Master Global Sourcing of Marathon Shoes for Competitive

Guide to Marathon Shoes

- Introduction: Navigating the Global Market for marathon shoes

- Understanding marathon shoes Types and Variations

- Key Industrial Applications of marathon shoes

- Strategic Material Selection Guide for marathon shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for marathon shoes

- Comprehensive Cost and Pricing Analysis for marathon shoes Sourcing

- Spotlight on Potential marathon shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for marathon shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the marathon shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of marathon shoes

- Strategic Sourcing Conclusion and Outlook for marathon shoes

Introduction: Navigating the Global Market for marathon shoes

In the highly competitive world of endurance sports, marathon shoes are more than just footwear—they are a critical factor influencing athlete performance, brand reputation, and market success. For international B2B buyers, understanding the nuances of this specialized product is essential to making informed sourcing decisions that meet quality standards, cost expectations, and consumer demands across diverse markets.

This comprehensive guide offers an in-depth exploration of the marathon shoe industry, covering key aspects such as product types, innovative materials, manufacturing processes, quality control protocols, and supplier sourcing strategies. It also provides actionable insights into pricing dynamics, regional market preferences, and regulatory considerations vital for strategic procurement.

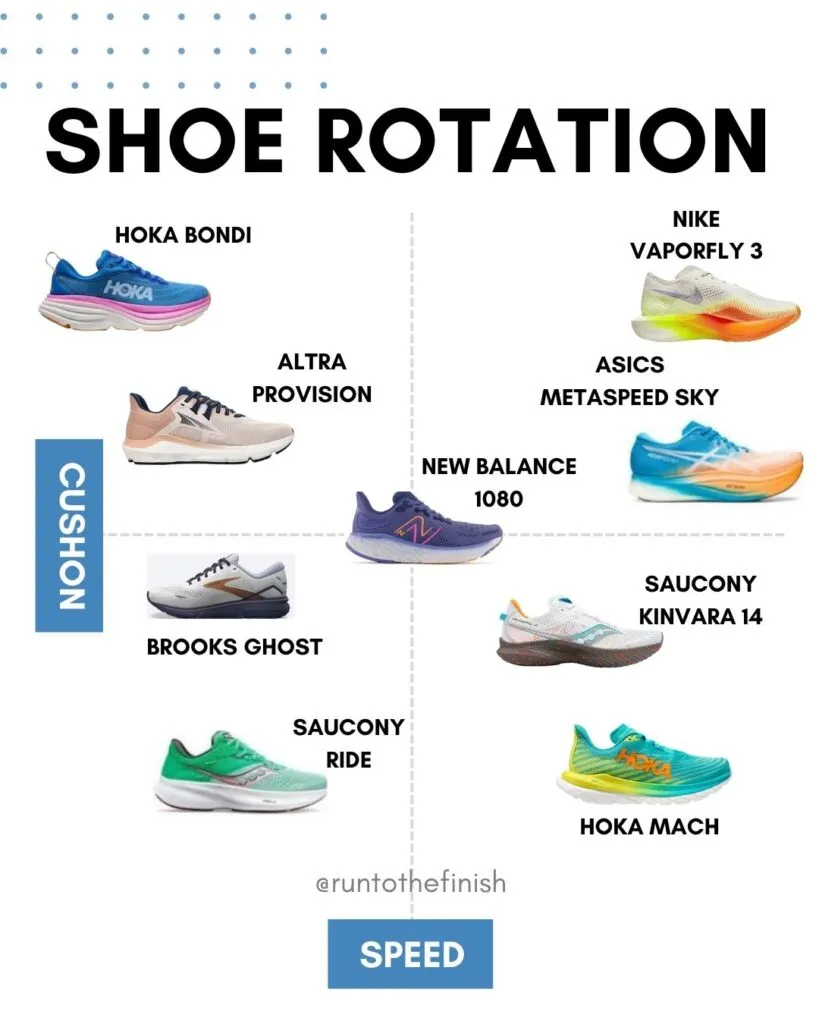

Illustrative Image (Source: Google Search)

By equipping buyers from Africa, South America, the Middle East, and Europe—such as France and Brazil—with authoritative knowledge, this guide aims to streamline their sourcing process and reduce risks. Whether establishing new supplier relationships or optimizing existing supply chains, this resource empowers you to navigate the global marathon shoe market confidently, ensuring you deliver high-performance products tailored to your target markets’ unique needs.

Understanding marathon shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Lightweight Racing Shoes | Minimal cushioning, thin soles, aerodynamic design | Professional race events, elite training | Pros: High performance, competitive edge; Cons: Limited durability, higher cost per unit |

| Maximalist Marathon Shoes | Extra cushioning, thick midsoles, plush upper material | Long-distance training, mass-market retail | Pros: Superior comfort, injury prevention; Cons: Heavier, less responsive, higher manufacturing costs |

| Stability Shoes | Supportive structure, medial posts, reinforced heel counter | Runners with overpronation, injury-prone athletes | Pros: Enhanced support, injury mitigation; Cons: Bulkier, potentially higher price for specialized features |

| Neutral Shoes | Balanced cushioning, flexible midsole, moderate support | General marathon runners, diverse foot types | Pros: Versatile, widely applicable; Cons: Less specialized support for specific needs |

| Custom/Hybrid Shoes | Tailored features, adjustable components, hybrid cushioning systems | Niche markets, bespoke retail, specialty stores | Pros: High customization, targeted performance; Cons: Higher lead times, increased costs |

Lightweight Racing Shoes

Lightweight racing shoes are engineered for speed, featuring minimal cushioning and thin soles to reduce weight and enhance responsiveness. These shoes are ideal for elite athletes and competitive runners aiming for maximum efficiency. For B2B buyers, sourcing high-performance lightweight shoes requires attention to durability, as reduced material thickness can compromise lifespan. Bulk purchasing from reputable manufacturers with proven quality control ensures consistent product performance, critical for maintaining brand reputation in high-stakes markets.

Maximalist Marathon Shoes

Maximalist shoes prioritize cushioning and comfort, with thick midsoles and plush uppers designed to absorb impact over long distances. They appeal to a broad segment, including recreational runners and those seeking injury prevention. B2B buyers should consider the trade-off between comfort and weight, as these shoes tend to be heavier and may incur higher manufacturing costs. Sourcing from brands that emphasize innovative foam technologies can provide a competitive edge in markets emphasizing health and injury reduction.

Stability Shoes

Designed for runners with overpronation or those requiring additional support, stability shoes feature medial posts and reinforced heel counters. They are suitable for long-distance runners with specific biomechanical needs, making them a staple in medical and sports specialty markets. When procuring stability shoes, buyers should verify the consistency of support features and ensure compliance with regional safety standards. Bulk orders benefit from partnerships with manufacturers offering customizable stability features to cater to diverse consumer needs.

Neutral Shoes

Neutral shoes offer a balanced combination of cushioning and flexibility, making them suitable for a wide range of runners. They are popular in mass-market retail and general sporting goods channels. For B2B buyers, sourcing neutral shoes involves assessing manufacturing quality, especially in cushioning materials and flexibility. These shoes often serve as a baseline product, so establishing relationships with reliable suppliers ensures steady supply and the ability to adapt to evolving consumer preferences.

Custom/Hybrid Shoes

Custom or hybrid marathon shoes combine various features tailored to specific runner profiles, often incorporating adjustable components or hybrid cushioning systems. They cater to niche markets, including high-end retail and specialty sports stores. B2B buyers should focus on establishing partnerships with manufacturers capable of delivering bespoke solutions with consistent quality. While costs are higher, the ability to offer customized products can significantly differentiate a retailer in competitive markets, especially in regions like Europe and North America where personalization is valued.

Key Industrial Applications of marathon shoes

| Industry/Sector | Specific Application of marathon shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports & Athletic Wear | Manufacturing high-performance running shoes for professional and amateur athletes | Enhances brand reputation, supports premium product lines | Material quality, durability, compliance with international sports standards |

| Healthcare & Rehabilitation | Designing specialized footwear for injury recovery and orthopedics | Provides tailored solutions, expands market reach | Customization capabilities, biocompatibility, regulatory approvals |

| Military & Defense | Developing rugged, high-traction footwear for personnel in demanding environments | Improves safety and operational effectiveness | Ruggedness, slip resistance, compliance with military standards |

| Corporate & Promotional Events | Creating branded marathon shoes for sponsorships and corporate challenges | Boosts brand visibility, creates unique promotional merchandise | Customization options, branding fidelity, lead time considerations |

| Retail & Wholesale Distribution | Supplying durable, affordable marathon shoes for mass retail chains | Increases sales volume, broadens market penetration | Cost competitiveness, consistent quality, reliable supply chain |

Sports & Athletic Wear

Marathon shoes are central to the production of high-performance athletic footwear aimed at professional athletes and fitness enthusiasts. These shoes are engineered for optimal cushioning, lightweight design, and durability, catering to the needs of competitive runners. For B2B buyers in regions like Europe or Brazil, sourcing high-quality materials and adhering to international sports standards is essential to meet consumer expectations and build brand credibility. Reliable supply chains and innovative design capabilities can also provide a competitive edge in the global sportswear market.

Healthcare & Rehabilitation

In the healthcare sector, marathon shoes are increasingly used to develop specialized footwear for injury recovery, orthopedics, and mobility support. These shoes often feature custom orthotic insoles, enhanced cushioning, and ergonomic designs to aid rehabilitation. International buyers from Africa or the Middle East seeking to expand into medical supplies must prioritize sourcing from manufacturers with strong regulatory compliance, biocompatible materials, and customization expertise. This ensures the delivery of safe, effective products that meet local healthcare standards.

Military & Defense

Marathon shoes are utilized in the design of rugged, high-traction footwear for military personnel operating in diverse and challenging environments. These shoes must withstand extreme conditions, provide slip resistance, and support prolonged wear. For B2B buyers in regions like South America or the Middle East, sourcing durable, military-grade footwear involves evaluating material toughness, adherence to military standards, and supply chain reliability. Such footwear enhances operational safety and performance, making it a strategic procurement priority.

Corporate & Promotional Events

Marathon shoes serve as effective promotional tools when customized with corporate branding for sponsorships, charity runs, or corporate wellness initiatives. These shoes create memorable branding opportunities and foster community engagement. International buyers from Europe or Africa should focus on suppliers offering high-quality customization, quick turnaround times, and consistent branding fidelity. This approach maximizes brand visibility while maintaining product quality during large-scale promotional campaigns.

Retail & Wholesale Distribution

Marathon shoes are a staple in mass retail and wholesale distribution channels, offering consumers durable and affordable options for daily running or fitness activities. B2B buyers in emerging markets, such as Brazil or parts of Africa, benefit from sourcing reliable, cost-competitive products that meet international quality standards. Ensuring supply chain stability and consistent product quality is vital for building consumer trust and expanding market share in competitive retail environments.

Strategic Material Selection Guide for marathon shoes

Material Analysis for Marathon Shoe Manufacturing

Selecting the appropriate materials for marathon shoes is critical for ensuring optimal performance, durability, and cost-effectiveness. For international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, understanding the properties and implications of each material is essential for making informed procurement decisions.

Thermoplastic Polyurethane (TPU)

Key Properties:

TPU is a versatile polymer known for its excellent elasticity, abrasion resistance, and flexibility. It maintains performance across a wide temperature range (-40°C to +80°C), making it suitable for various climates. Its chemical resistance includes oils, greases, and some solvents, which enhances durability in diverse environments.

Pros & Cons:

* Pros:*

– High durability and flexibility, ideal for outsole and midsole components.

– Good weather resistance, including UV stability.

– Relatively easy to process via injection molding or extrusion, suitable for mass production.

- Cons:*

- Higher cost compared to standard rubber or EVA.

- Manufacturing requires specialized equipment, increasing initial investment.

- Recycling can be complex, impacting sustainability considerations.

Impact on Application & International Considerations:

TPU performs well in high-wear areas, reducing the frequency of replacement. For markets like Europe and France, compliance with REACH regulations and other environmental standards is necessary. In regions like Africa and South America, supply chain stability and local supplier availability can influence costs and lead times.

Ethylene Vinyl Acetate (EVA)

Key Properties:

EVA is a lightweight, flexible foam material with excellent shock absorption properties. It performs reliably in a broad temperature range (-30°C to +60°C), though it can become brittle in extreme cold. Its chemical resistance is moderate, with susceptibility to certain solvents.

Pros & Cons:

* Pros:*

– Cost-effective, making it popular for midsole cushioning.

– Lightweight, enhancing overall shoe performance.

– Easy to mold into complex shapes, suitable for customized insoles.

- Cons:*

- Less durable under prolonged exposure to UV and ozone, leading to potential cracking over time.

- Can degrade faster in humid or tropical climates if not properly treated.

- Limited recyclability, raising sustainability concerns.

Impact on Application & International Considerations:

EVA’s affordability makes it attractive in emerging markets like Brazil and parts of Africa. However, buyers should verify supplier compliance with local environmental standards, such as the European REACH or Brazil’s ABNT standards. Proper formulation and UV stabilizers can mitigate some durability issues.

Carbon Fiber Reinforced Composites

Key Properties:

These composites combine carbon fibers with resin matrices, resulting in materials with exceptional strength-to-weight ratios. They withstand high mechanical stresses and have excellent fatigue resistance. Temperature tolerance varies depending on the resin, typically between -40°C and +150°C.

Pros & Cons:

* Pros:*

– Significantly reduces weight while maintaining strength, ideal for performance-enhancing shoe components.

– High fatigue and impact resistance.

– Long-lasting, reducing replacement frequency.

- Cons:*

- Very high manufacturing costs, often limiting use to premium products.

- Complex fabrication processes requiring specialized equipment and expertise.

- Recycling is challenging, potentially impacting sustainability credentials.

Impact on Application & International Considerations:

For high-end marathon shoes targeting elite athletes, carbon fiber composites are increasingly popular. Buyers in Europe and the Middle East should ensure suppliers meet strict safety and environmental standards, such as REACH and RoHS. In emerging markets, cost constraints may limit adoption to premium segments.

Natural Rubber

Key Properties:

Natural rubber offers excellent elasticity, resilience, and grip. It performs well across a temperature range of -50°C to +50°C, with good abrasion and tear resistance. However, it is susceptible to environmental degradation from ozone, UV, and certain chemicals.

Pros & Cons:

* Pros:*

– Cost-effective and readily available in regions like Africa and South America.

– Excellent grip and shock absorption, beneficial for outsole performance.

– Biodegradable, aligning with sustainability goals.

- Cons:*

- Limited weather resistance; prone to cracking in UV-heavy environments.

- Can degrade faster in tropical climates if not properly treated.

- Variability in quality depending on sourcing.

Impact on Application & International Considerations:

Natural rubber is favored in markets with local rubber industries, such as Brazil and parts of Africa. Buyers should verify quality standards (e.g., ASTM D1566) and consider supplier certifications. Environmental regulations, especially in Europe, may require documentation on sustainable sourcing and processing.

Summary Table

| Material | Typical Use Case for marathon shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic Polyurethane (TPU) | Outsole, midsole reinforcement | High durability and weather resistance | Higher cost, complex recycling | High |

| Ethylene Vinyl Acetate (EVA) | Midsole cushioning, insoles | Lightweight, cost-effective | Less durable in UV/tropical climates | Low |

| Carbon Fiber Reinforced Composites | Structural components, performance-enhancing parts | Ultra-lightweight, high strength | Very high cost, complex manufacturing | High |

| Natural Rubber | Outsole, grip surfaces | Excellent grip and elasticity | Weather and ozone susceptibility | Low |

This comprehensive understanding of material properties and regional considerations will enable B2B buyers to optimize procurement strategies, ensuring product quality, compliance, and cost-efficiency tailored to their target markets.

In-depth Look: Manufacturing Processes and Quality Assurance for marathon shoes

Manufacturing Processes for Marathon Shoes

The production of marathon shoes involves a complex series of stages designed to optimize performance, durability, and comfort. Understanding these stages enables B2B buyers to better evaluate supplier capabilities and ensure product quality.

1. Material Preparation

The process begins with sourcing high-quality raw materials such as synthetic meshes, thermoplastic polyurethane (TPU), EVA foam, rubber compounds, and specialized adhesives. Suppliers often source these materials from certified providers to meet international standards. Material inspection at this stage involves checking for defects, consistency, and compliance with specifications, often through incoming quality control (IQC).

2. Forming and Molding

Once materials pass initial inspection, they are cut and shaped into components using advanced techniques like CNC cutting, die-cutting, and thermoforming. For midsoles and outsoles, injection molding and compression molding are common, ensuring precise dimensions and structural integrity. This stage requires strict control over temperature, pressure, and cycle times to maintain consistency across batches.

3. Assembly and Stitching

The assembled components—upper, midsole, outsole, and lacing system—are joined using high-frequency welding, heat bonding, or stitching. Automated sewing machines are often employed for uniformity, especially in high-volume production. Adhesives used must meet safety and environmental standards (e.g., REACH compliance in Europe). Proper assembly is critical to ensure that the shoes withstand rigorous marathon conditions.

4. Finishing and Quality Checks

Final finishing involves trimming excess material, applying logos, and adding functional elements like reflective strips or padding. Surface treatments such as waterproofing or anti-slip coatings are also applied. The completed shoes undergo initial visual inspections to identify cosmetic defects and ensure adherence to design specifications.

Quality Assurance Frameworks and Standards

Robust quality assurance (QA) is essential to meet international market demands and ensure consumer safety. Key standards and checkpoints include:

1. International Standards

– ISO 9001: The cornerstone of quality management systems, ISO 9001 certification indicates that a manufacturer adheres to consistent quality processes. Many international buyers require this certification as a baseline.

– ISO 14001: Environmental management standards may also be relevant, particularly for eco-conscious markets.

– Other Relevant Certifications: CE marking (Europe), ASTM standards, and specific industry certifications like API (for certain performance aspects) may apply depending on the target market.

2. Industry-Specific Certifications

– CE Marking (European Market): Ensures compliance with safety, health, and environmental protection standards.

– API Standards: For shoes designed for specific performance or safety requirements, such as slip resistance or waterproofing, API standards may be relevant.

Quality Control (QC) Checkpoints and Testing Methods

Effective QC involves multiple layers throughout the manufacturing process:

1. Incoming Quality Control (IQC)

Materials are inspected upon arrival for defects, dimensional accuracy, and compliance with specifications. Techniques include visual inspections, sample testing, and chemical analysis to verify material properties.

2. In-Process Quality Control (IPQC)

During manufacturing, checkpoints monitor critical parameters such as molding temperature, assembly alignment, stitching quality, and adhesive bonding. Automated inspection systems and manual audits ensure consistency.

3. Final Quality Control (FQC)

Before shipment, finished shoes undergo comprehensive testing, including:

– Visual Inspection: Checking for cosmetic defects, loose threads, or misalignments.

– Dimensional Checks: Ensuring size and shape accuracy.

– Functional Tests: Testing outsole grip, flexibility, and water resistance.

– Durability Tests: Simulating long-term wear through mechanical fatigue, flex testing, and abrasion testing.

4. Laboratory Testing Methods

– Mechanical Testing: Tensile, compression, and fatigue tests to evaluate structural integrity.

– Environmental Testing: Exposure to UV, temperature extremes, and moisture to assess durability.

– Slip Resistance Testing: Ensures soles meet safety standards for various surfaces.

How B2B Buyers Can Verify Supplier QC

To mitigate risks and ensure product quality, buyers should adopt a proactive approach:

- Supplier Audits: Conduct on-site inspections or utilize third-party auditors familiar with manufacturing standards to assess facilities, processes, and quality management systems.

- Review Quality Reports: Request detailed quality reports, test certificates, and ISO certifications to verify compliance.

- Third-Party Inspection Services: Engage independent inspection firms (e.g., SGS, Bureau Veritas) to perform pre-shipment inspections and random sampling tests.

- Sample Testing: Arrange for independent testing of samples to validate claims about durability, performance, and safety standards.

Considerations for International B2B Buyers from Different Regions

Africa and South America:

Manufacturers targeting these markets should demonstrate adherence to international standards, especially ISO 9001, and provide transparent documentation. Buyers should verify compliance with local import regulations and standards, such as the South American INMETRO or African Bureau of Standards. Additionally, establishing long-term partnerships with suppliers who have experience exporting to these regions ensures smoother logistics and compliance.

Middle East:

Given the emphasis on safety and premium quality, suppliers with CE marking and ISO certifications are preferred. Buyers should also verify adherence to environmental standards, as many Middle Eastern countries are increasingly focused on sustainable manufacturing practices.

Europe (e.g., France):

European buyers often prioritize environmental and safety standards, requiring thorough documentation of compliance with CE, REACH, and other regulations. Certification audits and third-party testing are highly valued. Demonstrating ongoing quality management, traceability, and sustainability initiatives enhances supplier credibility.

Brazil:

Brazilian importers seek suppliers with ISO 9001 certification and compliance with local standards such as INMETRO. Clear documentation and third-party test reports facilitate customs clearance and market acceptance. B2B buyers should also verify suppliers’ capacity to meet high-volume demands and their experience with export logistics.

Final Recommendations for B2B Buyers

- Prioritize Suppliers with Certified Quality Management Systems: ISO 9001 and industry-specific certifications reduce risks and ensure consistent quality.

- Implement Rigorous Due Diligence: Combine audits, documentation reviews, and independent testing to validate supplier claims.

- Establish Clear Quality Expectations: Include detailed quality clauses in contracts, specifying testing methods, inspection frequency, and compliance standards.

- Foster Transparent Communication: Maintain open channels with suppliers to address QC issues promptly and ensure continuous improvement.

By understanding and rigorously evaluating manufacturing processes and quality assurance protocols, B2B buyers can confidently select reliable partners capable of delivering high-performance marathon shoes tailored for diverse international markets.

Comprehensive Cost and Pricing Analysis for marathon shoes Sourcing

Breakdown of Cost Components in Marathon Shoe Manufacturing

Understanding the cost structure of marathon shoes is crucial for international B2B buyers aiming to optimize procurement. The primary cost components include:

-

Materials: High-performance synthetic uppers, lightweight foams, durable rubber outsoles, and specialized insoles contribute significantly to costs. Premium materials that enhance breathability, flexibility, and durability typically command higher prices but can justify premium retail positioning.

-

Labor: Labor costs vary widely based on the sourcing country. Manufacturers in Asia (e.g., Vietnam, China) often offer lower wages, while suppliers in Eastern Europe or North Africa may provide a balance of cost and quality. Ensure that labor standards and compliance certifications are verified to mitigate reputational and legal risks.

-

Manufacturing Overhead: This includes factory maintenance, energy, equipment depreciation, and quality control processes. Efficient factories with advanced automation tend to have lower overhead per unit, influencing overall pricing favorably.

-

Tooling and Setup Costs: Initial tooling for molds and specialized equipment can be substantial but are amortized over large production runs. For smaller orders or customization, these costs can inflate unit prices.

-

Quality Control (QC): Rigorous QC processes ensure compliance with safety and performance standards, especially for international markets requiring certifications like ISO or CE. High QC standards may slightly increase costs but reduce downstream returns and reputational risks.

-

Logistics: Shipping costs depend on order volume, destination, and chosen Incoterms. Bulk shipments via sea freight are more economical but slower, while air freight offers speed at a premium. Consider customs duties, taxes, and import tariffs in the total landed cost.

-

Profit Margin: Suppliers typically add a margin to cover their risks and ensure profitability. Margins can vary based on order size, payment terms, and supplier reputation.

Key Price Influencers for B2B Sourcing

Several factors impact the final pricing and should be carefully negotiated:

-

Order Volume & MOQ: Higher volumes generally lead to lower unit prices due to economies of scale. Many suppliers offer discounts for large orders, but minimum order quantities (MOQs) can be a barrier for smaller buyers.

-

Specifications & Customization: Customized designs, branding, or specific performance features (e.g., enhanced grip, specialized cushioning) increase costs. Clear specifications upfront help in accurate quoting and avoiding unexpected charges.

-

Material Choices: Opting for premium or eco-friendly materials can elevate costs but appeal to target markets emphasizing sustainability. Conversely, standard materials may reduce costs but limit premium positioning.

-

Certifications & Standards: Compliance with regional standards (e.g., EU REACH, Brazilian INMETRO) or performance certifications can add costs but are often necessary for market entry.

-

Supplier Factors: Reputation, reliability, and production capacity influence pricing. Established suppliers with certifications and quality track records may charge a premium but reduce sourcing risks.

-

Incoterms & Logistics: FOB (Free on Board) prices are common, but buyers should consider additional costs like freight, insurance, and customs clearance. Negotiating favorable Incoterms can significantly impact total landed costs.

Practical Tips for International B2B Buyers

-

Negotiate for Better Pricing & Terms: Leverage volume, long-term commitments, or multiple product lines to negotiate discounts or favorable payment terms. Building strong supplier relationships can lead to better pricing over time.

-

Focus on Total Cost of Ownership (TCO): Beyond unit price, consider logistics, customs, quality assurance, and after-sales support. Sometimes paying slightly more upfront reduces downstream costs and risks.

-

Understand Pricing Nuances: Prices can vary based on order size, seasonality, and market demand. Request detailed quotes that specify all cost components to avoid hidden charges.

-

Assess Supplier Credibility: Verify certifications, quality control processes, and references. A cheaper quote from an unverified supplier might incur higher costs due to delays or quality issues.

-

Plan for Lead Times & Flexibility: Manufacturing and shipping timelines impact costs and inventory planning. Ensure suppliers can meet your schedule to avoid expedited shipping costs.

Disclaimer on Price Ranges

Indicative prices for marathon shoes typically range from $10 to $30 per pair at large production volumes for standard models. Premium or customized shoes may range from $30 to $60+ per pair. These figures are approximate and can fluctuate based on regional supplier pricing, material costs, and economic conditions. Always request detailed quotes and conduct supplier audits before finalizing agreements.

By understanding these components and factors, international B2B buyers from Africa, South America, the Middle East, and Europe can make informed sourcing decisions that balance cost, quality, and reliability—ultimately ensuring competitive advantage in their target markets.

Spotlight on Potential marathon shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for marathon shoes.)*

Essential Technical Properties and Trade Terminology for marathon shoes

Key Technical Properties

1. Material Grade and Composition

The choice of materials—such as the type of foam, mesh, and rubber—is fundamental. High-grade EVA or Pebax foams are preferred for lightweight cushioning, while durable rubber compounds ensure longevity. For international buyers, sourcing consistent material grades guarantees product quality, reduces return rates, and aligns with specific market standards.

2. Weight and Thickness

The overall weight of marathon shoes significantly impacts runner performance and comfort. Lightweight shoes (typically under 200 grams per shoe) are favored for competitive racing. Thickness of the midsole influences cushioning and shock absorption; precise specifications help buyers match shoes to different race conditions and athlete preferences.

3. Flexibility and Durability

Flexibility, often measured through bend tests, ensures the shoe moves naturally with the foot, reducing fatigue. Durability, assessed via abrasion resistance tests, guarantees the shoes withstand long-distance use without premature wear. These properties are crucial for athletes and ensure the product’s reliability across diverse terrains.

4. Fit and Comfort Specifications

Technical parameters such as arch support, heel cup stability, and toe box volume must meet ergonomic standards. Precise sizing tolerances (e.g., ±1 mm) ensure consistent fit across batches, minimizing returns and enhancing athlete satisfaction. For B2B buyers, understanding these specs aids in selecting products suited for regional foot shapes.

5. Breathability and Weighting Technologies

Advanced textiles with moisture-wicking properties and lightweight mesh uppers improve comfort during extended runs. Incorporating these features can differentiate products in competitive markets, especially in warmer climates like Brazil or the Middle East.

Industry and Trade Terms

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce marathon shoes branded by other firms. Understanding OEM relationships helps B2B buyers negotiate product customization, branding rights, and production timelines, essential for private-label or white-label strategies.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce per order. Knowing the MOQ is vital for planning inventory levels and negotiating pricing, especially when entering new markets or testing product acceptance in regions like Africa or Europe.

3. RFQ (Request for Quotation)

A formal request sent to suppliers asking for detailed pricing, lead times, and terms. Utilizing RFQs allows buyers to compare offers accurately, ensure competitive pricing, and clarify technical specifications before committing.

4. Incoterms (International Commercial Terms)

Standardized trade terms such as FOB (Free on Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid) define responsibilities and costs during shipping. Mastery of Incoterms ensures clear logistics planning and cost control across diverse regions.

5. Lead Time

The period between order placement and product delivery. Awareness of lead times helps buyers synchronize production schedules, particularly important when managing seasonal demand or launching marketing campaigns in target markets.

6. Certification and Compliance Terms

Standards such as ISO, CE, or regional safety certifications ensure products meet legal requirements. Confirming these standards prevents delays at customs and ensures acceptance in markets with strict regulatory environments, like Europe or Brazil.

In Summary:

For international B2B buyers, mastering these technical properties and trade terms is essential for making informed procurement decisions. Clear understanding of material specifications ensures product quality suited to regional needs. Familiarity with trade jargon like OEM, MOQ, and Incoterms streamlines negotiations, reduces risks, and optimizes supply chain efficiency. This strategic knowledge foundation enables buyers to secure competitive, high-quality marathon shoes tailored to their markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the marathon shoes Sector

Market Overview & Key Trends

The global marathon shoes market is experiencing robust growth driven by increasing participation in long-distance running events, rising health consciousness, and technological advancements in footwear. For international B2B buyers from regions like Africa, South America, the Middle East, and Europe, understanding these drivers is crucial to capitalizing on emerging opportunities.

Technological innovation remains a key trend, with brands investing heavily in lightweight, breathable materials, energy-returning midsoles, and customized fit solutions. Digitalization is transforming sourcing and procurement processes, enabling more streamlined supply chains through advanced analytics, online marketplaces, and real-time inventory management.

Illustrative Image (Source: Google Search)

Emerging markets, particularly in Africa and South America, are witnessing a surge in local manufacturing capabilities, driven by government incentives and rising consumer demand for affordable, quality athletic footwear. European markets, especially countries like France, are pushing for high-performance, sustainable products, influencing global supply chain standards. The Middle East presents a unique opportunity, with a growing middle class seeking premium, technologically advanced marathon shoes.

For B2B buyers, sourcing trends include a shift toward direct-from-manufacturer procurement, reducing intermediaries, and leveraging factory collaborations for innovation. Sustainability-focused sourcing is increasingly prioritized, with brands seeking suppliers who can meet environmental standards and certifications. Understanding regional preferences, regulatory environments, and local manufacturing capabilities is essential for effective market penetration and supply chain resilience.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer optional but a core criterion in sourcing marathon shoes. The environmental impact of footwear production, particularly in terms of carbon emissions, water usage, and waste management, has come under scrutiny from consumers, regulators, and industry stakeholders. B2B buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers with transparent, ethical supply chains that adhere to internationally recognized standards.

Key certifications such as ISO 14001 (Environmental Management), Fair Trade, and Bluesign® are increasingly demanded by brands committed to sustainability. The use of eco-friendly materials—such as recycled polyester, biodegradable rubbers, and plant-based adhesives—can significantly reduce the environmental footprint of marathon shoes. Additionally, incorporating circular economy principles, like designing for recyclability and facilitating product take-back programs, can enhance brand reputation and meet regulatory requirements.

Ethical sourcing involves ensuring fair labor practices, safe working conditions, and traceability across the supply chain. B2B buyers should conduct thorough audits and establish long-term partnerships with suppliers committed to social responsibility. Investing in sustainable materials and ethical manufacturing not only aligns with global trends but also opens access to premium markets where eco-conscious consumers are willing to pay a premium for sustainably produced footwear.

Brief Evolution/History

The evolution of marathon shoes reflects technological innovation and changing consumer expectations. Initially, running shoes prioritized basic cushioning and durability. Over time, advancements like Nike’s Air Max and Adidas’ Boost technology revolutionized comfort and performance. The integration of lightweight materials, improved biomechanics, and smart textiles has transformed marathon footwear into high-performance gear tailored for competitive athletes and enthusiasts alike.

Illustrative Image (Source: Google Search)

For B2B buyers, understanding this evolution is key to sourcing products that balance innovation, cost, and sustainability. Long-term partnerships with R&D-focused manufacturers can provide access to cutting-edge designs and materials, ensuring competitiveness in a rapidly evolving market. Recognizing the importance of historical trends helps in forecasting future shifts, such as the increasing emphasis on eco-friendly materials and digital customization capabilities.

Frequently Asked Questions (FAQs) for B2B Buyers of marathon shoes

1. How can I effectively vet marathon shoe suppliers to ensure quality and reliability?

To vet suppliers effectively, start by requesting comprehensive company credentials, including business licenses, manufacturing certifications (such as ISO or BSCI), and quality assurance documents. Review their product catalogs and request samples to assess material quality, craftsmanship, and comfort. Check references from other international buyers and seek supplier certifications like OEKO-TEX or REACH compliance to ensure safety standards. Conduct virtual factory visits or third-party audits if possible. Additionally, evaluate their communication responsiveness and transparency, which are vital indicators of reliability for long-term partnerships.

2. What customization options are typically available for marathon shoes, and how do they impact MOQ and lead times?

Suppliers often offer customization in areas such as branding (logos, labels), colorways, materials, and sole designs. Some may also provide custom packaging or specific technical features like enhanced grip or arch support. Customization usually requires higher Minimum Order Quantities (MOQs) and longer lead times, often ranging from 4 to 12 weeks depending on complexity. To optimize costs and timelines, clearly define your specifications early and negotiate flexible MOQs or phased production runs. Confirm whether the supplier can accommodate rapid prototyping or smaller batches if needed for market testing.

3. What are typical MOQ, lead times, and payment terms for bulk marathon shoe orders?

MOQ varies significantly depending on the manufacturer, typically ranging from 500 to 5,000 pairs for standard models. Lead times generally span 4 to 12 weeks after order confirmation, influenced by production capacity and customization requirements. Payment terms are often 30% upfront with the balance payable before shipment, though some suppliers may offer letters of credit or trade finance options for large orders. Negotiating favorable terms involves building trust, providing clear forecasts, and establishing long-term relationships, which can lead to better payment conditions and priority production.

4. Which certifications and quality assurance measures should I verify before importing marathon shoes?

Ensure the supplier complies with relevant safety and quality standards applicable in your target market. Common certifications include ISO 9001 (quality management), OEKO-TEX (chemical safety), REACH (chemical regulation in Europe), and ASTM or ISO standards for athletic footwear performance. Request detailed Quality Control (QC) reports, inspection certificates, and testing reports for durability, slip resistance, and comfort. Consider engaging third-party inspection agencies for pre-shipment quality checks, especially when importing large volumes. These measures help mitigate risks of product recalls, legal issues, or customer dissatisfaction.

5. How can I manage logistics and shipping effectively for international marathon shoe orders?

Start by selecting reliable freight forwarders experienced in handling footwear shipments, considering options like sea freight for cost efficiency or air freight for faster delivery. Clarify incoterms (e.g., FOB, CIF) to define responsibilities and costs. Factor in customs clearance procedures, import duties, and taxes in your target markets—these can significantly impact total landed costs. Establish clear communication channels with suppliers and logistics partners to track shipments and handle delays proactively. Consider warehousing options in your region for faster distribution, and plan inventory buffers to accommodate lead time variability.

6. What are common dispute resolution mechanisms in international B2B transactions for marathon shoes?

Disputes often arise from quality issues, delivery delays, or payment disagreements. To mitigate risks, include clear arbitration clauses in contracts, specifying jurisdictions such as Hong Kong, Singapore, or your local legal system. Use Incoterms to clearly define responsibility and liability points. Maintain thorough documentation of all communications, purchase agreements, and inspection reports. Engaging third-party mediators or arbitration centers can facilitate faster resolution. Building strong, transparent relationships with suppliers also reduces conflict likelihood. Always have contingency plans, such as alternative suppliers, to minimize disruption.

7. How do I ensure compliance with local regulations and standards when importing marathon shoes into my country?

Research your country’s import regulations, including product safety standards, labeling requirements, and certification mandates. For example, European markets require CE marking and compliance with REACH, while Brazil may require specific INMETRO certifications. Work with suppliers who understand these standards and can provide necessary documentation. Engage local customs brokers or compliance consultants to navigate procedures efficiently. Regularly update your knowledge base as regulations evolve, and maintain meticulous records of certifications and test reports to facilitate smooth customs clearance and avoid penalties.

8. What strategies can I use to build long-term, mutually beneficial relationships with marathon shoe suppliers?

Focus on transparent communication and consistent order volumes to foster trust. Offer timely payments and clear forecasts to help suppliers plan production efficiently. Provide constructive feedback on samples and shipments to improve product quality. Explore partnership opportunities like joint product development or exclusivity agreements to secure better pricing and priority treatment. Invest in supplier visits or virtual tours to understand their operations better. Developing a collaborative approach and demonstrating reliability encourages suppliers to prioritize your orders, ensuring consistent quality and supply continuity in the long run.

Strategic Sourcing Conclusion and Outlook for marathon shoes

Conclusion and Future Perspective

Effective strategic sourcing is essential for B2B buyers seeking to capitalize on the growing global demand for high-performance marathon shoes. By prioritizing supplier diversification, quality assurance, and cost optimization, organizations from Africa, South America, the Middle East, and Europe can establish resilient supply chains that meet both market standards and consumer expectations.

Leveraging innovative manufacturing technologies and fostering strong supplier partnerships will be key to staying competitive. Additionally, understanding regional market nuances—such as sourcing from emerging suppliers in Brazil or exploring sustainable materials from European innovators—can provide a strategic edge.

Looking ahead, the marathon shoe industry will continue to evolve with advancements in materials and design, offering new opportunities for international buyers. Proactive engagement in global sourcing networks and staying informed on industry trends will be critical for sustained success.

Actionable Takeaway: Embrace a strategic, data-driven approach to sourcing, prioritize quality and sustainability, and cultivate collaborative supplier relationships. Doing so will position your organization at the forefront of this dynamic market, unlocking growth opportunities across Africa, South America, the Middle East, and Europe.