Your Ultimate Guide to Sourcing Black Shoe Polish

Guide to Black Shoe Polish

- Introduction: Navigating the Global Market for black shoe polish

- Understanding black shoe polish Types and Variations

- Key Industrial Applications of black shoe polish

- Strategic Material Selection Guide for black shoe polish

- In-depth Look: Manufacturing Processes and Quality Assurance for black shoe polish

- Comprehensive Cost and Pricing Analysis for black shoe polish Sourcing

- Spotlight on Potential black shoe polish Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for black shoe polish

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the black shoe polish Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of black shoe polish

- Strategic Sourcing Conclusion and Outlook for black shoe polish

Introduction: Navigating the Global Market for black shoe polish

In the competitive landscape of footwear and leather care, black shoe polish remains an essential product for maintaining professional appearance, extending the lifespan of footwear, and reinforcing brand image. For international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe—including key markets like Brazil and Australia—understanding the nuances of this market is vital for strategic sourcing and inventory management. The global demand for high-quality, cost-effective black shoe polish continues to grow, driven by sectors such as hospitality, corporate uniform providers, and retail footwear chains.

This comprehensive guide aims to equip you with critical insights into the black shoe polish industry—from the various types and formulations to manufacturing standards, quality control, and supplier landscapes. It also covers cost considerations, market trends, and frequently asked questions, enabling you to make informed purchasing decisions that align with your operational needs and quality expectations. Whether you’re sourcing from established suppliers or exploring emerging markets, understanding these key factors will help mitigate risks, optimize procurement strategies, and secure reliable supply chains.

By leveraging this knowledge, B2B buyers can navigate complex international markets with confidence, ensuring they select the right products at the right price points. Ultimately, this guide empowers you to build resilient, efficient sourcing frameworks that support your business growth in a globalized economy.

Understanding black shoe polish Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cream Polish | Thick, wax-based, often with added oils; easy to apply and buff for shine | Shoe repair shops, retail suppliers, corporate uniform providers | Pros: Easy application, good for quick shine; Cons: Less durable, requires frequent reapplication |

| Paste Polish | Dense, concentrated wax formula; offers high gloss finish | Shoe manufacturers, professional cobblers | Pros: Long-lasting, excellent shine; Cons: Slightly more effort to apply, needs polishing tools |

| Liquid/Fluid Polish | Thin, liquid formulation; quick-drying and easy to spread | Large-scale distributors, maintenance services | Pros: Fast application, suitable for bulk use; Cons: Less durable, may require multiple coats for durability |

| Wax-Based Polish | Solid or semi-solid wax; provides a protective layer and shine | Custom brands, premium shoe care lines | Pros: Superior protection and shine; Cons: More time-consuming application process |

| Conditioning/Restorative Polish | Enriched with conditioners and oils; restores and nourishes leather | Shoe refurbishers, repair centers, luxury brands | Pros: Restores old or damaged leather; Cons: Higher cost, needs careful handling to avoid over-conditioning |

Cream Polish

Cream polish is characterized by its thick, wax-based consistency combined with oils and sometimes pigments for color matching. It is favored for its ease of application and ability to quickly produce a moderate shine. Suitable for shoe repair shops, retail suppliers, and companies providing uniform services, cream polish is ideal for regular maintenance routines. B2B buyers should consider its limited durability—requiring frequent reapplication—when sourcing for high-volume or long-term use. Its affordability and ease of use make it a practical choice for quick turnaround operations, but premium markets may prefer more durable options.

Paste Polish

Paste polish is a dense, concentrated wax formulation that delivers a high-gloss finish and durable protection. It is often preferred by professional cobblers and shoe manufacturers for its longevity and superior shine. For B2B buyers, paste polish offers value through its long-lasting effects, reducing the frequency of reapplication. However, it demands more effort and proper tools during application, which may impact labor costs. When sourcing, buyers should evaluate the compatibility with different leather types and consider the packaging size for bulk orders to optimize logistics and cost efficiency.

Liquid/Fluid Polish

This type features a thin, liquid formulation that dries quickly and is easy to spread across large quantities of footwear. It is especially suitable for bulk applications, such as maintenance services for airlines, hotels, or large corporations with extensive shoe fleets. Liquid polishes are valued for their fast application process, enabling quick turnaround times. However, they tend to be less durable than wax or paste types, often requiring multiple coats for sufficient protection. B2B buyers should focus on sourcing from reputable manufacturers to ensure consistent quality, especially when used in high-volume settings.

Wax-Based Polish

Wax-based polish combines solid or semi-solid waxes with other ingredients to form a protective layer on leather surfaces. It provides a high-gloss finish and superior protection against moisture and scuffs. Premium brands and luxury shoe care lines prefer this type for its aesthetic and protective qualities. For bulk procurement, buyers should assess the wax composition, packaging options, and shelf life. While offering excellent durability and shine, wax-based polishes require more time and effort to apply properly, which should be factored into operational planning.

Conditioning/Restorative Polish

This variation is enriched with conditioners, oils, and sometimes dyes to restore and nourish aged or damaged leather. It is ideal for refurbishing shoes in repair centers or for premium brands maintaining high-quality standards. B2B buyers need to consider the higher cost and ensure proper handling during application to avoid over-conditioning, which can damage leather. Sourcing from reliable suppliers with consistent formulations is crucial to maintain quality standards, especially when used for restoring valuable or antique footwear. This type offers a strategic advantage in markets emphasizing leather preservation and luxury branding.

Key Industrial Applications of black shoe polish

| Industry/Sector | Specific Application of black shoe polish | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality & Tourism | Polishing uniforms and footwear of hotel staff and service personnel | Enhances professional appearance, maintains brand standards, boosts guest confidence | Consistent quality, easy application, long-lasting shine, and reliable supply chains |

| Defense & Security | Maintenance of military and security personnel footwear | Ensures uniformity, durability, and a polished appearance in operational environments | Compatibility with rugged footwear, weather resistance, and compliance with military standards |

| Fashion & Retail | Shoe care products for high-end footwear collections | Adds value to luxury products, supports brand reputation, and offers after-sales care | Premium formulation, branding potential, and supply consistency for retail outlets |

| Transport & Aviation | Maintenance of crew uniforms and footwear | Preserves professional image, reduces wear and tear, and supports safety protocols | Compatibility with diverse materials, quick drying, and minimal residue |

| Manufacturing & Customization | Custom shoe polishing solutions for corporate branding | Provides a uniform corporate look, supports branding efforts, and enhances employee presentation | Customizable formulations, bulk sourcing options, and compliance with safety standards |

Hospitality & Tourism

Black shoe polish plays a vital role in the hospitality industry by maintaining the impeccable appearance of uniforms for hotel staff, waitstaff, and service personnel. For international B2B buyers, sourcing high-quality polish ensures consistent shine and ease of application, which directly impacts guest perceptions and brand reputation. Suppliers must prioritize formulations that deliver a long-lasting, high-gloss finish while being easy to apply across large volumes, especially in regions with varying climatic conditions such as Africa and South America.

Defense & Security

In the defense sector, black shoe polish is crucial for maintaining the disciplined, uniform appearance of military and security personnel. The polish must adhere well to different footwear materials, withstand harsh environmental conditions, and provide a durable shine that endures wear and weather. International buyers from regions like the Middle East and Europe should seek products with proven weather resistance and compliance with military standards to ensure reliability in operational settings.

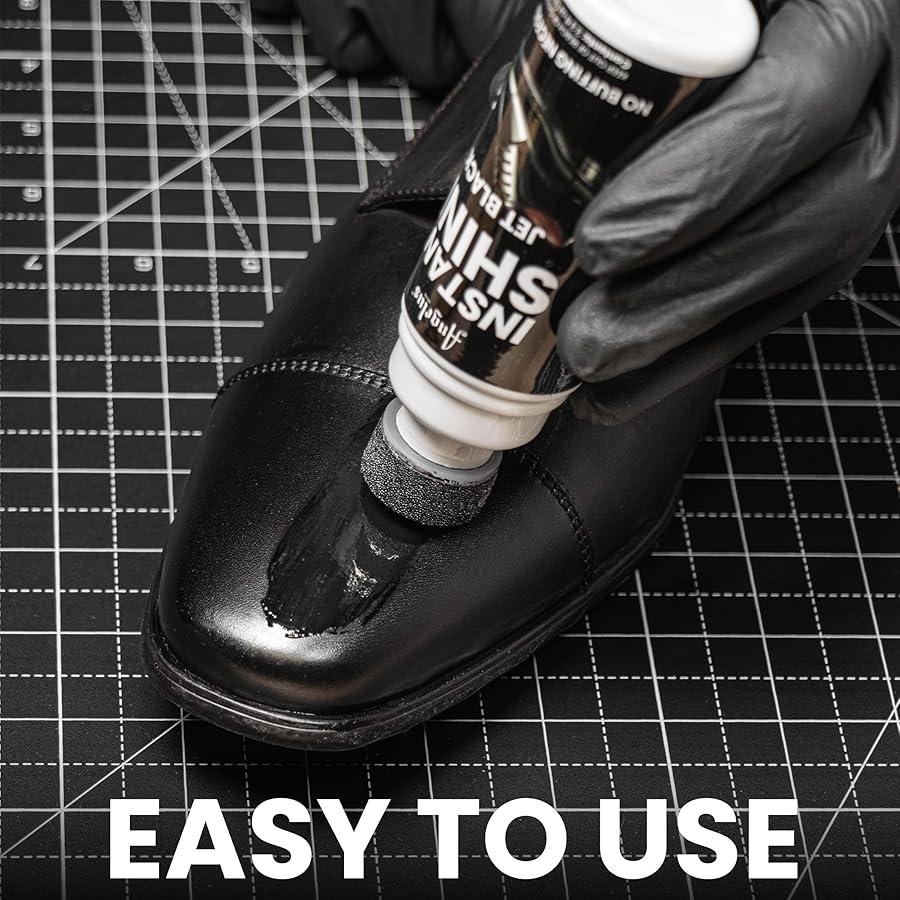

Illustrative Image (Source: Google Search)

Fashion & Retail

Luxury footwear brands and retail outlets utilize black shoe polish as part of their after-sales care offerings, reinforcing their premium image. For B2B buyers, sourcing high-quality, aesthetically appealing polishes supports product value and customer satisfaction. Emphasizing formulations that provide a deep, glossy finish and are compatible with high-end leather enhances brand reputation. Consistent supply and branding potential are key for retail chains across diverse markets, including Australia and South America.

Transport & Aviation

In the transport and aviation industries, black shoe polish helps maintain a professional, polished appearance for crew uniforms and footwear. The polish must be quick-drying, residue-free, and compatible with various shoe materials, including leather and synthetic composites. For international buyers, especially in regions with high humidity or temperature variations, sourcing products that perform reliably under diverse conditions minimizes maintenance downtime and preserves safety standards.

Manufacturing & Customization

Some industries require customized shoe polishing solutions for corporate branding or specialized footwear. These products can be tailored in color, branding, and formulation to meet specific client needs. B2B buyers should focus on sourcing suppliers capable of providing large-volume, customizable options that comply with safety and environmental standards, ensuring a consistent and professional corporate appearance across regions like Europe and Africa.

Strategic Material Selection Guide for black shoe polish

Material Analysis for Black Shoe Polish

In developing high-quality black shoe polish, selecting the appropriate raw materials is crucial for ensuring product performance, durability, and compliance with international standards. Below is an in-depth analysis of three common materials used in black shoe polish formulations from a B2B perspective, focusing on their key properties, advantages, limitations, and considerations for international buyers across Africa, South America, the Middle East, and Europe.

1. Wax (Beeswax and Carnauba Wax)

Key Properties:

Wax components like beeswax and carnauba wax serve as primary film-forming agents, providing shine and water resistance. Beeswax offers moderate melting points (~62-64°C), while carnauba wax has a higher melting point (~82-86°C) and excellent hardness.

Pros & Cons:

– Pros: Natural, biodegradable, excellent water repellency, and high gloss finish. Carnauba wax is highly durable and resistant to UV degradation, making it suitable for outdoor use.

– Cons: Costlier than synthetic alternatives, especially carnauba wax, and can be challenging to process uniformly due to high melting points. Beeswax may have limited hardness, affecting longevity.

Impact on Application:

Wax compatibility influences the polish’s ease of spreading and buffing. High-quality waxes improve durability but require precise temperature control during manufacturing to avoid defects.

International Considerations:

For buyers in regions like Brazil (a major source of carnauba wax), sourcing quality waxes can be cost-effective but requires verification of purity and sustainability certifications. In Europe and the Middle East, compliance with environmental standards (e.g., REACH) is essential. Wax suppliers should provide documentation on origin, processing, and eco-certifications.

2. Petroleum-Based Oils (Mineral Oil, Paraffin Oil)

Key Properties:

These oils act as carriers and moisturizers, aiding in application and enhancing flexibility. Mineral oils are inert, stable, and have a broad temperature tolerance (-20°C to 150°C).

Pros & Cons:

– Pros: Cost-effective, readily available, and improve the ease of application. They also help in maintaining the leather’s suppleness.

– Cons: Potential environmental concerns regarding non-biodegradability, and some oils may cause discoloration or staining if not properly refined. Overuse can lead to buildup, affecting breathability.

Impact on Application:

Petroleum oils improve spreadability but must be carefully balanced to avoid excessive buildup, especially important for high-end or delicate leather products.

International Considerations:

Buyers from regions with strict environmental regulations (e.g., Europe, Australia) should verify that oils meet standards like ASTM D-4814 for petroleum products. Sourcing from suppliers with ISO 9001 and ISO 14001 certifications ensures consistent quality and environmental compliance.

3. Pigments (Carbon Black)

Key Properties:

Carbon black provides the characteristic black coloration. It is a fine particulate with high tinting strength, UV resistance, and stability.

Pros & Cons:

– Pros: Cost-effective, provides deep, uniform black color, and enhances UV stability.

– Cons: Fine particles can pose inhalation hazards during manufacturing, requiring proper handling and PPE. Excessive use can affect flexibility and adhesion.

Impact on Application:

The quality and particle size of carbon black influence the polish’s color depth and uniformity. High-quality pigments ensure consistent color and longevity.

International Considerations:

Regulatory standards such as REACH (Europe), TSCA (US), and local safety regulations in Africa and South America necessitate sourcing carbon black from suppliers compliant with safety and environmental standards. Transparency in supply chain and certification (e.g., ISO 9001) is crucial for quality assurance.

Summary Table of Material Selection

| Material | Typical Use Case for black shoe polish | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Beeswax / Carnauba Wax | Film formation, water resistance, gloss | Natural, biodegradable, UV resistant | Costly (especially carnauba), processing challenges | Med/High |

| Petroleum-Based Oils | Carrier, moisturization, flexibility | Cost-effective, stable, enhances application | Environmental concerns, potential staining | Low |

| Carbon Black | Coloring, UV protection | Deep black color, UV stability | Handling hazards, potential for color inconsistency | Low |

Final Remarks for International B2B Buyers

When sourcing raw materials for black shoe polish, buyers should prioritize suppliers with robust quality assurance, environmental compliance, and traceability. For regions like Africa, South America, and the Middle East, local sourcing of certain materials (e.g., waxes, pigments) can reduce costs and lead times, but verification of quality standards remains critical. European and Australian buyers should emphasize adherence to strict environmental and safety standards, demanding detailed documentation and certifications.

In conclusion, a balanced combination of natural waxes, refined oils, and high-grade pigments tailored to regional preferences and regulatory requirements will ensure the production of durable, high-quality black shoe polish suited for diverse markets worldwide.

In-depth Look: Manufacturing Processes and Quality Assurance for black shoe polish

Manufacturing Processes for Black Shoe Polish

The production of black shoe polish involves a series of carefully controlled stages designed to ensure product consistency, efficacy, and safety. Understanding these stages enables B2B buyers to evaluate supplier capabilities and ensure compliance with international standards.

Material Preparation

The process begins with sourcing high-quality raw materials, including waxes (carnauba, beeswax, paraffin), oils (lanolin, mineral oil), pigments (carbon black for black color), solvents (turpentine, mineral spirits), and preservatives. Suppliers should have robust supplier qualification procedures, including verification of raw material certifications and compliance with hazardous substance regulations (e.g., REACH, OSHA).

Key considerations for buyers:

– Verify supplier certifications for raw materials.

– Ensure raw materials meet relevant safety and environmental standards.

– Assess the supplier’s ability to source consistent quality inputs.

Formulation and Mixing

The prepared raw materials are blended in precise formulations to achieve desired properties such as shine, durability, and ease of application. Modern manufacturing employs high-shear mixers and homogenizers to ensure uniform dispersion of pigments and waxes, critical for color consistency and product stability.

Actionable insight: B2B buyers should request detailed formulation data and batch records, along with third-party testing reports, to verify formulation integrity.

Forming and Packaging

Once mixed, the product is transferred into containers via filling lines equipped with automated pumps and fillers, ensuring minimal contamination and wastage. Packaging options vary from tins and tubes to aerosol sprays, each requiring specific filling and sealing techniques.

Quality tip: Ensure packaging lines are validated for hygiene and leak-proof integrity, especially for aerosol products which require pressurization controls.

Finishing and Labeling

Final inspection involves visual checks for consistency, proper labeling, and packaging integrity. Labels should include batch numbers, expiry dates, safety warnings, and certifications, which are vital for traceability and compliance in international markets.

Quality Assurance (QC) in Black Shoe Polish Manufacturing

Robust quality assurance is essential for meeting international standards and satisfying B2B buyers’ expectations, especially when exporting across diverse regions like Africa, South America, the Middle East, and Europe.

International and Industry Standards

- ISO 9001: Most reputable manufacturers adhere to ISO 9001 quality management systems, ensuring systematic control over production, documentation, and continuous improvement.

- Regional Standards: Depending on destination markets, additional certifications such as CE (European Economic Area), SGS testing, or API (for specific industrial applications) might be required. For example, European buyers often demand compliance with REACH regulations concerning chemical safety.

Tip for buyers: Request copies of certification documents and audit reports to verify compliance.

Quality Control Checkpoints

1. Incoming Quality Control (IQC): Raw materials are inspected upon arrival for conformity with specifications, including pigment stability, wax melting points, and absence of contaminants. Suppliers should maintain detailed IQC reports.

2. In-Process Quality Control (IPQC): During formulation and mixing, parameters like temperature, mixing time, and viscosity are monitored. Regular sampling ensures batch-to-batch consistency.

3. Final Quality Control (FQC): Post-production, the finished product undergoes tests such as:

– Color consistency: Using spectrophotometers.

– Viscosity and flow properties: Using rheometers.

– Adhesion and flexibility: Through standardized peel tests.

– Durability and shine: Via simulated wear tests.

– Chemical stability: Accelerated aging tests to predict shelf life.

4. Packaging Inspection: Ensures labels are accurate, containers are sealed properly, and safety warnings are clear.

Testing Methods and Validation

To guarantee product quality, manufacturers employ various testing techniques:

– Spectrophotometry: For precise color matching and consistency.

– Viscometry: To control flow properties.

– Tensile and adhesion tests: To assess durability and adherence to shoe leather.

– Accelerated aging: To simulate long-term storage conditions.

– Toxicological assessments: Ensuring safety compliance with chemical regulations.

For B2B buyers: Request detailed test reports, third-party inspection certificates, and, if possible, conduct on-site audits or third-party inspections to verify QC claims.

Verifying Supplier QC Capabilities

International buyers should adopt a proactive approach to supplier verification, especially when sourcing from regions with varying regulatory environments.

- Supplier Audits: Conduct or commission audits focusing on manufacturing processes, QC procedures, and laboratory facilities.

- Third-party Inspection Services: Engage firms like SGS, Bureau Veritas, or Intertek to perform pre-shipment inspections, verifying product quality, packaging, and documentation.

- Quality Documentation: Require comprehensive Certificates of Analysis (CoA), Material Safety Data Sheets (MSDS), and compliance certificates.

- Sample Testing: Perform independent testing on samples from initial and subsequent batches to confirm consistency with specifications.

Nuances for International B2B Buyers from Diverse Regions

Buyers from Africa, South America, the Middle East, and Europe face unique challenges and considerations:

- Regulatory Compliance: European buyers must ensure products meet REACH and CLP regulations, while Middle Eastern buyers might prioritize GSO standards.

- Quality Traceability: Emphasize detailed batch records and supply chain transparency to mitigate risks associated with counterfeit or substandard products.

- Communication and Documentation: Ensure that technical specifications, safety data sheets, and certificates are available in local languages and align with regional standards.

- Supplier Relationships: Building long-term partnerships with manufacturers who have proven QC systems reduces risk and facilitates compliance with evolving regulations.

Actionable steps for buyers:

– Prioritize suppliers with ISO 9001 certification and relevant regional certifications.

– Incorporate periodic audits into procurement processes.

– Use third-party inspection reports as a standard part of supplier evaluation.

– Foster open communication to clarify QC expectations and compliance requirements.

Conclusion

A comprehensive understanding of manufacturing processes and rigorous quality assurance protocols are critical for B2B buyers seeking reliable black shoe polish suppliers. By scrutinizing raw material sourcing, process controls, and testing procedures—and leveraging third-party inspections—buyers can mitigate risks and ensure consistent product quality across diverse international markets. Tailoring verification strategies to regional standards and regulations further enhances supply chain integrity and fosters long-term, compliant partnerships.

Comprehensive Cost and Pricing Analysis for black shoe polish Sourcing

Understanding the Cost Structure for Black Shoe Polish

A comprehensive grasp of the cost components involved in sourcing black shoe polish is essential for international buyers aiming to optimize procurement strategies. The primary cost elements include raw materials, labor, manufacturing overheads, tooling, quality control, logistics, and profit margins. Raw materials—such as waxes, oils, dyes, and solvents—constitute a significant portion, with prices influenced by global commodity markets, sourcing regions, and quality specifications. Labor costs vary markedly between regions; manufacturers in Europe and Australia tend to have higher wages compared to suppliers in parts of Africa and South America, impacting overall production costs.

Manufacturing overheads encompass factory expenses, energy, equipment depreciation, and compliance costs, which are often higher in developed economies due to stricter regulations. Tooling costs are typically upfront investments needed for molds or specific packaging, amortized over production runs. Quality assurance (QA) and quality control (QC) are critical, especially when sourcing for markets with strict certifications (e.g., ISO, REACH), adding to per-unit costs. Logistics costs, including freight, customs duties, and inland transportation, can significantly influence final pricing, especially when sourcing from regions with less developed infrastructure.

Price Influencers and Market Dynamics

Several factors influence the final pricing of black shoe polish in B2B transactions. Order volume and minimum order quantities (MOQs) are pivotal—larger orders usually benefit from economies of scale, reducing per-unit costs. Conversely, small or customized orders often carry premium pricing due to setup and handling complexities.

Product specifications and customization also impact costs; formulations tailored to specific markets (e.g., eco-friendly, hypoallergenic, or with unique scent profiles) may incur higher development and production expenses. The choice of raw materials—premium dyes or natural waxes—can elevate costs but may also command higher retail prices or meet specific customer demands.

Quality standards and certifications are non-negotiable in many markets, especially in Europe and Australia, where strict regulations necessitate higher-quality inputs and rigorous testing, increasing costs. Supplier factors, including production capacity, reputation, and proximity, influence pricing; established suppliers with robust quality systems often charge premium but offer reliability and consistency.

Incoterms (International Commercial Terms) determine who bears costs and risks at various shipping stages. FOB (Free on Board) prices typically exclude freight and insurance, whereas CIF (Cost, Insurance, and Freight) prices include these, affecting the total landed cost for buyers.

Strategic Tips for International Buyers

To optimize costs, buyers should negotiate directly with manufacturers or leverage sourcing agents who have established relationships, especially in regions like Africa, South America, or the Middle East where local market knowledge can be advantageous. Emphasize long-term partnerships—bulk orders and consistent purchasing volumes often unlock better pricing and payment terms.

Consider total cost of ownership (TCO) rather than just unit price. This includes freight, customs duties, taxes, storage, and potential rework or QC failures. For buyers in regions with high import tariffs (e.g., some South American or African countries), exploring local or regional manufacturing options can significantly reduce costs.

Pricing nuances are crucial; suppliers may offer attractive base prices but add surcharges for customization, special packaging, or expedited delivery. Transparent communication about specifications and anticipated volumes helps avoid unexpected costs.

Price Range and Indicative Costs

While prices vary widely based on quality, region, and order size, a general range for bulk black shoe polish is approximately $1.50 to $3.50 per kilogram for standard formulations from established manufacturers. Premium or specialized formulations can exceed this range, particularly when incorporating eco-friendly ingredients or certifications.

For smaller quantities or niche markets, prices can escalate to $4.00–$6.00 per kilogram, reflecting higher per-unit costs associated with setup and lower economies of scale.

Disclaimer: These figures are indicative and subject to fluctuation based on raw material prices, geopolitical factors, and market demand. Buyers should conduct due diligence and request detailed quotations tailored to their specific needs.

By understanding these cost components and market influences, B2B buyers from Africa, South America, the Middle East, and Europe can strategically plan their sourcing, negotiate effectively, and optimize their overall procurement costs for black shoe polish.

Spotlight on Potential black shoe polish Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for black shoe polish.)*

Essential Technical Properties and Trade Terminology for black shoe polish

Key Technical Properties for Black Shoe Polish

1. Material Composition and Grade

The raw materials—such as waxes (beeswax, carnauba), oils (linseed, castor), and pigments—determine the polish’s durability, shine, and ease of application. High-quality grades ensure consistency, longer shelf life, and superior finish, which are critical for meeting client expectations across different markets.

2. Viscosity and Consistency

Viscosity affects how easily the polish spreads and penetrates leather surfaces. Industry standards specify acceptable viscosity ranges to ensure uniform application, especially important for automated or large-scale production lines. Consistent viscosity reduces waste and rework, lowering costs.

3. Drying and Curing Time

The time it takes for the polish to dry and cure impacts logistical planning and product turnover. Faster-drying formulas are preferred for retail environments, while longer curing times might be acceptable for specialized industrial applications. Understanding this property helps in scheduling and inventory management.

4. Colorfastness and Stability

Black shoe polish must retain its color without fading or transferring onto clothing. Stability under various environmental conditions (humidity, temperature fluctuations) is vital for preserving product quality during storage and transport, especially across diverse climatic zones.

5. Shelf Life and Storage Conditions

A product’s shelf life indicates its usability period, influencing procurement and inventory strategies. Proper packaging and storage recommendations ensure the polish maintains its properties over time, reducing product returns or complaints.

6. Packaging Specifications

Standard packaging types include tins, tubes, or bottles, with specific size options. Packaging must meet safety and regulatory standards, facilitate ease of use, and align with logistical needs—especially important for bulk shipments or retail distribution.

Essential Industry and Trade Terms

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce shoe polish under a brand specified by another company. B2B buyers often source OEM products to customize branding or specifications, offering flexibility and cost advantages.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to accept per order. Understanding MOQ helps buyers plan procurement budgets and manage inventory efficiently, especially when entering new markets or testing product acceptance.

3. RFQ (Request for Quotation)

A formal process where buyers solicit price, lead times, and product details from suppliers. An RFQ ensures competitive pricing and clear communication of technical requirements, vital for establishing reliable supply chains.

4. Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce, defining responsibilities for shipping, customs, and risk transfer. Familiarity with Incoterms like FOB (Free On Board) or CIF (Cost, Insurance, Freight) ensures clarity in negotiations and cost calculations.

5. Certification and Compliance Terms

Includes standards such as ISO, REACH, or ASTM, which verify product safety, environmental compliance, and quality. Confirming certifications is crucial for market access, especially in regulated regions like the EU or Middle East.

6. Lead Time

The period between placing an order and receiving the goods. Accurate knowledge of lead times helps in planning production schedules, avoiding stockouts, and meeting seasonal or contractual demands.

Actionable Insights for Buyers

Understanding these properties and terms ensures better communication with suppliers, reduces misunderstandings, and enhances procurement efficiency. For markets like Africa, South America, the Middle East, and Europe, aligning technical specifications with regional standards and compliance requirements is essential to ensure smooth trade and product acceptance. Clear knowledge of trade terms facilitates negotiations, risk management, and cost control, positioning buyers for successful sourcing in a competitive landscape.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the black shoe polish Sector

Market Overview & Key Trends

The global black shoe polish market is influenced by a combination of traditional craftsmanship and emerging technological innovations. Key drivers include increasing demand from both formal and informal sectors across regions such as Africa, South America, the Middle East, and Europe. In these markets, footwear maintenance remains vital for professional, military, and everyday use, supporting consistent demand for reliable shoe care products.

Emerging B2B sourcing trends highlight a shift toward more sustainable and technologically advanced formulations. Companies are investing in eco-friendly ingredients, such as natural waxes and plant-based dyes, to meet rising consumer and regulatory expectations. Additionally, digital platforms and supply chain transparency tools are transforming procurement processes, enabling buyers to verify supplier credentials and sustainability claims more efficiently.

Market dynamics for international B2B buyers reflect fluctuating raw material costs, geopolitical influences, and evolving regulatory environments. For instance, sourcing from regions with abundant natural resources like Brazil or India can offer cost advantages but may pose logistical or compliance challenges. Buyers from Africa and South America should leverage local supplier relationships and consider regional trade agreements to optimize supply chains.

In Europe and Australia, there’s a notable trend toward premium, bespoke shoe polish products with enhanced durability and eco-credentials. These markets often demand certifications such as ISO 14001 or FSC, emphasizing sustainability and quality assurance. As technology advances, automation in manufacturing and quality control also plays a crucial role in maintaining competitive advantage.

Illustrative Image (Source: Google Search)

Overall, B2B buyers should stay attuned to innovations in formulation, digital sourcing platforms, and regional trade policies to navigate the complex landscape effectively. Building strategic partnerships with certified, environmentally conscious suppliers can ensure resilience amid fluctuating market conditions.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical criterion in sourcing black shoe polish, driven by increased environmental awareness and consumer demand for ethically produced goods. The environmental impact of traditional formulations—often reliant on petroleum-based waxes, synthetic dyes, and volatile organic compounds—raises concerns about pollution and resource depletion.

For B2B buyers, prioritizing suppliers with transparent, ethical supply chains is essential. This includes verifying sourcing practices for raw materials like beeswax, carnauba wax, and natural dyes, ensuring they are harvested responsibly without harming ecosystems or local communities. Certifications such as Fair Trade, Organic, and FSC play a vital role in establishing credibility and aligning procurement with sustainability goals.

Eco-conscious formulations are gaining prominence, with many suppliers innovating to develop ‘green’ shoe polishes that utilize biodegradable ingredients, minimal packaging, and renewable resources. Incorporating recycled materials into packaging and reducing carbon footprints through optimized logistics further enhances sustainability credentials.

In regions like Europe and Australia, regulatory frameworks increasingly mandate environmental compliance, making sustainability certifications not just a moral choice but a legal necessity. For buyers in Africa and South America, establishing partnerships with local suppliers committed to sustainable practices can foster community development and long-term supply stability.

Adopting a comprehensive sustainability strategy—covering raw material sourcing, manufacturing processes, and distribution—can differentiate products in competitive markets. It also aligns with global trends towards corporate responsibility, helping B2B buyers meet both regulatory and consumer expectations for environmentally and ethically responsible products.

Brief Evolution/History (Optional)

The black shoe polish industry has evolved significantly over the past century, transitioning from simple wax formulations to sophisticated products incorporating advanced polymers and natural ingredients. Historically, formulations relied heavily on petroleum derivatives and synthetic dyes, which, while effective, posed environmental and health concerns.

In recent decades, a shift toward sustainable and natural ingredients has gained momentum, driven by regulatory pressures and consumer preferences. This evolution reflects a broader trend within the personal care and maintenance sectors, emphasizing eco-friendly practices and ethical sourcing. As a result, many manufacturers now invest in research and development to create formulations that balance performance with environmental responsibility.

For B2B buyers, understanding this historical progression can inform sourcing decisions, especially when evaluating supplier claims of sustainability or technological innovation. Recognizing the industry’s trajectory toward greener practices helps anticipate future standards and opportunities for differentiation in an increasingly eco-conscious market.

Frequently Asked Questions (FAQs) for B2B Buyers of black shoe polish

1. How can I effectively vet suppliers of black shoe polish to ensure product quality and reliability?

Vetting suppliers begins with thorough research of their reputation, certifications, and compliance standards. Request samples for testing to verify color consistency, texture, and longevity. Check for industry certifications such as ISO, GMP, or specific chemical safety standards relevant to your target markets. Conduct supplier audits or third-party inspections when possible, especially for large orders. Review customer references and feedback from other international buyers. Establish clear communication channels to assess responsiveness and transparency. Partnering with verified trade associations or sourcing platforms can also help identify reputable suppliers with proven track records.

Illustrative Image (Source: Google Search)

2. What customization options are typically available, and how do they impact minimum order quantities and lead times?

Many suppliers offer customization in packaging, branding, fragrance, and formulation (e.g., hypoallergenic, eco-friendly). Custom orders usually require higher MOQs due to setup costs and production adjustments, often ranging from 1,000 to 10,000 units. Lead times for customized products can extend from 4 to 12 weeks, depending on complexity. To optimize supply chain efficiency, clarify your specifications early and negotiate for flexible MOQ options or phased deliveries. Establishing long-term relationships can often lead to better terms on customization and reduced lead times over time.

3. What are typical MOQ, lead times, and payment terms for international bulk orders of black shoe polish?

MOQ for bulk international orders generally ranges between 1,000 to 10,000 units, though some manufacturers may accept smaller quantities for trial or promotional purposes. Lead times are typically between 4 to 8 weeks, influenced by order size, customization, and logistics. Payment terms often include a 30% upfront deposit with the balance payable before shipment, though flexible terms such as letter of credit or open account can be negotiated, especially for trusted buyers. Establish clear contractual agreements to protect both parties and consider utilizing escrow services for larger transactions.

4. What certifications and quality assurance measures should I look for in a supplier?

Look for suppliers with relevant certifications such as ISO 9001 (quality management), ISO 14001 (environmental management), and chemical safety standards like REACH or OSHA compliance. Request detailed Quality Assurance (QA) protocols, including batch testing reports, stability testing, and safety data sheets (SDS). Suppliers should provide lab analysis reports confirming the absence of harmful substances and adherence to your target market’s regulations. Implementing third-party inspections or audits at the manufacturing site ensures consistent quality and compliance, reducing risks of product recalls or regulatory issues.

5. How can I manage logistics and shipping effectively when importing black shoe polish internationally?

Partner with experienced freight forwarders familiar with your destination country’s import regulations, customs procedures, and preferred shipping routes. Consider cost-effective options like sea freight for large volumes or air freight for urgent shipments. Ensure all documentation (commercial invoice, packing list, certificates of origin, and safety data sheets) is accurate and complete to prevent delays. Negotiate Incoterms (e.g., FOB, CIF) that clearly define responsibilities and costs. Utilizing track-and-trace systems provides real-time shipment updates, enabling proactive planning for customs clearance and distribution.

6. What should I do if there is a dispute or quality issue with a supplier’s product?

Immediately document the issue with detailed photos, samples, and correspondence. Engage the supplier promptly to seek a resolution, such as replacement, refund, or corrective action. Establish clear contractual clauses for dispute resolution, including arbitration or mediation, preferably under internationally recognized frameworks. Maintain open communication and remain professional; often, disputes can be resolved through negotiation. If recurring issues arise, consider switching suppliers or implementing stricter quality controls, such as third-party audits or ongoing testing, to safeguard your supply chain.

7. How can I ensure compliance with local regulations and standards in different markets?

Research the specific regulatory requirements for cosmetic and chemical products in your target markets, such as the EU’s Cosmetics Regulation, the US FDA, or Brazil’s ANVISA standards. Work with suppliers who understand and can provide necessary documentation, like safety data sheets and compliance certificates. Conduct or commission independent lab testing when needed to verify adherence. Stay updated on changes in regulations through trade associations or regulatory consultants. Building compliance into your sourcing process minimizes legal risks, product recalls, and market entry delays.

8. What are best practices for building long-term relationships with reliable suppliers?

Establish clear communication channels and mutual expectations from the outset. Regularly review supplier performance through audits, quality feedback, and delivery timelines. Offer prompt payments and constructive feedback to foster trust. Consider long-term contracts or volume commitments that incentivize supplier loyalty. Stay informed about market trends and share insights with your suppliers to encourage innovation and continuous improvement. Developing personal relationships, understanding cultural nuances, and maintaining transparency help create resilient partnerships capable of navigating market fluctuations and evolving demands.

Strategic Sourcing Conclusion and Outlook for black shoe polish

Final Insights and Future Outlook

Effective strategic sourcing of black shoe polish is essential for international B2B buyers seeking quality, cost efficiency, and supply chain resilience. Key considerations include diversifying supplier bases across regions such as Europe, South America, Africa, and the Middle East, and leveraging local manufacturing strengths to reduce lead times and logistical complexities. Emphasizing sustainable sourcing practices and product innovation can also enhance competitiveness in a rapidly evolving market.

By establishing strong partnerships and conducting thorough supplier assessments, buyers can mitigate risks related to price fluctuations, regulatory changes, and supply disruptions. Moreover, staying informed on emerging trends—such as eco-friendly formulations and digital procurement platforms—can unlock new value streams and market opportunities.

Looking ahead, proactive sourcing strategies will be critical as global trade dynamics shift and consumer preferences evolve. Buyers from Africa, South America, the Middle East, and Europe should prioritize building resilient, adaptable supply chains that capitalize on regional strengths. Embrace innovation, foster strategic alliances, and continuously monitor market developments to secure a competitive advantage in the black shoe polish industry.