Your Ultimate Guide to Sourcing Shoes For Crews Promo Code

Guide to Shoes For Crews Promo Code

- Introduction: Navigating the Global Market for shoes for crews promo code

- Understanding shoes for crews promo code Types and Variations

- Key Industrial Applications of shoes for crews promo code

- Strategic Material Selection Guide for shoes for crews promo code

- In-depth Look: Manufacturing Processes and Quality Assurance for shoes for crews promo code

- Comprehensive Cost and Pricing Analysis for shoes for crews promo code Sourcing

- Spotlight on Potential shoes for crews promo code Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for shoes for crews promo code

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the shoes for crews promo code Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of shoes for crews promo code

- Strategic Sourcing Conclusion and Outlook for shoes for crews promo code

Introduction: Navigating the Global Market for shoes for crews promo code

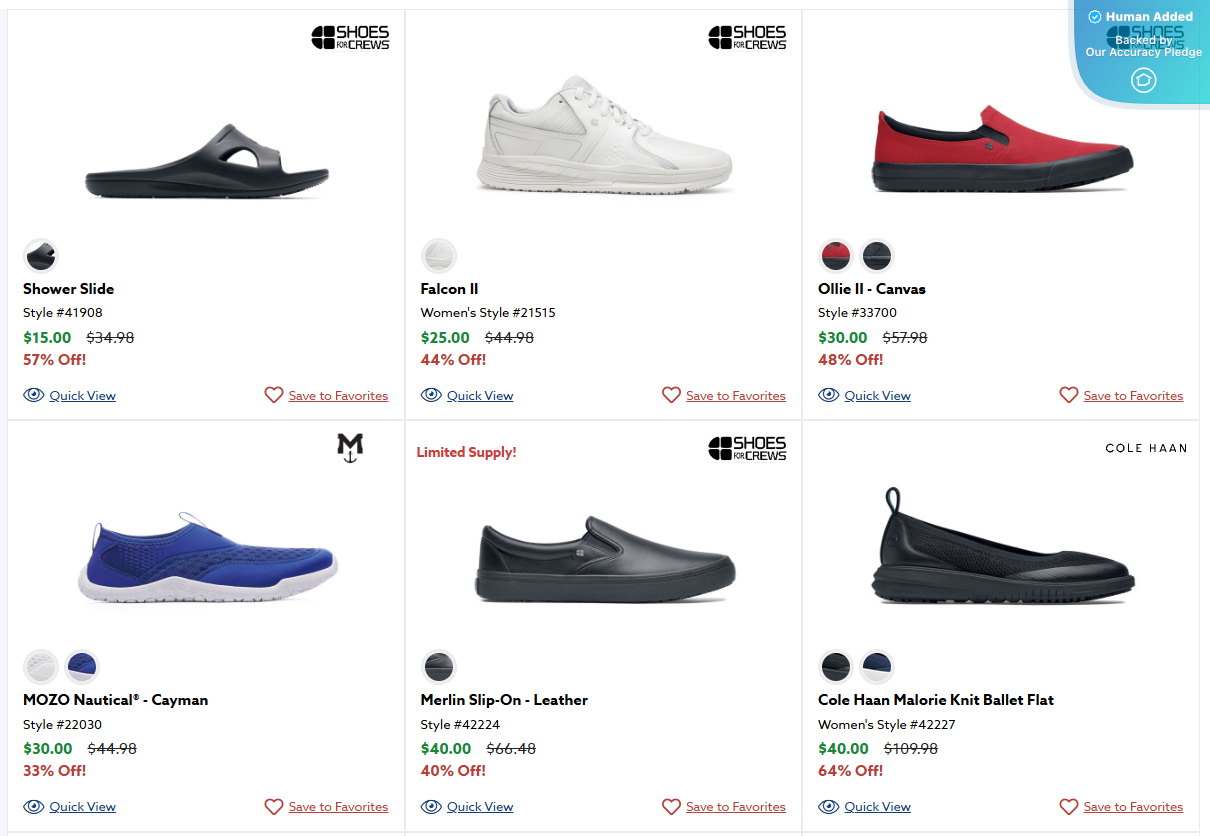

In today’s highly interconnected global economy, sourcing reliable and cost-effective footwear solutions for crews has become more complex—and more critical—than ever before. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, leveraging tools like shoes for crews promo codes can unlock significant savings and streamline procurement processes. These promo codes not only reduce upfront costs but also provide access to premium suppliers and manufacturers, ensuring quality standards are met without compromising budget constraints.

Illustrative Image (Source: Google Search)

This comprehensive guide is designed to empower you with actionable insights across every stage of your sourcing journey. We cover a wide spectrum of essential topics, including the different types of crew shoes suited for various industries, material options that balance durability and comfort, manufacturing and quality control considerations, and how to identify reputable suppliers globally—particularly in key markets like Egypt, Thailand, and beyond. Additionally, we delve into cost analysis, market trends, and frequently asked questions to clarify common uncertainties.

By understanding the nuances of the shoes for crews promo code landscape, your organization can make smarter, more strategic procurement decisions. Whether you’re optimizing for price, quality, or supplier reliability, this guide aims to equip you with the knowledge needed to navigate the complexities of international sourcing confidently—maximizing value while maintaining high standards across your operations worldwide.

Understanding shoes for crews promo code Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Discount Code Bundles | Multiple codes bundled for bulk purchasing discounts | Wholesale procurement, large-scale orders | Cost-effective for large orders; complexity in management but offers significant savings |

| Tiered Discount Codes | Varying discounts based on purchase volume or customer tier | Supplier partnerships, loyalty programs | Encourages higher volume purchases; may require tracking systems but enhances buyer loyalty |

| Limited-Time Promo Codes | Time-sensitive codes offering short-term discounts | Promotional campaigns, seasonal sales | Creates urgency, boosts short-term sales; limited window may restrict immediate use |

| Exclusive Partner Codes | Codes provided through authorized partners or affiliates | B2B reseller channels, strategic alliances | Ensures brand control, potential for targeted outreach; may limit broad accessibility |

| Customizable Promo Codes | Codes tailored to specific buyer needs or campaigns | Custom B2B marketing, personalized offers | Enhances buyer engagement, flexible; requires setup and management resources |

Discount Code Bundles

Discount code bundles are designed to incentivize large-volume purchases by offering multiple codes within a single package. These are ideal for wholesale buyers and distributors who plan to order in bulk regularly. The primary advantage is significant cost savings, which can improve profit margins for B2B buyers. However, managing multiple codes can become complex, especially if not integrated into existing procurement systems. Proper tracking and clear communication are essential to maximize benefits.

Tiered Discount Codes

Tiered discount codes offer varying levels of discounts based on purchase volume or customer loyalty tiers. This variation motivates buyers to increase order sizes and foster long-term relationships. Suitable for suppliers seeking to build repeat business or incentivize high-volume buyers, these codes require robust tracking mechanisms to ensure accurate application. While they can boost sales and customer retention, buyers should evaluate whether the tier structure aligns with their purchasing patterns to optimize value.

Limited-Time Promo Codes

Limited-time promo codes create a sense of urgency, encouraging quick decision-making among buyers. They are particularly effective during promotional campaigns, seasonal sales, or product launches. For international buyers, understanding the validity period and time zone considerations is crucial to avoid missing out. Although they generate immediate sales boosts, their short validity period necessitates prompt action, which may not always align with procurement cycles.

Exclusive Partner Codes

These codes are distributed through authorized partners or affiliates, allowing brands to control distribution channels and target specific markets. They are useful in strategic alliances, reseller programs, or regional campaigns. Buyers benefit from exclusivity and targeted offers, but access may be limited to certain channels, potentially restricting broad market penetration. Ensuring clear communication and partnership agreements is vital for maximizing the effectiveness of these codes.

Customizable Promo Codes

Customizable promo codes are tailored to specific campaigns or buyer segments, offering personalized discounts or benefits. They are highly effective for targeted marketing efforts, enabling brands to address unique customer needs or regional preferences. For B2B buyers, this flexibility can translate into better negotiation leverage and tailored incentives. However, setting up and managing these codes requires dedicated resources and strategic planning to ensure they deliver intended value without complicating the sales process.

Key Industrial Applications of shoes for crews promo code

| Industry/Sector | Specific Application of shoes for crews promo code | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Infrastructure | Safety footwear for construction crews on-site | Ensures worker safety, reduces injury risk, and complies with safety standards | Durability, slip resistance, certification (EN, ASTM), comfort for long shifts |

| Oil & Gas | Protective boots for offshore and onshore personnel | Provides chemical, oil, and impact resistance; enhances safety compliance | Material compatibility with chemicals, waterproofing, slip resistance, certification |

| Manufacturing & Warehousing | Anti-fatigue and slip-resistant shoes for factory workers | Improves worker comfort and safety, reduces downtime due to injuries | Ergonomic design, slip resistance, durability, ease of cleaning |

| Agriculture & Farming | Durable footwear for field workers exposed to mud, water, and rough terrain | Protects against environmental hazards, enhances productivity | Waterproofing, slip resistance, rugged sole design, climate adaptability |

| Mining & Heavy Industry | Heavy-duty boots for miners and industrial laborers | Ensures safety in hazardous environments, impact and puncture resistance | Heavy-duty construction, steel toe options, certification standards, comfort |

Construction & Infrastructure

In the construction industry, crews require footwear that balances safety, durability, and comfort. Shoes for crews promo codes enable procurement of high-quality safety boots that meet international safety standards such as EN or ASTM. These shoes are designed to withstand harsh environments, provide slip resistance on uneven surfaces, and protect against falling objects. For international buyers, especially from regions like Egypt or Thailand, sourcing reliable, certified footwear ensures compliance with local safety regulations while reducing injury-related costs. Bulk purchasing through promo codes streamlines procurement and ensures consistent safety standards across projects.

Oil & Gas

Offshore and onshore oil and gas operations demand specialized footwear capable of resisting chemicals, oil, and extreme conditions. Shoes for crews promo codes facilitate access to protective boots that feature chemical-resistant materials, waterproofing, and impact protection. For buyers in the Middle East or South America, where safety compliance is critical, sourcing certified, high-performance footwear minimizes operational risks and ensures worker safety in hazardous environments. Bulk buying options help manage costs and ensure uniform safety standards across multiple sites.

Manufacturing & Warehousing

Factory and warehouse workers often face risks from slips, trips, and fatigue. Shoes for crews promo codes allow companies to acquire slip-resistant, ergonomic footwear that enhances safety and comfort during long shifts. For European or African industrial sectors, reliable sourcing of durable shoes reduces injury rates and downtime, ultimately improving productivity. These shoes also facilitate compliance with occupational safety standards and simplify procurement processes through volume discounts and streamlined ordering.

Agriculture & Farming

Agricultural workers are exposed to water, mud, and rough terrain, necessitating rugged, waterproof footwear. Shoes for crews promo codes enable bulk procurement of durable, slip-resistant boots tailored for outdoor conditions. For buyers in regions like South America or North Africa, where environmental conditions vary widely, sourcing footwear that offers environmental protection and comfort improves worker safety and operational efficiency. Consistent quality and affordability through promo codes help maintain safety standards across large farming operations.

Mining & Heavy Industry

Mining and heavy industrial sectors require heavy-duty boots with impact and puncture resistance to ensure worker safety in hazardous environments. Shoes for crews promo codes facilitate sourcing of certified, durable footwear with steel toes and specialized soles. For European or Middle Eastern buyers, maintaining high safety standards is critical to regulatory compliance and worker safety. Bulk purchasing options help manage costs while ensuring that all personnel are equipped with reliable, compliant footwear, reducing safety incidents and operational disruptions.

Strategic Material Selection Guide for shoes for crews promo code

Analysis of Common Materials for Shoes for Crews Promo Code

When selecting materials for footwear designed for crews, especially under promotional programs, it is crucial to consider the balance between durability, cost, manufacturing complexity, and compliance with international standards. Different regions—such as Africa, South America, the Middle East, and Europe—have varying environmental conditions, regulatory standards, and market preferences that influence material choice.

Rubber and Thermoplastic Elastomers (TPE)

Key Properties:

Rubber and TPE are highly flexible, resilient, and provide excellent slip resistance—key features for safety-critical work environments. They are resistant to water, oils, and many chemicals, making them ideal for outdoor and industrial settings.

Pros & Cons:

Rubber offers superior durability and cushioning but tends to be heavier and may incur higher manufacturing costs due to vulcanization processes. TPE is lighter, easier to mold, and often more cost-effective, but may have slightly lower wear resistance over extended use.

Impact on Application:

Both materials are compatible with various outsole designs and can be molded into complex tread patterns. Rubber’s chemical resistance makes it suitable for environments with exposure to oils or solvents, while TPE’s flexibility supports ergonomic comfort.

International Considerations:

In regions like Europe and the Middle East, compliance with standards such as EN ISO 20345 (for safety footwear) is critical. Rubber and TPE are generally compliant but require certification. For African and South American markets, durability against harsh environmental conditions is paramount, making rubber a preferred choice despite higher costs.

Leather (Full Grain and Synthetic)

Key Properties:

Leather provides natural breathability, flexibility, and a premium appearance. Full grain leather is highly durable and ages well, whereas synthetic leather offers a lower-cost alternative with easier maintenance.

Pros & Cons:

Full grain leather is highly durable and comfortable but involves complex manufacturing processes and higher costs. Synthetic leather reduces initial costs and simplifies manufacturing but may degrade faster under extreme conditions like high humidity or exposure to chemicals.

Impact on Application:

Leather is suitable for dress shoes or safety shoes where aesthetics and comfort are prioritized. It is less ideal for environments with high moisture or chemical exposure unless treated appropriately.

International Considerations:

European markets often favor high-quality leather due to standards related to sustainability and animal welfare. In regions like Africa and South America, cost considerations may drive preference toward synthetic options. Compliance with local environmental regulations (e.g., REACH in Europe) must be verified.

Polyester and Nylon Fabrics

Key Properties:

These synthetic fabrics are lightweight, breathable, and resistant to abrasion and chemicals. They are often used in combination with other materials for uppers or linings.

Pros & Cons:

Polyester and nylon are cost-effective, easy to manufacture, and quick-drying. However, they may lack the structural integrity needed for heavy-duty applications without reinforcement, and their chemical resistance varies depending on treatment.

Impact on Application:

Ideal for lightweight, breathable shoes or as part of composite structures. They perform well in environments where moisture management and flexibility are priorities.

International Considerations:

In regions with high humidity or temperature fluctuations, such as parts of Africa and Southeast Asia, these fabrics help prevent foot fatigue and discomfort. Compliance with standards like ASTM F2413 (for safety footwear) is necessary, especially for industrial applications.

Summary Table

| Material | Typical Use Case for shoes for crews promo code | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber and TPE | Outsoles for industrial and outdoor footwear | Excellent slip resistance, chemical resistance, durability | Heavier (rubber), manufacturing complexity (rubber), slightly lower flexibility (TPE) | Low (TPE), High (Rubber) |

| Leather (Full Grain & Synthetic) | Dress shoes, safety footwear, premium work shoes | Natural breathability, durability, aesthetic appeal | Higher cost, sensitive to moisture and chemicals (full grain), environmental concerns | High (full grain), Low/Med (synthetic) |

| Polyester & Nylon Fabrics | Uppers, linings, lightweight work shoes | Cost-effective, lightweight, quick-drying | Less durable under heavy stress, limited chemical resistance | Low |

This comprehensive understanding of material properties and regional considerations enables B2B buyers to make informed decisions aligned with their target markets, compliance requirements, and budget constraints. Selecting the right materials ensures product longevity, safety, and customer satisfaction across diverse international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for shoes for crews promo code

Manufacturing Processes in Shoe Production for Crews Promo Code

The manufacturing of shoes intended for commercial or crew use follows a structured, multi-stage process that emphasizes efficiency, durability, and compliance with international standards. Understanding each stage helps B2B buyers evaluate supplier capabilities and ensure product quality.

1. Material Preparation

This initial stage involves sourcing and preparing raw materials such as leather, synthetic fabrics, rubber, EVA foam, and adhesives. Suppliers should prioritize high-quality, tested materials that meet industry standards like REACH or OEKO-TEX for chemical safety. For international buyers, verifying material certifications is crucial, especially when importing to regions with strict regulations such as Europe or North America.

2. Forming and Cutting

In this phase, patterns are created based on the shoe design, and materials are cut using automated CNC machines or laser cutters for precision. Advanced suppliers utilize computer-aided design (CAD) and manufacturing (CAM) systems to ensure consistency across batches. For bulk orders, automation reduces variability, which is critical for maintaining uniformity in large-scale production.

3. Assembly and Stitching

Components—such as uppers, insoles, midsoles, and outsoles—are assembled. Stitching employs high-frequency or lock-stitch machines, with quality stitching critical for durability, especially in crew shoes that undergo intensive use. Adhesive bonding and heat welding are also common, especially for waterproof or slip-resistant features. Suppliers should document assembly processes and employ standardized procedures to facilitate quality control.

4. Finishing and Quality Checks

Final steps include applying finishing touches like polishing, labeling, and adding insoles or laces. Surface treatments such as waterproofing or anti-slip coatings are applied here. Finishing is followed by initial inspections to identify visible defects, ensuring only compliant units proceed to final quality checks.

Quality Assurance Framework for Shoe Manufacturing

Robust quality assurance (QA) processes are vital for B2B buyers to mitigate risks associated with product defects, non-compliance, or delays. International standards and industry-specific certifications serve as benchmarks for assessing supplier reliability.

1. International Standards & Certifications

– ISO 9001: Most reputable manufacturers operate under ISO 9001, indicating a quality management system that ensures consistent product quality and continuous improvement.

– CE Marking: For shoes exported to Europe, CE certification confirms compliance with safety, health, and environmental requirements.

– Other Certifications: Depending on the target market, certifications like ASTM for North America or SGS testing reports may be relevant. Suppliers should be transparent about their certifications and provide documentation upon request.

2. Quality Control Checkpoints

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival for defects, chemical composition, and compliance with specifications. Suppliers should maintain detailed IQC reports, including test results for chemical safety and physical properties.

– In-Process Quality Control (IPQC): During manufacturing, checkpoints include stitching integrity, dimensional accuracy, and assembly conformity. Regular sampling and statistical process control (SPC) are used to monitor consistency.

– Final Quality Control (FQC): Before packaging, finished shoes undergo thorough inspections for defects, uniformity, and adherence to client specifications. This includes visual checks, weight measurements, and functional tests.

3. Testing Methods and Protocols

– Physical Tests: Tensile strength, abrasion resistance, and flexibility tests ensure durability.

– Chemical Tests: Verifying chemical emissions, solvent residues, and allergen presence aligns with regulatory requirements.

– Environmental Tests: For shoes used in demanding environments, testing for waterproofing, slip resistance, and temperature resilience may be necessary.

Verifying Supplier Quality Control Capabilities

B2B buyers should adopt proactive measures to validate supplier QC processes, especially when dealing with international suppliers from diverse regions such as Africa, South America, the Middle East, and Europe.

1. Factory Audits and Inspections

Engage third-party inspection firms or conduct on-site audits to evaluate manufacturing facilities. Key focus areas include cleanliness, equipment calibration, documentation practices, and employee training programs. Audits should verify adherence to ISO 9001 and other relevant standards.

2. Review of Quality Reports and Certifications

Request recent inspection reports, test certificates, and audit summaries. Reputable suppliers provide detailed documentation that demonstrates compliance with international standards, often verified by third-party labs or certifying bodies.

3. Sample Testing and Pre-shipment Inspections

Order pre-production samples for independent testing, or arrange third-party inspections before shipment. This ensures that the final product matches quality expectations and specifications.

4. Ongoing Quality Monitoring

Establish clear communication channels for quality issues and implement periodic review of QC reports. Consider long-term partnerships with suppliers who demonstrate transparency and continuous improvement.

Considerations for International B2B Buyers

When sourcing shoes from regions like Egypt, Thailand, or other manufacturing hubs, regional nuances influence QC procedures:

- Regional Certification Recognition: Buyers should familiarize themselves with region-specific standards (e.g., CE in Europe, ASTM in North America) and ensure suppliers’ certifications are current and valid.

- Language and Documentation: Clear communication about quality expectations requires documentation in accessible languages and detailed technical sheets.

- Supply Chain Transparency: Due to varying levels of manufacturing infrastructure, buyers should prioritize suppliers with transparent supply chains and traceability systems.

- Cultural and Regulatory Differences: Recognize local manufacturing practices and adapt inspection protocols accordingly, possibly engaging local third-party inspectors familiar with regional standards.

Final Recommendations for B2B Buyers

- Develop a comprehensive supplier qualification process that includes audits, certification verification, and sample testing.

- Prioritize suppliers with ISO 9001 and relevant industry certifications to ensure baseline quality management practices.

- Implement rigorous incoming, in-process, and final inspections aligned with international standards.

- Leverage third-party inspection agencies for unbiased quality validation, especially when dealing with suppliers from regions with developing manufacturing infrastructure.

- Maintain open communication and detailed documentation to foster transparency and accountability.

By meticulously evaluating manufacturing processes and embedding strict quality assurance protocols, international B2B buyers can mitigate risks, ensure product consistency, and forge reliable partnerships in the shoe supply chain globally.

Comprehensive Cost and Pricing Analysis for shoes for crews promo code Sourcing

Cost Structure Breakdown

Understanding the comprehensive cost components involved in sourcing shoes for crews is crucial for international B2B buyers aiming to optimize procurement budgets. The primary cost elements include:

-

Materials: The choice of upper fabrics (leather, mesh, synthetic), soles (rubber, EVA, PU), and additional components (laces, insoles) significantly influence costs. Premium materials like genuine leather or specialized composites escalate expenses, while synthetic alternatives can reduce costs but may impact durability and appeal.

-

Labor: Manufacturing labor costs vary widely based on the country of production. For example, factories in Southeast Asia (e.g., Thailand, Vietnam) tend to offer lower wages compared to Middle Eastern or European facilities. Buyers should assess the skill level required and the associated wage rates to estimate labor costs accurately.

-

Manufacturing Overhead: This includes factory utilities, machinery depreciation, and administrative expenses. Overhead costs tend to be more stable but can fluctuate with energy prices or factory efficiency. Larger orders often benefit from economies of scale, reducing per-unit overhead.

-

Tooling and Setup Fees: Initial molds, dies, and tooling setups represent a significant upfront investment, particularly for customized designs or specific sizing requirements. These costs are amortized over the production volume; thus, higher MOQs (Minimum Order Quantities) can lower per-unit costs.

-

Quality Control (QC): Ensuring consistent quality involves inspection, testing, and sometimes third-party certifications, especially for markets requiring compliance with standards like ISO or local safety certifications. QC costs are usually embedded in the unit price but can be negotiated separately.

-

Logistics and Shipping: Transportation costs depend heavily on origin-destination pairs, shipping modes (air, sea, land), and incoterms. For example, shipping from Asia to Africa may incur different costs compared to Europe to South America. Customs duties, tariffs, and import taxes further influence final landed costs.

-

Profit Margin: Suppliers add a margin to cover risks, investment, and profit objectives. Margins vary by supplier size, reputation, and market competitiveness but typically range from 10% to 30%.

Price Influencers

Several factors directly impact the final pricing for shoes sourced via promo codes:

-

Order Volume & MOQ: Larger orders generally unlock discounts due to economies of scale. Buyers should negotiate for better unit prices when committing to higher volumes, especially for ongoing supply agreements.

-

Specifications & Customization: Custom features such as branding, colorways, specialized materials, or design modifications increase costs. Standard models are more cost-effective, but customization can add a premium.

-

Materials & Certifications: Use of premium or eco-friendly materials, along with compliance certifications (e.g., REACH, ISO, Fair Trade), can elevate costs but may be necessary for certain markets to meet regulatory or consumer expectations.

-

Supplier Factors: Factory reputation, capacity, and reliability influence pricing. Established suppliers with robust quality records might charge higher premiums but offer better assurance of delivery and quality.

-

Incoterms & Shipping Conditions: FOB (Free On Board) prices are common, but buyers should consider CIF (Cost, Insurance, Freight) or DDP (Delivered Duty Paid) arrangements for clarity on total landed costs. Incoterms impact who bears logistics costs and risks.

Buyer Tips for Cost Optimization

-

Negotiate Effectively: Leverage volume commitments, long-term relationships, or flexible payment terms to negotiate better prices. Emphasize the potential for repeat business to secure discounts.

-

Focus on Total Cost of Ownership (TCO): Consider not just unit price but also shipping, customs, taxes, and potential rework costs. Sometimes, sourcing locally or regionally can reduce overall TCO despite higher unit prices.

-

Understand Pricing Nuances: Pricing can vary significantly based on seasonality, supplier capacity, or geopolitical factors. For example, tariffs or import restrictions in Egypt or South America might increase landed costs, so factor these into negotiations.

-

Request Transparent Quotations: Ensure quotes specify all cost components, including tooling, QC, shipping, and duties. Clarify whether prices are fixed or subject to fluctuation.

-

Sample Testing & Quality Assurance: Always order samples before large-scale procurement to verify quality, fit, and compliance with specifications. This step minimizes costly reworks or returns.

Price Range Estimates (Indicative)

- Basic models: $10–$20 per pair, suitable for bulk, non-customized shoes.

- Mid-range models: $20–$40, with better materials or slight customization.

- Premium models: $40–$70+, featuring high-end materials, branding, or certifications.

Disclaimer: These figures are approximate and can fluctuate based on order volume, supplier location, and market conditions. Buyers should conduct due diligence and obtain multiple quotes for accurate budgeting.

Optimizing costs in sourcing shoes for crews requires a strategic approach that balances quality, customization, and logistics considerations. By understanding the detailed cost structure and leveraging negotiation tactics, international buyers from Africa, South America, the Middle East, and Europe can secure competitive pricing while ensuring product standards are met.

Spotlight on Potential shoes for crews promo code Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for shoes for crews promo code.)*

Essential Technical Properties and Trade Terminology for shoes for crews promo code

Critical Technical Properties for Shoes for Crews Promo Code

1. Material Grade and Composition

The quality of materials used in shoes directly impacts durability, comfort, and safety. For B2B transactions, specifying the material grade—such as premium leather, high-grade synthetic fabrics, or specialized rubber—is essential. Higher grades typically command better performance and longevity, making them attractive for bulk procurement. Understanding the material composition also helps buyers assess suitability for specific industries, like healthcare or hospitality.

2. Tolerance and Manufacturing Precision

Tolerance refers to the acceptable deviation in dimensions during manufacturing, often measured in millimeters. Precise tolerances ensure consistent fit and comfort across large orders. For international buyers, clear specifications on tolerances reduce the risk of product returns or dissatisfaction, especially when scaling production across different factories or suppliers.

3. Sole and Traction Properties

The outsole material and tread design are crucial for safety and functionality. Non-slip, slip-resistant soles made from durable rubber or polyurethane are often preferred in environments with liquids or oils. Buyers should verify the traction properties and wear resistance to ensure shoes meet safety standards relevant to their industry.

4. Weight and Flexibility

Lightweight shoes reduce fatigue during long shifts, while flexibility enhances comfort and range of motion. For bulk procurement, requesting specifications on shoe weight and flexibility ratings helps in selecting products suitable for various operational needs, such as healthcare workers or service staff.

5. Breathability and Comfort Features

Materials with good breathability, such as mesh panels or moisture-wicking linings, improve wearer comfort. These features are especially important for high-temperature environments or extended wear, impacting employee satisfaction and productivity.

6. Compliance with Safety Standards

Many industries require footwear to meet specific safety standards, such as slip resistance, electrical hazard protection, or chemical resistance. Confirming the compliance certifications (e.g., ASTM, EN ISO) ensures the shoes are suitable for the intended workplace conditions, reducing liability and ensuring worker safety.

Essential Industry and Trade Terms

1. OEM (Original Equipment Manufacturer)

OEM refers to manufacturers that produce shoes based on the buyer’s specifications or branding. Understanding whether a supplier offers OEM services allows buyers to customize designs, logos, or specific features, which is crucial for brand consistency and differentiation in competitive markets.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity a supplier is willing to produce or sell. For international buyers, negotiating MOQ is essential to balance inventory costs with production economies. Lower MOQs can facilitate smaller, more flexible orders, especially when testing new markets or designs.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers solicit detailed price quotes, lead times, and terms from multiple suppliers. A well-prepared RFQ streamlines procurement, helps compare offers objectively, and ensures clarity on specifications, delivery, and payment conditions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, risk transfer, and costs. Familiarity with terms like FOB (Free On Board), CIF (Cost, Insurance, Freight), or DDP (Delivered Duty Paid) helps international buyers negotiate logistics and control costs effectively, minimizing misunderstandings during transit.

5. Lead Time

Lead time refers to the duration from order placement to delivery. Understanding and negotiating lead times is vital for inventory planning, especially in rapidly changing markets or seasonal demand. Clear communication ensures timely supply and avoids stock shortages.

6. Certification and Compliance Standards

Standards such as ASTM, ISO, or EN certifications verify that shoes meet safety, quality, and environmental requirements. For B2B buyers, verifying compliance ensures products are suitable for their industry regulations, reducing legal risks and enhancing product credibility.

By understanding these technical properties and trade terms, B2B buyers from Africa, South America, the Middle East, and Europe can make informed decisions, negotiate effectively, and establish reliable supply chains for shoes for crews. Mastery of these concepts ensures that procurement aligns with quality standards, safety requirements, and logistical considerations, ultimately supporting operational success across diverse markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the shoes for crews promo code Sector

Market Overview & Key Trends

The global shoes for crews promo code sector is experiencing dynamic shifts driven by evolving consumer preferences, technological advancements, and geopolitical factors. Increasing demand for affordable, durable, and customizable footwear in industries such as hospitality, construction, and manufacturing fuels B2B sourcing activities across regions like Africa, South America, the Middle East, and Europe.

Emerging trends include the integration of digital sourcing platforms that streamline supplier vetting, order management, and real-time tracking—crucial for international buyers seeking transparency and efficiency. Additionally, manufacturers are adopting automation and advanced quality control to meet stringent international standards, reducing lead times and minimizing risks associated with cross-border procurement.

Market dynamics are also influenced by tariff policies, trade agreements, and regional manufacturing hubs. For instance, Southeast Asian countries like Thailand continue to dominate due to their established footwear industries, offering competitive pricing and reliable supply chains. Conversely, African and South American markets are gaining prominence through investments in local production facilities and strategic partnerships aimed at reducing dependency on imports.

For buyers from Egypt, the Middle East, or Europe, understanding regional sourcing nuances is vital. Europe’s focus on premium, ethically sourced footwear contrasts with Africa and South America’s emphasis on cost-effective, scalable production. Navigating these differences requires a keen understanding of regional infrastructure, labor standards, and technological adoption to optimize procurement strategies effectively.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical component in sourcing shoes for crews, driven by increasing regulatory pressures and a shifting consumer landscape favoring environmentally responsible products. For B2B buyers, prioritizing suppliers with robust sustainability credentials not only enhances brand reputation but also mitigates risks associated with supply chain disruptions and reputational damage.

Environmental impacts of shoe manufacturing—such as water consumption, waste generation, and chemical usage—are under scrutiny. Suppliers adopting eco-friendly practices, like using recycled materials or implementing water-saving processes, are gaining a competitive edge. Certifications such as Global Organic Textile Standard (GOTS), Forest Stewardship Council (FSC), and ISO 14001 serve as valuable indicators of a supplier’s commitment to ethical and sustainable practices.

Ethical sourcing extends beyond environmental considerations to labor rights and fair wages. Buyers should prioritize suppliers with transparent supply chains, fair labor certifications, and adherence to international labor standards. Developing long-term partnerships with verified ethical manufacturers reduces the risk of supply chain disruptions and aligns procurement with corporate social responsibility (CSR) goals.

Investing in ‘green’ materials—such as biodegradable rubber or recycled textiles—can also meet the growing market demand for eco-conscious footwear. For international buyers, establishing clear sustainability criteria in RFQs and supplier evaluations ensures alignment with global best practices and supports the transition toward a more sustainable footwear industry.

Brief Evolution/History (Optional)

The shoes for crews promo code sector has evolved significantly over the past few decades, transitioning from basic, utilitarian footwear to highly specialized, technology-driven products. Historically, manufacturers focused on cost minimization and durability, often sourcing from low-cost regions with limited emphasis on environmental or social standards.

In recent years, however, sustainability and ethical considerations have shifted industry priorities. International regulations, consumer activism, and corporate CSR initiatives have prompted manufacturers to adopt greener practices and transparent supply chains. Technological innovations—such as 3D printing, automation, and digital supply chain management—have further transformed sourcing efficiencies and product customization.

This evolution underscores the importance for B2B buyers to stay informed about industry standards, technological advancements, and regional manufacturing capabilities. Embracing these developments can lead to more resilient, responsible, and competitive procurement strategies in the shoes for crews promo code market.

Illustrative Image (Source: Google Search)

Frequently Asked Questions (FAQs) for B2B Buyers of shoes for crews promo code

1. How can I ensure the reliability and credibility of a shoe supplier offering promo codes?

Verifying supplier credibility is crucial for international B2B transactions. Start by requesting verifiable business licenses, certifications (such as ISO or OEKO-TEX), and recent client references. Conduct online research to review their reputation on industry platforms and trade directories like Alibaba, Global Sources, or Made-in-China. Request samples to assess quality before committing. Additionally, consider visiting supplier facilities if feasible or engaging third-party inspection services to verify manufacturing standards. A transparent communication process and positive reviews from other international buyers further indicate a trustworthy partner.

2. What customization options are typically available, and how do they impact lead times and costs?

Suppliers often offer customization such as branding (logos, labels), colorways, material choices, and design modifications. These options can significantly enhance your product appeal but may also extend lead times—ranging from a few days to several weeks depending on complexity. Customizations usually incur additional costs, especially for large orders or complex designs. To manage expectations, clearly define your specifications upfront and request detailed quotes, including lead times. Establishing a reliable communication channel with the supplier ensures smoother customization processes aligned with your delivery schedules.

Illustrative Image (Source: Google Search)

3. What are typical minimum order quantities (MOQs), and how do they affect pricing and delivery?

Most suppliers set MOQs based on production costs, often ranging from 300 to 1,000 pairs for shoes. Lower MOQs may be available but could lead to higher per-unit costs. For international buyers, larger orders often result in better pricing and more favorable shipping rates. However, consider your market demand and storage capacity. Negotiating flexible MOQs or phased orders can help balance cost-efficiency with inventory needs. Always clarify MOQs during negotiations and ensure the supplier’s lead times align with your procurement calendar.

4. How can I ensure quality assurance and certification compliance across different regions?

Quality assurance (QA) is critical, especially when importing footwear to meet regional safety standards. Request detailed QA procedures, including third-party inspection reports, pre-shipment testing, and certification documentation (e.g., CE, SGS, or local compliance marks). Confirm that the supplier adheres to internationally recognized standards for durability, safety, and environmental impact. Establish quality checkpoints during production and before shipment. Employ third-party inspection agencies for random sampling and testing, especially when dealing with new suppliers or high-volume orders, to prevent costly defects and ensure compliance with your target market’s regulations.

5. What are the best practices for managing international logistics and shipping costs?

Effective logistics management requires early planning. Negotiate shipping terms—FOB (Free on Board), CIF (Cost, Insurance, Freight), or DDP (Delivered Duty Paid)—based on your experience and preferences. Consolidate shipments when possible to reduce costs and minimize delays. Engage reputable freight forwarders with experience in your region (e.g., Egypt, Thailand, or South America) to navigate customs procedures smoothly. Factor in customs duties, taxes, and import regulations specific to your country. Using freight tracking systems and maintaining open communication with your logistics provider can help mitigate risks and ensure timely delivery.

6. How do I handle disputes or quality issues after shipment?

Disputes often arise from quality mismatches, delays, or damaged goods. To mitigate this, establish clear contractual terms specifying quality standards, inspection rights, and dispute resolution mechanisms before ordering. Maintain comprehensive documentation, including photos, inspection reports, and correspondence. If issues occur, communicate promptly with the supplier, referencing the agreed standards and evidence. Consider arbitration clauses or third-party mediation for international disputes. Building a relationship based on transparency and accountability can facilitate quicker resolutions and protect your investment.

7. What payment methods are secure and suitable for international B2B transactions?

Secure payment methods include bank transfers (T/T), letters of credit (L/C), or escrow services that protect both parties. T/T is common for smaller, trusted suppliers, but always confirm the recipient’s banking details beforehand. Letters of credit offer security for large orders by providing a payment guarantee from your bank. Escrow services, provided by trusted third-party platforms, release funds only upon verified shipment and quality checks. Avoid upfront full payments without guarantees. Negotiating payment terms that align with production milestones and inspections minimizes financial risks.

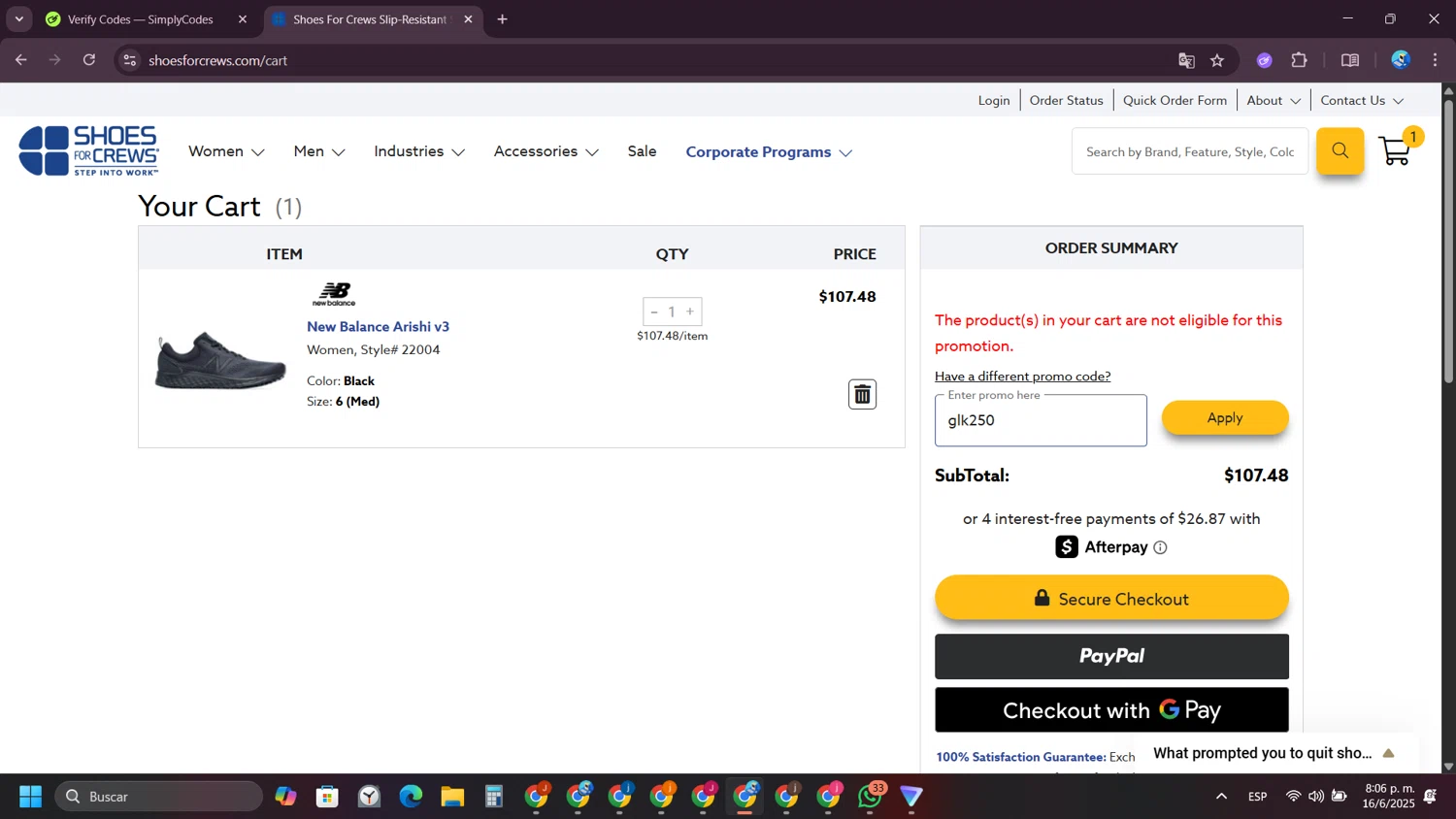

8. How can I leverage promo codes effectively to maximize savings?

Maximize the benefits of promo codes by planning your orders during promotional periods, such as industry sales or supplier anniversaries. Combine promo codes with bulk purchasing to achieve substantial discounts. Negotiate exclusive or tiered promo codes for repeat business or large-volume orders. Always verify the validity period, applicable products, and any minimum purchase requirements. Keep track of promo code terms to avoid unexpected restrictions. Using promo codes strategically can significantly reduce procurement costs, allowing you to reinvest savings into product quality or marketing efforts in your target markets.

Strategic Sourcing Conclusion and Outlook for shoes for crews promo code

Conclusion and Future Outlook

Effective strategic sourcing remains essential for international B2B buyers seeking to optimize procurement of shoes for crews, particularly when leveraging promo codes to maximize cost savings. By focusing on reliable suppliers, assessing product quality, and negotiating favorable terms, buyers from regions such as Africa, South America, the Middle East, and Europe can secure competitive advantages in a dynamic market. Understanding regional manufacturing hubs and supply chain logistics enables better decision-making and risk mitigation.

As the footwear industry continues to evolve with innovations in sustainable materials and digital sourcing platforms, proactive engagement with trusted suppliers will be vital. Embracing these trends can lead to improved product quality, reduced costs, and stronger supplier relationships.

Looking ahead, international buyers are encouraged to leverage data-driven insights and diversify sourcing channels to adapt to shifting market conditions. By maintaining strategic agility and fostering collaborative partnerships, buyers from emerging markets like Egypt and Thailand can capitalize on global opportunities, ensuring long-term supply chain resilience and growth.