Your Ultimate Guide to Sourcing Nike Boxing Shoes

Guide to Nike Boxing Shoes

- Introduction: Navigating the Global Market for nike boxing shoes

- Understanding nike boxing shoes Types and Variations

- Key Industrial Applications of nike boxing shoes

- Strategic Material Selection Guide for nike boxing shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for nike boxing shoes

- Comprehensive Cost and Pricing Analysis for nike boxing shoes Sourcing

- Spotlight on Potential nike boxing shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for nike boxing shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the nike boxing shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of nike boxing shoes

- Strategic Sourcing Conclusion and Outlook for nike boxing shoes

Introduction: Navigating the Global Market for nike boxing shoes

In the highly competitive world of sports footwear, Nike boxing shoes stand out as a vital product category, combining innovation, performance, and brand prestige. For B2B buyers across Africa, South America, the Middle East, and Europe—markets characterized by diverse consumer preferences and growing demand—sourcing authentic, high-quality Nike boxing shoes is crucial to maintaining competitive advantage and meeting market expectations. This guide provides a strategic roadmap to navigate the complexities of global sourcing, ensuring informed decision-making at every stage.

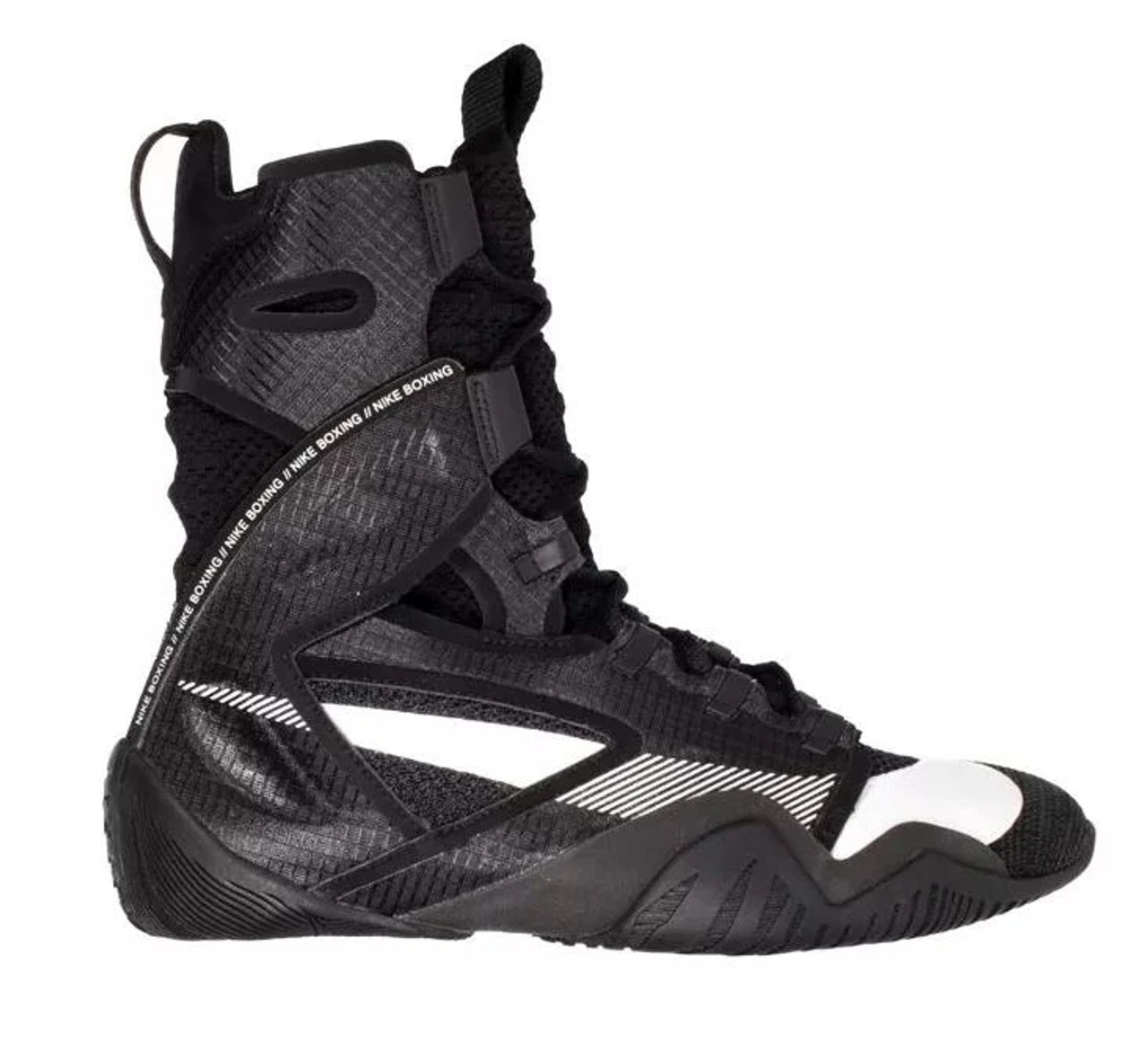

Illustrative Image (Source: Google Search)

Covering the full spectrum—from the different types of Nike boxing shoes and their key materials to manufacturing processes and quality control standards—this resource empowers international buyers to optimize their procurement strategies. It also offers insights into reputable suppliers, cost structures, and market trends, equipping buyers with the knowledge to negotiate effectively and establish resilient supply chains.

Furthermore, the guide addresses common FAQs and regulatory considerations specific to regions like Nigeria, Egypt, and other emerging markets, ensuring compliance and sustainable sourcing practices. By leveraging this comprehensive overview, B2B buyers can confidently identify reliable partners, mitigate risks, and capitalize on the growing global demand for Nike boxing shoes—ultimately enhancing their market positioning and customer satisfaction. This authoritative resource is designed to support strategic growth and responsible sourcing in an evolving international landscape.

Illustrative Image (Source: Google Search)

Understanding nike boxing shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Boxing Shoes | Lightweight, low-top design with minimal cushioning, breathable mesh upper | Wholesale sports retailers, gyms, training centers | Pros: Cost-effective, versatile for various training needs. Cons: Limited ankle support for advanced fighters. |

| Competition-Level Shoes | Higher ankle support, specialized grip, reinforced sole for competitive use | Distributors supplying professional gyms | Pros: Enhanced performance, durability. Cons: Higher cost, limited to competitive markets. |

| Training & Practice Shoes | Moderate ankle support, durable outsole, cushioned insole for extended wear | Bulk supply to training academies and schools | Pros: Balances support and comfort, good for daily training. Cons: Slightly heavier, less specialized for competitions. |

| Customizable Nike Boxing Shoes | Options for branding, color, and minor modifications | Promotional bulk orders, brand collaborations | Pros: Brand differentiation, tailored to client needs. Cons: Longer lead times, higher minimum order quantities. |

| Youth & Junior Shoes | Smaller sizes, lightweight, vibrant colors, flexible fit | Suppliers targeting youth boxing programs | Pros: Encourages youth participation, affordable. Cons: Limited durability for intense use, smaller size range. |

Classic Boxing Shoes

The classic Nike boxing shoes are characterized by their lightweight, low-top design, emphasizing breathability and agility. They typically feature mesh uppers combined with synthetic overlays to keep costs manageable while offering basic support. These shoes are ideal for wholesale distributors, gyms, and training centers seeking affordable, reliable footwear for general training. Their primary advantage lies in cost-efficiency and versatility, making them suitable for a broad customer base. However, they provide limited ankle support, which may be a drawback for more aggressive or advanced fighters requiring enhanced stability.

Illustrative Image (Source: Google Search)

Competition-Level Shoes

Designed for professional and serious amateur boxers, Nike’s competition shoes boast higher ankle support, reinforced soles, and specialized grip patterns to maximize performance during bouts. These shoes are often sold through specialized sports distributors and high-end retailers targeting competitive gyms and athletes. Their key benefits include durability and performance optimization, crucial for high-stakes environments. The main considerations for B2B buyers involve higher procurement costs and limited applicability outside competitive markets, making them a strategic choice for premium segments.

Training & Practice Shoes

Nike’s training shoes for boxing strike a balance between support, durability, and comfort. They feature moderate ankle support, resilient outsoles for multi-directional movement, and cushioned insoles designed for extended wear. These shoes are popular among bulk buyers such as sports academies, schools, and training facilities. They offer a practical solution for daily training needs, combining affordability with functional support. Buyers should consider their target demographic’s activity level, as these shoes may be slightly heavier than competition models but excel in durability and comfort.

Customizable Nike Boxing Shoes

Customizable models allow B2B clients to order shoes with branding, color schemes, and minor modifications, making them ideal for promotional campaigns, brand collaborations, or team uniforms. These shoes are often purchased in bulk, with lead times influenced by customization complexity. Their advantages include brand differentiation and tailored offerings, which can enhance client loyalty and market appeal. However, customization typically involves longer production cycles and higher minimum order quantities, requiring strategic planning and forecasting for large-scale procurement.

Youth & Junior Shoes

Nike’s youth boxing shoes are specifically designed for smaller feet, featuring lightweight construction, flexible materials, and vibrant color options to appeal to younger athletes. They are mainly targeted at suppliers and organizations promoting youth sports programs. The primary benefit is encouraging early participation in boxing, with affordable pricing and a focus on comfort. Limitations include reduced durability compared to adult models and a narrower size range, so B2B buyers must ensure they align product offerings with the expected intensity of use and demographic needs.

These variations enable B2B buyers across regions like Africa, South America, the Middle East, and Europe to diversify their product portfolios effectively. Understanding the distinct features and applications helps optimize procurement strategies, ensuring the right models reach the appropriate markets while balancing cost, quality, and performance expectations.

Related Video: Review of the New and Improved boxing shoes Nike Hyperko 2

Key Industrial Applications of nike boxing shoes

| Industry/Sector | Specific Application of nike boxing shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports & Fitness Equipment Manufacturing | Production of specialized boxing footwear for athletes | Enhances product portfolio with high-performance, branded footwear | Consistent quality control, sourcing sustainable materials, adherence to international safety standards |

| Retail & Wholesale Sports Goods | Bulk procurement for sports retailers and gyms | Increases sales through premium branded products, boosts brand loyalty | Reliable supply chain, competitive pricing, regional distribution capabilities |

| Military & Security Training | Training gear for military and security personnel involved in combat sports | Provides durable, comfortable footwear that supports rigorous training | Robustness and durability, compliance with safety regulations, regional customization options |

| Corporate & Event Sponsorships | Promotional giveaways and branded merchandise for sports events | Elevates brand visibility and engagement during international tournaments | Customization options, consistent branding quality, timely delivery across regions |

| E-commerce & Online Retail Platforms | Distribution of Nike boxing shoes through online marketplaces targeting global markets | Expands market reach, offers direct-to-consumer sales, enhances brand presence | Supply chain agility, authenticity verification, regional logistics partnerships |

Manufacturing and Product Development in Sports & Fitness Equipment

Nike boxing shoes are integral to the manufacturing of high-performance athletic footwear, especially for boxing and combat sports. International B2B buyers from regions such as Africa and South America leverage Nike’s expertise to develop products that meet global standards for comfort, support, and durability. These shoes are designed with specialized features like non-slip soles, ankle support, and breathable materials, solving common problems like foot injury and inadequate grip. Buyers benefit from sourcing Nike’s proven quality, ensuring their end consumers receive reliable, high-quality products that enhance athletic performance and safety. For manufacturers, maintaining consistent quality and sustainable sourcing—particularly in regions with variable supply chain infrastructure—is crucial for competitiveness and compliance with international standards.

Retail & Wholesale Distribution

Large retail chains, sporting goods wholesalers, and gym operators across Europe, the Middle East, and emerging markets like Nigeria and Egypt depend on Nike boxing shoes to meet consumer demand for premium branded sports footwear. These buyers focus on securing a steady supply of authentic Nike products, which help boost their sales and strengthen brand loyalty among athletes and fitness enthusiasts. Sourcing considerations include establishing strong regional distribution networks, ensuring timely delivery, and negotiating competitive pricing to maximize margins. Additionally, regional customization—such as sizing or color options—can enhance appeal to local markets, making Nike boxing shoes a preferred choice for retailers seeking to differentiate their offerings.

Military & Security Training

In regions such as the Middle East and Africa, military and security agencies incorporate Nike boxing shoes into their combat sports and physical training programs. These shoes are selected for their durability, ankle support, and comfort during rigorous training sessions, which are critical for operational readiness. International B2B buyers in these sectors require footwear that withstands extreme conditions, offers reliable grip, and reduces injury risk. Sourcing considerations include verifying compliance with safety and durability standards, securing bulk procurement agreements, and ensuring regional availability to avoid delays that could hinder training schedules. Nike’s reputation for quality and innovation provides an added advantage in fulfilling these specialized needs.

Promotional & Event Sponsorships

Global sports events and local tournaments in Africa, South America, and Europe often feature Nike boxing shoes as part of sponsorship and promotional campaigns. These shoes serve as branded merchandise, giveaways, or athlete gear, increasing brand visibility and engagement. For B2B buyers, sourcing Nike boxing shoes for large-scale events involves ensuring timely delivery, customization options for branding, and maintaining product authenticity. The strategic use of Nike’s high-profile association can significantly enhance brand recognition in target markets, especially during international competitions where regional and global audiences are present. This application underscores Nike’s role not only as a manufacturer but also as a key marketing partner.

E-commerce & Distribution Channels

Online retail platforms targeting global markets, including Africa, South America, and Europe, rely on Nike boxing shoes to expand their product range and reach diverse customer segments. These platforms benefit from Nike’s established brand reputation, offering consumers authentic, high-quality boxing footwear directly through digital channels. Sourcing considerations include maintaining a flexible supply chain to meet fluctuating demand, ensuring product authenticity to prevent counterfeits, and establishing regional logistics partnerships for efficient delivery. Nike’s global distribution network supports rapid replenishment and regional customization, enabling online sellers to meet the expectations of international buyers seeking premium boxing shoes for personal or professional use.

Related Video: New NIKE Machomai 3 Boxing Boots FULL IN DEPTH REVIEW AND RATING

Strategic Material Selection Guide for nike boxing shoes

Analysis of Common Materials for Nike Boxing Shoes

Leather (Full-Grain and Synthetic)

Leather remains a primary material in high-quality boxing shoes due to its excellent durability, flexibility, and breathability. Full-grain leather offers superior abrasion resistance and molds well to the foot over time, providing optimal support during intense training and matches. Synthetic leather, on the other hand, is often used for cost reduction and weight savings, offering decent durability but generally less breathable and prone to cracking under prolonged stress.

Pros & Cons:

– Pros: High durability, good support, natural breathability (full-grain), aesthetically appealing.

– Cons: Higher cost (full-grain), potential for water absorption (full-grain), manufacturing complexity (especially for genuine leather).

Impact on Application:

Leather’s flexibility and support make it suitable for the upper part of boxing shoes, especially in environments requiring abrasion resistance. However, in humid or wet climates, genuine leather may degrade faster unless treated properly.

International Buyer Considerations:

Leather products must comply with regional regulations regarding animal products, such as CITES. Buyers from Africa and South America should verify sourcing certifications, while European markets may have stricter animal welfare standards. Synthetic alternatives are favored where ethical or legal restrictions apply.

Mesh and Textile Fabrics

Mesh and synthetic textiles are widely used for the upper sections of boxing shoes to enhance breathability and reduce weight. These materials are engineered to allow airflow, helping to keep the athlete’s feet cool during vigorous activity. Modern textiles also incorporate moisture-wicking properties, which are critical in humid climates.

Pros & Cons:

– Pros: Lightweight, excellent breathability, lower cost, easy to manufacture in various styles.

– Cons: Less durable than leather, prone to tearing if overstressed, limited support in high-stress zones.

Impact on Application:

Textile materials are ideal for training shoes used in hot climates, such as Nigeria or Egypt, where moisture management is critical. They are also suitable for lightweight competition shoes but may require reinforcement for longevity.

International Buyer Considerations:

Compliance with standards like ASTM D6540 (for textiles) ensures quality and safety. Buyers should also consider local climate conditions—favoring moisture-wicking and quick-drying fabrics in tropical regions.

Rubber and EVA (Ethylene Vinyl Acetate) Soles

The outsole of Nike boxing shoes typically employs rubber or EVA foam. Rubber provides excellent grip, durability, and abrasion resistance, essential for the ring surface and training environments. EVA foam is used in midsoles for cushioning, offering lightweight shock absorption.

Pros & Cons:

– Pros: Rubber offers high durability and slip resistance; EVA provides lightweight cushioning at a lower cost.

– Cons: Rubber can be heavier and more expensive; EVA may degrade faster under extreme conditions, such as high heat or prolonged UV exposure.

Impact on Application:

Rubber soles are suitable for diverse surfaces, including mats and concrete, common in gyms across Africa, South America, and the Middle East. EVA midsoles contribute to comfort but require proper sealing to prevent moisture ingress.

International Buyer Considerations:

Compliance with standards like DIN 53505 (for rubber) ensures safety and performance. Buyers should verify the environmental impact of rubber sourcing, especially in regions with strict chemical regulations.

Synthetic Polymers (e.g., TPU, PVC)

Synthetic polymers are increasingly used for various shoe components, including reinforcements, overlays, and decorative elements. Thermoplastic Polyurethane (TPU) offers excellent elasticity, abrasion resistance, and weatherability, making it suitable for structural parts that require flexibility and strength.

Pros & Cons:

– Pros: Cost-effective, versatile, resistant to environmental factors, customizable.

– Cons: Can be less breathable, may degrade under prolonged UV exposure, and sometimes produce environmental concerns during manufacturing.

Impact on Application:

Suitable for overlays and structural reinforcements, especially in regions where weather resistance is necessary. For example, in humid climates, TPU’s weatherability helps maintain product integrity.

International Buyer Considerations:

Buyers should ensure materials meet local environmental and safety standards, such as REACH in Europe. Compatibility with regional manufacturing capabilities and supply chain logistics should also be evaluated.

Summary Table

| Material | Typical Use Case for Nike Boxing Shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather (Full-Grain/Synthetic) | Upper support, durability, aesthetic appeal | High durability, support, natural breathability | Higher cost, water absorption (full-grain), manufacturing complexity | High |

| Mesh and Textile Fabrics | Breathable upper, moisture management | Lightweight, breathable, cost-effective | Less durable, tear-prone, limited support in high-stress zones | Med |

| Rubber and EVA Soles | Outsole grip, midsole cushioning | Excellent grip, lightweight cushioning | Rubber heavier and costly; EVA degrades faster under extreme conditions | Med |

| Synthetic Polymers (TPU, PVC) | Overlays, reinforcements, decorative elements | Cost-effective, weather-resistant, versatile | Less breathable, environmental concerns | Low |

This detailed analysis equips international B2B buyers from Africa, South America, the Middle East, and Europe with the critical insights needed to select appropriate materials for Nike boxing shoes, considering regional standards, climate conditions, and sourcing regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for nike boxing shoes

Manufacturing Process Overview for Nike Boxing Shoes

The manufacturing of Nike boxing shoes involves a highly systematic and quality-driven process, designed to meet both Nike’s internal standards and international regulatory requirements. This process can be broken down into four primary stages: material preparation, forming, assembly, and finishing. Each stage incorporates specialized techniques and rigorous quality controls to ensure durability, comfort, and compliance with safety standards.

1. Material Preparation

The process begins with sourcing high-quality raw materials, including synthetic leathers, mesh fabrics, rubber, and specialized foam insoles. Suppliers are typically certified to international standards such as ISO 9001, ensuring consistent quality and traceability. Material inspection at this stage involves visual checks for defects, dimensional accuracy, and material integrity, often using ultrasonic testing or microscopy for detailed assessments. For B2B buyers, verifying supplier certifications and audit reports is crucial to confirm material quality aligns with Nike’s standards.

2. Forming and Cutting

The prepared materials are then cut into precise patterns using computer-controlled cutting machines (e.g., CAD/CAM systems). This stage ensures minimal waste and high precision, vital for maintaining product consistency. Advanced laser cutting or die-cutting techniques are employed to achieve tight tolerances, especially for complex components like the upper and lining sections. Suppliers should provide detailed process documentation and third-party inspection reports to validate adherence to specifications.

3. Assembly and Stitching

Assembling involves stitching the cut components together using industrial sewing machines, often employing high-strength, abrasion-resistant threads such as nylon or polyester. Automated sewing lines are used for large-scale production, but manual stitching may be involved for intricate parts. During assembly, critical quality checks are performed, including seam strength testing and dimensional verification. Suppliers adhering to industry standards like ISO 9001 incorporate in-process quality controls (IPQC), ensuring each batch meets predetermined specifications.

4. Finishing and Quality Control

The final stages include attaching soles, adding branding logos, and applying finishing touches like polishing or coating for aesthetic appeal and durability. Rubber outsoles are molded using injection or compression molding, depending on design complexity. The shoes then undergo finishing inspections, including visual quality checks for surface defects, color consistency, and overall craftsmanship. This stage also involves functional testing, such as flexibility, shock absorption, and grip performance.

Quality Assurance Framework

Nike’s commitment to quality is embedded within a comprehensive quality management system aligned with international standards like ISO 9001. This framework emphasizes continuous improvement, supplier collaboration, and adherence to global safety standards.

1. Inspection and Testing Protocols

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival for defects, measurement accuracy, and compliance with specifications. Suppliers must provide test certificates for properties like tensile strength, abrasion resistance, and chemical safety, especially for materials used in impact zones.

– In-Process Quality Control (IPQC): During manufacturing, regular inspections verify process consistency. Automated checks for seam integrity, dimensional accuracy, and material placement are common. Random sampling and statistical process control (SPC) techniques help detect deviations early.

– Final Quality Control (FQC): Before shipment, finished shoes undergo comprehensive testing, including visual inspections, durability assessments, and performance tests such as slip resistance and shock absorption. For international markets, compliance with standards like CE (Europe), ASTM F2413 (for impact resistance), or ISO 20345 safety standards is mandatory.

2. Industry-Specific Certifications and Standards

– CE Certification (Europe): Ensures compliance with health, safety, and environmental protection standards. B2B buyers should verify that manufacturing facilities are certified and that products carry the CE mark where applicable.

– ISO 9001 Certification: Demonstrates adherence to internationally recognized quality management principles, including customer focus, process approach, and continuous improvement.

– Other Certifications: Depending on the target market, certifications like API (for impact protection in some sports footwear) or REACH (chemical safety compliance in Europe) may be relevant.

3. Third-Party Inspections and Audits

B2B buyers from Africa, South America, the Middle East, and Europe should leverage third-party inspection agencies (e.g., SGS, Bureau Veritas, Intertek) to verify supplier claims. These audits assess manufacturing practices, quality control systems, and compliance with contractual standards. Regular audits help identify potential risks, such as substandard raw materials or inconsistent production practices, enabling proactive remediation.

4. Supplier Transparency and Documentation

Request detailed quality reports, test certificates, and audit summaries. Transparent documentation allows buyers to assess supplier capabilities and compliance history. Establish clear contractual quality clauses that specify inspection rights, defect tolerance levels, and corrective action procedures.

Tailoring QC for International B2B Buyers

International buyers must recognize that QC practices can vary significantly across regions. For instance, suppliers in Nigeria or Egypt might have different quality management maturity levels compared to European or South American suppliers. Therefore, B2B buyers should:

- Implement Rigorous Pre-Qualification Processes: Enforce strict supplier qualification procedures, including reviewing certifications, past audit reports, and production capacity assessments.

- Conduct Regular Audits and On-Site Inspections: Schedule periodic visits to manufacturing sites, especially in regions with emerging manufacturing capabilities. Use standardized audit checklists aligned with ISO 9001 and industry-specific standards.

- Require Third-Party Testing and Certification: Demand recent third-party test reports for critical safety and performance parameters, ensuring compliance with regional standards such as CE in Europe or ASTM in North America.

- Establish Clear Quality KPIs: Define measurable quality KPIs and enforce penalty clauses for non-compliance to incentivize consistent quality delivery.

Strategic Considerations for B2B Buyers in Different Regions

- Africa (e.g., Nigeria): Focus on assessing the supplier’s compliance with local and international standards, and verify their certifications. Consider partnering with third-party inspectors familiar with regional manufacturing practices.

- South America (e.g., Brazil, Argentina): Emphasize on supply chain transparency and certification audits, especially for compliance with REACH and ASTM standards. Leverage regional trade agreements that may influence quality requirements.

- Middle East (e.g., Egypt, UAE): Prioritize certifications such as CE and ISO 9001. Ensure suppliers adhere to chemical safety standards and environmental regulations, considering regional climate and material durability.

- Europe (e.g., Germany, Italy): Rely on suppliers with proven ISO 9001 certification and compliance with European safety standards. Conduct thorough audits, including product testing and process reviews, to ensure adherence to strict quality norms.

Final Recommendations for B2B Buyers

- Develop Clear Quality Specifications: Provide detailed technical specifications and quality expectations upfront to prevent misunderstandings.

- Engage in Continuous Supplier Development: Collaborate with suppliers to improve manufacturing processes, especially in emerging markets.

- Leverage Technology: Use digital platforms for real-time quality monitoring, documentation, and audit management.

- Build Long-Term Relationships: Establish trust through consistent quality performance and transparent communication, which can lead to better compliance and innovation.

By understanding and integrating these manufacturing and quality assurance practices, international B2B buyers can effectively source Nike boxing shoes that meet global standards while addressing regional compliance nuances. This strategic approach minimizes risks, enhances product reliability, and supports sustainable supply chain partnerships across diverse markets.

Related Video: How Nike Shoes Are Made | Amazing Shoes Factory Process

Comprehensive Cost and Pricing Analysis for nike boxing shoes Sourcing

Cost Components Breakdown

When sourcing Nike boxing shoes, understanding the detailed cost structure is essential for effective negotiation and pricing strategy. The primary cost components include:

-

Materials: High-quality synthetic leathers, mesh fabrics, rubber outsoles, and specialized foam insoles constitute the bulk of material costs. Sourcing premium or sustainable materials can increase expenses but may also add value through differentiation and branding.

-

Labor: Manufacturing labor costs vary significantly by region. For suppliers in Africa, South America, or parts of the Middle East, wages are generally lower than in Europe, but quality and compliance standards must be maintained. Ensuring fair labor practices is crucial and can influence overall costs.

-

Manufacturing Overheads: These include factory utilities, machinery maintenance, and workforce management. Efficient production processes and economies of scale can reduce overhead per unit, especially when order volumes are substantial.

-

Tooling & Development: Initial tooling costs for molds and dies are fixed expenses that are amortized over production runs. For customized or limited editions, tooling costs can be higher, impacting the unit price.

-

Quality Control (QC): Rigorous QC measures, including certifications (e.g., ISO, sustainability standards), add to costs but are vital for brand reputation and compliance, especially in European and Middle Eastern markets.

-

Logistics & Shipping: Transportation costs depend on shipment size, mode (sea, air, land), and destination. For African and South American buyers, sea freight offers cost advantages for bulk shipments, though transit times are longer. Incoterms (FOB, CIF, DDP) significantly influence the total landed cost.

-

Profit Margin: Nike maintains a strategic margin that reflects brand value, innovation, and market positioning. B2B buyers should consider this margin when negotiating pricing, especially when ordering in large volumes.

Price Influencers

Several factors affect the final price of Nike boxing shoes in international B2B transactions:

-

Order Volume & MOQ: Larger orders typically unlock volume discounts. Suppliers prefer high MOQs to optimize production efficiency, but flexibility can be negotiated for smaller, strategic orders.

-

Specifications & Customization: Unique designs, branding, or specialized features (e.g., enhanced grip, specific padding) increase production complexity and costs. Buyers seeking customization should budget accordingly and understand that this may extend lead times.

-

Materials & Certifications: Use of premium or eco-friendly materials, along with necessary certifications (e.g., Fair Labor, sustainability labels), can elevate costs but also enhance market appeal, especially in Europe and Middle East markets where consumers prioritize ethical sourcing.

-

Supplier Factors: The supplier’s location, capacity, reputation, and compliance record impact pricing. Suppliers with robust sustainability practices and certifications may charge a premium but offer better long-term value.

-

Incoterms & Logistics: FOB (free on board) terms shift shipping costs to the buyer, while CIF (cost, insurance, freight) includes shipping, simplifying budgeting but often at a higher initial price. Buyers must evaluate total landed costs to compare offers effectively.

Buyer Tips for Cost Optimization

-

Negotiate Based on Total Cost of Ownership (TCO): Focus on the overall value—consider quality, lead times, reliability, and after-sales support—rather than solely on unit price.

-

Leverage Volume for Discounts: Large or recurring orders can significantly reduce per-unit costs. Establish long-term relationships to benefit from preferential pricing.

-

Understand Pricing Nuances: Prices often vary based on currency fluctuations, regional tariffs, and local taxes. In markets like Nigeria or Egypt, import duties and VAT can add 10-30% to landed costs, so factor these into your negotiations.

-

Optimize Logistics & Incoterms: Selecting appropriate shipping terms can reduce costs. For example, FOB arrangements allow buyers to manage freight and insurance, potentially reducing overall expenses if they have reliable logistics partners.

-

Assess Local Market Conditions: Currency stability, political factors, and infrastructure quality influence costs. In regions with logistical challenges, higher transportation or customs handling fees may apply.

Disclaimer for Indicative Pricing

While specific prices fluctuate based on order size, specifications, and supplier relationships, typical FOB manufacturing costs for Nike boxing shoes range between $15 to $30 per pair for bulk orders. Landed costs in Africa, South America, or Middle East markets could range from $25 to $45 per pair, inclusive of shipping, duties, and taxes. European markets might see slightly higher prices due to stricter compliance standards and higher logistics costs. Buyers should conduct detailed supplier negotiations and consider all factors influencing final landed costs for accurate budgeting.

By thoroughly analyzing these cost components and influencing factors, international B2B buyers can develop strategic sourcing plans that optimize cost-efficiency while maintaining Nike’s quality standards.

Spotlight on Potential nike boxing shoes Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘nike boxing shoes’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for nike boxing shoes

Critical Technical Properties for Nike Boxing Shoes

1. Material Grade and Composition

The selection of high-quality materials, such as premium synthetic leathers or mesh fabrics, is essential for durability, flexibility, and breathability. Material grades are specified by standards (e.g., ISO, ASTM) to ensure consistency across batches. For B2B procurement, verifying material certifications guarantees compliance with safety and sustainability standards, reducing risks of product failures or recalls.

2. Manufacturing Tolerance

Tolerance refers to the acceptable variation in dimensions and construction during production, typically measured in millimeters or as a percentage. Precise tolerances ensure the shoes fit correctly, maintain structural integrity, and meet brand specifications. Suppliers with tight tolerances reduce the need for rework, speeding up time-to-market and maintaining quality consistency.

3. Cushioning and Support Technologies

Advanced cushioning systems (e.g., Nike Zoom Air, foam midsoles) are vital for shock absorption and athlete performance. Specifications include foam density, air pressure, and placement accuracy. These technical properties influence comfort, safety, and competitive advantage, making them critical parameters for OEMs and buyers to specify.

4. Weight and Flexibility

Lightweight construction enhances agility and reduces fatigue during boxing matches. Flexibility is often measured by bending tests or flexion angles. Suppliers must adhere to strict weight tolerances and flexibility standards to meet performance expectations, which are key differentiators in the competitive sports footwear market.

5. Traction and Outsole Composition

The outsole material, often rubber or specialized compounds, must provide optimal grip under diverse conditions. Tread pattern and rubber hardness (measured by durometer) are specified to ensure durability and slip resistance. Consistent outsole properties directly impact safety and athlete confidence, making them a primary focus in quality assessments.

6. Durability and Wear Resistance

Metrics such as abrasion resistance and fatigue life are evaluated through standardized testing. These properties determine how well the shoes withstand repeated impacts, toe dragging, and intense use. For B2B buyers, selecting suppliers with proven durability metrics minimizes warranty claims and enhances brand reputation.

Common Trade Terms in Nike Boxing Shoes Industry

1. OEM (Original Equipment Manufacturer)

Refers to a manufacturer that produces boxing shoes according to a brand’s specifications and designs. OEMs are responsible for ensuring quality, compliance, and consistency. Understanding OEM capabilities helps buyers assess manufacturing reliability and potential for customization.

2. MOQ (Minimum Order Quantity)

The smallest number of units a supplier agrees to produce or sell in a single order. MOQ impacts procurement planning, costs, and inventory management, especially when sourcing innovative or premium models. Negotiating favorable MOQ terms is crucial for market entry or limited edition releases.

3. RFQ (Request for Quotation)

A formal document sent by buyers to suppliers requesting pricing, lead times, and technical details for specific shoe models. RFQs are essential for comparing supplier offerings, ensuring competitive pricing, and clarifying technical requirements before procurement.

4. Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce that define responsibilities for shipping, insurance, and tariffs. Common Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, Freight) clarify who bears costs and risks at each stage, aiding in transparent negotiations and logistics planning.

5. Lead Time

The period from order placement to product delivery. For Nike boxing shoes, understanding supplier lead times helps optimize inventory levels, meet seasonal demand, and plan marketing campaigns effectively. Shorter lead times are often preferred but may come at a premium.

6. Certification and Compliance Terms

Terms such as ISO, REACH, or CPSIA indicate adherence to safety, environmental, and labor standards. Ensuring suppliers possess relevant certifications is vital for legal compliance, market access, especially in regions like Europe and North America, and aligning with Nike’s sustainability goals.

Summary:

For international B2B buyers, understanding these technical properties and trade terms ensures a seamless procurement process, minimizes risks, and aligns product quality with brand standards. Clear specifications on materials, manufacturing tolerances, and technological features directly impact product performance and customer satisfaction. Simultaneously, familiarization with trade jargon facilitates effective negotiations, cost control, and compliance across diverse markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the nike boxing shoes Sector

Market Overview & Key Trends

The global market for athletic footwear, including niche segments like boxing shoes, is experiencing rapid growth driven by increasing participation in combat sports, rising health consciousness, and expanding retail channels. For B2B buyers from Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial to sourcing effectively. Emerging trends such as digital sourcing platforms, supply chain transparency tools, and data-driven demand forecasting are transforming procurement strategies.

In regions like Nigeria, Egypt, Brazil, and Turkey, local sports culture and rising disposable incomes are fueling demand for high-performance, branded boxing shoes. International buyers must navigate complex market dynamics characterized by fluctuating raw material costs, geopolitical influences, and evolving consumer preferences. The shift towards direct sourcing from manufacturers, facilitated by digital marketplaces, offers opportunities for cost reduction and quality assurance. Additionally, supply chain resilience—highlighted by recent global disruptions—underscores the importance of diversified sourcing networks.

Furthermore, technological advancements such as 3D printing and innovative material development are enabling faster prototyping and customization, appealing to regional markets seeking unique product offerings. Sustainability considerations are increasingly influencing purchasing decisions, prompting buyers to prioritize suppliers with strong compliance and eco-friendly practices. Staying abreast of these trends allows B2B buyers to optimize sourcing, negotiate better terms, and ensure market competitiveness.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a central pillar in sourcing decisions within the Nike boxing shoes sector. As a globally recognized brand committed to responsible manufacturing, Nike emphasizes reducing environmental impact through eco-conscious materials and transparent supply chains. For international B2B buyers, sourcing from suppliers aligned with these standards not only enhances brand reputation but also ensures compliance with regional regulations and consumer expectations.

Key sustainability initiatives include the use of recycled polyester, organic cotton, and innovative bio-based materials that lower carbon footprints and reduce resource depletion. Certification programs such as Fair Trade, Global Organic Textile Standard (GOTS), and LEED are valuable indicators of a supplier’s commitment to environmental and social responsibility. For buyers in regions like Africa and South America, engaging with suppliers holding these certifications can facilitate access to premium markets and foster long-term partnerships.

Ethical sourcing extends beyond materials to encompass fair labor practices, safe working conditions, and supply chain transparency. Nike’s focus on supplier performance scorecards and ongoing audits helps ensure compliance and continuous improvement. B2B buyers should prioritize suppliers with proven track records of responsible sourcing, leveraging third-party verifications and sustainability reporting. Integrating sustainability into procurement processes not only mitigates risks but also aligns with global consumer trends favoring environmentally and socially responsible products, ultimately enhancing market positioning and stakeholder trust.

Brief Evolution/History

Historically, Nike’s approach to sourcing and manufacturing has evolved from a focus on cost minimization to a comprehensive sustainability and ethical standards framework. During the 2000s, the company faced criticism over labor practices, prompting a strategic shift towards greater transparency and responsible sourcing. Today, Nike invests heavily in supplier development programs, sustainability initiatives, and digital monitoring systems to ensure compliance and innovation.

For B2B buyers, understanding this evolution underscores the importance of partnering with suppliers committed to continuous improvement in quality, sustainability, and social responsibility. The company’s proactive stance on environmental impact and labor standards positions it as a leader in responsible manufacturing, providing confidence to buyers seeking long-term, compliant sourcing options. This historical progression highlights that responsible sourcing is integral to Nike’s global strategy, fostering resilience and aligning with international standards, especially critical in emerging markets where regulatory landscapes are rapidly changing.

Frequently Asked Questions (FAQs) for B2B Buyers of nike boxing shoes

1. How can I effectively vet Nike suppliers for boxing shoes to ensure quality, compliance, and sustainability standards?

To vet Nike suppliers thoroughly, start by requesting their compliance certifications, such as ISO quality standards, social responsibility audits, and sustainability credentials aligned with Nike’s supplier requirements. Review their performance scorecards, focusing on quality, delivery reliability, and sustainability metrics. Engage in site visits or virtual audits to verify manufacturing conditions, labor practices, and environmental compliance. Additionally, confirm their adherence to Nike’s Code of Conduct and Fair Labor standards. Establish clear communication channels for ongoing performance monitoring and leverage Nike’s supplier performance tools, such as feedback via Better Buying, to ensure continuous improvement and risk mitigation.

2. What customization options are available for Nike boxing shoes, and how can I negotiate for tailored designs or branding?

Nike offers a range of customization options for boxing shoes, including branding, color schemes, and specific design features to meet your market needs. To access these, collaborate directly with Nike’s strategic sourcing or regional account managers, who can facilitate design consultations and prototypes. Be prepared to meet minimum order quantities (MOQs) and lead times that align with your customization scope. Negotiating terms for branding rights, packaging, and exclusive designs can provide a competitive edge. Ensure contractual clarity on intellectual property rights and quality standards, and leverage Nike’s innovation teams for exclusive or co-branded product lines tailored to your target markets.

3. What are typical minimum order quantities, lead times, and payment terms for Nike boxing shoes in international trade?

Nike’s MOQs for boxing shoes generally range from several hundred to a few thousand pairs, depending on the complexity of customization and regional supplier capabilities. Lead times typically vary from 60 to 120 days, influenced by production volume, design complexity, and logistics. Payment terms often include 30-50% upfront deposits, with the balance payable upon shipment or delivery, aligned with Nike’s global procurement policies. It’s crucial to establish clear contractual terms and leverage Nike’s multi-year sourcing forecasts to plan inventory and cash flow effectively, especially for high-demand or seasonal markets in Africa, South America, the Middle East, and Europe.

4. What quality assurance measures and certifications should I verify before importing Nike boxing shoes?

Ensure your supplier complies with Nike’s strict quality assurance protocols, including certifications such as ISO 9001, social compliance audits (e.g., SA8000), and environmental standards (e.g., ISO 14001). Request documentation of recent factory audits, testing reports for durability, slip resistance, and material safety, and adherence to Nike’s Responsible Sourcing guidelines. Implement pre-shipment inspections and third-party QA testing to verify product quality before dispatch. Additionally, confirm that products meet regional safety standards and import regulations—such as CE marking for Europe or local certifications in Nigeria, Egypt, or other markets—to prevent customs delays and compliance issues.

5. How can I coordinate logistics and shipping to ensure timely delivery of Nike boxing shoes across different regions?

Coordinate with Nike’s logistics partners or regional distributors to establish reliable shipping routes, considering port congestion, customs procedures, and regional transit times. Leverage Nike’s supply chain tools to obtain multi-year forecasts and shipping schedules, enabling proactive planning. Choose shipping methods—air, sea, or land—based on cost sensitivity and urgency; for example, air freight for urgent replenishments and sea freight for bulk orders. Work with experienced freight forwarders familiar with Nike’s import/export procedures and regional customs requirements. Incorporate tracking and real-time updates into your supply chain management to minimize delays and optimize inventory levels.

6. What common disputes arise in international sourcing of Nike boxing shoes, and how can they be effectively resolved?

Common disputes include quality discrepancies, late deliveries, payment disagreements, and intellectual property issues. To mitigate these, establish clear contractual terms covering quality standards, delivery timelines, and payment conditions aligned with Nike’s procurement policies. Use detailed inspection protocols and enforce warranty or return policies. For resolution, prioritize open communication and dispute resolution clauses—such as arbitration under recognized legal frameworks—embedded in your contracts. Building strong supplier relationships based on transparency and regular audits can prevent misunderstandings. If disputes escalate, leverage Nike’s regional supplier support teams or legal counsel familiar with international trade laws.

7. How do Nike’s sustainability and responsible sourcing policies impact international B2B transactions?

Nike’s sustainability initiatives emphasize responsible sourcing, fair labor practices, and environmental impact reduction, influencing procurement decisions globally. As a B2B buyer, prioritize suppliers committed to Nike’s sustainability scorecards and certifications, which can enhance brand reputation and consumer trust in your markets. Incorporate sustainability clauses into contracts and seek suppliers with transparent supply chain traceability, eco-friendly materials, and social compliance certifications. These policies may influence pricing and lead times but offer long-term benefits, including access to exclusive eco-friendly product lines and alignment with global ESG standards, especially appealing in markets like Europe and the Middle East.

8. What strategies should I adopt to resolve potential disputes or quality issues with Nike boxing shoes after import?

Proactively establish clear communication channels and detailed contractual quality standards before purchase. Conduct pre-shipment inspections and third-party testing to verify product compliance with agreed specifications. In case of disputes, document all correspondence, inspection reports, and test results to support your claim. Engage Nike’s regional support teams or authorized representatives for mediation. Consider including arbitration clauses and clear warranty policies in your agreements. Maintaining a collaborative approach—focused on corrective actions and continuous improvement—can foster long-term supplier relationships and minimize recurrence of issues, ensuring your market remains supplied with high-quality Nike boxing shoes.

This structured approach ensures B2B buyers from diverse regions can navigate the complexities of sourcing Nike boxing shoes effectively, aligning with global standards while tailoring to regional market needs.

Strategic Sourcing Conclusion and Outlook for nike boxing shoes

Key Takeaways for International B2B Buyers

Effective strategic sourcing is vital for securing high-quality Nike boxing shoes while maintaining competitive costs and sustainability standards. Nike’s rigorous supplier evaluation, emphasis on transparency, and commitment to sustainable practices demonstrate the importance of building long-term, mutually beneficial relationships. Leveraging detailed performance scorecards and ongoing supplier development can help buyers identify reliable partners aligned with global sustainability goals.

The Value of Strategic Sourcing

Strategic sourcing not only optimizes procurement efficiency but also enhances product quality and supply chain resilience. Nike’s approach—focused on innovation, sustainability, and ethical compliance—serves as a benchmark for buyers seeking to strengthen their supply chains. By adopting similar practices, B2B buyers can mitigate risks, foster supplier loyalty, and contribute positively to social and environmental impacts.

Future Outlook and Call to Action

Looking ahead, international buyers from Africa, South America, the Middle East, and Europe should prioritize strategic sourcing as a competitive advantage. Engaging with Nike’s supplier ecosystem offers opportunities for collaboration, innovation, and sustainable growth. Now is the time to evaluate and refine sourcing strategies—partner with trusted suppliers, embrace sustainability, and position your business for resilient, future-ready supply chains.