Your Ultimate Guide to Sourcing Ll Bean Shoes

Guide to Ll Bean Shoes

- Introduction: Navigating the Global Market for ll bean shoes

- Understanding ll bean shoes Types and Variations

- Key Industrial Applications of ll bean shoes

- Strategic Material Selection Guide for ll bean shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for ll bean shoes

- Comprehensive Cost and Pricing Analysis for ll bean shoes Sourcing

- Spotlight on Potential ll bean shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for ll bean shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ll bean shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of ll bean shoes

- Strategic Sourcing Conclusion and Outlook for ll bean shoes

Introduction: Navigating the Global Market for ll bean shoes

In today’s competitive global marketplace, sourcing high-quality footwear like LL Bean shoes requires strategic insight and comprehensive knowledge of international trade dynamics. For B2B buyers across Africa, South America, the Middle East, and Europe—such as Egypt and Saudi Arabia—understanding the nuances of LL Bean’s product offerings is crucial to making informed procurement decisions that balance quality, cost, and supply chain reliability.

LL Bean is renowned for its durable, functional, and environmentally conscious footwear, making it a sought-after brand in diverse markets. This guide provides an in-depth overview of the brand’s product range, from casual to specialized outdoor shoes, emphasizing key factors such as materials, manufacturing practices, and quality control standards. It also explores sourcing options, including domestic and international suppliers, to help buyers identify optimal partnerships that meet their regional demands.

Furthermore, this resource addresses critical considerations such as cost analysis, import regulations, and market trends, empowering buyers to navigate complex trade environments confidently. Whether you are establishing new supply chains or expanding existing ones, this guide offers actionable insights to streamline sourcing processes, mitigate risks, and ensure competitive advantage.

By equipping you with comprehensive knowledge and practical strategies, this guide aims to facilitate smarter purchasing decisions, enabling your business to succeed in diverse markets while maintaining the integrity and reputation of LL Bean shoes.

Understanding ll bean shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Bean Boots | Waterproof leather upper, rubber sole, mid-calf height | Outdoor retailers, specialty footwear suppliers | Durable and versatile; high demand in outdoor markets but higher cost |

| Duck Boots | Similar to classic Bean boots but with more emphasis on waterproofing | Outdoor gear distributors, fashion boutiques | Excellent for rugged use; limited style variations, higher MOQ |

| Slip-On Shoes | Low-profile, easy-to-wear, slip-on design, various materials | Casual footwear suppliers, uniform providers | Convenient for bulk orders; limited styles, moderate price point |

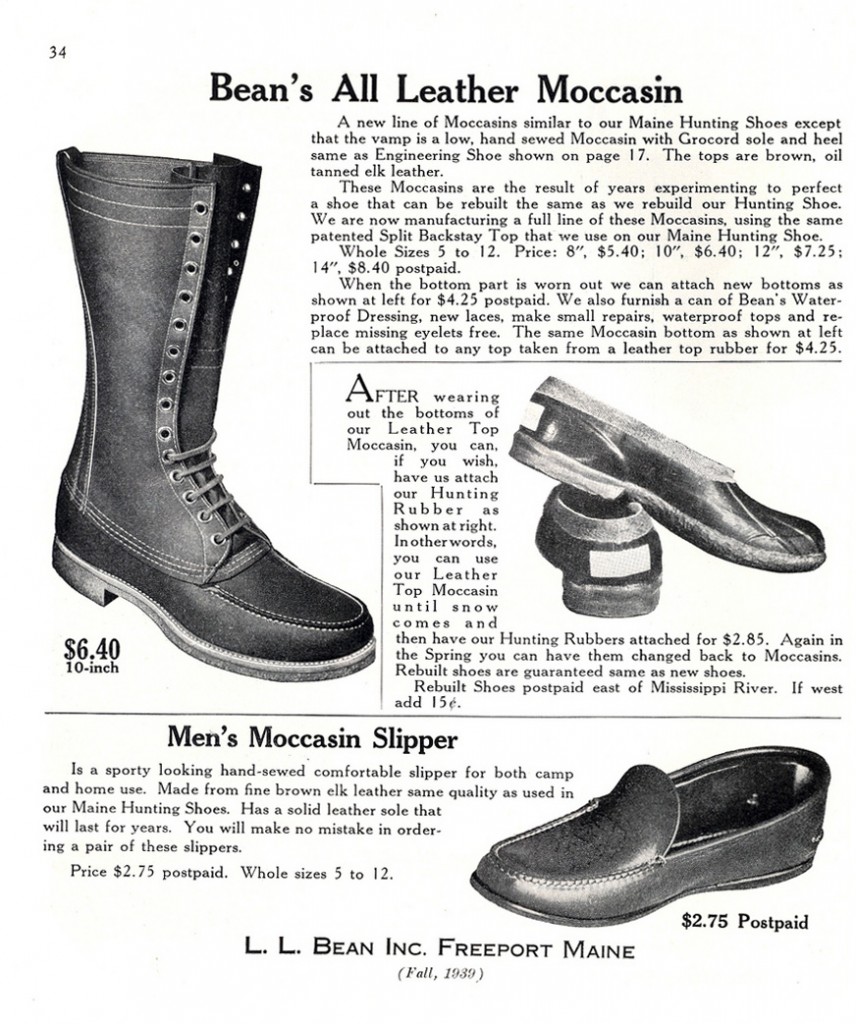

| Moccasin-Style Shoes | Soft leather, flexible sole, moccasin stitching | Comfort-focused retailers, hospitality sectors | High comfort; lower durability, niche market appeal |

| Trail & Hiking Shoes | Enhanced grip, reinforced toe, specialized waterproofing | Sports and outdoor equipment distributors | High-performance; premium pricing, suitable for specialty markets |

Classic Bean Boots

The Classic Bean Boots are the flagship product, characterized by their waterproof leather uppers and rubber soles, designed for durability in outdoor conditions. They are suitable for outdoor retailers and specialty footwear suppliers targeting markets with outdoor activities or rugged terrains. For B2B buyers, bulk purchasing offers cost efficiencies, but attention should be paid to minimum order quantities and inventory management, especially given seasonal demand fluctuations. Their reputation for longevity and versatility makes them a staple in outdoor and casual footwear segments, appealing to consumers in regions with diverse climates.

Duck Boots

A variation of the classic design, Duck Boots emphasize waterproofing and durability, often with slightly different styling or materials. They are ideal for outdoor gear distributors and fashion boutiques seeking functional yet stylish footwear. B2B buyers should consider the high demand during colder months and the importance of maintaining consistent stock levels. These shoes are particularly suitable for markets with harsh weather conditions, such as parts of Europe or South America, where outdoor durability is a key purchasing criterion. Their robust construction justifies a premium price point, making them attractive for value-focused retail channels.

Slip-On Shoes

Designed for convenience, Slip-On Shoes feature low-profile, easy-to-wear designs that appeal to casual and uniform markets. They are well-suited for bulk orders to retailers serving hospitality or institutional sectors, including schools and corporate uniforms. Buyers should evaluate the variety of materials and styles available to meet regional preferences, especially in markets like Africa and the Middle East where comfort and ease of use are prioritized. Their moderate price point and simplicity facilitate large volume orders, but limited style variation might restrict appeal in fashion-forward segments.

Moccasin-Style Shoes

Moccasin-Style Shoes emphasize comfort with soft leather uppers and flexible soles, often featuring traditional moccasin stitching. They are targeted at comfort-focused retailers and sectors like hospitality, where casual, comfortable footwear is valued. These shoes are suitable for markets with a preference for relaxed footwear, such as parts of Europe and South America. B2B buyers should consider the lower durability compared to rugged boots but can capitalize on the niche market for premium comfort products. They typically require careful inventory planning due to their specialized appeal.

Trail & Hiking Shoes

Designed for high-performance outdoor activities, Trail & Hiking Shoes feature reinforced toes, enhanced grip, and waterproofing. They are essential for outdoor sports retailers and specialty outdoor equipment distributors. These shoes often come at a higher price point, reflecting their technical features, making them suitable for premium markets. B2B buyers should focus on establishing reliable supply chains and understanding regional outdoor activity trends, especially in Europe and Middle Eastern markets where outdoor pursuits are popular. Their durability and technical specifications make them a valuable addition to specialized outdoor product lines.

Key Industrial Applications of ll bean shoes

| Industry/Sector | Specific Application of ll bean shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Infrastructure | Worker safety footwear in construction sites | Durable, slip-resistant, and comfortable shoes reduce workplace accidents and improve productivity | Material durability in harsh environments, compliance with safety standards, and reliable supply chains |

| Agriculture & Forestry | Fieldwork and farm labor footwear | Waterproof and supportive shoes protect against mud, water, and rough terrain, enhancing worker endurance | Resistance to mud, water, and chemicals; availability in bulk quantities; local adaptation needs |

| Logistics & Warehousing | Employee footwear for warehouse operations | Comfortable, slip-resistant shoes minimize accidents and fatigue, boosting efficiency | Ergonomic design, slip resistance, and ease of maintenance for high-traffic environments |

| Hospitality & Tourism | Staff footwear in hotels and resorts | Stylish yet functional shoes support staff comfort and appearance, improving guest experience | Aesthetic versatility, comfort for long shifts, and availability in various sizes and styles |

| Retail & Commercial Services | Employee footwear for retail staff | Durable, comfortable shoes enhance employee well-being and reduce turnover | Cost-effective sourcing, consistent quality, and compliance with local safety standards |

Construction & Infrastructure

In the construction industry, ll bean shoes are used as safety footwear for workers on-site. Their rugged construction, slip-resistant soles, and supportive design help prevent slips, trips, and falls, which are common hazards in construction environments. For international buyers in regions like Egypt or Saudi Arabia, sourcing shoes that withstand extreme temperatures and abrasive materials is critical. Ensuring compliance with local safety standards and availability of bulk orders can significantly reduce operational risks and improve worker safety.

Agriculture & Forestry

In agricultural and forestry sectors across Africa, South America, and the Middle East, ll bean shoes serve as protective footwear for field workers. Waterproof features and durable soles help guard against mud, water, and rough terrain, extending the footwear’s lifespan in demanding outdoor conditions. Buyers should prioritize sourcing shoes with resistance to chemicals and environmental factors prevalent in their regions. Bulk procurement and supply chain reliability are essential for maintaining continuous operations in remote areas.

Logistics & Warehousing

For logistics companies and warehouse operations, comfortable and slip-resistant shoes from ll bean are vital for employee safety and productivity. Workers often stand for long hours on concrete floors, where the risk of slips and fatigue is high. International buyers should focus on sourcing shoes with ergonomic support, durability, and ease of maintenance. Ensuring consistent quality and timely delivery in regions like Europe or South America enhances operational efficiency and reduces workplace injuries.

Hospitality & Tourism

In the hospitality sector, ll bean shoes are used by staff in hotels, resorts, and restaurants, where a blend of style and functionality is desired. These shoes provide comfort for long shifts and help maintain a professional appearance. For buyers in the Middle East or Africa, sourcing shoes that combine aesthetic appeal with durability against local environmental conditions (such as heat and humidity) is crucial. Availability in various sizes and styles ensures staff comfort and guest satisfaction.

Retail & Commercial Services

Retail employees require durable, comfortable footwear to handle long hours on their feet. ll bean shoes offer an ideal solution, reducing fatigue and minimizing slip hazards in busy retail environments. International B2B buyers should consider sourcing cost-effective, high-quality shoes that meet local safety regulations. Consistent supply and quality assurance are key to reducing employee turnover and enhancing customer service standards across diverse markets.

Strategic Material Selection Guide for ll bean shoes

Material Analysis for ll Bean Shoes

When selecting materials for ll Bean shoes, B2B buyers must consider a range of factors including durability, environmental resistance, manufacturing complexity, and compliance with international standards. Here, we analyze four common materials used in ll Bean shoes from a strategic perspective, emphasizing their suitability for different markets such as Africa, South America, the Middle East, and Europe.

Leather

Key Properties:

Leather is renowned for its durability, breathability, and aesthetic appeal. It offers excellent resistance to wear and tear, with the ability to conform to foot shape over time. Depending on the grade, leather can also provide some water resistance, especially when treated.

Pros & Cons:

Pros include high durability, a premium appearance, and natural breathability, making it ideal for outdoor and casual footwear. Cons involve higher costs, complex manufacturing processes, and the need for regular maintenance to prevent cracking or drying. Leather’s environmental footprint and compliance with animal welfare standards are also considerations, especially in European markets with strict regulations.

Impact on Application:

Leather performs well in dry to mildly wet conditions but requires treatment for enhanced water resistance in humid or rainy environments. It is suitable for markets where premium quality and aesthetics are prioritized, such as Europe and parts of South America.

International Considerations:

Buyers in regions like Egypt and Saudi Arabia should verify leather sourcing and treatment compliance with local and international standards (e.g., REACH, ISO 9001). Eco-friendly and ethically sourced leather may appeal to European consumers and meet regulatory requirements.

Rubber

Key Properties:

Rubber offers excellent flexibility, shock absorption, and water resistance. It can withstand a wide temperature range, from cold to hot climates, and provides good slip resistance.

Pros & Cons:

Rubber is cost-effective, easy to mold, and highly durable under various conditions. However, it can be heavy, and prolonged exposure to UV rays or ozone can degrade its properties unless stabilized. Manufacturing complexity is moderate, often requiring vulcanization processes.

Impact on Application:

Ideal for soles and waterproof components, rubber is essential for outdoor footwear in rugged environments. It is particularly suitable for markets with high rainfall or rugged terrain, such as parts of South America and Africa.

International Considerations:

Buyers should ensure rubber materials meet local safety standards (e.g., ASTM, DIN, JIS). For regions with high UV exposure, selecting stabilized rubber formulations can extend product lifespan. Cost considerations are favorable for mass production in emerging markets.

Synthetic Fabrics (e.g., Nylon, Polyester)

Key Properties:

Synthetic fabrics are lightweight, resistant to moisture, and easy to dye. They provide flexibility and can be engineered for specific performance attributes like breathability or water resistance.

Pros & Cons:

Advantages include lower cost, ease of manufacturing, and consistent quality. Disadvantages involve lower durability compared to natural fibers, potential environmental concerns related to microplastics, and less breathability unless combined with other materials.

Impact on Application:

Suitable for uppers and linings, synthetic fabrics are often used in casual and outdoor shoes. They perform well in humid climates but may require additional treatments for UV or abrasion resistance.

International Considerations:

Buyers should verify compliance with environmental standards (e.g., REACH, OEKO-TEX) and ensure that fabrics are sourced from suppliers adhering to fair labor practices. In regions like the Middle East, heat and UV stability are critical factors.

EVA Foam (Ethylene-Vinyl Acetate)

Key Properties:

EVA foam is lightweight, flexible, and provides excellent cushioning. It has good shock absorption and is resistant to cracking and UV degradation.

Pros & Cons:

It is cost-effective and easy to mold into various shapes, making it popular for midsoles and insoles. However, EVA can compress over time, reducing cushioning effectiveness, and may degrade under prolonged exposure to heat.

Impact on Application:

EVA is ideal for midsoles, providing comfort and shock absorption in casual and outdoor shoes. Its lightweight nature benefits markets where comfort and weight are critical, such as for travel or outdoor activities.

International Considerations:

Buyers should confirm that EVA foam complies with safety standards (e.g., REACH, ASTM F963). In hot climates, selecting UV-stabilized EVA can enhance product longevity.

Summary Table

| Material | Typical Use Case for ll Bean shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Uppers, overlays, premium outdoor footwear | Durability, aesthetic appeal | High cost, maintenance required, environmental concerns | High |

| Rubber | Soles, waterproof components | Water resistance, durability | Heavyweight, UV degradation risk | Med |

| Synthetic Fabrics | Uppers, linings, lightweight outdoor shoes | Cost-effective, moisture resistant | Lower durability, environmental impact | Low |

| EVA Foam | Midsoles, insoles | Lightweight, shock absorption | Compression over time, heat sensitivity | Low |

This strategic material analysis aims to guide international B2B buyers in selecting optimal materials for ll Bean shoes tailored to their specific market conditions, regulatory environments, and consumer preferences. Understanding these nuances ensures better product performance, compliance, and market acceptance across diverse regions.

In-depth Look: Manufacturing Processes and Quality Assurance for ll bean shoes

Manufacturing Processes of LL Bean Shoes

The manufacturing of LL Bean shoes involves a meticulously structured process designed to ensure durability, comfort, and quality. For international B2B buyers, understanding these stages is crucial to evaluate supplier capabilities and compliance with quality standards.

1. Material Preparation

The process begins with sourcing high-quality raw materials, including leather, textiles, rubber, and specialized adhesives. Leather is often sourced from tanneries compliant with environmental and safety standards, such as ISO 14001. Material preparation involves cleaning, cutting, and treating materials to meet specific specifications. Advanced techniques like laser cutting are employed for precision, reducing waste and ensuring consistency.

2. Forming and Component Manufacturing

In this stage, components such as uppers, insoles, and outsoles are formed. The uppers are shaped using molds or lasts, which replicate foot anatomy for comfort. For leather uppers, techniques like injection molding or hand-stitching are common. Outsoles are molded using rubber or synthetic compounds through compression or injection molding methods. Modern manufacturing facilities often integrate automation to enhance uniformity and reduce lead times.

3. Assembly and Stitching

Assembly involves attaching the upper to the sole, often through a combination of cementing, stitching, and heat-sealing techniques. High-frequency stitching machines ensure durable seams, with double or reinforced stitches used in high-stress areas. Adhesives must meet environmental regulations and provide long-lasting bonding, especially for waterproof or rugged models. Quality at this stage depends on precision assembly to prevent defects like misalignment or weak bonds.

4. Finishing and Quality Control

Post-assembly, shoes undergo finishing processes such as trimming excess material, polishing, and applying protective coatings. Final inspections check for aesthetic defects, stitching integrity, and proper fit. Additional treatments like waterproofing or branding are applied at this stage. The finished products are then prepared for packaging, with labels and certifications affixed as per market requirements.

Quality Assurance Framework

Ensuring consistent quality in LL Bean shoes relies on rigorous quality control protocols aligned with international standards. For B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding these standards is essential for supplier evaluation and compliance.

1. International Standards and Certifications

- ISO 9001: Most reputable manufacturers adopt ISO 9001 standards, emphasizing a quality management system that covers process control, customer satisfaction, and continual improvement.

- CE Marking: For shoes sold within the European Economic Area, CE marking indicates compliance with safety, health, and environmental directives.

- Additional Certifications: Depending on the market, certifications such as REACH (chemical safety), Fair Trade, or environmental sustainability standards may be relevant.

2. Quality Control Checkpoints

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify specifications, including leather thickness, rubber compound consistency, and adhesive properties. Suppliers should provide detailed test reports and certificates of conformity.

- In-Process Quality Control (IPQC): During manufacturing, checkpoints include stitching quality, component fitting, dimensional accuracy, and adherence to process parameters. Automated inspection systems, such as vision systems, are increasingly used to detect defects in real time.

- Final Quality Control (FQC): Before shipment, shoes are subjected to comprehensive inspections, including visual defect checks, measurement verification, and functional testing (e.g., flexibility, waterproofing). Random sampling and statistical process control (SPC) methods are common.

3. Testing Methods

- Physical Testing: Durability tests (e.g., flex testing, abrasion resistance), slip resistance, and waterproofing tests are conducted in accredited labs.

- Chemical Testing: Ensures materials meet chemical safety standards, with tests for heavy metals, formaldehyde, and other hazardous substances.

- Performance Testing: Includes comfort assessments, weight, and ergonomic evaluation, critical for premium or specialized models.

Verifying Supplier Quality for International Buyers

International B2B buyers can implement several strategies to verify and monitor supplier quality:

- Third-party Inspections: Engage recognized inspection agencies (e.g., SGS, Bureau Veritas, Intertek) to conduct pre-shipment audits, verifying manufacturing processes, documentation, and product compliance.

- Factory Audits: Conduct comprehensive audits focusing on quality management systems, worker safety, environmental practices, and record-keeping. For buyers in regions like Africa or South America, local agents or consultants can facilitate access and communication.

- Sample Testing: Request product samples for independent testing aligned with your market standards, especially for critical attributes like waterproofing or load-bearing capacity.

- Documentation and Certifications: Ensure suppliers provide detailed certificates, test reports, and traceability records. Electronic documentation facilitates compliance verification across borders.

- Ongoing Monitoring: Establish a schedule for periodic audits and quality reviews, leveraging digital tools or third-party services to maintain consistent quality standards.

Special Considerations for B2B Buyers in Diverse Regions

Regional Regulations and Standards:

Buyers from Europe and the Middle East should prioritize suppliers with CE certification and compliance with REACH and other chemical regulations. For African and South American markets, local standards may vary; thus, verifying adherence to regional safety and environmental regulations is vital.

Cultural and Logistical Factors:

Language barriers and logistical complexities can impact quality verification. Engaging local agents familiar with regional standards and inspection practices can streamline communication and oversight.

Customs and Certification Challenges:

Ensure that suppliers understand export documentation requirements, such as Certificates of Origin, Export Licenses, and Compliance Certificates, to prevent delays at customs.

Sustainability and Ethical Standards:

Given increasing emphasis on sustainable manufacturing, B2B buyers should verify suppliers’ adherence to environmental and social standards, requesting relevant certifications and audit reports.

Conclusion

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding the manufacturing and quality assurance processes behind LL Bean shoes is essential for making informed procurement decisions. By focusing on transparent supplier practices, verifying compliance with international standards, and implementing rigorous inspection protocols, buyers can ensure the delivery of high-quality, durable footwear aligned with their market expectations. Establishing strong supplier relationships rooted in quality assurance not only minimizes risks but also fosters long-term partnerships conducive to mutual growth.

Comprehensive Cost and Pricing Analysis for ll bean shoes Sourcing

Cost Structure Breakdown for LL Bean Shoes

Understanding the comprehensive cost structure is vital for international buyers aiming to optimize sourcing strategies for LL Bean shoes. The primary cost components include:

-

Materials: The quality of leather, textiles, rubber, and specialized components significantly influences costs. LL Bean emphasizes durable, high-quality materials, which tend to be more expensive but essential for their brand reputation. Sourcing from regions with access to premium materials can reduce costs, but quality assurance is critical.

-

Labor: Manufacturing costs vary widely based on the sourcing country. Countries like China, Vietnam, and Indonesia offer competitive labor rates, but buyers from Africa or South America should consider potential costs associated with skilled labor shortages or higher wages in certain regions.

-

Manufacturing Overheads: These include factory utilities, equipment depreciation, and compliance costs. Efficient, automated factories tend to have lower overheads, but certification costs (e.g., ISO, sustainability standards) may add to expenses.

-

Tooling and Setup Costs: Initial investment in molds, dies, and setup processes is significant but amortized over large production runs. For smaller orders or customized shoes, these costs proportionally increase the unit price.

-

Quality Control (QC): Rigorous QC processes are integral to LL Bean’s brand promise. Inspection costs can add to the overall price but help prevent costly returns and rework, especially critical for international shipments.

-

Logistics & Shipping: Shipping costs are influenced by shipment volume, mode (air vs. sea), and destination. For regions like Africa and South America, sea freight is more economical but slower, while air freight offers speed at a premium. Incoterms (e.g., FOB, CIF) significantly impact buyer responsibilities and costs.

-

Margins: Suppliers typically add a markup to cover profit, handling, and risk. For bulk orders, margins tend to decrease, but buyers should negotiate for favorable terms, especially for large, consistent orders.

Price Influencers & Key Factors

Several factors can sway the final unit price for LL Bean shoes:

-

Order Volume & MOQ: Larger orders benefit from economies of scale, reducing per-unit costs. Many suppliers offer discounts for bulk purchasing, but minimum order quantities (MOQs) can be a barrier for smaller buyers.

-

Specifications & Customization: Standard models are less expensive than customized designs, which require additional tooling, specifications, and quality checks. Buyers seeking specific features (e.g., eco-friendly materials, special insoles) should budget accordingly.

-

Material Choices: Premium or imported materials increase costs. Sourcing locally or opting for alternative materials can reduce expenses but may impact quality or brand perception.

-

Quality Certifications & Standards: Certifications like ISO, environmental standards, or safety marks (e.g., ASTM, REACH) can add costs but are often necessary for market acceptance, especially in Europe and the Middle East.

-

Supplier Factors: Established suppliers with proven quality records might charge higher prices but offer better reliability. Newer or lesser-known factories may offer lower prices but pose risks related to quality and compliance.

-

Incoterms & Shipping Conditions: FOB (Free On Board) terms place responsibility on the buyer for shipping, while CIF (Cost, Insurance, Freight) includes shipping costs. Buyers should evaluate these options to optimize total landed costs.

Strategic Tips for International B2B Buyers

-

Negotiate for Volume Discounts: Larger orders typically command better pricing. Establish long-term relationships to leverage continuous volume discounts and priority service.

-

Focus on Total Cost of Ownership (TCO): Beyond unit price, factor in shipping, customs duties, taxes, warehousing, and potential rework costs. This holistic view ensures more accurate budgeting.

-

Leverage Local Sourcing & Regional Factories: For buyers in Africa, South America, or the Middle East, consider sourcing from nearby regions to reduce lead times and shipping costs, while maintaining quality standards.

-

Understand Pricing Nuances: Be aware that initial quotes may exclude hidden costs such as tariffs, import taxes, or certification fees. Clarify these upfront to avoid surprises.

-

Optimize Logistics & Incoterms: Choose shipping terms that align with your logistics capabilities. For example, FOB can reduce upfront costs but increases responsibilities, while CIF simplifies import procedures.

-

Engage in Strategic Negotiation: Use market research and comparative quotes to negotiate better terms. Emphasize long-term partnership potential, quality standards, and compliance assurances.

Disclaimer: Indicative Pricing & Variability

Pricing for LL Bean shoes can vary significantly based on order size, customization, region, and current market conditions. As a general guideline, unit costs for standard models typically range from $10 to $20 FOB for large-volume orders. Custom or premium models may exceed this range. Always request detailed quotations and factor in all associated costs for accurate budgeting.

By thoroughly analyzing these components and leveraging strategic negotiation, international buyers from Africa, South America, the Middle East, and Europe can optimize their sourcing costs for LL Bean shoes, ensuring competitive pricing without compromising quality.

Spotlight on Potential ll bean shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for ll bean shoes.)*

Essential Technical Properties and Trade Terminology for ll bean shoes

Critical Technical Properties for ll Bean Shoes

1. Material Grade and Composition

The quality of materials used in ll Bean shoes, such as leather, rubber, and textiles, directly impacts durability, comfort, and overall product performance. Higher-grade materials—like full-grain leather or premium waterproof fabrics—are essential for meeting international quality standards and customer expectations. B2B buyers should specify material grades during sourcing to ensure consistency and compliance with regional regulations.

2. Sole Construction and Tolerance

The sole’s design—whether rubber, EVA, or polyurethane—affects grip, shock absorption, and longevity. Precise manufacturing tolerances (e.g., ±0.2 mm for sole thickness) are critical to ensure product uniformity, especially when scaling production for large orders. Clear specifications help reduce defects and facilitate quality assurance across different batches.

3. Waterproofing and Breathability Ratings

Many ll Bean shoes are known for their waterproof features. Technical specifications such as hydrostatic head ratings (measured in mm) quantify waterproofing effectiveness. Simultaneously, breathability ratings (e.g., grams of moisture vapor transmitted per square meter per 24 hours) ensure comfort in various climates. These properties are vital for meeting regional customer needs and regulatory standards.

4. Stitching and Seam Strength

Durability depends heavily on the quality of stitching and seam sealing. Specifications like thread type (e.g., nylon, polyester), stitch density (stitches per inch), and seam sealing techniques (e.g., waterproof tape) are crucial. Ensuring high seam strength minimizes product failure, especially in demanding environments common in Africa, South America, the Middle East, and Europe.

5. Weight and Flexibility

Lightweight shoes with optimal flexibility are preferred for comfort and performance. Precise weight specifications (e.g., grams per pair) and flexibility measurements (e.g., bend tests) help buyers evaluate suitability for different end-user activities. These properties influence user satisfaction and product positioning in target markets.

Essential Trade Terminology for ll Bean Shoes

1. OEM (Original Equipment Manufacturer)

Refers to a manufacturer that produces shoes based on the buyer’s specifications, branding, and design. Understanding OEM relationships helps buyers assess manufacturing flexibility, control over product quality, and potential for private labeling.

2. MOQ (Minimum Order Quantity)

The smallest quantity of shoes a manufacturer will accept per order. Knowing the MOQ is crucial for planning procurement budgets and inventory levels, especially when entering new markets with limited initial demand.

3. RFQ (Request for Quotation)

A formal request sent to suppliers asking for price estimates, lead times, and terms. An RFQ process enables buyers to compare multiple suppliers efficiently and negotiate better terms, ensuring cost competitiveness and supply reliability.

4. Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce that define responsibilities for shipping, insurance, and customs clearance. Familiarity with Incoterms (e.g., FOB, CIF, DDP) helps B2B buyers clarify costs, risk transfer points, and delivery obligations across different regions.

5. Lead Time

The period from order placement to product delivery. Accurate understanding of lead times helps in planning inventory and aligning product launches, especially when dealing with international logistics complexities.

6. Quality Assurance (QA) & Compliance Standards

Refers to the processes and certifications (e.g., ISO, CE) ensuring products meet safety, environmental, and quality standards relevant to each region. B2B buyers should verify QA procedures to mitigate risks of non-compliance, product recalls, or rejection at customs.

Strategic Insights for International B2B Buyers

Understanding these technical properties and trade terms enhances your ability to communicate effectively with suppliers, negotiate favorable conditions, and ensure product quality. Clarify specifications upfront—especially material grades and construction tolerances—to prevent costly rework or delays. Familiarity with trade terminology streamlines procurement processes, reduces misunderstandings, and positions you for successful market entry in regions with diverse regulatory and climatic conditions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ll bean shoes Sector

Market Overview & Key Trends

The global footwear market is experiencing dynamic shifts driven by technological innovation, evolving consumer preferences, and supply chain reconfigurations. For B2B buyers from Africa, South America, the Middle East, and Europe, understanding these trends is crucial to optimizing sourcing strategies for LL Bean shoes.

One prominent driver is the increasing demand for high-quality, durable outdoor footwear—LL Bean’s core strength—especially in regions with outdoor leisure activities or rugged terrains. Emerging sourcing trends include the adoption of digital supply chain management tools, such as blockchain for transparency and AI-driven demand forecasting, which enhance efficiency and reduce lead times. Additionally, the rise of nearshoring and regional manufacturing hubs in Eastern Europe, North Africa, and Latin America offers new opportunities for shorter, more resilient supply chains, reducing dependence on traditional Asian manufacturing centers.

Market dynamics also reflect shifting consumer preferences toward sustainability and ethical production, prompting brands to seek suppliers that adhere to environmental and social standards. For B2B buyers, this means evaluating suppliers not only on cost but also on their technological capabilities, compliance with international standards, and agility in responding to market fluctuations.

Illustrative Image (Source: Google Search)

Furthermore, geopolitical factors, such as trade agreements and tariffs, influence sourcing decisions. For instance, European buyers are increasingly exploring suppliers within the EU to avoid tariffs, while Middle Eastern markets benefit from proximity to manufacturing hubs in North Africa and Turkey.

In summary, international B2B buyers should leverage technological advancements, regional manufacturing options, and sustainability commitments to navigate the evolving landscape of LL Bean shoes sourcing effectively. A strategic focus on transparency, agility, and regional advantages can provide a competitive edge in this resilient yet competitive market.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a fundamental criterion for sourcing LL Bean shoes, especially as global consumers and regulatory bodies heighten their expectations for environmentally responsible practices. For B2B buyers, integrating sustainability into procurement strategies involves assessing suppliers’ environmental impact, ethical labor practices, and certifications.

LL Bean’s commitment to quality and durability aligns well with eco-friendly initiatives, such as reducing waste and minimizing carbon footprints. Suppliers offering ‘green’ certifications—such as Global Organic Textile Standard (GOTS), Forest Stewardship Council (FSC), or bluesign®—demonstrate compliance with rigorous environmental standards. These certifications assure buyers that raw materials like leather, rubber, and textiles are sourced responsibly, with minimal ecological harm.

The use of sustainable materials, such as recycled rubber or organic cotton, not only enhances brand reputation but also aligns with global trends toward circular economy practices. B2B buyers should prioritize establishing partnerships with suppliers who transparently report their environmental impact and are committed to continuous improvement.

Ethical sourcing extends beyond environmental considerations to labor practices. Ensuring suppliers adhere to fair wages, safe working conditions, and anti-child labor policies is critical. Many international standards, such as SA8000 or BSCI, provide frameworks for verifying ethical compliance.

Incorporating sustainability into procurement can also offer tangible benefits, including risk mitigation, improved supply chain resilience, and access to markets with stringent environmental regulations. For LL Bean shoes, a focus on sustainable sourcing not only enhances brand integrity but also meets the growing demand from consumers and regulators for responsible products. B2B buyers should actively seek suppliers with proven sustainability credentials and integrate these criteria into their sourcing evaluations.

Brief Evolution/History (Optional)

While LL Bean’s origins date back to 1912, its evolution into a trusted outdoor footwear brand reflects a consistent emphasis on quality, durability, and customer-centric innovation. Over the decades, the company has expanded its product range and adopted sustainable practices, aligning with global market shifts. For B2B buyers, understanding this history underscores LL Bean’s long-term commitment to responsible manufacturing and product excellence, which can be a compelling factor in sourcing decisions. This legacy of resilience and innovation provides a stable foundation for building sustainable, high-quality supply partnerships in the footwear sector.

Frequently Asked Questions (FAQs) for B2B Buyers of ll bean shoes

1. How can I verify the reliability and authenticity of an LL Bean shoe supplier?

To ensure supplier credibility, start by requesting official business licenses, certifications, and references from previous clients. Verify their manufacturing credentials, such as ISO or other quality standards relevant to footwear. Conduct virtual or in-person audits if possible, focusing on production facilities and quality control processes. Additionally, review their compliance with international trade standards and export documentation. Engaging with suppliers who have a strong online presence, positive reviews, and transparent communication reduces risks. Establish clear contractual terms covering quality expectations, delivery timelines, and dispute resolution to safeguard your investments.

2. Can LL Bean shoes be customized for my market, and what are the options?

Yes, LL Bean offers customization options suitable for B2B buyers aiming to differentiate their offerings. Customizations can include branding (logos, labels), specific colorways, and limited design modifications. Discuss your market’s preferences with the supplier early to explore feasible options. Keep in mind that customization may impact lead times and minimum order quantities (MOQs). Some suppliers may offer private labeling services, allowing you to sell shoes under your own brand. Ensure that customization aligns with your target market’s needs and that suppliers have the capacity to deliver consistent quality with your specifications.

3. What are typical MOQs, lead times, and payment terms for bulk LL Bean shoe orders?

MOQ and lead times vary depending on the supplier’s capacity and order complexity but generally range from 500 to 5,000 pairs for B2B purchases. Lead times are typically between 4 to 12 weeks, including manufacturing, quality checks, and shipping. Payment terms often include a 30% deposit upfront with the remaining balance payable before shipment or upon delivery. Some suppliers may offer flexible terms for repeat customers or large orders. Negotiating these terms early and establishing a clear schedule helps avoid delays, especially important for timely market entry in regions like Africa, South America, or the Middle East.

4. What quality assurance and certification standards should I look for when importing LL Bean shoes?

Ensure that the supplier adheres to recognized quality standards such as ISO 9001, which indicates a robust quality management system. Additionally, look for compliance with international safety standards relevant to footwear, such as CE marking for European markets or ASTM standards for North America. Certifications related to environmental and labor practices (e.g., OEKO-TEX, Fair Trade) are also valuable, especially for markets with strict consumer protection laws. Request sample testing reports, factory audit certificates, and product compliance documents to verify that shoes meet your target market’s safety and quality expectations.

5. How can I manage logistics and shipping efficiently for international LL Bean shoe orders?

Partner with experienced freight forwarders familiar with your target region to optimize shipping routes and costs. Consider incoterms like FOB (Free on Board) or CIF (Cost, Insurance, Freight) to clarify responsibilities and expenses. Consolidate shipments to reduce costs and ensure timely delivery. Be aware of import duties, taxes, and customs clearance procedures specific to your country—these can significantly impact timelines and costs. Establish clear communication channels with your supplier and logistics providers to track shipments and address issues proactively, ensuring a smooth supply chain flow.

6. What steps should I take to handle disputes or quality issues with my LL Bean shoe supplier?

Develop a comprehensive quality agreement that clearly defines inspection processes, acceptance criteria, and dispute resolution procedures. Conduct pre-shipment inspections or third-party audits to identify potential issues early. If disputes arise, document all communications, inspection reports, and photographs as evidence. Engage in transparent negotiations, aiming for amicable solutions such as product replacements, refunds, or corrective actions. If necessary, include arbitration clauses in contracts specifying neutral dispute resolution mechanisms. Establishing strong supplier relationships and clear contractual terms minimizes risks and expedites resolution when problems occur.

7. Are there specific import regulations or tariffs I should be aware of when sourcing LL Bean shoes from the US to my country?

Yes, each country has unique import regulations, tariffs, and quota systems. For African, South American, Middle Eastern, and European markets, research specific import duties applicable to footwear and textiles, as well as any trade agreements that might reduce tariffs. Ensure compliance with local standards regarding product safety, labeling, and packaging. Engage customs brokers experienced in your region’s import procedures to streamline clearance processes. Staying updated on policy changes and maintaining accurate documentation (commercial invoices, certificates of origin, compliance certificates) will prevent delays and unexpected costs.

Illustrative Image (Source: Google Search)

8. How do I ensure long-term supply stability and build a strong partnership with LL Bean shoe suppliers?

Establish ongoing communication and collaboration with your supplier, emphasizing transparency and mutual growth. Place regular, forecasted orders to help suppliers plan production and inventory management. Build trust by paying on time and providing constructive feedback. Consider signing long-term contracts or partnership agreements that include volume discounts and priority production slots. Stay informed about the supplier’s capacity, new product offerings, and compliance updates. Investing in a good relationship reduces risks of supply disruptions, quality fluctuations, and price volatility, ultimately supporting your market expansion efforts in regions like Africa, South America, the Middle East, or Europe.

Illustrative Image (Source: Google Search)

Strategic Sourcing Conclusion and Outlook for ll bean shoes

Strategic Sourcing Outlook for ll Bean Shoes

Effective strategic sourcing remains crucial for international B2B buyers seeking to capitalize on the quality and reputation of ll Bean shoes. By prioritizing supplier reliability, ethical manufacturing practices, and cost efficiencies, buyers from Africa, South America, the Middle East, and Europe can secure competitive advantages in their markets. Diversifying sourcing channels and establishing strong supplier relationships will mitigate risks and ensure product consistency, particularly amid global supply chain disruptions.

Investing in supplier audits and sustainability assessments not only aligns with evolving consumer expectations but also enhances brand integrity. As ll Bean continues to expand its global footprint, proactive engagement with authorized distributors and direct partnerships can unlock better pricing, faster delivery, and tailored product offerings suited to regional preferences.

Looking ahead, the strategic sourcing landscape will increasingly favor transparency, innovation, and agility. International buyers should leverage data-driven insights and collaborate closely with suppliers to optimize supply chains. By doing so, they can position themselves as reliable partners in delivering high-quality ll Bean shoes to their markets—driving growth, customer satisfaction, and long-term success in an increasingly competitive environment.