Master Global Sourcing for Authentic MBT Shoes and Maximize

Guide to Mbt Shoes

- Introduction: Navigating the Global Market for mbt shoes

- Understanding mbt shoes Types and Variations

- Key Industrial Applications of mbt shoes

- Strategic Material Selection Guide for mbt shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for mbt shoes

- Comprehensive Cost and Pricing Analysis for mbt shoes Sourcing

- Spotlight on Potential mbt shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for mbt shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the mbt shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of mbt shoes

- Strategic Sourcing Conclusion and Outlook for mbt shoes

Introduction: Navigating the Global Market for mbt shoes

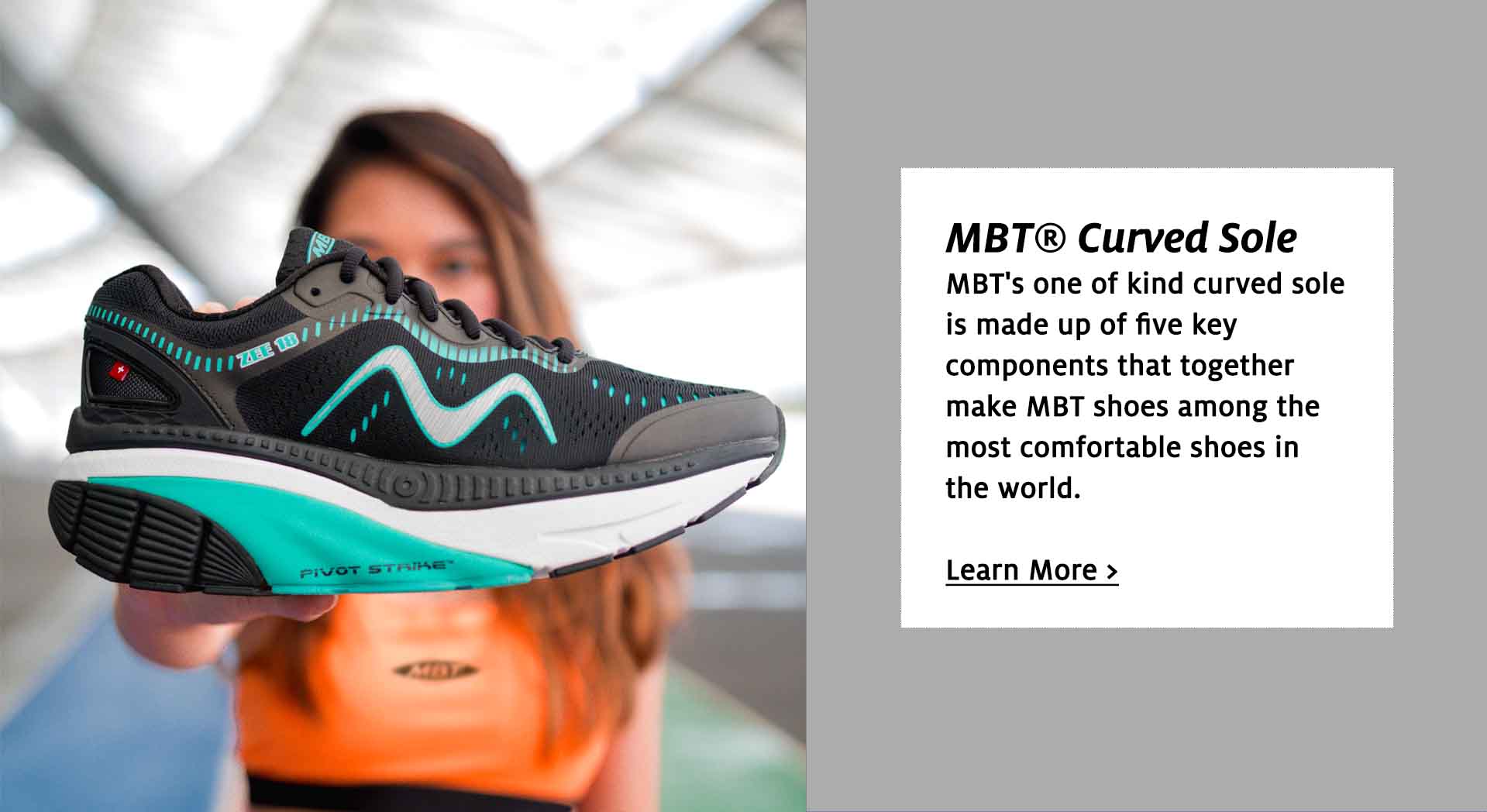

In the competitive landscape of global footwear, MBT shoes stand out as a pioneering innovation that combines health benefits with distinctive design. For B2B buyers across Africa, South America, the Middle East, and Europe—such as Egypt and Spain—understanding the strategic importance of sourcing authentic MBT footwear is crucial. These shoes are not merely fashion items; they cater to a growing market segment focused on wellness, ergonomic support, and active lifestyles, making them a valuable addition to your product portfolio.

Illustrative Image (Source: Google Search)

This comprehensive guide offers an in-depth overview of the MBT shoe market, including the different types available, key materials used, and manufacturing standards that ensure quality. It also covers sourcing strategies, reliable supplier networks, and cost considerations critical for making informed purchasing decisions. Additionally, you’ll find insights into quality control processes, certification requirements, and logistical considerations tailored to diverse regional markets.

By equipping yourself with this knowledge, you can navigate the complexities of international sourcing confidently, mitigate risks, and capitalize on emerging opportunities within this dynamic segment. Whether you’re exploring new supplier partnerships or expanding your product offerings, this guide empowers B2B buyers to make strategic, data-driven decisions—ultimately enhancing your competitive edge in the global marketplace for MBT shoes.

Understanding mbt shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic MBT Shoes | Rounded, rocker sole with a focus on natural instability | Retail, wholesale, specialty sports outlets | Pros: High demand, proven ergonomic benefits; Cons: Higher manufacturing costs, limited style variations |

| Performance MBT Shoes | Enhanced cushioning, lightweight materials, sport-oriented | Sports retailers, activewear distributors | Pros: Appeal to athletes, niche markets; Cons: Smaller target market, premium price point |

| Casual MBT Shoes | Stylish designs with less pronounced rocker features | Fashion-focused retailers, casual footwear outlets | Pros: Broader consumer appeal, fashion versatility; Cons: Slightly higher price, limited technical features |

| Orthopedic MBT Shoes | Specialized support with orthopedic insoles, tailored fit | Medical supply chains, orthopedics, clinics | Pros: Growing healthcare demand, high margin; Cons: Longer lead times, specialized procurement processes |

| Eco-friendly MBT Shoes | Made from sustainable materials, eco-conscious manufacturing | Eco-focused retail channels, sustainable brands | Pros: Growing consumer demand, brand differentiation; Cons: Higher production costs, limited supply chain options |

Characteristics and Suitability

Classic MBT Shoes are the foundational model, featuring a rounded, rocker sole designed to mimic walking on uneven terrain. They promote natural movement and are widely used in retail and wholesale channels targeting health-conscious consumers. B2B buyers should consider manufacturing quality and authenticity, as these are critical for maintaining brand reputation. Sourcing reliable suppliers with consistent quality is essential, especially for bulk orders.

Performance MBT Shoes are engineered for active users, incorporating lightweight materials and enhanced cushioning for sports or outdoor activities. They appeal to niche markets such as athletes or outdoor enthusiasts. B2B buyers should evaluate the technical specifications, certifications, and brand reputation to ensure product authenticity and durability. These shoes often command higher prices, which can improve margins but may limit volume sales.

Casual MBT Shoes blend style with the ergonomic benefits of the original design, making them suitable for everyday wear. They target fashion-forward consumers who seek comfort without sacrificing aesthetics. For B2B buyers, it’s vital to select suppliers offering a variety of designs and sizes to meet diverse market preferences. The balance between style and functionality influences market acceptance and sales volume.

Orthopedic MBT Shoes are tailored for medical or therapeutic purposes, featuring specialized insoles and support structures. They are often sold through healthcare channels, clinics, or orthopedics specialists. Buyers should prioritize suppliers with medical certifications and proven efficacy. These shoes typically involve longer lead times and require careful quality control, but they offer high margins and access to growing healthcare markets.

Eco-friendly MBT Shoes are produced from sustainable materials, appealing to environmentally conscious consumers. They are increasingly relevant in markets with strong sustainability trends, such as Europe and parts of South America. B2B buyers should verify the authenticity of eco claims, supply chain transparency, and certification standards. While costs may be higher, these shoes can differentiate brands and tap into a premium market segment.

By understanding these variations, B2B buyers can better match product offerings to their target markets, optimize supply chain decisions, and develop tailored marketing strategies that resonate with regional consumer preferences.

Key Industrial Applications of mbt shoes

| Industry/Sector | Specific Application of mbt shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Heavy Industry | Anti-slip footwear for construction site workers | Enhances worker safety, reduces slip-and-fall accidents, and ensures compliance with safety standards | Certification for industrial safety, durability in harsh environments, availability in bulk quantities |

| Healthcare & Medical Facilities | Supportive footwear for healthcare staff | Improves comfort during long shifts, reduces fatigue, and minimizes slip hazards | Medical-grade certifications, ergonomic design, consistent supply chain |

| Hospitality & Food Service | Non-slip shoes for kitchen and service staff | Prevents slips in high-risk areas, ensures hygiene compliance, and boosts staff productivity | Food-safe materials, slip-resistance ratings, adaptable sizing options |

| Logistics & Warehousing | Comfortable, supportive shoes for warehouse workers | Reduces fatigue, enhances mobility, and minimizes injury-related downtime | Heavy-duty construction, anti-fatigue features, reliable sourcing channels |

| Retail & Customer Service | Casual yet supportive footwear for retail staff | Improves employee comfort, supports active movements, and reduces injury risk | Style versatility, compliance with workplace safety standards, scalable supply |

Construction & Heavy Industry

In construction and heavy industry sectors, mbt shoes are primarily used as anti-slip footwear to safeguard workers on uneven or wet surfaces. These shoes are designed with specialized soles that provide superior grip, reducing the risk of slips and falls—a critical concern on construction sites, especially in regions with variable weather conditions like Egypt or parts of South America. B2B buyers should prioritize sourcing shoes with industrial safety certifications and durability to withstand harsh environments, ensuring long-term value and compliance with local safety regulations.

Healthcare & Medical Facilities

Healthcare professionals often work long hours on their feet, making comfort and safety paramount. mbt shoes offer ergonomic support that alleviates fatigue and enhances mobility, which is vital in hospitals and clinics. For international buyers from Europe or the Middle East, sourcing shoes with medical-grade certifications and slip-resistant soles is essential to meet strict hygiene and safety standards. Consistent supply and customization options can further support large healthcare institutions or supply chain needs.

Hospitality & Food Service

In kitchens and food service environments, non-slip footwear is critical to prevent accidents caused by spills and wet floors. mbt shoes provide excellent slip resistance while maintaining comfort during extended shifts. For B2B buyers in regions like Spain or South America, sourcing shoes made with food-safe, easy-to-clean materials is key. Additionally, shoes should meet hygiene standards and be available in various sizes to accommodate diverse staff needs, supporting operational efficiency and safety.

Logistics & Warehousing

Supportive footwear is vital for warehouse workers who spend long hours on their feet, often in physically demanding environments. mbt shoes reduce fatigue, improve mobility, and help prevent musculoskeletal injuries, which can lead to costly downtime. Buyers should seek shoes with heavy-duty construction, anti-fatigue features, and reliable supply chains to ensure continuous inventory flow. Sourcing from reputable manufacturers with proven quality standards is essential for large logistics operations across Africa, Europe, or South America.

Retail & Customer Service

Retail staff benefit from comfortable, supportive footwear that allows active movement throughout their shifts. mbt shoes enhance employee comfort, reduce fatigue, and support quick, agile movements—crucial for customer interaction and store management. For B2B buyers, sourcing shoes that combine style with safety, meet workplace standards, and are available in scalable quantities ensures that retail operations remain efficient and staff well-supported across diverse markets.

Strategic Material Selection Guide for mbt shoes

Analysis of Common Materials for MBT Shoes

Selecting the right materials for MBT shoes is critical for ensuring product performance, durability, and compliance with international standards. Below is an in-depth analysis of four common materials used in MBT shoe manufacturing from a B2B perspective, focusing on their properties, advantages, limitations, and considerations for international buyers.

Illustrative Image (Source: Google Search)

1. Thermoplastic Polyurethane (TPU)

Key Properties:

TPU is a versatile polymer known for its excellent elasticity, abrasion resistance, and flexibility. It withstands a wide temperature range (-40°C to +80°C) and offers good chemical and oil resistance. Its impact absorption makes it suitable for midsoles and stabilizers in MBT shoes.

Pros & Cons:

* Pros: High durability, lightweight, good shock absorption, and resistance to cracking over time. It can be easily molded into complex shapes, reducing manufacturing complexity.

* Cons: Slightly higher material cost compared to basic plastics, and its environmental footprint is less favorable due to challenges in recycling.

Impact on Application:

TPU performs well in environments with variable temperatures, making it suitable for diverse climates. Its chemical resistance ensures longevity in humid or oily conditions, common in many regions, including parts of Africa and South America.

International B2B Considerations:

TPU complies with many international standards such as ASTM and REACH. For buyers in Europe and the Middle East, ensuring suppliers meet local environmental regulations (e.g., RoHS) is vital. Cost variations depend on grade and supplier, but generally, TPU is considered a medium-cost material.

2. Ethylene Vinyl Acetate (EVA)

Key Properties:

EVA is a soft, flexible, and lightweight foam material with excellent cushioning properties. It offers good shock absorption, flexibility, and weather resistance, making it ideal for midsoles and insoles.

Pros & Cons:

* Pros: Cost-effective, easy to process, and provides excellent comfort. Its lightweight nature reduces overall shoe weight, enhancing user experience.

* Cons: Less durable under heavy or abrasive conditions; prone to compression set over time, which can affect cushioning performance.

Impact on Application:

EVA is highly suitable for applications requiring cushioning and comfort, especially in regions with hot climates like Egypt or Spain. However, in harsh environments with rough terrain, its wear resistance may be limited.

International B2B Considerations:

EVA materials generally meet global standards such as ASTM D3574 for foam products. Buyers should verify supplier certifications for safety and environmental compliance, especially in Europe where regulations are strict. Cost-wise, EVA is typically low to medium, making it attractive for mass production.

3. Leather (Natural and Synthetic)

Key Properties:

Leather provides durability, breathability, and a premium aesthetic. Natural leather is highly resilient, offering excellent abrasion resistance and aging well over time. Synthetic leather (PU or PVC) mimics natural leather with added benefits like lower cost and easier maintenance.

Pros & Cons:

* Pros: Natural leather offers superior durability and comfort; synthetic options are more affordable and easier to produce in large quantities.

* Cons: Natural leather requires significant processing and environmental considerations; synthetic leather may lack breathability and can crack over time.

Impact on Application:

Leather is often used in upper components, especially for premium MBT shoes targeting European markets. Synthetic leather is more common in budget-friendly models for regions with price sensitivity, such as parts of Africa and South America.

International B2B Considerations:

Compliance with environmental standards such as the EU’s REACH or the US’s TSCA is crucial, especially for natural leather tanned with chemicals. Buyers should prefer suppliers with certifications like ISO 9001 or OEKO-TEX. Cost varies significantly: natural leather is high-cost, while synthetic leather is medium to low.

4. Rubber (Natural and Synthetic)

Key Properties:

Rubber provides excellent grip, flexibility, and impact resistance. Natural rubber offers superior elasticity, while synthetic variants like SBR or NBR are tailored for specific media resistance, such as oils or chemicals.

Pros & Cons:

* Pros: High durability, excellent slip resistance, and weather resistance. Suitable for outsole and tread applications.

* Cons: Natural rubber can be affected by ozone and UV exposure; synthetic rubbers may be more expensive depending on formulation.

Impact on Application:

Rubber is essential for outsole construction, especially in regions with diverse terrains and climates. Its resistance to water and oils makes it suitable for outdoor and industrial applications.

International B2B Considerations:

Rubber materials must meet standards such as ASTM D2000 for elastomers. For buyers in Europe and the Middle East, sourcing from suppliers with environmental certifications (e.g., FSC, ISO 14001) is advantageous. Cost varies: natural rubber tends to be lower, while high-grade synthetic rubbers are more expensive.

Summary Table

| Material | Typical Use Case for mbt shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic Polyurethane (TPU) | Midsoles, stabilizers, structural components | High durability, excellent impact absorption | Higher cost, recycling challenges | Med |

| Ethylene Vinyl Acetate (EVA) | Midsoles, insoles, cushioning layers | Lightweight, cost-effective, excellent cushioning | Less durable under heavy wear, compression set | Low |

| Leather (Natural & Synthetic) | Upper materials, premium shoe components | Durable, breathable, aesthetic appeal | Environmental concerns, variable costs | Varies (High for natural, Med/Low for synthetic) |

| Rubber (Natural & Synthetic) | Outsoles, treads | Slip-resistant, impact-resistant, weatherproof | Environmental impact, formulation costs | Low to Med |

This comprehensive analysis equips B2B buyers with critical insights into material selection, ensuring they align product performance with regional demands, compliance standards, and cost considerations. Tailoring material choices to specific markets enhances competitiveness and sustainability in the global MBT shoe industry.

In-depth Look: Manufacturing Processes and Quality Assurance for mbt shoes

Manufacturing Processes of MBT Shoes

The production of MBT (Masai Barefoot Technology) shoes involves a series of meticulously controlled stages designed to ensure comfort, durability, and adherence to international standards. For B2B buyers, understanding these key manufacturing phases is crucial to assessing supplier capability and product quality.

Material Preparation

The process begins with sourcing high-quality raw materials, primarily specialized midsole foam, durable outsole rubber, and breathable upper textiles or leathers. Suppliers often use foams with specific densities and resilience properties to achieve the characteristic cushioning and stability of MBT shoes. Material verification involves checking compliance with international standards such as ISO 9001 for quality management and relevant safety certifications.

Forming and Molding

The core of MBT shoe manufacturing lies in the forming process, where molds are used to shape the midsole and outsole components. Injection molding and compression molding are common techniques, depending on the material and design complexity. The midsole’s distinctive curved design, which provides the unstable surface for natural foot movement, is carefully crafted through computer-aided design (CAD) and precision molding. Attention to detail during this stage ensures consistency across production batches.

Assembly

Once individual components—midsole, outsole, upper, and insole—are prepared, they are assembled through a combination of adhesive bonding, stitching, and mechanical fastening. High-quality adhesives that meet environmental and health standards (such as REACH compliance in Europe) are vital. The assembly process also involves attaching features like straps or laces, with a focus on durability and ergonomic fit.

Finishing

The final stage involves quality finishing touches, including surface treatments, color matching, and inspection for defects. The shoes undergo cleaning, trimming, and sometimes branding or logo application. Final quality checks ensure that each pair meets the specified design and comfort standards before packaging.

Quality Assurance (QA) and Control (QC) in MBT Shoe Manufacturing

For international B2B buyers, ensuring consistent quality from suppliers is paramount. The manufacturing of MBT shoes is governed by a combination of global standards and industry-specific certifications, complemented by rigorous internal and third-party QC procedures.

International Standards and Certifications

- ISO 9001: Most reputable manufacturers adhere to ISO 9001 standards for quality management systems, ensuring continuous process improvement and customer satisfaction.

- CE Certification: Critical for European markets, CE marking confirms compliance with health, safety, and environmental requirements.

- Other Certifications: Depending on the target market, suppliers may also hold certifications like REACH (chemical safety), FDA (if applicable), or ASTM standards for footwear.

QC Checkpoints

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival for defects, conformity to specifications, and safety standards. This prevents substandard components from entering production.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections monitor dimensional accuracy, assembly integrity, and adherence to process parameters. Techniques include visual checks, measuring tools, and functional testing.

- Final Quality Control (FQC): Before shipment, finished shoes undergo comprehensive inspection, including durability testing, visual inspection for defects, and functional assessments such as flexibility and slip resistance.

Testing Methods

- Mechanical Testing: Assessments of shock absorption, flexibility, and tensile strength are conducted using standardized testing equipment.

- Environmental Testing: Shoes are tested for resistance to water, UV exposure, and temperature variations to ensure durability in different climates.

- Ergonomic Evaluation: Fit and comfort are verified through biomechanical assessments, especially relevant for MBT shoes due to their unique design.

Verifying Supplier QC Capabilities for International B2B Buyers

B2B buyers from Africa, South America, the Middle East, and Europe should adopt proactive measures to verify supplier quality systems:

- Supplier Audits: Conduct on-site audits or engage third-party inspection agencies to evaluate manufacturing facilities, quality management systems, and compliance with certifications.

- Review Inspection Reports: Request detailed QC reports, test results, and certificates of conformity for raw materials and finished products.

- Sample Testing: Perform independent testing on samples to verify claims related to durability, safety, and comfort.

- Third-Party Inspection Services: Utilize organizations such as SGS, TUV, or Intertek to conduct pre-shipment inspections, ensuring products meet contractual specifications.

Nuances in QC and Certification for Different Regions

Regional considerations influence QC and certification requirements:

- Africa & South America: Buyers should emphasize supplier adherence to international standards like ISO and CE, while also considering local import regulations. Verifying supplier accreditation through recognized third-party audits enhances trust.

- Middle East: Given high temperature and humidity, testing for environmental durability is critical. Suppliers should demonstrate compliance with regional standards such as Gulf Standards (GSO).

- Europe (e.g., Spain): Strict enforcement of CE marking and REACH compliance is essential. Buyers often require detailed documentation and may perform their own audits or third-party testing to verify claims.

Final Recommendations for B2B Buyers

- Establish clear specifications aligned with international standards.

- Prioritize suppliers with proven certifications, robust QC procedures, and transparent reporting.

- Incorporate periodic audits and testing as part of ongoing supplier evaluation.

- Leverage third-party inspection agencies to mitigate risks and ensure compliance across diverse markets.

By understanding and scrutinizing each stage of manufacturing and QC, international buyers can confidently select MBT shoe suppliers that deliver consistent quality, safety, and performance across global markets.

Comprehensive Cost and Pricing Analysis for mbt shoes Sourcing

Cost Components in mbt Shoes Production

Understanding the detailed cost structure of MBT shoes is essential for effective sourcing and pricing negotiations. The primary components include:

-

Materials: The cost of high-quality, durable materials such as specialized rubber, EVA foam, leather, and eco-friendly fabrics. Material costs can vary significantly based on quality, origin, and supplier negotiations.

-

Labor: Wages differ markedly across regions. For example, suppliers in Asia (e.g., Vietnam, China) often offer lower labor costs compared to European or Middle Eastern manufacturers. However, skilled craftsmanship and compliance with labor standards can influence costs.

-

Manufacturing Overhead: Includes factory expenses such as machinery maintenance, energy, and administrative costs. Overhead costs tend to be higher in regions with stricter regulations or higher energy prices.

-

Tooling and Development: Initial tooling costs for molds and prototypes can be substantial but are amortized over large production volumes. Custom designs or unique features increase tooling expenses.

-

Quality Control & Certifications: Ensuring consistent quality and obtaining certifications (e.g., ISO, eco-labels) add to costs but are crucial for market acceptance, especially in Europe and the Middle East.

-

Logistics & Shipping: Costs depend on shipment size, mode (air, sea, land), and destination. European buyers might face higher logistics costs due to stricter import regulations, while African and South American buyers should consider inland transportation expenses.

-

Margins: Manufacturers typically apply a markup ranging from 20% to 50%, depending on order volume, customization, and relationship strength.

Key Price Influencers

Several factors can significantly impact the final FOB (Free on Board) or CIF (Cost, Insurance, Freight) prices:

-

Order Volume & MOQ: Larger orders usually command better unit prices due to economies of scale. Many suppliers offer tiered pricing, incentivizing buyers to commit to higher volumes.

-

Specifications & Customization: Unique designs, branding, or special features (e.g., eco-friendly materials, orthotic inserts) increase costs. Standard models are more price-competitive.

-

Material Choices: Premium or imported materials elevate costs, while local sourcing can reduce expenses but might affect quality or certification eligibility.

-

Quality & Certifications: High-quality standards and certifications (e.g., sustainability, safety) can add to manufacturing costs but are often necessary for market entry, especially in Europe and the Middle East.

-

Supplier Factors: Supplier reputation, production capacity, and negotiation skills influence pricing. Established suppliers with reliable quality may charge premium prices but offer better consistency.

-

Incoterms & Delivery Terms: The choice of Incoterms (e.g., FOB, CIF, DDP) affects who bears transportation and customs costs, impacting the overall landed cost for the buyer.

Strategic Tips for International B2B Buyers

-

Negotiate for Volume Discounts: Aim for tiered pricing by committing to larger orders or long-term contracts, which can significantly lower unit costs.

-

Focus on Total Cost of Ownership (TCO): Beyond unit price, consider logistics, customs duties, taxes, and potential quality-related costs that may arise from lower-cost suppliers.

-

Leverage Certifications & Quality Standards: Suppliers with recognized certifications can streamline import procedures and reduce compliance costs, especially in regulated markets like Europe and the Middle East.

-

Optimize Logistics & Incoterms: For buyers in Africa and South America, FOB terms might be more manageable, but negotiating for inclusive delivery (e.g., DDP) can simplify import procedures.

-

Build Strong Supplier Relationships: Reliable communication and consistent quality can lead to better prices, priority treatment, and flexible terms.

Price Range and Market Variability

Indicative FOB prices for standard MBT shoes typically range from $15 to $30 per pair, depending on volume, customization, and quality requirements. European buyers might face higher prices due to stricter standards and certifications, whereas suppliers in Asia often offer competitive rates. African and South American buyers should account for additional import duties, taxes, and inland logistics, which can increase total landed costs by 10-30%.

Disclaimer: These figures are approximate and can fluctuate based on market conditions, currency exchange rates, and supplier negotiations. Always conduct detailed quotes and consider a comprehensive cost analysis tailored to your specific requirements.

Spotlight on Potential mbt shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for mbt shoes.)*

Essential Technical Properties and Trade Terminology for mbt shoes

Key Technical Properties of MBT Shoes

1. Material Grade and Composition

The choice of materials significantly impacts durability, comfort, and overall product quality. High-grade leathers, synthetic fibers, and specialized foam are commonly used. For B2B buyers, specifying the exact material grade (e.g., full-grain leather vs. bonded leather) ensures consistent quality and reduces the risk of returns or complaints. Material specifications should align with the target market’s durability expectations and environmental standards.

2. Sole and Midsole Construction

MBT shoes are distinguished by their unique curved sole designed for biomechanical benefits. The sole’s composition—often rubber or thermoplastic polyurethane (TPU)—must meet specific standards for flexibility, slip resistance, and wear resistance. Precise manufacturing tolerances are critical here; deviations can affect comfort, stability, and safety, which are key for consumer satisfaction.

3. Tolerance Levels

Tolerance refers to the permissible variation in manufacturing dimensions (e.g., sole height, width, or stitching). Tight tolerances (e.g., ±1mm) ensure product uniformity, critical for fitting and performance consistency across batches. For international buyers, clear specifications on tolerances help maintain quality control, especially when sourcing from different factories or regions.

4. Weight and Flexibility

Weight impacts comfort and usability, especially for active wear. Lightweight materials and optimized design reduce fatigue, while flexibility in key areas improves natural movement. When evaluating suppliers, request detailed technical sheets showing weight specifications and flexibility ratings to match consumer expectations across diverse markets.

5. Finishing and Quality Control Standards

Surface finishing, stitching quality, and adherence to safety standards are vital indicators of product reliability. Certifications like ISO 9001 or equivalent indicate a manufacturer’s commitment to quality management, which is essential for B2B buyers seeking consistent supply and minimal defects.

Essential Trade Terms for MBT Shoes

1. OEM (Original Equipment Manufacturer)

Refers to a manufacturer producing shoes that are branded and sold by another company. Understanding OEM agreements helps buyers negotiate pricing, intellectual property rights, and customization options. OEM relationships are common in private-label branding, especially for large retailers.

2. MOQ (Minimum Order Quantity)

The smallest number of units a supplier agrees to produce per order. Knowing the MOQ helps buyers plan inventory and negotiate better terms. For new markets or smaller brands, flexible MOQs may be available, but larger orders often reduce unit costs.

3. RFQ (Request for Quotation)

A formal process where buyers solicit price quotes, specifications, and lead times from multiple suppliers. An RFQ ensures transparency and competitive pricing, vital for buyers aiming to balance quality with cost-effectiveness across different regions.

4. Incoterms (International Commercial Terms)

Standardized trade terms published by the ICC that define responsibilities for shipping, insurance, and tariffs. Common Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, Freight) clarify who bears costs and risks at each supply chain stage, essential for international transactions.

5. Lead Time

The period from order confirmation to product delivery. Accurate knowledge of lead times enables better inventory planning and reduces stockouts, especially important when dealing with international logistics complexities and customs procedures.

6. Certification and Compliance Terms

Includes standards like CE (Conformité Européenne), ISO, or local safety certifications. Compliance ensures products meet regional regulations, reducing the risk of customs delays or rejection. For African, Middle Eastern, and European markets, understanding these certifications is critical for seamless entry and consumer trust.

Conclusion:

By understanding these technical properties and trade terms, B2B buyers from diverse regions can make informed decisions, negotiate effectively, and establish reliable supply chains for MBT shoes. Clear communication of specifications and contractual terms minimizes risks and enhances long-term partnerships in the global footwear market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the mbt shoes Sector

Market Overview & Key Trends

The global MBT (Masai Barefoot Technology) shoes market is driven by increasing consumer awareness of health, wellness, and ergonomic footwear solutions. As a pioneer in the “natural instability” concept, MBT appeals to health-conscious consumers across Europe, the Middle East, South America, and Africa. For B2B buyers, understanding regional market dynamics is essential. In Europe, especially Spain and Germany, demand is bolstered by a mature retail infrastructure and a focus on sustainable, innovative products. The Middle East, including Egypt, shows rapid growth driven by rising disposable incomes and a cultural preference for premium lifestyle brands.

Emerging sourcing trends include a shift toward digitalization and transparency. Many manufacturers are adopting Industry 4.0 technologies such as blockchain for supply chain traceability, AI-driven demand forecasting, and virtual sampling, which reduce lead times and costs. Additionally, regional sourcing is gaining traction: for example, sourcing from Asia (China, Vietnam) remains prevalent, but there is a growing interest in Nearshoring to regions like Eastern Europe and North Africa to reduce logistics costs and improve agility.

Market dynamics are influenced by geopolitical factors, tariffs, and trade agreements. Buyers from Africa and South America should leverage regional trade blocs such as MERCOSUR or the African Continental Free Trade Area (AfCFTA) to negotiate better terms. Sustainability considerations are increasingly shaping procurement decisions, with brands and retailers prioritizing suppliers that can demonstrate compliance with environmental standards. Overall, the sector is poised for steady growth, with innovation and ethical sourcing becoming central to competitive advantage.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer optional but a strategic imperative within the MBT shoes supply chain. The environmental footprint of footwear manufacturing—particularly in areas like raw material extraction, water use, and waste management—has come under scrutiny from consumers and regulators alike. B2B buyers should prioritize suppliers that embrace eco-friendly practices, such as utilizing recycled or organic materials, implementing water and energy conservation measures, and reducing chemical usage.

Certifications such as Global Organic Textile Standard (GOTS), Forest Stewardship Council (FSC), and ISO 14001 are critical indicators of a supplier’s commitment to sustainability. For MBT shoes, sourcing from suppliers that use biodegradable or recycled components—like eco-friendly soles or natural fibers—can serve as a key differentiator in the marketplace. Additionally, traceability systems, including blockchain solutions, enhance transparency, allowing buyers to verify ethical labor practices and environmental compliance.

Ethical sourcing extends beyond materials to encompass fair labor practices, safe working conditions, and fair wages. Buyers should establish clear standards aligned with internationally recognized frameworks such as SA8000 or Fair Trade certifications. Developing long-term partnerships with suppliers committed to continuous improvement in sustainability can mitigate risks related to reputational damage, supply disruptions, and regulatory penalties. Embracing a sustainability-driven procurement approach not only aligns with global trends but also appeals to increasingly conscious consumers across Africa, South America, Europe, and the Middle East.

Brief Evolution/History (Optional)

The MBT shoes brand was founded in the late 1990s, pioneering the concept of footwear that promotes natural walking and improved posture. Originally targeting health-conscious consumers, the brand expanded into the B2B space by collaborating with retailers, healthcare providers, and corporate wellness programs. Over the years, the focus shifted toward integrating sustainable practices, driven by rising consumer demand for eco-friendly products and stricter regulatory standards. This evolution underscores the importance for B2B buyers to stay abreast of technological advancements and sustainability standards, ensuring their supply chains remain competitive and compliant.

Frequently Asked Questions (FAQs) for B2B Buyers of mbt shoes

1. How can I effectively vet MBT shoe suppliers to ensure product quality and reliability?

Vetting suppliers begins with verifying their credentials, such as business licenses, certifications (ISO, CE, etc.), and industry reputation. Request comprehensive product samples to assess quality, comfort, and durability firsthand. Conduct factory audits or virtual tours when possible, focusing on manufacturing processes, quality control systems, and labor practices. Review customer references and seek feedback from existing clients, especially in your region. Additionally, check for compliance with international standards relevant to your market, ensuring the supplier can meet your quality expectations consistently. Establish clear communication channels and negotiate transparent terms to foster a trustworthy partnership.

2. Can I customize MBT shoes to align with my brand or specific market needs?

Yes, many MBT suppliers offer customization options, including branding through logo placement, packaging, and sometimes design modifications to suit regional preferences. Discuss your specific requirements early, such as color schemes, materials, or sole designs, to confirm feasibility. Keep in mind that customization may influence minimum order quantities (MOQs) and lead times, so plan accordingly. Establish detailed agreements covering intellectual property rights, sample approvals, and quality standards. Working with a supplier experienced in OEM/ODM services can streamline the process and ensure your branding aligns with international standards, helping you differentiate in competitive markets.

3. What are typical MOQs, lead times, and payment terms for importing MBT shoes?

MOQs for MBT shoes generally range from 500 to 2,000 pairs per style, depending on the supplier and customization level. Lead times typically span 4 to 12 weeks, accounting for production, quality checks, and logistics, but can vary based on order size and supplier location. Payment terms often include a 30% deposit upfront, with the remaining balance payable before shipment or upon receipt of goods. Some suppliers may offer flexible terms for repeat buyers or large orders. Always negotiate clear payment schedules and consider using secure payment methods like letters of credit or escrow to mitigate risks.

Illustrative Image (Source: Google Search)

4. What certifications and quality assurance processes should I look for in MBT shoe suppliers?

Ensure your supplier holds relevant certifications such as ISO 9001 for quality management, CE marking for European markets, or other regional standards. Request detailed quality assurance protocols, including material testing reports, durability assessments, and compliance with safety standards. Suppliers should have rigorous inspection procedures at various production stages, with documented quality control reports. Additionally, consider third-party testing or lab certifications for specific markets, especially if importing to regions with strict safety and environmental regulations. These measures help safeguard your brand reputation and reduce the risk of defective products reaching your customers.

5. How do I manage logistics and shipping when importing MBT shoes from overseas suppliers?

Effective logistics management involves selecting reliable freight forwarders experienced in international trade, especially in your target regions. Decide on shipping methods—air freight for faster delivery or sea freight for cost efficiency—based on your inventory needs. Clarify Incoterms (e.g., FOB, CIF) with your supplier to define responsibilities and costs. Ensure all customs documentation, including commercial invoices, packing lists, and certificates of origin, are accurate and complete to prevent delays. Establish clear communication channels with your logistics partners and plan for potential disruptions, such as port congestion or customs inspections, to maintain a steady supply chain.

6. How should I handle disputes or quality issues with my MBT shoe supplier?

Start with a detailed, written quality agreement that specifies inspection procedures, defect tolerances, and remedies. In case of disputes, promptly communicate with your supplier, providing evidence such as photos or inspection reports. Negotiate amicably to resolve issues, whether through product replacements, refunds, or discounts. If disagreements persist, consider involving third-party arbitration or mediation, especially if your contract includes dispute resolution clauses. Building strong, transparent relationships and maintaining open communication channels can prevent misunderstandings. Regular quality audits and pre-shipment inspections also minimize the risk of receiving non-conforming goods.

7. What are best practices for establishing long-term B2B relationships with MBT shoe suppliers?

Long-term relationships are built on trust, consistent quality, and mutual benefit. Start with small pilot orders to evaluate performance and build rapport. Maintain clear, professional communication and provide constructive feedback to foster continuous improvement. Consider integrating supplier development programs or shared quality initiatives. Timely payments, reliability, and transparency help solidify partnerships. Regular visits, virtual meetings, and participation in trade shows can strengthen ties and keep you updated on new products or innovations. Prioritize suppliers who demonstrate flexibility, responsiveness, and a proactive approach to resolving challenges, ensuring a sustainable supply chain.

8. How can I ensure compliance with regional regulations when importing MBT shoes into markets like Egypt, Spain, or South America?

Familiarize yourself with each market’s import regulations, standards, and certification requirements. For example, European markets demand CE marking and compliance with REACH regulations, while South American countries may require specific safety or environmental certifications. Work with local customs brokers or trade consultants to navigate tariffs, taxes, and documentation procedures efficiently. Conduct due diligence on supplier compliance to avoid delays or penalties. Staying updated on regulatory changes and maintaining proper documentation, including test reports and certificates, ensures seamless customs clearance and market entry, protecting your investment and brand reputation.

This comprehensive FAQ section provides actionable insights tailored to international B2B buyers sourcing MBT shoes, emphasizing due diligence, customization, logistics, and compliance—crucial factors for success in global markets.

Strategic Sourcing Conclusion and Outlook for mbt shoes

Strategic Sourcing Outlook for mbt Shoes

Effective strategic sourcing is vital for international B2B buyers aiming to capitalize on the growing demand for MBT shoes across diverse markets. Key considerations include establishing strong supplier relationships, ensuring quality compliance, and optimizing supply chain agility to respond to fluctuating market conditions. Leveraging local sourcing opportunities in regions like Egypt, Spain, and other European countries can reduce costs and improve lead times, while also supporting sustainable procurement practices.

For buyers from Africa, South America, the Middle East, and Europe, a tailored sourcing strategy that balances cost-efficiency with quality assurance will be crucial in gaining a competitive edge. Engaging with trusted manufacturers and diversifying supply sources can mitigate risks associated with geopolitical uncertainties and supply disruptions. Additionally, embracing innovations in logistics and digital procurement platforms can streamline operations and foster transparency.

Looking ahead, the global demand for ergonomic footwear like MBT shoes is poised to expand further. B2B buyers should prioritize building resilient, flexible supply chains and stay informed about emerging market trends. Proactively cultivating strategic partnerships will enable you to meet evolving consumer needs, maximize profitability, and sustain long-term growth in this dynamic industry.