Your Ultimate Guide to Sourcing Wooden Shoes

Guide to Wooden Shoes

- Introduction: Navigating the Global Market for wooden shoes

- Understanding wooden shoes Types and Variations

- Key Industrial Applications of wooden shoes

- Strategic Material Selection Guide for wooden shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for wooden shoes

- Comprehensive Cost and Pricing Analysis for wooden shoes Sourcing

- Spotlight on Potential wooden shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for wooden shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the wooden shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of wooden shoes

- Strategic Sourcing Conclusion and Outlook for wooden shoes

Introduction: Navigating the Global Market for wooden shoes

In today’s interconnected global economy, sourcing high-quality wooden shoes demands strategic insight and a nuanced understanding of international markets. For B2B buyers across Africa, South America, the Middle East, and Europe—particularly regions like France and Spain—access to reliable suppliers and comprehensive product knowledge is essential to gain a competitive edge. Wooden shoes, once traditional footwear, have evolved into versatile products spanning fashion, craftsmanship, and functional uses, making them a valuable addition to diverse product portfolios.

This guide provides a detailed roadmap for navigating the complex landscape of wooden shoe sourcing. It covers critical aspects such as the different types of wooden shoes, material selection, manufacturing processes, quality control standards, and supplier identification. Additionally, it offers practical insights into cost considerations, market trends, and regulatory requirements, empowering buyers to make informed, strategic decisions. Whether you’re seeking artisanal craftsmanship or mass-produced options, understanding these elements ensures your sourcing aligns with your quality standards and market demands.

By leveraging this comprehensive resource, international buyers will be better equipped to identify reputable suppliers, evaluate product specifications, and optimize costs. This guide aims to streamline your procurement process, minimize risks, and unlock new growth opportunities in the global wooden shoe market—helping you stay competitive and responsive to evolving customer preferences across diverse regions.

Understanding wooden shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Dutch Clogs | Made from solid wood, typically oak or beech; hand-carved; often with decorative carvings | Cultural exports, artisanal markets | Pros: Authentic appeal, high craftsmanship; Cons: Higher cost, limited scalability |

| Molded Wooden Shoes | Constructed via steam molding or injection techniques; often lighter and more uniform | Industrial safety footwear, ergonomic products | Pros: Consistent quality, mass production; Cons: Less traditional aesthetic |

| Custom Carved Shoes | Hand-carved with intricate designs, often customized for brands or cultural motifs | Luxury, promotional items, cultural exports | Pros: Unique branding opportunities; Cons: Higher price point, longer lead times |

| Lightweight Wooden Shoes | Use of lightweight woods or composites; designed for comfort and extended wear | Workwear, fashion footwear, specialty markets | Pros: Comfort, versatility; Cons: Potential durability issues if not properly engineered |

| Eco-Friendly Wooden Shoes | Made from sustainably sourced or recycled wood; focus on eco-conscious production | Green markets, sustainable fashion, export to eco-aware regions | Pros: Sustainability appeal, compliance with environmental standards; Cons: Cost may be higher, limited raw material sources |

Traditional Dutch Clogs

Traditional Dutch wooden clogs are crafted from dense hardwoods like oak or beech, often carved by skilled artisans. They are highly durable, offering excellent resistance to moisture and rough conditions, making them suitable for agricultural and industrial uses. For B2B buyers, sourcing authentic Dutch clogs involves evaluating craftsmanship quality and consistency, especially when scaling for export. Cost considerations include labor-intensive production, which can elevate prices, but the authentic appeal can command premium markets, particularly in Europe and cultural markets globally.

Molded Wooden Shoes

Molded wooden shoes are produced through modern techniques such as steam molding or injection processes, allowing for mass production with consistent quality. These shoes are often lighter and more ergonomically designed, suitable for industrial applications or ergonomic footwear lines. B2B buyers should focus on manufacturing standards, material sourcing, and scalability when considering molded options. They are ideal for companies seeking uniformity, especially for large orders or export to markets demanding reliable, standardized products.

Custom Carved Shoes

Custom carved wooden shoes are distinguished by intricate, hand-made designs, often reflecting cultural motifs or brand logos. These are primarily used as promotional items, luxury collectibles, or cultural exports. For B2B buyers, the key considerations include craftsmanship quality, lead times, and customization capabilities. While they command higher prices, their uniqueness and cultural significance make them valuable for niche markets, especially in Europe and specialty retail sectors.

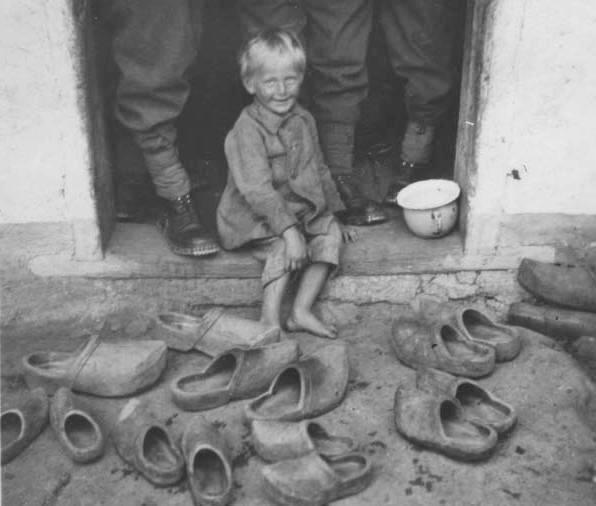

Illustrative Image (Source: Google Search)

Lightweight Wooden Shoes

Utilizing lightweight woods or composites, these shoes emphasize comfort and extended wearability. They are suitable for work environments or fashion segments that prioritize comfort without sacrificing durability. Buyers should assess material quality, weight specifications, and potential trade-offs in durability. These shoes are particularly attractive to markets focused on ergonomic design, such as healthcare or hospitality sectors, and can be scaled for mass distribution.

Eco-Friendly Wooden Shoes

Manufactured from sustainably sourced or recycled wood, eco-friendly shoes appeal strongly to environmentally conscious markets. They are suitable for green fashion brands, export to eco-aware regions like parts of Europe, and for companies seeking to enhance sustainability credentials. B2B buyers should evaluate certification standards, raw material traceability, and production practices. While potentially more costly, these shoes can open access to premium eco-market segments and enhance brand reputation.

Key Industrial Applications of wooden shoes

| Industry/Sector | Specific Application of Wooden Shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Protective footwear for farm workers | Durable, breathable, and cost-effective protection against mud, water, and rough terrain | Material quality, slip resistance, comfort, and customization options |

| Construction & Mining | Anti-vibration and impact-absorbing footwear | Reduces fatigue and injury risk in heavy-duty environments, enhancing worker safety | Shock absorption capacity, compliance with safety standards, sourcing consistency |

| Food Processing | Hygienic, non-porous footwear for food plants | Prevents cross-contamination, easy to clean, meets hygiene regulations | Food-grade materials, ease of sanitation, certification requirements |

| Cultural & Tourism | Traditional or souvenir wooden clogs for cultural displays | Enhances authenticity, supports cultural branding, and tourist engagement | Authentic craftsmanship, regional styles, export readiness |

| Manufacturing & Craftsmanship | Custom wooden shoes for artisanal workshops | Supports bespoke product lines, maintains traditional craftsmanship appeal | Craftsmanship quality, material sourcing, scalability for bulk orders |

Agricultural Applications

Wooden shoes serve as protective footwear for agricultural workers, especially in regions with muddy, uneven, or waterlogged fields. Their natural breathability helps prevent foot ailments, while their durability withstands harsh outdoor conditions. International B2B buyers from Africa and South America should prioritize sourcing from regions with established craftsmanship, ensuring the shoes meet local safety standards and offer customization for different crop environments. Cost-effectiveness and ease of maintenance are crucial for large-scale deployment.

Construction & Mining Applications

In construction and mining sectors, wooden shoes act as impact-absorbing footwear that reduces fatigue and injury risk. They are especially valuable in environments where metal or plastic alternatives may cause slips or fatigue due to weight. For international buyers, sourcing high-quality, shock-absorbent wooden shoes that comply with safety certifications (e.g., EN standards in Europe) is essential. The focus should be on consistent quality, comfort, and the ability to customize designs for specific industrial hazards.

Food Processing Industry

Wooden shoes are favored in food processing plants for their non-porous, hygienic qualities, making them compliant with strict sanitation standards. They prevent cross-contamination and are easy to clean, which is vital in environments with high hygiene demands. Buyers from Europe and Middle Eastern markets should ensure the shoes are made from food-grade, certified materials, and are durable enough to withstand frequent sanitation procedures. Bulk sourcing from reputable manufacturers ensures consistency and regulatory compliance.

Cultural & Tourism Sectors

Traditional wooden clogs are integral to cultural displays and tourism branding, especially in European countries like France and Spain. They serve as authentic souvenirs and are used in cultural festivals, supporting local artisans and boosting regional identity. B2B buyers should focus on sourcing handcrafted, region-specific styles that appeal to tourists and collectors. Ensuring authenticity and export readiness is vital for international distribution and maintaining cultural integrity.

Manufacturing & Craftsmanship

Artisanal workshops and bespoke footwear manufacturers utilize wooden shoes to create custom, high-end products that emphasize craftsmanship and tradition. These shoes are often used in fashion, cultural exhibitions, or as luxury souvenirs. Sourcing from skilled artisans with a focus on quality, authenticity, and scalability is key. Buyers should evaluate the craftsmanship, material sourcing, and the ability to produce in bulk without compromising artisanal standards, especially for export markets.

Strategic Material Selection Guide for wooden shoes

Analysis of Common Materials for Wooden Shoes

1. Hardwood (e.g., Oak, Maple, Beech)

Hardwoods are the most traditional and widely used materials for wooden shoes due to their strength and durability. They possess high compressive and bending strength, making them suitable for footwear subjected to significant pressure and wear. These woods typically have good dimensional stability and resistance to impact, which enhances the longevity of the final product.

Pros & Cons:

– Pros: Excellent durability, high wear resistance, relatively easy to machine, and aesthetically appealing with fine grain patterns.

– Cons: Generally higher cost compared to softwoods, heavier weight, and longer processing times. Some hardwoods may require specialized tools for shaping, increasing manufacturing complexity.

Impact on Application:

Hardwoods are suitable for both indoor and outdoor use, especially in environments with moderate to high mechanical stress. They are resistant to cracking and splitting, making them ideal for footwear that needs longevity.

International Buyer Considerations:

European buyers, especially in France and Spain, often prefer sustainably sourced hardwoods that meet FSC or PEFC standards. Compliance with ASTM D1990 (hardwood grading) and DIN standards for wood quality is common. Buyers from Africa and South America should verify import regulations regarding timber origin and certifications to avoid legal issues and ensure product authenticity.

2. Softwood (e.g., Pine, Spruce, Cedar)

Softwoods are more abundant and generally less expensive than hardwoods. They are easier to work with, which can reduce manufacturing costs and lead times. Softwoods tend to be lighter, which is advantageous for reducing the overall weight of wooden shoes, especially for mass-produced items.

Pros & Cons:

– Pros: Cost-effective, lightweight, easier to shape and finish, suitable for mass production.

– Cons: Lower durability and wear resistance, higher susceptibility to dents and scratches, less suitable for heavy-duty applications.

Impact on Application:

Softwoods are often used for indoor or decorative wooden shoes, or for components that are not subject to intense mechanical stress. They may require additional treatment or reinforcement for outdoor or industrial use.

International Buyer Considerations:

Buyers from regions with strict import standards, such as the European Union, should check for pest treatment certifications (e.g., ISPM 15). Softwood products should meet local standards for moisture content and treatment to prevent issues like warping or pest infestation. Cost considerations are significant for buyers in Africa and South America, where softwoods are often more accessible and affordable.

3. Engineered Wood (e.g., Plywood, MDF)

Engineered woods combine layers of wood veneer or fibers bonded with adhesives to produce a stable, uniform material. Plywood is especially common due to its strength and resistance to warping, while MDF offers a smooth surface that is easy to finish.

Illustrative Image (Source: Google Search)

Pros & Cons:

– Pros: Consistent quality, high stability, often more affordable than solid hardwoods, and customizable sizes.

– Cons: Limited natural aesthetic appeal, potential issues with adhesives (off-gassing), and lower resistance to moisture unless specially treated.

Impact on Application:

Engineered woods are suitable for mass-produced, decorative, or indoor wooden shoes. They may not be ideal for outdoor use unless treated with water-resistant coatings. They are also beneficial for lightweight designs.

International Buyer Considerations:

Buyers should verify the type of adhesives used, especially in regions with strict VOC regulations (e.g., EU REACH standards). For African and South American markets, sourcing from suppliers compliant with local environmental standards is crucial. Certification such as CARB Phase 2 or FSC for plywood can enhance market acceptance.

4. Bamboo (Technically a Grass, Used as a Wood Substitute)

Bamboo has gained popularity as a sustainable alternative to traditional woods. It offers high strength-to-weight ratio, rapid renewability, and unique aesthetic appeal.

Pros & Cons:

– Pros: Eco-friendly, lightweight, high tensile strength, and fast-growing.

– Cons: Limited availability in some regions, variable quality depending on processing, and potential challenges in machining.

Impact on Application:

Bamboo is suitable for eco-conscious markets and lightweight footwear designs. It performs well in indoor applications but may require treatment for outdoor durability.

International Buyer Considerations:

Buyers from Europe and the Middle East with sustainability mandates favor bamboo products with clear FSC or equivalent certification. In Africa and South America, sourcing reliable suppliers with consistent quality and compliance with local standards (e.g., ISPM 15 for treatment) is essential.

Summary Table

| Material | Typical Use Case for wooden shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Hardwood | Heavy-duty outdoor and indoor footwear, long-lasting shoes | High durability, aesthetic appeal, good wear resistance | Higher cost, heavier weight, longer processing time | High |

| Softwood | Indoor, decorative, or lightweight footwear | Cost-effective, lightweight, easy to work with | Lower durability, susceptible to dents and scratches | Low |

| Engineered Wood | Mass-produced indoor shoes, decorative designs | Consistent quality, stable, cost-efficient | Less natural appearance, moisture sensitivity | Med |

| Bamboo | Eco-friendly, lightweight shoes, especially for sustainable markets | Fast-growing, sustainable, high strength-to-weight ratio | Limited regional availability, variable quality | Med |

This comprehensive analysis provides international B2B buyers with clear insights into material selection, emphasizing compliance, cost considerations, and application suitability across diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for wooden shoes

Manufacturing Processes for Wooden Shoes

The production of high-quality wooden shoes involves a series of meticulously coordinated stages, each critical to ensuring durability, comfort, and aesthetic appeal. For international B2B buyers, understanding these processes facilitates better supplier evaluation and quality control.

Material Preparation

The process begins with selecting suitable raw materials, predominantly hardwoods like beech, oak, or maple, chosen for their strength, density, and workability. Suppliers often source these from sustainably managed forests, aligning with environmental standards relevant to European and other global markets. The wood is then dried using kiln or air-drying techniques to achieve optimal moisture content, typically around 8-12%, reducing warping and splitting during subsequent processing.

Forming and Shaping

Once prepared, the wood undergoes cutting and shaping using CNC machines or traditional hand tools, depending on the manufacturer’s scale and craftsmanship level. The sole and upper components are carved out with precision to ensure proper fit and comfort. Innovative techniques, such as steam bending, may be employed to shape curved elements without compromising structural integrity. For mass production, automation ensures consistency and efficiency.

Assembly and Joinery

Assembly involves joining various components—such as the sole, upper, and decorative elements—using traditional methods like dowel joints, or modern adhesives that comply with safety standards. Some manufacturers incorporate metal or leather reinforcements for added durability. This stage often includes pressing or clamping to ensure tight bonds, followed by curing periods to solidify adhesives.

Finishing Processes

The finishing phase enhances aesthetic appeal and functional durability. Techniques include sanding, polishing, and applying protective coatings such as natural oils, lacquers, or eco-friendly varnishes. Custom decorative elements—paint, carvings, or inlays—are added at this stage. Finally, the shoes are inspected for defects, and any necessary touch-ups are performed before packaging.

Quality Assurance Protocols for Wooden Shoe Manufacturing

Robust quality assurance (QA) measures are essential to meet international standards and satisfy B2B buyers’ expectations, especially when dealing with markets that have specific regulatory requirements.

International Standards and Certifications

Most reputable manufacturers adhere to ISO 9001 standards, which specify requirements for a quality management system focusing on customer satisfaction and continuous improvement. For products destined for the European market, compliance with CE marking is crucial, indicating conformity with safety, health, and environmental protection directives. Manufacturers aiming for North American markets might seek API or other industry-specific certifications, especially if the shoes are used in specialized contexts.

Key Inspection Points

- Incoming Quality Control (IQC): Raw materials are inspected for defects, moisture content, and consistency. Suppliers should provide material test reports verifying compliance with specifications.

- In-Process Quality Control (IPQC): During manufacturing, checkpoints are established for dimensional accuracy, joint strength, and surface quality. Use of gauges, calipers, and non-destructive testing methods ensures ongoing compliance.

- Final Quality Control (FQC): Before shipment, finished shoes undergo comprehensive inspection for visual defects, structural integrity, and finishing quality. Random sampling and detailed reports are standard.

Testing Methods

- Mechanical Tests: Assess joint strength, impact resistance, and load-bearing capacity using standardized test rigs.

- Visual and Dimensional Inspection: Ensure uniformity, absence of cracks, splinters, or surface blemishes.

- Environmental Testing: Evaluate resistance to moisture, temperature fluctuations, and UV exposure—particularly relevant for outdoor or climate-sensitive markets.

- Safety Tests: Check for sharp edges, protrusions, or hazardous substances, aligning with European REACH regulations and other regional standards.

How B2B Buyers Can Verify Supplier Quality

Effective verification extends beyond supplier claims and requires diligent due diligence.

- Audits and Factory Visits: Conduct comprehensive audits focusing on manufacturing processes, quality management systems, and working conditions. European buyers often leverage third-party inspection firms or certification bodies to facilitate these visits.

- Review of Quality Documentation: Request detailed quality reports, test certificates, and batch traceability records. Suppliers should provide documented evidence of compliance with relevant standards.

- Third-Party Inspection Services: Engage independent inspection agencies (e.g., SGS, Bureau Veritas) to perform pre-shipment inspections, ensuring adherence to agreed specifications.

- Sample Testing: Procure samples for independent testing against international standards before placing large orders.

- Certifications and Compliance Proofs: Verify authenticity of certifications like ISO 9001, CE, or other relevant industry standards through issuing bodies or certification databases.

Nuances for International B2B Buyers from Africa, South America, the Middle East, and Europe

Different regions have unique regulatory landscapes and market expectations that influence manufacturing and QC practices.

- Africa and South America: Buyers should prioritize suppliers with transparent traceability and compliance with environmental standards such as FSC or PEFC certifications. Due to variable regulatory enforcement, third-party audits are often essential to verify quality claims.

- Middle East: Market-specific standards, including Gulf Standards (GSO), may necessitate additional testing for safety and durability. Suppliers with ISO 9001 and CE certifications are generally preferred.

- Europe (e.g., France, Spain): Strict adherence to EU directives on product safety, chemical substances (REACH), and environmental sustainability is mandatory. Buyers should seek suppliers with documented compliance and regularly updated certifications. Local or regional certification bodies can assist in verifying supplier claims.

Final Recommendations for B2B Buyers

- Build long-term relationships with suppliers who demonstrate transparency in their manufacturing and QC processes.

- Specify detailed quality requirements in purchase agreements, including reference standards and testing protocols.

- Regularly audit and verify supplier claims, especially when entering new markets or working with unfamiliar manufacturers.

- Leverage third-party inspection and certification services to mitigate risks associated with quality and compliance.

- Stay informed about regional regulatory changes and industry standards to ensure ongoing compliance and product acceptance.

By understanding the intricacies of manufacturing and quality assurance for wooden shoes, international B2B buyers can make informed procurement decisions, ensure product consistency, and foster mutually beneficial partnerships across diverse markets.

Illustrative Image (Source: Google Search)

Comprehensive Cost and Pricing Analysis for wooden shoes Sourcing

Cost Structure Breakdown for Wooden Shoes

Understanding the comprehensive cost components involved in sourcing wooden shoes is essential for effective negotiation and pricing strategy. The primary cost drivers include:

- Materials: The quality and type of wood (e.g., beech, maple, or exotic hardwoods) significantly influence costs. Typically, raw material costs range from $2 to $8 per pair, depending on wood quality and sourcing region.

- Labor: Skilled craftsmanship is crucial, especially for hand-crafted or artisanal shoes. Labor costs can vary widely—ranging from $1 to $5 per pair—based on the country of production and complexity of design.

- Manufacturing Overheads: These encompass factory utilities, machinery maintenance, and wages for supporting staff, generally adding 10-20% to the direct manufacturing costs.

- Tooling & Setup: Initial mold creation and tooling can be a one-time expense, often ranging from $500 to $2,000 for small to medium runs. This cost is amortized over the production volume.

- Quality Control: Ensuring consistent quality through inspection adds approximately $0.50 to $2 per pair, depending on standards and certification requirements.

- Logistics & Shipping: Freight costs depend on order volume, destination, and shipping mode. For example, sea freight from Asia to Europe might range from $500 to $1,500 per container, influencing per-unit logistics costs.

- Profit Margin: Typically, suppliers aim for a gross margin of 10-30%, depending on market competitiveness and order size.

Price Influencers and Their Impact

Several factors can significantly influence the final price of wooden shoes:

- Order Volume & MOQ: Larger orders usually benefit from lower unit costs due to economies of scale. Minimum order quantities (MOQs) may range from 100 to 1,000 pairs, with prices decreasing as volume increases.

- Customization & Specifications: Custom designs, branding, or specific features (e.g., waterproofing, special finishes) can add 10-30% to the base price. Clear specifications upfront help prevent unexpected costs.

- Material Choice: Exotic or sustainably sourced woods tend to be more expensive, sometimes adding 20-50% to the material costs.

- Quality Certifications: Standards like FSC or ISO certification can justify higher prices, especially when targeting premium markets in Europe or the Middle East.

- Supplier Factors: The supplier’s location, reputation, and production capacity influence pricing. Suppliers from regions with lower labor costs (e.g., Southeast Asia, North Africa) often offer more competitive prices.

- Incoterms & Shipping Terms: FOB (Free on Board) or CIF (Cost, Insurance, Freight) terms affect how costs are distributed. Buyers should evaluate whether they prefer to manage logistics or include it in the supplier’s quote.

Strategic Tips for International Buyers

- Negotiate for Better Terms: Leverage volume commitments to negotiate lower unit prices or favorable payment terms. Establishing long-term relationships can lead to discounts and priority service.

- Focus on Total Cost of Ownership: Beyond unit price, consider logistics, customs duties, tariffs, and potential storage costs. For instance, importing into France or Spain may involve VAT and import duties, impacting overall profitability.

- Request Detailed Quotes & Samples: Ensure transparency by requesting itemized quotes that specify all cost components. Testing samples can prevent costly rework or quality issues post-shipment.

- Understand Pricing Nuances: Be aware that prices may fluctuate seasonally, with raw material availability or currency exchange rates influencing costs. Always factor in buffer margins for price volatility.

- Customization & Certification Premiums: When targeting niche markets or premium segments, factor in the added costs for higher-quality materials and certifications, which can be pivotal for market acceptance.

Indicative Price Range (Disclaimer)

For standard, non-customized wooden shoes, prices generally fall within $10 to $25 per pair at the factory gate, depending on volume and quality. Premium or highly customized models may range from $30 to $50+ per pair. These figures are indicative and can vary based on regional factors, supplier negotiations, and specific project requirements.

This detailed analysis aims to equip B2B buyers with the insights needed to effectively evaluate costs, negotiate better deals, and optimize their total investment in wooden shoe sourcing across diverse markets.

Spotlight on Potential wooden shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for wooden shoes.)*

Essential Technical Properties and Trade Terminology for wooden shoes

Critical Technical Properties of Wooden Shoes

Understanding key technical specifications is vital for international buyers to ensure product quality, compliance, and durability. Below are the most critical properties to consider:

1. Material Grade and Type

The primary material for wooden shoes is typically hardwoods such as oak, beech, or maple. The grade indicates the quality and uniformity of the wood, affecting the shoe’s strength, appearance, and longevity. Higher-grade materials usually have fewer knots, cracks, or defects, which is essential for premium or export markets. Confirm the material grade aligns with your end-use requirements, whether for traditional craftsmanship or industrial applications.

2. Dimensions and Tolerance

Precise measurements of length, width, and thickness are crucial, especially when fitting or ergonomic design is prioritized. Tolerance levels specify acceptable deviations from nominal dimensions, ensuring consistent quality across batches. Tight tolerances reduce the risk of mismatched parts or assembly issues, which is vital for large-scale procurement or custom orders.

3. Finish and Surface Quality

The surface finish impacts both aesthetics and safety. A smooth, well-finished surface minimizes splinters and improves comfort. It also influences how easily the shoes can be painted or decorated if required. Clear specifications on surface roughness and finishing processes help prevent misunderstandings during quality inspections.

4. Load-Bearing and Structural Integrity

Strength properties such as modulus of rupture and impact resistance determine how well the shoes withstand daily use and heavy loads. For industrial or work-related wooden shoes, these properties ensure safety and durability. Manufacturers should provide test reports confirming compliance with relevant standards.

5. Moisture Content and Treatment

Wooden shoes must have a controlled moisture content (typically between 8-12%) to prevent warping, cracking, or mold growth during transportation and use. Some products undergo chemical or thermal treatments for enhanced durability or pest resistance, which should be clearly specified and compliant with importing country regulations.

6. Weight and Density

The weight influences shipping costs and user comfort. Denser woods tend to be stronger but heavier, whereas lighter woods may be more comfortable but less durable. Clarifying the density range helps buyers assess suitability for specific applications, whether for fashion, safety, or utility.

Essential Trade Terms for Wooden Shoe Transactions

Familiarity with industry jargon streamlines negotiations and ensures clarity in communication. Here are the most relevant trade terms:

1. OEM (Original Equipment Manufacturer)

Refers to factories producing wooden shoes under a buyer’s brand or specifications. Understanding OEM capabilities helps buyers customize products, negotiate branding rights, and assess manufacturing capacity for large orders.

2. MOQ (Minimum Order Quantity)

The smallest quantity a manufacturer is willing to produce per order. Knowing MOQ levels helps buyers plan procurement strategies, especially when entering new markets or testing product acceptance. It also influences pricing and inventory planning.

3. RFQ (Request for Quotation)

A formal process where buyers solicit price proposals, technical details, and delivery timelines from multiple suppliers. Sending a detailed RFQ ensures competitive pricing and clear communication of specifications, reducing the risk of misunderstandings.

4. Incoterms (International Commercial Terms)

Standardized trade terms published by the ICC that define responsibilities for shipping, insurance, and tariffs. Common Incoterms like FOB (Free On Board) or CIF (Cost, Insurance, Freight) specify who bears costs and risks at each stage of transportation, vital for international logistics planning.

5. Lead Time

The period from order placement to product delivery. Accurate knowledge of lead times enables better supply chain management, especially for seasonal or large-volume orders. Confirming lead times upfront reduces delays and stockouts.

6. Quality Certification

Documents such as CE, ISO, or FSC certifications verify compliance with safety, environmental, or sustainability standards. For international markets, especially in Europe and the Middle East, certification can facilitate customs clearance and enhance product credibility.

Actionable Insights for B2B Buyers

- Always specify material grades and tolerances explicitly in purchase agreements to avoid quality issues.

- Clarify Incoterms and lead times early to align logistics and reduce delays.

- Use RFQs to compare multiple suppliers and negotiate better terms, especially when entering new markets.

- Confirm certification requirements based on target markets to ensure compliance and smooth customs clearance.

- Understand MOQ and weight considerations to optimize inventory levels and shipping costs.

By mastering these technical properties and trade terms, international buyers can make informed decisions, mitigate risks, and establish strong, transparent supplier relationships in the wooden shoe industry.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the wooden shoes Sector

Market Overview & Key Trends

The global wooden shoes market is experiencing notable shifts driven by evolving consumer preferences, technological advancements, and increasing emphasis on sustainability. Traditionally rooted in European craftsmanship, especially in countries like France and Spain, the sector is now expanding through innovative manufacturing techniques and diversified sourcing strategies. Emerging B2B trends include the adoption of digital platforms for procurement, enabling international buyers from Africa, South America, and the Middle East to access a broader range of suppliers with greater transparency.

Market dynamics are influenced by a rising demand for eco-friendly and ethically sourced footwear, particularly in Europe where consumers and regulators prioritize sustainability. Additionally, the development of specialized materials—such as sustainably harvested wood and biodegradable finishes—enhances product appeal. For international B2B buyers, understanding regional sourcing hubs is crucial: European countries often lead in quality and craftsmanship, while emerging markets in South America and Africa provide cost-effective manufacturing options with increasing adherence to sustainability standards.

Technological integration, including 3D modeling and supply chain management software, streamlines production and logistics, making it easier for buyers to coordinate large orders efficiently. The COVID-19 pandemic accelerated digital adoption, prompting many suppliers to establish online marketplaces and virtual showrooms, which facilitate transparent, real-time negotiations. As global markets become more interconnected, buyers should also monitor geopolitical factors, trade policies, and tariffs that can influence sourcing costs and lead times.

In conclusion, for B2B buyers from diverse regions, success hinges on leveraging digital sourcing tools, understanding regional strengths, and aligning procurement strategies with global sustainability trends. Building relationships with certified, environmentally responsible suppliers will be increasingly vital in maintaining competitive advantage and ensuring compliance with evolving regulations.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer optional in the wooden shoes industry; it is a core criterion shaping procurement decisions across Europe, the Middle East, Africa, and South America. Environmental considerations include responsible forestry practices, reduction of carbon footprints, and the use of renewable or biodegradable materials. Buyers should prioritize suppliers with credible environmental certifications such as FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification), which verify sustainable harvesting and responsible land management.

Ethical sourcing extends beyond environmental impact, encompassing fair labor practices, transparent supply chains, and community engagement. For B2B buyers, establishing partnerships with suppliers who adhere to international labor standards—such as Fair Trade or SA8000—is essential for mitigating reputational risks and ensuring product integrity. Traceability is increasingly important; digital tools like blockchain can enhance transparency by providing verifiable records of sourcing origins.

Incorporating ‘green’ certifications and eco-labels into procurement criteria not only aligns with global sustainability goals but also appeals to environmentally conscious markets, especially in Europe and parts of the Middle East. Additionally, sourcing from suppliers committed to reducing waste, utilizing eco-friendly finishes, and implementing energy-efficient manufacturing processes demonstrates a genuine commitment to sustainability.

For international buyers, fostering long-term relationships with certified suppliers can lead to better pricing, priority access to new eco-friendly products, and shared innovation in sustainable design. Investing in supplier education and capacity building around sustainability practices can further strengthen supply chain resilience and compliance.

Brief Evolution/History (Optional)

Historically, wooden shoes—clogs—originated as practical footwear in rural Europe, notably in regions like the Netherlands, France, and Spain. Their design prioritized durability and protection for agricultural and industrial workers. Over centuries, craftsmanship evolved, integrating regional aesthetics and craftsmanship techniques. Today, the industry balances tradition with innovation, embracing sustainable materials and modern manufacturing methods. This historical evolution informs the current emphasis on quality, authenticity, and environmental responsibility—key considerations for B2B buyers seeking reliable, culturally authentic, and sustainable products in an increasingly conscious marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of wooden shoes

1. How can I effectively vet wooden shoe suppliers to ensure product quality and reliability?

Vetting international suppliers begins with comprehensive due diligence. Start by requesting certifications such as ISO, FSC, or CE to verify compliance with safety and environmental standards. Review their company background, including years in operation, production capacity, and client references. Conduct virtual factory audits or visit in person if feasible, focusing on manufacturing processes, quality control measures, and labor practices. Utilize third-party inspection services for quality audits before shipment. Establish clear communication channels and request samples to assess craftsmanship, materials, and finishing. Building a strong, transparent relationship reduces risks and ensures consistent product quality.

2. What customization options are typically available for wooden shoes, and how do they impact MOQ and lead times?

Suppliers often offer customization in terms of size, color, engraving, branding, and design details. Advanced customization, such as personalized carvings or specific wood types, may require higher MOQs and longer lead times due to setup and tooling. Standard customizations usually have lower MOQs (sometimes as low as 50-100 pairs) and quicker turnaround (2-4 weeks). For large orders or complex designs, negotiate lead times upfront and consider sample development to ensure alignment with your specifications. Clearly communicate your customization needs early to avoid delays and ensure the supplier can meet your quality and quantity expectations.

3. What are typical MOQs, lead times, and payment terms for international B2B orders of wooden shoes?

Most suppliers set MOQs between 50 to 500 pairs, depending on the complexity and customization level. Lead times generally range from 2 to 8 weeks, influenced by order size, production capacity, and customization. Common payment terms include a 30% deposit upfront with the balance payable before shipment, or letters of credit for larger transactions. Some suppliers may offer flexible terms for repeat or bulk orders. Always negotiate payment conditions that mitigate risk, such as escrow services or partial payments upon milestones. Confirm all terms in a detailed contract to avoid misunderstandings.

4. What quality assurance certifications and standards should I look for when sourcing wooden shoes internationally?

Key certifications include ISO 9001 for quality management, FSC for sustainable wood sourcing, and CE marking for safety standards in Europe. These certifications ensure compliance with environmental, safety, and quality norms. Additionally, ask for test reports on durability, slip resistance, and non-toxicity of finishes and dyes. For European markets, compliance with REACH regulations is crucial. Verify that suppliers regularly conduct quality control inspections and provide documentation. Working with certified suppliers reduces risk of product recalls, legal issues, and ensures your products meet the standards of your target markets.

5. How should I manage logistics and shipping when importing wooden shoes from overseas suppliers?

Start by selecting reliable freight forwarders experienced in handling wooden footwear, considering sea freight for cost efficiency or air freight for urgent deliveries. Clarify incoterms (e.g., FOB, CIF) to define responsibility for shipping costs and risks. Ensure proper packaging to prevent damage during transit, especially for delicate or intricately designed shoes. Understand customs clearance procedures in your country, including duties, taxes, and import restrictions. Coordinate with suppliers for timely documentation such as invoices, packing lists, and certificates. Establish a tracking system to monitor shipments and plan inventory accordingly, minimizing delays and stockouts.

6. How do I handle disputes or quality issues with overseas wooden shoe suppliers?

Establish clear contractual terms outlining quality standards, inspection procedures, and dispute resolution mechanisms before placing orders. Conduct pre-shipment inspections or third-party audits to catch issues early. If problems arise, communicate promptly and document discrepancies with photographs and detailed reports. Negotiate amicably for corrective actions, such as replacements or refunds, according to your contract terms. Consider including arbitration clauses or choosing dispute resolution centers familiar with international trade. Building a collaborative relationship and maintaining open communication often leads to quicker resolutions and long-term partnerships, reducing the risk of recurring issues.

7. What are best practices for ensuring sustainable and eco-friendly sourcing of wooden shoes?

Prioritize suppliers with FSC or PEFC certification, confirming responsible forest management and sustainable harvesting. Request transparency in the supply chain, including sourcing regions and environmental practices. Opt for suppliers who use eco-friendly finishes, dyes, and adhesives that comply with REACH or similar regulations. Incorporate sustainability criteria into your supplier evaluation process and consider audits focused on environmental impact. Promoting eco-conscious sourcing not only aligns with global trends but also enhances your brand’s reputation and appeals to environmentally aware customers in Europe, Africa, and beyond.

8. How can I build long-term relationships with reliable wooden shoe suppliers across different regions?

Develop clear communication channels and maintain regular contact through virtual meetings and site visits when possible. Negotiate mutually beneficial terms that accommodate regional differences in business practices. Establish trust by paying on time and providing constructive feedback. Consider partnering with suppliers for joint product development or sustainability initiatives, fostering collaboration. Attend international trade shows and industry fairs to identify new partners and stay informed about market trends. Building a diverse supplier network mitigates risks, ensures supply chain resilience, and allows for flexibility in meeting evolving market demands across Africa, South America, the Middle East, and Europe.

Strategic Sourcing Conclusion and Outlook for wooden shoes

Final Thoughts on Strategic Sourcing for Wooden Shoes

Effective strategic sourcing is vital for international B2B buyers seeking to capitalize on the unique opportunities within the wooden shoe market. By prioritizing quality craftsmanship, sustainable sourcing practices, and reliable supply chain partnerships, buyers can secure products that meet both market demand and environmental standards. Diversifying sourcing regions—such as exploring suppliers in Europe, South America, Africa, and the Middle East—can mitigate risks and optimize cost efficiencies.

For buyers in France, Spain, and broader European markets, establishing close collaborations with experienced artisans and manufacturers offers the dual benefit of authenticity and innovation. Meanwhile, emerging markets in Africa, South America, and the Middle East present significant growth potential, provided that due diligence and supplier vetting are thorough.

Looking ahead, the wooden shoe industry is poised for sustainable growth driven by increasing consumer awareness of eco-friendly products and cultural heritage preservation. B2B buyers should adopt a proactive, strategic approach—leveraging market insights and fostering long-term partnerships—to stay ahead of evolving trends and secure a competitive edge in this niche yet expanding market.