Your Ultimate Guide to Sourcing Open Toe Shoes

Guide to Open Toe Shoes

- Introduction: Navigating the Global Market for open toe shoes

- Understanding open toe shoes Types and Variations

- Key Industrial Applications of open toe shoes

- Strategic Material Selection Guide for open toe shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for open toe shoes

- Comprehensive Cost and Pricing Analysis for open toe shoes Sourcing

- Spotlight on Potential open toe shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for open toe shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the open toe shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of open toe shoes

- Strategic Sourcing Conclusion and Outlook for open toe shoes

Introduction: Navigating the Global Market for open toe shoes

Understanding the global demand for open toe shoes is crucial for B2B buyers seeking competitive advantage in this vibrant market segment. As a footwear category that combines style, comfort, and seasonal versatility, open toe shoes are increasingly favored across diverse markets—from fashion-conscious consumers in Europe to emerging markets in Africa, South America, and the Middle East. Their popularity underscores the importance of sourcing high-quality, innovative products that meet regional preferences, durability standards, and price points.

This comprehensive guide is designed to equip international buyers with critical insights into every aspect of open toe shoe sourcing. It covers key topics such as product varieties, material options, manufacturing processes, quality control measures, reliable supplier identification, cost considerations, and market trends. Additionally, it addresses frequently asked questions to streamline decision-making and mitigate risks associated with cross-border procurement.

For buyers from regions like Poland, Vietnam, or emerging markets in Africa and South America, understanding these elements enables smarter sourcing strategies—whether negotiating with suppliers, evaluating product quality, or assessing market fit. By leveraging this knowledge, you can optimize your supply chain, reduce costs, and introduce innovative, consumer-aligned open toe footwear to your markets. Ultimately, this guide empowers you to make informed, strategic decisions that enhance competitiveness and foster sustainable growth in the global open toe shoe industry.

Understanding open toe shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Open Toe Sandals | Open toe design with minimal straps, often made from leather or synthetic materials | Fashion retail, footwear manufacturing | Pros: Widely accepted style, high demand in warm climates; Cons: Limited seasonal applicability |

| Dress Open Toe Shoes | Elegant, often with embellishments, suitable for formal occasions | High-end fashion, corporate gifting | Pros: High perceived value, premium margins; Cons: Higher material costs, limited casual use |

| Casual Open Toe Shoes | Comfort-focused, with cushioned soles and relaxed designs | Mass-market retail, casual footwear brands | Pros: Broad consumer appeal, versatile; Cons: Lower price points, high competition |

| Sports/Open Toe Sneakers | Sporty designs with breathable mesh and supportive soles | Athletic brands, outdoor retailers | Pros: Growing demand for athleisure; Cons: Technical specifications require precision manufacturing |

| Open Toe Boots | Ankle or knee-high boots with open toe cut-outs | Fashion-forward markets, seasonal collections | Pros: Niche market with premium pricing; Cons: Limited seasonal and geographic suitability |

Classic Open Toe Sandals

This category features minimalistic designs primarily crafted from leather, synthetic, or mixed materials, emphasizing simplicity and comfort. They are highly versatile and suitable for both casual and semi-formal markets, especially in warmer regions. For B2B buyers, sourcing quality materials and ensuring consistent craftsmanship is critical to meet retail standards. Bulk purchasing from reliable suppliers ensures cost efficiency, especially when catering to seasonal demand spikes.

Dress Open Toe Shoes

Designed with elegance, these shoes often incorporate embellishments like rhinestones, satin finishes, or metallic accents. They target the premium segment, making them ideal for formal events, weddings, and corporate gifting. B2B buyers should focus on high-quality materials and craftsmanship, as these influence perceived value and margins. Sourcing from established manufacturers with a track record of luxury footwear production can reduce defect rates and ensure timely delivery.

Casual Open Toe Shoes

Prioritized for comfort and everyday wear, these shoes feature cushioned soles, breathable fabrics, and relaxed designs. They are popular across mass-market retail channels and are suited for diverse climates. For buyers, selecting suppliers with scalable production capabilities and consistent quality control is essential to meet high-volume demands. Price competitiveness and reliable supply chains are key considerations to maximize market penetration.

Sports/Open Toe Sneakers

Combining athletic performance with breathability, these shoes often utilize mesh uppers and supportive soles. They appeal to the growing athleisure market, especially in urban centers and active lifestyles. B2B buyers should prioritize technical specifications, such as durability and comfort, and establish relationships with manufacturers experienced in technical footwear. Volume discounts and customization options can enhance competitiveness.

Open Toe Boots

This niche segment offers fashionable footwear with open toe features, often in ankle or knee-high styles. They cater to fashion-forward consumers and seasonal collections in markets with a strong trend focus. Buyers should evaluate material durability and seasonal demand patterns, especially in European and Middle Eastern markets. Partnering with innovative manufacturers can help differentiate product offerings and command premium pricing.

By understanding these variations, B2B buyers can strategically select suppliers aligned with their target markets, optimize inventory, and maximize profit margins through tailored product offerings.

Key Industrial Applications of open toe shoes

| Industry/Sector | Specific Application of open toe shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Heavy Industry | Protective footwear for site inspections and light tasks | Enhanced safety and comfort for workers, reduced fatigue | Durability, slip resistance, compliance with safety standards, material quality |

| Food Processing & Hospitality | Open toe shoes for kitchen staff and food service workers | Improved hygiene, comfort during long shifts, ease of cleaning | Food-safe materials, slip resistance, hygiene standards compliance |

| Healthcare & Medical | Footwear for medical staff during non-sterile tasks | Comfort for extended wear, quick donning and doffing | Antimicrobial properties, slip resistance, ease of cleaning |

| Retail & Customer Service | Casual footwear for employees in retail environments | Comfort for long hours, approachable appearance | Aesthetic appeal, comfort, lightweight design |

| Light Manufacturing & Warehousing | Indoor footwear for assembly line workers and warehouse staff | Reduced fatigue, safety in indoor environments | Slip resistance, ergonomic design, material durability |

Construction & Heavy Industry

Open toe shoes in construction and light industrial settings serve as protective footwear during site inspections, equipment maintenance, and non-heavy-duty tasks. They offer an ergonomic advantage by providing breathability and comfort, reducing worker fatigue during extended periods of standing or walking. B2B buyers should prioritize sourcing options that meet safety standards such as ASTM or EN certifications, with durable, slip-resistant soles and robust materials to withstand rough conditions. For international buyers from regions like Africa or South America, sourcing locally compliant and durable open toe shoes ensures safety and reduces logistical complexities.

Food Processing & Hospitality

In food processing plants, kitchens, and hospitality environments, open toe shoes are favored for their hygiene benefits and comfort. They allow for better airflow, helping prevent foot sweating and related hygiene issues. These shoes must be made from food-safe, easy-to-clean materials, with slip-resistant soles to prevent accidents in wet or greasy environments. For European or Middle Eastern buyers, sourcing shoes with antimicrobial properties and compliance with food safety standards (such as HACCP) enhances safety and operational efficiency, especially in high-turnover settings.

Healthcare & Medical

Healthcare workers engaged in non-sterile tasks, such as patient transport or administrative duties, benefit from open toe shoes that combine comfort with safety. These shoes facilitate quick removal and donning, essential in fast-paced medical environments. B2B buyers should focus on shoes with antimicrobial coatings, slip-resistant soles, and materials that are easy to disinfect. For buyers in regions like Vietnam or Poland, sourcing options that meet international medical safety standards ensures compliance and supports staff well-being.

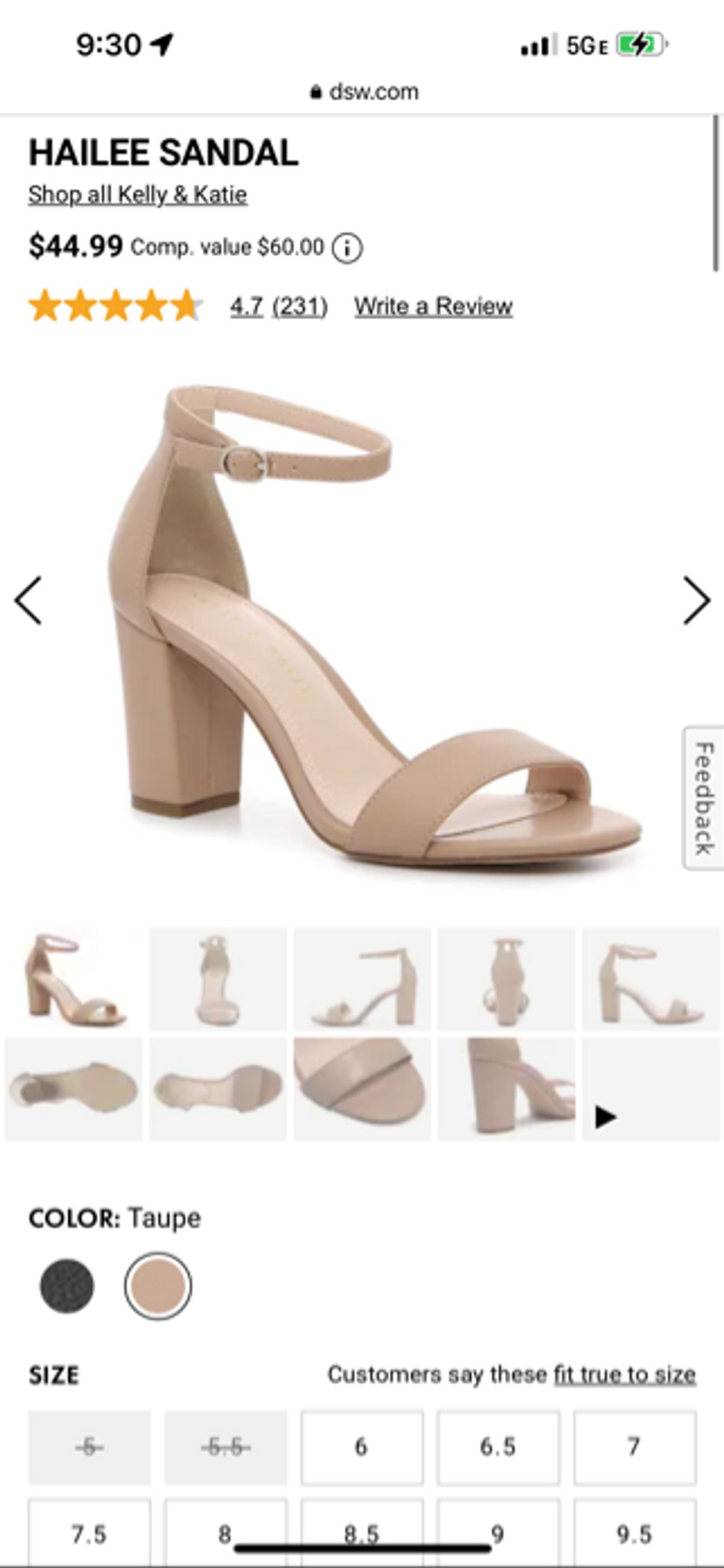

Illustrative Image (Source: Google Search)

Retail & Customer Service

In retail and customer-facing roles, open toe shoes provide a casual, approachable appearance while ensuring comfort during long shifts. They are ideal for indoor environments with smooth flooring, where slip resistance and ergonomic support are critical. Sourcing lightweight, aesthetically appealing open toe shoes that meet safety and comfort standards enables retailers to enhance employee satisfaction. European and Middle Eastern buyers should emphasize style, durability, and ease of maintenance to align with brand image and operational needs.

Light Manufacturing & Warehousing

Indoor manufacturing and warehousing operations often require footwear that balances safety with comfort. Open toe shoes can be suitable for environments with minimal exposure to heavy machinery or hazardous materials, offering breathability and reducing heat buildup. Key sourcing considerations include slip resistance, ergonomic fit, and durable materials capable of withstanding daily wear. For African and South American markets, sourcing locally compliant, cost-effective options that meet international safety standards can streamline procurement and ensure worker safety.

Illustrative Image (Source: Google Search)

Strategic Material Selection Guide for open toe shoes

Material Analysis for Open Toe Shoes

Selecting the appropriate materials for open toe shoes is critical for ensuring product performance, durability, and compliance with international standards. Different markets, such as Africa, South America, the Middle East, and Europe, have unique demands based on climate, regulatory standards, and consumer preferences. Here, we analyze four common materials—leather, synthetic polymers, rubber, and textiles—focusing on their properties, advantages, limitations, and considerations for B2B buyers.

Leather

Key Properties:

Leather is a natural material known for its durability, breathability, and aesthetic appeal. It offers moderate flexibility and excellent aging characteristics. Leather performs well in moderate temperature ranges but can be susceptible to moisture and environmental conditions.

Pros & Cons:

Leather’s primary advantage is its premium look and feel, making it highly desirable in fashion markets across Europe and parts of South America. It is highly durable, resistant to tearing, and ages well with proper care. However, genuine leather can be costly, involves complex manufacturing processes, and requires significant maintenance. It is also sensitive to water and humidity, which can lead to deterioration if not properly treated.

Impact on Application:

Leather’s breathability makes it suitable for warmer climates, but in humid or rainy regions (e.g., parts of Africa or South America), additional waterproofing treatments are necessary. Compliance with standards such as REACH (Europe) and ASTM (North America) regarding chemical treatments is essential for international trade.

International Buyer Considerations:

Buyers from regions with strict environmental regulations (e.g., the EU) should verify leather sourcing and tanning processes to ensure compliance with sustainability standards. Leather suppliers should provide documentation on origin, tanning methods, and chemical use to facilitate customs clearance and consumer trust.

Synthetic Polymers (e.g., Polyurethane, PVC)

Key Properties:

Synthetic materials like polyurethane (PU) and polyvinyl chloride (PVC) are versatile, lightweight, and can mimic leather’s appearance. They are resistant to water, chemicals, and environmental wear, with good flexibility and color retention.

Pros & Cons:

Synthetic polymers are generally more affordable than genuine leather, with easier manufacturing processes. They are highly resistant to moisture and temperature fluctuations, making them suitable for humid or rainy climates. However, they tend to have lower breathability, which can cause discomfort in hot environments. Environmental concerns about plastic waste and chemical emissions during production are notable drawbacks.

Impact on Application:

For markets in Africa and South America with high humidity, synthetic materials offer practical benefits. They also meet many international safety standards, but buyers should ensure suppliers adhere to environmental regulations, especially regarding chemical emissions and recyclability.

International Buyer Considerations:

Buyers should prioritize suppliers with certifications such as OEKO-TEX or REACH compliance to ensure eco-friendly manufacturing. Cost-effectiveness and consistent quality make synthetics attractive, but transparency about chemical content is critical for regulatory approval.

Rubber

Key Properties:

Rubber, especially natural or synthetic variants, offers excellent elasticity, shock absorption, and water resistance. It performs well under pressure and is highly resistant to abrasion.

Pros & Cons:

Rubber’s flexibility and durability make it ideal for outsole components of open toe shoes, especially in casual or outdoor footwear. Natural rubber is biodegradable but can be more expensive and sensitive to temperature extremes. Synthetic rubber (e.g., neoprene) offers better weather resistance but may be less environmentally friendly.

Impact on Application:

In hot climates, rubber maintains its performance but can become sticky or degrade if exposed to prolonged UV radiation. For regions with high moisture or salt exposure (e.g., coastal Middle Eastern areas), synthetic rubber formulations with enhanced corrosion resistance are preferable.

International Buyer Considerations:

Buyers should verify rubber source sustainability, especially for natural rubber, due to environmental concerns. Certification standards like FSC or ISO can help ensure responsible sourcing. Compatibility with regional standards for footwear safety and environmental impact should also be confirmed.

Textiles (e.g., Cotton, Mesh, Synthetic Fabrics)

Key Properties:

Textile materials provide lightweight, flexible, and breathable options. They are often used for linings, straps, or decorative elements in open toe shoes.

Pros & Cons:

Textiles are generally low-cost and easy to manufacture, with high comfort levels. They are suitable for casual and fashion-oriented footwear. However, textiles tend to have lower durability, are susceptible to staining, and may require additional treatments for water resistance.

Impact on Application:

In humid or rainy regions, textile components need waterproofing or quick-drying treatments. Textile suppliers should ensure compliance with standards like OEKO-TEX for chemical safety and durability, especially for markets with strict consumer protection laws.

International Buyer Considerations:

Buyers should assess the sourcing of textiles for environmental sustainability and chemical safety. Preference for natural fibers or recycled fabrics aligns with growing eco-conscious markets, especially in Europe and parts of South America.

Summary Table

| Material | Typical Use Case for open toe shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Premium fashion, formal footwear | Durable, breathable, high aesthetic appeal | Expensive, sensitive to moisture, complex processing | High |

| Synthetic Polymers | Casual, everyday footwear, outdoor use | Water-resistant, cost-effective, versatile | Lower breathability, environmental concerns | Med |

| Rubber | Outsoles, shock absorption, outdoor footwear | Highly durable, flexible, water-resistant | Temperature sensitivity, environmental impact | Med |

| Textiles | Decorative elements, linings, casual footwear | Lightweight, breathable, low cost | Low durability, stain-prone, moisture issues | Low |

This comprehensive analysis enables international B2B buyers to make informed decisions aligned with regional demands, compliance standards, and market preferences, ensuring optimal material selection for open toe shoes across diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for open toe shoes

Manufacturing Processes for Open Toe Shoes

The production of open toe shoes involves a series of meticulously coordinated stages designed to ensure both aesthetic appeal and durability. For international B2B buyers, understanding these stages helps in evaluating supplier capabilities and quality consistency.

Material Preparation

The manufacturing process begins with sourcing and preparing high-quality raw materials. Commonly used materials include genuine or synthetic leather, textiles, and flexible soles such as rubber or thermoplastic elastomers (TPE). Suppliers should conduct thorough inspections of incoming materials, checking for defects, uniformity, and compliance with relevant standards like ISO 9001. For open toe shoes, special attention is paid to the material’s flexibility and edge finishing to ensure a clean, durable open toe design.

Forming and Cutting

The upper components are cut from prepared materials using precise patterning, often with computer-aided design (CAD) and automated cutting machines. This stage ensures minimal waste and high accuracy, which is vital for matching the open toe shape consistently. For leather or synthetic uppers, laser cutting or die-cutting techniques are preferred for their precision and clean edges, reducing post-production finishing.

Assembly and Bonding

The assembly phase involves attaching the upper to the sole. Typically, manufacturers employ a combination of adhesive bonding, stitching, and sometimes heat-pressing, depending on the material and design complexity. For open toe shoes, reinforced stitching around the open edges ensures durability, especially in high-stress areas. Adhesives used should meet industry standards for flexibility and strength, such as water-based or solvent-based polyurethane adhesives, which are tested for environmental compliance.

Illustrative Image (Source: Google Search)

Finishing

The final steps include edge finishing, surface treatments, and quality checks. Edges around the open toe are carefully sealed or reinforced to prevent fraying or tearing. Surface treatments may involve polishing, embossing, or applying protective coatings to enhance appearance and longevity. This stage also includes attaching decorative elements like buckles or straps, if applicable.

Quality Control (QC) Standards and Protocols

Effective QC is critical in ensuring that open toe shoes meet international standards and customer expectations. B2B buyers should scrutinize supplier QC practices, especially when dealing with manufacturers from regions such as Africa, South America, the Middle East, and Europe.

International Standards

- ISO 9001: The cornerstone of quality management, ISO 9001 certification indicates a manufacturer’s commitment to consistent quality, process improvement, and customer satisfaction.

- CE Marking: For European markets, CE certification verifies compliance with health, safety, and environmental protection standards.

- Industry-specific standards: Depending on the target market, additional certifications like ASTM standards for footwear safety or API standards for material safety may be relevant.

Inspection Checkpoints

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival. Tests include visual inspection for defects, dimensional accuracy, and material property testing such as tensile strength and color fastness.

- In-Process Quality Control (IPQC): Conducted during each manufacturing stage, IPQC verifies process adherence and product consistency. For example, checks on stitching tension, adhesive application, and edge finishing.

- Final Quality Control (FQC): Before shipment, finished shoes undergo comprehensive inspection, including visual assessment, measurement verification, and functional testing (e.g., flexibility, bending, and wear tests).

Testing Methods

- Dimensional Accuracy: Using calipers and gauges to ensure consistent sizing.

- Adhesion Tests: Pull tests to verify the bonding strength between upper and sole.

- Flexibility & Durability: Bending and fatigue tests simulate real-world wear.

- Color Fastness & Surface Resistance: Tests for color stability under UV exposure and resistance to scratches or stains.

- Safety & Compliance Testing: Ensuring materials do not contain harmful substances, often verified through third-party labs following standards like OEKO-TEX or REACH.

Verifying Supplier QC for International B2B Buyers

Buyers should adopt rigorous verification methods to ensure suppliers uphold quality standards:

- Factory Audits: Conduct or commission third-party audits focusing on QC processes, equipment calibration, and staff training. Audits should verify compliance with ISO 9001 and relevant certifications.

- Inspection Reports: Request detailed inspection reports, including test results, defect logs, and process documentation. Transparent reporting indicates a mature quality management system.

- Third-party Inspection Services: Engage independent inspection agencies (e.g., SGS, Bureau Veritas) for pre-shipment inspections, especially for bulk orders. These agencies provide unbiased verification of product conformity.

- Sample Testing: Prior to large orders, perform comprehensive testing on samples to verify material quality, construction, and compliance with specifications.

QC & Certification Nuances for Different Regions

For B2B buyers from Africa, South America, the Middle East, and Europe, regional standards and expectations influence QC processes:

- Europe (e.g., Poland): Emphasizes strict compliance with CE marking, chemical safety (REACH), and environmental standards. Suppliers should demonstrate adherence through detailed documentation and third-party certifications.

- Africa & South America: While local standards may be less stringent, buyers should prioritize ISO 9001 certification and independent lab testing to mitigate risks of non-compliance. Import regulations might require specific certifications or test reports.

- Middle East: Focus on compliance with Gulf Cooperation Council (GCC) standards, which include chemical safety and product safety certifications. Suppliers should be familiar with local import regulations and provide necessary documentation.

Practical Tips for B2B Buyers

- Establish Clear Specifications: Define material quality, construction standards, and testing requirements upfront.

- Visit Factories or Use Audits: Whenever feasible, conduct on-site visits or audits to verify manufacturing capabilities and QC practices.

- Request Certification Documentation: Demand copies of ISO 9001 certificates, test reports, and compliance certificates relevant to target markets.

- Sample Testing & Pilot Orders: Use initial small-volume orders for testing and validation before scaling production.

- Build Long-term Relationships: Partner with suppliers committed to continuous improvement and transparent QC reporting.

By understanding the detailed manufacturing processes and implementing rigorous quality assurance measures, B2B buyers can significantly reduce risks, ensure product compliance, and foster successful international partnerships in the open toe shoe market.

Comprehensive Cost and Pricing Analysis for open toe shoes Sourcing

Cost Structure Breakdown for Open Toe Shoes

Understanding the detailed cost components involved in sourcing open toe shoes is essential for effective pricing negotiations and margin management. The primary cost elements include:

-

Materials: The choice of upper materials (leather, synthetic, textiles) significantly influences costs. Leather tends to be more expensive but offers premium appeal, whereas synthetics may reduce costs. Outsoles, linings, and decorative elements also contribute variably.

-

Labor: Manufacturing labor costs vary widely based on country and complexity of design. Countries like Vietnam and Poland typically offer competitive wages, but efficiency and skill levels impact overall costs.

-

Manufacturing Overhead: These include factory expenses, machinery depreciation, and utility costs. Overhead can differ based on factory size, technology adoption, and local economic conditions.

-

Tooling & Setup: Initial mold creation and setup charges are often one-time costs but can influence unit prices, especially for small batches or customized designs.

-

Quality Control & Certifications: Ensuring compliance with standards such as ISO, REACH, or specific regional certifications adds to costs but is crucial for market acceptance, especially in Europe and the Middle East.

-

Logistics & Customs: Shipping costs depend on order volume, destination port, and chosen Incoterms. Additional customs duties, taxes, and import tariffs can significantly alter the total landed cost, particularly for buyers in Africa and South America.

-

Profit Margin: Suppliers typically add a markup ranging from 10% to 30%, depending on order volume, relationship, and market conditions.

Price Influencers and Variability

Several factors directly impact the final unit price of open toe shoes in B2B transactions:

-

Order Volume & MOQ: Larger orders benefit from economies of scale, reducing per-unit costs. Suppliers often offer discounts for high-volume orders or when committing to long-term contracts.

-

Design & Customization: Custom features—such as specific colors, materials, or branding—can increase costs due to additional tooling or longer lead times.

-

Material Choices: Premium materials or sustainable options (e.g., eco-friendly leather) tend to raise the price but can also justify higher retail pricing or meet niche market demands.

-

Quality Certifications: Higher quality standards and certifications (e.g., EU compliance, REACH) may increase initial costs but reduce risks of market barriers or recalls.

-

Supplier Factors: Supplier reputation, production capacity, and proximity to key markets influence pricing. Established manufacturers in Vietnam or Poland may command higher prices but offer better reliability and quality assurance.

-

Incoterms & Logistics: FOB (Free on Board) prices are common, but CIF (Cost, Insurance, Freight) includes shipping costs. Buyers should evaluate total landed costs when comparing suppliers.

Strategic Tips for International Buyers

-

Negotiate Beyond Price: Focus on total cost of ownership, including shipping, customs duties, and potential delays. Negotiating for flexible MOQs or reduced tooling fees can offer significant savings.

-

Leverage Volume & Long-term Commitments: Larger, consistent orders often unlock better pricing, priority production slots, and improved payment terms.

-

Assess Total Landed Cost: Always consider import tariffs, VAT, and certification costs—these can dramatically influence overall expenses, especially for buyers in Africa and South America.

-

Request Transparent Pricing & Samples: Clear quotes including breakdowns help identify cost drivers and potential areas for savings.

-

Understand Market Variances: Prices from suppliers in Vietnam, Poland, or the Middle East can differ due to local wages, material availability, and regional economic factors. Comparing multiple sources ensures competitive pricing.

Indicative Price Range (Disclaimer)

As a guideline, the manufacturing cost for standard open toe shoes typically ranges between $8 to $20 per pair, depending on material quality, complexity, and order volume. Retail-ready prices, including margins and logistics, often fall between $25 to $60 per pair in international markets. However, prices can vary significantly based on customization, certifications, and supplier location.

Note: These figures are indicative and subject to change based on market dynamics, supplier negotiations, and specific project requirements. Always conduct direct supplier inquiries and request detailed quotes for accurate budgeting.

By understanding these cost components and influencing factors, international B2B buyers from Africa, South America, the Middle East, and Europe can optimize their sourcing strategies, negotiate effectively, and ensure competitive pricing aligned with market standards.

Spotlight on Potential open toe shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for open toe shoes.)*

Essential Technical Properties and Trade Terminology for open toe shoes

Key Technical Properties for Open Toe Shoes

1. Material Grade and Composition

The choice of materials significantly impacts durability, comfort, and aesthetic appeal. High-quality leather (full-grain, top-grain) or advanced synthetic composites are preferred for premium open toe shoes. Material grade standards ensure consistency across batches, which is crucial for brand reputation and customer satisfaction. For B2B buyers, specifying the required material grade helps in sourcing products that meet durability and aesthetic expectations.

2. Sole Flexibility and Tread Pattern

The sole’s flexibility influences comfort, especially for prolonged wear. A flexible sole allows natural foot movement, reducing fatigue. The tread pattern, whether smooth or textured, affects slip resistance and grip. Clear specifications enable buyers to select shoes suitable for specific environments, such as non-slip soles for industrial or outdoor use.

3. Tolerance and Dimensional Accuracy

Precise measurements of shoe length, width, and heel height are critical. Tolerance levels (e.g., ±1mm) ensure that shoes fit consistently across production batches. For bulk orders, establishing strict tolerances minimizes returns and exchanges, streamlining logistics and inventory management.

4. Finish and Stitching Quality

The finishing quality, including stitching, edge treatment, and surface smoothness, directly influences product durability and visual appeal. Uniform stitching reduces seam failures, which is essential for high-end markets. B2B buyers should specify standards for finish quality to maintain brand integrity.

5. Ventilation and Comfort Features

Open toe shoes often emphasize breathability. Features such as perforations, mesh inserts, or breathable lining materials enhance comfort, especially in warmer climates. Clarifying these technical features aids in selecting shoes optimized for specific geographic markets.

6. Colorfastness and Material Treatments

For export markets, colorfastness ensures that shoes retain their appearance after cleaning or exposure to elements. Additional treatments, such as water resistance or anti-bacterial coatings, add value depending on end-use. B2B buyers should specify required standards for these properties based on target customer needs.

Industry and Trade Terms for Open Toe Shoes

1. OEM (Original Equipment Manufacturer)

Refers to manufacturers producing shoes under a buyer’s brand name. Understanding OEM capabilities helps buyers assess whether a supplier can produce custom designs, logos, or specific technical features at scale.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier will accept per order. MOQs vary widely based on production complexity and supplier size. Knowing MOQs allows buyers to plan procurement budgets and inventory levels efficiently.

3. RFQ (Request for Quotation)

A formal process where buyers solicit detailed price proposals from multiple suppliers. An RFQ typically includes technical specifications, quality standards, and delivery timelines, enabling accurate comparison and negotiation.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs duties. Common Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, Freight) clarify cost-sharing between buyer and seller, critical for international transactions.

5. Lead Time

The duration from order placement to delivery. Accurate lead time estimates are vital for supply chain planning, especially for seasonal or bulk orders. Clear communication on lead times helps prevent stockouts and production delays.

6. Quality Certification Standards

Standards such as ISO, SGS, or CE mark compliance verify that products meet international safety and quality benchmarks. For buyers from regions with strict import regulations, ensuring suppliers possess relevant certifications reduces compliance risks.

By understanding these technical properties and trade terms, B2B buyers from Africa, South America, the Middle East, and Europe can make informed sourcing decisions, negotiate effectively, and establish reliable supply chains for open toe shoes. Clear specifications and familiarity with industry jargon streamline communication and ensure product quality aligns with market expectations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the open toe shoes Sector

Market Overview & Key Trends

The global open toe shoes market is experiencing dynamic growth driven by evolving consumer preferences, technological advancements, and shifting manufacturing landscapes. Key drivers include increasing demand for stylish, comfortable footwear across all age groups, with particular momentum in emerging markets such as Africa, South America, and parts of the Middle East. These regions are witnessing rising disposable incomes and urbanization, fueling local demand and creating opportunities for international B2B buyers to establish sourcing partnerships.

Emerging sourcing trends emphasize digitalization and supply chain transparency. Platforms that facilitate direct communication between buyers and manufacturers—such as online marketplaces and B2B portals—are streamlining procurement processes. Additionally, the adoption of Industry 4.0 technologies like AI-driven demand forecasting and automated quality control is enhancing efficiency and reducing lead times.

For European buyers, sourcing from countries like Vietnam and Poland offers benefits such as competitive pricing, high-quality craftsmanship, and proximity to key markets. African and South American buyers are increasingly exploring partnerships in Asia and Eastern Europe to diversify supply chains and mitigate geopolitical risks. Overall, market dynamics are shaped by a blend of technological innovation, shifting consumer trends favoring eco-friendly products, and the need for agile, resilient supply chains.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical factor influencing procurement decisions in the open toe shoes sector. Consumers worldwide are increasingly prioritizing eco-friendly and ethically produced footwear, prompting manufacturers to adopt greener practices. For B2B buyers, ensuring supply chain transparency and environmental responsibility is essential to meet brand commitments and consumer expectations.

Implementing sustainable sourcing involves selecting suppliers that adhere to recognized environmental standards, such as ISO 14001 or GOTS certification for organic materials. The use of eco-friendly materials—like recycled plastics, natural rubber, or plant-based dyes—reduces environmental impact and aligns with global sustainability goals. Additionally, fair labor practices and transparent supply chains are vital to avoid reputational risks associated with unethical labor exploitation.

Many manufacturers are now pursuing ‘green’ certifications to demonstrate their commitment to sustainability. These include LEED certification for factories, Fair Trade accreditation, and eco-labels specific to footwear. For B2B buyers, establishing long-term partnerships with certified suppliers not only enhances brand integrity but also ensures compliance with international regulations and consumer demands for responsible sourcing.

Brief Evolution/History

The open toe shoes sector has evolved significantly over the past century, transitioning from basic utilitarian footwear to a fashion-forward, technologically advanced industry. Initially driven by comfort and practicality, the market has shifted towards design innovation, with a focus on aesthetics, comfort, and sustainability. This evolution reflects broader trends in footwear manufacturing, including the adoption of sustainable materials and digital supply chain management.

Historically, manufacturing was concentrated in traditional hubs like Italy and the USA, but recent decades have seen a shift towards Asian countries such as Vietnam and China, offering cost advantages and manufacturing flexibility. For B2B buyers, understanding this evolution helps in assessing supplier reliability, quality standards, and the potential for innovation collaborations. Recognizing the sector’s trajectory towards sustainability and technological integration is crucial for making informed sourcing decisions in today’s competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of open toe shoes

1. How can I effectively vet open toe shoe suppliers to ensure product quality and reliability?

To vet suppliers effectively, start by requesting detailed company credentials, including business licenses and export certifications. Review their product catalogs and ask for samples to assess craftsmanship, materials, and finishing. Check references from other international buyers and seek third-party audit reports if available. Conduct virtual factory visits or video inspections when possible. Verify their compliance with international standards like ISO, REACH, or Fair Trade certifications. A transparent supplier with a proven track record reduces risks and ensures consistent product quality aligned with your specifications.

2. What customization options are typically available for open toe shoes, and how do they impact lead times and costs?

Common customization options include material selection, colorways, branding (logos or tags), sole design, and packaging. Some suppliers also offer design modifications, such as strap styles or embellishments. Customization generally increases lead times by 2-4 weeks and may incur setup or tooling costs, especially for complex designs. To optimize costs and timelines, define your specifications clearly upfront and negotiate minimum order quantities (MOQs) that reflect your customization needs. Working with suppliers experienced in OEM/ODM services can streamline the process and ensure your branding requirements are met efficiently.

3. What are typical minimum order quantities (MOQs), lead times, and payment terms for bulk open toe shoe orders?

MOQs for open toe shoes vary widely, often ranging from 300 to 1,000 pairs depending on the manufacturer and customization level. Lead times generally span 4-8 weeks after order confirmation, influenced by production complexity and supplier capacity. Payment terms are typically 30% upfront deposit with the balance payable before shipment, though some suppliers may offer letters of credit or trade financing options. Negotiating flexible terms, especially for larger orders or long-term partnerships, can improve cash flow and reduce risks. Always clarify these terms before finalizing contracts.

4. How can I ensure that open toe shoes meet international safety and quality standards?

Ensure your supplier provides relevant certifications such as ISO, REACH, or OEKO-TEX, indicating compliance with safety and environmental standards. Request detailed quality assurance (QA) reports and inspection protocols. Consider engaging third-party inspection agencies (e.g., SGS, Bureau Veritas) for pre-shipment audits. Establish clear quality specifications in your purchase agreement, including acceptable defect rates and testing procedures. Regular audits and random sampling during production help maintain standards. Staying informed about regional standards applicable to your target markets (e.g., CE marking for Europe) is crucial for compliance.

5. What are the best logistics strategies for importing open toe shoes to Africa, South America, the Middle East, or Europe?

Partner with experienced freight forwarders familiar with your target regions to optimize shipping routes and costs. Consider sea freight for large volumes due to lower costs, but plan for longer transit times, and air freight for urgent shipments. Use reliable incoterms (e.g., FOB, CIF) to clarify responsibilities and costs. Ensure proper packaging to prevent damage during transit, especially for open toe shoes which may be more vulnerable. Collaborate with customs brokers to navigate import regulations efficiently, and consider warehousing options near your target markets for faster distribution.

6. How should I handle disputes or quality issues with international open toe shoe suppliers?

Establish clear contractual clauses outlining quality standards, inspection rights, and dispute resolution mechanisms, preferably including arbitration clauses in neutral jurisdictions. Maintain detailed documentation, including inspection reports, photos, and correspondence, to support claims. Implement pre-shipment inspections and accept only goods that meet agreed standards before shipment. If issues arise, communicate promptly with suppliers and seek amicable resolutions. If unresolved, escalate through legal channels or arbitration, and consider involving trade associations or industry mediators. Building strong supplier relationships based on transparency and trust can prevent many disputes.

7. What are key factors to consider when choosing suppliers from regions like Vietnam, Poland, or South America?

Region-specific factors include manufacturing expertise, cost competitiveness, and shipping logistics. Vietnam offers competitive prices and a robust footwear industry but may have longer lead times due to distance from Europe and North America. Poland benefits from proximity to European markets, shorter lead times, and adherence to EU standards, but may have higher costs. South American suppliers can offer regional advantages and potentially lower tariffs, but may face infrastructure limitations. Evaluate supplier certifications, capacity for large orders, and experience with international trade. Conduct site visits or virtual audits to understand factory conditions and operational standards in each region.

8. How can I build long-term relationships with open toe shoe suppliers to ensure consistent supply and quality?

Start by establishing clear communication channels and transparent expectations from the outset. Regularly visit or audit suppliers to build trust and verify ongoing compliance. Offer volume commitments or long-term contracts to incentivize dedicated service and better pricing. Provide constructive feedback and collaborate on product development to foster mutual growth. Stay informed about market trends and share your strategic plans, enabling suppliers to adapt proactively. Developing cultural understanding and maintaining professional rapport enhances loyalty and responsiveness, ensuring a stable supply chain for your open toe shoe needs.

Strategic Sourcing Conclusion and Outlook for open toe shoes

Conclusion and Future Outlook

Effective strategic sourcing is essential for international buyers aiming to capitalize on the growing demand for open toe shoes across diverse markets. By prioritizing reliable suppliers, assessing manufacturing capabilities, and considering regional advantages—such as cost efficiency in Vietnam or quality standards in Europe—buyers can optimize their supply chains and reduce risks. Additionally, fostering strong supplier relationships and emphasizing sustainable practices will enhance brand reputation and ensure long-term success.

Looking ahead, the open toe shoe market is poised for continued innovation driven by evolving consumer preferences and technological advancements. Buyers from Africa, South America, the Middle East, and Europe should stay vigilant to emerging trends, such as eco-friendly materials and customization options, to meet diverse customer demands.

Actionable insight: Develop a comprehensive sourcing strategy that emphasizes flexibility, quality assurance, and sustainability. Proactively engage with suppliers across key regions to leverage regional strengths and navigate potential disruptions. By doing so, international B2B buyers can secure a competitive edge and capitalize on the expanding global market for open toe shoes.