Your Ultimate Guide to Sourcing Shoe Inserts For Heels

Guide to Shoe Inserts For Heels

- Introduction: Navigating the Global Market for shoe inserts for heels

- Understanding shoe inserts for heels Types and Variations

- Key Industrial Applications of shoe inserts for heels

- Strategic Material Selection Guide for shoe inserts for heels

- In-depth Look: Manufacturing Processes and Quality Assurance for shoe inserts for heels

- Comprehensive Cost and Pricing Analysis for shoe inserts for heels Sourcing

- Spotlight on Potential shoe inserts for heels Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for shoe inserts for heels

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the shoe inserts for heels Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of shoe inserts for heels

- Strategic Sourcing Conclusion and Outlook for shoe inserts for heels

Introduction: Navigating the Global Market for shoe inserts for heels

In the competitive landscape of footwear accessories, shoe inserts for heels have emerged as a vital component for enhancing comfort, performance, and style. For B2B buyers across Africa, South America, the Middle East, and Europe—such as South Africa and the UAE—sourcing high-quality inserts is essential to meet diverse market demands and elevate product offerings. The global market offers a broad spectrum of options, from basic comfort pads to advanced ergonomic solutions, making informed sourcing decisions crucial for maintaining competitiveness and profitability.

This comprehensive guide is designed to empower international buyers with actionable insights into every facet of the shoe inserts for heels industry. It covers essential topics including types and materials, manufacturing standards and quality control, supplier identification, cost considerations, and market trends. Additionally, it addresses frequently asked questions to clarify common concerns and streamline procurement processes.

By understanding the nuances of product specifications, supplier capabilities, and market dynamics, B2B buyers can optimize sourcing strategies to find reliable partners and secure competitive pricing. Whether you’re expanding your product portfolio or entering new regional markets, this guide provides the knowledge needed to navigate the complexities of the global shoe inserts market confidently. Ultimately, it positions you to make smarter, more strategic purchasing decisions that support growth and customer satisfaction across your target regions.

Understanding shoe inserts for heels Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gel Cushions | Soft gel material, contouring for comfort, often adhesive-backed | High-end footwear, custom retail orders | Pros: Excellent shock absorption, reusable; Cons: Higher cost, limited durability under heavy use |

| Foam Padding | Lightweight, flexible foam, often multi-layered for support | Mass-produced heels, casual footwear | Pros: Cost-effective, easy to customize; Cons: Less durable, may lose shape over time |

| Silicone Inserts | Transparent, flexible silicone, often with adhesive or slip-on design | Formal shoes, luxury brands | Pros: Discreet, long-lasting, easy to insert; Cons: Can be slippery if not properly designed |

| Gel and Foam Hybrid | Combination of gel and foam for balanced support and comfort | Premium and mid-range footwear manufacturing | Pros: Versatile, enhances comfort; Cons: Slightly more complex manufacturing process |

| Custom Molded Inserts | Precisely shaped to individual foot contours, often made via 3D scanning | Orthopedic, bespoke shoe brands | Pros: Perfect fit, high customer satisfaction; Cons: Higher production cost, longer lead times |

Gel Cushions

Gel cushions are prized for their superior shock absorption and contouring capabilities. They are typically made from soft, flexible gel that molds to the foot’s shape, providing comfort for prolonged wear. B2B buyers should consider sourcing high-quality gel materials that can withstand repeated compression without losing shape. Ideal for premium footwear lines or custom orders, gel cushions appeal to customers seeking luxury and comfort. However, they tend to be more expensive and may have limited durability under heavy or rigorous use, making them suitable mainly for high-end or specialty products.

Foam Padding

Foam padding is a versatile, lightweight option widely used in mass-produced footwear. It offers basic cushioning and support, often in multiple layers to enhance comfort and stability. For B2B buyers, foam inserts are attractive due to their low cost and ease of customization, including cut-to-fit options. They are suitable for casual or everyday heels, especially in large-volume manufacturing. The primary consideration is durability; foam can degrade or lose its supportive properties over time, especially under frequent or intense use. Proper quality control and sourcing from reputable suppliers are essential to ensure product longevity.

Silicone Inserts

Silicone inserts are popular for their discreet appearance and flexibility. They are often transparent or skin-colored, making them less visible in finished shoes. Silicone’s inherent slip-resistant properties help keep the insert in place, enhancing comfort and stability. These inserts are well-suited for formal or luxury footwear, where aesthetics are critical. B2B buyers should focus on sourcing high-grade silicone with consistent quality to prevent issues like slipping or tearing. Their durability and ease of insertion make them a preferred choice for premium brands, though they may be relatively more expensive than foam or gel alternatives.

Gel and Foam Hybrid

Hybrid inserts combine the cushioning benefits of gel with the flexibility and lightweight nature of foam. They offer a balanced support system suitable for a broad range of footwear, from mid-range to premium segments. These inserts are adaptable, providing enhanced comfort without significantly increasing manufacturing complexity. For B2B buyers, hybrid options are appealing for their versatility and potential to meet diverse customer preferences. Considerations include sourcing stable, compatible materials and managing production costs, as hybrid designs can involve more complex manufacturing processes.

Custom Molded Inserts

Custom molded inserts are tailored to an individual’s foot shape, often created through advanced methods like 3D scanning or impression molding. They are ideal for orthopedic shoes or bespoke footwear brands aiming for a premium offering. B2B buyers should evaluate the cost-to-benefit ratio, as these inserts involve higher manufacturing costs and longer lead times. Their primary advantage is a perfect fit, which significantly enhances customer satisfaction and reduces return rates. They are best suited for markets with demand for personalized solutions, such as medical or high-end fashion footwear segments.

Key Industrial Applications of shoe inserts for heels

| Industry/Sector | Specific Application of shoe inserts for heels | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Footwear Manufacturing | Custom orthotic inserts for high-end designer heels | Enhances product differentiation, improves comfort, and reduces return rates | Material durability, aesthetic integration, compliance with safety standards |

| Healthcare & Orthopedics | Medical-grade heel inserts for therapeutic footwear | Provides targeted support, reduces patient discomfort, and boosts brand credibility | Medical certifications, biocompatibility, consistent quality control |

| Retail & E-commerce | Ready-to-wear comfort inserts for mass-market retail sales | Increases customer satisfaction, encourages repeat purchases, and broadens market appeal | Cost efficiency, packaging compatibility, branding flexibility |

| Hospitality & Event Planning | Customized heel inserts for luxury events and corporate gifting | Elevates brand image, offers personalized solutions, and opens premium market segments | Customization options, lead times, luxury packaging, premium material sourcing |

| Sports & Performance Gear | Specialized heel inserts for athletes and active professionals | Improves performance, prevents injuries, and differentiates product lines | Shock absorption properties, lightweight design, moisture resistance |

Footwear Manufacturing

In the footwear industry, especially among high-end designers and bespoke brands, shoe inserts for heels are used to create custom orthotics that enhance both aesthetics and comfort. These inserts help reduce heel pain and improve fit, which minimizes product returns and enhances brand reputation. For international B2B buyers, sourcing durable, high-quality materials that can be seamlessly integrated into luxury footwear is critical. Ensuring compliance with safety and environmental standards across regions like South Africa, UAE, and Brazil is also vital to maintain global market access.

Healthcare & Orthopedics

In the healthcare sector, heel inserts are essential components of therapeutic footwear aimed at alleviating conditions such as plantar fasciitis, heel spurs, and other foot ailments. These medical-grade inserts require precise support and biocompatibility, making material quality and certifications non-negotiable. For B2B buyers in regions like Europe and the Middle East, sourcing certified, hypoallergenic materials that meet international medical standards ensures product efficacy and regulatory compliance, fostering trust with healthcare providers and patients.

Retail & E-commerce

Mass-market retail brands leverage ready-to-wear heel inserts to enhance comfort and appeal for everyday consumers. These inserts are designed for easy use, offering immediate relief and improved shoe fit. For international B2B buyers, focusing on cost-effective manufacturing, flexible packaging, and branding options is crucial to scale production and meet diverse market preferences across Africa, South America, and Europe. Quick turnaround times and consistent quality are essential to stay competitive in fast-moving retail environments.

Hospitality & Event Planning

Luxury hotels, event planners, and corporate gifting companies often source customized heel inserts as premium accessories. These products serve as personalized gifts that reinforce brand prestige and customer loyalty. Sourcing premium, customizable materials that accommodate branding or logo placement, along with luxury packaging, is key for B2B buyers targeting high-net-worth clients in markets like the UAE and South Africa. Lead times and the ability to deliver bespoke solutions are critical success factors in this niche.

Sports & Performance Gear

Athletic and active professionals seek heel inserts that provide shock absorption, stability, and moisture resistance to prevent injuries during high-impact activities. These specialized inserts can be integrated into sports footwear, offering a competitive edge and brand differentiation. For international B2B buyers, sourcing lightweight, durable, and moisture-wicking materials that meet performance standards is essential. Ensuring consistent supply and adherence to quality standards across regions like Europe and South America supports brand reputation and customer satisfaction.

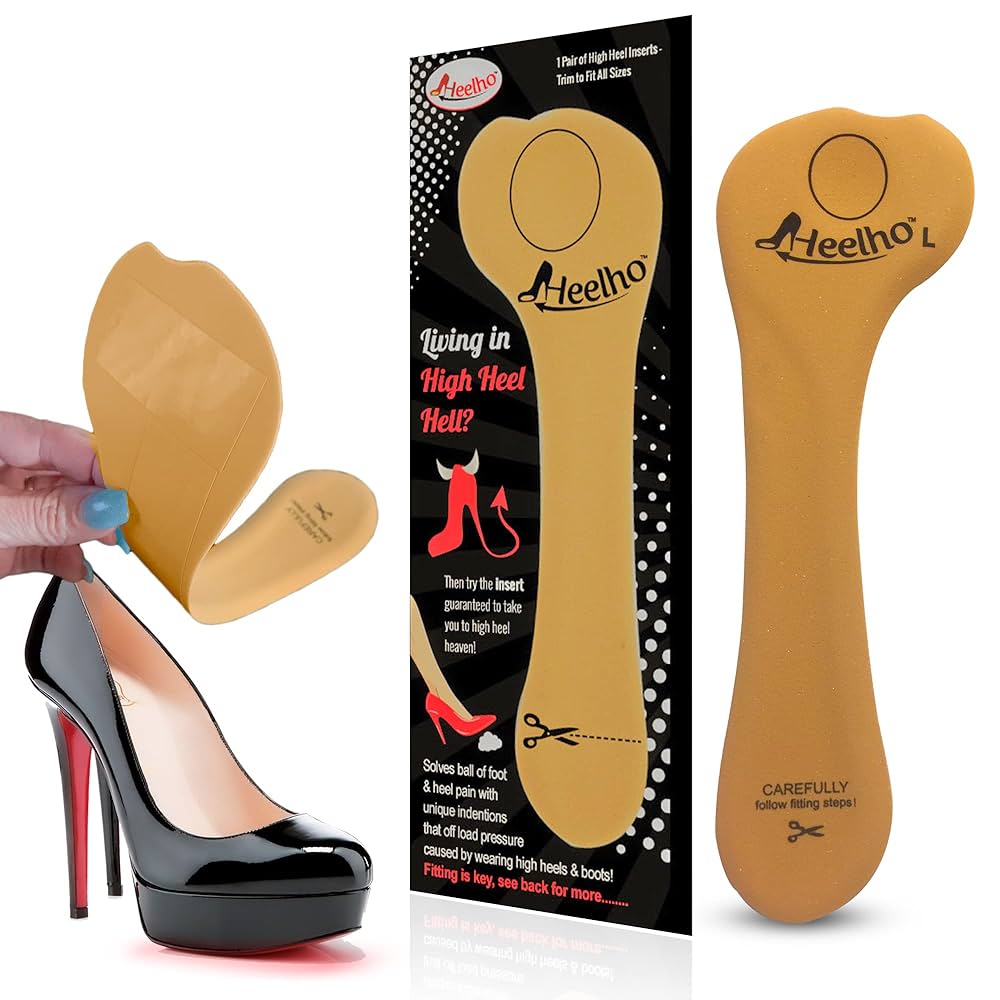

Illustrative Image (Source: Google Search)

Strategic Material Selection Guide for shoe inserts for heels

Material Analysis for Shoe Inserts for Heels

Selecting the appropriate material for shoe inserts in heels is crucial for ensuring product performance, durability, and customer satisfaction. Different materials offer varied properties that influence comfort, longevity, manufacturing complexity, and compliance with international standards. For B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe, understanding these factors is essential for making informed procurement decisions.

1. Ethylene Vinyl Acetate (EVA)

Key Properties:

EVA is a lightweight, flexible, and cushioning foam material with excellent shock absorption qualities. It performs well across a broad temperature range, maintaining its elasticity and resilience from -30°C to +60°C. EVA is also resistant to water, UV radiation, and many chemicals, making it suitable for various environments.

Pros & Cons:

* Pros:*

– Cost-effective and readily available globally

– Easy to mold and shape during manufacturing

– Good cushioning and comfort for heel inserts

– Resistant to moisture and UV damage

- Cons:*

- Moderate durability; can compress over extended use

- Susceptible to degradation under prolonged exposure to oils or solvents

- Limited structural support compared to denser materials

Impact on Application:

EVA’s compatibility with injection molding and lamination processes makes it versatile for custom-fit inserts. Its water resistance is advantageous in humid or wet climates common in regions like South America and parts of Africa.

International Buyer Considerations:

EVA complies with many international standards such as ASTM and REACH, facilitating global trade. Its affordability and ease of processing appeal to manufacturers in emerging markets, while European and Middle Eastern buyers benefit from its proven performance and regulatory compliance.

2. Polyurethane (PU)

Key Properties:

Polyurethane is a versatile polymer available in various densities and hardness levels. It offers excellent resilience, abrasion resistance, and load-bearing capacity. PU maintains its properties over a wide temperature spectrum (-20°C to +70°C) and exhibits good chemical resistance, especially to oils and solvents.

Pros & Cons:

* Pros:*

– Highly durable and long-lasting

– Good shock absorption and support

– Suitable for high-end, premium heel inserts

– Can be customized for specific firmness levels

- Cons:*

- Generally higher cost compared to EVA

- More complex manufacturing process, requiring specialized equipment

- Heavier than EVA, which may impact overall shoe weight

Impact on Application:

PU’s durability makes it ideal for inserts intended for frequent use or high-stress environments. Its chemical resistance is beneficial in regions with exposure to oils, lotions, or cleaning agents.

International Buyer Considerations:

PU materials often meet strict international standards, including ISO and ASTM. Buyers in Europe and the Middle East, where premium quality is demanded, favor PU for its longevity. Importers should verify compliance with local regulations regarding VOC emissions and chemical safety.

3. Thermoplastic Elastomers (TPE)

Key Properties:

TPEs combine the elastic properties of rubber with the processing advantages of plastics. They are flexible, resilient, and capable of returning to their original shape after deformation. TPEs are resistant to temperature fluctuations (-40°C to +80°C) and chemicals, including oils and greases.

Pros & Cons:

* Pros:*

– Excellent flexibility and shock absorption

– Recyclable and environmentally friendly

– Good resistance to weathering and aging

– Suitable for custom, ergonomic heel inserts

- Cons:*

- Slightly higher cost than EVA

- Manufacturing complexity varies depending on grade

- May require specialized processing equipment

Impact on Application:

TPEs are suitable for ergonomic and comfort-focused inserts, especially in markets emphasizing eco-friendly products. Their recyclability aligns with sustainability trends prevalent in Europe and increasingly in Middle Eastern markets.

International Buyer Considerations:

TPEs often conform to global standards like ASTM D412 and ISO 18064. Buyers should consider local regulations regarding recycled content and environmental certifications, especially in European markets where sustainability is prioritized.

Summary Table

| Material | Typical Use Case for shoe inserts for heels | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Ethylene Vinyl Acetate (EVA) | Cushioned, lightweight heel inserts | Cost-effective, water-resistant, easy to mold | Moderate durability, can compress over time | Low |

| Polyurethane (PU) | Durable, high-support heel inserts | Long-lasting, customizable firmness | Higher cost, heavier, complex manufacturing | High |

| Thermoplastic Elastomers (TPE) | Ergonomic, eco-friendly heel inserts | Recyclable, excellent flexibility | Slightly higher cost, processing varies | Med |

This comprehensive understanding of material properties and regional considerations enables B2B buyers to select the most suitable materials for their target markets, balancing performance, cost, and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for shoe inserts for heels

Manufacturing Processes for Shoe Inserts for Heels

The production of shoe inserts for heels involves a series of carefully controlled stages to ensure quality, durability, and comfort. Understanding these processes allows B2B buyers to better evaluate supplier capabilities and compliance with international standards.

1. Material Preparation

The manufacturing process begins with sourcing and preparing raw materials, which are critical for the performance of the final product. Common materials include:

- Foams: Memory foam, EVA, PU, or gel-infused foams for cushioning.

- Covering fabrics: Microfiber, microfiber leather, or moisture-wicking textiles.

- Adhesives: Non-toxic, durable adhesives suitable for bonding different layers.

Suppliers typically source materials from reputable vendors, adhering to international standards such as ISO 9001 for quality management. Material preparation involves cutting, conditioning, and sometimes blending different components to meet specific ergonomic and aesthetic requirements.

2. Forming and Shaping

Once materials are ready, the next stage is forming the inserts into the desired shape, which is especially critical for heel-specific comfort and support. Techniques include:

- Molding: Heat and pressure are applied to foam materials using molds that replicate the ergonomic shape of the heel and arch.

- Lamination: Multiple layers of foam or gel are bonded for enhanced shock absorption.

- Cutting and trimming: Precision cutting ensures consistency across batches, often using CNC or die-cutting machines.

Advanced forming techniques enable customization for various heel heights and foot anatomies, which is vital for B2B buyers offering bespoke or semi-custom solutions.

3. Assembly and Integration

In this stage, additional components such as gel pads, arch supports, or anti-slip bases are integrated:

- Layer bonding: Adhesives or heat presses are used to bond layers securely.

- Embedding features: Gel inserts or metallic supports are embedded during molding or assembly for targeted support.

- Surface finishing: The top cover fabric is glued or sewn onto the foam core, often with finishing to prevent fraying or delamination.

Efficient assembly lines with precise quality controls ensure consistency and reduce waste, which is crucial for large-scale B2B supply.

4. Final Finishing and Packaging

The final stage involves quality checks, surface finishing, and packaging:

- Trimming and contouring: Ensuring the final shape matches design specifications.

- Surface treatment: Anti-bacterial coatings, moisture barriers, or aesthetic embellishments.

- Packaging: Individual wrapping, bulk packaging, and labeling aligned with regulatory and branding requirements.

Automation and eco-friendly packaging practices are increasingly valued by international markets, especially in Europe and the Middle East.

Quality Assurance (QA) and Control in Shoe Insert Manufacturing

Robust QA practices are essential for ensuring that shoe inserts meet both industry standards and client specifications. International B2B buyers should scrutinize suppliers’ quality systems and testing capabilities.

1. International Standards and Certifications

- ISO 9001: The foundation for quality management systems, ensuring consistent product quality and process improvements.

- CE Marking: Indicates compliance with European health, safety, and environmental requirements, vital for markets like the EU and Middle East.

- Other Certifications: API (American Petroleum Institute) for specific materials, or ASTM standards for mechanical testing.

Suppliers compliant with these standards demonstrate a commitment to quality and safety, reducing risks for international buyers.

2. Quality Control Checkpoints

Quality assurance typically involves multiple inspection stages:

- Incoming Quality Control (IQC): Raw materials are inspected upon receipt for defects, dimensions, and compliance with specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing, including dimensional checks, adhesion tests, and visual inspections.

- Final Quality Control (FQC): Comprehensive testing of finished inserts for durability, comfort, and appearance before packaging.

3. Testing Methods and Techniques

Effective QC relies on a variety of testing methods, such as:

- Mechanical Testing: Tensile strength, compression resilience, and tear resistance tests to evaluate durability.

- Adhesion and Bonding Tests: Ensuring layers remain bonded under stress, crucial for layered inserts.

- Environmental Testing: Assessing resistance to humidity, temperature fluctuations, and UV exposure for outdoor or tropical markets.

- Comfort and Ergonomic Testing: Simulating wear conditions to measure shock absorption and support.

4. Verification for International Buyers

B2B buyers should adopt proactive verification measures:

- Supplier Audits: Conduct on-site audits or third-party inspections to verify manufacturing capabilities, cleanliness, and process controls.

- Inspection Reports: Request detailed QC reports, test certificates, and compliance documentation for each batch.

- Third-party Inspection: Engage reputable inspection agencies (e.g., SGS, Bureau Veritas) to validate quality before shipment.

- Sample Testing: Perform independent testing on samples to confirm supplier claims.

Special Considerations for Buyers from Africa, South America, the Middle East, and Europe

International buyers face unique challenges and opportunities in QC verification:

- Regulatory Compliance: Ensure products meet regional standards such as the European REACH regulation, Middle Eastern safety standards, or South African Bureau of Standards (SABS) requirements.

- Language and Communication: Clear documentation and bilingual QC reports facilitate understanding and compliance.

- Supply Chain Transparency: Verify traceability of materials, especially for regions with strict import regulations.

- Cultural and Market Preferences: Consider local preferences for eco-friendly materials, anti-bacterial features, or specific aesthetic finishes.

Final Recommendations for B2B Buyers

- Establish Clear Quality Specifications: Define detailed requirements for materials, construction, and testing protocols upfront.

- Select Reputable Suppliers with Certifications: Prioritize manufacturers with ISO 9001 and relevant regional certifications.

- Perform Regular Audits and Inspections: Maintain ongoing oversight, especially when working with new suppliers.

- Leverage Third-party Testing: Use independent labs and inspection agencies to validate product quality, reducing risk and ensuring compliance.

- Foster Transparent Communication: Maintain open dialogue regarding QC processes, challenges, and improvements to build a reliable supply partnership.

By understanding and rigorously evaluating manufacturing and quality assurance practices, international B2B buyers from diverse regions can confidently source high-quality shoe inserts for heels that meet their market needs and regulatory standards.

Comprehensive Cost and Pricing Analysis for shoe inserts for heels Sourcing

Cost Structure Breakdown for Shoe Inserts for Heels

Understanding the comprehensive cost structure is essential for international buyers aiming to optimize procurement and negotiate effectively. The primary cost components include:

-

Materials: High-quality foam, gel, silicone, or specialty fabrics used in manufacturing. Material costs can vary significantly based on specifications, durability, and certifications (e.g., eco-friendly or hypoallergenic). Premium materials, often required for comfort and durability, will increase unit costs.

-

Labor: Manufacturing labor costs differ markedly across regions. For example, Asian countries like China and Vietnam typically offer lower labor costs compared to South Africa, Brazil, or Middle Eastern suppliers. Skilled labor for quality assurance adds to costs but ensures better product standards.

-

Manufacturing Overhead: Includes factory utilities, machinery depreciation, and maintenance. Overheads are generally embedded within unit costs but can be higher in facilities with advanced machinery or stringent quality standards.

-

Tooling and Setup: Initial tooling costs for molds or custom designs can range from a few hundred to several thousand dollars, especially for customized or branded inserts. These costs are amortized over the production volume.

-

Quality Control and Certifications: International buyers, especially from regions with strict standards (e.g., Europe’s REACH compliance or UAE’s safety certifications), should factor in additional QC expenses. Certification costs may also influence overall pricing.

-

Logistics: Shipping, customs duties, and insurance significantly impact landed costs. FOB (Free on Board) prices typically exclude these, but CIF (Cost, Insurance, and Freight) prices include them. Choosing between air freight (faster, more expensive) and sea freight (cheaper, longer lead times) depends on order urgency and volume.

-

Profit Margin: Suppliers usually add a markup ranging from 10% to 30%, depending on order size, relationship, and market conditions. Larger, regular orders often benefit from negotiated discounts.

Price Influencers and Their Impact

Several factors can influence the final pricing of shoe inserts for heels:

-

Order Volume and MOQ: Higher volumes generally lead to lower unit costs due to economies of scale. Many suppliers offer discounts for large orders or long-term partnerships.

-

Customization and Specifications: Custom shapes, branding, unique materials, or specialized features (e.g., anti-slip surfaces) increase costs. Buyers should balance customization needs with cost implications.

-

Materials and Quality Standards: Premium, eco-certified, or medically certified materials elevate prices. Conversely, standard materials can reduce costs but may affect product positioning.

-

Certifications and Compliance: Products meeting international standards or certifications (e.g., ISO, CE) often command higher prices but are crucial for accessing certain markets.

-

Supplier Factors: Larger or more established suppliers may charge higher prices but offer better quality assurance. Newer or smaller factories might offer lower prices but with increased risk.

-

Incoterms and Shipping Terms: FOB, CIF, or DDP (Delivered Duty Paid) terms influence landed costs. Buyers should clarify who bears shipping and customs costs, affecting overall pricing.

Strategic Tips for International B2B Buyers

-

Negotiate for Better Terms: Leverage order volume, long-term commitments, or multiple product categories to negotiate discounts, especially with suppliers in regions like China, India, or Turkey.

-

Focus on Total Cost of Ownership (TCO): Consider not just unit price but also shipping, customs, quality assurance, and after-sales support. Sometimes paying slightly higher unit prices reduces total costs and mitigates risks.

-

Standardize or Customize Wisely: While customization can enhance product appeal, it often increases costs. Evaluate the market demand and weigh customization against price sensitivity.

-

Understand Pricing Nuances: Different regions may have varying pricing norms. For example, African and South American buyers often face higher logistics costs; European and Middle Eastern buyers might encounter stricter compliance costs.

-

Build Supplier Relationships: Strong partnerships can lead to better pricing, priority service, and flexible payment terms, especially vital in regions with volatile currency or political climates.

Price Range Estimates (Indicative)

While prices vary widely based on specifications, region, and order volume, typical FOB prices for standard shoe inserts for heels range approximately:

- Low-end (mass-produced, basic materials): $0.50 – $1.00 per pair

- Mid-range (better materials, some customization): $1.00 – $2.50 per pair

- Premium (specialized materials, certifications, branding): $2.50 – $5.00+ per pair

Note: These figures are indicative and subject to change based on market conditions, order specifics, and supplier negotiations.

Final Thoughts

Effective sourcing of shoe inserts for heels requires a comprehensive understanding of cost components and influencing factors. By analyzing these elements and applying strategic negotiation and logistics planning, international buyers from Africa, South America, the Middle East, and Europe can optimize costs, ensure quality, and access competitive pricing. Always request detailed quotations, clarify all costs upfront, and consider the total cost of ownership to make informed procurement decisions.

Spotlight on Potential shoe inserts for heels Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for shoe inserts for heels.)*

Essential Technical Properties and Trade Terminology for shoe inserts for heels

Critical Technical Properties for Shoe Inserts for Heels

1. Material Grade and Composition

The quality of materials used in heel inserts directly impacts durability, comfort, and product consistency. High-grade materials such as medical-grade silicone, memory foam, or specialized EVA ensure longevity and optimal shock absorption. B2B buyers should specify material certifications to guarantee compliance with safety standards, especially when importing to regions with strict regulations like the EU or Middle East.

2. Thickness and Density

The thickness of heel inserts influences comfort and support, with common ranges from 2mm to 10mm depending on customer needs. Density affects firmness; higher-density inserts provide more support but may feel less cushioned. Precise specifications enable manufacturers to produce consistent products that meet different market preferences, from comfort-focused to corrective support.

3. Tolerance and Dimensional Accuracy

Manufacturing tolerances specify acceptable deviations in size and shape, typically within ±0.5mm. Tight tolerances are crucial for ensuring the insert fits securely into various shoe sizes and styles, reducing returns or complaints. B2B buyers should verify tolerance levels during quality checks and specify them clearly in purchase agreements.

4. Adhesive Compatibility and Finish

Many heel inserts feature adhesive backing for secure placement. The type of adhesive must be compatible with both the insert material and shoe lining, ensuring it remains effective over time without damaging footwear. Additionally, surface finish—smooth or textured—affects slip resistance and aesthetic appeal, influencing customer satisfaction.

5. Resistance Properties

Resistance to wear, moisture, and temperature fluctuations is vital. A high resistance to compression ensures the insert maintains its supportive shape, while moisture resistance prevents odor and material degradation. These properties are especially relevant for markets with humid climates, such as parts of Africa, South America, and the Middle East.

6. Certification and Compliance Standards

Certifications like ISO, CE, or regional safety standards demonstrate the product’s compliance with health and safety regulations. For international trade, especially into markets with strict import controls, these certifications facilitate smoother customs clearance and build buyer confidence.

Common Industry and Trade Terms

1. OEM (Original Equipment Manufacturer)

Refers to manufacturers that produce heel inserts based on the buyer’s specifications and branding. Understanding OEM capabilities helps buyers negotiate custom solutions, branding rights, and production lead times.

2. MOQ (Minimum Order Quantity)

The smallest quantity a manufacturer accepts for a production run. Clarifying MOQ assists buyers in planning inventory and managing costs, especially in markets where demand may be seasonal or limited.

3. RFQ (Request for Quotation)

A formal process where buyers solicit price and lead time details from multiple suppliers. Using RFQs allows international buyers to compare offers, negotiate better prices, and ensure specifications are clearly communicated.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs duties. Familiarity with Incoterms (e.g., FOB, CIF, DDP) ensures clarity on delivery obligations, costs, and risk transfer points, vital for cross-border transactions.

5. Lead Time

The duration from order placement to product delivery. Knowing lead times helps buyers coordinate production schedules and inventory planning, especially in regions with logistical challenges.

6. Quality Assurance (QA) and Testing

Procedures implemented to verify product specifications and safety compliance. B2B buyers should specify QA protocols and testing requirements to ensure consistent quality across batches, reducing post-sale issues.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions, streamline procurement processes, and establish reliable partnerships in the growing market of shoe inserts for heels.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the shoe inserts for heels Sector

Market Overview & Key Trends

The global market for shoe inserts for heels is experiencing robust growth driven by increasing demand for comfort, orthotic support, and aesthetic enhancement. Rising disposable incomes and evolving fashion trends across regions such as Africa, South America, the Middle East, and Europe are fueling this expansion. In particular, markets like South Africa and the UAE are witnessing heightened consumer awareness around foot health and premium footwear accessories, creating lucrative opportunities for B2B suppliers.

Emerging technological innovations are transforming sourcing and manufacturing processes. 3D printing, for example, enables rapid prototyping and customization, allowing brands to offer tailored solutions at competitive prices. Meanwhile, the adoption of advanced materials—such as memory foam, gel-infused layers, and eco-friendly bioplastics—is expanding product functionality and sustainability profiles.

For international B2B buyers, understanding regional market nuances is critical. In Europe, there is a strong preference for high-quality, sustainable products, driven by stringent regulations and consumer awareness. Conversely, markets like South America and Africa often prioritize affordability and durability, with growth driven by expanding retail networks and local manufacturing capabilities. Digital sourcing platforms and trade shows are increasingly important channels for discovering suppliers, enabling buyers to assess quality, certifications, and lead times efficiently.

Supply chain resilience is becoming a focal point amid global disruptions, prompting buyers to diversify sourcing options. Nearshoring and regional manufacturing hubs are gaining popularity, especially in the Middle East and parts of Europe, to reduce lead times and improve supply chain agility. Staying abreast of these trends will empower B2B buyers to make strategic sourcing decisions aligned with regional demands and future growth trajectories.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer optional but a fundamental criterion in sourcing shoe inserts for heels. Environmental concerns such as plastic waste, carbon emissions, and resource depletion are prompting buyers to prioritize eco-friendly materials and ethical supply chains. Certifications like Global Organic Textile Standard (GOTS), Forest Stewardship Council (FSC), and ISO 14001 are becoming standard benchmarks for suppliers aiming to demonstrate their commitment to sustainability.

Illustrative Image (Source: Google Search)

Eco-conscious materials—such as biodegradable foams, natural latex, cork, and recycled fabrics—are increasingly adopted to meet rising consumer expectations in mature markets like Europe and the Middle East. For B2B buyers, partnering with suppliers holding green certifications ensures compliance with local regulations and enhances brand reputation. Transparency in sourcing practices, including supply chain audits and fair labor certifications, is crucial for building trust and mitigating reputational risks.

Additionally, sustainable innovations such as plant-based adhesives, water-based dyes, and waste reduction initiatives are gaining traction. Buyers should actively seek suppliers committed to continuous improvement and lifecycle management of their products. Incorporating sustainability into procurement strategies not only aligns with global environmental goals but also offers a competitive edge in markets where eco-friendly credentials influence purchasing decisions.

Brief Evolution/History (Optional)

The evolution of shoe inserts for heels reflects broader shifts in footwear and orthotic industries. Initially, the focus was purely on comfort and durability, with basic foam and gel inserts. Over time, technological advancements introduced specialized materials and ergonomic designs tailored to specific needs such as arch support and shock absorption. The rise of sustainable materials and ethical manufacturing practices in recent years signifies a paradigm shift towards environmentally responsible and socially conscious sourcing. Understanding this evolution helps B2B buyers anticipate future innovations and align their sourcing strategies with industry best practices.

Frequently Asked Questions (FAQs) for B2B Buyers of shoe inserts for heels

1. How can I effectively vet shoe insert suppliers to ensure product quality and reliability?

To vet suppliers effectively, start with comprehensive background checks focusing on their manufacturing certifications (ISO, CE, etc.), quality control processes, and reputation in the industry. Request samples for quality assessment and verify their compliance with international standards. Additionally, seek references from other B2B clients, especially those in similar markets, to assess their reliability. Conduct virtual factory audits if possible, and evaluate their communication responsiveness. Establish clear expectations upfront regarding quality benchmarks, lead times, and after-sales support. This due diligence minimizes risks and ensures a dependable partnership.

2. What customization options are typically available for shoe inserts, and how can I ensure they meet my target market’s needs?

Most suppliers offer customization in materials (gel, foam, leather), thickness, cushioning density, and branding (logos, packaging). Some also provide design modifications for specific heel heights or ergonomic features. To ensure they meet your market’s needs, conduct detailed market research on consumer preferences and footwear trends. Communicate these requirements clearly to suppliers and request prototypes for testing. Collaborate closely during the design process, and consider local market feedback. Working with a supplier experienced in international exports and customization will help you develop a product that aligns with regional customer expectations.

3. What are typical MOQs, lead times, and payment terms for international B2B purchases of shoe inserts for heels?

MOQ (Minimum Order Quantity) varies widely but generally ranges from 500 to 10,000 pairs, depending on the supplier’s scale and customization level. Lead times typically span 4–8 weeks after order confirmation, factoring in production and shipping. Payment terms often include 30% upfront via bank transfer or letter of credit, with the balance payable before shipment or upon delivery. Negotiating flexible terms is possible, especially for larger or repeat orders. Building strong supplier relationships and clear communication about your volume forecasts can help optimize MOQs and payment conditions.

4. What certifications and quality assurance measures should I look for in a shoe insert supplier?

Key certifications include ISO 9001 (quality management), CE marking (European market compliance), and environmental standards like ISO 14001. Suppliers should also provide test reports confirming safety, durability, and allergen-free materials. Quality assurance measures include in-house testing, third-party lab certifications, and traceability systems for raw materials. Request detailed QA protocols and documentation, and consider visiting factories or engaging third-party inspectors to verify compliance. Ensuring these certifications and QA measures reduces liability risks and guarantees your products meet international safety and quality standards.

5. How can I manage international logistics efficiently when importing shoe inserts, considering customs, tariffs, and shipping options?

Partner with experienced freight forwarders familiar with your target markets to navigate customs procedures and tariffs efficiently. Choose reliable shipping methods such as sea freight for bulk orders or air freight for urgent needs, balancing cost and speed. Prepare all necessary documentation—commercial invoices, packing lists, certificates of origin—to streamline customs clearance. Stay informed about import duties and VAT applicable in your region (e.g., South Africa, UAE). Establish clear communication channels with your suppliers and logistics providers to track shipments in real-time and handle any delays proactively.

6. What are common dispute resolution strategies in international B2B transactions for shoe inserts?

Disputes often arise over quality issues, delivery delays, or payment disagreements. To mitigate these, include clear terms in your contracts, such as arbitration clauses under recognized international bodies like ICC or LCIA. Maintain detailed records of all communications, agreements, and inspection reports. Engage in proactive dispute resolution by negotiating directly with suppliers initially, and escalate to arbitration if necessary. Employ third-party inspection agencies for quality disputes, and seek legal counsel familiar with international trade laws in your region. Establishing transparent processes and contractual protections minimizes costly conflicts.

7. How do I ensure compliance with regional safety and environmental standards for shoe inserts in different markets?

Research specific regional standards—CE marking for Europe, SASO for Saudi Arabia, or SABS for South Africa—to ensure compliance. Communicate these requirements to your suppliers upfront, requesting documentation and test reports demonstrating adherence. Prefer suppliers who are familiar with export standards and have relevant certifications. Incorporate compliance checks into your quality control processes, including lab testing of raw materials and finished products. Staying updated on evolving regulations and establishing ongoing supplier audits helps ensure your products remain compliant across different markets, reducing the risk of shipment rejections or legal penalties.

8. What strategies can I use to build long-term, mutually beneficial relationships with shoe insert suppliers?

Focus on clear, consistent communication and setting mutual expectations from the outset. Offer volume commitments or regular orders to incentivize supplier loyalty. Provide constructive feedback on product quality and lead times to foster continuous improvement. Consider establishing strategic partnerships, including joint development projects or exclusive agreements, to deepen collaboration. Timely payments and prompt resolution of issues build trust. Attending trade shows, visiting manufacturing sites, and maintaining open dialogue about market trends and innovations also strengthen relationships. These strategies promote reliability, better pricing, and priority service over the long term.

Strategic Sourcing Conclusion and Outlook for shoe inserts for heels

Strategic Sourcing Conclusion and Outlook for shoe inserts for heels

Effective strategic sourcing is vital for B2B buyers seeking to meet the diverse demands of the global footwear market, especially in the niche of shoe inserts for heels. Key considerations include identifying reliable suppliers with proven quality standards, leveraging local manufacturing capabilities, and diversifying supply chains to mitigate risks. Emphasizing innovation, such as eco-friendly materials and ergonomic designs, can also provide a competitive edge.

Illustrative Image (Source: Google Search)

For international buyers from regions like Africa, South America, the Middle East, and Europe, building strong supplier relationships and conducting thorough due diligence will ensure product consistency and cost efficiency. Additionally, embracing digital procurement platforms and trade shows can expand sourcing options and foster strategic partnerships.

Looking ahead, the demand for comfortable, durable, and customizable heel inserts is set to rise, driven by evolving fashion trends and increasing awareness of foot health. Buyers should prioritize sustainable sourcing practices and stay adaptable to market shifts. By adopting a proactive, strategic approach to sourcing, international B2B buyers can secure a competitive advantage and meet the growing needs of their markets in the coming years.