Master Sourcing Tracy McGrady Shoes: The Ultimate B2B Guide

Guide to Tracy Mcgrady Shoes

- Introduction: Navigating the Global Market for tracy mcgrady shoes

- Understanding tracy mcgrady shoes Types and Variations

- Key Industrial Applications of tracy mcgrady shoes

- Strategic Material Selection Guide for tracy mcgrady shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for tracy mcgrady shoes

- Comprehensive Cost and Pricing Analysis for tracy mcgrady shoes Sourcing

- Spotlight on Potential tracy mcgrady shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for tracy mcgrady shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the tracy mcgrady shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of tracy mcgrady shoes

- Strategic Sourcing Conclusion and Outlook for tracy mcgrady shoes

Introduction: Navigating the Global Market for tracy mcgrady shoes

Navigating the global marketplace for Tracy McGrady shoes presents a significant opportunity for international B2B buyers seeking to capitalize on a high-demand, performance-driven footwear segment. As a former NBA superstar, Tracy McGrady’s branded shoes have transcended sports to become sought-after commodities across diverse markets, especially in regions like Africa, South America, the Middle East, and parts of Europe such as Thailand and Indonesia. Understanding the nuances of this niche enables buyers to make strategic sourcing decisions that optimize quality, cost, and market positioning.

This comprehensive guide offers an in-depth overview of Tracy McGrady shoes, covering essential aspects such as product types, material specifications, manufacturing processes, quality control standards, and key supplier profiles. It also provides actionable insights into pricing strategies, import regulations, and market trends, empowering buyers to navigate complex international trade environments confidently. Whether sourcing for retail, wholesale, or private label purposes, this resource aims to streamline your procurement process and mitigate risks.

By leveraging this guide, B2B buyers can identify reliable manufacturing partners, assess cost efficiencies, and understand regional market dynamics. It is designed to foster informed decision-making, ensuring your supply chain remains competitive and compliant across borders. In today’s interconnected global economy, mastering the intricacies of Tracy McGrady shoes sourcing is crucial for expanding your footprint in high-growth markets worldwide.

Understanding tracy mcgrady shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Signature T-Mac Series | Designed in collaboration with Tracy McGrady, featuring his signature tech | Retail outlets, sports apparel distributors | High brand recognition, premium pricing; limited flexibility in customization |

| Performance Performance Line | Focused on athletic performance, lightweight materials, advanced cushioning | Sporting goods stores, specialty sports shops | Attracts serious athletes, high quality; higher MOQ and manufacturing costs |

| Retro/Reissue Models | Nostalgic designs based on original models, often with modern updates | Collectors, streetwear markets, casual wear outlets | Appeals to collectors, moderate price point; limited innovation for performance |

| Budget/Entry-Level Shoes | Simplified design, lower-cost materials, targeted at emerging markets | Discount retailers, bulk B2B sales to emerging markets | Cost-effective, accessible; potentially lower durability and brand appeal |

| Limited Edition/Collaborations | Unique designs, limited runs, often featuring collaborations with artists or brands | High-end boutiques, exclusive distributors | High margins, exclusivity appeal; limited stock, high demand risk |

Characteristics and Suitability

Signature T-Mac Series shoes are the flagship offerings, embodying Tracy McGrady’s personal performance technology and design ethos. They are typically positioned at the premium end of the market, appealing to consumers seeking authenticity and proven performance. For B2B buyers, these shoes are ideal for premium sports stores or specialty outlets targeting dedicated basketball fans and collectors. The main consideration is managing higher wholesale prices and ensuring authenticity to avoid counterfeit issues.

Performance Performance Line shoes are engineered for athletes, emphasizing lightweight construction, advanced cushioning, and durability. These models are suitable for sporting goods chains, professional teams, or specialty sports shops. B2B buyers should evaluate the technical specifications closely to match regional athlete needs and consider the higher manufacturing costs associated with advanced materials. Bulk purchasing can unlock better margins.

Retro/Reissue Models capitalize on nostalgia, often reviving classic designs with modern enhancements. They are popular in streetwear and casual segments, making them suitable for urban apparel retailers and casual sportswear distributors. B2B buyers should focus on marketing strategies that emphasize heritage and exclusivity, as these models typically command a premium but have moderate performance features.

Budget/Entry-Level Shoes are designed to penetrate emerging markets with cost-effective materials and simplified designs. These are attractive to discount retailers or B2B buyers looking for volume sales in price-sensitive regions such as parts of Africa, Southeast Asia, or Latin America. The key is balancing affordability with acceptable quality to sustain brand reputation and minimize returns or warranty issues.

Limited Edition/Collaborations shoes are highly exclusive, often produced in small quantities with unique designs. They are best suited for high-end boutiques, collectors, or distributors targeting premium customers. B2B buyers should prepare for high demand, limited stock, and the necessity of strong marketing to maximize margins. These models can significantly elevate brand prestige when managed correctly.

B2B Purchasing Insights

For international buyers, understanding these variations aids in tailoring procurement strategies to regional markets. Signature and performance lines are ideal for markets with a strong basketball culture or sports performance focus, such as Europe or the Middle East. Retro and limited editions appeal to fashion-conscious demographics in urban centers across Africa and South America, where streetwear influence is strong. Budget lines facilitate market entry in price-sensitive regions, enabling volume sales with manageable risks. Strategic sourcing should consider local consumer preferences, import regulations, and the ability to authenticate products to protect brand integrity and maximize profitability.

Key Industrial Applications of tracy mcgrady shoes

| Industry/Sector | Specific Application of tracy mcgrady shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports & Athletic Wear | Custom branded athletic shoes for team sponsorships and retail sales | Enhances brand visibility, drives consumer engagement, and boosts sales | Authenticity certifications, reliable supply chain, and customization options |

| Healthcare & Rehabilitation | Specialized footwear for sports injury recovery and orthopedics | Supports rehabilitation, reduces injury recurrence, and improves patient outcomes | Material safety standards, compliance with medical device regulations, and durability |

| Fashion & Lifestyle | Trend-driven, limited-edition sneakers for fashion retailers | Attracts fashion-conscious consumers, elevates brand prestige, and creates buzz | Trend alignment, exclusive distribution channels, and high-quality finishes |

| Corporate & Promotional | Branded shoes for corporate gifting and promotional campaigns | Reinforces brand identity, increases visibility, and fosters client loyalty | Cost-effectiveness, bulk sourcing options, and customizable branding features |

| Manufacturing & Customization | OEM production for private label footwear brands | Expands product portfolio, reduces manufacturing costs, and enhances market reach | Production capacity, quality control standards, and intellectual property protection |

Sports & Athletic Wear

Tracy McGrady shoes are highly valued in the sports and athletic wear industry for their performance and brand appeal. B2B buyers can leverage these shoes for team sponsorships, retail distribution, or custom branding initiatives. These shoes help sports teams and athletic brands enhance their visibility and credibility, especially in emerging markets like Africa and Southeast Asia. International buyers should prioritize sourcing from suppliers with proven authenticity certifications and reliable logistics to ensure timely delivery and brand integrity.

Healthcare & Rehabilitation

In the healthcare sector, Tracy McGrady shoes are increasingly used for injury prevention and recovery, particularly in orthopedics and sports medicine. They are designed to provide optimal support, shock absorption, and comfort, making them suitable for rehabilitation clinics and medical device suppliers. B2B buyers must ensure that these shoes meet stringent safety standards and medical regulations, especially when exporting to regions with strict compliance requirements such as Europe and the Middle East.

Fashion & Lifestyle

The fashion industry benefits from Tracy McGrady shoes through their trend-setting designs and limited-edition releases. Retailers and fashion brands can incorporate these shoes into exclusive collections, appealing to consumers seeking stylish and sporty footwear. To succeed, buyers should focus on sourcing high-quality, authentic products with exclusive designs, and establish distribution channels that target fashion-forward markets like Europe, Indonesia, and South America.

Corporate & Promotional

Companies can utilize Tracy McGrady shoes as promotional merchandise or corporate gifts to strengthen brand loyalty and recognition. Customized shoes bearing corporate logos or campaign slogans serve as memorable giveaways at events or as employee incentives. B2B buyers should evaluate cost-effective bulk sourcing, customization capabilities, and delivery reliability to maximize the impact of their promotional campaigns across diverse regions.

Manufacturing & Customization

OEM manufacturers and private label brands can incorporate Tracy McGrady shoes into their product lines through licensing agreements or white-label arrangements. This enables brands in Africa, Asia, and Europe to expand their footwear offerings without extensive R&D investment. Key considerations include ensuring consistent quality control, scalable production capacity, and protection of intellectual property rights, especially when operating across different legal jurisdictions.

Strategic Material Selection Guide for tracy mcgrady shoes

Material Analysis for Tracy McGrady Shoes

When selecting materials for Tracy McGrady shoes, B2B buyers must consider a range of factors including performance characteristics, manufacturing complexities, cost implications, and compliance with regional standards. The choice of materials directly impacts product durability, comfort, weight, and aesthetic appeal—all critical for competitive positioning in diverse markets such as Africa, South America, the Middle East, and Europe.

Leather and Synthetic Leather

Leather remains a popular choice for high-end basketball shoes due to its durability, breathability, and premium appearance. Genuine leather offers excellent abrasion resistance and molds to the wearer’s foot over time, enhancing comfort. Synthetic leather, on the other hand, provides a more cost-effective alternative with similar aesthetic qualities and easier manufacturing processes.

Key Properties:

– Leather: Natural material, high tensile strength, good breathability, moderate water resistance.

– Synthetic Leather: Made from polyurethane or PVC, consistent quality, lower cost, less breathable.

Pros & Cons:

– Leather: Highly durable, premium look, but expensive and requires complex tanning processes. It can also be sensitive to moisture, leading to potential deterioration if not properly treated.

– Synthetic Leather: Cost-efficient, lightweight, easy to produce, but less durable and can crack or peel over time.

Impact on Application:

– Leather is suitable for premium models targeting markets with high purchasing power (Europe, Middle East).

– Synthetic options are favored in cost-sensitive regions like parts of Africa and South America, where affordability is critical.

International Considerations:

– Compliance with regional standards such as REACH (Europe) or local chemical regulations is essential.

– Buyers should verify supplier certifications for sustainable sourcing and chemical safety, especially in markets with strict import regulations.

EVA and PU Foam

EVA (Ethylene Vinyl Acetate) and polyurethane (PU) foam are primarily used in midsoles for cushioning and shock absorption.

Key Properties:

– EVA: Lightweight, flexible, excellent shock absorption, low density.

– PU Foam: Denser, more resilient, better energy return but heavier.

Pros & Cons:

– EVA: Cost-effective, easy to mold, but can degrade faster under UV exposure and temperature fluctuations.

– PU Foam: Longer-lasting, provides superior support, but more expensive and heavier.

Impact on Application:

– EVA is ideal for mass-market models aimed at affordability and comfort, especially in regions with variable climate conditions.

– PU foam is suited for premium shoes requiring enhanced durability and performance, appealing to consumers in Europe and the Middle East.

International Considerations:

– Material safety standards such as ASTM or EN 71 must be met, especially for products exported to Europe.

– Regional climate considerations (heat, humidity) influence material choice; EVA’s UV sensitivity may be a concern in sunny regions.

Rubber and Outsole Materials

The outsole is critical for traction, durability, and overall shoe performance. Rubber compounds vary significantly based on regional needs.

Key Properties:

– Natural Rubber: High elasticity, excellent grip, good abrasion resistance.

– Synthetic Rubber (e.g., EVA-based compounds): Customizable properties, often more resistant to temperature extremes.

Pros & Cons:

– Natural Rubber: Superior grip and durability but can be more expensive and susceptible to environmental degradation if not properly treated.

– Synthetic Rubber: Cost-effective, adaptable to specific performance needs, but may lack some of natural rubber’s resilience.

Impact on Application:

– Durable rubber compounds are essential for outdoor courts common in Africa and South America.

– Softer, more flexible rubbers are preferred for indoor sports shoes, common in Europe and the Middle East.

International Considerations:

– Compliance with environmental standards such as REACH or RoHS is critical for import into Europe and other regions with strict chemical regulations.

– Suppliers should provide detailed material safety data sheets (MSDS) to facilitate customs clearance.

Summary Table of Material Selection for Tracy McGrady Shoes

| Material | Typical Use Case for Tracy McGrady Shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather & Synthetic Leather | Upper material for premium and mid-range models | Durability, aesthetic appeal, comfort | Leather: high cost, maintenance; Synthetic: less durable | Med |

| EVA & PU Foam | Midsoles for cushioning and shock absorption | Lightweight, good shock absorption, customizable | EVA degrades under UV; PU is heavier and costlier | Low to Med |

| Rubber & Outsole Materials | Outsoles for traction and durability | Excellent grip, abrasion resistance | Cost varies; natural rubber can be expensive | Low to Med |

| Mesh & Textile Fabrics | Ventilation and lightweight uppers | Breathability, flexibility | Less durable, can stain or wear quickly | Low |

This comprehensive analysis enables international B2B buyers to make informed decisions aligned with regional market demands, compliance standards, and cost considerations. Selecting the right combination of materials ensures product performance, market competitiveness, and regulatory adherence across diverse global markets.

In-depth Look: Manufacturing Processes and Quality Assurance for tracy mcgrady shoes

Manufacturing Processes for Tracy McGrady Shoes

The manufacturing of Tracy McGrady shoes involves a series of meticulously planned stages designed to ensure high quality, durability, and performance. For international B2B buyers, understanding these stages is crucial to assessing supplier capabilities and ensuring compliance with your regional standards.

1. Material Preparation

This initial phase focuses on sourcing and preparing high-quality raw materials, including synthetic or genuine leather, mesh fabrics, rubber compounds, foam insoles, and specialized adhesives. Suppliers often source materials from certified vendors adhering to environmental and safety standards such as ISO 9001 or OEKO-TEX. Material inspection at this stage ensures consistency in texture, thickness, and durability, serving as the foundation for subsequent processes.

2. Forming and Molding

The upper components are cut and shaped using computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies, ensuring precision and repeatability. Molding processes, such as injection molding for synthetic components or lasting for the upper, utilize molds designed for specific shoe models. Advanced machinery ensures tight tolerances, which are critical for fit and comfort.

3. Assembly

This core stage involves stitching, bonding, and attaching various components—upper, midsole, outsole, insoles, and lacing systems—using automated and semi-automated equipment. Techniques like ultrasonic welding and heat sealing are common for seamless bonding, reducing material waste and enhancing durability. The assembly process often incorporates ergonomic fixtures to maintain uniformity across batches.

4. Finishing

Final touches include cleaning, polishing, and applying branding elements such as logos and decorative features. Quality control measures are integrated into this stage to identify cosmetic flaws or assembly defects. In some cases, waterproofing or special coatings are applied to meet specific market requirements, especially for outdoor or performance shoes.

Quality Control (QC) in Manufacturing

Ensuring consistent quality across batches is vital for B2B buyers, especially when importing into regions with diverse regulatory environments such as Africa, South America, the Middle East, and Europe.

International Standards and Industry Certifications

- ISO 9001: The primary standard for quality management systems, ensuring manufacturers follow systematic processes that promote continuous improvement.

- CE Marking: Essential for shoes marketed within the European Economic Area, indicating compliance with safety, health, and environmental protection standards.

- ASTM and ISO Testing Standards: For performance, durability, and safety testing, including abrasion resistance, slip resistance, and impact testing.

- Other Certifications: API (American Petroleum Institute) for certain materials, or regional standards like SNI in Indonesia or INMETRO in Brazil.

Key QC Checkpoints

- Incoming Quality Control (IQC): Inspection of raw materials upon receipt, verifying specifications and identifying defects early.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing, including dimensional checks, stitching quality, bonding strength, and functional tests.

- Final Quality Control (FQC): Comprehensive inspection of finished shoes, assessing visual appearance, structural integrity, and functional performance before packaging.

Testing Methods

- Visual Inspection: Checking for cosmetic flaws, color consistency, and branding accuracy.

- Mechanical Tests: Tensile strength, flexibility, and adhesion tests for glued or stitched components.

- Durability Tests: Abrasion resistance, outsole adhesion, and shock absorption simulations.

- Comfort and Fit Tests: Ensuring ergonomic standards are met, often through sample wear tests or biomechanical assessments.

Verifying Supplier Quality Assurance

For B2B buyers, especially from regions with varying regulatory frameworks, verifying a supplier’s QC processes is critical.

- Supplier Audits: Conduct on-site audits focusing on manufacturing facilities, QC procedures, and compliance documentation. International third-party auditors, such as SGS, Bureau Veritas, or Intertek, can provide impartial assessments.

- Inspection Reports: Request detailed inspection and test reports for each batch, including certificates of analysis (COA) and compliance certificates.

- Third-Party Inspections: Engage independent inspection agencies to perform pre-shipment audits, ensuring products meet contractual specifications and regional standards.

- Factory Certifications: Confirm the presence of recognized industry certifications (ISO 9001, ISO 14001, etc.) and regional compliance marks.

Nuances for International B2B Buyers

- Regional Regulatory Alignment: Buyers from Africa, South America, the Middle East, and Europe should verify that suppliers adhere to local standards, such as REACH compliance in Europe or SNI certification in Indonesia.

- Cultural and Market-Specific Requirements: Some regions demand specific features, like anti-slip soles for wet climates or eco-friendly materials for environmentally conscious markets. Clarify these requirements early.

- Customs and Documentation: Ensure suppliers can provide comprehensive documentation, including test certificates, material declarations, and origin certificates to facilitate smooth customs clearance.

Strategic Recommendations for B2B Buyers

- Develop a Robust Supplier Qualification Program: Include factory audits, sample testing, and review of QC documentation before establishing long-term partnerships.

- Leverage Third-Party Inspection Agencies: Regular inspections by recognized agencies can mitigate risks associated with quality inconsistencies.

- Implement Clear Quality Agreements: Define specific QC standards, testing protocols, and documentation requirements in your purchase contracts.

- Stay Informed on Regional Standards: Keep abreast of evolving standards and regulations in your target markets to ensure compliance and avoid delays or penalties.

By understanding the detailed manufacturing stages and implementing rigorous quality assurance protocols, international B2B buyers can confidently source Tracy McGrady shoes that meet their market standards, ensuring customer satisfaction and brand reputation across diverse regions.

Comprehensive Cost and Pricing Analysis for tracy mcgrady shoes Sourcing

Cost Structure Breakdown for Tracy McGrady Shoes

Understanding the comprehensive cost structure of Tracy McGrady shoes is vital for international B2B buyers aiming to optimize procurement strategies. The primary cost components include:

-

Materials: High-quality synthetic or genuine leather, mesh fabrics, and rubber soles form the core material costs. The choice of materials significantly influences both quality and price, with premium materials increasing costs but enhancing product appeal.

-

Labor: Manufacturing labor costs vary notably by region. For example, factories in Southeast Asia (Thailand, Indonesia) tend to offer competitive wages, often resulting in lower labor costs compared to Middle Eastern or European manufacturers. Skilled labor ensures better quality but can increase costs.

-

Manufacturing Overhead: This encompasses factory utilities, machinery depreciation, and management expenses. Efficient factories with high automation levels can reduce overhead per unit, but initial capital investments may be higher.

-

Tooling & Setup: One-time costs for molds and tooling can be substantial, especially if customization or specific design features are involved. These costs are amortized over large production volumes, lowering the unit price for bulk orders.

-

Quality Control & Certifications: Ensuring compliance with international standards (ISO, ISO 9001, or specific safety certifications) adds to costs but is crucial for market access, particularly in Europe and North America.

-

Logistics & Shipping: International shipping, customs duties, and warehousing significantly influence final landed costs. Buyers from Africa, South America, and the Middle East should account for longer transit times and potential tariffs, which can add 10-30% to the product cost.

-

Profit Margin & Markup: Suppliers typically add a margin of 10-25%, depending on order volume, relationship, and market competitiveness. Larger, repeat orders generally secure better pricing.

Key Price Influencers and Variations

Several factors impact the final price and should be carefully negotiated:

-

Order Volume & MOQ: Higher volumes reduce per-unit costs through economies of scale. Many manufacturers offer tiered pricing, with discounts increasing at larger MOQ levels (e.g., 1,000+ pairs).

-

Product Specifications & Customization: Custom designs, branding, or specialized features (e.g., enhanced cushioning, eco-friendly materials) escalate costs. Buyers seeking exclusivity should budget accordingly, especially if molds or specific certifications are involved.

-

Material Selection: Premium or rare materials drive up costs, but they can also command higher retail prices. Conversely, standard materials may lower initial costs but could impact brand perception.

-

Quality & Certifications: Higher quality standards and international certifications (CE, ASTM, ISO) incur additional testing and compliance costs. These are essential for markets with strict safety and quality regulations, such as Europe and North America.

-

Supplier Factors: Established manufacturers with a reputation for quality often charge higher prices but offer better reliability. New entrants might provide lower quotes but pose risks related to consistency and compliance.

-

Incoterms & Shipping Terms: FOB (Free on Board) and CIF (Cost, Insurance, Freight) terms influence who bears shipping costs and risks. Buyers should clarify these terms upfront to avoid unexpected expenses.

Strategic Tips for International B2B Buyers

-

Negotiate for Volume Discounts: Leverage large orders or long-term partnerships to secure better pricing. Establish clear MOQ requirements and explore tiered pricing structures.

-

Focus on Total Cost of Ownership (TCO): Beyond unit price, consider logistics, customs, tariffs, and potential delays. A cheaper product that incurs high shipping or compliance costs may not be cost-effective.

-

Standardize Specifications: Minimize customization to reduce tooling and certification expenses. Use standardized designs that can be produced at scale efficiently.

-

Prioritize Quality & Certifications: Investing in certified suppliers reduces risks of product recalls or market access issues, especially in stringent markets like Europe and the Middle East.

-

Localize Supply Chain Elements: For buyers in Africa, South America, and the Middle East, consider working with regional warehouses or agents to reduce logistics costs and lead times.

-

Pricing Transparency & Due Diligence: Always request detailed quotations, including breakdowns of all costs. Verify supplier credentials, reviews, and compliance records before finalizing deals.

Disclaimer

Indicative prices for Tracy McGrady shoes from reputable manufacturers typically range from $15 to $35 per pair at bulk volumes (1,000+ units), depending on specifications, quality standards, and customization levels. However, prices can fluctuate based on market conditions, supplier negotiations, and geopolitical factors. It is essential for buyers to conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing.

By understanding these cost components and influencing factors, B2B buyers from diverse regions can develop more effective sourcing strategies, optimize their procurement costs, and establish reliable supply partnerships for Tracy McGrady shoes.

Spotlight on Potential tracy mcgrady shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for tracy mcgrady shoes.)*

Essential Technical Properties and Trade Terminology for tracy mcgrady shoes

Critical Technical Properties of Tracy McGrady Shoes

1. Material Grade and Composition

The quality of materials used in Tracy McGrady shoes significantly impacts durability, performance, and customer satisfaction. Commonly used materials include high-grade synthetic leathers, mesh fabrics, and specialized foam for cushioning. For B2B buyers, sourcing shoes made with certified, high-quality materials ensures consistent product performance and reduces the risk of returns or warranty claims. It’s essential to specify material grades (e.g., ASTM standards) to maintain quality consistency across batches.

2. Manufacturing Tolerance and Precision

Tolerance refers to the permissible deviation during manufacturing, such as size, shape, or fit. Tight tolerances (e.g., ±0.5mm for sole dimensions) indicate high manufacturing precision, critical for ensuring product consistency and customer trust. For international buyers, understanding tolerance levels helps prevent issues like misfit or manufacturing defects, which could lead to costly rework or rejected shipments.

3. Weight and Flexibility

Lightweight shoes enhance athletic performance and comfort, a key selling point for Tracy McGrady shoes. The weight is often measured in grams or ounces, with specifications indicating the maximum weight for different models. Flexibility, measured through bend tests, indicates how well the shoe adapts to natural foot movement. Buyers should specify these properties to meet target market demands, particularly in regions where active lifestyles are prevalent.

4. Sole and Traction Properties

The outsole material and tread pattern influence grip and durability. High-quality rubber compounds with specific tread designs provide superior traction, especially in diverse climatic conditions common in Africa, South America, and the Middle East. Confirming sole hardness (measured in Shore A) and slip resistance ensures products meet safety standards and perform reliably across various terrains.

5. Cushioning and Support Technology

Advanced cushioning systems (e.g., EVA foam, Air units) enhance comfort and shock absorption. Structural support features, such as reinforced heel counters or arch support, are crucial for high-performance models. For B2B buyers, verifying these technical features ensures the shoes meet athletes’ expectations and align with regional activity levels.

Key Industry and Trade Terms

1. OEM (Original Equipment Manufacturer)

An OEM produces products that are branded and sold by another company. In the context of Tracy McGrady shoes, many brands outsource manufacturing to OEMs to leverage specialized expertise and reduce costs. Understanding OEM relationships helps buyers assess product authenticity, quality control, and customization options.

2. MOQ (Minimum Order Quantity)

This is the smallest quantity a supplier is willing to produce or sell in a single order. For new market entries or bulk imports, knowing the MOQ helps buyers plan inventory and negotiate better terms. It’s especially relevant when sourcing high-quality or custom-designed Tracy McGrady shoes.

3. RFQ (Request for Quotation)

An RFQ is a formal request sent by buyers to suppliers to obtain price, lead time, and other terms for specific products. Clear RFQs allow suppliers to provide accurate quotations, facilitating comparison and decision-making. For international transactions, detailed RFQs help clarify specifications and avoid misunderstandings.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities between buyers and sellers regarding shipping, risk, and costs. Common Incoterms include FOB (Free on Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid). Understanding these terms helps B2B buyers plan logistics, budget accurately, and manage customs procedures efficiently across different regions.

5. Quality Certification and Standards

Certifications such as ISO, SGS testing, or regional safety standards ensure product compliance and quality assurance. Buyers should verify that Tracy McGrady shoes meet relevant safety and quality standards applicable in their markets, reducing regulatory risks and enhancing consumer trust.

6. Lead Time

The period from order placement to product delivery. Accurate knowledge of lead times allows buyers to plan inventory, marketing campaigns, and sales forecasts, especially when entering new markets or coordinating large shipments.

By understanding these technical properties and trade terms, international B2B buyers from Africa, South America, the Middle East, and Europe can make more informed decisions, optimize supply chain efficiency, and ensure product quality and compliance in their target markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the tracy mcgrady shoes Sector

Market Overview & Key Trends

The global market for athletic footwear, including Tracy McGrady shoes, is experiencing rapid evolution driven by technological innovation, shifting consumer preferences, and expanding e-commerce channels. Key drivers include increased demand for performance-oriented and lifestyle sneakers, particularly among younger demographics across Africa, South America, the Middle East, and Europe. These regions are witnessing rising disposable incomes and a growing middle class, which fuels local retail growth and international sourcing opportunities.

Emerging sourcing trends focus on digitalization, supply chain transparency, and lean manufacturing processes. Advanced manufacturing technologies such as 3D printing, automation, and AI-driven inventory management are enabling brands and suppliers to reduce costs, improve product customization, and shorten lead times. For international B2B buyers from regions like Thailand and Indonesia, these innovations offer avenues for competitive pricing and rapid market entry.

Market dynamics are also influenced by geopolitical factors, trade agreements, and tariffs, which can impact sourcing costs and logistics. For instance, tariffs on Chinese imports have prompted buyers in Europe and South America to diversify sourcing to Southeast Asia and Africa. The rise of direct-to-consumer (DTC) models and online marketplaces further accelerates the distribution of Tracy McGrady shoes, demanding flexible, scalable supply chain solutions.

To capitalize on these trends, B2B buyers should prioritize establishing strong relationships with manufacturers that leverage sustainable and innovative production techniques. Staying informed about regional trade policies, technological advancements, and consumer preferences will be crucial for successful market navigation and competitive positioning.

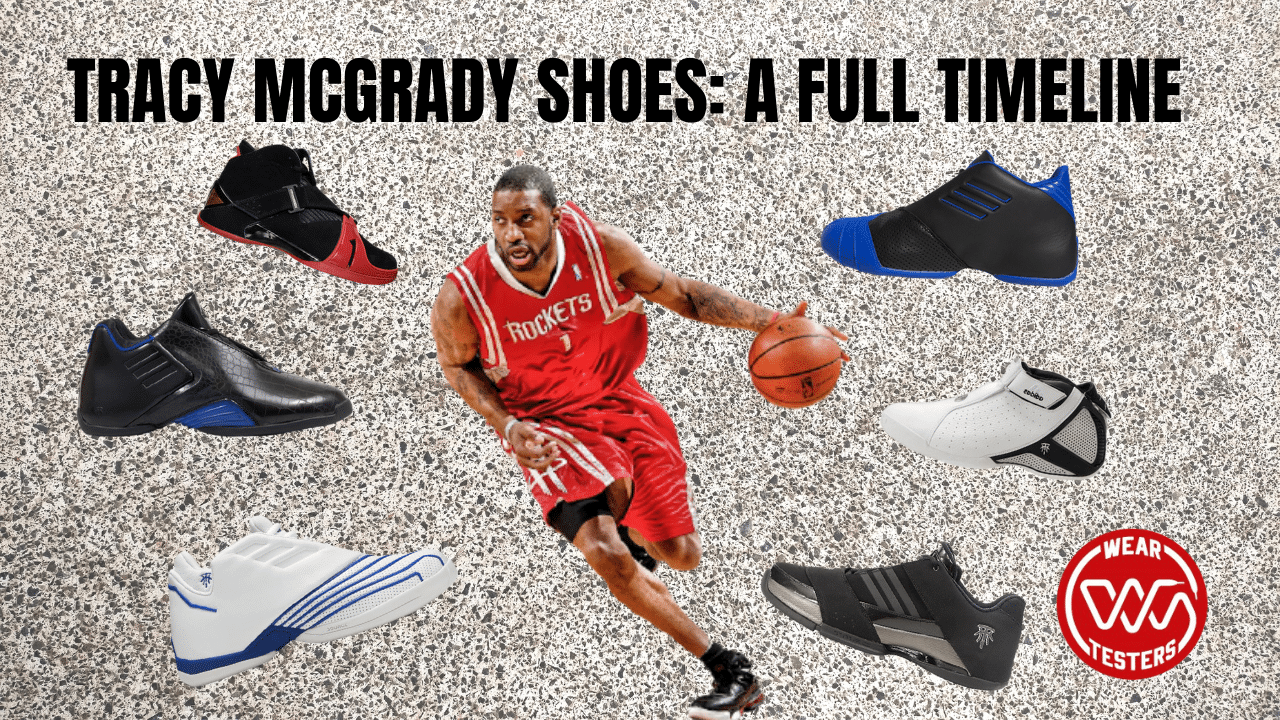

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal factor in the footwear industry, with brands and consumers increasingly prioritizing environmentally responsible products. For B2B buyers sourcing Tracy McGrady shoes, integrating sustainable practices is not only a moral imperative but also a strategic advantage, enhancing brand reputation and consumer trust across diverse markets.

Environmental impact reduction begins with sourcing eco-friendly materials such as recycled polyester, organic cotton, and biodegradable sole components. Certifications like Global Organic Textile Standard (GOTS), Leather Working Group (LWG), and Forest Stewardship Council (FSC) are critical benchmarks for verifying sustainable practices. Manufacturers that hold these certifications demonstrate adherence to strict environmental and social standards, reducing risks associated with supply chain disruptions and reputational damage.

Ethical sourcing also involves ensuring fair labor practices, safe working conditions, and transparent supply chains. Buyers should conduct thorough audits and require suppliers to comply with international labor standards, such as those outlined by the International Labour Organization (ILO). Emphasizing traceability through blockchain or other digital tools can further ensure the integrity of the supply chain.

For regions like Africa, South America, the Middle East, and Southeast Asia, engaging with suppliers committed to green initiatives can unlock access to eco-labels and preferential trade terms. Incorporating sustainable materials and ethical sourcing practices can differentiate Tracy McGrady shoes in competitive markets, appealing to environmentally conscious consumers and aligning with global regulatory trends toward stricter environmental legislation.

Brief Evolution/History (Optional)

The Tracy McGrady shoe line originated in the early 2000s, capitalizing on the athlete’s NBA success and popularity. Initially driven by performance needs, the brand has evolved to include lifestyle and fashion-forward designs, aligning with broader sneaker culture. For B2B buyers, understanding this evolution is important to anticipate future product lines and market positioning, especially as collaborations with designers or athletes can influence demand and supply chain strategies. Recognizing the brand’s heritage can also help in negotiating sourcing contracts and marketing partnerships across diverse regions.

Frequently Asked Questions (FAQs) for B2B Buyers of tracy mcgrady shoes

1. How can I verify the credibility and reliability of Tracy McGrady shoe suppliers?

To ensure supplier credibility, conduct thorough due diligence by requesting business licenses, export licenses, and relevant certifications such as ISO or factory audits. Check references from other international buyers, review online reputation, and verify their production capacity and experience in footwear manufacturing. Visiting the supplier’s facility, if possible, can provide firsthand insight into their operations. Additionally, leverage third-party inspection services before shipment to confirm production quality and adherence to standards. Building a strong relationship based on transparent communication and clear contractual terms minimizes risks associated with unreliable suppliers.

2. What customization options are available for Tracy McGrady shoes, and how do they affect lead times?

Most reputable suppliers offer a range of customization options, including branding (logos, labels), colorways, materials, and packaging. Advanced customization, such as unique designs or specialized features, may require longer lead times—typically 4-8 weeks depending on complexity and order volume. Clear communication of your specifications upfront is essential. Suppliers often provide prototypes or samples for approval before mass production. Be aware that customization may also impact MOQ requirements and pricing, so negotiate these terms early to align with your project timelines and market demands.

3. What are typical MOQ, lead times, and payment terms for international B2B orders of Tracy McGrady shoes?

Minimum order quantities (MOQs) for Tracy McGrady shoes generally range from 500 to 2,000 pairs, depending on the supplier and customization level. Lead times usually span 4-8 weeks from order confirmation to delivery, influenced by order size and production complexity. Common payment terms include a 30% deposit upfront with the balance payable before shipment, or letters of credit for larger transactions. Establish clear payment agreements and consider escrow services for added security. Building a reliable payment and logistics plan early helps prevent delays and cash flow issues.

4. What certifications and quality assurance standards should I look for in Tracy McGrady shoe suppliers?

Ensure suppliers possess relevant certifications such as ISO 9001 for quality management, CE marking for European compliance, or other regional standards like SGS or BSCI audits. These certifications demonstrate adherence to safety, environmental, and labor standards. Request detailed QA procedures, including material testing, durability assessments, and factory inspection reports. Request samples for independent testing if necessary. Working with certified suppliers reduces compliance risks, enhances product credibility, and ensures your products meet international standards, facilitating smoother customs clearance and customer satisfaction.

5. How can I manage international logistics and shipping for Tracy McGrady shoes effectively?

Coordinate with suppliers experienced in international shipping, preferably those with established logistics partners. Choose reliable freight methods—sea freight for cost efficiency or air freight for faster delivery—based on your urgency and budget. Clarify Incoterms (e.g., FOB, CIF) to define responsibilities and costs. Consider customs duties, taxes, and import regulations specific to your country (e.g., tariffs in Africa, South America, Middle East, or Europe). Employ customs brokers or freight forwarders to streamline clearance processes. Tracking shipments and maintaining clear communication with logistics providers helps mitigate delays and unexpected costs.

6. What should I do if there is a dispute or quality issue with my Tracy McGrady shoe order?

Establish clear contractual clauses covering quality standards, inspection procedures, and dispute resolution mechanisms before placing an order. If issues arise, document the problem thoroughly with photos and detailed descriptions. Engage in direct communication with the supplier to seek a resolution—rework, replacement, or refund—based on agreed terms. If unresolved, escalate through arbitration or legal channels in accordance with the contract. Working with suppliers who have a reputation for transparency and fair dispute handling reduces risks. Regular quality inspections during production can also prevent major issues before shipment.

7. How do I ensure compliance with regional regulations and import standards for Tracy McGrady shoes?

Research specific import regulations, safety standards, and labeling requirements in your target market (e.g., CE compliance for Europe, SASO for Saudi Arabia, or local standards in African and South American countries). Request supplier documentation demonstrating compliance, such as test reports and certificates. Incorporate these requirements into your purchase agreements. Employ third-party testing labs to validate product safety and standards if necessary. Staying informed about evolving regulations helps avoid customs delays, fines, or product recalls, ensuring a smooth entry into your market.

8. What are best practices for building long-term relationships with Tracy McGrady shoe suppliers?

Develop open, transparent communication channels and foster trust through consistent payments and timely feedback. Regularly visit supplier facilities or conduct virtual audits to stay updated on their capabilities and quality standards. Negotiate flexible terms that accommodate your market fluctuations, such as adjustable MOQs or lead times. Invest in supplier development programs, including joint planning or shared quality initiatives. Maintaining a partnership approach rather than transactional relationships encourages better service, innovation, and priority access to new products or customization options, ultimately strengthening your supply chain resilience.

Illustrative Image (Source: Google Search)

Strategic Sourcing Conclusion and Outlook for tracy mcgrady shoes

Strategic Sourcing Conclusion and Outlook for Tracy McGrady Shoes

Effective strategic sourcing is essential for international B2B buyers seeking to capitalize on the growing demand for Tracy McGrady shoes across diverse markets. By prioritizing supplier reliability, quality assurance, and cost optimization, buyers can secure competitive advantages and foster long-term partnerships that support sustainable growth. Recognizing regional nuances—such as sourcing from Asia for manufacturing efficiency or exploring emerging markets for new distribution channels—can further enhance supply chain resilience.

As the global footwear market evolves, staying informed about innovations in materials, manufacturing practices, and compliance standards will be critical. Embracing a proactive sourcing approach enables buyers from Africa, South America, the Middle East, and Europe to navigate supply chain complexities and capitalize on market opportunities effectively.

Illustrative Image (Source: Google Search)

Looking ahead, strategic sourcing will continue to be a key driver of success in the Tracy McGrady shoes segment. International buyers are encouraged to strengthen supplier relationships, leverage local market insights, and adopt flexible sourcing strategies. By doing so, they can ensure a competitive edge, meet increasing consumer demand, and position themselves as leaders in this dynamic industry.