Your Ultimate Guide to Sourcing Charles Barkley Shoes

Guide to Charles Barkley Shoes

- Introduction: Navigating the Global Market for charles barkley shoes

- Understanding charles barkley shoes Types and Variations

- Key Industrial Applications of charles barkley shoes

- Strategic Material Selection Guide for charles barkley shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for charles barkley shoes

- Comprehensive Cost and Pricing Analysis for charles barkley shoes Sourcing

- Spotlight on Potential charles barkley shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for charles barkley shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the charles barkley shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of charles barkley shoes

- Strategic Sourcing Conclusion and Outlook for charles barkley shoes

Introduction: Navigating the Global Market for charles barkley shoes

In today’s competitive global footwear landscape, Charles Barkley shoes have solidified their position as a high-demand product across diverse markets. Their unique blend of performance, style, and cultural appeal makes them a strategic asset for international B2B buyers seeking to expand their product portfolios. For buyers in Africa, South America, the Middle East, and Europe—including key markets like Vietnam and Argentina—understanding the nuances of sourcing these iconic sneakers is crucial to maximizing profitability and ensuring supply chain resilience.

This comprehensive guide offers vital insights into every aspect of Charles Barkley shoes—from various models and materials to manufacturing processes and quality control standards. It explores sourcing options, identifies reliable suppliers, and provides detailed cost analysis to help optimize procurement strategies. Additionally, it addresses market trends, regulatory considerations, and frequently asked questions, empowering buyers to make informed, strategic decisions.

By leveraging this guide, international B2B buyers can navigate complex supply chains with confidence, mitigate risks, and capitalize on emerging opportunities. Whether establishing new sourcing channels or strengthening existing partnerships, this resource equips you with the industry expertise needed to succeed in the global market for Charles Barkley shoes. Ultimately, it positions your business to stay competitive and responsive in a dynamic, ever-evolving footwear industry.

Understanding charles barkley shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Barkley Signature Model | Retro-inspired design, signature colorways, iconic silhouette | Sports retail, sneaker boutiques, brand licensing | Pros: Recognizable brand, high demand; Cons: Limited customization options, higher MOQ needed |

| Performance Basketball Model | High-top construction, enhanced ankle support, lightweight materials | Sporting goods stores, athletic distributors | Pros: Strong performance appeal, durability; Cons: Higher production costs, niche market focus |

| Lifestyle Casual Model | Low-profile, trendy aesthetics, versatile color options | Fashion retailers, casual footwear markets | Pros: Broad consumer appeal, trendy; Cons: Less technical features, price sensitivity issues |

| Limited Edition Collectors | Special collaborations, unique colorways, numbered releases | Collector shops, premium sneaker outlets | Pros: High margins, exclusivity; Cons: Limited stock, unpredictable demand |

| Youth/Kids Models | Smaller sizes, playful designs, durable materials | Children’s footwear distributors, retail chains | Pros: Expanding market segment, brand loyalty; Cons: Smaller margins, shorter product lifecycle |

Classic Barkley Signature Model

The classic Barkley signature shoes are characterized by their retro aesthetic, iconic colorways, and instantly recognizable silhouette. They are primarily targeted at sneaker enthusiasts, sports memorabilia collectors, and brand loyalists. These models offer high brand recognition, making them ideal for large-scale retail and licensing deals. However, their limited customization options and typically higher minimum order quantities (MOQs) can pose challenges for smaller buyers or those seeking niche designs. They are best suited for markets with strong brand affinity, such as Europe and North America, but can also find niche appeal in emerging markets like South America and Africa with proper branding strategies.

Performance Basketball Model

Designed with high-performance features, these shoes incorporate high-top construction, advanced ankle support, and lightweight, durable materials. They are aimed at sporting goods stores, athletic distributors, and specialty basketball retailers. Their technical specifications make them attractive for markets that value sports performance, such as Europe with its strong basketball culture or Middle Eastern markets with active lifestyles. The main considerations for buyers include higher production costs due to technical features and the relatively niche market segment, which requires targeted marketing and inventory planning.

Lifestyle Casual Model

These shoes emphasize fashion-forward, low-profile designs with versatile color options suitable for everyday wear. They appeal to fashion retailers and casual footwear markets across diverse regions, including South America and Africa, where casual and streetwear styles are increasingly popular. They typically have broader consumer appeal due to their trendy aesthetic, but buyers should note their less technical features and potential price sensitivity. Sourcing these models involves balancing quality and cost, with an emphasis on maintaining trendy designs aligned with current fashion trends.

Limited Edition Collectors

Limited edition Barkley shoes are often released through collaborations, featuring unique colorways, special materials, and numbered exclusives. They target high-end sneaker boutiques, collector shops, and premium outlets. The primary advantage is high profit margins driven by exclusivity and demand. However, the unpredictable nature of demand and limited stock require careful inventory management. These models are especially suitable for markets with active sneaker communities, such as Europe and North America, but can also appeal to collectors in emerging markets if marketed effectively.

Youth/Kids Models

Smaller-sized Charles Barkley shoes are designed with playful aesthetics, durable materials, and comfort in mind. They are targeted at children’s footwear distributors and retail chains focused on youth markets. These models offer expansion into growing segments, fostering brand loyalty among young consumers. The main challenges include smaller profit margins and shorter product lifecycles due to rapid market shifts and seasonal demand. For B2B buyers, establishing reliable supply chains and flexible MOQ arrangements is crucial to meet market needs efficiently, especially in regions like Africa and South America where youth markets are expanding rapidly.

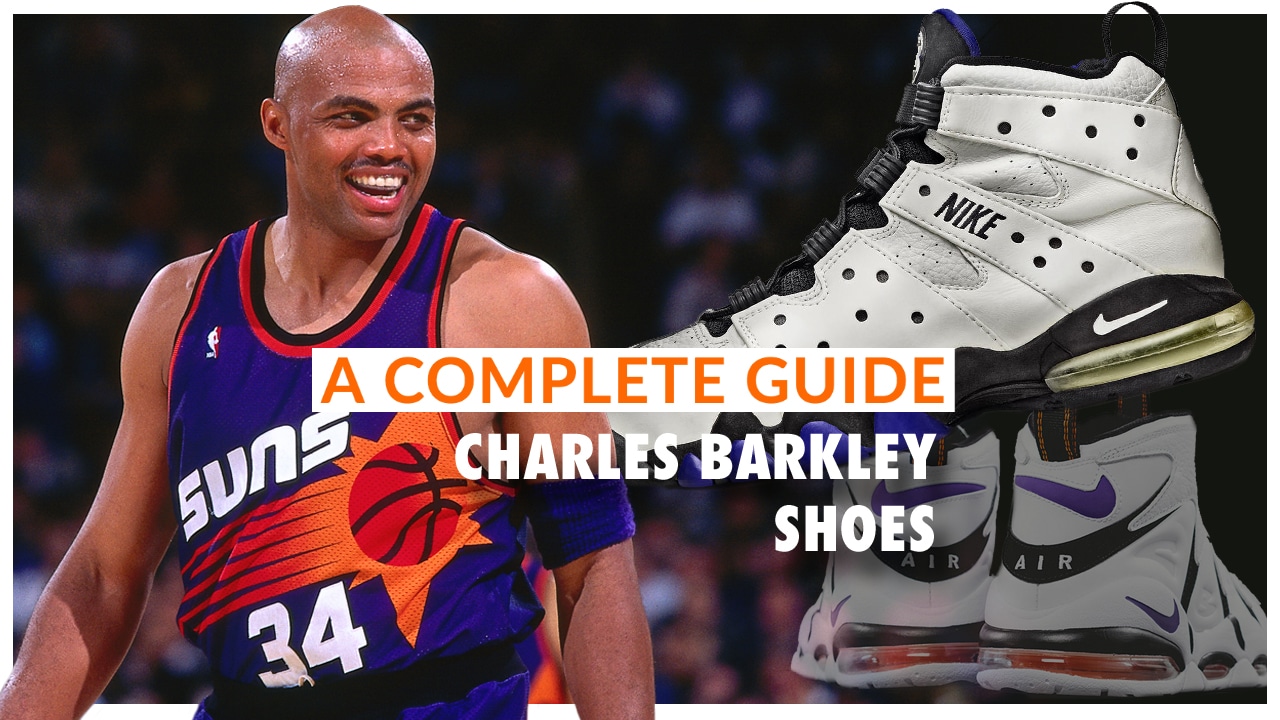

Related Video: Charles Barkley Shoes: A Complete Guide

Key Industrial Applications of charles barkley shoes

| Industry/Sector | Specific Application of Charles Barkley Shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports & Athletic Retail | Custom branded basketball shoes for team sponsorships | Enhances brand visibility, drives sales, and fosters customer loyalty | Quality assurance, brand customization options, reliable supply chain |

| Healthcare & Medical | Specialized footwear for healthcare workers requiring durable, supportive shoes | Improves worker safety, reduces fatigue, and enhances productivity | Compliance with health standards, durability, comfort features |

| Hospitality & Tourism | Comfortable, durable shoes for hotel staff and tour guides | Ensures staff comfort, reduces turnover, and maintains professional appearance | Material quality, slip resistance, adaptability to various climates |

| Military & Defense | Tactical footwear with high durability and support | Meets rigorous operational demands, enhances soldier safety | Certification standards, ruggedness, supply reliability |

| Manufacturing & Industrial | Slip-resistant, supportive shoes for factory workers | Reduces workplace accidents, improves worker safety and efficiency | Safety certifications, slip resistance, consistent quality standards |

Sports & Athletic Retail

Charles Barkley shoes are highly popular in the sports and athletic retail industry, especially as branded basketball shoes. B2B buyers from Africa, South America, the Middle East, and Europe can source these shoes for team sponsorships, retail outlets, and promotional events. They offer high-performance features such as superior grip, ankle support, and cushioning, which appeal to sports enthusiasts. Sourcing considerations include ensuring consistent quality, customization for branding, and reliable delivery timelines to meet seasonal demand spikes. These shoes can significantly boost brand visibility and customer engagement in competitive markets.

Illustrative Image (Source: Google Search)

Healthcare & Medical

In the healthcare sector, Charles Barkley shoes can be adapted into specialized footwear designed for medical staff who spend long hours on their feet. Their durability, ergonomic support, and slip-resistant soles address common workplace hazards, reducing fatigue and the risk of slips and falls. For international B2B buyers, especially in regions with high humidity or variable climates, sourcing shoes with breathable materials and robust construction is critical. Ensuring compliance with health and safety standards across different markets enhances product credibility and reduces compliance risks.

Hospitality & Tourism

The hospitality and tourism industry benefits from Charles Barkley shoes by providing staff with comfortable, durable footwear that maintains a professional appearance. Hotel staff, tour guides, and service personnel require shoes that withstand daily wear while offering comfort during long shifts. Sourcing considerations include slip resistance for safety, material durability for frequent cleaning, and adaptability to diverse climates—from the hot Middle East to humid South American regions. These shoes help reduce staff turnover by improving comfort and support, ultimately enhancing guest experiences.

Military & Defense

For military and defense applications, Charles Barkley shoes are suitable as tactical footwear due to their high durability, ankle support, and rugged construction. They are designed to withstand harsh environments and rigorous physical activity, making them ideal for supply to armed forces in various regions. International B2B buyers must prioritize sourcing shoes that meet strict certification standards, including durability, support, and environmental resistance. Reliable supply chains and customization options for camouflage or insignia further enhance their appeal in defense markets.

Manufacturing & Industrial

In manufacturing and industrial settings, Charles Barkley shoes serve as slip-resistant, supportive footwear for factory and warehouse workers. These shoes are designed to reduce workplace accidents caused by slips, trips, and falls, especially on oily or uneven surfaces. For B2B buyers in regions with high industrial activity, sourcing considerations include compliance with safety standards such as ASTM or EN certifications, consistent slip resistance, and durability under heavy use. Supplying high-quality, safety-certified shoes can improve worker safety and operational efficiency significantly.

Related Video: Uses and Gratifications Theory

Strategic Material Selection Guide for charles barkley shoes

Analysis of Common Materials for Charles Barkley Shoes

Leather

Leather remains a primary material in high-performance basketball shoes like those associated with Charles Barkley, valued for its durability, breathability, and premium feel. Typically, full-grain or top-grain leather provides excellent abrasion resistance and moldability, ensuring the shoe maintains its shape over time. However, leather’s manufacturing complexity can increase costs, especially when sourcing high-quality grades, and it requires proper treatment to resist moisture and environmental degradation.

From a performance perspective, leather offers good support and comfort, but it can be heavier than synthetic alternatives, impacting agility. Its susceptibility to water damage and environmental wear makes it less ideal in humid or rainy climates, which are common in many parts of Africa and South America. For international buyers, compliance with environmental standards (e.g., REACH in Europe) and sourcing from tanneries adhering to ethical practices are critical considerations.

Synthetic Materials (e.g., Mesh, Microfiber)

Synthetic textiles like mesh and microfiber are increasingly popular in basketball footwear due to their lightweight nature and breathability. Mesh fabrics allow for enhanced airflow, reducing foot sweat and improving comfort during intense activity. Microfiber, on the other hand, offers a balance of durability and flexibility, often used in overlays for added support.

The primary advantage of synthetics is cost efficiency, with manufacturing processes being more straightforward than leather. They also tend to be lighter, improving athletic performance. However, synthetics may degrade faster under UV exposure or in harsh environmental conditions, which could be a concern for buyers in regions with high sun exposure or extreme weather. Additionally, some synthetic materials may not meet certain environmental or safety standards, requiring thorough supplier vetting for compliance with regulations such as ASTM or EU standards.

Rubber and EVA (Ethylene Vinyl Acetate)

Rubber and EVA are fundamental in the outsole and midsole components of Charles Barkley shoes. Rubber provides excellent grip, abrasion resistance, and durability, making it suitable for the outsole to ensure traction on various court surfaces. EVA is widely used in midsoles due to its lightweight cushioning properties and shock absorption capabilities.

From a manufacturing standpoint, rubber and EVA are cost-effective, with rubber offering high wear resistance but sometimes requiring complex vulcanization processes. EVA is easier to mold and lighter, but it may compress over time, reducing cushioning effectiveness. For international buyers, sourcing compliant rubber and EVA materials involves ensuring they meet standards like DIN, ASTM, or JIS, especially to avoid issues related to chemical safety and environmental impact.

Considerations for International B2B Buyers

When sourcing materials for Charles Barkley shoes across different regions, several factors must be prioritized:

-

Compliance & Standards: Buyers in Europe must ensure materials meet REACH, OEKO-TEX, or EU-specific regulations. In Africa and South America, adherence to local environmental and safety standards (e.g., INMETRO in Brazil, SANS in South Africa) is essential. Suppliers should provide certification documents verifying compliance.

-

Environmental & Ethical Sourcing: Increasingly, consumers and regulators demand transparency in sourcing, especially for leather and synthetic components. Buyers should verify supplier adherence to sustainable practices, such as responsible leather tanning or eco-friendly synthetic production.

-

Cost & Supply Chain Stability: Cost varies significantly based on material grade and origin. Buyers should evaluate local manufacturing capabilities, import tariffs, and logistical considerations, especially in regions with complex trade policies like the Middle East or South America.

-

Durability & Climate Suitability: Materials must withstand regional environmental conditions. For instance, in humid climates, water-resistant or treated leathers and UV-stable synthetics are preferable. Rubber outsoles should be selected based on the court surface and weather conditions typical to the region.

Summary Table

| Material | Typical Use Case for Charles Barkley Shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Upper overlays, support panels | Durable, breathable, molds well | Heavy, susceptible to water damage, higher cost | High |

| Synthetic (Mesh, Microfiber) | Upper panels, overlays | Lightweight, breathable, cost-effective | Less durable in harsh environments, environmental concerns | Med |

| Rubber & EVA | Outsole, midsole | Excellent grip, cushioning, lightweight | Rubber can be costly, EVA compresses over time | Low |

This comprehensive understanding of material properties and regional considerations allows B2B buyers to make informed decisions, ensuring product quality, compliance, and market suitability across diverse international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for charles barkley shoes

Manufacturing Workflow for Charles Barkley Shoes

The production of Charles Barkley shoes involves a multi-stage process meticulously designed to ensure durability, comfort, and brand consistency. The manufacturing begins with material preparation, where high-quality raw materials such as synthetic fabrics, leather, rubber, and foam are sourced in compliance with international standards. Suppliers must adhere to strict specifications for material properties, including tensile strength, flexibility, and environmental safety.

Next is forming, which involves cutting, molding, and shaping the components. Advanced techniques such as computer-aided design (CAD) and computer numerical control (CNC) cutting are employed to achieve precise dimensions and patterns. For athletic and lifestyle shoes, injection molding is common for midsoles and outsoles, ensuring uniformity and high performance.

The assembly stage consolidates the pre-formed components—upper, midsole, outsole, and insoles—using high-frequency welding, stitching, and adhesive bonding. Automated assembly lines increase efficiency and consistency, while manual quality checks ensure that intricate details meet design specifications. Special attention is paid to bonding strength and alignment to prevent defects like separation or misfit.

Finally, finishing involves quality-enhancing steps such as cleaning, polishing, and applying branding elements like logos and tags. Additional processes include packaging, labeling, and preparing the shoes for shipment. Throughout, industry best practices emphasize sustainability, waste reduction, and compliance with environmental regulations.

Illustrative Image (Source: Google Search)

Quality Assurance: Standards, Checks, and Industry Best Practices

Quality assurance (QA) for Charles Barkley shoes aligns with international standards such as ISO 9001, which emphasizes a systematic approach to quality management. Suppliers and manufacturers must develop comprehensive quality control systems that integrate multiple checkpoints throughout the production cycle.

Key QA checkpoints include:

-

Incoming Quality Control (IQC): Raw materials undergo rigorous testing before acceptance, verifying parameters like material thickness, colorfastness, elasticity, and chemical composition. For example, leather is tested for tanneries’ compliance and absence of harmful substances, adhering to regulations such as OEKO-TEX or REACH.

-

In-Process Quality Control (IPQC): During manufacturing, continuous inspections monitor critical processes such as cutting accuracy, molding precision, stitching quality, and assembly alignment. Statistical process control (SPC) tools are employed to detect deviations early, minimizing rework and scrap.

-

Final Quality Control (FQC): Completed shoes undergo comprehensive testing, including visual inspection for cosmetic defects, dimensional verification, and functional tests like flexibility, adhesion strength, and shock absorption. This stage ensures products meet both brand standards and regulatory requirements.

Testing methods include mechanical stress testing, flex testing, and environmental simulations such as temperature and humidity cycling. For footwear, abrasion resistance, slip testing, and sole durability assessments are standard industry procedures.

Industry Standards and Certifications Relevant to Charles Barkley Shoes

In addition to ISO 9001, B2B buyers should seek suppliers certified under other relevant standards:

-

CE Marking (European Conformity): Ensures compliance with health, safety, and environmental protection standards within the European Union. Critical for export to Europe, especially for footwear with electrical components or specific safety features.

-

ASTM and ISO Standards: For mechanical testing, material safety, and ergonomic assessments, compliance with ASTM F2413 (for protective footwear) or ISO 20345 (for safety shoes) can be a valuable indicator of quality.

-

Environmental and Social Certifications: Certifications such as BSCI or SA8000 demonstrate adherence to social compliance and fair labor practices, crucial for buyers in regions like Africa, South America, and the Middle East.

QC Inspection Types and Protocols

1. Incoming Quality Control (IQC): Focuses on verifying raw material conformity before production begins. For B2B buyers, it’s vital to review IQC reports and perform supplier audits to ensure raw materials meet specified standards.

2. In-Process Quality Control (IPQC): Conducted during manufacturing, often using statistical sampling to identify defects early. Buyers should request detailed process control documentation and audit reports to verify ongoing compliance.

3. Final Quality Control (FQC): The last checkpoint before shipment, involving thorough visual and functional inspections. For international buyers, engaging third-party inspection agencies—such as SGS or Bureau Veritas—can provide unbiased verification of quality.

How B2B Buyers Can Verify Supplier QC

Effective verification extends beyond initial supplier audits. Consider the following approaches:

-

Third-Party Inspections: Contract independent inspection firms to conduct pre-shipment audits, random sampling, and testing, especially for high-volume orders or new suppliers.

-

Inspection Reports & Documentation: Require detailed QC reports, including test results, process control records, and non-conformance reports. These documents provide transparency and traceability.

-

Factory Audits & Certifications: Regular on-site audits help verify adherence to quality standards, social compliance, and environmental practices. Certifications like ISO 9001, BSCI, or WRAP serve as indicators of established QA systems.

-

Sample Testing & Pilot Orders: Before large-scale production, validate quality through samples tested against performance and durability benchmarks. This step minimizes risks associated with supplier variability.

Considerations for International B2B Buyers in Africa, South America, the Middle East, and Europe

Buyers from diverse regions face unique challenges and opportunities in managing manufacturing and QA:

-

Regulatory Alignment: European buyers should prioritize suppliers with CE marking and ISO certifications to ensure compliance with strict EU standards. Buyers in Africa and South America should verify adherence to local import regulations and safety standards.

-

Supply Chain Transparency: Regional political stability, infrastructure quality, and logistical capabilities influence quality management. Engage with suppliers who maintain comprehensive documentation and are transparent about their processes.

-

Capacity for Quality Audits: Buyers should establish relationships with trusted third-party inspection agencies familiar with regional manufacturing nuances. This mitigates risks of counterfeit parts, substandard raw materials, or non-compliance.

-

Training & Continuous Improvement: Collaborate with suppliers committed to ongoing staff training and process enhancements. This fosters higher quality standards and aligns manufacturing practices with evolving industry norms.

-

Cultural & Language Considerations: Clear communication and culturally aware auditing practices ensure that quality expectations are understood and met. Providing detailed specifications and training materials in local languages can enhance compliance.

In conclusion, for B2B buyers seeking reliable manufacturing partners for Charles Barkley shoes, understanding the detailed processes and rigorous quality assurance protocols is essential. Establishing clear communication channels, demanding transparent documentation, and leveraging third-party verification will significantly reduce risks and ensure product quality aligns with brand and regional standards. Tailoring these practices to regional contexts ensures smoother supply chain operations and fosters long-term, mutually beneficial partnerships.

Related Video: Amazing Shoe Making Process | Footwear Manufacturing Factory | Mass Production | Unbox Engineering

Comprehensive Cost and Pricing Analysis for charles barkley shoes Sourcing

Cost Components Breakdown

Effective sourcing of Charles Barkley shoes requires a comprehensive understanding of the key cost components that influence the final price.

-

Materials: The primary materials include synthetic textiles, rubber, and occasionally leather overlays, depending on the model. Material costs fluctuate based on quality, source origin, and global commodity prices. For example, synthetic textiles sourced from Asia tend to be more cost-effective, whereas premium leather from Europe or South America commands higher prices.

-

Labor: Manufacturing costs vary significantly by region. Countries like Vietnam, China, and Indonesia offer competitive labor rates, often ranging from $0.50 to $2.00 per pair, depending on complexity and quality standards. European or North American factories typically have higher wages, which impacts overall costs.

-

Manufacturing Overhead: This includes factory utilities, equipment depreciation, and labor management expenses. Overhead costs are generally lower in developing regions but can rise with stricter compliance and quality assurance standards.

-

Tooling and Development: Initial tooling, molds, and design customization can add substantial upfront costs, often ranging from $10,000 to $50,000 for a batch of models. These are amortized over large volume orders, reducing per-unit costs as order quantities increase.

-

Quality Control and Certifications: International buyers, especially from Europe and the Middle East, often require compliance with standards such as ISO, REACH, or ASTM. Ensuring adherence adds to costs but is crucial for market acceptance.

-

Logistics and Shipping: Freight costs depend on shipment volume, destination port, and Incoterms. For Africa and South America, shipping from Asian manufacturing hubs can range from $2 to $5 per pair for sea freight, with additional costs for customs clearance and inland transportation.

-

Margins: Typically, wholesale margins for footwear brands range from 20% to 50%, depending on brand positioning, order volume, and negotiation power. Buyers should factor in these margins to establish competitive yet profitable resale prices.

Price Influencers and Their Impact

Several factors significantly influence the landed cost of Charles Barkley shoes:

-

Order Volume and MOQ: Larger orders benefit from economies of scale, reducing per-unit costs. Manufacturers often offer better pricing for MOQs exceeding 1,000 pairs, making volume negotiation critical.

-

Specifications and Customization: Unique designs, special materials, or custom branding increase costs due to additional tooling, longer lead times, and quality checks.

-

Material Choices: Premium materials like genuine leather or high-performance textiles elevate costs but may command higher retail prices, enhancing margins for buyers.

-

Quality and Certifications: Higher quality standards, including certifications for safety or environmental compliance, can add to the cost but are essential for accessing certain markets.

-

Supplier Factors: Reliable suppliers with proven compliance, shorter lead times, and strong communication channels often command premium prices but reduce risks of delays and quality issues.

-

Incoterms: FOB (Free on Board) is common, allowing buyers to manage shipping and customs. CIF (Cost, Insurance, Freight) includes shipping costs, simplifying logistics but increasing initial costs.

Buyer Tips for Optimizing Cost and Price

To maximize value and ensure profitability, international buyers should adopt strategic approaches:

-

Negotiate Volume Discounts: Emphasize long-term partnerships and larger purchase volumes to secure better pricing and flexible payment terms.

-

Leverage Total Cost of Ownership (TCO): Consider all costs—materials, freight, customs, duties, warehousing, and after-sales support—beyond just unit price. Sometimes, paying slightly higher upfront costs yields savings downstream.

-

Understand Pricing Nuances: Recognize that prices can vary based on the supplier’s location, compliance costs, and market conditions. Transparent communication about specifications and expectations can prevent hidden charges.

-

Develop Strong Supplier Relationships: Building trust and consistent order flow encourages suppliers to offer preferential rates, faster lead times, and better quality assurance.

-

Stay Informed on Market Trends: Fluctuations in raw material prices, freight costs, and exchange rates impact overall costs. Regularly monitor industry reports and commodity trends relevant to footwear manufacturing.

-

Consider Lead Times: Longer lead times may reduce costs but risk market delays. Conversely, expedited shipping increases costs but may be necessary for timely market entry.

Indicative Price Range

While actual costs vary based on specifications, order volume, and region, a typical wholesale price for Charles Barkley shoes sourced from Asia ranges between $20 and $40 per pair for standard models in bulk. Retail prices in target markets can be marked up by 50% to 100%, depending on branding and market positioning.

Disclaimer: These prices are indicative and subject to change based on market dynamics, supplier negotiations, and specific customization requirements. Buyers should conduct thorough due diligence and request detailed quotes tailored to their specifications.

By understanding these cost components, influencing factors, and negotiation strategies, B2B buyers from Africa, South America, the Middle East, and Europe can optimize their sourcing processes, reduce costs, and improve margins while ensuring quality and compliance.

Spotlight on Potential charles barkley shoes Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘charles barkley shoes’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for charles barkley shoes

Critical Technical Properties of Charles Barkley Shoes

1. Material Grade and Composition

The quality and type of materials used in Charles Barkley shoes significantly influence durability, comfort, and brand perception. Common upper materials include genuine leather, synthetic leathers, or mesh fabrics, each with specified grades indicating thickness, tensile strength, and breathability. For B2B buyers, ensuring consistent material grades across production batches guarantees product uniformity and reduces defect rates.

2. Sole Material and Tolerance

The outsole is typically made from rubber or foam compounds, designed for grip and shock absorption. Precise tolerances in sole thickness and composition are crucial to meet performance standards and safety regulations. Suppliers should provide detailed specifications on material hardness (measured in Shore A), abrasion resistance, and flexibility, which directly affect the shoe’s performance and lifespan.

3. Stitching and Construction Tolerance

Manufacturing precision, especially in stitching quality and seam alignment, impacts both aesthetics and durability. Tolerance levels specify acceptable deviations in stitch length, seam strength, and component fit. Maintaining strict tolerances minimizes returns, enhances product integrity, and aligns with quality standards expected in international markets.

4. Weight and Balance Specifications

The weight of the shoe, particularly in high-performance models, affects comfort and athlete performance. Tolerances for weight are expressed in grams, with strict limits to ensure consistency. Proper balance and weight distribution are also vital, influencing user experience and safety, especially for sports footwear.

5. Color Fastness and Material Finishing

Color fastness measures how well the shoe’s color resists fading or bleeding during use and cleaning. Industry standards specify minimum fastness ratings (often ISO or ASTM standards). Finishing processes, such as coating or polishing, should meet these standards to ensure longevity and aesthetic appeal across international markets.

6. Compliance and Certification Standards

Technical properties must align with regional safety and environmental standards, such as REACH (Europe), CPSIA (North America), or other local regulations. Certification confirms that materials and manufacturing processes meet required legal and safety benchmarks, crucial for market entry and consumer trust.

Essential Industry and Trade Terms

1. OEM (Original Equipment Manufacturer)

Refers to a manufacturer that produces footwear based on a brand’s design and specifications. B2B buyers often source Charles Barkley shoes from OEMs to ensure product authenticity and control over quality, cost, and lead times.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier agrees to produce or sell per order. Understanding MOQ helps buyers plan procurement strategies, optimize inventory, and negotiate prices effectively, especially when entering new markets like Africa or South America.

3. RFQ (Request for Quotation)

A formal document issued by buyers to suppliers requesting price, lead time, and terms for specific shoe models or components. Accurate RFQs streamline procurement and ensure competitive bidding, vital for managing costs across diverse regions.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and tariffs between buyers and sellers. Common Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, Freight) specify who bears costs and risks at each shipping stage, essential for international logistics planning.

5. Lead Time

The duration from order placement to delivery. Accurate lead times are critical for inventory management, especially in regions with fluctuating demand or logistical challenges, such as Africa or South America.

6. Quality Assurance (QA) Standards

Protocols and inspections to verify that footwear meets specified technical and safety standards. Ensuring strict QA processes reduces returns, enhances brand reputation, and complies with regional regulations.

Strategic Takeaways for B2B Buyers

Understanding these technical properties and trade terms enables international buyers to evaluate supplier offerings accurately, negotiate effectively, and ensure compliance with regional standards. Clear communication of specifications related to material quality, construction tolerances, and certification requirements minimizes risks and facilitates smoother market entry for Charles Barkley shoes across diverse regions. Emphasizing transparency and standardization in these areas will support sustainable supply chain relationships and product excellence in competitive global markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the charles barkley shoes Sector

Market Overview & Key Trends

The global market for Charles Barkley shoes, primarily driven by Nike’s iconic branding, is experiencing dynamic shifts influenced by broader industry trends and technological advancements. International B2B buyers from Africa, South America, the Middle East, and Europe—such as Vietnam and Argentina—are increasingly seeking to capitalize on these shifts to optimize supply chains and expand their market presence.

Emerging sourcing trends include the adoption of digital procurement platforms, which streamline supplier vetting, order management, and compliance tracking. Advanced data analytics enable buyers to forecast demand more accurately, mitigate risks, and negotiate better terms with manufacturers. Additionally, there is a growing preference for localized manufacturing or near-shoring to reduce lead times and navigate tariffs, especially amidst ongoing global trade disruptions.

Market dynamics are also influenced by fluctuating raw material costs—cotton, rubber, leather, and synthetics—prompting buyers to diversify their supplier base and explore alternative, cost-effective materials. The rise of e-commerce and direct-to-consumer channels further impacts wholesale strategies, pushing for more flexible, scalable supply solutions. For African, South American, and Middle Eastern buyers, engaging with established footwear manufacturers that adhere to international quality standards and leverage innovative production techniques is vital for maintaining competitiveness.

Furthermore, sustainability is becoming a key differentiator. Buyers are prioritizing partners with transparent supply chains, eco-friendly materials, and compliance with social standards. Staying ahead in this evolving landscape requires a proactive approach to sourcing—embracing technology, diversification, and sustainability—to secure reliable, cost-effective, and ethically produced Charles Barkley shoes.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly central to sourcing decisions in the Charles Barkley shoes sector, driven by consumer demand, regulatory pressures, and corporate social responsibility commitments. Environmental impacts of footwear manufacturing—including water usage, chemical emissions, and waste—necessitate a strategic shift towards greener practices. B2B buyers from emerging markets like Africa, South America, and the Middle East must prioritize partnerships with suppliers committed to reducing their carbon footprint and adopting environmentally friendly materials.

Certifications such as ISO 14001 (Environmental Management) and Fair Trade or SA8000 (Social Accountability) are critical benchmarks for ensuring ethical compliance. These certifications demonstrate adherence to responsible sourcing, fair labor practices, and sustainable environmental management. Incorporating ‘green’ materials—such as recycled textiles, bio-based rubbers, and responsibly sourced leather—can significantly enhance the sustainability profile of Charles Barkley shoes.

Moreover, transparency throughout the supply chain is essential. Implementing traceability solutions, such as blockchain, allows buyers to verify the origin of raw materials and ensure compliance with environmental and social standards. This not only mitigates reputational risks but also aligns with global trends towards circular economy models, where recycling and upcycling are prioritized.

For B2B buyers, establishing long-term relationships with suppliers who invest in sustainable practices offers strategic advantages, including premium positioning and access to eco-conscious markets. As environmental regulations tighten globally, early adoption of sustainable sourcing practices will be critical for maintaining competitiveness and ensuring regulatory compliance.

Brief Evolution/History (Optional)

The Charles Barkley shoes sector has evolved from its initial basketball-centric designs in the late 1980s to a broader lifestyle and athletic footwear market. Nike’s strategic collaboration with Barkley transformed his line into a symbol of performance and cultural relevance. Over time, the focus has shifted towards integrating innovative materials and sustainable manufacturing techniques to meet evolving consumer and regulatory expectations.

For B2B players, understanding this evolution underscores the importance of innovation and brand positioning. Partnering with manufacturers that have a proven track record in product innovation and sustainability can provide a competitive edge. As the market continues to grow, especially in emerging economies, leveraging historical brand strength alongside modern, eco-friendly practices will be key to long-term success in the Charles Barkley shoes segment.

Related Video: What is the Strait of Hormuz – and why does it matter to global trade?

Frequently Asked Questions (FAQs) for B2B Buyers of charles barkley shoes

-

How can I verify the reliability and compliance standards of Charles Barkley shoe suppliers?

To ensure supplier reliability, conduct thorough due diligence by requesting certifications such as ISO, SA8000, or social compliance audits aligned with international standards. Verify their manufacturing licenses, factory audits, and social responsibility reports. Engage with third-party inspection agencies to conduct on-site inspections before placing large orders. Additionally, review supplier reputation through industry networks, trade associations, and online B2B platforms like Alibaba or Global Sources. Establish clear contractual clauses on quality, delivery, and compliance to mitigate risks. Regular audits and transparent communication are essential to maintain ongoing supplier compliance and trustworthiness. -

What customization options are available for bulk orders, and how do they impact MOQ and lead times?

Most suppliers offer customization in branding, packaging, and design elements such as colorways, logo placement, or material choices. Customization typically requires higher MOQs—often ranging from 500 to 2,000 pairs—due to setup costs. Lead times extend accordingly, usually by 4-8 weeks depending on complexity. To optimize, negotiate flexible minimums or phased orders with suppliers who support smaller batch runs or rapid prototyping. Clear specifications and early communication about your customization needs help streamline production and avoid delays, ensuring your branded shoes meet international market standards. -

What are typical payment terms, and how can I mitigate financial risks when sourcing Charles Barkley shoes internationally?

Common payment terms include 30% upfront deposit with 70% balance before shipment, or letters of credit for larger transactions. To mitigate risks, consider working with escrow services or using trade finance instruments that protect both parties. Establish clear contractual terms covering payment deadlines, penalties for delays, and quality acceptance criteria. Conduct due diligence on the supplier’s financial stability, possibly through credit reports or references. Building strong relationships and phased payments aligned with production milestones can also reduce exposure to non-performance or quality issues. -

What quality assurance processes and certifications should I look for in Charles Barkley shoe suppliers?

Reliable suppliers should adhere to internationally recognized quality standards such as ISO 9001, and have certifications related to safety, environmental management (ISO 14001), and social compliance (SA8000). Ask for detailed Quality Control (QC) procedures, including pre-production samples, in-line inspections, and final audits. Request test reports for material safety, durability, and compliance with regional regulations like REACH or CPSIA. Engaging third-party inspection agencies at various production stages ensures consistent quality, reduces returns, and aligns your product with international standards. -

How do I manage logistics and shipping when importing Charles Barkley shoes to my country?

Start by selecting freight options based on cost, speed, and volume—air freight for urgent orders, sea freight for bulk shipments, or rail where applicable. Collaborate with experienced freight forwarders familiar with your region’s import regulations. Ensure proper documentation such as commercial invoices, packing lists, certificates of origin, and any regional compliance certificates. Clarify Incoterms (e.g., FOB, CIF) with your supplier to define responsibility and risk. Regular communication and tracking enable proactive handling of delays or customs issues, minimizing disruption to your supply chain. -

What steps should I take if there is a dispute over product quality or delivery?

Begin with detailed documentation—photos, inspection reports, and correspondence—to substantiate your claim. Communicate promptly with your supplier, referencing contractual terms and agreed standards. Negotiate a resolution such as rework, replacement, or refund, preferably through mediation or arbitration if necessary. Engage third-party inspectors or legal counsel familiar with international trade laws to support your case. Implement clear dispute resolution clauses in your contracts, including jurisdiction and arbitration procedures, to facilitate swift resolution and protect your business interests. -

How can I ensure compliance with regional import regulations and standards for Charles Barkley shoes?

Research specific regional standards such as CE marking for Europe, ASTM or CPSIA compliance for the US, or local certifications for Africa, South America, and the Middle East. Confirm that your supplier provides necessary test reports and Certificates of Conformity. Work with local customs brokers and compliance consultants to understand tariff classifications, import duties, and labeling requirements. Incorporate compliance checks into your quality assurance process and request supplier documentation proactively. Staying updated with regional trade policies and standards ensures smooth customs clearance and reduces the risk of penalties or shipment delays. -

What are best practices for building sustainable and long-term relationships with Charles Barkley shoe suppliers?

Establish open, transparent communication channels and clearly define expectations from the outset. Prioritize mutual trust by paying on time and providing constructive feedback. Engage in regular performance evaluations and audits to uphold quality and compliance standards. Consider collaborative planning, such as joint development projects or shared sustainability goals, to foster loyalty. Offering consistent order volumes and prompt payments can incentivize suppliers to prioritize your business. Building personal relationships and understanding cultural nuances also enhance partnership longevity, ensuring a reliable supply chain aligned with your strategic growth objectives.

Strategic Sourcing Conclusion and Outlook for charles barkley shoes

Strategic Sourcing Outlook and Actionable Insights

Effective strategic sourcing remains essential for B2B buyers seeking to capitalize on the growing global demand for Charles Barkley shoes. Prioritizing supply chain transparency, compliance with social and environmental standards, and cost optimization will enable buyers from Africa, South America, the Middle East, and Europe to secure quality products while mitigating risks associated with disruptions and regulatory changes. Leveraging local manufacturing hubs, such as Vietnam or Argentina, can offer significant advantages in reducing lead times and tariffs, provided due diligence on factory compliance and sustainable practices is maintained.

Looking ahead, international buyers should deepen partnerships with vetted suppliers that uphold ethical standards and innovative manufacturing practices. Embracing data-driven sourcing strategies and engaging with industry resources—such as footwear compliance centers and trade associations—can further enhance competitiveness. As the footwear market evolves, proactive and strategic procurement will be key to capturing growth opportunities, ensuring product authenticity, and maintaining long-term sustainability in the Charles Barkley shoes segment. Now is the time to refine sourcing strategies to stay ahead in this dynamic industry landscape.

Illustrative Image (Source: Google Search)