Master Global Sourcing with Our Definitive Ronaldo Shoes

Guide to Ronaldo Shoes

- Introduction: Navigating the Global Market for ronaldo shoes

- Understanding ronaldo shoes Types and Variations

- Key Industrial Applications of ronaldo shoes

- Strategic Material Selection Guide for ronaldo shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for ronaldo shoes

- Comprehensive Cost and Pricing Analysis for ronaldo shoes Sourcing

- Spotlight on Potential ronaldo shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for ronaldo shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ronaldo shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of ronaldo shoes

- Strategic Sourcing Conclusion and Outlook for ronaldo shoes

Introduction: Navigating the Global Market for ronaldo shoes

In the highly competitive and dynamic landscape of athletic footwear, Ronaldo shoes have established themselves as a globally recognized brand, combining performance excellence with premium branding. For international B2B buyers—from distributors in Africa and South America to retailers in the Middle East and Europe—sourcing authentic Ronaldo shoes offers a significant opportunity to meet rising consumer demand for quality sportswear and branded footwear. However, navigating this market requires a strategic understanding of product varieties, manufacturing standards, supplier credibility, and market dynamics.

This comprehensive guide equips buyers with critical insights to optimize their sourcing decisions. It covers essential topics including the different types of Ronaldo shoes—ranging from performance models to casual wear—highlighting key material choices and manufacturing practices that influence quality and cost. You will also learn how to evaluate suppliers based on quality control processes, certification standards, and authenticity verification, minimizing risks associated with counterfeit products.

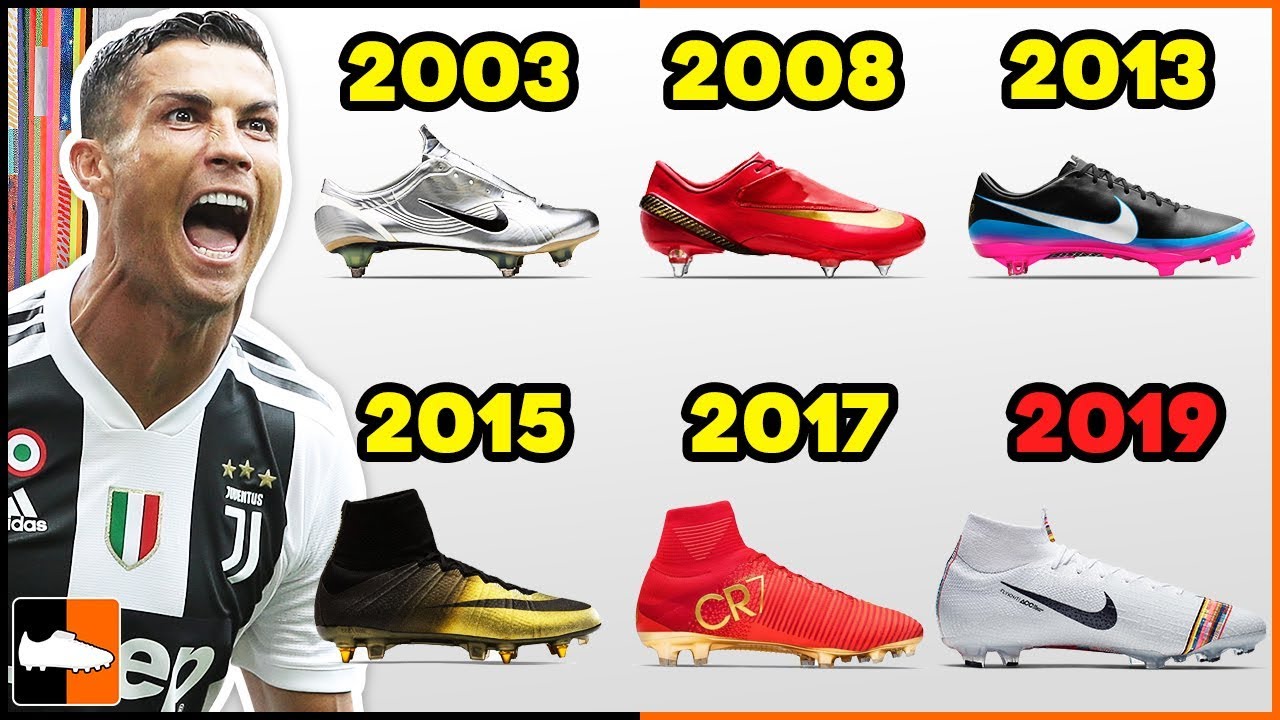

Illustrative Image (Source: Google Search)

Furthermore, the guide provides actionable intelligence on cost structures, import/export considerations, and regional market trends, empowering buyers to negotiate effectively and establish reliable supply chains. Whether you’re seeking bulk orders or establishing long-term partnerships, this resource helps you navigate complexities with confidence. Ultimately, it aims to enable informed, strategic sourcing tailored to your regional market needs, ensuring your business capitalizes on the global demand for Ronaldo shoes with efficiency and security.

Understanding ronaldo shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Ronaldo Model | Traditional design, leather upper, standard sole unit | Retail, wholesale distribution, sports stores | Pros: Widely recognized, consistent quality; Cons: Less innovative, limited customization options |

| Performance Series | Lightweight, enhanced grip, responsive sole technology | Athletic stores, specialty sports outlets | Pros: High-performance appeal, attracts sports-focused clients; Cons: Higher unit cost, niche market focus |

| Customizable Editions | Modular components, customizable colors/materials | Premium sports retailers, corporate gifting | Pros: High brand engagement, tailored solutions; Cons: Longer lead times, higher MOQ requirements |

| Eco-Friendly Variants | Made from sustainable materials, eco-conscious branding | Green retail outlets, eco-focused markets | Pros: Aligns with sustainability trends, differentiates product line; Cons: Potential cost premium, limited availability |

| Limited Edition Collaborations | Special designs, exclusive branding, limited runs | Collector markets, high-end boutiques | Pros: High margin potential, brand prestige; Cons: Scarcity limits volume, higher procurement risk |

Classic Ronaldo Model

This is the foundational version of Ronaldo shoes, characterized by a traditional leather upper and a standard sole unit suitable for everyday wear. It appeals broadly to retail and wholesale channels targeting sports enthusiasts and general consumers. For B2B buyers, these models offer reliable quality and consistent supply, making them ideal for mass distribution. However, their conservative design and limited innovation can be a drawback in highly competitive markets seeking latest trends or performance features.

Performance Series

Designed with athletes in mind, Performance Series Ronaldo shoes feature lightweight construction, advanced grip technology, and responsive soles that enhance on-field performance. These are best suited for specialty sports stores or outlets catering to professional and amateur athletes. B2B buyers should consider the higher unit costs against the potential for premium pricing and higher margins. This series appeals to clients prioritizing performance, making it a strategic choice in markets with active sports communities.

Customizable Editions

Offering modular components and a variety of customizable options, these Ronaldo shoes allow brands to tailor products to specific customer preferences or corporate branding needs. They are ideal for premium sports retailers or companies seeking bespoke promotional items. Buyers should be aware that customization involves longer lead times and often higher minimum order quantities (MOQs). These editions are effective for building brand loyalty and capturing high-value segments but require careful planning and supplier coordination.

Eco-Friendly Variants

Sustainable Ronaldo shoes leverage eco-conscious materials and manufacturing processes, aligning with global trends toward sustainability. They are suitable for eco-focused retail outlets or markets with strong environmental values, such as Europe or progressive Middle Eastern regions. While these variants can command higher prices and differentiate a product line, they may also involve premium costs and limited availability, requiring buyers to assess supply chain capabilities and pricing strategies.

Limited Edition Collaborations

These shoes feature exclusive designs, collaborations with artists or influencers, and limited production runs. They target collector markets, high-end boutiques, and brand enthusiasts. For B2B buyers, such editions often yield higher margins due to their exclusivity and prestige. However, their scarcity limits volume, and procurement involves higher risks related to demand forecasting. They are best used as strategic inventory to elevate brand positioning and attract premium customers.

Key Industrial Applications of ronaldo shoes

| Industry/Sector | Specific Application of ronaldo shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Downhole drilling equipment components | Enhanced durability and high-pressure resistance, reducing downtime | Material compatibility with corrosive media, API or ISO certification |

| Mining | Conveyor belt systems and heavy-duty machinery parts | Superior wear resistance, minimizing maintenance costs | Reliability under extreme conditions, certification for rugged environments |

| Construction & Infrastructure | Heavy machinery footwear and safety boots | Improved safety, comfort, and longevity in demanding environments | Certification standards (e.g., CE, ANSI), compliance with safety regulations |

| Manufacturing & Automation | Industrial automation parts and robotics components | Precise fit and high durability, ensuring operational efficiency | Customization options, quality assurance, and supply chain stability |

| Transportation & Logistics | Heavy-duty vehicle parts, including suspension components | Increased load capacity, reduced wear and tear, longer service life | Compatibility with regional standards, lead times, and bulk sourcing options |

Oil & Gas

In the oil and gas sector, ronaldo shoes are integrated into downhole drilling equipment, such as drill collars and stabilizers. These components require materials that withstand extreme pressures, high temperatures, and corrosive substances. B2B buyers from Africa, South America, the Middle East, and regions like Australia seek suppliers offering products with proven API or ISO certifications to ensure safety and reliability. Sourcing high-quality ronaldo shoes reduces equipment failure risks, minimizes costly downtime, and extends operational lifespan, making them a critical choice for maintaining continuous exploration and extraction activities.

Mining

Mining operations demand machinery and conveyor systems capable of enduring harsh environments, heavy loads, and abrasive materials. Ronaldo shoes are used in conveyor belt rollers, gearboxes, and heavy-duty machinery parts to provide exceptional wear resistance and mechanical strength. For international buyers, especially those operating in remote or rugged locations, sourcing ronaldo shoes that meet strict durability standards ensures lower maintenance costs and higher operational uptime. Suppliers must focus on material toughness, certification for extreme conditions, and consistent supply chains to meet the demanding needs of global mining projects.

Construction & Infrastructure

Construction sites and infrastructure projects rely heavily on heavy machinery, including excavators, cranes, and safety footwear for personnel. Ronaldo shoes are incorporated into safety boots and machinery components where durability, safety, and comfort are paramount. Buyers from Europe, Asia (like Thailand), and the Middle East prioritize products that comply with regional safety standards such as CE or ANSI. Sourcing high-quality ronaldo shoes ensures extended equipment life, reduces replacement frequency, and enhances worker safety, which is vital for large-scale, long-term projects.

Manufacturing & Automation

In manufacturing and automation, ronaldo shoes are used in robotic joints, precision machinery, and automation components that require high durability and exact fit. These applications benefit from the shoes’ resilience to wear and their ability to maintain performance over time. For B2B buyers across continents, especially in regions with high production volumes, sourcing reliable ronaldo shoes supports operational efficiency, reduces downtime, and ensures product quality. Customization options, consistent quality assurance, and timely delivery are essential considerations in this sector.

Illustrative Image (Source: Google Search)

Transportation & Logistics

Heavy-duty vehicle parts, such as suspension components and chassis fittings, incorporate ronaldo shoes to enhance load-bearing capacity and reduce wear. This application is particularly relevant for logistics companies and transportation fleets operating in diverse environments, including remote regions of Africa, South America, or Australia. Sourcing high-quality ronaldo shoes ensures longer service intervals, reduced maintenance costs, and improved vehicle safety. Buyers should prioritize suppliers offering regional compliance, scalable supply options, and consistent product quality to support large fleet operations efficiently.

Strategic Material Selection Guide for ronaldo shoes

Material Analysis for Ronaldo Shoes

When selecting materials for Ronaldo shoes, B2B buyers must consider a balance of performance, durability, cost, and compliance with international standards. The choice of material directly influences product quality, manufacturing complexity, and market acceptance across diverse regions such as Africa, South America, the Middle East, and Europe. Below is an in-depth analysis of four common materials used in Ronaldo shoes, emphasizing their key properties, advantages, limitations, and considerations for international procurement.

Leather (Full-Grain and Synthetic Variants)

Key Properties:

Leather, especially full-grain, offers excellent breathability, flexibility, and aesthetic appeal. Synthetic leather provides similar visual qualities but with enhanced consistency and lower manufacturing costs. Both types are generally durable and conform well to foot shape over time.

Pros & Cons:

– Pros: High durability, premium feel, good moisture management, and aesthetic versatility. Synthetic options are cost-effective and easier to produce at scale.

– Cons: Full-grain leather can be expensive and requires significant care. Synthetic leather may lack breathability and can degrade faster under harsh conditions.

Impact on Application:

Leather’s breathability makes it suitable for sports and casual footwear, especially in moderate climates. Synthetic variants are more resistant to environmental factors like moisture and temperature extremes, making them versatile for regions with diverse climates.

International Buyer Considerations:

Leather products must meet regional standards such as the EU’s REACH regulations or ASTM safety standards. Buyers from Africa and South America should verify supplier certifications for sustainable sourcing, while Middle Eastern markets may prioritize heat resistance. European markets often favor eco-friendly and ethically sourced leather, influencing procurement decisions.

Thermoplastic Polyurethane (TPU)

Key Properties:

TPU is a versatile polymer known for excellent abrasion resistance, flexibility, and elasticity. It withstands a wide temperature range (-40°C to +80°C), making it suitable for various environmental conditions.

Pros & Cons:

– Pros: High durability, resistance to oil, grease, and abrasion, lightweight, and relatively cost-effective.

– Cons: Manufacturing complexity can increase costs, especially for specialized formulations. It may not provide the same premium feel as leather.

Impact on Application:

TPU is ideal for outsole components, overlays, and reinforcements. Its resistance to environmental factors makes it suitable for regions with high humidity or temperature fluctuations, such as tropical Africa or Middle Eastern climates.

International Buyer Considerations:

TPU complies with many international standards, but buyers should confirm chemical safety certifications (e.g., REACH, RoHS). Cost considerations are crucial for buyers in developing markets; sourcing from regions with established TPU manufacturing can reduce expenses.

EVA (Ethylene-Vinyl Acetate)

Key Properties:

EVA is a lightweight, flexible foam material widely used in midsoles for shock absorption. It offers good cushioning and is resistant to cracking and UV degradation.

Pros & Cons:

– Pros: Low cost, excellent cushioning, lightweight, easy to mold, and environmentally friendly options are available.

– Cons: Less durable under heavy use; prone to compression set over time, reducing shock absorption capacity.

Impact on Application:

EVA is primarily used in midsoles, making it critical for comfort-focused shoes. Its properties are advantageous in markets where comfort is a priority, such as Europe or Australia.

International Buyer Considerations:

EVA’s compliance with safety standards like ASTM or EN is generally straightforward. Cost-sensitive markets may favor EVA for its affordability, but buyers should evaluate the trade-off between cost and longevity, especially in high-wear applications.

Polyurethane (PU)

Key Properties:

PU is a versatile polymer used in midsoles and outsoles, known for its high resilience, flexibility, and abrasion resistance. It can be formulated for varying hardness levels.

Pros & Cons:

– Pros: Durable, provides excellent support, and can be customized for different performance needs.

– Cons: Heavier than EVA, potentially more expensive, and manufacturing complexity can increase costs.

Impact on Application:

PU’s strength makes it suitable for high-performance sports shoes, especially in regions where durability is a priority. It performs well in diverse climates but may require additional considerations for weight-sensitive applications.

International Buyer Considerations:

PU materials must meet regional safety and environmental standards. Buyers should verify supplier compliance with standards like ISO or ASTM. The higher cost may be justified by the longer lifespan and performance benefits, especially in premium markets.

Summary Table

| Material | Typical Use Case for Ronaldo Shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather (Full-Grain/Synthetic) | Upper material, premium footwear | Aesthetic appeal, breathability, durability | Costly (full-grain), variable environmental impact | Med |

| Thermoplastic Polyurethane (TPU) | Outsole overlays, reinforcements | Abrasion resistance, flexibility, lightweight | Manufacturing complexity, moderate cost | Med |

| EVA | Midsoles, cushioning layers | Cost-effective, lightweight, shock absorption | Less durable under heavy use | Low |

| Polyurethane (PU) | Midsoles, outsoles, support structures | High resilience, support, durability | Heavier, more expensive | Med-High |

This comprehensive analysis enables international B2B buyers to make informed decisions tailored to regional demands, manufacturing capabilities, and market preferences. Selecting the right materials ensures product excellence, compliance, and competitive advantage across diverse global markets.

In-depth Look: Manufacturing Processes and Quality Assurance for ronaldo shoes

Manufacturing Processes of Ronaldo Shoes

The manufacturing of Ronaldo shoes involves a series of meticulously controlled stages, each critical to ensuring product quality, durability, and compliance with international standards. For B2B buyers, understanding these stages can facilitate better supplier evaluation and quality assurance integration.

1. Material Preparation and Procurement

The process begins with sourcing high-grade raw materials, including leather, synthetic fibers, rubber, and textiles. Reputable manufacturers often collaborate with certified suppliers to ensure materials meet international standards such as ISO 9001 and industry-specific certifications (e.g., REACH compliance for chemical safety). Buyers should request detailed material certificates and conduct supplier audits to verify quality sources.

2. Forming and Component Manufacturing

This stage involves cutting, molding, and shaping various components such as uppers, insoles, midsoles, and outsoles. Techniques like CNC cutting, injection molding, and heat pressing are common. Advanced manufacturers utilize CAD/CAM technology for precision and consistency, reducing waste and ensuring uniformity across batches.

3. Assembly and Stitching

Components are assembled through stitching, bonding, or adhesive processes. Automated sewing machines ensure tight, uniform stitches, while bonding techniques may involve heat or solvent-based adhesives for seamless joints. For high-end Ronaldo shoes, attention to detail during assembly significantly impacts comfort and longevity.

4. Finishing and Quality Controls

Final steps include polishing, dyeing, and applying protective coatings. This stage also involves quality checks such as surface inspection, color consistency, and functional testing (e.g., flexibility, water resistance). Manufacturers often employ automated inspection systems combined with manual review to detect defects.

Quality Assurance Protocols and Standards

Robust quality assurance (QA) processes are essential for B2B buyers to ensure the shoes meet their specific market requirements and safety standards.

1. International Standards Compliance

Most reputable Ronaldo shoe manufacturers operate under ISO 9001 certification, emphasizing a quality management system focused on continuous improvement and customer satisfaction. Depending on the target market, additional certifications may include CE marking (Europe), ASTM standards (North America), or specific industry certifications like API for safety-critical components.

2. Industry-Specific Certifications and Testing

– CE Marking: Ensures compliance with European safety, health, and environmental requirements.

– ASTM & ISO Testing: Includes flex testing, abrasion resistance, slip resistance, and toxicology assessments.

– Chemical Testing: Ensures dyes, adhesives, and components do not contain harmful substances, complying with regulations like REACH or OEKO-TEX standards.

3. QC Checkpoints and Inspection Types

– Incoming Quality Control (IQC): Verifies raw materials and components upon receipt, checking for defects, correct specifications, and certifications.

– In-Process Quality Control (IPQC): Monitors each manufacturing stage, ensuring adherence to process parameters, stitch counts, and dimensional tolerances.

– Final Quality Control (FQC): Conducted before shipment, including visual inspection, functional testing (flexibility, water resistance), and packaging verification.

4. Testing Methods

– Physical Tests: Tensile strength, tear resistance, and abrasion resistance tests for materials.

– Functional Tests: Flexibility, shock absorption, and slip resistance.

– Environmental Tests: UV exposure, temperature cycling, and water ingress testing to simulate real-world conditions.

Verification and Due Diligence for International B2B Buyers

B2B buyers from Africa, South America, the Middle East, and Europe should adopt rigorous supplier verification processes to mitigate risks and ensure product quality.

1. Supplier Audits and Factory Visits

On-site audits are the gold standard for assessing manufacturing capabilities, quality systems, and compliance. Buyers should verify ISO certifications, review quality control procedures, and inspect production facilities for cleanliness, safety, and equipment condition.

2. Request for Quality Documentation

Suppliers should provide detailed reports, test certificates, and inspection records. For critical markets, third-party inspection reports from agencies like SGS, Bureau Veritas, or TUV add credibility and transparency.

3. Third-Party Inspection and Certification

Engaging independent inspectors during production or pre-shipment phases ensures unbiased quality verification. These inspections can include sampling, testing, and compliance verification against specified standards.

4. Sample Evaluation and Pilot Orders

Before large-scale procurement, buyers should request samples for functional testing and aesthetic evaluation. This step helps verify that the manufacturing process consistently produces shoes aligned with contractual specifications.

Nuances and Considerations for International B2B Engagements

1. Variability in Quality Management Maturity

Manufacturers in different regions may have varying levels of quality management maturity. European and Australian suppliers often adhere to stricter standards, whereas some suppliers in Africa, South America, or the Middle East may require additional oversight or third-party verification.

2. Certification Recognition and Equivalence

Buyers should understand regional certification equivalence—e.g., CE vs. local safety marks—and verify that certifications are current and valid. This is especially relevant when importing into markets with strict regulatory regimes.

3. Customs and Compliance Documentation

Ensure suppliers provide complete documentation, including Declaration of Conformity, Material Safety Data Sheets (MSDS), and test reports, to facilitate smooth customs clearance and compliance verification.

4. Post-Sale Quality Monitoring

Establish processes for ongoing quality monitoring, such as periodic audits, sample testing of received batches, and supplier performance reviews. This proactive approach helps maintain consistent quality standards over time.

Summary for B2B Buyers

A comprehensive understanding of Ronaldo shoe manufacturing and quality assurance processes enables buyers to make informed sourcing decisions. Prioritizing certified, transparent, and well-documented suppliers, coupled with rigorous audits and testing, ensures product integrity across diverse international markets. Tailoring verification strategies to regional standards and market-specific regulations will enhance supply chain resilience and customer satisfaction in your target markets.

Comprehensive Cost and Pricing Analysis for ronaldo shoes Sourcing

Cost Structure Breakdown for Ronaldo Shoes

Understanding the comprehensive cost structure is crucial for international buyers aiming to optimize sourcing strategies for Ronaldo shoes. The primary components include:

-

Materials: The choice of upper fabrics (synthetic, leather, mesh), midsole foam, outsole rubber, and decorative elements significantly influence costs. Premium materials with enhanced durability or branding features naturally command higher prices.

-

Labor: Manufacturing labor costs vary widely depending on the sourcing country. Countries like China, Vietnam, and India offer competitive wages with established footwear manufacturing ecosystems, whereas suppliers from Turkey or Eastern Europe may have higher labor rates but offer different quality standards.

-

Manufacturing Overheads: These encompass factory utilities, equipment depreciation, and workforce management. Factories with advanced automation or sustainable practices might incur higher upfront costs but can offer efficiencies over time.

-

Tooling & Setup Fees: Initial mold creation for molds, dies, and patterns can be substantial, especially for customized designs or limited editions. These are typically amortized over large production runs to reduce per-unit costs.

-

Quality Control & Certifications: Implementing rigorous QC processes and obtaining certifications (ISO, environmental standards, safety compliance) add to costs but are vital for meeting international standards, especially for European and Middle Eastern markets.

-

Logistics & Shipping: Freight costs depend on shipment volume, mode (air vs. sea), and destination. For Africa and South America, sea freight remains economical but slower, whereas air freight is faster but costlier. Incoterms (FOB, CIF, DDP) significantly impact the buyer’s responsibilities and costs.

-

Margins: Suppliers typically build margins into their pricing, influenced by order volume, payment terms, and relationship strength. Larger orders usually attract better pricing, but buyers should negotiate for favorable terms to maximize cost-efficiency.

Key Price Influencers

Several factors influence the final price of Ronaldo shoes, which buyers must consider:

-

Order Volume & MOQ: Higher volumes usually secure better unit prices due to economies of scale. Many suppliers offer tiered pricing, with discounts for bulk orders exceeding 10,000 pairs.

-

Product Specifications & Customization: Special features such as bespoke designs, unique colorways, or advanced cushioning increase costs. Customization often entails additional tooling and setup fees.

-

Material Choices: Opting for synthetic materials reduces costs compared to genuine leather but might affect perceived quality. Conversely, premium materials demand higher prices but appeal to high-end markets.

-

Quality & Certification Standards: Meeting international standards (e.g., CE, ISO, environmental standards) may necessitate additional testing and documentation, impacting overall costs.

-

Supplier & Country Factors: Established suppliers with a reputation for quality may command premium prices. Additionally, sourcing from countries with higher labor or compliance costs will naturally influence pricing.

-

Incoterms & Logistics Terms: FOB (Free on Board) prices exclude shipping, while CIF (Cost, Insurance, Freight) and DDP (Delivered Duty Paid) include logistics and customs clearance, affecting the buyer’s total landed cost.

Strategic Tips for International B2B Buyers

-

Negotiate for Volume Discounts: Engage suppliers early to lock in favorable prices, especially for large or recurring orders. Consider consolidating shipments to reduce freight costs.

-

Focus on Total Cost of Ownership: Beyond unit price, evaluate logistics, customs duties, tariffs, and potential rework or warranty costs. A lower initial quote might not be cost-effective if logistics are complex or delays are frequent.

-

Understand Pricing Nuances: Pricing can vary based on order size, customization, and supplier location. Be aware of hidden costs such as tooling fees, certifications, or special packaging.

-

Leverage Supplier Relationships: Building trust can lead to better payment terms, priority in production, and price concessions. Long-term partnerships often yield the most cost-efficient results.

-

Evaluate Logistics & Incoterms Carefully: For buyers in Africa, South America, or remote markets like Australia, selecting appropriate Incoterms can significantly influence landed costs and delivery timelines.

Disclaimer

Indicative prices for Ronaldo shoes range approximately from $15 to $50 per pair at the factory gate for standard models, depending on volume, quality, and customization. Premium or highly customized products may cost more. Always obtain detailed quotes from multiple suppliers and consider all related costs to accurately assess the total investment.

By understanding these components and strategies, international buyers from diverse regions can optimize their sourcing processes, negotiate better terms, and ensure cost-effective procurement of Ronaldo shoes tailored to their market needs.

Illustrative Image (Source: Google Search)

Spotlight on Potential ronaldo shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for ronaldo shoes.)*

Essential Technical Properties and Trade Terminology for ronaldo shoes

Critical Technical Properties of Ronaldo Shoes

Understanding the technical specifications of Ronaldo shoes is essential for international B2B buyers aiming to ensure product quality, compatibility, and market competitiveness. Here are the key properties to consider:

1. Material Grade and Composition

The primary materials—such as synthetic leather, mesh fabrics, rubber soles, and foam insoles—must meet industry standards for durability, comfort, and performance. Higher-grade materials typically offer better wear resistance and customer satisfaction. Buyers should specify the required material grades (e.g., ASTM or ISO standards) to ensure consistency across batches and to match regional preferences.

2. Manufacturing Tolerance

Tolerance levels define the permissible deviation in dimensions, weight, and construction of the shoes. Tight tolerances (e.g., ±0.5 mm in sole thickness) are critical for consistent fit and function, especially for high-performance models. Precise tolerances reduce return rates and warranty claims, safeguarding brand reputation in diverse markets.

3. Sole Flexibility and Traction

Technical properties related to outsole design—such as flexibility, grip, and slip resistance—are vital for athletic shoes. Buyers should specify the rubber compound and tread pattern to match the intended use (e.g., indoor vs. outdoor sports). Proper outsole engineering enhances safety and performance, key selling points across markets.

4. Weight and Breathability

Lightweight construction improves athletic performance and comfort. Material choices like mesh panels or lightweight foam influence overall shoe weight. Breathability features, such as ventilation holes or moisture-wicking linings, are increasingly demanded in warmer regions, impacting comfort and customer satisfaction.

5. Color Fastness and Finish

Durability of the shoe’s appearance depends on color fastness to wear, washing, and UV exposure. Technical specifications should include standards (e.g., ISO 105) to ensure color stability. A high-quality finish also reduces defects and enhances the product’s premium look, crucial for export markets.

Essential Trade Terms for Ronaldo Shoes

Familiarity with industry jargon and trade terms enables smoother negotiations and clearer communication across borders. Here are key terms every B2B buyer should know:

1. OEM (Original Equipment Manufacturer)

Refers to factories producing shoes under another company’s brand name. Understanding OEM arrangements helps buyers gauge production flexibility, customization options, and intellectual property considerations. It’s common for brands to partner with OEMs for cost-effective manufacturing.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce or sell per order. MOQs vary widely and impact inventory planning and pricing. Buyers should negotiate MOQs that align with their market size and storage capabilities, especially for new or niche markets.

3. RFQ (Request for Quotation)

A formal document issued by buyers to solicit price and lead-time quotes from suppliers. An RFQ clarifies product specifications, quality standards, and delivery timelines, enabling accurate comparison and selection of suppliers.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining the responsibilities of buyers and sellers regarding shipping, insurance, and customs clearance. Common Incoterms include FOB (Free on Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid). Selecting the appropriate Incoterm affects overall costs and logistical planning, especially for international shipments.

5. Lead Time

The duration from order placement to product delivery. Longer lead times may affect inventory management, especially in markets with seasonal fluctuations. Buyers should confirm lead times during negotiations and consider supplier reliability.

6. Quality Inspection Standards

Agreements on quality control processes—such as ISO 9001 certification or third-party audits—are crucial for ensuring product consistency. Clear standards help mitigate risks of defects, delays, and non-compliance with regional regulations.

In summary, mastering these technical properties and trade terms enhances your ability to evaluate Ronaldo shoe suppliers effectively, negotiate favorable terms, and ensure that products meet the specific needs of diverse markets across Africa, South America, the Middle East, and Europe. This knowledge is fundamental for building reliable supply chains and achieving long-term success in the global footwear industry.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ronaldo shoes Sector

Market Overview & Key Trends

The global Ronaldo shoes market is influenced by several macroeconomic and technological factors that shape sourcing strategies for international B2B buyers. Emerging markets in Africa, South America, the Middle East, and regions like Southeast Asia (notably Thailand) and Oceania (such as Australia) are increasingly pivotal due to their expanding consumer bases and manufacturing capabilities.

Key drivers include rising demand for athletic and casual footwear driven by urbanization, lifestyle shifts, and the popularity of sports icons like Ronaldo himself. B2B buyers are leveraging digital platforms and e-commerce technologies to streamline sourcing, reduce lead times, and enhance transparency. Innovations such as blockchain for supply chain traceability, AI-driven demand forecasting, and virtual sampling are transforming traditional sourcing paradigms.

Market dynamics are also shaped by fluctuating raw material costs, geopolitical considerations, and trade policies. Countries with favorable trade agreements or lower tariffs—such as Mexico, Vietnam, and certain African nations—offer attractive sourcing options. Meanwhile, regional preferences influence design customization and branding strategies; for example, European markets often favor premium, sustainable products, whereas emerging markets prioritize affordability and durability.

For B2B buyers, understanding these trends facilitates strategic sourcing decisions, risk mitigation, and market entry planning. Embracing digital procurement tools, fostering supplier relationships in emerging markets, and monitoring geopolitical shifts are crucial to maintaining competitiveness and ensuring supply chain resilience.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a central concern in the Ronaldo shoes sector, driven by both consumer demand and regulatory pressures. B2B buyers are increasingly prioritizing suppliers that demonstrate robust environmental and social responsibility credentials. This shift impacts sourcing strategies, encouraging partnerships with manufacturers committed to reducing carbon footprints, minimizing waste, and employing eco-friendly materials.

Environmental impact considerations include the use of recycled or biodegradable materials, water-efficient manufacturing processes, and renewable energy adoption. Certifications such as Global Organic Textile Standard (GOTS), Leather Working Group (LWG), and Forest Stewardship Council (FSC) are valuable indicators of compliance with environmental standards.

Ethical sourcing encompasses fair labor practices, transparent supply chains, and humane working conditions. Buyers should conduct rigorous supplier audits and seek partners with credible social compliance certifications like SA8000 or BSCI. Traceability technologies, such as blockchain, enable end-to-end visibility, ensuring raw materials are ethically sourced and production processes adhere to international standards.

Investing in sustainability not only mitigates risks but also enhances brand reputation and market differentiation. For Ronaldo shoes, integrating ‘green’ materials and ethical practices can unlock new market segments, particularly in Europe and Australia, where consumers are highly conscious of sustainability issues. Establishing long-term, transparent supplier relationships aligned with environmental and social standards is essential for sustainable growth in this competitive sector.

Brief Evolution/History (Optional)

The Ronaldo shoes sector has evolved from simple, mass-produced athletic footwear to a sophisticated industry emphasizing innovation, branding, and sustainability. Initially characterized by basic designs and low-cost manufacturing, the market has shifted towards premium, technologically advanced products that leverage Ronaldo’s global brand influence.

This evolution has been driven by technological advancements in materials science, manufacturing automation, and digital marketing. As consumer expectations have grown, so has the emphasis on ethical sourcing and environmental responsibility, prompting brands to adopt greener practices and transparent supply chains. For B2B buyers, understanding this trajectory helps anticipate future market shifts, such as increased demand for sustainable materials and digital traceability solutions, ensuring they remain competitive and aligned with industry best practices.

Frequently Asked Questions (FAQs) for B2B Buyers of ronaldo shoes

1. How can I verify the credibility and reliability of Ronaldo shoe suppliers internationally?

To ensure supplier credibility, conduct thorough due diligence by reviewing company credentials, certifications, and client references. Request and verify trade licenses, manufacturing permits, and quality management certifications like ISO or CE. Consider visiting the supplier’s facility if feasible or engaging third-party inspection services. Additionally, check online trade platforms (e.g., Alibaba, Global Sources) for verified supplier badges and reviews. Establish clear communication channels to assess responsiveness and transparency. Working with reputable trading agents or sourcing consultants familiar with the footwear industry in your region can also mitigate risks.

2. What are the options for customizing Ronaldo shoes for my market, and how does this impact lead times?

Many Ronaldo shoe suppliers offer customization options such as branding, colorways, packaging, and even design modifications. Customization typically requires additional lead time—usually between 2 to 8 weeks—depending on complexity and order volume. Early planning and clear specifications are crucial to avoid delays. Ensure your supplier provides detailed timelines and prototypes for approval before mass production. For faster turnaround, opt for standard designs or minimal customization, but if branding or specific features are essential, factor in extended lead times into your procurement schedule.

3. What is the typical minimum order quantity (MOQ), and how do payment terms vary for international B2B transactions?

MOQs for Ronaldo shoes vary widely, often ranging from 200 to 1,000 pairs, depending on the manufacturer and customization level. Negotiating flexible MOQs is possible, especially for long-term partnerships or larger orders. Payment terms commonly include 30% deposit upfront with the balance payable before shipment, or letter of credit (L/C) arrangements for added security. Some suppliers may offer net terms for established buyers. Always clarify payment methods, currency options, and potential discounts for bulk orders to optimize cash flow and reduce financial risks.

4. What quality assurance processes and certifications should I look for when sourcing Ronaldo shoes?

Reliable suppliers should adhere to strict QA processes, including raw material inspection, in-process checks, and final quality control before shipment. Look for certifications such as ISO 9001, CE marking, or other industry-specific standards that demonstrate compliance with safety and quality regulations. Request detailed QA reports, sample testing results, and compliance certificates. Additionally, consider third-party inspections or lab testing for durability, comfort, and safety standards, especially if exporting to markets with strict import regulations like Europe or Australia.

5. How can I manage logistics effectively when importing Ronaldo shoes to my country?

Effective logistics management involves selecting reliable freight forwarders experienced in footwear shipments and understanding incoterms (e.g., FOB, CIF). Factor in transit times, customs clearance procedures, and import duties specific to your country. Collaborate with suppliers to arrange shipping schedules aligned with your sales cycle. Consider using bonded warehouses or local distribution centers to expedite delivery. Regular communication with logistics providers and customs brokers can prevent delays. Additionally, plan for contingencies such as delays or damage, and ensure proper insurance coverage for international shipments.

6. What are common dispute resolution methods with international Ronaldo shoe suppliers, and how can I protect my interests?

Disputes may arise over quality, delivery delays, or payment issues. To mitigate risks, include clear terms in your contracts specifying dispute resolution methods—preferably arbitration in a neutral jurisdiction or via international trade organizations like ICC. Maintain detailed documentation of all communications, agreements, and shipment records. Using escrow payment services or letters of credit can also safeguard payments. Building strong relationships and transparent communication can prevent misunderstandings. If disputes occur, seek resolution through negotiation first, then escalate to arbitration or legal channels if necessary.

7. How do I stay updated on market trends and pricing fluctuations for Ronaldo shoes in different regions?

Regularly monitor industry reports, trade publications, and online marketplaces to track pricing trends and consumer preferences. Engage with local distributors and attend trade shows or footwear expos in your target regions (Africa, South America, Middle East, Europe). Joining industry associations or B2B networks can provide insights into regional demand shifts. Establish long-term relationships with multiple suppliers to negotiate better prices and stay informed about production costs. Also, leverage data analytics and market intelligence platforms to anticipate price fluctuations and adjust your procurement strategies proactively.

8. What are key legal considerations when importing Ronaldo shoes into different countries?

Understand import regulations, tariffs, and standards applicable in your country—such as safety standards, labeling requirements, and intellectual property rights. Ensure that the supplier provides all necessary export documentation, including invoices, certificates of origin, and compliance certificates. Engage local customs brokers to navigate complex procedures and avoid delays or penalties. Protect your brand by verifying that the supplier holds proper rights to the designs and trademarks used. Draft comprehensive purchase agreements that specify quality standards, delivery schedules, and dispute resolution mechanisms to safeguard your investments in international trade.

Strategic Sourcing Conclusion and Outlook for ronaldo shoes

Final Thoughts and Future Outlook

Effective strategic sourcing is essential for international buyers seeking to capitalize on the growing market for Ronaldo shoes. Prioritizing reliable suppliers, quality assurance, and cost optimization can significantly enhance competitiveness across diverse regions such as Africa, South America, the Middle East, and Europe. By establishing strong supplier relationships and leveraging global supply chain networks, buyers can mitigate risks and respond swiftly to market demands.

Looking ahead, the Ronaldo shoes market is poised for continued growth driven by evolving consumer preferences and brand expansion. B2B buyers should stay vigilant to emerging trends, technological innovations, and sustainable sourcing practices that can create a competitive edge. Developing a flexible, transparent supply chain will be key to navigating the complexities of international trade.

Actionable Takeaway: Proactively engage with diverse suppliers, invest in quality control, and explore regional sourcing opportunities to optimize costs and ensure product authenticity. Embracing a strategic sourcing mindset today will position your business to capitalize on future market opportunities and foster long-term growth in the Ronaldo shoes industry.