Master Sourcing High-Quality Toddler Dress Shoes for Global

Guide to Toddler Dress Shoes

- Introduction: Navigating the Global Market for toddler dress shoes

- Understanding toddler dress shoes Types and Variations

- Key Industrial Applications of toddler dress shoes

- Strategic Material Selection Guide for toddler dress shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for toddler dress shoes

- Comprehensive Cost and Pricing Analysis for toddler dress shoes Sourcing

- Spotlight on Potential toddler dress shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for toddler dress shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the toddler dress shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of toddler dress shoes

- Strategic Sourcing Conclusion and Outlook for toddler dress shoes

Introduction: Navigating the Global Market for toddler dress shoes

In the competitive landscape of children’s footwear, toddler dress shoes represent a vital segment that combines style, comfort, and safety—elements critical to both parents and retailers worldwide. For international B2B buyers, understanding the nuances of this market is essential to sourcing high-quality products that meet diverse consumer expectations and regulatory standards across regions such as Africa, South America, the Middle East, and Europe. As these markets evolve, the demand for premium, stylish, and durable toddler dress shoes continues to grow, driven by increasing disposable incomes and shifting fashion preferences.

This comprehensive guide offers actionable insights into every facet of the global toddler dress shoe industry—from identifying the most sought-after types and materials, to navigating manufacturing quality control, sourcing reliable suppliers, and managing costs effectively. It also provides market analysis tailored to key regions, along with frequently asked questions that address common concerns faced by international buyers. Whether you are exploring new supplier partnerships or expanding your product portfolio, this resource is designed to empower you with the knowledge needed to make informed, strategic sourcing decisions.

By leveraging this guide, B2B buyers from Africa, South America, the Middle East, and Europe will be better equipped to identify quality manufacturers, negotiate favorable terms, and meet the specific demands of their local markets—ultimately strengthening their competitive edge in the global toddler footwear industry.

Understanding toddler dress shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Mary Jane Shoes | Rounded toe, strap across the instep, leather or synthetic upper | Retail, wholesale, boutique supply | Pros: Timeless style, versatile for formal occasions; Cons: Limited design variation |

| Formal Lace-up Shoes | Closed lacing system, often with polished finish, leather or faux leather | Department stores, specialty suppliers | Pros: Elegant appearance, durable; Cons: Higher manufacturing complexity, potentially higher cost |

| Ballet Flats / D’Orsay | Soft, flexible sole, minimal structure, often with decorative elements | Discount retailers, online marketplaces | Pros: Lightweight, easy to produce in bulk; Cons: Less supportive, suited for dress rather than active use |

| Ankle Booties | Cover ankle, side zippers or elastic panels, varied materials | Seasonal collections, premium lines | Pros: Fashion-forward, versatile for different weather; Cons: Slightly higher manufacturing costs, sizing considerations |

| Slip-On Dress Shoes | Elastic or slip-on design, minimal fastenings, formal appearance | Mass-market retailers, export markets | Pros: Easy to put on, high consumer convenience; Cons: Less adjustable fit, limited style options |

Classic Mary Jane Shoes

Mary Jane shoes are characterized by their rounded toe and a strap that fastens across the instep, typically made from leather or synthetic materials. They are a staple in toddler formalwear due to their timeless style and comfort. For B2B buyers, these shoes are ideal for wholesale to boutiques and retail chains aiming for classic, versatile designs. Key considerations include sourcing quality materials to ensure durability and comfort, especially since they are intended for active toddlers. Pricing strategies should account for the premium perception of leather, while synthetic options can offer cost advantages for large-volume orders.

Formal Lace-up Shoes

Lace-up toddler dress shoes mimic adult formal footwear with a closed lacing system, often finished with a polished look. Made predominantly from leather or faux leather, they suit formal events and upscale retail outlets. B2B buyers should focus on establishing reliable supply chains for high-quality leather and consistent manufacturing standards to meet the expectations of premium markets. These shoes tend to have higher production costs due to detailed craftsmanship but can command higher retail prices. They are suitable for export markets where formal attire is highly valued, such as in Europe and the Middle East.

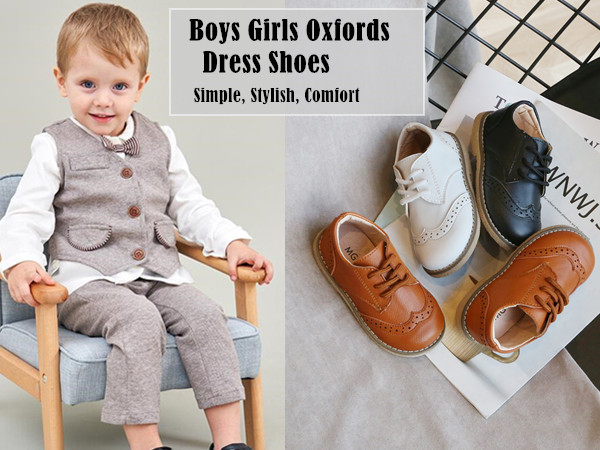

Illustrative Image (Source: Google Search)

Ballet Flats / D’Orsay

These lightweight, flexible shoes resemble adult ballet flats, featuring minimal structure and often decorative embellishments. They are popular in discount retail segments and online marketplaces targeting budget-conscious consumers. For bulk purchasing, B2B buyers should evaluate suppliers for quality control, especially regarding sole durability and stitching. Their simple design allows for rapid production and wide variety, making them attractive for large orders. However, their limited support makes them less suitable for active toddlers, so buyers should position them primarily as dress accessories rather than everyday footwear.

Ankle Booties

Ankle booties combine fashion and function, covering the ankle with side zippers or elastic panels for easy wear. Made from leather, suede, or synthetic materials, they are suitable for seasonal collections and more premium markets. B2B buyers should consider material sourcing and manufacturing complexity, as varied designs and materials can affect lead times and costs. They appeal to markets seeking versatile, stylish options that transition across seasons, particularly in Europe and Latin America. Proper sizing and quality assurance are critical to meet customer expectations for durability and comfort.

Slip-On Dress Shoes

Designed for convenience, slip-on dress shoes feature elastic panels or simple fastenings, offering an elegant yet practical solution for busy parents. They are widely used in mass-market retail and export channels due to ease of distribution and broad appeal. For B2B buyers, establishing relationships with manufacturers specializing in elastic or stretch materials is key to ensuring consistent quality. These shoes are cost-effective to produce in bulk, making them attractive for large-scale distribution. However, their limited adjustability and style variations necessitate positioning them as functional, formal options suitable for casual dress occasions.

Key Industrial Applications of toddler dress shoes

| Industry/Sector | Specific Application of toddler dress shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Retail | Premium boutique collections, seasonal fashion lines | Enhances brand reputation, attracts high-end clientele, and supports premium pricing | Quality craftsmanship, authentic design, reliable supply chain, compliance with safety standards |

| Hospitality & Events | Special occasion footwear for hotel boutiques, event gifts | Differentiates offerings, increases sales through exclusive products | Customization options, attractive packaging, consistent quality, timely delivery |

| Manufacturing & OEM | Private label toddler dress shoes for global brands | Expands product portfolio, builds long-term partnerships, access to new markets | Competitive pricing, flexible MOQ, certification standards, scalable production capabilities |

| E-commerce & Wholesale | Distribution through online platforms and bulk buyers | Broadens market reach, reduces inventory costs, facilitates rapid scaling | Cost-effective logistics, strong quality control, flexible order quantities |

| Export & Import | Cross-border trade of toddler dress shoes for retail chains | Opens new markets, diversifies risk, maximizes profit margins | Compliance with international standards, reliable logistics, adaptable product specifications |

Fashion & Retail

In the fashion industry, toddler dress shoes are often incorporated into luxury and seasonal collections aimed at high-end boutiques and department stores. These shoes serve as a key accessory that elevates a brand’s prestige, especially when crafted with premium materials and detailed craftsmanship. For international B2B buyers from regions like Europe and South Africa, sourcing high-quality toddler dress shoes can bolster brand reputation and command premium prices. Ensuring authenticity, design uniqueness, and compliance with safety standards is crucial to meet consumer expectations and avoid reputational risks.

Hospitality & Events

Luxury hotels, event planners, and boutique gift shops frequently include toddler dress shoes as part of exclusive packages or event souvenirs, such as weddings or family celebrations. These shoes offer a distinctive product that enhances the guest experience and provides a memorable keepsake. B2B buyers from Mexico and the Middle East should prioritize sourcing from manufacturers capable of delivering customized designs, attractive packaging, and consistent quality. Timely delivery and flexibility in order quantities are vital to meet the dynamic demands of the hospitality sector.

Manufacturing & OEM

Many global brands and private label companies seek OEM partnerships for toddler dress shoes to expand their product ranges without investing in manufacturing infrastructure. These partnerships enable brands across Africa, South America, and Europe to offer exclusive designs while benefiting from reliable production and cost efficiencies. Buyers should focus on sourcing manufacturers with scalable capacity, adherence to safety and quality certifications, and the ability to meet specific branding requirements. Strong relationships and transparent communication are key to long-term success in this sector.

E-commerce & Wholesale

Online platforms and wholesale distributors are increasingly vital channels for toddler dress shoes, especially in emerging markets. This sector benefits from sourcing partners who can provide consistent quality, competitive pricing, and flexible order quantities to accommodate rapid inventory turnover. For B2B buyers in regions like South Africa and Latin America, establishing reliable logistics and quality control processes ensures customer satisfaction and reduces return rates. Building partnerships with suppliers capable of supporting large-scale distribution is essential for scalable growth.

Export & Import

Cross-border trade of toddler dress shoes is a strategic avenue for expanding market presence, especially for brands targeting retail chains and large distributors in Europe, the Middle East, and South America. Compliance with international standards, such as safety certifications and import regulations, is critical to avoid delays and penalties. Buyers should seek suppliers with robust logistics networks, adaptable product specifications, and the ability to meet diverse market demands. Establishing reliable sourcing channels can significantly enhance export opportunities and profitability.

Strategic Material Selection Guide for toddler dress shoes

Analysis of Common Materials for Toddler Dress Shoes

Selecting the appropriate materials for toddler dress shoes is critical for ensuring safety, durability, comfort, and compliance with international standards. Different markets—such as Africa, South America, the Middle East, and Europe—have unique considerations including climate, regulatory requirements, and consumer preferences. Here, we analyze four common materials: leather, synthetic fabrics, thermoplastics, and rubber, focusing on their properties, advantages, limitations, and implications for international B2B buyers.

Leather

Leather remains the most traditional and premium material for toddler dress shoes. It offers excellent breathability, flexibility, and a natural aesthetic that appeals to many consumers globally. High-quality leather, such as full-grain or top-grain, provides durability and ages well, often developing a unique patina over time.

Illustrative Image (Source: Google Search)

Properties:

– Breathable, flexible, and conforming to foot shape

– Moderate water resistance (depending on treatment)

– Can be treated for enhanced durability and water resistance

– Meets many international standards like ASTM D2099 for leather testing

Pros & Cons:

– Pros: Superior comfort, natural look, good aging characteristics, high-end appeal

– Cons: Higher cost, manufacturing complexity, potential variability in quality, environmental concerns related to tanning processes

Impact on Application:

Leather’s breathability makes it suitable for warmer climates, but it may require additional waterproofing treatments in rainy regions. It is compatible with various dyes and finishes, allowing customization.

International Considerations:

European markets often favor vegetable-tanned leather, aligning with stricter environmental standards. African and South American markets may have more flexible standards but require compliance with local import regulations. Middle Eastern markets may prioritize treated, water-resistant leather. B2B buyers should verify leather sourcing (e.g., eco-friendly tanning) and ensure compliance with regional standards like REACH (Europe) or local environmental laws.

Synthetic Fabrics (e.g., PU, PVC)

Synthetic materials are widely used due to their affordability and ease of manufacturing. Polyurethane (PU) and polyvinyl chloride (PVC) are common choices, offering a variety of finishes and colors.

Properties:

– Lightweight and flexible

– Water-resistant and easy to clean

– Consistent quality and appearance

– Meets standards like ASTM F963 for toy safety (for parts) and general footwear safety

Pros & Cons:

– Pros: Cost-effective, scalable manufacturing, wide design flexibility, good for mass production

– Cons: Less breathable, may cause sweating, environmental concerns over non-biodegradability, potential for cracking or peeling over time

Impact on Application:

Synthetic materials are suitable for indoor or formal occasions but may be less comfortable in hot climates unless designed with breathability in mind. They are compatible with various coatings and embellishments.

International Considerations:

In regions like Africa and South America, cost is a significant factor, making synthetics attractive. However, buyers should ensure materials meet local safety standards and avoid harmful chemicals like phthalates. European and Middle Eastern markets increasingly favor eco-friendly and non-toxic synthetics, so sourcing from suppliers with certifications (e.g., OEKO-TEX) is advantageous.

Thermoplastics (e.g., EVA, TPU)

Thermoplastics like Ethylene Vinyl Acetate (EVA) and Thermoplastic Polyurethane (TPU) are popular for soles and decorative elements.

Properties:

– Highly impact-absorbing (EVA)

– Flexible, lightweight, and resistant to cracking (TPU)

– Good chemical resistance and weatherability

– Meets standards like ISO 20345 for safety footwear

Pros & Cons:

– Pros: Excellent shock absorption, lightweight, easy to mold, cost-effective

– Cons: Limited durability for upper parts, UV degradation if not stabilized, environmental concerns

Impact on Application:

Ideal for soles, providing cushioning and slip resistance. TPU can be used for decorative overlays or flexible components. Their chemical resistance makes them suitable for diverse climates.

International Considerations:

Buyers in regions with high UV exposure (e.g., Middle East) should specify stabilized grades. European markets often demand environmentally friendly formulations, prompting interest in recyclable or bio-based thermoplastics. Compliance with safety standards like EN 71 or ASTM F963 is essential.

Rubber

Rubber is primarily used for outsoles due to its durability and slip resistance. Natural rubber offers excellent resilience, while synthetic variants can be engineered for specific properties.

Properties:

– High elasticity and resilience

– Excellent slip resistance and shock absorption

– Good weather and temperature resistance

– Meets standards like ASTM D2000 for rubber products

Pros & Cons:

– Pros: Durable, slip-resistant, flexible in various temperatures

– Cons: Heavier than synthetics, potential allergen issues with natural rubber, environmental concerns

Impact on Application:

Rubber outsoles are ideal for outdoor use, providing traction and longevity. The choice between natural and synthetic rubber depends on cost and environmental considerations.

International Considerations:

In markets like South America and Africa, natural rubber is often preferred due to availability and cost. However, synthetic rubber may be favored in regions with strict allergen regulations or environmental standards. B2B buyers should verify compliance with standards such as REACH or ASTM D2000.

Summary Table

| Material | Typical Use Case for toddler dress shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Upper, lining, decorative elements | Natural breathability, premium look | High cost, environmental impact in tanning | High |

| Synthetic Fabrics | Uppers, decorative overlays | Cost-effective, customizable, water-resistant | Less breathable, environmental concerns | Med |

| Thermoplastics | Soles, decorative accents | Impact absorption, lightweight | Limited durability for upper parts | Med |

| Rubber | Outsoles | Slip resistance, durability | Heavier, allergen potential | Med |

This comprehensive analysis equips international B2B buyers with the insights needed to select materials that align with regional preferences, regulatory standards, and end-user expectations. Proper material sourcing and compliance verification are essential steps to ensure product quality, safety, and market acceptance across diverse global markets.

In-depth Look: Manufacturing Processes and Quality Assurance for toddler dress shoes

Manufacturing Processes for Toddler Dress Shoes

The production of toddler dress shoes involves a series of carefully coordinated stages designed to ensure safety, comfort, and aesthetic appeal. Understanding these processes is crucial for international B2B buyers aiming to select reliable suppliers and ensure product consistency.

Material Preparation and Selection

The manufacturing process begins with sourcing high-quality, child-safe materials. Common upper materials include genuine leather, synthetic leather, or textile fabrics that meet safety standards. Soles are typically made from rubber, thermoplastic elastomers (TPE), or EVA foam, chosen for durability and lightweight properties. For international buyers, verifying that suppliers use compliant, non-toxic, and eco-friendly materials—such as those certified under OEKO-TEX or REACH—is essential.

Forming and Cutting

In this stage, materials are cut into patterns using computer-controlled cutting machines or manual methods, depending on the factory scale. Advanced automation ensures precision, reducing waste and inconsistencies. For toddler shoes, the focus is on ergonomic shaping to support foot development, with molds designed to meet specific age group dimensions.

Assembly and Stitching

The assembled components—including the upper, lining, insole, and outsole—are stitched or glued together. Industry-standard techniques include:

– Stitching: Double-stitched seams with reinforced thread for durability.

– Gluing: Use of non-toxic, flexible adhesives that comply with safety standards.

– Lasting: The upper is shaped over a mold (last) to ensure proper fit and aesthetic form.

Automation and skilled craftsmanship are both prevalent, with many suppliers employing computerized sewing machines for consistency.

Illustrative Image (Source: Google Search)

Finishing

Final touches include attaching decorative elements, applying branding, and performing surface treatments such as polishing or coating. For toddler shoes, finishing processes emphasize smooth edges, no protruding stitches, and non-toxic dyes or paints. The shoes are then subjected to cleaning and quality checks before packaging.

Quality Assurance (QA) and Control Processes

Maintaining consistent quality in toddler dress shoes is paramount given the safety and comfort requirements. B2B buyers must understand the multi-tiered QA protocols employed by manufacturers and how to verify compliance.

International Standards and Certifications

- ISO 9001: The foundational quality management system standard. Suppliers certified under ISO 9001 demonstrate a systematic approach to quality across design, production, and delivery.

- CE Marking (European Market): Indicates compliance with EU safety, health, and environmental requirements, including footwear safety directives.

- ASTM and ISO Testing Standards: For physical properties like slip resistance, durability, and impact absorption.

- REACH & OEKO-TEX: Ensure materials are free from harmful substances, critical for products intended for children.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival for defects, compliance, and specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing, including seam strength tests, dimensional checks, and adhesion tests.

- Final Quality Control (FQC): Post-production inspection focusing on overall appearance, structural integrity, and safety features such as slip resistance and heel stability.

Testing Methods

- Physical Tests: Flexibility, tensile strength, and impact resistance tests simulate real-world usage.

- Safety Tests: Non-slip sole testing, edge smoothness checks, and toxicity assessments.

- Durability Tests: Wear and tear simulations to ensure longevity through multiple cycles of use.

Verifying Supplier Quality for International B2B Buyers

International buyers should adopt rigorous verification methods to ensure suppliers meet quality standards consistently:

– Factory Audits: Conduct comprehensive audits focusing on quality management systems, manufacturing practices, and worker safety.

– Inspection Reports: Require detailed third-party inspection reports, ideally from recognized agencies like SGS, Bureau Veritas, or Intertek.

– Sample Testing: Request pre-shipment samples for independent testing against international standards.

– Certifications Verification: Confirm authenticity of certifications and ensure they are up-to-date and relevant to the target markets.

Nuances for Different Regions

For buyers from Africa, South America, the Middle East, and Europe, understanding regional compliance nuances is critical:

– Africa (e.g., South Africa): Emphasize certifications aligned with South African Bureau of Standards (SABS) and local safety regulations. Many buyers prefer suppliers with ISO 9001 and SABS approval.

– South America (e.g., Mexico): Look for compliance with NOM standards and adherence to REACH for chemical safety. Suppliers should also demonstrate environmental sustainability practices.

– Middle East: Suppliers should meet Gulf Standards (GSO) and CE requirements for European markets. Emphasis on product safety and eco-friendly materials is often prioritized.

– Europe: Strict enforcement of CE marking, REACH compliance, and adherence to EN standards for footwear safety and durability. Buyers should verify ongoing compliance through audits and periodic testing.

Strategic Recommendations for B2B Buyers

- Engage in Due Diligence: Prioritize factories with transparent QA processes, documented certifications, and proven track records.

- Leverage Third-party Audits: Regular third-party inspections mitigate risks associated with non-compliance and subpar quality.

- Request Detailed Documentation: Quality manuals, test reports, and process certifications provide transparency.

- Establish Long-term Partnerships: Developing ongoing relationships encourages suppliers to maintain high standards and adapt to evolving market requirements.

By understanding and scrutinizing manufacturing and quality assurance practices, international B2B buyers can confidently source toddler dress shoes that meet safety, durability, and aesthetic expectations across diverse markets.

Comprehensive Cost and Pricing Analysis for toddler dress shoes Sourcing

Cost Structure Breakdown for Toddler Dress Shoes

Understanding the comprehensive cost structure is vital for international buyers aiming to optimize procurement strategies. The primary cost components include:

-

Materials: Premium leather, synthetic fabrics, and eco-friendly alternatives are common. Material costs can fluctuate based on quality, origin, and certifications (e.g., eco-labels). For instance, genuine leather tends to elevate costs but offers durability and aesthetic appeal.

-

Labor: Manufacturing costs vary significantly by country. For example, factories in Southeast Asia or parts of Africa may offer lower wages, reducing costs, but quality control becomes critical. European or Middle Eastern manufacturers might have higher labor costs but often provide superior craftsmanship.

-

Manufacturing Overheads: These include factory utilities, machinery depreciation, and management expenses. Efficient factories with high automation can reduce overhead costs, influencing the final price.

-

Tooling and Setup: Initial mold creation and tooling for toddler dress shoes can be a substantial upfront expense, especially for customized designs or small batch orders. These costs are amortized over larger production volumes.

-

Quality Control & Certifications: Ensuring compliance with safety standards (like EN, ASTM, or ISO certifications) adds to costs but mitigates risks associated with recalls or non-compliance penalties.

-

Logistics & Shipping: Freight costs depend on shipment volume, destination, and shipping mode (air freight being faster but more expensive than sea freight). Incoterms (e.g., FOB, CIF) significantly impact who bears freight and insurance costs.

-

Profit Margin: Suppliers typically add a margin to cover risks and ensure profitability, ranging from 10% to 30%, depending on order size, relationship, and market competitiveness.

Key Factors Influencing Pricing

Several variables impact the final landed cost of toddler dress shoes:

-

Order Volume & MOQ: Larger orders often attract discounts due to economies of scale. Minimum Order Quantities (MOQs) can range from 500 to 5,000 pairs, influencing per-unit costs substantially.

-

Design & Customization: Custom features like unique patterns, branding, or specific materials increase costs. Standard designs are more cost-effective, but customization can differentiate your product in competitive markets.

-

Material Selection: High-quality leathers or sustainable materials elevate costs but can justify premium pricing, especially in markets with eco-conscious consumers.

-

Quality & Certifications: Meeting international safety standards and acquiring relevant certifications may add to manufacturing costs but reduce liability risks and enhance market acceptance.

-

Supplier Location & Capabilities: Established suppliers with advanced quality control and reliable logistics tend to charge higher prices but offer better consistency and compliance.

-

Incoterms & Delivery Terms: FOB (Free on Board) is common for buyers managing shipping, while CIF (Cost, Insurance, Freight) shifts more responsibility to the supplier. Clear understanding of these terms helps in accurately assessing total costs.

Strategic Tips for International B2B Buyers

-

Negotiate for Volume Discounts: Larger orders often unlock better pricing, but ensure your forecasts justify increased inventory holding costs.

-

Focus on Total Cost of Ownership: Consider all expenses—production, shipping, customs, taxes, warehousing, and after-sales support—rather than just unit price.

-

Leverage Multiple Suppliers: Diversifying sources can mitigate risks, improve pricing leverage, and ensure supply chain resilience, especially in regions with political or logistical uncertainties.

-

Understand Pricing Nuances: Be aware of hidden costs, such as customs duties, VAT, or import restrictions, which vary by country (e.g., South Africa, Mexico). Factor these into your procurement budget.

-

Build Long-Term Relationships: Developing trust with suppliers can lead to better terms, priority in production, and access to innovations.

Indicative Price Ranges (Disclaimers Apply)

While prices fluctuate based on the above factors, typical FOB prices for toddler dress shoes from major manufacturing hubs range from $4 to $12 per pair for standard designs in bulk orders. Customized or premium-quality shoes may range from $12 to $20+ per pair. Smaller orders or less experienced suppliers tend to have higher unit costs.

In summary, effective cost and pricing analysis demands a holistic view of all contributing factors. By understanding the cost components, influencing variables, and strategic negotiation points, international B2B buyers from Africa, South America, the Middle East, and Europe can optimize their sourcing, reduce total costs, and secure high-quality toddler dress shoes tailored to their markets.

Spotlight on Potential toddler dress shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for toddler dress shoes.)*

Essential Technical Properties and Trade Terminology for toddler dress shoes

Key Technical Properties in Toddler Dress Shoes

1. Material Grade and Composition

The quality of materials used in toddler dress shoes directly impacts durability, comfort, and safety. High-grade leathers, eco-friendly synthetic fabrics, and non-toxic adhesives are preferred. For B2B transactions, specifying material grades ensures consistent product quality and compliance with safety standards across markets.

2. Sole Flexibility and Thickness

Soles must balance flexibility with sufficient thickness to protect delicate toddler feet. Flexible soles promote natural movement, crucial for development, while a minimum thickness (measured in millimeters) ensures durability. Clear specifications help in assessing product longevity and safety, especially in markets with varying terrain.

3. Tolerance Levels and Precision

Manufacturing tolerances—acceptable deviations in dimensions—are vital for ensuring proper fit. For toddler shoes, tolerances are typically tighter (e.g., ±0.5 mm) to prevent discomfort or safety hazards. Precise tolerances facilitate smoother mass production and reduce return rates due to sizing issues.

4. Fastening and Closure Systems

Velcro straps, elastic laces, or slip-on designs are common. The choice affects ease of use, security, and aesthetic appeal. B2B buyers should specify preferred closure types and quality standards to ensure product consistency and customer satisfaction.

5. Breathability and Comfort Features

Materials with moisture-wicking properties and breathable linings reduce sweat and prevent skin irritation. These features are increasingly demanded across markets, especially where climate varies significantly, impacting comfort and hygiene.

6. Colorfastness and Finish Durability

Colors and finishes must withstand frequent cleaning and exposure to elements without fading or cracking. B2B buyers should specify testing standards (e.g., ASTM or ISO) to guarantee long-lasting appearance, essential for maintaining brand reputation in international markets.

Common Industry and Trade Terms

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce shoes based on the buyer’s design specifications. Understanding OEM relationships allows buyers to customize products while leveraging manufacturing expertise, often at lower costs.

2. MOQ (Minimum Order Quantity)

The smallest quantity a manufacturer agrees to produce per order. Recognizing MOQ helps buyers plan inventory and negotiate pricing, especially when entering new markets or testing product acceptance.

3. RFQ (Request for Quotation)

A formal process where buyers solicit price quotes from multiple suppliers. A clear RFQ detailing specifications, quantities, and delivery timelines streamlines procurement and ensures competitive pricing.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibility, risk, and cost allocation between buyer and seller during shipping. Familiarity with Incoterms (e.g., FOB, CIF) ensures clarity in logistics, especially when dealing with international shipments to regions like Africa or South America.

5. Sample Development and Approval

The process of creating prototype shoes for review before mass production. Critical for ensuring design accuracy, quality, and compliance with regional standards. B2B buyers should establish clear timelines and quality benchmarks during sample approval stages.

6. Quality Certification Standards

Certifications such as ISO, ASTM, or regional safety standards verify that products meet safety, environmental, and quality benchmarks. Securing and understanding these standards is essential to access markets with strict regulatory requirements, like Europe or the Middle East.

Actionable Insights for International Buyers

- Prioritize clear communication of technical specifications, including material grades and tolerances, to ensure product consistency across markets.

- Understand and negotiate MOQs to balance inventory needs with manufacturing capacity, especially when sourcing from emerging markets.

- Familiarize with Incoterms and logistics processes to optimize shipping costs and minimize delays, particularly for destinations with complex import regulations.

- Leverage certifications and compliance standards to enhance market access and consumer trust in diverse regions.

- Use detailed RFQs and sample approvals as tools to mitigate risks and align expectations before large-scale orders.

By mastering these technical properties and trade terms, B2B buyers can streamline procurement, ensure quality, and successfully expand toddler dress shoe offerings across global markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the toddler dress shoes Sector

Market Overview & Key Trends

The global toddler dress shoes sector is experiencing dynamic shifts driven by evolving consumer preferences, technological advancements, and supply chain innovations. Emerging markets in Africa, South America, the Middle East, and Europe are becoming increasingly significant, each with unique drivers. For instance, in regions like South Africa and Mexico, rising disposable incomes and increasing urbanization are fueling demand for premium, stylish, and comfortable footwear for toddlers, prompting B2B buyers to seek high-quality, design-forward products.

Technological advancements such as 3D printing, digital sampling, and AI-driven trend forecasting are transforming sourcing processes, enabling faster product development cycles and more precise demand planning. E-commerce platforms and B2B marketplaces are also gaining prominence, facilitating direct sourcing from manufacturers in Asia, Europe, and Latin America, reducing lead times and costs.

Market dynamics are further influenced by demographic shifts, with a growing emphasis on early childhood fashion and parental preferences for eco-friendly, durable, and hypoallergenic materials. Buyers from Africa, South America, the Middle East, and Europe are increasingly prioritizing agility in sourcing, diversified supplier networks, and the integration of digital tools to mitigate risks related to geopolitical tensions, currency fluctuations, and supply chain disruptions. Staying attuned to these trends can help B2B buyers optimize their procurement strategies and capitalize on emerging opportunities.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical factor in sourcing toddler dress shoes, driven by heightened consumer awareness and regulatory pressures. Environmentally conscious buyers are prioritizing products made from sustainable materials such as organic cotton, recycled PET, and biodegradable leathers, which minimize ecological footprints. Certifications like GOTS (Global Organic Textile Standard), OEKO-TEX, and Forest Stewardship Council (FSC) are increasingly becoming prerequisites for B2B transactions, signaling commitment to ethical practices.

Ethical sourcing is equally vital, especially in regions where labor practices are under scrutiny. B2B buyers should rigorously vet suppliers for fair labor standards, safe working conditions, and transparent supply chains. Partnering with suppliers who adhere to international labor standards not only mitigates reputational risks but also aligns with global trends towards corporate social responsibility.

Implementing green manufacturing practices—such as water and energy conservation, waste reduction, and non-toxic dyeing—further enhances brand value and consumer trust. For international buyers, engaging with suppliers who hold credible sustainability certifications and participate in fair trade initiatives ensures compliance with global standards and appeals to eco-conscious markets. This proactive approach to sustainability can serve as a competitive differentiator and foster long-term supplier relationships.

Evolution and Industry Context

While the core design of toddler dress shoes has remained relatively consistent—focusing on comfort, safety, and style—the industry has undergone significant evolution in recent decades. Historically driven by traditional craftsmanship and local materials, the sector has shifted towards mass customization, rapid prototyping, and sustainable production practices. This evolution reflects broader shifts in consumer expectations and technological capabilities.

For B2B buyers, understanding this history underscores the importance of partnering with innovative, adaptable manufacturers capable of meeting evolving demands. It also highlights the increasing importance of transparency and traceability in supply chains, as brands and retailers seek to ensure product authenticity and sustainability. The ongoing digital transformation and emphasis on ethical manufacturing practices are shaping the future landscape, making agility and responsibility key pillars for success in sourcing toddler dress shoes globally.

Frequently Asked Questions (FAQs) for B2B Buyers of toddler dress shoes

1. How can I effectively vet and select reliable suppliers for toddler dress shoes internationally?

To ensure supplier reliability, start with comprehensive due diligence. Verify their business licenses, certifications (such as ISO, CE, or ASTM), and check for compliance with international safety standards. Request references from existing clients, especially from your region, to assess their reputation. Evaluate their production capacity, quality control processes, and turnaround times. Consider visiting their manufacturing facilities if feasible or hire third-party inspection services for audits. Building a strong relationship based on transparent communication and clear contractual terms minimizes risks and ensures consistent product quality.

2. What are the typical customization options available for toddler dress shoes, and how do they impact lead times and costs?

Most suppliers offer customization in areas such as design, color, material, embellishments, and packaging. Custom features like logos or unique patterns may require additional tooling or minimum order quantities, impacting unit costs. Lead times for customized orders generally range from 4 to 12 weeks, depending on complexity and supplier capacity. To optimize costs and timelines, clearly define your specifications upfront and work with suppliers who have experience in your target markets. Establishing prototypes early can help avoid costly revisions and ensure final products meet your standards.

3. What are typical MOQ requirements, lead times, and payment terms for international B2B purchases of toddler dress shoes?

MOQ varies widely, typically from 500 to 5,000 pairs, depending on the manufacturer and customization level. Lead times usually range from 4 to 16 weeks, influenced by order complexity, stock availability, and shipping logistics. Common payment terms include a 30% deposit upfront with the balance paid before shipment or upon delivery, often via bank transfer or letter of credit. Negotiating flexible payment terms is possible with established suppliers, especially for larger orders or long-term partnerships. Always ensure clear contractual agreements to mitigate payment risks.

4. What quality assurance and certification standards should I look for when sourcing toddler dress shoes internationally?

Prioritize suppliers with relevant safety certifications such as ASTM F963, CE, or ISO 9001, indicating compliance with safety, environmental, and quality management standards. Verify that the shoes meet child safety regulations regarding non-toxic materials, proper sole grip, and durability. Request test reports and third-party inspection certificates for each batch. Conduct or commission pre-shipment inspections to confirm adherence to quality standards. Ensuring product safety and quality compliance is crucial for market acceptance and avoiding legal liabilities in your target regions.

5. How can I manage logistics and shipping efficiently when importing toddler dress shoes from overseas?

Establish a reliable logistics plan by selecting experienced freight forwarders familiar with your target markets. Consider Incoterms like FOB or CIF to clarify responsibilities and costs. Evaluate multiple shipping options—sea freight for bulk orders offers cost savings, while air freight ensures faster delivery for urgent needs. Be aware of import duties, taxes, and customs clearance procedures specific to your country. Collaborate with customs brokers to streamline clearance processes and avoid delays. Building strong relationships with logistics providers can improve tracking, reduce costs, and ensure timely delivery.

6. What are common dispute resolution mechanisms in international B2B transactions for toddler dress shoes?

Disputes are best managed through clear contractual clauses. Include arbitration clauses specifying a neutral jurisdiction, such as Singapore, London, or Dubai, to ensure impartial resolution. Use internationally recognized arbitration institutions like ICC or LCIA for dispute settlement. Maintain detailed records of all communications, invoices, and inspection reports to support your case. Engaging legal counsel familiar with international trade laws can help draft enforceable contracts. Proactive communication and establishing mutual expectations upfront significantly reduce the likelihood of disputes escalating.

7. How can I ensure compliance with safety and environmental regulations in different target markets?

Research and understand the specific safety and environmental standards applicable in your target markets, such as the European REACH regulation, Mexico’s NOM standards, or South Africa’s SABS requirements. Work with suppliers who have certifications demonstrating compliance with these standards. Incorporate quality control checks focused on toxic substances, labeling, and eco-friendly materials during production. Regular audits and third-party testing can help maintain compliance. Staying updated on regulatory changes ensures your products remain market-ready and reduces the risk of recalls or legal penalties.

8. What strategies can I implement to build long-term, mutually beneficial relationships with international suppliers?

Develop trust through consistent communication, timely payments, and constructive feedback. Invest in understanding your supplier’s business environment and cultural nuances, which fosters mutual respect. Consider establishing long-term contracts with favorable terms and volume commitments to secure priority production and better pricing. Share market insights and collaborate on product development to align offerings with regional preferences. Regular visits, virtual meetings, and participation in trade fairs strengthen relationships. A partnership approach, emphasizing transparency and shared success, encourages suppliers to prioritize your needs and innovate collaboratively.

Strategic Sourcing Conclusion and Outlook for toddler dress shoes

Conclusion and Future Outlook

Effective strategic sourcing is crucial for international buyers aiming to succeed in the toddler dress shoe market. Prioritizing quality, cost-efficiency, and reliable supply chains allows buyers from regions such as Africa, South America, the Middle East, and Europe to meet growing consumer demands while maintaining competitive margins. Diversifying sourcing channels—by engaging with both established manufacturers and emerging suppliers—can mitigate risks and foster innovation.

Building strong, transparent partnerships with suppliers ensures consistent product quality and adherence to safety standards, which are paramount in the children’s footwear sector. Additionally, staying informed about regional manufacturing trends and leveraging trade agreements can unlock cost advantages and streamline logistics.

Looking ahead, the market will continue to evolve with a focus on sustainable practices and customization options. B2B buyers should proactively explore new sourcing opportunities, harness digital procurement tools, and foster collaborative relationships to stay ahead of industry shifts. By adopting a strategic, forward-thinking approach, buyers from Africa, South America, the Middle East, and Europe can capitalize on emerging trends, expand their market share, and deliver value-driven toddler dress shoes that meet global standards.