include:

-

Materials: The choice of synthetic or natural leather, mesh fabrics, and specialized dyes for lime green coloration significantly impacts costs. High-quality, certified materials, especially those with eco-labels or compliance with international standards, tend to command higher prices but can enhance product appeal and reduce compliance risks.

-

Labor: Labor costs vary widely based on the sourcing country. For instance, suppliers in Egypt and other North African countries often offer competitive wages, whereas European manufacturers might have higher labor costs but offer superior craftsmanship and consistency.

-

Manufacturing Overhead: This encompasses factory utilities, machinery maintenance, and quality control processes. Advanced automation and certifications (e.g., ISO standards) can influence overhead costs, often correlating with higher quality assurance.

-

Tooling and Setup: Initial mold creation and tooling for lime green shoes can be a significant upfront expense, especially if customization or unique designs are involved. These costs are typically amortized over the production volume.

-

Quality Control: Rigorous QC procedures, including testing for colorfastness, durability, and compliance with safety standards, add to costs but are essential for international markets to meet regulatory and consumer expectations.

-

Logistics and Shipping: Freight costs depend on the sourcing country, destination port, and shipping method (air freight for speed or sea freight for economy). Incoterms like FOB, CIF, or DDP influence who bears these costs and risks.

-

Profit Margin: Suppliers factor in their desired profit margins, which can vary based on order volume, relationship strength, and market competition.

Price Influencers and Their Impact

Several factors directly influence the final price of lime green shoes in B2B transactions:

-

Order Volume & MOQ: Larger orders typically attract lower unit costs due to economies of scale. Many Asian and African manufacturers offer tiered pricing based on volume, making bulk purchasing more cost-effective.

-

Customization & Specifications: Unique shades of lime green, specialized materials, or design features increase production complexity and costs. Clear specifications and prototypes can help prevent costly revisions.

-

Material Quality & Certifications: Higher-grade materials and certifications (e.g., REACH compliance, eco-labels) often increase costs but are increasingly demanded in European and Middle Eastern markets.

-

Quality & Certification Standards: Buyers targeting regulated markets must ensure supplier adherence to standards like ISO, ASTM, or local certifications, which can add inspection and compliance costs.

-

Supplier Factors: Supplier reputation, experience, and capacity influence pricing. Established suppliers with robust quality systems may charge premium but offer reliability and consistency.

-

Incoterms & Logistics: Choosing appropriate Incoterms impacts total landed costs. FOB terms shift logistics costs to the buyer, while DDP includes all costs upfront, influencing cash flow and budgeting.

Strategic Tips for International B2B Buyers

-

Negotiate for Better Terms: Leverage order volume and long-term relationships to secure discounts, favorable payment terms, or included services like quality inspections.

-

Focus on Total Cost of Ownership: Consider not just the unit price but also shipping, customs duties, inspection costs, and potential rework or returns, especially when sourcing from regions with varying quality standards.

-

Understand Pricing Nuances: Price differences can reflect quality, certification, or supply chain efficiencies. Always request detailed quotations and clarify inclusions to avoid hidden costs.

-

Tap into Local Market Dynamics: Buyers from Africa, South America, the Middle East, and Europe should assess regional supplier strengths—such as proximity, language, and cultural compatibility—to optimize communication and reduce lead times.

-

Plan for Fluctuations: Currency exchange rates, raw material price volatility, and geopolitical factors can affect costs over time. Building flexibility into contracts can mitigate these risks.

Disclaimer

Indicative prices for lime green shoes typically range from $15 to $40 per pair for bulk orders, depending on quality, customization, and supplier location. European or North American suppliers might price higher due to stricter standards, while Asian and African manufacturers often offer more competitive rates. Always request detailed quotations tailored to your specifications and consider logistical costs and tariffs in your total cost assessment.

Spotlight on Potential lime green shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for lime green shoes.)*

Essential Technical Properties and Trade Terminology for lime green shoes

Critical Technical Properties of Lime Green Shoes

1. Material Grade and Composition

The choice of materials—such as genuine leather, synthetic leather, mesh, or rubber—directly impacts durability, comfort, and aesthetic appeal. Higher-grade materials typically offer better wear resistance and colorfastness, which are essential for brand reputation. For international buyers, specifying the material grade ensures consistency across batches and helps avoid quality issues that could lead to costly returns or rework.

2. Colorfastness and Shade Consistency

Lime green shoes must meet strict colorfastness standards to withstand exposure to sunlight, moisture, and friction without fading or discoloration. Precise shade matching is critical for branding and consumer appeal, especially in markets where vibrant colors are a key selling point. Suppliers should provide test reports confirming color stability under various conditions.

3. Tolerance and Fit Specifications

Dimension tolerances—such as length, width, and height—are vital for ensuring uniform fit across production batches. Standard tolerances typically range from ±1mm to ±2mm. Maintaining tight tolerances reduces returns, enhances customer satisfaction, and facilitates smoother international logistics where sizing discrepancies can cause issues.

4. Sole and Stitching Strength

The mechanical strength of soles and stitching influences the shoe’s longevity. Specifications like stitch density (stitches per inch) and sole adhesion strength should meet industry standards to prevent premature wear. For export markets, adherence to these specs reduces warranty claims and boosts brand reliability.

5. Flexibility and Comfort Metrics

Technical properties such as flexibility (measured via bending tests) and shock absorption impact comfort, especially for active or everyday footwear. Buyers should request compliance with recognized testing standards (e.g., ASTM, ISO) to ensure the shoes meet user expectations in different climates and usage scenarios.

6. Environmental Compliance

Increasingly, international markets demand eco-friendly manufacturing. Properties such as low VOC emissions, sustainable materials, and compliance with certifications like REACH or CPSIA are crucial. These not only meet legal requirements but also appeal to environmentally conscious consumers.

Essential Trade Terminology for Lime Green Shoes

1. OEM (Original Equipment Manufacturer)

Refers to factories that produce shoes based on the buyer’s specifications and designs. Understanding OEM relationships helps buyers ensure quality control and intellectual property protection while maintaining production flexibility.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce per order. Knowing MOQ is essential for planning budgets and inventory, especially when entering new markets or testing product acceptance in regions like Africa or South America.

3. RFQ (Request for Quotation)

A formal request sent by buyers to suppliers asking for detailed price and lead time estimates. Efficient RFQ processes facilitate competitive bidding, enabling buyers to compare offers and select the best value.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and tariffs (e.g., FOB, CIF, DDP). Mastery of Incoterms helps buyers from different regions understand cost-sharing and risk allocation, vital for smooth cross-border transactions.

5. Lead Time

The period from order placement to shipment readiness. Shorter lead times are advantageous for meeting market demand fluctuations, especially in fast-moving fashion sectors. Clear communication of lead times prevents supply chain disruptions.

6. Quality Assurance (QA) & Inspection

Refers to processes and standards used to verify product quality before shipment. Buyers should specify QA protocols, including third-party inspections, to minimize defects and ensure compliance with technical specs across diverse markets.

By understanding these technical properties and trade terms, international B2B buyers can make more informed decisions, negotiate effectively, and establish reliable supply chains for lime green shoes across global markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the lime green shoes Sector

Market Overview & Key Trends

The global market for lime green shoes is experiencing dynamic growth driven by shifting consumer preferences, technological advancements, and sustainability imperatives. Bright, eye-catching footwear like lime green shoes appeals to a broad demographic, particularly among younger consumers seeking bold fashion statements. This trend is reinforced by the rise of social media influencers and digital marketing, which amplify visibility and demand.

For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding regional market nuances is crucial. Emerging markets like Egypt and other African nations show increased demand for fashionable, affordable footwear, often driven by urban youth and fast fashion trends. Meanwhile, European markets, especially Germany, emphasize quality, sustainability, and innovative sourcing—creating opportunities for suppliers that prioritize eco-friendly materials and transparent supply chains.

Current sourcing trends focus heavily on digital platforms and supply chain transparency. Online B2B marketplaces and trade shows are facilitating easier access to suppliers specializing in vibrant footwear designs. Additionally, rapid prototyping and customization technologies enable buyers to meet niche demands efficiently. The integration of automation and AI in manufacturing processes also enhances efficiency and reduces lead times, making lime green shoes a more accessible product for international buyers.

Market dynamics are influenced by fluctuating raw material costs, geopolitical factors, and trade policies. Buyers must remain agile, fostering relationships with multiple suppliers across regions to mitigate risks. Sourcing from regions with strong manufacturing infrastructure and favorable trade agreements, such as the European Union or Egypt’s industrial zones, can optimize costs and ensure timely delivery.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal factor in sourcing lime green shoes, driven by increasing consumer awareness and regulatory pressures. Environmental impacts associated with footwear production—such as water consumption, chemical use, and waste—necessitate adopting eco-friendly practices. B2B buyers should prioritize suppliers that utilize sustainable materials like recycled plastics, organic cotton, and eco-certified synthetic leathers, which align with the vibrant aesthetic of lime green shoes while reducing ecological footprints.

Certifications such as Global Organic Textile Standard (GOTS), Forest Stewardship Council (FSC), and ISO 14001 are vital indicators of ethical and environmental compliance. These credentials assure buyers that suppliers adhere to environmentally responsible manufacturing practices, including waste management, energy efficiency, and fair labor conditions.

Ethical sourcing also extends to social responsibility—ensuring fair wages, safe working environments, and transparency across the supply chain. For buyers from regions like South America or the Middle East, establishing direct relationships with certified suppliers can mitigate risks of unethical practices and ensure product authenticity. Incorporating sustainability criteria into supplier selection not only enhances brand reputation but also aligns with global trends toward eco-conscious consumption.

Investing in greener production methods and materials can sometimes entail higher upfront costs; however, these are offset by increased consumer loyalty and compliance with international standards. Leveraging blockchain technology for traceability and engaging in supplier audits further reinforce the integrity of the supply chain.

Brief Evolution/History (Optional)

The evolution of lime green shoes within the footwear industry reflects broader trends in fashion and sustainability. Initially driven by youth culture and streetwear, the use of bold colors like lime green gained prominence in the late 20th century. Over time, technological innovations in dyes and synthetic materials allowed for more durable and vibrant designs. Recently, the focus has shifted toward eco-friendly production, with brands and manufacturers adopting sustainable materials and transparent supply chains. This evolution is especially pertinent for B2B buyers seeking to align their sourcing strategies with evolving consumer values and regulatory landscapes, emphasizing the importance of agility and innovation in the lime green shoes sector.

Frequently Asked Questions (FAQs) for B2B Buyers of lime green shoes

1. How can I verify the credibility and reliability of lime green shoe suppliers?

Ensuring supplier credibility is crucial for a successful B2B partnership. Start by requesting company credentials, including business licenses, certifications (ISO, sustainability standards), and references from previous clients. Conduct virtual or in-person audits when possible, focusing on production facilities, quality control processes, and compliance measures. Utilize third-party verification platforms like Alibaba’s Verified Supplier or Global Sources to assess reputation and review histories. Additionally, seek samples before committing to large orders to evaluate craftsmanship and material quality firsthand. Building relationships with suppliers who are transparent and responsive reduces risks and fosters long-term cooperation.

2. What customization options are typically available for lime green shoes in B2B orders?

Most suppliers offer a range of customization options to meet brand and market needs. Common customizations include color shades, branding (logos, tags), packaging, and design modifications such as sole type or upper materials. Some suppliers also provide custom sizing, limited edition styles, or collaborative designs. Clearly communicate your specifications early, including Pantone color codes for precise lime green shades, and request samples of customized designs before bulk production. Confirm whether customization incurs additional costs or lead times, and ensure the supplier can meet your quality standards and deadlines to avoid disruptions.

3. What are typical minimum order quantities (MOQs), lead times, and payment terms for importing lime green shoes?

MOQs for lime green shoes generally range from 500 to 5,000 pairs, depending on the manufacturer’s capacity and customization level. Lead times usually span 4–12 weeks, including sample development, production, and shipping, but can vary based on order size and destination. Payment terms commonly include 30% upfront deposit with the balance payable before shipment, or letters of credit for larger transactions. Negotiate flexible terms where possible, especially for initial orders, and build in buffer periods for delays. Establish clear communication channels to align expectations and ensure smooth transactions.

Illustrative Image (Source: Google Search)

4. What certifications and quality assurance measures should I look for in suppliers?

Suppliers should have certifications demonstrating compliance with international safety, environmental, and labor standards. Look for ISO 9001 for quality management, ISO 14001 for environmental practices, and Fair Labor certifications like SA8000. Request detailed quality control procedures, including inspection reports, material testing, and in-process checks. Verify if the supplier participates in recognized industry standards or has third-party testing results for durability, colorfastness, and safety. Establish quality agreements upfront, including procedures for handling defective products or discrepancies, to mitigate risks of non-compliance or substandard quality.

5. How can I manage logistics and shipping efficiently when importing lime green shoes internationally?

Effective logistics management involves selecting reliable freight forwarders experienced in international shipments, especially to your region. Consider options like sea freight for cost efficiency or air freight for faster delivery. Work with suppliers who can provide comprehensive shipping documentation, including invoices, packing lists, and certificates of origin. Negotiate Incoterms (e.g., FOB, CIF) that suit your risk and cost preferences. Use tracking systems to monitor shipments in real-time, and plan for customs clearance procedures in your country. Building strong relationships with logistics partners ensures timely deliveries and minimizes delays or unexpected costs.

6. What common disputes might arise, and how can I proactively prevent or resolve them?

Disputes often involve quality discrepancies, late deliveries, or payment issues. To prevent these, establish detailed contracts covering specifications, timelines, penalties, and dispute resolution mechanisms (e.g., arbitration). Maintain clear communication throughout the order process, including regular updates and inspections. Document all agreements, amendments, and correspondences. In case of disputes, approach resolution collaboratively, leveraging third-party mediators if necessary. Having a well-defined return and warranty policy also helps manage quality concerns. Proactive relationship management and transparent communication are key to minimizing conflicts and ensuring swift resolution.

7. How do I ensure compliance with regional import regulations and standards?

Research import regulations specific to your country, including tariffs, taxes, and product standards. For example, in Europe, compliance with CE marking and REACH regulations is mandatory, while in Egypt or South America, specific local standards may apply. Work with suppliers familiar with these requirements or engage customs consultants to facilitate smooth clearance. Request compliance documentation, such as test reports or certificates, to verify adherence. Regularly monitor regulatory updates to avoid non-compliance issues that could delay shipments or incur penalties. Building a compliance-aware procurement process reduces risks and enhances your reputation in the market.

8. What are best practices for establishing long-term B2B relationships with lime green shoe suppliers?

Long-term relationships are built on trust, transparency, and mutual benefit. Start with small, manageable orders to test supplier performance and quality. Provide clear feedback and communicate your evolving needs openly. Offer timely payments and consider volume commitments or long-term contracts to incentivize suppliers. Visit manufacturing facilities if possible, to strengthen relationships and ensure ongoing quality control. Share market insights and collaborate on product innovation to foster loyalty. Maintaining consistent communication, resolving issues swiftly, and honoring agreements position you as a valued partner, encouraging suppliers to prioritize your orders and support your growth strategy.

This comprehensive FAQ aims to equip international B2B buyers from diverse regions with practical, actionable insights for sourcing lime green shoes effectively and securely.

Strategic Sourcing Conclusion and Outlook for lime green shoes

Strategic Sourcing Outlook for Lime Green Shoes

Effective strategic sourcing is vital for international B2B buyers seeking to capitalize on the vibrant market potential of lime green shoes. Key considerations include establishing reliable supply chains, assessing quality standards, and negotiating favorable terms with suppliers across regions such as Africa, South America, the Middle East, and Europe. Diversifying sourcing channels can mitigate risks associated with geopolitical fluctuations, currency volatility, and supply disruptions.

Looking ahead, embracing innovation in materials and manufacturing processes will be crucial to meeting evolving consumer preferences and sustainability expectations. Buyers should prioritize building strong supplier relationships, leveraging trade agreements, and staying informed about regional market dynamics to secure competitive advantages.

For Africa, South America, the Middle East, and Europe—regions rich in manufacturing talent and emerging markets—there is significant opportunity to develop strategic partnerships that enhance product differentiation and market penetration.

Actionable Takeaway: Proactively engage with regional suppliers, invest in quality assurance, and continuously monitor market trends to ensure a resilient and forward-looking sourcing strategy. The future of lime green shoes lies in agility, innovation, and strategic collaboration—elements that will empower international buyers to succeed in this vibrant segment.