Your Ultimate Guide to Sourcing Red Basketball Shoes

Guide to Red Basketball Shoes

- Introduction: Navigating the Global Market for red basketball shoes

- Understanding red basketball shoes Types and Variations

- Key Industrial Applications of red basketball shoes

- Strategic Material Selection Guide for red basketball shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for red basketball shoes

- Comprehensive Cost and Pricing Analysis for red basketball shoes Sourcing

- Spotlight on Potential red basketball shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for red basketball shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the red basketball shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of red basketball shoes

- Strategic Sourcing Conclusion and Outlook for red basketball shoes

Introduction: Navigating the Global Market for red basketball shoes

In the highly competitive and dynamic global sports footwear market, red basketball shoes have emerged as a powerful symbol of athleticism, style, and brand identity. For international B2B buyers—especially from regions such as Africa, South America, the Middle East, and Europe—understanding the nuances of sourcing these products is essential to capitalize on market demand and consumer preferences. Red basketball shoes are not only a staple on courts worldwide but also a lucrative segment for retailers, distributors, and manufacturers aiming to differentiate their offerings.

This comprehensive guide is designed to equip you with actionable insights across critical areas, including product types, materials, manufacturing quality control, supplier sourcing, cost considerations, and market trends. Whether you’re seeking OEM partnerships, private label opportunities, or wholesale procurement, understanding these facets will empower you to make informed, strategic sourcing decisions.

By exploring frequently asked questions and providing practical recommendations, this guide aims to streamline your procurement process, reduce risks, and optimize your supply chain. Navigating the complexities of international markets requires a nuanced approach, especially when dealing with diverse regulatory standards, quality expectations, and price points across continents. Armed with this knowledge, B2B buyers from Africa, South America, the Middle East, and Europe can confidently tap into the vibrant market for red basketball shoes, driving growth and competitive advantage in their respective regions.

Understanding red basketball shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Performance/Competitive Shoes | Lightweight, high-grip soles, advanced cushioning technology | Sports retailers, professional teams, sports academies | Pros: High demand among athletes; enhances brand reputation. Cons: Higher manufacturing costs, limited bulk discounts. |

| Lifestyle/Casual Basketball Shoes | Trendy design, versatile style, moderate performance features | Fashion retailers, casual sportswear brands | Pros: Broader market appeal, higher margin potential. Cons: Lower technical specifications may reduce appeal to serious athletes. |

| Retro/Heritage Models | Classic designs, nostalgic colorways, vintage branding | Specialty boutiques, collectors, premium markets | Pros: Niche market with loyal customer base; premium pricing. Cons: Smaller volume, higher marketing effort needed. |

| Custom/Personalized Shoes | Fully customizable colorways, branding options | Custom sports stores, corporate branding initiatives | Pros: High customer engagement, premium pricing. Cons: Longer production times, complex logistics. |

| Specialized/Performance Variants | Advanced materials for specific conditions (e.g., outdoor use) | Outdoor sports retailers, niche markets | Pros: Differentiated product offering, high customer loyalty. Cons: Higher R&D costs, limited mass-market appeal. |

Performance/Competitive Shoes

These shoes are engineered for maximum athletic performance, featuring lightweight materials, superior grip, and advanced cushioning to support high-impact movements. They are ideal for sports retailers targeting professional teams or serious athletes. B2B buyers should consider the higher manufacturing costs associated with advanced tech but can benefit from premium pricing and brand positioning. Bulk purchasing can help reduce costs, but ensuring consistent quality is crucial to meet athlete expectations.

Lifestyle/Casual Basketball Shoes

Designed with style and versatility in mind, these shoes combine sporty aesthetics with everyday wearability. They appeal to a broader consumer base, including casual players and fashion-conscious buyers. For B2B buyers, sourcing these shoes offers higher margins due to their trendy appeal, but they must balance style trends with durability to sustain reputation. Effective marketing and clear branding are key to maximizing sales in this segment.

Retro/Heritage Models

Retro basketball shoes capitalize on nostalgia, featuring vintage designs and iconic colorways, including red variants. These appeal to collectors and consumers seeking unique, limited-edition items. B2B buyers should focus on establishing partnerships with specialty boutiques or online collectors’ platforms. While profit margins are typically higher, sales volume may be limited, requiring targeted marketing efforts and strategic inventory management.

Custom/Personalized Shoes

Offering customization options—such as personalized colorways, logos, and branding—these shoes cater to corporate clients, sports teams, or individual consumers seeking exclusivity. They provide significant upselling opportunities but involve longer lead times and complex logistics. B2B buyers should evaluate reliable suppliers with flexible manufacturing capabilities and consider minimum order quantities to optimize profitability.

Specialized/Performance Variants

These shoes are tailored for specific conditions, such as outdoor courts or extreme weather, using durable materials and specialized outsoles. They are suitable for niche outdoor sports markets or regional retailers focusing on outdoor activities. While they command premium prices and foster customer loyalty, B2B buyers should carefully assess R&D costs and ensure proper inventory management to avoid overstocking less popular variants.

Key Industrial Applications of red basketball shoes

| Industry/Sector | Specific Application of red basketball shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sportswear & Athletic Apparel | Custom branding and promotional giveaways at sports events | Enhances brand visibility and loyalty among target demographics | Quality consistency, branding customization options, lead times |

| Retail & Wholesale Distribution | Bulk procurement for sports retail chains or online marketplaces | Cost-effective inventory expansion, competitive pricing | Bulk order discounts, reliable supply chain, certification standards |

| Event & Sports Sponsorship | Promotional merchandise for sports tournaments or team sponsorships | Increases brand exposure during high-visibility events | Authenticity verification, compliance with event sponsorship rules |

| Corporate Gifting & Incentives | Branded red basketball shoes as employee or partner incentives | Strengthens corporate relationships, reinforces brand identity | Customization options, delivery timelines, branding quality |

| Manufacturing & Customization | OEM manufacturing or private label branding for local markets | Entry into new markets with tailored products | Manufacturing flexibility, MOQ requirements, quality assurance |

Custom branding and promotional giveaways at sports events

Red basketball shoes are widely used as promotional items in the sportswear industry, especially during major basketball tournaments or local sporting events. For international B2B buyers, sourcing high-quality, customizable shoes allows brands to leverage the vibrant color for maximum visibility, creating memorable brand impressions. These shoes can be distributed as giveaways or used as merchandise, boosting brand recognition among diverse audiences, including in Africa, South America, the Middle East, and Europe. Buyers should prioritize suppliers offering reliable customization options, consistent quality, and timely delivery to meet event schedules.

Bulk procurement for retail & wholesale distribution

Retailers and distributors across continents often seek bulk purchases of red basketball shoes to stock sports specialty stores or online platforms. These shoes appeal to a broad demographic, from youth sports enthusiasts to casual consumers. For B2B buyers, securing cost-effective, high-volume supplies from reputable manufacturers ensures competitive pricing and steady inventory levels. Sourcing considerations include verifying product authenticity, compliance with safety standards, and establishing long-term relationships with suppliers capable of scaling production without compromising quality.

Promotional merchandise for sports sponsorships

Red basketball shoes serve as impactful promotional merchandise during sports tournaments and team sponsorships. Their eye-catching color makes them ideal for branding efforts, especially when customized with logos or sponsor marks. For international buyers, this application offers a strategic channel to increase brand exposure among large audiences. Key sourcing factors include authentic product sourcing to avoid counterfeit issues, adherence to sponsorship regulations, and the ability to produce in bulk within tight timelines.

Branded incentives for corporate relationships

Many companies utilize branded red basketball shoes as part of incentive programs for employees or partners. This approach reinforces corporate branding and fosters loyalty, particularly in markets where sports culture is prominent. For B2B buyers, sourcing high-quality, customizable shoes that meet specific branding standards is crucial. Considerations include flexible branding options, reliable logistics, and product durability to ensure the shoes serve as effective incentives over time.

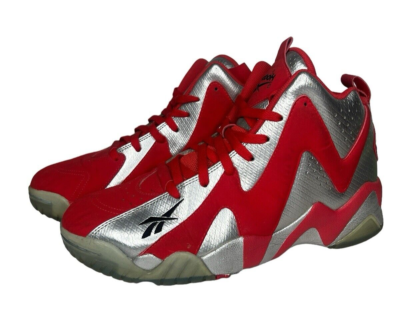

Illustrative Image (Source: Google Search)

OEM manufacturing and private label branding

Manufacturers and private label brands aiming to enter new markets often turn to OEM partnerships for red basketball shoes. These shoes can be tailored to local preferences, with specific design elements or branding requirements. For international B2B buyers, selecting suppliers with flexible manufacturing capabilities, quality assurance processes, and clear communication channels is essential. This approach enables market-specific product offerings that resonate with consumers in Africa, South America, the Middle East, and Europe, facilitating faster market entry and brand localization.

Strategic Material Selection Guide for red basketball shoes

Material Analysis for Red Basketball Shoes

When selecting materials for manufacturing red basketball shoes, B2B buyers must consider performance, durability, cost, and compliance with international standards. The choice of materials influences not only the shoe’s athletic performance but also its market acceptance across regions such as Africa, South America, the Middle East, and Europe. Below is an in-depth analysis of three common materials used in this product category: synthetic leather, mesh fabrics, and rubber compounds.

Synthetic Leather

Key Properties:

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers a balance of flexibility, aesthetic appeal, and ease of manufacturing. It provides good abrasion resistance and can be manufactured to mimic natural leather’s look and feel. Its surface can be easily dyed red, enabling vibrant color options.

Pros & Cons:

– Pros: Cost-effective, lightweight, versatile in design, and resistant to water and stains. It also allows for consistent quality and color uniformity, which is critical for branding and product differentiation.

– Cons: Less breathable than natural leather or fabric, potentially leading to discomfort during prolonged use. It can degrade over time with exposure to UV light and high temperatures, leading to cracking or peeling.

Impact on Application:

Synthetic leather’s compatibility with various adhesives and stitching techniques makes it suitable for upper construction. However, its limited breathability may require additional mesh or fabric inserts to improve ventilation, especially for high-performance basketball shoes.

International Buyer Considerations:

Synthetic leather complies with most international standards such as ASTM and EN standards for footwear materials. Buyers in regions with strict chemical regulations, like the EU’s REACH, should verify that the material is free from harmful phthalates or other restricted chemicals. Cost considerations are favorable for emerging markets like Africa and South America, where price sensitivity is high.

Mesh Fabrics

Key Properties:

Mesh fabrics used in basketball shoes are typically made from polyester or nylon. They are characterized by their open-weave structure, which enhances breathability and moisture management. Advanced mesh options incorporate moisture-wicking fibers and antimicrobial treatments.

Pros & Cons:

– Pros: Excellent airflow, lightweight, and flexible, contributing to comfort and reduced fatigue. They also allow for aesthetic customization, including vibrant red hues.

– Cons: Lower durability compared to synthetic leather, especially under abrasive conditions or prolonged exposure to dirt and moisture. They may require reinforcement in high-stress areas to prevent tearing.

Impact on Application:

Mesh is ideal for the tongue, side panels, and lining of basketball shoes. Its breathability enhances athletic performance, but it must be combined with durable overlays or reinforcements for longevity.

International Buyer Considerations:

Mesh fabrics must meet specific standards for colorfastness and durability, especially in humid or dusty environments common in regions like Colombia or Middle Eastern countries. Buyers should ensure suppliers provide certifications for antimicrobial and moisture-wicking treatments. Cost varies, but high-quality mesh can be slightly more expensive, impacting overall shoe pricing.

Rubber Compounds

Key Properties:

Rubber used in the outsole of basketball shoes provides traction, shock absorption, and durability. Types include natural rubber, synthetic rubber (such as EVA or TPU), and thermoplastic elastomers. These materials are selected based on grip performance and wear resistance.

Pros & Cons:

– Pros: Excellent grip on various surfaces, high durability, and good shock absorption. Rubber compounds can be formulated for specific performance needs, including flexibility and hardness.

– Cons: Heavier than foam or fabric components, potentially affecting overall shoe weight. Some synthetic rubbers may degrade faster under extreme temperatures or UV exposure.

Impact on Application:

The outsole’s material directly influences performance on indoor and outdoor courts. For international markets, especially in regions with rugged terrains or outdoor courts, durable rubber formulations are essential.

International Buyer Considerations:

Rubber compounds must comply with safety standards like ASTM F2913 or ISO 9001. Buyers should verify supplier certifications for eco-friendly production, especially in regions with strict environmental regulations like Europe. Cost ranges from medium to high depending on the formulation and performance specifications.

Summary Table

| Material | Typical Use Case for red basketball shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Synthetic Leather | Upper panels, overlays, branding accents | Cost-effective, water-resistant, customizable colors | Less breathable, prone to cracking over time | Medium |

| Mesh Fabrics | Side panels, tongue, lining | Excellent breathability, lightweight, moisture-wicking | Less durable, needs reinforcement in high-stress areas | Low to Medium |

| Rubber Compounds | Outsole, traction zones | Superior grip, high durability, shock absorption | Heavier, potential degradation under extreme conditions | Medium to High |

Conclusion

For international B2B buyers, understanding the specific properties and limitations of these materials is vital for making informed purchasing decisions. Emphasizing compliance with regional standards, environmental regulations, and market preferences ensures product success across diverse markets. Balancing cost with performance requirements will help optimize product offerings for regions like Africa, South America, the Middle East, and Europe, ultimately supporting sustainable and competitive footwear manufacturing.

Illustrative Image (Source: Google Search)

In-depth Look: Manufacturing Processes and Quality Assurance for red basketball shoes

Manufacturing Processes for Red Basketball Shoes

The production of red basketball shoes involves a series of meticulously coordinated stages, each critical to ensuring high quality and consistency. Understanding these steps allows B2B buyers to better evaluate supplier capabilities and compliance.

1. Material Preparation

The process begins with sourcing and preparing raw materials, including synthetic or genuine leather, mesh fabrics, rubber soles, foam insoles, and adhesives. For red shoes, specific pigments and dyes are integrated during material processing to achieve vibrant, colorfast finishes. Suppliers often utilize advanced dyeing techniques, such as pigment or solution dyeing, to ensure consistent color across batches and improve durability.

2. Forming and Cutting

Next, materials are cut into precise patterns using CNC cutting machines or die-cutting processes. This stage emphasizes accuracy to minimize waste and ensure uniformity across production lots. For high-performance basketball shoes, special attention is paid to the shoe’s structural components—such as heel counters and toe boxes—to support athletic performance and durability.

3. Assembly and Stitching

The cut components are then assembled through various techniques, including ultrasonic welding, heat sealing, and stitching. For red basketball shoes, color-matched or contrasting threads are used to enhance aesthetic appeal. Modern manufacturing often employs automated sewing lines for consistency, though manual assembly may be involved for complex designs or quality control.

4. Finishing

The final stages involve attaching soles via vulcanization or adhesive bonding, applying branding elements, and adding cushioning components. Surface treatments, such as polishing or coating, enhance appearance and protect against environmental factors. For red shoes, surface finishing must ensure the vibrancy and uniformity of the color, with additional coatings to prevent fading or peeling.

Quality Control (QC) in Manufacturing

Implementing rigorous QC processes is essential for producing reliable, high-quality basketball shoes that meet international standards and consumer expectations.

1. International Standards Compliance

Most reputable manufacturers adhere to ISO 9001 for quality management systems, emphasizing continuous improvement, customer satisfaction, and process control. For footwear, additional certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant, especially concerning safety and environmental impact. B2B buyers should verify that suppliers possess current certifications and understand their scope.

2. Inspection Points and Testing Methods

– Incoming Quality Control (IQC): Raw materials are inspected upon receipt for color consistency, physical defects, and compliance with specifications. For dyes used in red shoes, colorfastness tests ensure resistance to fading or bleeding.

– In-Process Quality Control (IPQC): Throughout manufacturing, checkpoints verify dimensional accuracy, stitching quality, adhesion strength, and surface finish. Non-destructive testing methods such as ultrasonic testing can detect internal flaws in soles or structural components.

– Final Quality Control (FQC): Before shipment, comprehensive inspections include visual assessments for color uniformity, surface defects, and assembly integrity, along with functional tests like flexibility, adhesion, and shock absorption.

3. Testing and Certification

Common testing methods include tensile strength tests for adhesives, abrasion resistance for soles, and flex testing to simulate wear over time. For international markets, compliance with regional standards—such as the European EN standards or Colombian INCONTEC standards—is crucial. B2B buyers should request detailed test reports and certifications from suppliers, ideally verified by third-party laboratories.

Verifying Supplier Quality and Compliance

To mitigate risks and ensure consistent quality, B2B buyers should adopt robust supplier verification practices:

- Supplier Audits: Conduct on-site audits focusing on manufacturing processes, quality management systems, and environmental compliance. Audits should include review of QC records, process controls, and employee training programs.

- Documentation and Reports: Request detailed quality reports, test certificates, and process documentation. Transparent suppliers will readily provide these, demonstrating commitment to quality standards.

- Third-Party Inspections: Engage independent inspection agencies (e.g., SGS, Bureau Veritas) for pre-shipment inspections. These inspections can verify product conformity, correct labeling, and packaging standards, especially critical for exports to Europe or South America.

QC and Certification Nuances for Different Regions

Africa and South America:

Suppliers targeting these markets often face varied regulatory landscapes. B2B buyers should verify compliance with local standards—such as the Colombian INCONTEC or South African SABS standards—and ensure that suppliers understand regional import requirements. Certifications like ISO 9001 are highly valued, but additional product-specific testing may be necessary.

Middle East:

Markets such as the UAE and Saudi Arabia emphasize safety, environmental standards, and branding authenticity. Suppliers with CE certification and adherence to ASTM standards for footwear are preferred. B2B buyers should also verify that suppliers comply with regional customs and labeling regulations.

Europe (e.g., France):

European buyers prioritize strict adherence to EU standards, including REACH compliance for chemical safety and CE certification. Transparency in testing processes and detailed documentation are critical. Suppliers should also demonstrate environmentally sustainable manufacturing practices, aligning with EU Green Deal initiatives.

Final Recommendations for B2B Buyers

- Establish clear quality specifications and communicate them explicitly to suppliers.

- Prioritize suppliers with recognized certifications and a track record of consistent quality.

- Incorporate regular audits and third-party inspections into procurement cycles.

- Request comprehensive testing documentation and verify compliance with regional standards.

- Foster ongoing supplier development programs to improve quality and adherence to evolving standards.

By understanding and actively managing manufacturing and quality assurance processes, B2B buyers can ensure the procurement of high-quality red basketball shoes that meet international standards, satisfy end-market requirements, and foster long-term supplier partnerships.

Comprehensive Cost and Pricing Analysis for red basketball shoes Sourcing

Cost Structure Overview for Red Basketball Shoes

Understanding the comprehensive cost structure is vital for international buyers sourcing red basketball shoes. The primary components include raw materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margins.

Materials: The core material—synthetic or genuine leather, mesh fabrics, rubber outsoles, and decorative elements—constitutes a significant portion of the cost. The choice of high-performance or eco-friendly materials can elevate costs but may also serve as a competitive differentiator.

Labor: Labor costs vary substantially based on the sourcing country. Asian manufacturers, particularly in China and Vietnam, often offer lower wages, leading to reduced costs. Conversely, European or Middle Eastern producers might charge higher wages, impacting overall pricing.

Manufacturing Overhead: This includes factory utilities, machinery depreciation, and workforce management. Efficient factories with high automation tend to lower overhead per unit, influencing the final price.

Tooling and Development: Initial mold and tooling costs are usually amortized over large production runs. Customization or special design features can increase upfront costs but reduce unit price at scale.

Quality Control (QC): Rigorous QC processes ensure product consistency, especially important for branded or performance shoes. Higher QC standards might marginally increase costs but reduce returns and rework.

Logistics and Shipping: Incoterms, shipping mode (air, sea, land), and destination port influence logistics expenses. Bulk shipping reduces per-unit costs, but freight delays or customs issues can inflate overall expenses.

Profit Margin: Manufacturers typically add a markup to cover risks, currency fluctuations, and market positioning. Buyers should negotiate margins, especially for large orders.

Key Price Influencers for Red Basketball Shoes

Several factors directly impact the final pricing, and understanding these can empower buyers to negotiate better deals:

-

Order Volume and MOQ: Higher order quantities generally lead to lower unit costs due to economies of scale. Many suppliers offer discounts for large MOQs, but buyers should balance inventory risks with cost savings.

-

Specifications and Customization: Unique designs, branding, or technical specifications (e.g., enhanced grip, lightweight materials) increase costs. Standard models are more affordable, while customization commands premium pricing.

-

Material Choices: Premium or eco-friendly materials tend to be more expensive. Buyers should specify quality requirements early to avoid unexpected costs.

-

Certifications and Standards: Compliance with safety, environmental, or sports performance certifications (e.g., ISO, REACH, ASTM) can add to costs but are often mandatory for certain markets.

-

Supplier Factors: Supplier reputation, capacity, and location influence pricing. Established manufacturers with high quality standards typically charge more but offer reliability and consistent quality.

-

Incoterms and Delivery Terms: FOB (Free on Board) and CIF (Cost, Insurance, and Freight) are common. FOB allows buyers to control shipping costs directly, while CIF includes supplier-managed logistics, often at a premium.

Strategic Tips for International B2B Buyers

-

Negotiate Terms and Prices: Leverage large order volumes to negotiate better prices, especially for repeated or bulk purchases. Clarify if discounts are volume-based or tied to specific customization.

-

Assess Total Cost of Ownership (TCO): Consider not just unit price but also shipping, customs duties, taxes, warehousing, and potential rework costs. For example, sourcing from Asia may be cheaper initially but could incur higher logistics expenses for distant markets.

-

Understand Price Nuances in Different Markets: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional tariffs, import duties, and local standards that can significantly impact landed costs.

-

Factor in Lead Times: Longer lead times for manufacturing or shipping can increase inventory costs and affect market responsiveness. Building strong supplier relationships can help streamline processes and reduce delays.

-

Utilize Cost-Effective Logistics: Consolidate shipments, choose optimal shipping modes, and explore free trade agreements (e.g., EU trade agreements, Mercosur) to reduce costs.

Indicative Price Range

While prices fluctuate based on specifications, volume, and supplier country, a typical range for bulk purchase of standard red basketball shoes can be approximately $20 to $50 per pair FOB Asia. Premium, customized, or certified shoes may range from $50 to $80+ per pair. Buyers should request detailed quotations and consider all associated costs for accurate budgeting.

Disclaimer: Prices are indicative and subject to market fluctuations, supplier negotiations, and specific order requirements. Conduct thorough due diligence and obtain multiple quotations before finalizing sourcing decisions.

Spotlight on Potential red basketball shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for red basketball shoes.)*

Essential Technical Properties and Trade Terminology for red basketball shoes

Critical Technical Properties for Red Basketball Shoes

1. Material Grade and Composition

The quality of materials used—such as synthetic leather, mesh fabrics, and rubber compounds—directly impacts durability, performance, and aesthetic appeal. Higher-grade materials typically offer better wear resistance and colorfastness, essential for maintaining the vibrant red hue over extended use. B2B buyers should specify material standards (e.g., ISO or ASTM grades) to ensure consistency across production batches.

2. Sole Tolerance and Flexibility

The sole’s manufacturing precision, including its thickness and flexibility, influences grip, shock absorption, and overall player comfort. Precise tolerances (measured in millimeters) are critical for ensuring shoes fit uniformly and meet performance expectations. Suppliers should provide detailed technical sheets outlining tolerances to prevent issues like uneven wear or compromised traction.

3. Color Fastness and Finish

Given the prominence of red in these shoes, color fastness—the ability of the dye to resist fading or bleeding—is paramount. A high-quality finish prevents color transfer onto court surfaces or apparel, which can damage brand reputation. B2B buyers should specify testing standards (e.g., AATCC or ISO) to verify color stability under various conditions.

4. Weight and Breathability

Lightweight construction enhances agility, while breathable materials prevent excessive sweating, improving comfort during intense gameplay. Precise specifications on weight (grams per shoe) and ventilation features should be included in product documentation to match performance needs and target markets.

5. Reinforcement and Stitching Quality

High-stress areas like the toe box and heel require reinforced stitching and durable overlays. These technical properties affect the shoe’s lifespan and resistance to tearing. Suppliers should provide details on stitching types (e.g., double-stitched, reinforced seams) and material overlays to assess longevity.

Common Industry and Trade Terms

1. OEM (Original Equipment Manufacturer)

Refers to manufacturers that produce footwear based on the buyer’s design specifications. Understanding OEM relationships helps B2B buyers negotiate customization options, branding, and production capacity, especially vital for private-label or branded shoes.

2. MOQ (Minimum Order Quantity)

The smallest quantity of shoes a supplier is willing to produce per order. Clarifying MOQ is essential for buyers to plan inventory levels and negotiate pricing, particularly when entering new markets or launching limited editions.

3. RFQ (Request for Quotation)

A formal document sent to suppliers requesting price estimates, lead times, and technical details. Using RFQs enables buyers to compare multiple suppliers efficiently, ensuring competitive pricing and adherence to technical standards.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities between buyers and sellers regarding shipping, risk, and costs. Familiarity with Incoterms like FOB (Free On Board) or CIF (Cost, Insurance, Freight) ensures clear contractual obligations, reducing misunderstandings during international transactions.

5. Lead Time

The period from order confirmation to shipment readiness. Accurate lead time estimates allow buyers to synchronize procurement with project timelines, avoiding delays in product rollout.

6. Quality Certification Standards

Certifications such as ISO 9001 or compliance with safety and environmental regulations (e.g., REACH, CPSIA) are critical for market acceptance and regulatory adherence. Buyers should verify that suppliers hold relevant certifications to mitigate risks and ensure product reliability.

In Summary:

For effective international procurement of red basketball shoes, understanding these technical properties ensures product quality aligns with performance expectations. Familiarity with trade terminology streamlines negotiations, clarifies responsibilities, and reduces supply chain risks. Both technical diligence and clear communication are essential for successful B2B transactions across diverse markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the red basketball shoes Sector

Market Overview & Key Trends

The global market for red basketball shoes is experiencing robust growth driven by increasing sports participation, rising consumer demand for athletic footwear, and the influence of basketball culture worldwide. Key drivers include the expanding middle class in emerging markets, heightened brand engagement through digital channels, and collaborations with sports personalities that boost brand visibility. For international B2B buyers from Africa, South America, the Middle East, and Europe, understanding regional consumer preferences is essential—while consumers in Europe and France often favor premium, technologically advanced models, markets in Colombia or Middle Eastern countries may prioritize affordability and style.

Emerging sourcing trends are reshaping the supply chain landscape. Digital platforms and data analytics now enable more precise demand forecasting and inventory management, reducing lead times and minimizing overstock risks. Additionally, the adoption of 3D printing and modular manufacturing techniques allows for faster customization and innovation cycles, which are crucial for meeting regional tastes and fashion trends.

Trade policies, tariffs, and geopolitical factors also influence market dynamics. For instance, tariffs on imports from Asia can impact pricing strategies, prompting buyers to explore alternative sourcing options like local manufacturing or regional suppliers. Sustainability is increasingly shaping purchasing decisions, with buyers seeking suppliers who adhere to environmentally responsible practices.

For B2B buyers in these regions, building strong relationships with reputable manufacturers—especially those offering flexible, scalable production—is vital. Leveraging digital sourcing platforms and attending regional trade shows can facilitate connections with reliable suppliers. Staying informed about technological innovations and regional market shifts will enable buyers to adapt quickly and capitalize on emerging opportunities.

Sustainability & Ethical Sourcing

Sustainability has become a critical criterion for B2B buyers in the red basketball shoes sector, driven by consumer awareness, regulatory pressures, and corporate responsibility commitments. Environmentally responsible sourcing begins with selecting suppliers who prioritize low-impact manufacturing processes, such as water-efficient dyeing, renewable energy use, and waste reduction initiatives.

The environmental footprint of materials is a major concern. Buyers should favor suppliers utilizing sustainable, ethically sourced raw materials like recycled rubber, organic cotton, and plant-based dyes. Certifications such as FSC (Forest Stewardship Council), GRS (Global Recycled Standard), and Fair Trade are indicators of ethical compliance and environmental responsibility, providing added assurance of supply chain integrity.

Ethical sourcing also encompasses labor practices, ensuring fair wages, safe working conditions, and the absence of child or forced labor. Transparency in the supply chain is crucial; buyers should conduct due diligence through audits and third-party verification to mitigate risks associated with unethical practices.

Incorporating sustainability into procurement strategies offers long-term benefits, including brand differentiation and compliance with international regulations like the EU’s Green Deal or South American environmental standards. For B2B buyers, establishing partnerships with suppliers committed to green practices not only aligns with global trends but also enhances supply chain resilience by reducing exposure to regulatory penalties and reputational risks.

Brief Evolution/History (Optional)

While the core design of red basketball shoes has remained consistent—combining performance features with vibrant aesthetics—the industry has seen significant evolution in materials and manufacturing processes. The shift from traditional synthetic leathers to eco-friendly, recycled, and bio-based materials reflects a broader emphasis on sustainability. Technological advancements such as 3D printing and digital prototyping have accelerated innovation cycles, enabling faster response to market trends.

Historically, collaborations with athletes and cultural icons have driven brand loyalty, a trend that continues to influence B2B sourcing decisions. Understanding these historical shifts helps buyers anticipate future trends, such as increased demand for customizable and environmentally friendly footwear, positioning them for strategic procurement and partnership development in this competitive sector.

Frequently Asked Questions (FAQs) for B2B Buyers of red basketball shoes

1. How can I verify the credibility and reliability of a red basketball shoe supplier?

To ensure supplier credibility, start by requesting comprehensive company credentials, including business licenses, export licenses, and industry certifications (ISO, CE, etc.). Conduct background checks through trade associations or verified B2B platforms like Alibaba or Global Sources. Request references from previous international clients to gauge past performance. Additionally, consider visiting the supplier’s facilities if feasible or engaging third-party inspection services prior to placing large orders. Establish clear communication channels and verify responsiveness to assess their professionalism. Reliable suppliers will be transparent about their manufacturing processes and willing to provide samples for quality evaluation.

Illustrative Image (Source: Google Search)

2. What are the key customization options available for red basketball shoes in B2B transactions?

Most manufacturers offer extensive customization options to meet branding and design specifications. Common options include color shades, logo placement, and custom packaging. You can also choose specific materials (e.g., synthetic leather, mesh), sole designs, and ventilation features. For bulk orders, OEM and ODM services are typically available—allowing you to develop unique styles or incorporate your brand identity. Communicate your requirements clearly, including size ranges, color codes, and branding elements. Confirm lead times for customization to align with your supply chain schedules, and request prototypes before full production to ensure alignment with your expectations.

3. What are typical minimum order quantities (MOQs), lead times, and payment terms for importing red basketball shoes?

MOQs for B2B purchases of basketball shoes generally range from 300 to 1,000 pairs, depending on the manufacturer and customization complexity. Lead times vary from 4 to 12 weeks, influenced by order volume and customization needs. It’s advisable to negotiate flexible lead times if you have urgent requirements. Payment terms often include 30% deposit upfront with the balance paid before shipment, or letters of credit for larger transactions. Some suppliers may offer discounts for bulk orders or early payments. Establish clear, mutually agreed payment terms upfront and consider using secure payment methods like escrow or trade finance options to mitigate risks.

4. What quality assurance measures and certifications should I look for when sourcing red basketball shoes internationally?

Ensure your supplier adheres to recognized quality standards by requesting relevant certifications such as ISO 9001 for quality management, CE marking for compliance with European safety standards, or other region-specific certifications. Insist on factory audits or third-party inspection reports that verify manufacturing practices, material quality, and final product testing. Request samples for physical inspection and testing, especially for durability, grip, and colorfastness. Establish quality control procedures, including pre-shipment inspections, to prevent defective shipments. Suppliers with transparent quality assurance processes and certifications are more likely to deliver consistent, high-quality products that meet international standards.

5. How should I plan logistics and shipping for international B2B orders of red basketball shoes?

Coordinate with your supplier early to determine the most cost-effective and reliable shipping methods—air freight for urgent deliveries or sea freight for larger, bulk shipments. Clarify Incoterms (e.g., FOB, CIF, DDP) to understand responsibilities and costs. Ensure your supplier provides detailed documentation, including commercial invoices, packing lists, and certificates of origin. Consider partnering with experienced freight forwarders who understand customs regulations in your country (e.g., Colombia, France, Nigeria). Factor in customs duties, taxes, and import restrictions to avoid delays. Finally, track shipments actively and maintain communication with logistics providers to manage transit issues proactively.

6. How can I handle disputes or quality issues with international suppliers effectively?

Establish clear contractual terms covering quality standards, inspection procedures, and dispute resolution mechanisms before placing orders. Include clauses for product returns, replacements, or refunds if quality issues arise. Maintain detailed records of all communications, inspections, and received goods to support claims. Engage third-party inspection agencies during production and pre-shipment stages for unbiased quality verification. If disputes occur, pursue resolution through negotiation, mediation, or arbitration as specified in your contract. Building strong, transparent relationships with suppliers fosters trust and facilitates smoother resolution processes, minimizing disruptions to your supply chain.

7. What are the main challenges when importing red basketball shoes from emerging markets, and how can I mitigate them?

Challenges include inconsistent product quality, longer lead times, language barriers, and logistical complexities. To mitigate these, conduct thorough supplier vetting, request samples, and verify certifications. Establish clear communication channels and use bilingual agents if necessary. Develop detailed contracts specifying quality standards, delivery schedules, and dispute processes. Build buffer time into your planning to accommodate delays and consider working with local or regional logistics partners familiar with customs procedures. Regular audits and quality checks, along with diversified supplier sources, can reduce dependency on a single provider and improve supply chain resilience.

8. What are best practices for building long-term B2B relationships with international suppliers of red basketball shoes?

Focus on clear, consistent communication and transparency from the outset. Start with smaller trial orders to assess quality and reliability before scaling up. Cultivate mutual understanding of expectations regarding lead times, quality standards, and payment terms. Maintain regular contact and provide feedback to foster trust and continuous improvement. Consider visiting suppliers’ facilities if possible or engaging local agents to facilitate communication. Long-term partnerships benefit from shared growth strategies, collaborative product development, and flexible payment arrangements. Building rapport and demonstrating loyalty can lead to better pricing, priority treatment, and access to new product lines, strengthening your competitive advantage.

Strategic Sourcing Conclusion and Outlook for red basketball shoes

Conclusion and Future Outlook

Effective strategic sourcing is critical for international B2B buyers aiming to capitalize on the growing demand for red basketball shoes across diverse markets such as Africa, South America, the Middle East, and Europe. By prioritizing supplier diversification, quality assurance, and cost optimization, buyers can secure competitive advantages while mitigating supply chain risks. Leveraging regional manufacturing hubs and establishing strong supplier relationships can further enhance flexibility and responsiveness to market trends.

Looking ahead, the increasing popularity of branded and innovative designs presents significant opportunities for buyers who adopt a proactive sourcing approach. Staying informed about emerging suppliers, technological advancements, and sustainability practices will be essential for maintaining a competitive edge.

For buyers in France, Colombia, and beyond, embracing a strategic, data-driven sourcing framework will facilitate access to high-quality red basketball shoes at optimal costs, ensuring market relevance and consumer satisfaction. Now is the time to refine sourcing strategies, foster global supplier collaborations, and position your enterprise for sustainable growth in this dynamic segment.