Your Ultimate Guide to Sourcing New Balance Pickleball Shoes

Guide to New Balance Pickleball Shoes

- Introduction: Navigating the Global Market for new balance pickleball shoes

- Understanding new balance pickleball shoes Types and Variations

- Key Industrial Applications of new balance pickleball shoes

- Strategic Material Selection Guide for new balance pickleball shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for new balance pickleball shoes

- Comprehensive Cost and Pricing Analysis for new balance pickleball shoes Sourcing

- Spotlight on Potential new balance pickleball shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for new balance pickleball shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the new balance pickleball shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of new balance pickleball shoes

- Strategic Sourcing Conclusion and Outlook for new balance pickleball shoes

Introduction: Navigating the Global Market for new balance pickleball shoes

In the rapidly expanding world of pickleball, New Balance pickleball shoes have emerged as a critical product for retailers, distributors, and sports equipment suppliers aiming to meet the surging demand for high-performance footwear. For international B2B buyers—from Africa, South America, the Middle East, and Europe—understanding the nuances of this niche market is essential for strategic sourcing and competitive advantage. As the sport gains popularity across diverse regions, so does the need for reliable, quality footwear that combines innovation with brand reputation.

This comprehensive guide is designed to empower you with actionable insights across key areas: the various types of New Balance pickleball shoes, their material compositions, manufacturing and quality control standards, sourcing options, pricing considerations, and market trends. Additionally, it addresses frequently asked questions to streamline your decision-making process. Whether you’re exploring new supplier partnerships or expanding your product portfolio, this resource provides the critical knowledge needed to navigate the complexities of the global market confidently.

By leveraging this guide, B2B buyers can make informed sourcing decisions that optimize quality, cost-efficiency, and supply chain resilience. With tailored insights for regions such as Africa, South America, the Middle East, and Europe—including Australia and Thailand—this guide aims to unlock new opportunities and foster sustainable growth in the competitive landscape of pickleball footwear.

Understanding new balance pickleball shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Performance/Competitive Model | Lightweight, responsive design with enhanced grip and agility features | Retail sports stores, specialty sports suppliers | Pros: High demand among serious players; easy to market as premium product. Cons: Higher manufacturing costs, limited target market segment. |

| Recreational/Entry-Level Model | More cushioned, durable, with supportive midsole for casual play | Mass-market sports retailers, bulk distributors | Pros: Broader appeal, cost-effective for large orders. Cons: Lower margins, less specialized features. |

| Custom/Private Label Shoes | Customizable branding, colors, and logos for clubs or tournaments | Corporate buyers, team suppliers, event organizers | Pros: High brand value, exclusivity; strong B2B relationships. Cons: Longer lead times, higher setup costs. |

| Eco-Friendly/Sustainable Model | Made from recycled or sustainable materials, eco-conscious design | Niche eco-focused markets, green retailers | Pros: Differentiation in eco-conscious markets; aligns with CSR goals. Cons: Potentially higher production costs, limited supplier options. |

| High-Performance/Professional Model | Advanced traction, stability, and durability features for elite players | Professional clubs, high-end specialty outlets | Pros: Premium positioning, high margins. Cons: Smaller customer base, higher R&D requirements. |

Performance/Competitive Model

This type is engineered for serious players seeking agility, speed, and superior grip. Typically featuring lightweight materials and enhanced traction soles, these shoes cater to competitive markets and specialty sports outlets. B2B buyers should consider sourcing from manufacturers with proven R&D capabilities to ensure consistent quality. While this model commands premium pricing, it appeals to niche markets willing to invest in top-tier gear, making it suitable for premium retail channels or specialty sports distributors.

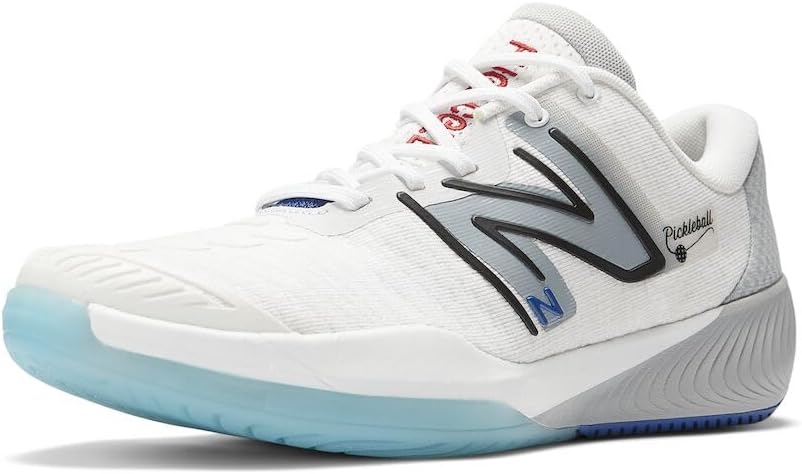

Illustrative Image (Source: Google Search)

Recreational/Entry-Level Model

Designed for casual players and beginners, this variation emphasizes comfort, durability, and affordability. It’s ideal for bulk purchasing by mass-market sports retailers or distributors targeting schools and community centers. Buyers benefit from the broad market appeal and faster inventory turnover. However, margins may be lower, and these models often require cost-effective manufacturing solutions. Ensuring consistent quality and reliable supply chains is critical to meet the expectations of novice players and maintain brand reputation.

Custom/Private Label Shoes

Customizable shoes allow B2B buyers to offer branded products for clubs, tournaments, or corporate events. They provide a strategic advantage in building brand loyalty and exclusivity. These shoes often feature specific color schemes, logos, or design elements aligned with client branding. Buyers should evaluate supplier capabilities for quick turnaround times and quality control processes. While setup costs and lead times are higher, the potential for high-margin, exclusive products makes this a valuable segment for strategic partnerships.

Eco-Friendly/Sustainable Model

This category caters to environmentally conscious markets, emphasizing sustainable materials and eco-friendly manufacturing processes. B2B buyers targeting niche markets or promoting CSR initiatives can leverage these shoes to differentiate their offerings. Sourcing from suppliers with transparent sustainability credentials is essential. Although costs may be higher, the growing demand for green products can justify premium pricing and foster long-term loyalty among eco-minded consumers.

High-Performance/Professional Model

Focused on elite players, this type incorporates cutting-edge traction systems, advanced support, and durability features. Suitable for high-end specialty retailers, professional clubs, or bespoke B2B partnerships with sports organizations. These shoes often require significant investment in R&D and quality assurance. Buyers should prioritize suppliers with proven track records in high-performance sports footwear, as these products command premium prices and can elevate brand positioning within competitive markets.

Key Industrial Applications of new balance pickleball shoes

| Industry/Sector | Specific Application of new balance pickleball shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports & Recreational Facilities | Providing durable, high-performance footwear for pickleball courts and training centers | Enhances athlete performance, reduces injury risk, and extends footwear lifespan | Product durability, supply chain reliability, and compliance with safety standards |

| Wholesale Sports Retailers | Bulk procurement for sports stores and online sportswear platforms | Boosts sales through high-quality, trending footwear; improves brand reputation | Consistent quality, competitive pricing, and flexible logistics options |

| International Sports Events & Tournaments | Supplying official footwear for athletes and officials at international pickleball competitions | Increases brand visibility and credibility; supports athlete safety and performance | Certification for international standards, branding opportunities, and logistics planning |

| Healthcare & Rehabilitation Centers | Using pickleball shoes for physiotherapy and low-impact sports programs | Promotes injury prevention and recovery; supports active aging initiatives | Footwear comfort, ergonomic design, and suitability for diverse patient needs |

| Corporate Wellness & Team Building | Facilitating active corporate wellness programs with pickleball activities | Encourages employee engagement, improves health outcomes, and fosters team cohesion | Custom branding options, bulk discounts, and ease of distribution |

Sports & Recreational Facilities

Pickleball courts, especially in regions like Europe and Australia, are increasingly adopting specialized footwear to meet the sport’s dynamic demands. New Balance pickleball shoes offer high durability, grip, and support, essential for athletes performing rapid lateral movements. For B2B buyers, sourcing these shoes ensures facilities provide top-tier equipment, reducing injury risks and enhancing player satisfaction. International buyers should prioritize suppliers with proven quality standards and reliable distribution channels to maintain consistent stock levels across multiple venues.

Wholesale Sports Retailers

Retailers across Africa, South America, and the Middle East are expanding their offerings to include trending pickleball footwear due to rising popularity. Bulk procurement of New Balance pickleball shoes can enhance product margins and elevate store reputation for quality. Buyers must focus on securing authentic products with consistent quality, competitive pricing, and flexible logistics to meet regional demand fluctuations. Establishing strong supplier relationships ensures timely replenishment and brand loyalty.

International Sports Events & Tournaments

Global pickleball tournaments, particularly in Europe and Australia, require official footwear suppliers to support athlete performance and safety. New Balance’s reputation for quality and innovation makes their shoes ideal for official endorsements. B2B buyers should verify certifications aligning with international standards, negotiate branding rights, and plan logistics meticulously to meet tight event schedules. Such partnerships can significantly boost brand visibility and open avenues for future collaborations.

Healthcare & Rehabilitation Centers

Pickleball shoes are increasingly incorporated into physiotherapy and active aging programs across regions like the Middle East and South America. Their ergonomic design and shock absorption features support injury prevention and aid recovery. Healthcare providers and B2B buyers should focus on sourcing shoes that meet medical standards for comfort and support, ensuring they cater to diverse patient needs. Consistent quality and availability are critical for integrating these shoes into health and wellness protocols.

Corporate Wellness & Team Building

Organizations in Europe, Thailand, and Africa leverage pickleball as part of corporate wellness initiatives. Providing high-quality New Balance pickleball shoes encourages active participation, improves health outcomes, and fosters team cohesion. B2B buyers should consider custom branding options, bulk discounts, and easy distribution logistics to maximize program effectiveness. Reliable supply chains and adaptable product offerings are essential to meet the diverse needs of corporate clients across different regions.

Strategic Material Selection Guide for new balance pickleball shoes

Material Analysis for New Balance Pickleball Shoes

Selecting the appropriate materials for manufacturing New Balance pickleball shoes is critical for ensuring optimal performance, durability, and compliance across diverse international markets. The choice of materials directly influences product quality, cost, manufacturing complexity, and suitability for end-users in regions such as Africa, South America, the Middle East, and Europe (including Australia and Thailand). Here, we analyze three common materials—EVA foam, synthetic leather, and rubber—to guide B2B buyers in making informed procurement decisions.

EVA Foam (Ethylene Vinyl Acetate)

Key Properties:

EVA foam is lightweight, flexible, and offers excellent cushioning, making it ideal for midsole applications. It exhibits good shock absorption and maintains flexibility across a wide temperature range, typically from -30°C to 80°C. Its chemical resistance is moderate, but it can degrade under prolonged exposure to UV light and certain solvents.

Pros & Cons:

– Pros: Cost-effective, lightweight, excellent cushioning, easy to mold during manufacturing, and widely available.

– Cons: Less durable than rubber or TPU, prone to compression set over time, and can degrade under UV exposure, affecting longevity.

Impact on Application:

EVA’s compatibility with adhesives and other sole components is high, facilitating manufacturing. However, in regions with high UV exposure (e.g., Middle East, Australia), UV-resistant additives or coatings are advisable to extend product life.

International Considerations:

For African and South American markets, where climate variability is significant, suppliers should ensure EVA formulations include UV stabilizers. Compliance with standards like ASTM D256 (impact resistance) and REACH regulations in Europe is essential. Additionally, cost considerations favor EVA for mass production, but durability enhancements may be necessary for high-use environments.

Synthetic Leather (Polyurethane-based)

Key Properties:

Synthetic leather offers a balance of durability, aesthetic appeal, and ease of maintenance. It is typically composed of a polyurethane (PU) coating on a fabric backing, providing a surface resistant to abrasion and moisture. Its flexibility and breathability can be tailored during manufacturing.

Pros & Cons:

– Pros: High durability, water-resistant, customizable appearance, and consistent quality.

– Cons: Heavier than mesh or textile, can be less breathable, and manufacturing involves complex coating processes increasing costs.

Impact on Application:

Synthetic leather enhances the shoe’s structural integrity and aesthetic appeal, especially in upper designs. For regions with high humidity or frequent rain (e.g., parts of South America and Southeast Asia), water-resistant properties are advantageous. Compatibility with standard adhesives and stitching is high, but care must be taken to meet regional standards for VOC emissions and chemical safety.

International Considerations:

Buyers should verify compliance with local standards such as DIN EN 71 (safety of toys and materials) or JIS standards for chemical safety. In markets like Europe, adherence to REACH and OEKO-TEX certifications can influence consumer acceptance. Cost varies depending on grade; premium grades offer enhanced breathability and finish but at higher prices.

Rubber (Natural and Synthetic)

Key Properties:

Rubber is primarily used in outsoles for its excellent grip, flexibility, and abrasion resistance. Natural rubber offers high resilience and elasticity, while synthetic variants (e.g., SBR, NBR) are engineered for specific performance attributes like chemical resistance or temperature tolerance.

Pros & Cons:

– Pros: Superior durability, excellent slip resistance, and good resilience under repeated stress.

– Cons: Heavier than EVA, can be more expensive, and synthetic variants may have environmental concerns related to production.

Impact on Application:

Rubber’s chemical resistance makes it suitable for outdoor courts and variable weather conditions. It also performs well across temperature extremes, which is vital for international markets with diverse climates. Manufacturing complexity is higher, especially for natural rubber, which can be affected by supply chain fluctuations.

International Considerations:

For markets with strict environmental regulations (e.g., Europe’s REACH), suppliers must ensure rubber formulations are compliant. In developing regions, sourcing sustainable or recycled rubber can be a competitive advantage. Cost considerations are significant; synthetic rubbers offer a middle ground in terms price and performance.

Summary Table of Material Options

| Material | Typical Use Case for New Balance Pickleball Shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| EVA Foam | Midsole cushioning | Lightweight, cost-effective, excellent shock absorption | Less durable, UV-sensitive, prone to compression | Low |

| Synthetic Leather | Upper material | Durable, water-resistant, customizable appearance | Heavier, less breathable, higher manufacturing complexity | Medium |

| Rubber | Outsole | Superior grip, abrasion-resistant, weather-tolerant | Heavier, more expensive, environmental concerns | Medium to High |

This detailed analysis enables B2B buyers to select materials aligned with regional climate conditions, compliance standards, and cost constraints. Considering regional preferences and regulatory requirements ensures the production of high-quality, compliant, and competitive pickleball shoes for diverse international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for new balance pickleball shoes

Manufacturing Processes for New Balance Pickleball Shoes

The production of New Balance pickleball shoes involves a series of meticulously controlled stages, ensuring consistency, performance, and durability. Understanding these processes allows B2B buyers to assess supplier capabilities and compliance with international standards.

Illustrative Image (Source: Google Search)

Material Preparation and Procurement

The manufacturing process begins with sourcing high-quality raw materials, including synthetic meshes, leather, rubber, EVA foam, and specialized adhesives. Suppliers adhering to ISO 9001 standards typically establish rigorous supplier qualification procedures, including audits and certification checks, to ensure material consistency and safety. For B2B buyers, verifying the origin and certification of materials—such as REACH compliance for Europe or ISO 14001 for environmental management—is crucial.

Forming and Molding

In this stage, components like the midsole and outsole are shaped using injection molding or compression molding techniques. Precision molds, often CNC-machined, are employed to achieve tight dimensional tolerances. For high-performance pickleball shoes, manufacturers may incorporate lightweight, shock-absorbing foams and reinforced structures to enhance stability. Suppliers often utilize computer-aided design (CAD) and finite element analysis (FEA) to optimize material distribution and structural integrity, especially for international markets with diverse playing conditions.

Assembly and Stitching

The assembly process integrates various components—upper, midsole, outsole, and lacing system—using advanced stitching, adhesive bonding, and heat sealing methods. Industry-leading manufacturers employ automated robotic systems for consistent stitching and bonding, reducing variability. Attention to detail during assembly is vital to prevent defects such as misaligned seams or weak bondings, which can compromise performance and safety.

Finishing and Packaging

Final steps include surface finishing—such as polishing, dyeing, and branding—and quality inspections before packaging. Specialized equipment ensures color consistency, logo placement accuracy, and overall aesthetic standards. Packaging is designed to protect the shoes during transit, with eco-friendly options increasingly favored in international markets.

Quality Assurance Frameworks and Standards

Ensuring product quality for international markets requires adherence to global standards alongside industry-specific certifications. B2B buyers should scrutinize supplier quality management systems and verify compliance through documented certifications and audit reports.

International Standards and Certifications

- ISO 9001: The cornerstone of quality management systems, ISO 9001 certification indicates a manufacturer’s commitment to consistent quality, process control, and continuous improvement. B2B buyers should request the supplier’s ISO certificates and audit reports, especially when dealing with manufacturers in regions like Africa or South America, where certification enforcement varies.

- CE Marking: For European markets, CE certification confirms compliance with safety, health, and environmental requirements, including footwear standards EN ISO 20345 or 20347.

- Other Industry Certifications: Additional certifications such as ASTM standards for impact absorption or ASTM F2413 for footwear protective features may be relevant depending on the market and product specifications.

Quality Control (QC) Checkpoints

Effective QC involves multiple inspection stages:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival for defects, material composition, and compliance with specifications. Techniques include visual inspection, dimensional measurement, and material testing.

- In-Process Quality Control (IPQC): During manufacturing, checkpoints verify parameters such as stitch quality, bonding strength, and dimensional accuracy. Statistical process control (SPC) charts monitor process stability.

- Final Quality Control (FQC): Finished shoes undergo comprehensive testing, including visual inspection, functional testing (e.g., flexibility, grip), and packaging inspection.

Testing Methods and Validation

- Mechanical Testing: Drop tests, compression tests, and fatigue testing ensure durability under typical use conditions.

- Environmental Testing: Accelerated aging, water resistance, and UV exposure tests simulate long-term wear.

- Performance Testing: Grip, shock absorption, and stability are verified through biomechanical assessments.

- Certifications for Testing: Many manufacturers utilize third-party labs accredited under ISO/IEC 17025 to validate testing procedures and results.

Verifying Supplier Quality and Compliance

B2B buyers should adopt a rigorous approach to verifying supplier quality systems and certifications:

- Supplier Audits: Conduct or commission on-site audits focusing on production facilities, QC processes, and document controls. Audits should include evaluation of adherence to ISO 9001, environmental standards, and social compliance.

- Inspection Reports and Documentation: Request detailed inspection reports, test certificates, and batch traceability documentation. Transparent suppliers provide comprehensive records demonstrating consistent quality.

- Third-Party Inspection Services: Engage independent inspection firms like SGS, Bureau Veritas, or Intertek to perform pre-shipment inspections, ensuring compliance with contractual and regulatory standards.

Special Considerations for International B2B Buyers

International buyers from Africa, South America, the Middle East, and regions like Australia or Thailand face unique challenges and opportunities:

- Regional Certification Recognition: Ensure that certifications such as CE, ASTM, or local standards are recognized and accepted in your target markets. Some regions may require additional compliance documentation or local testing.

- Supply Chain Transparency: Verify the transparency of the supply chain to avoid counterfeit or substandard components, which can be prevalent in less regulated markets.

- Cultural and Market Adaptation: Consider suppliers’ ability to adapt designs, packaging, and labeling to local languages and cultural preferences, which can influence quality perception and customer satisfaction.

- Logistics and Lead Times: Assess the supplier’s capacity to meet international shipping requirements, including documentation, customs clearance, and delivery schedules.

Conclusion

For B2B buyers sourcing New Balance pickleball shoes, understanding the detailed manufacturing processes and rigorous quality assurance protocols is essential to ensure product integrity and compliance in diverse international markets. Establishing clear communication channels, conducting thorough audits, and verifying certifications empower buyers to mitigate risks and foster long-term supplier relationships that uphold quality standards globally.

Comprehensive Cost and Pricing Analysis for new balance pickleball shoes Sourcing

Cost Structure Breakdown for New Balance Pickleball Shoes

Understanding the comprehensive cost components involved in sourcing New Balance pickleball shoes is essential for international B2B buyers. The primary cost elements include raw materials, manufacturing labor, overhead, tooling, quality control, logistics, and margin.

Materials: High-performance synthetic uppers, durable rubber outsoles, and specialized insoles contribute significantly to material costs. The choice of materials impacts both quality and price; premium materials with certifications (e.g., eco-labels or safety standards) tend to elevate costs but can justify premium pricing.

Labor: Manufacturing costs vary based on the country of production. For example, sourcing from Asian factories (China, Vietnam) often offers lower labor costs, whereas facilities in Europe or Australia may have higher wages, influencing overall pricing.

Manufacturing Overhead: This includes factory utilities, equipment depreciation, and labor management expenses. Efficient factories with high automation can reduce overhead per unit, providing more competitive prices.

Tooling and Setup: Initial mold creation and tooling costs are significant for new models but are amortized over large production runs. Larger volumes reduce per-unit tooling costs, making high-volume sourcing more cost-effective.

Quality Control (QC): Rigorous QC processes ensure product consistency and compliance with international standards. QC costs may include inspections, testing, and certifications, especially critical for markets demanding high safety or environmental standards.

Logistics and Incoterms: Shipping costs depend on destination, mode (air, sea, land), and Incoterms negotiated. FOB (Free on Board) terms shift some logistics responsibility to the buyer, while DDP (Delivered Duty Paid) includes all costs in the price. Buyers should consider customs duties, taxes, and import regulations in their region.

Margin: Suppliers typically add a markup to cover profit margins, which varies based on order volume, relationship, and market competitiveness.

Price Influencers and Strategic Considerations

Several factors influence the final pricing of New Balance pickleball shoes:

-

Order Volume & MOQ: Larger orders typically attract better unit prices due to economies of scale. Buyers should negotiate for volume discounts, especially for sustained partnerships.

-

Specifications & Customization: Customized designs, branding, or specialized features (e.g., extra grip, colorways) increase costs. Standard models are more economical, but customization can command premium pricing.

-

Materials & Certifications: Using premium or certified materials (e.g., eco-friendly or hypoallergenic) raises costs but can differentiate products in competitive markets.

-

Quality & Certifications: International standards (ISO, ASTM, or local certifications) influence supplier selection and pricing. Suppliers with proven quality records often command higher prices but reduce risk.

-

Supplier Factors: Factory reputation, production capacity, and geopolitical stability impact pricing. Established suppliers with reliable delivery and quality tend to have higher base prices but reduce supply chain risks.

-

Incoterms & Shipping: Negotiating favorable Incoterms can significantly affect landed costs. Buyers in Africa, South America, or remote regions should evaluate shipping options to optimize total landed cost, including duties and taxes.

Actionable Tips for International B2B Buyers

-

Negotiate for Volume Discounts: Leverage large or repeat orders to secure better unit prices. Establish long-term relationships to benefit from preferential terms.

-

Assess Total Cost of Ownership (TCO): Consider all costs—manufacturing, logistics, customs, and post-sale support—rather than just unit price. A lower upfront cost might incur higher total costs due to logistics or quality issues.

-

Prioritize Quality & Certifications: While cheaper options exist, investing in quality-certified suppliers reduces risks of product recalls, delays, or compliance issues, especially vital for markets with strict regulations like Europe or Australia.

-

Understand Pricing Nuances: Be aware that prices fluctuate based on raw material costs, currency exchange rates, and geopolitical factors. Regularly review and renegotiate terms as needed.

-

Local Market Considerations: For regions like Africa or South America, factor in additional logistics costs and import duties. Partnering with local agents or distributors can streamline customs clearance and reduce delays.

-

Sample & Pilot Orders: Always request samples and conduct quality assessments before large orders. This mitigates risks associated with supplier variability and ensures product meets regional standards.

Disclaimer on Price Estimates

Indicative pricing for New Balance pickleball shoes typically ranges from $20 to $50 per pair at the factory gate for standard models in high-volume orders. Customization, premium materials, or smaller quantities can push prices higher. Shipping, duties, and taxes can add 10-30% to the landed cost, depending on the destination country.

By thoroughly analyzing these cost components and strategic factors, international B2B buyers can optimize their sourcing decisions, negotiate effectively, and ensure competitive pricing tailored to their market needs.

Spotlight on Potential new balance pickleball shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for new balance pickleball shoes.)*

Essential Technical Properties and Trade Terminology for new balance pickleball shoes

Technical Properties Critical for B2B Evaluation

1. Material Grade and Composition

The quality of materials used in pickleball shoes directly impacts durability, comfort, and performance. High-grade synthetic uppers, lightweight mesh, and durable rubber outsoles are standard benchmarks. For B2B buyers, specifying material grades ensures consistency across production batches and helps assess the product’s suitability for various markets, especially where environmental conditions differ.

2. Manufacturing Tolerance Levels

Tolerance refers to the permissible variation in dimensions and construction during manufacturing. Tight tolerances (e.g., ±1mm for sole thickness) indicate high precision, which is crucial for consistent fit and performance. Buyers should verify tolerance specifications to ensure product uniformity, especially when scaling up orders across multiple regions with different quality standards.

3. Cushioning and Support Technology

Advanced cushioning systems—such as EVA foam midsoles or specialized gel inserts—enhance shock absorption and reduce injury risk. For international buyers, understanding these technical features helps evaluate the shoe’s performance in different climatic and playing conditions, influencing market positioning and customer satisfaction.

4. Traction and Outsole Design

The outsole’s material and tread pattern determine grip and stability on various court surfaces. A high-quality rubber compound with a multidirectional tread pattern provides better traction. B2B buyers should focus on these specs to tailor product offerings for specific regional courts, such as outdoor versus indoor courts, enhancing product relevance.

5. Weight and Breathability

Lightweight shoes improve player agility, while breathable materials prevent overheating. These properties are measurable through weight specifications (grams per shoe) and fabric breathability ratings. For international markets, these technical features are key selling points aligned with local player preferences and climate conditions.

6. Durability and Wear Resistance

Assessments like abrasion resistance ratings on the outsole and upper materials indicate longevity. Durable shoes reduce replacement frequency, offering better value for end-users. B2B buyers should prioritize products with proven wear resistance to meet customer expectations in competitive markets.

Industry and Trade Terminology for B2B Clarity

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce pickleball shoes under another brand’s specifications. Understanding OEM relationships helps buyers identify manufacturing partners, negotiate pricing, and ensure quality control, especially when sourcing from overseas factories.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce or sell in a single order. Knowledge of MOQ is vital for planning inventory levels, managing cash flow, and negotiating better terms, particularly when entering new markets with uncertain demand.

3. RFQ (Request for Quotation)

A formal request sent by buyers to suppliers asking for detailed pricing, lead times, and terms for specific product specifications. Efficient use of RFQs accelerates decision-making, ensures clarity, and helps compare supplier offerings across regions.

4. Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce (ICC) that define responsibilities for shipping, insurance, and tariffs. Common terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) determine cost-sharing and risk transfer points, essential for international shipping negotiations.

5. Lead Time

The period from order placement to product delivery. Accurate knowledge of lead times allows buyers to plan inventory and marketing strategies, especially critical when dealing with international logistics and customs procedures.

6. Certification and Compliance Standards

References to safety, environmental, and quality standards such as ISO, REACH, or local certifications. Ensuring products meet these standards is crucial for market entry, legal compliance, and consumer trust in different regions.

Understanding these technical properties and trade terms equips international B2B buyers with the knowledge to evaluate, negotiate, and source high-quality pickleball shoes effectively. Clear comprehension of specifications ensures product suitability for local markets, while familiarity with trade terminology streamlines communication and contract management across borders.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the new balance pickleball shoes Sector

Market Overview & Key Trends

The global pickleball shoe market is experiencing rapid growth driven by the sport’s expanding popularity across North America, Europe, and emerging markets such as Australia and parts of Asia. For international B2B buyers from regions like Africa, South America, and the Middle East, this growth presents significant sourcing opportunities, especially as local sports infrastructure and consumer interest deepen.

Current industry trends emphasize technological innovation—such as lightweight, high-traction soles, moisture-wicking materials, and enhanced stability features—catering to athletes seeking performance and durability. Additionally, digital sourcing platforms and data-driven supply chain management tools are transforming procurement processes, enabling buyers to identify reliable manufacturers and optimize logistics efficiently.

Market dynamics are influenced by factors such as fluctuating raw material costs, geopolitical considerations, and evolving trade policies. Buyers should monitor tariffs, import regulations, and regional trade agreements, especially when sourcing from Asia, Europe, or the Middle East. Diversifying supply chains through regional manufacturing hubs—like Turkey, Vietnam, or Eastern Europe—can mitigate risks and reduce lead times.

Emerging B2B tech trends include blockchain for supply chain transparency, AI-driven demand forecasting, and virtual showrooms, allowing buyers from diverse markets to make informed sourcing decisions. For Africa and South America, establishing local distribution or assembly centers can enhance market responsiveness and reduce costs, while European and Australian buyers benefit from advanced logistics networks and established supplier ecosystems.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical factor in sourcing decisions within the pickleball footwear sector. Buyers are increasingly prioritizing suppliers with transparent, ethical supply chains that adhere to environmental standards. This shift is driven by consumer demand for eco-friendly products and corporate responsibility commitments, which influence brand reputation and market competitiveness.

Environmental impacts of footwear production—such as water consumption, chemical use, and carbon emissions—are under scrutiny. Leading brands like New Balance are adopting sustainable practices, including the use of recycled materials (e.g., recycled polyester, rubber), biodegradable components, and low-impact dyeing processes. For B2B buyers, sourcing from suppliers with recognized green certifications—such as ISO 14001, LEED, or Bluesign—can ensure compliance with environmental standards.

Ethical sourcing also encompasses fair labor practices, safe working conditions, and supply chain transparency. Buyers should verify suppliers’ adherence to international labor standards, such as those outlined by the Ethical Trading Initiative or SA8000. Engaging with suppliers committed to reducing carbon footprints, implementing water-saving initiatives, and utilizing renewable energy sources can significantly bolster sustainability credentials.

In regions like Europe and Australia, stricter regulations and consumer awareness drive demand for sustainably produced footwear. Conversely, buyers in Africa, South America, and the Middle East should focus on establishing partnerships with suppliers demonstrating genuine sustainability commitments, supported by third-party audits and certifications. This not only aligns with global best practices but also enhances market access and brand integrity in diverse regions.

Brief Evolution/History (Optional)

The evolution of pickleball shoes, including those by New Balance, reflects broader shifts in sports footwear, emphasizing lightweight design, grip, and comfort. Initially modeled after tennis or badminton shoes, they have transitioned into specialized performance gear tailored to pickleball’s unique demands. For B2B buyers, understanding this trajectory highlights the importance of innovation and quality assurance in sourcing high-performance footwear. As the sport gains international traction, manufacturers are investing in R&D to develop more sustainable, durable, and technologically advanced shoes, creating new sourcing opportunities and competitive differentiation.

Frequently Asked Questions (FAQs) for B2B Buyers of new balance pickleball shoes

-

How can I verify the credibility and reliability of a New Balance pickleball shoe supplier?

To ensure supplier credibility, conduct thorough due diligence by checking their business licenses, certifications, and track record in athletic footwear manufacturing. Request references from other international buyers and review their client portfolio, especially within your region. Additionally, verify their compliance with international quality standards such as ISO or CE markings. Visiting their manufacturing facilities or requesting virtual tours can provide insights into their production capabilities. Utilizing third-party inspection services before shipment can further mitigate risks, ensuring the supplier’s reliability aligns with your quality and delivery expectations. -

What customization options are available for bulk orders, and how do they impact lead times?

Most reputable suppliers offer customization options such as branding (logo placement), color schemes, and specific design features tailored to your market needs. Customization typically requires additional lead time—usually 4-8 weeks—depending on complexity and order volume. It’s essential to communicate your specifications early and confirm the supplier’s capacity to meet deadlines. Establishing clear agreements on customization scope and deadlines helps prevent delays. For faster turnaround, consider pre-approved templates or limited customization options that align with your branding strategy. -

What are typical minimum order quantities (MOQs), and how do they influence pricing and logistics?

MOQs for New Balance pickleball shoes generally range from 300 to 1,000 pairs, varying by supplier and customization level. Larger MOQs often result in lower unit prices due to economies of scale, but they require higher upfront investment. For buyers in regions like Africa, South America, or the Middle East, negotiating flexible MOQs is vital to align with market demand and cash flow. Lower MOQs may increase per-unit costs but offer greater flexibility. Consider consolidating orders or collaborating with local distributors to optimize logistics and cost-efficiency. -

What are typical payment terms, and how can I mitigate financial risks?

Common payment terms include a 30% deposit upfront with the remaining 70% payable before shipment or upon delivery, especially for first-time orders. To mitigate risks, negotiate secure payment methods such as letters of credit (L/C) or escrow services, which protect both parties. Establish clear contractual terms covering penalties for delays or quality issues. For ongoing partnerships, flexible terms like net 60 or early payment discounts can improve cash flow. Always verify the supplier’s financial stability and history of honoring payment commitments before committing. -

What quality assurance measures and certifications should I look for in a supplier?

Ensure the supplier adheres to international quality standards such as ISO 9001 for quality management and possesses relevant certifications like CE, ASTM, or other regional safety standards. Request detailed quality assurance protocols, including inspection reports, testing procedures, and batch sampling. Suppliers should provide Product Specification Sheets (PSS) and Factory Audit Reports. Conduct or commission third-party inspections during production and pre-shipment testing to verify compliance. These steps ensure the shoes meet safety, durability, and performance expectations for your target markets. -

How can I manage international logistics and shipping efficiently?

Collaborate with experienced freight forwarders familiar with your region to streamline customs clearance, tariffs, and import regulations. Opt for Incoterms like FOB or CIF to clearly define responsibilities and costs. Consider consolidating shipments to reduce freight costs and minimize delays. Establish reliable tracking systems and communicate regularly with logistics partners. Be aware of regional import duties, taxes, and documentation requirements specific to Africa, South America, the Middle East, or Australia. Building strong logistics partnerships reduces lead times and ensures timely delivery to your distribution centers. -

What steps should I take in case of disputes or quality issues post-shipment?

Maintain detailed records of all communications, contracts, inspection reports, and shipping documents. If quality issues arise, promptly notify the supplier with clear evidence and request corrective actions or replacements. Refer to your contractual terms regarding dispute resolution—preferably arbitration or mediation—before legal proceedings. Establish a clear warranty policy with the supplier covering defects or non-conformance. Developing a good relationship with the supplier can facilitate amicable resolutions, but always have contingency plans such as alternative suppliers or local repair options. -

How do I ensure compliance with regional regulations and import standards?

Research and understand the import regulations, safety standards, and labeling requirements in your target markets. For example, the European Union mandates CE certification, while Australia requires ACCC approval. Ensure the supplier provides all necessary documentation, including certificates of compliance, test reports, and proper labeling. Working with local customs brokers or regulatory consultants can help navigate complex procedures. Incorporate compliance checks into your quality assurance process and establish ongoing monitoring to adapt to any regulatory updates, reducing the risk of shipment delays or penalties.

Strategic Sourcing Conclusion and Outlook for new balance pickleball shoes

Final Insights and Future Outlook for Strategic Sourcing of New Balance Pickleball Shoes

Effective strategic sourcing is pivotal for international B2B buyers aiming to capitalize on the growing pickleball market with New Balance shoes. Key takeaways include prioritizing suppliers with proven quality standards, leveraging regional manufacturing advantages, and fostering long-term partnerships to ensure supply chain resilience. Understanding regional market dynamics—such as emerging consumer preferences in Africa, South America, the Middle East, and Europe—can unlock competitive advantages and optimize inventory management.

As the pickleball segment expands globally, staying ahead through innovative sourcing strategies will be essential. Embracing digital procurement tools, diversifying supply sources, and aligning with sustainable practices can enhance your market positioning and reduce risks.

Looking forward, proactive engagement with trusted manufacturing partners and continuous market analysis will be crucial for sustained growth. International buyers from diverse regions should view strategic sourcing not just as a cost-saving measure, but as a strategic enabler for market differentiation. Now is the time to strengthen supply chain agility and seize emerging opportunities in the dynamic world of pickleball footwear.