Your Ultimate Guide to Sourcing Cross Country Running Shoes

Guide to Cross Country Running Shoes

- Introduction: Navigating the Global Market for cross country running shoes

- Understanding cross country running shoes Types and Variations

- Key Industrial Applications of cross country running shoes

- Strategic Material Selection Guide for cross country running shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for cross country running shoes

- Comprehensive Cost and Pricing Analysis for cross country running shoes Sourcing

- Spotlight on Potential cross country running shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for cross country running shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the cross country running shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of cross country running shoes

- Strategic Sourcing Conclusion and Outlook for cross country running shoes

Introduction: Navigating the Global Market for cross country running shoes

In the competitive landscape of international sports footwear, cross country running shoes have emerged as a vital product category for brands, retailers, and distributors seeking to meet the growing demand of athletes and enthusiasts worldwide. For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of this specialized segment is essential to making strategic sourcing decisions that optimize quality, cost, and supply chain reliability.

This comprehensive guide offers a detailed exploration of the cross country running shoe market—from the different types and materials used to manufacturing processes and quality control standards. It also provides actionable insights into identifying reliable suppliers, evaluating costs, and understanding regional market dynamics. Whether sourcing from Asia, Europe, or emerging manufacturing hubs, buyers will find critical information to mitigate risks and capitalize on growth opportunities.

By equipping you with knowledge about key industry trends, supplier selection criteria, and frequently asked questions, this guide aims to empower you to navigate the complexities of global sourcing confidently. Whether you’re establishing new supply chains or optimizing existing ones, this resource is designed to support informed, strategic decisions—helping you stay competitive in a rapidly evolving market landscape.

Understanding cross country running shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Trail Running Shoes | Reinforced uppers, aggressive outsole lugs, moderate cushioning | Retail, sports stores, specialty outdoor suppliers | Pros: Widely accepted, versatile for various terrains. Cons: May lack specialized grip for extreme conditions. |

| Lightweight Cross Country Spikes | Minimalist design, metal spikes or pins, low profile, lightweight materials | Schools, clubs, competitive teams | Pros: High performance for racing, quick turnover. Cons: Limited durability, not suitable for training. |

| Maximalist Cross Country Shoes | Extra cushioning, wider sole platform, cushioned midsoles | High-end retail, premium sports brands | Pros: Superior comfort, shock absorption. Cons: Heavier, may reduce speed on technical courses. |

| All-Terrain Hybrid Shoes | Combination of trail and road features, moderate spike compatibility | Suppliers targeting diverse terrains | Pros: Multi-purpose, adaptable for different courses. Cons: May compromise on specialized grip. |

| Customizable/Modular Shoes | Interchangeable spikes, adjustable fit systems, modular outsole options | Niche markets, custom sports gear suppliers | Pros: Tailored fit and performance, longer product lifecycle. Cons: Higher manufacturing costs, complex inventory management. |

Traditional Trail Running Shoes

Traditional trail running shoes are designed for general outdoor use, featuring reinforced uppers for durability and aggressive lug patterns for grip on uneven terrain. They are suitable for retail outlets and outdoor specialty stores aiming to serve a broad customer base. For B2B buyers, these shoes offer a reliable product with mass-market appeal, but they may lack the specialized grip needed for extreme or highly technical courses. Purchasing considerations include material quality, outsole durability, and compatibility with different terrains to ensure consistent quality across batches.

Lightweight Cross Country Spikes

These shoes are characterized by their minimal weight, low-profile design, and metal spikes or pins that enhance traction on soft or muddy courses. They are primarily used by schools, clubs, and competitive teams seeking high-speed performance. B2B buyers should focus on sourcing spike plates that balance weight and durability, and consider the spike compatibility for different racing conditions. While they excel in racing environments, their limited durability makes them less suitable for training or multi-use scenarios, requiring careful inventory management.

Maximalist Cross Country Shoes

Maximalist shoes feature abundant cushioning and a wider sole platform, prioritizing comfort and shock absorption. They are targeted at premium sports brands and high-end retail channels. For B2B buyers, these shoes appeal to a niche market of athletes seeking extra comfort, especially for longer or more technical courses. The key considerations include sourcing high-quality cushioning materials and ensuring weight management to avoid excessive heaviness that could hinder speed. They tend to have higher price points but can command premium margins.

All-Terrain Hybrid Shoes

Designed to bridge trail and road running needs, these shoes combine features such as moderate spike compatibility, versatile outsole patterns, and balanced cushioning. They are ideal for suppliers looking to offer multi-purpose footwear suitable for diverse courses. B2B buyers should evaluate the outsole design, spike compatibility, and material flexibility to meet varied customer demands. Their adaptability makes them appealing in regions with unpredictable terrain, but they may sacrifice some specialized performance features of dedicated trail or spike shoes.

Customizable/Modular Shoes

These shoes incorporate interchangeable spikes, adjustable fit systems, and modular outsole components, allowing athletes to tailor their footwear to specific race conditions. They target niche markets and premium sports gear suppliers. For B2B buyers, the focus should be on sourcing reliable modular components, managing inventory complexity, and understanding customer preferences for customization options. While offering high performance and product longevity, they come with higher manufacturing costs and require precise quality control. This makes them suitable for markets where athletes demand personalized solutions and are willing to pay a premium.

Key Industrial Applications of cross country running shoes

| Industry/Sector | Specific Application of cross country running shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Infrastructure | Worker footwear for uneven terrain, site inspections, and outdoor tasks | Enhanced safety, stability, and comfort in rugged environments | Durability, slip resistance, comfort, and adaptability to diverse terrains |

| Agriculture & Forestry | Field workers navigating rough, muddy, or uneven farmland and forested areas | Improved worker safety, reduced fatigue, and increased productivity | Traction, waterproofing, breathability, and durability under harsh conditions |

| Military & Defense | Training exercises and operational activities in varied terrains | Superior grip, stability, and support for demanding field operations | Ruggedness, slip resistance, lightweight design, and compliance with safety standards |

| Outdoor Sports & Recreation | Adventure tourism, expedition teams, and outdoor event staff | Reliable footwear for unpredictable terrains, reducing injury risk | Traction, durability, lightweight construction, and weather resistance |

| Logistics & Supply Chain | Workers in warehousing, distribution centers, and last-mile delivery in outdoor environments | Comfort and stability for long shifts, minimizing fatigue and injury | Comfort, slip resistance, durability, and adaptability to outdoor working conditions |

Construction & Infrastructure

Cross country running shoes are increasingly adopted by construction workers operating on uneven or unfinished sites. Their rugged soles and supportive design provide superior grip and stability, reducing slip-and-fall risks common in muddy or rocky environments. International B2B buyers from regions like Nigeria or Brazil should prioritize sourcing shoes with high durability, slip resistance, and weather-resistant materials to withstand harsh outdoor conditions. These features ensure worker safety and minimize replacement costs, making them a cost-effective solution for infrastructure projects.

Agriculture & Forestry

In agriculture and forestry, workers often face challenging terrains such as muddy fields, steep slopes, and dense forests. Cross country shoes offer excellent traction and waterproofing, essential for maintaining footing and comfort in these demanding environments. For buyers in countries like Vietnam or Argentina, sourcing shoes with high durability, breathable yet waterproof materials, and reinforced soles can significantly enhance productivity and worker safety. These shoes help reduce fatigue and injury, particularly in regions with unpredictable weather and rugged landscapes.

Military & Defense

Military personnel engaged in training or operational activities across varied terrains require footwear that offers grip, support, and durability. Cross country running shoes meet these needs with their rugged construction and multi-surface traction capabilities. B2B buyers from the Middle East or Eastern Europe should focus on sourcing lightweight, high-performance shoes that comply with safety standards and offer excellent support for prolonged use. Such footwear enhances operational readiness and reduces injury risks during intense physical activities.

Outdoor Sports & Recreation

Adventure tourism companies, expedition teams, and outdoor event organizers depend on reliable footwear that can handle unpredictable terrains like rocky trails, muddy paths, and loose gravel. Cross country shoes provide the necessary grip, lightweight comfort, and weather resistance for outdoor enthusiasts. For European or South American buyers, sourcing shoes with high traction, quick-drying materials, and durable construction ensures safety and enhances the outdoor experience, reducing liability and equipment costs.

Logistics & Supply Chain

In outdoor logistics operations, such as warehouse outdoor loading zones or last-mile delivery in less developed areas, workers benefit from footwear that offers stability and comfort over long shifts. Cross country shoes help prevent fatigue and slips, especially on uneven or slippery surfaces. B2B buyers in regions like Nigeria or Vietnam should focus on sourcing shoes with slip-resistant soles, breathable materials, and robust construction to improve worker safety, reduce downtime, and optimize operational efficiency in outdoor environments.

Strategic Material Selection Guide for cross country running shoes

Material Analysis for Cross Country Running Shoes

Selecting the appropriate materials is crucial for manufacturing high-performance cross country running shoes that meet diverse international standards and consumer expectations. Below is an in-depth analysis of three common materials—EVA foam, TPU (Thermoplastic Polyurethane), and rubber compounds—focusing on their properties, advantages, limitations, and considerations for B2B buyers from regions such as Africa, South America, the Middle East, and Europe.

EVA Foam (Ethylene-Vinyl Acetate)

Key Properties:

EVA foam is lightweight, flexible, and offers excellent cushioning, making it ideal for midsoles. It exhibits good shock absorption and is resistant to water and UV degradation to some extent. However, EVA’s thermal stability is limited, and it can degrade under prolonged exposure to high temperatures.

Pros & Cons:

* Pros:*

– Cost-effective and widely available

– Easy to mold and process during manufacturing

– Provides good cushioning, reducing runner fatigue

- Cons:*

- Less durable over time, especially under heavy or abrasive use

- Susceptible to compression set, leading to loss of cushioning

- Can degrade faster in hot climates, affecting longevity

Impact on Application:

EVA’s compatibility with various adhesives and surface treatments makes it versatile for different shoe designs. However, in regions with high ambient temperatures (e.g., Middle East), EVA may soften excessively, impacting structural integrity.

International Buyer Considerations:

Buyers should verify EVA foam compliance with regional standards such as ASTM or EN standards for safety and environmental regulations. For markets like Nigeria and Vietnam, sourcing EVA from reputable suppliers ensures consistent quality and adherence to local import standards. Cost considerations favor EVA, but durability expectations should be managed accordingly.

TPU (Thermoplastic Polyurethane)

Key Properties:

TPU is known for its excellent elasticity, abrasion resistance, and flexibility. It maintains its properties across a wide temperature range, from cold European climates to hot Middle Eastern environments. TPU also offers good chemical resistance, including against oils and greases.

Pros & Cons:

* Pros:*

– Highly durable and resistant to wear and tear

– Suitable for high-stress components like outsoles and overlays

– Recyclable and environmentally friendly in some formulations

- Cons:*

- Higher manufacturing complexity and cost compared to EVA

- Requires specialized processing equipment (e.g., injection molding)

- Potentially heavier than softer materials, impacting overall shoe weight

Impact on Application:

TPU’s strength makes it suitable for outsole components and protective overlays, especially in rugged cross country terrains. Its resistance to environmental factors ensures longevity in diverse climates, from humid South American regions to dry Middle Eastern deserts.

International Buyer Considerations:

Buyers should confirm TPU compliance with regional standards such as ISO or ASTM. In markets like Nigeria and Vietnam, sourcing from suppliers with certified eco-labels and environmental compliance (e.g., REACH, RoHS) is advantageous. While more costly, TPU’s durability can reduce replacement frequency, offering long-term savings.

Rubber Compounds (Natural and Synthetic Rubber)

Key Properties:

Rubber compounds are the traditional choice for outsoles, offering excellent grip, flexibility, and abrasion resistance. Natural rubber provides superior elasticity, while synthetic variants (e.g., SBR, NBR) can be formulated for specific performance needs.

Pros & Cons:

* Pros:*

– Exceptional traction on varied surfaces

– High durability and resilience under repeated stress

– Good resistance to tearing and punctures

- Cons:*

- Heavier than foam-based materials, potentially affecting performance

- Natural rubber can degrade with prolonged UV exposure unless treated

- Synthetic rubbers may involve higher raw material costs

Impact on Application:

Rubber compounds are critical for outsole durability, especially in cross country environments with uneven terrains. They perform well across temperature ranges but may require specific formulations to optimize performance in extreme climates.

International Buyer Considerations:

Buyers should ensure rubber materials meet local standards such as ASTM D2000 or JIS K 6253. For regions like Africa and South America, sourcing from suppliers with proven quality certifications ensures consistent performance. Cost varies depending on the type and formulation, but the investment is justified by longevity and safety.

Summary Table

| Material | Typical Use Case for cross country running shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| EVA Foam | Midsole cushioning | Cost-effective, lightweight, good shock absorption | Less durable over time, degrades in heat | Low |

| TPU | Outsole components, overlays | Highly durable, abrasion-resistant, flexible | Higher manufacturing complexity and cost | High |

| Rubber Compounds | Outsoles | Excellent grip, abrasion resistance, durability | Heavier, can degrade under UV if untreated | Med |

This detailed analysis aims to guide international B2B buyers in selecting materials that balance performance, cost, and compliance with regional standards. By understanding each material’s properties and limitations, buyers can optimize their supply chains for diverse markets, ensuring high-quality cross country running shoes tailored to regional needs.

In-depth Look: Manufacturing Processes and Quality Assurance for cross country running shoes

Manufacturing Processes for Cross Country Running Shoes

The production of cross country running shoes involves a complex sequence of carefully orchestrated stages designed to ensure durability, performance, and comfort. For B2B buyers, understanding these stages is crucial to evaluating supplier capabilities and ensuring quality consistency across international markets.

1. Material Preparation

The manufacturing process begins with sourcing and preparing raw materials such as rubber, EVA foam, synthetic textiles, mesh fabrics, and thermoplastic polyurethane (TPU). Suppliers often pre-treat materials to enhance adhesion and durability, with an emphasis on sourcing eco-friendly or performance-enhancing materials compliant with international standards. For international buyers, verifying the quality certifications of raw materials—such as REACH or OEKO-TEX—can serve as an initial quality indicator.

2. Forming and Cutting

In this stage, upper components are cut from textiles or synthetic materials using automated cutting machines with CAD/CAM technology for precision. The outsole and midsole molds are created through injection molding or compression molding processes, ensuring consistent shape and density. Advanced techniques like laser cutting or ultrasonic welding may be employed for intricate design features, which are especially relevant for customized or high-performance cross country shoes.

3. Assembly and Stitching

The upper parts are assembled through stitching, welding, or adhesive bonding, often combining multiple materials to optimize breathability and support. The midsole and outsole are attached via adhesive bonding, vulcanization, or mechanical fastening, depending on the design. Precision in assembly is critical to prevent defects such as delamination or weak joints, which can compromise shoe integrity during rigorous cross country activity.

4. Finishing and Quality Checks

Final steps include adding laces, insoles, branding, and finishing touches. Surface treatments, such as waterproofing or anti-slip coatings, are applied at this stage. The shoes undergo initial visual inspections and functional tests before moving to more rigorous quality checks. For B2B buyers, the finishing process should be documented with traceability codes to facilitate post-delivery quality audits.

Quality Assurance (QA) and Standards

Effective quality assurance (QA) is fundamental to ensure that cross country shoes meet performance specifications and regulatory requirements across markets. Implementing a structured QA process aligned with international and industry-specific standards can mitigate risks associated with product failure or non-compliance.

1. International Standards and Certifications

– ISO 9001: Most reputable manufacturers adhere to ISO 9001 standards, establishing a robust Quality Management System (QMS) that covers design, production, and after-sales support. This certification ensures continuous improvement and customer satisfaction.

– CE Marking (Europe): For shoes sold within the European Economic Area, CE marking indicates compliance with safety, health, and environmental directives, including slip resistance and chemical safety.

– Other Certifications: Depending on the market, certifications like ASTM (for performance testing), REACH (chemical safety), or specific industry standards such as API (for certain manufacturing processes) may be relevant.

2. Quality Control Checkpoints

– Incoming Quality Control (IQC): Raw materials and components are inspected upon receipt for conformity to specifications, including dimensional accuracy, material integrity, and chemical safety.

– In-Process Quality Control (IPQC): During manufacturing, checkpoints focus on process parameters such as stitching quality, mold accuracy, bonding strength, and assembly precision. Techniques like statistical process control (SPC) are often employed here.

– Final Quality Control (FQC): Finished shoes undergo comprehensive inspections, including visual assessment for defects, functional testing (e.g., flexibility, shock absorption), and dimensional checks. Sampling methods like AQL (Acceptable Quality Level) standards guide inspection rigor.

3. Testing Methods

– Mechanical Testing: Tensile, shear, and peel tests assess the strength of adhesives and seams. Drop tests evaluate shock absorption, while flex tests simulate walking or running stresses.

– Environmental Testing: Shoes are subjected to water immersion, UV exposure, and temperature cycling to ensure durability under different climate conditions.

– Chemical Testing: Ensures absence of harmful substances such as heavy metals or volatile organic compounds (VOCs), in line with REACH and other regulations.

Verifying Supplier Quality and Ensuring Compliance

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying the quality systems of manufacturing partners is critical. Several strategies can be employed:

- Factory Audits: Conduct comprehensive audits focusing on quality management practices, production capabilities, and compliance with certifications like ISO 9001. Audits can be performed on-site or via third-party inspection agencies.

- Inspection Reports and Documentation: Request detailed QC reports, test certificates, and process documentation. Consistent record-keeping demonstrates transparency and adherence to quality standards.

- Third-party Inspections: Engaging reputable third-party inspection firms (e.g., SGS, Bureau Veritas) provides unbiased assessments of product quality before shipment, reducing risks of non-compliance or defects.

- Sample Testing: Sending samples for independent testing can validate manufacturer claims, especially regarding chemical safety and mechanical performance.

Nuances for International B2B Buyers

Cultural and Regulatory Considerations:

Buyers from different regions should be aware of local regulations and cultural expectations. For instance, European buyers often require comprehensive chemical safety documentation (REACH compliance), while buyers from Nigeria or Vietnam may prioritize durability under high-temperature or humid conditions.

Supply Chain Transparency:

Ensuring traceability of raw materials and manufacturing processes is vital. Suppliers capable of providing detailed origin data, batch records, and compliance certificates facilitate smoother import processes and reduce legal risks.

Customization and Certification:

Buyers seeking custom designs or specific certifications must verify that the manufacturer has the capacity for tailored production and possesses relevant certifications. Building long-term relationships with compliant, transparent suppliers enhances quality assurance and reduces procurement risks.

Final Insights for B2B Buyers

Understanding the intricacies of manufacturing and quality assurance in cross country running shoes empowers international buyers to make informed sourcing decisions. Prioritize suppliers with recognized certifications, transparent quality documentation, and proven testing capabilities. Regular audits, third-party inspections, and rigorous testing regimes help mitigate risks associated with cross-border procurement and ensure that the final product meets the demanding standards of cross country athletes worldwide.

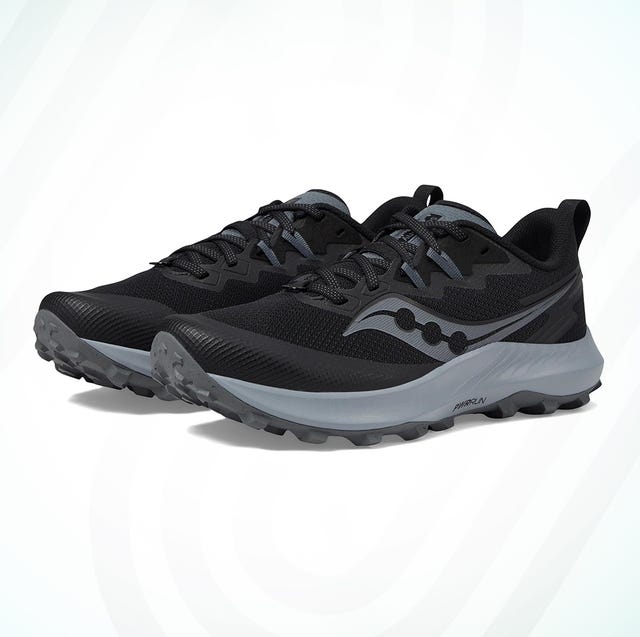

Illustrative Image (Source: Google Search)

Comprehensive Cost and Pricing Analysis for cross country running shoes Sourcing

Cost Structure Breakdown

Understanding the comprehensive cost structure of cross country running shoes is essential for effective sourcing and pricing negotiations. The primary components include:

- Materials: High-performance synthetics, mesh uppers, specialized rubber outsoles, and foam insoles contribute significantly to cost. Premium materials with enhanced durability, breathability, or eco-friendly features will elevate material expenses.

- Labor: Manufacturing costs vary based on the country of production, labor laws, and skill levels. For instance, factories in Vietnam or China often offer competitive wages with high efficiency, while facilities in Africa or South America may have lower labor costs but potentially higher variability.

- Manufacturing Overhead: This encompasses factory utilities, machinery depreciation, and administrative expenses. Efficient factories with modern equipment tend to have lower overheads, impacting the final price.

- Tooling and Development: Initial mold creation and design customization can be substantial, especially for bespoke models or advanced sole designs. These costs are amortized over larger production runs.

- Quality Control (QC): Rigorous QC processes, including testing for durability, flexibility, and compliance with international standards, add to costs but are crucial for brand reputation and reducing returns.

- Logistics: Shipping costs, freight insurance, customs duties, and port handling fees significantly influence landed costs. Sourcing from Asia typically incurs lower logistics costs compared to shipping from other regions, but regional import tariffs can vary.

- Margins: Suppliers add a markup to cover risks, profit margins, and currency fluctuations. Margins typically range from 10% to 30% depending on the supplier’s market position and relationship.

Price Influencers

Several factors impact the final price of cross country shoes in the B2B context:

- Order Volume & MOQ: Larger orders generally attract better unit prices due to economies of scale. Minimum order quantities (MOQs) vary, but buyers should aim for higher volumes to negotiate discounts.

- Specifications & Customization: Customized designs, special features (e.g., waterproofing, custom branding), or unique sole constructions increase costs. Suppliers often charge premiums for tailored specifications.

- Materials & Certifications: Using premium or eco-certified materials can raise costs but may appeal to niche markets. Certifications such as ISO, environmental, or safety standards can also influence pricing.

- Supplier Capabilities & Reliability: Well-established manufacturers with a proven track record tend to have higher prices but offer greater assurance of quality and compliance.

- Incoterms & Shipping Terms: FOB (Free on Board), CIF (Cost, Insurance, Freight), and DDP (Delivered Duty Paid) terms affect overall costs. Buyers must consider logistics and import duties when calculating landed costs.

Strategic Buyer Tips

- Negotiation Leverage: Build long-term relationships and commit to larger orders to negotiate better pricing. Highlighting consistent volume can often lead to discounts or flexible payment terms.

- Focus on Total Cost of Ownership (TCO): Beyond unit price, consider costs related to quality control, delays, customs clearance, and after-sales support. A cheaper initial quote might incur higher TCO if quality issues arise.

- Understand Pricing Nuances: International buyers, especially from Africa, South America, the Middle East, and Europe, should be aware of regional tariffs, import taxes, and currency exchange risks. These factors can significantly alter the final landed cost.

- Customization & Lead Time Management: Early communication on design and specifications can reduce tooling costs and lead times. Suppliers often charge premiums for rushed orders or late-stage changes.

- Sample & Inspection Costs: Always allocate budget for sampling and pre-shipment inspections, especially when dealing with new suppliers or regions with variable quality standards.

Indicative Price Range (Disclaimer)

While prices fluctuate based on specifications, order volume, and regional factors, a typical FOB price for standard cross country running shoes from Asian manufacturers ranges approximately between $10 to $25 per pair for bulk orders (minimum 1,000 pairs). Premium models with advanced features or eco-certifications may cost $25 to $40+ per pair. European or North American suppliers often have higher base prices due to labor and operational costs.

In conclusion, effective sourcing of cross country running shoes requires a detailed understanding of these cost components and influencing factors. Strategic negotiations, thorough supplier vetting, and comprehensive cost analysis will enable international B2B buyers to optimize their procurement, ensuring quality and profitability across diverse markets.

Spotlight on Potential cross country running shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for cross country running shoes.)*

Essential Technical Properties and Trade Terminology for cross country running shoes

Key Technical Properties for Cross Country Running Shoes

1. Material Grade and Composition

The choice of materials directly influences durability, weight, and performance. High-quality synthetic uppers, often made from mesh or engineered fabrics, provide breathability and flexibility. Outsole rubber compounds should meet industry standards for abrasion resistance, ensuring longevity across varied terrains. For B2B buyers, selecting suppliers that specify material grades aligned with international standards (e.g., ASTM, ISO) guarantees consistency and quality.

2. Tolerance and Manufacturing Precision

Tolerance refers to the acceptable deviation during manufacturing, affecting fit, comfort, and performance. Tight tolerances (e.g., ±0.5mm) are crucial for ensuring consistent sizing, especially when scaling production. Reliable suppliers maintain strict control over tolerances, reducing issues like misalignment or poor fit, which can lead to returns or dissatisfaction.

3. Traction and Outsole Design

Effective outsole patterns and rubber compounds are essential for grip on uneven or muddy cross country terrains. Deep lugs and multidirectional patterns enhance stability, while specific compounds improve slip resistance. When sourcing, verify that outsole designs are tested and certified for the intended terrain types to ensure product reliability.

4. Cushioning and Midsole Technology

Midsole materials, such as EVA or polyurethane, influence shock absorption and comfort. Advanced cushioning technologies (e.g., gel inserts or foam layers) can reduce fatigue over long distances. B2B buyers should inquire about the technical specifications and performance testing results to ensure the shoes meet athlete or user expectations for impact protection.

5. Weight and Flexibility

Lightweight shoes improve running efficiency, while flexibility ensures natural movement. Materials and design choices, such as minimal overlays and flexible sole structures, contribute to these properties. Suppliers should provide detailed weight specifications and flexibility ratings, enabling buyers to select products tailored to performance needs.

6. Waterproofing and Breathability

Depending on the climate, waterproofing can be vital, especially in muddy or rainy conditions. Breathable materials prevent overheating, enhancing comfort. Suppliers often offer shoes with Gore-Tex or similar membranes; understanding the technical limits and certifications of these features helps buyers assess suitability for different environments.

Industry and Trade Terminology

1. OEM (Original Equipment Manufacturer)

Refers to manufacturers that produce shoes under a brand’s specifications. Understanding OEM relationships helps B2B buyers manage quality control, branding, and customization options, ensuring product alignment with market needs.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce or sell per order. Recognizing MOQ requirements helps buyers plan procurement budgets and inventory levels, especially when entering new markets or testing new designs.

3. RFQ (Request for Quotation)

A formal process where buyers solicit price, lead times, and terms from multiple suppliers. Effective RFQs facilitate competitive pricing and clear communication of specifications, crucial for securing the best deals.

4. Incoterms (International Commercial Terms)

Standardized trade terms published by the ICC that define responsibilities for shipping, insurance, and tariffs. Familiarity with Incoterms (e.g., FOB, CIF) ensures clarity in delivery obligations, cost sharing, and risk management across international borders.

5. Lead Time

The period from order placement to delivery. Understanding lead times allows buyers to plan production schedules, inventory replenishment, and promotional activities efficiently, avoiding stockouts or delays.

6. Certification and Compliance Terms

Terms like ISO, ASTM, or CE indicate compliance with international safety, quality, or environmental standards. Ensuring products meet these certifications reduces legal risks and enhances market acceptance in regions with strict import regulations.

Summary:

For B2B buyers in emerging markets, grasping these technical properties and trade terms is essential for making informed procurement decisions. Accurate specifications ensure product performance aligns with end-user expectations, while understanding industry jargon streamlines negotiations, reduces risks, and optimizes supply chain efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the cross country running shoes Sector

Market Overview & Key Trends

The global cross country running shoes market is experiencing dynamic shifts driven by technological advancements, evolving consumer preferences, and expanding international trade networks. Key drivers include increasing participation in trail and cross country sports, rising awareness of performance-enhancing footwear, and a surge in outdoor recreational activities worldwide. For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding these drivers is crucial for effective sourcing and market positioning.

Emerging trends include the integration of innovative materials such as lightweight synthetics and eco-friendly textiles, which cater to both performance needs and sustainability demands. Advanced manufacturing techniques like 3D knitting and digital prototyping are reducing lead times and enabling customization, appealing to niche markets and premium segments. Additionally, digital platforms and e-commerce channels are transforming procurement processes, offering greater transparency and direct access to manufacturers.

Market dynamics are influenced by global supply chain disruptions, geopolitical factors, and fluctuating raw material costs. For instance, regions like Vietnam and China continue to dominate manufacturing due to established infrastructure, but buyers from Nigeria, Brazil, or the Middle East are increasingly exploring alternative suppliers in Turkey, Eastern Europe, and Latin America to diversify risks.

For international B2B buyers, particularly from developing regions, forging direct relationships with manufacturers, leveraging trade shows, and adopting digital sourcing platforms can optimize procurement strategies. Staying attuned to regional trade agreements and tariffs also enhances cost competitiveness and market access.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing

Sustainability has become a cornerstone in the cross country running shoes sector, influencing sourcing decisions and supplier evaluations. Environmental impacts of footwear production—particularly water consumption, chemical use, and waste generation—are under scrutiny from both consumers and regulators. B2B buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers committed to reducing carbon footprints and minimizing ecological harm.

Ethical sourcing practices, including fair labor conditions and transparent supply chains, are increasingly demanded by global brands and consumers. Certifications such as Fair Trade, SA8000, and ISO 14001 provide assurance of responsible manufacturing. Engaging with suppliers that adhere to these standards not only mitigates reputational risks but also aligns with long-term sustainability goals.

Illustrative Image (Source: Google Search)

In terms of materials, the shift toward ‘green’ materials—such as recycled polyester, natural rubber, and plant-based foams—offers dual benefits of performance and environmental responsibility. For B2B buyers, establishing partnerships with suppliers who hold sustainability certifications and who are transparent about their sourcing practices can enhance brand integrity and meet evolving market expectations.

Furthermore, adopting circular economy principles—like designing for recyclability and implementing take-back programs—can reduce waste and foster brand loyalty. Leveraging sustainability as a competitive differentiator enables buyers to access premium markets and meet the growing demand for ethically produced footwear.

Brief Evolution/History (Optional)

The cross country running shoes sector has evolved significantly over the past few decades, transitioning from basic, function-focused designs to highly specialized, technologically advanced products. Early models prioritized durability and grip, but recent innovations emphasize lightweight construction, cushioning, and sustainability. This evolution reflects broader trends in athletic footwear, driven by consumer demand for performance and environmental responsibility.

For B2B buyers, understanding this trajectory is vital for sourcing high-quality products that meet current standards and anticipate future trends. Partnering with manufacturers who invest in research and development ensures access to cutting-edge designs and materials, providing a competitive edge in a growing global market.

Frequently Asked Questions (FAQs) for B2B Buyers of cross country running shoes

1. How can I effectively vet and select reliable cross country shoe suppliers internationally?

To ensure supplier reliability, start with comprehensive due diligence. Verify their business licenses, certifications (ISO, environmental, quality standards), and ask for references from previous international clients. Review their production capacity, quality control processes, and compliance with international trade standards. Consider visiting their facilities if feasible or requesting detailed factory audits and third-party inspection reports. Establish clear communication channels to assess responsiveness and transparency. Building relationships with suppliers who demonstrate consistent quality, timely delivery, and good after-sales support reduces risks and fosters long-term partnerships.

2. What are the key customization options available for cross country shoes, and how do they impact lead times and costs?

Suppliers often offer customization in areas such as outsole design, upper materials, branding (logos, colors), and specialized features like waterproofing or extra grip. Customization allows brands to differentiate in competitive markets. However, it can influence lead times, typically adding 4-8 weeks depending on complexity, and increase costs due to tooling and setup fees. To optimize your supply chain, define your specifications early, communicate your volume requirements clearly, and negotiate flexible minimum order quantities (MOQs). Balancing customization with production efficiency can help manage costs and meet market deadlines.

3. What are typical MOQs, lead times, and payment terms for international orders of cross country shoes?

Most manufacturers set MOQs ranging from 500 to 2,000 pairs, depending on production scale and customization level. Lead times generally vary from 6 to 12 weeks after order confirmation, factoring in manufacturing, quality checks, and logistics. Payment terms often include a 30% upfront deposit, with the balance payable before shipment or upon delivery. Negotiating flexible terms is possible, especially for repeat orders or larger volumes. Establish clear contractual agreements outlining these terms to mitigate risks and ensure smooth cash flow management across borders.

4. What quality assurance standards and certifications should I look for in cross country shoe suppliers?

Reliable suppliers should adhere to international quality standards such as ISO 9001 for quality management and ISO 14001 for environmental practices. Certifications like SGS or TÜV testing reports validate product safety, durability, and compliance with regional regulations. For footwear, check for compliance with standards such as REACH (chemical safety in Europe) and ASTM or ASTM-like standards for performance. Request samples for testing or third-party lab reports to verify materials, stitching, and sole durability. These measures help prevent defective shipments, reduce returns, and ensure your brand’s reputation.

5. How can I optimize logistics and shipping when importing cross country shoes to Africa, South America, the Middle East, or Europe?

Efficient logistics involve selecting reliable freight forwarders experienced in handling footwear shipments. Consider multimodal options—sea freight for bulk orders offers cost savings, while air freight is suitable for urgent deliveries. Work with suppliers to consolidate shipments and optimize packaging to reduce volume and costs. Be aware of import duties, taxes, and customs procedures specific to each destination country; partnering with local customs brokers can streamline clearance. Establish clear Incoterms (e.g., FOB, CIF) and plan for potential delays. Building strong logistics partnerships minimizes disruptions and ensures timely delivery.

6. How should I handle disputes related to quality, delivery, or payment with international suppliers?

Dispute resolution begins with detailed contracts specifying quality standards, inspection rights, delivery timelines, and payment terms. Use clear, written communication to document issues promptly. Engage third-party inspection agencies at key milestones to verify product quality before shipment. If disputes arise, negotiate directly with the supplier first, referencing contractual clauses. If unresolved, consider mediation or arbitration under international trade laws or the supplier’s specified jurisdiction. Maintaining professional relationships and having well-documented evidence reduces the risk of costly legal battles and promotes fair resolution.

7. What are the critical factors influencing the pricing of cross country shoes in international trade?

Pricing depends on raw material costs, manufacturing complexity, order volume, customization level, and logistical expenses. Larger orders typically benefit from economies of scale, reducing unit costs. Currency fluctuations and regional tariffs also impact final pricing. Maintaining open communication with suppliers about your budget allows for negotiations on features and MOQs. Additionally, consider total landed cost—product price plus shipping, duties, taxes, and potential warehousing costs—to accurately assess profitability. Strategic sourcing from countries with favorable trade agreements or lower manufacturing costs can provide competitive advantages.

8. How can I ensure compliance with regional regulations and standards when importing cross country shoes?

Understanding regional standards is essential for market entry. In Europe, ensure compliance with CE marking, REACH regulations, and footwear safety standards. In Africa, South America, and the Middle East, verify import regulations, labelling requirements, and chemical safety standards. Collaborate with local importers or customs brokers familiar with regional rules to navigate complex compliance landscapes. Regularly update your knowledge on tariffs, trade agreements, and product standards. Implement thorough inspection and testing protocols before shipment to avoid delays, fines, or product recalls, safeguarding your brand reputation and market access.

Strategic Sourcing Conclusion and Outlook for cross country running shoes

Conclusion and Future Outlook

Effective strategic sourcing is vital for international buyers aiming to capitalize on the growing demand for high-quality cross country running shoes. By prioritizing supplier diversity, assessing manufacturing capabilities, and establishing strong quality assurance protocols, buyers can mitigate risks and secure competitive advantages in this dynamic market. Emphasizing sustainable practices and innovation will further differentiate your offerings and meet evolving consumer expectations.

Looking ahead, the cross country running shoe industry is poised for continued growth driven by increasing participation in endurance sports worldwide. Buyers from regions such as Africa, South America, the Middle East, and Europe should focus on building resilient supply chains, leveraging local manufacturing opportunities, and fostering long-term supplier relationships. This strategic approach not only enhances product quality and cost-efficiency but also aligns with global sustainability trends.

Actionable Takeaway: Proactively engage with emerging markets and diversify sourcing channels to stay agile in a competitive landscape. By adopting a forward-thinking, strategic sourcing mindset, international B2B buyers can capitalize on market opportunities, foster innovation, and ensure sustained growth in the cross country running shoes sector.