Your Ultimate Guide to Sourcing Suede Shoe Cleaner

Guide to Suede Shoe Cleaner

- Introduction: Navigating the Global Market for suede shoe cleaner

- Understanding suede shoe cleaner Types and Variations

- Key Industrial Applications of suede shoe cleaner

- Strategic Material Selection Guide for suede shoe cleaner

- In-depth Look: Manufacturing Processes and Quality Assurance for suede shoe cleaner

- Comprehensive Cost and Pricing Analysis for suede shoe cleaner Sourcing

- Spotlight on Potential suede shoe cleaner Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for suede shoe cleaner

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the suede shoe cleaner Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of suede shoe cleaner

- Strategic Sourcing Conclusion and Outlook for suede shoe cleaner

Introduction: Navigating the Global Market for suede shoe cleaner

In the competitive landscape of footwear maintenance, suede shoe cleaner has emerged as an essential product for brands, retailers, and service providers worldwide. Its significance lies in the delicate nature of suede material, which demands specialized cleaning solutions that preserve texture, color, and quality. For B2B buyers operating across diverse markets—including Africa, South America, the Middle East, and Europe—understanding the nuances of this market is critical to sourcing reliable, cost-effective, and high-quality products.

This comprehensive guide offers a strategic overview of the global suede shoe cleaner market, equipping buyers with actionable insights on product types, material formulations, manufacturing standards, and quality control practices. It also highlights key supplier regions, cost considerations, and supply chain dynamics, empowering you to make informed procurement decisions. Additionally, the guide addresses frequently asked questions and explores market trends, helping you anticipate future demand and innovation.

By navigating this guide, international B2B buyers will gain clarity on sourcing options tailored to their regional needs and quality expectations. Whether you’re seeking OEM partnerships in Europe, evaluating suppliers from emerging markets in South America, or establishing reliable supply chains in Africa and the Middle East, this resource is designed to enhance your strategic sourcing capabilities. Ultimately, it ensures you can select the best suede shoe cleaner solutions that meet your business standards, customer expectations, and market growth objectives.

Understanding suede shoe cleaner Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Spray-On Suede Cleaners | Aerosol or pump spray formulations, quick application, often includes protective agents | Retail, wholesale, and industrial cleaning services for footwear | Easy to apply and fast; may require multiple applications; potential overspray issues |

| Brush-Based Cleaners | Contain specialized suede brushes combined with cleaning solutions or conditioners | Shoe repair shops, cleaning service providers, bulk retail outlets | Effective for deep cleaning; can be abrasive if not designed properly; suitable for routine maintenance |

| Foam Cleaners | Foaming formulations that lift dirt with minimal moisture contact | Large-scale cleaning operations, professional shoe care services | Minimal water use reduces damage risk; can be more costly; requires proper dispensing equipment |

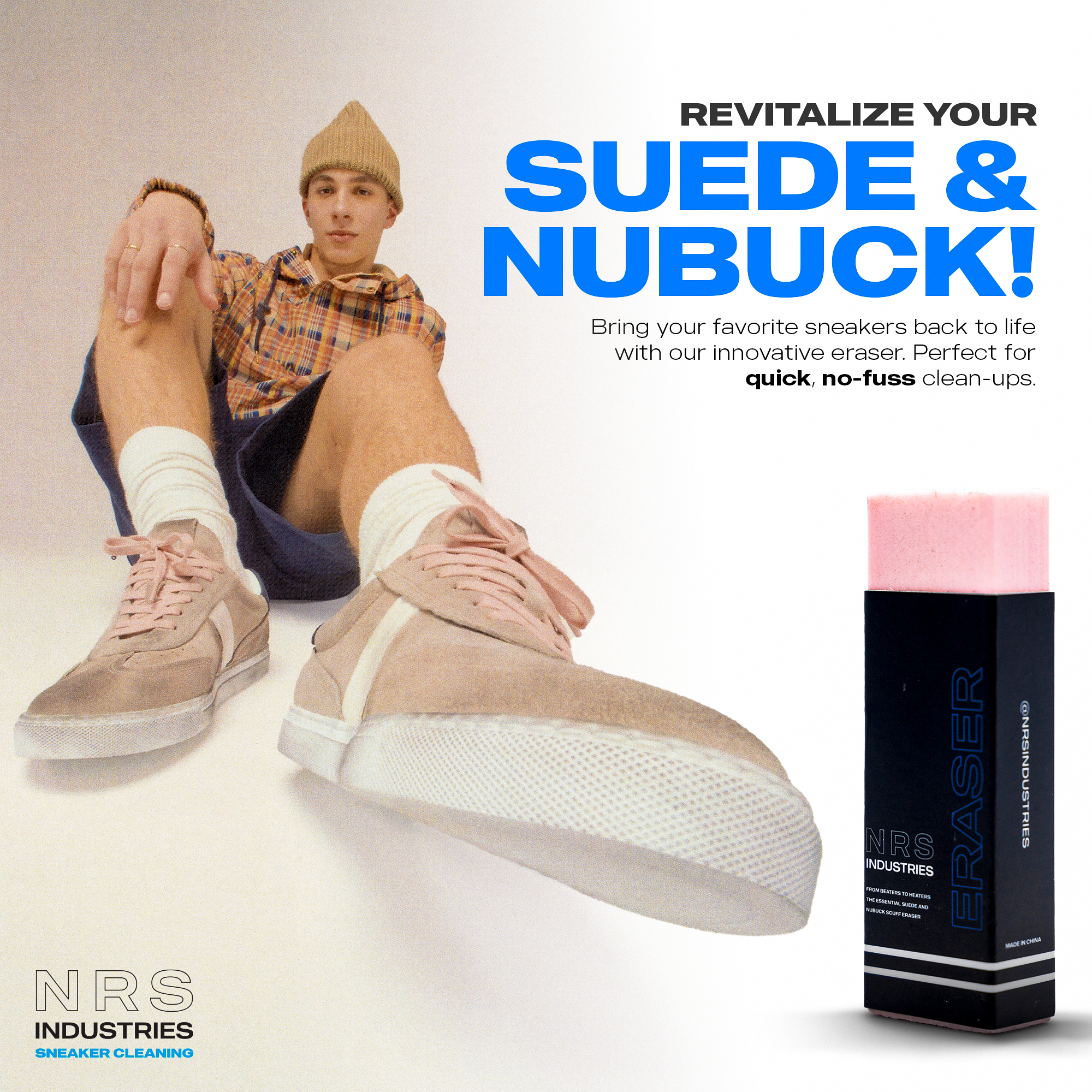

| Eraser and Spot Cleaners | Textured or chemical-based erasers targeting stains and spots | Specialty retail, shoe repair chains, B2B suppliers for targeted stain removal | Precise stain removal; limited for overall cleaning; cost-effective for specific tasks |

| Eco-Friendly & Natural Cleaners | Biodegradable, plant-based formulations with low VOCs | Environmentally conscious brands, eco-friendly retail chains | Safer for sensitive materials; may have limited shelf life; higher initial costs |

Spray-On Suede Cleaners

Spray-on suede cleaners are among the most versatile and widely used in B2B sectors due to their convenience and rapid action. These formulations often include protective agents that help repel dirt and water, making them suitable for ongoing maintenance. For bulk buyers, sourcing these in large quantities ensures consistent application across retail outlets or cleaning facilities. However, buyers should consider the potential for overspray, which can lead to wastage or contamination of nearby surfaces, especially in high-volume environments.

Brush-Based Cleaners

Brush-based cleaners combine specialized suede brushes with cleaning solutions designed to lift dirt without damaging delicate fibers. They are ideal for professional shoe repair shops and bulk cleaning operations where deep cleaning and gentle abrasion are required. When purchasing in bulk, buyers should evaluate the brush quality and compatibility with different suede types to ensure durability and effectiveness. While effective for routine maintenance, improper use or low-quality brushes can cause fiber damage, so training and quality assurance are critical.

Foam Cleaners

Foam-based suede cleaners are favored in large-scale operations due to their minimal moisture contact, reducing the risk of water stains or fiber deformation. These products are particularly suitable for professional cleaning services aiming for quick turnaround times. For B2B buyers, investing in compatible dispensing equipment and understanding foam density are essential to maximize efficiency. Although they tend to be more expensive than sprays, their controlled application minimizes waste and enhances safety, especially in high-volume settings.

Eraser and Spot Cleaners

Targeted stain removal tools such as textured erasers or chemical spot cleaners are valuable for specialty retail or shoe repair chains that require precision. These products are cost-effective for addressing localized stains without overhauling the entire shoe. B2B buyers should consider the compatibility with various suede colors and textures, as some chemicals may cause discoloration. Their primary application is in maintenance and restoration, making them essential for preserving the appearance of high-value footwear.

Eco-Friendly & Natural Cleaners

With increasing demand for sustainable products, eco-friendly suede cleaners are gaining prominence. These formulations typically use biodegradable ingredients and low VOCs, aligning with environmental standards in Europe, Africa, and South America. For B2B buyers, sourcing these products supports brand positioning and compliance with environmental regulations. While they often come at a premium, their safety profile makes them suitable for sensitive materials and health-conscious markets, offering a competitive edge in eco-aware sectors.

Key Industrial Applications of suede shoe cleaner

| Industry/Sector | Specific Application of suede shoe cleaner | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Footwear Manufacturing | Pre-production cleaning of suede materials to ensure quality and consistency | Enhances product appearance, reduces defect rates, and improves brand reputation | Compatibility with various suede types, eco-friendly formulations, consistent supply chain |

| Leather Goods & Accessories | Maintenance of suede handbags, belts, and accessories in retail or wholesale operations | Extends product lifespan, maintains aesthetic appeal, and reduces return rates | Effectiveness on different stains, ease of use, and availability in bulk quantities |

| Hospitality & Luxury Hotels | Professional cleaning of suede upholstery and footwear for guest services | Preserves luxury ambiance, enhances customer satisfaction, and protects asset investment | Non-damaging formulations, fast-drying, and compliance with safety standards |

| Cleaning & Maintenance Services | Commercial cleaning of suede items for corporate clients and events | Provides reliable, high-quality cleaning solutions, boosting service reputation | Scalability, cost-efficiency, and suitability for diverse client needs across regions |

| Fashion & Retail Distribution | Stocking of suede shoe cleaners for wholesale distribution to boutiques and online retailers | Expands product portfolio, drives sales, and meets increasing demand for suede care | Certification standards, packaging durability, and regional regulatory compliance |

Footwear Manufacturing

In the footwear industry, suede shoe cleaners are essential during the pre-production phase to prepare raw suede materials. These cleaners remove dirt, oils, and manufacturing residues, ensuring uniform surface quality. For international buyers, especially from regions like Europe and South America, sourcing eco-friendly, non-abrasive cleaners is crucial to meet sustainability standards and reduce environmental impact. Reliable supply chains and compatibility with various suede types help manufacturers maintain consistent product quality and minimize defects.

Leather Goods & Accessories

Luxury brands and wholesale suppliers utilize suede shoe cleaners to maintain the aesthetic appeal of accessories such as handbags, belts, and footwear. Regular cleaning prevents staining and wear, thereby extending product lifespan and reducing customer returns. B2B buyers from Africa and the Middle East should prioritize suppliers offering effective, gentle formulations that work on different stains without damaging delicate suede surfaces. Ease of application and availability in bulk are key for seamless inventory management.

Hospitality & Luxury Hotels

High-end hotels and resorts often offer suede footwear and upholstery as part of their premium guest services. Professional-grade suede cleaners are used to preserve the luxurious look of suede furniture, slippers, and accessories. For international buyers, especially in Europe and the UK, sourcing non-toxic, fast-drying, and hypoallergenic cleaners ensures guest safety and satisfaction. Consistent quality and adherence to safety standards are vital to protect hotel assets and uphold brand reputation.

Cleaning & Maintenance Services

Commercial cleaning companies serving corporate clients and events rely on specialized suede shoe cleaners to deliver high-quality maintenance services. These cleaners help remove stains, dirt, and oils efficiently, enhancing the service provider’s reputation. Buyers from South America and Africa should focus on scalable, cost-effective formulations that deliver consistent results across large volumes. Availability of eco-certified products and adaptable formulations for different suede types are important sourcing considerations.

Fashion & Retail Distribution

Distributors supplying suede shoe cleaners to boutiques and online retailers play a critical role in meeting the rising consumer demand for premium suede care products. Offering a range of effective, certified cleaners allows distributors to differentiate their portfolio and support retail partners. For international B2B buyers, especially in Europe and Germany, compliance with regional safety and environmental standards, as well as durable packaging suitable for diverse climates, are key factors to ensure product integrity during transit and storage.

Strategic Material Selection Guide for suede shoe cleaner

Material Analysis for Suede Shoe Cleaner

When selecting materials for manufacturing suede shoe cleaners, B2B buyers must consider properties that influence performance, durability, cost, and compliance with international standards. The following analysis examines common materials used in the construction of these products, focusing on their suitability for different markets such as Africa, South America, the Middle East, and Europe.

Illustrative Image (Source: Google Search)

1. Polypropylene (PP)

Key Properties:

Polypropylene is a thermoplastic polymer renowned for its chemical resistance, low moisture absorption, and good fatigue resistance. It can withstand moderate temperatures (up to approximately 100°C) and is resistant to many acids and bases, making it suitable for cleaning agents and applicator components.

Pros & Cons:

– Pros: Cost-effective, lightweight, highly resistant to chemicals, and easy to mold into various shapes. Its inert nature ensures compatibility with cleaning solutions without degradation.

– Cons: Moderate mechanical strength compared to other plastics; can crack under high impact or stress. Its surface may degrade over prolonged UV exposure unless stabilized.

Impact on Application:

Polypropylene’s chemical inertness makes it ideal for containers, brushes, and spray nozzles in suede shoe cleaners. Its resistance to cleaning agents ensures longevity and safety across different formulations.

International Considerations:

Polypropylene complies with ASTM D4101 and EN 13432 standards for recyclability, which is advantageous for markets emphasizing sustainability, such as Europe. Its widespread acceptance and cost-efficiency make it popular in developing regions like Africa and South America. Buyers should verify local regulations regarding plastic additives to ensure compliance.

2. Polyethylene (PE)

Key Properties:

Polyethylene, especially high-density polyethylene (HDPE), offers excellent chemical resistance, impact strength, and flexibility. It can handle temperatures up to 80-120°C depending on grade and is resistant to moisture and many chemicals.

Pros & Cons:

– Pros: Highly durable, resistant to cracking, and cost-effective. Its flexibility allows for manufacturing a variety of applicator parts and bottles.

– Cons: Lower temperature resistance compared to polypropylene, which can limit its use with hot cleaning solutions. Its surface may be less rigid, affecting precision in spray nozzles.

Impact on Application:

PE is suitable for bottles, caps, and flexible applicator components. Its impact resistance is beneficial in transportation and handling, especially in regions with rough logistics.

International Considerations:

PE products typically meet DIN 53438 and ASTM D1248 standards. For markets like Europe and Germany, recyclability and environmental impact are critical; PE’s recyclability aligns well with EU directives. In Africa and South America, cost and durability are primary considerations, making PE a practical choice.

3. Stainless Steel (e.g., 304 or 316 grades)

Key Properties:

Stainless steel offers exceptional corrosion resistance, high strength, and excellent temperature tolerance (up to 870°C for some grades). It is non-reactive, durable, and easy to sterilize, which is crucial for hygiene standards.

Pros & Cons:

– Pros: Long-lasting, resistant to corrosion and staining, suitable for high-pressure applications, and meets strict hygiene standards.

– Cons: Higher manufacturing costs, heavier weight, and requires specialized fabrication processes.

Impact on Application:

Ideal for high-pressure spray systems, nozzles, and structural components in premium suede cleaner models. Its durability reduces replacement frequency, especially in humid or saline environments common in Middle Eastern and coastal regions.

International Considerations:

Compliance with ASTM A240 and DIN EN 10088 ensures quality and safety. Buyers in Europe and Germany often prefer stainless steel for premium products due to environmental and health standards. In Africa and South America, initial costs may be higher, but long-term durability offers cost savings.

4. Rubber (Natural or Synthetic)

Key Properties:

Rubber materials like EPDM or silicone are valued for their flexibility, resilience, and chemical resistance. They can withstand a wide temperature range (from -50°C to 250°C depending on type) and resist aging and ozone degradation.

Pros & Cons:

– Pros: Excellent sealing and cushioning properties, resistant to many cleaning chemicals, and adaptable to various shapes.

– Cons: Susceptible to wear over time, especially under aggressive cleaning regimes; synthetic variants may contain additives that require compliance checks.

Impact on Application:

Rubber is often used for gaskets, seals, and flexible tubing in the cleaning equipment. Its elasticity ensures tight seals, preventing leaks and ensuring consistent spray performance.

International Considerations:

Compliance with JIS K 6254 and ASTM D2000 standards is common. Buyers should verify that rubber components meet local safety standards, especially in Europe where chemical additives are scrutinized. Cost varies depending on grade and synthetic formulation, but generally, rubber offers a good balance of performance and affordability.

Summary Table

| Material | Typical Use Case for suede shoe cleaner | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene (PP) | Containers, spray nozzles, brushes | Chemical resistance, cost-effective, easy to mold | Moderate impact strength, UV degradation risk | Low |

| Polyethylene (PE) | Bottles, flexible applicator parts | Impact resistance, durability, cost-effective | Lower temperature resistance, less rigidity | Low |

| Stainless Steel | High-pressure nozzles, structural components | Corrosion resistance, durability, high temperature tolerance | High cost, heavier weight | High |

| Rubber (EPDM, Silicone) | Seals, gaskets, tubing | Flexibility, chemical resistance, sealing capability | Wear over time, potential additive concerns | Med |

This detailed analysis guides B2B buyers in selecting materials that balance performance, cost, and compliance, tailored to the specific needs of different international markets. Ensuring the right material choice will optimize product longevity, safety, and market acceptance across diverse regions.

In-depth Look: Manufacturing Processes and Quality Assurance for suede shoe cleaner

Manufacturing Processes for Suede Shoe Cleaner

The production of high-quality suede shoe cleaners involves several carefully controlled stages, each critical to ensuring product efficacy, safety, and consistency.

1. Material Preparation:

The process begins with sourcing raw materials such as cleaning agents, emulsifiers, stabilizers, fragrances, and packaging components. Suppliers must adhere to international standards like ISO 9001 to ensure raw material quality, safety, and traceability. For B2B buyers, verifying supplier certifications and conducting supplier audits are essential to mitigate risks associated with substandard inputs, especially when sourcing from regions with varying regulatory oversight like Africa, South America, or the Middle East.

2. Formulation and Mixing:

Formulators develop the cleaning solution, balancing surfactants, solvents, and conditioners tailored for suede’s delicate surface. Precise mixing techniques, including high-shear blending and temperature control, are employed to ensure homogeneity. Advanced formulations often incorporate eco-friendly ingredients to meet emerging sustainability standards, which are increasingly prioritized by European and German buyers.

3. Filling and Packaging:

The prepared product is transferred into bottles or spray containers through automated filling lines that incorporate sterile and hygienic practices, complying with Good Manufacturing Practices (GMP). Labeling must include clear instructions, safety warnings, batch numbers, and expiration dates, with labels often required to meet regional regulations such as CE marking in Europe or API standards for certain formulations.

4. Final Inspection and Packaging:

Post-filling, products undergo visual inspection and functional testing to confirm package integrity and label accuracy. Automated systems can detect leaks, mislabeling, or contamination. Packaging may involve tamper-evident seals and child-resistant caps to enhance consumer safety and meet legal requirements across markets.

Quality Control (QC) in Manufacturing

Robust QC protocols are vital to deliver consistent, safe, and effective suede shoe cleaners. International standards and industry-specific certifications guide these practices.

1. International Standards Compliance:

ISO 9001 certification is the cornerstone of quality management, emphasizing process consistency, continuous improvement, and customer satisfaction. B2B buyers should prioritize suppliers holding ISO 9001 or equivalent certifications, which demonstrate rigorous internal QC systems.

2. Industry-Specific Certifications:

Depending on the destination market, additional certifications may be necessary. For example, CE marking indicates conformity with European health, safety, and environmental standards. API standards are relevant if the product contains petroleum-derived solvents or ingredients. Buyers from regions with strict regulatory environments should verify that suppliers possess relevant certifications and test reports.

3. QC Checkpoints and Testing Methods:

– Incoming Quality Control (IQC): Raw materials are tested upon receipt for purity, concentration, and compliance with specifications. Techniques include chromatography, titration, and spectrophotometry.

– In-Process Quality Control (IPQC): During formulation and filling, continuous checks monitor pH levels, viscosity, and microbial contamination. Automated sensors and inline testing equipment facilitate real-time QC.

– Final Quality Control (FQC): Before dispatch, the finished product undergoes comprehensive testing, including stability testing, efficacy assays (e.g., stain removal performance), and safety assessments like skin irritation tests.

4. Common Testing Methods:

– Chemical Analysis: To verify active ingredient concentrations and detect contaminants.

– Microbial Testing: Ensures microbial load is within safe limits, especially important for products with preservatives.

– Performance Testing: Simulates real-world cleaning scenarios on suede swatches to confirm efficacy.

– Packaging Integrity: Drop tests, pressure tests, and leak detection ensure package durability during transit.

Verifying Supplier Quality for International B2B Buyers

For buyers, especially from diverse regions with varying regulatory landscapes, verifying supplier QC processes is crucial.

- Supplier Audits: Conduct comprehensive on-site audits or third-party inspections to evaluate manufacturing practices, QC systems, and compliance documentation.

- Documentation and Certification Review: Request Certificates of Analysis (CoA), test reports, and certification copies. These documents should detail raw material sources, testing results, and compliance with regional standards.

- Third-Party Inspection Services: Engage independent inspection agencies (e.g., SGS, Bureau Veritas) to perform pre-shipment inspections, verifying product quality, packaging, and labeling accuracy.

- Sample Testing: Before large orders, obtain product samples for independent testing, ensuring they meet declared specifications and performance criteria.

Quality Assurance Nuances for Different Regions

Africa and South America:

Regulatory frameworks may be less standardized or vary regionally. Buyers should emphasize supplier adherence to internationally recognized standards like ISO 9001 and request detailed testing reports. Establishing long-term partnerships with certified manufacturers reduces supply chain risks.

Middle East:

Markets often require compliance with regional standards such as Gulf Standards (GSO). Suppliers with CE certification and adherence to local chemical safety regulations are preferable. B2B buyers should verify that suppliers maintain documentation for customs clearance and safety compliance.

Europe (UK, Germany):

European buyers demand strict compliance with REACH regulations, CLP classification, and eco-labeling standards. Suppliers should provide comprehensive safety data sheets (SDS), eco-label certifications, and proof of conformity assessments. Regular audits and third-party testing are recommended to maintain compliance and ensure product safety.

Final Recommendations for B2B Buyers

- Develop Clear Qualification Criteria: Define mandatory certifications, testing requirements, and documentation standards tailored to target markets.

- Establish Regular Audit Schedules: Periodic supplier audits help verify ongoing compliance and quality consistency.

- Leverage Technology: Use digital platforms for document verification, real-time QC monitoring, and supply chain transparency.

- Engage Local Expertise: Partner with regional testing labs and certification bodies to navigate local regulatory landscapes effectively.

By understanding and implementing rigorous manufacturing and QC evaluation practices, international B2B buyers can confidently source high-quality suede shoe cleaners that meet regional standards, ensuring product safety, efficacy, and customer satisfaction across diverse markets.

Comprehensive Cost and Pricing Analysis for suede shoe cleaner Sourcing

Cost Structure Breakdown

Understanding the comprehensive cost components involved in sourcing suede shoe cleaner is essential for accurate pricing and negotiation. The primary cost elements include:

-

Materials: The core ingredients—such as cleaning agents, emulsifiers, and conditioners—constitute a significant portion of the cost. High-quality, eco-friendly, or certified ingredients typically command higher prices but can add value and appeal to premium markets.

-

Labor: Manufacturing labor costs vary considerably based on country and factory standards. For suppliers in Asia, Eastern Europe, or Africa, labor may be more cost-effective, but buyers should verify compliance with local labor laws and quality standards.

-

Manufacturing Overhead: This includes factory utilities, machinery depreciation, and administrative expenses. Efficient factories with modern equipment tend to have better cost control, impacting overall pricing.

-

Tooling and Packaging: Initial tooling costs are generally amortized over production runs, influencing unit costs especially for smaller MOQ (Minimum Order Quantity). Packaging can also significantly affect the total cost—premium packaging or eco-friendly materials typically increase expenses but can boost product appeal.

-

Quality Control (QC): Rigorous QC processes ensure product consistency and safety, especially critical for chemical products. Investing in thorough QC can slightly increase costs but reduces risks of returns or compliance issues.

-

Logistics and Shipping: International freight, customs clearance, and local distribution costs are variable depending on the origin and destination. Bulk shipping reduces per-unit costs but requires larger upfront investment.

-

Margins: Suppliers typically add a markup to cover risks and profit margins. Markup percentages can range from 10% to 30%, depending on the supplier’s market position, product uniqueness, and volume.

Price Influencers and Market Dynamics

Several factors influence the final price of suede shoe cleaner in B2B transactions:

-

Volume and MOQ: Higher purchase volumes generally unlock lower unit prices due to economies of scale. Buyers should negotiate for favorable terms, especially if they can commit to larger orders or long-term partnerships.

-

Specifications and Customization: Customized formulations, branding, or packaging increase costs. Standard formulations tend to be more economical, but tailored solutions can command premium pricing.

-

Materials and Certifications: Organic, biodegradable, or certified ingredients (e.g., eco-labels, safety certifications) often come at a premium but can open access to niche or premium markets.

-

Supplier Capabilities and Reliability: Well-established suppliers with reliable delivery, quality certifications, and good track records may charge higher prices but reduce supply chain risks.

-

Incoterms and Delivery Terms: FOB (Free on Board) or CIF (Cost, Insurance, Freight) terms influence pricing structure. Buyers should consider additional costs such as insurance, customs duties, and inland transportation.

Strategic Buyer Tips

-

Negotiate Effectively: Leverage your purchase volume, long-term commitments, and market insights to negotiate better prices. Don’t shy away from requesting detailed cost breakdowns to identify areas for cost savings.

-

Prioritize Total Cost of Ownership (TCO): Consider not just the unit price but also costs associated with quality, compliance, logistics, and post-sale support. Cheaper products may incur higher downstream costs or quality issues.

-

Understand Pricing Nuances for International Sourcing: Customs duties, taxes, and import regulations differ across regions like Africa, South America, the Middle East, and Europe. Familiarize yourself with local tariffs and standards to avoid unexpected costs.

-

Factor in Lead Times and Flexibility: Suppliers with shorter lead times or flexible MOQs can reduce inventory costs and improve responsiveness, often justifying a slight premium.

Price Range and Indicative Costs

While prices vary widely based on specifications and supplier country, typical FOB prices for standard suede shoe cleaner formulations can range from $2 to $6 per liter for bulk orders of 1,000 liters or more. Premium, certified, or customized products may reach $8 to $15 per liter.

Disclaimer: These prices are indicative and should be validated through direct supplier quotations, considering your specific requirements, order volumes, and logistics arrangements.

By understanding these cost drivers and market influences, B2B buyers from Africa, South America, the Middle East, and Europe can better negotiate, optimize their procurement strategies, and ensure a balance between cost-efficiency and quality in sourcing suede shoe cleaners.

Spotlight on Potential suede shoe cleaner Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for suede shoe cleaner.)*

Essential Technical Properties and Trade Terminology for suede shoe cleaner

Critical Technical Properties for Suede Shoe Cleaners

1. Material Compatibility:

This refers to the cleaner’s ability to effectively treat suede without damaging its delicate fibers. High-quality suede cleaners are formulated to be pH-balanced and free of harsh chemicals, ensuring they preserve the texture, color, and integrity of various suede grades. For B2B buyers, verifying material compatibility prevents costly product returns and maintains brand reputation across diverse markets.

2. Cleaning Efficacy (Performance Rating):

This metric indicates the product’s ability to remove stains, dirt, and oils from suede surfaces. It is often assessed through standardized testing, with ratings from low to high efficacy. A high-performance cleaner reduces re-treatment needs, enhances customer satisfaction, and supports premium branding strategies.

3. Drying Time:

The duration required for the suede to dry after cleaning impacts operational efficiency. Faster drying times (typically under 30 minutes) enable quicker turnaround, especially critical for commercial shoe repair shops or retailers handling high volume. B2B buyers should consider products with predictable and consistent drying profiles.

4. Packaging and Storage Stability:

This property relates to the product’s shelf life, resistance to leakage, and ease of handling. Reliable packaging—such as airtight bottles or spray cans—ensures product stability during transit and storage. For international trade, packaging standards may vary; thus, understanding local regulations and storage conditions is vital.

5. Safety and Environmental Compliance:

Suede cleaners must meet industry safety standards, including VOC (Volatile Organic Compounds) limits and eco-label certifications. Compliance ensures the product can be legally sold across different regions, especially in markets with strict environmental regulations like Europe or certain Middle Eastern countries.

6. Concentration and Dilution Ratio:

This indicates how much product is needed per application, impacting cost-efficiency. Products with clear dilution instructions help businesses optimize usage and inventory management, reducing waste and maximizing margins.

Essential Trade Terms for Suede Shoe Cleaner Market

1. OEM (Original Equipment Manufacturer):

Refers to companies that produce products or components that are rebranded and sold by other firms. In the context of suede cleaners, OEM agreements allow B2B buyers to source private-label products, fostering brand differentiation in competitive markets like Europe or South America.

2. MOQ (Minimum Order Quantity):

The smallest amount of product a supplier is willing to sell in a single order. Understanding MOQs helps buyers plan inventory and negotiate pricing, particularly when entering new markets or testing product acceptance.

3. RFQ (Request for Quotation):

A formal process where buyers solicit price quotes and terms from multiple suppliers. Effective RFQs enable comparative analysis of product quality, pricing, and delivery timelines, ensuring informed procurement decisions.

4. Incoterms (International Commercial Terms):

Standardized trade terms published by the International Chamber of Commerce, defining responsibilities for shipping, insurance, and tariffs. Familiarity with Incoterms (e.g., FOB, CIF) ensures clarity in international transactions, reducing delivery risks and unexpected costs.

5. Lead Time:

The period between placing an order and receiving the goods. For international buyers, understanding lead times is crucial for inventory planning, especially when managing supply chains across continents like Africa or the Middle East.

6. Certification & Regulatory Compliance:

Includes product safety, environmental standards, and quality certifications (e.g., ISO, REACH). Ensuring suppliers meet these standards facilitates market entry and reduces legal risks, particularly in tightly regulated regions like Europe or South America.

Summary:

A thorough understanding of these technical properties and trade terms enables B2B buyers to make informed decisions, negotiate effectively, and ensure the consistent quality of suede shoe cleaners across international markets. Recognizing regional regulatory nuances and logistical considerations can significantly enhance supply chain resilience and customer satisfaction.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the suede shoe cleaner Sector

Market Overview & Key Trends

The global suede shoe cleaner sector is experiencing dynamic shifts driven by evolving consumer preferences, technological advancements, and supply chain innovations. Increasing awareness of footwear maintenance and fashion sustainability has expanded demand across multiple regions, notably in Europe, the Middle East, Africa, and South America. European markets, especially the UK and Germany, are characterized by high consumer standards for premium and eco-friendly products, pushing B2B suppliers to innovate with sustainable formulations and efficient packaging solutions.

Emerging B2B sourcing trends include the adoption of advanced formulations that combine cleaning efficacy with environmental safety, driven by stricter regulations and consumer demand for eco-conscious brands. Digital procurement platforms and supply chain transparency tools are becoming essential, enabling buyers from Africa and South America to access vetted, compliant suppliers globally. Furthermore, automation in manufacturing and quality control processes enhances consistency and reduces costs, making products more competitive internationally.

Market dynamics indicate a rising preference for concentrated formulations, which reduce shipping costs and environmental impact—an attractive proposition for importers and distributors in emerging markets. Additionally, the integration of smart labeling and traceability systems supports compliance with international standards, fostering trust among B2B partners. As sustainability regulations tighten, especially in Europe and the Middle East, buyers are prioritizing suppliers committed to ethical sourcing and environmentally friendly production practices.

For international buyers, understanding these trends means aligning procurement strategies with technological innovations and regulatory landscapes. Building relationships with suppliers who emphasize transparency, quality, and sustainability will be critical to maintaining competitive advantage and meeting evolving market expectations.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone of strategic sourcing in the suede shoe cleaner industry. Environmental impacts associated with chemical use, packaging waste, and transportation are under increasing scrutiny from regulators and consumers alike. Buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers that demonstrate commitment to reducing ecological footprints through environmentally friendly formulations, biodegradable packaging, and energy-efficient manufacturing processes.

Ethical sourcing is equally vital. The supply chain often involves raw materials such as surfactants and solvents whose origins can raise concerns regarding labor practices and environmental degradation. Suppliers adhering to certifications like ISO 14001 (Environmental Management), Fair Trade, or Global Organic Textile Standard (GOTS) indicate a commitment to responsible practices. These certifications can serve as a reliable benchmark for B2B buyers seeking to ensure compliance with local regulations and consumer expectations.

Illustrative Image (Source: Google Search)

In addition, transparent supply chain management—including traceability of raw materials and adherence to labor standards—fosters trust and reduces risk. For buyers, establishing partnerships with suppliers that provide detailed documentation and third-party audits supports compliance with environmental laws, such as the EU’s Green Deal or the US EPA regulations. Investing in green formulations, such as plant-based or mineral-based cleaning agents, aligns with broader corporate sustainability goals and enhances brand reputation in markets increasingly driven by eco-conscious consumers.

Brief Evolution/History

The development of the suede shoe cleaner sector reflects broader trends in footwear care and chemical innovation. Initially dominated by generic, solvent-based cleaners, the industry has shifted toward specialized, eco-friendly solutions over the past two decades. This evolution was driven by regulatory changes, such as the banning of certain volatile organic compounds (VOCs), and by consumer demand for safer, more sustainable products.

Recent innovations focus on water-based formulations, biodegradable ingredients, and multifunctional products that combine cleaning with conditioning. Technological advancements in formulation science and manufacturing automation have improved product efficacy and consistency, making them more attractive to B2B buyers worldwide. Understanding this evolution enables buyers to anticipate future trends, such as the integration of smart packaging and digital traceability, which will further enhance supply chain transparency and product integrity.

By aligning procurement strategies with these historical shifts, international buyers can better position themselves within a rapidly evolving market, ensuring access to cutting-edge, sustainable solutions that meet both regulatory standards and consumer expectations across diverse regions.

Frequently Asked Questions (FAQs) for B2B Buyers of suede shoe cleaner

-

How can I verify the reliability and credibility of a suede shoe cleaner supplier?

To ensure supplier credibility, conduct thorough due diligence by requesting industry certifications (e.g., ISO, GMP), customer references, and detailed company background information. Review their track record with international clients, especially in your region, and verify their production capacity and compliance with local import regulations. Visiting their facilities or engaging third-party inspection services can provide additional assurance. Establish clear communication channels and request product samples to assess quality firsthand before committing. Partnering with reputable sourcing platforms or trade associations can also help identify verified suppliers with proven quality standards. -

What customization options are typically available for suede shoe cleaners, and how do they impact lead times and costs?

Suppliers often offer customization in formulation (e.g., eco-friendly, hypoallergenic), packaging (labels, sizes), and branding (logo printing). Custom formulations may require additional R&D time, increasing lead times by 2-4 weeks. Customized packaging or branding can add 1-3 weeks depending on complexity. Costs vary based on the level of customization, order volume, and raw material adjustments. To optimize lead times and costs, clearly define your specifications early and negotiate MOQ discounts or flexible options. Establish a detailed timeline with your supplier to align production schedules with your market rollout plans. -

What are typical minimum order quantities (MOQs) and lead times for importing suede shoe cleaner products?

MOQs for suede shoe cleaner usually range from 500 to 5,000 units, depending on supplier size and production capacity. Larger manufacturers tend to offer lower per-unit costs at higher MOQs, while smaller suppliers may require fewer units but at a premium. Lead times generally span 4 to 8 weeks, including manufacturing, quality checks, and shipping. For urgent needs, consider suppliers with faster turnaround options or local distributors. Establish clear communication about your deadlines early to ensure the supplier can meet your delivery schedule, especially when planning for seasonal or promotional campaigns. -

What payment terms are common in international trade for B2B purchases of suede shoe cleaner, and how can I negotiate favorable conditions?

Common payment terms include 30% upfront via wire transfer or letter of credit, with the remaining 70% paid before shipment or upon delivery. Some suppliers may offer net 60 or net 90 days for trusted partners or bulk orders. To negotiate favorable terms, demonstrate your creditworthiness with references or prior purchase history. Consider trade finance options, such as escrow services or documentary collections, to mitigate risk. Building long-term relationships and committing to larger orders can also improve your bargaining power for better payment conditions. -

What quality assurance measures and certifications should I look for in a reputable suede shoe cleaner supplier?

Reputable suppliers should have ISO 9001 or equivalent quality management certifications, ensuring consistent product quality. Look for certifications related to safety and environmental standards, such as REACH or EPA compliance, especially if exporting to Europe or environmentally conscious markets. Request laboratory test reports verifying cleaning efficacy, safety, and absence of harmful chemicals. Suppliers with a robust QA system will perform regular batch testing, provide Certificates of Analysis (CoA), and offer product data sheets. These measures reduce the risk of receiving substandard products and facilitate compliance with your local regulations. -

How can I efficiently manage logistics and shipping for international B2B purchases of suede shoe cleaner?

Partner with freight forwarders experienced in international trade, particularly those familiar with your target regions. Choose shipping methods based on cost, speed, and product sensitivity—air freight for urgent needs, sea freight for bulk shipments, and consider FOB or CIF incoterms for clarity on responsibilities. Ensure your supplier provides comprehensive documentation, including bills of lading, export licenses, and certificates of origin. Factor in customs clearance procedures, import duties, and taxes specific to your country. Establish a tracking system and maintain open communication with logistics providers to address delays proactively. -

What should I do if there is a dispute over product quality or delivery terms?

Address disputes promptly through clear communication with your supplier, referencing contractual agreements, quality standards, and documented evidence such as photos or lab reports. Negotiate amicably to reach an acceptable resolution, whether through product replacement, refund, or partial credit. If necessary, involve third-party inspection agencies or mediators specializing in international trade disputes. Maintain detailed records of all correspondence, inspection reports, and shipping documentation to support your case. Establishing a dispute resolution clause in your contract can streamline future issues and reduce risks. -

What are the key factors to consider when selecting a suede shoe cleaner supplier for long-term partnership?

Prioritize suppliers with consistent product quality, reliable delivery, and transparent communication. Assess their capacity to scale with your business growth and their willingness to support customization or new formulations. Evaluate their compliance with international standards and environmental policies, especially for markets with strict regulations like Europe. Strong after-sales support, flexible payment terms, and proactive problem-solving are critical for a sustainable partnership. Building trust through regular audits, feedback, and shared goals ensures a mutually beneficial relationship that adapts to changing market demands.

Strategic Sourcing Conclusion and Outlook for suede shoe cleaner

Strategic Sourcing Conclusion and Outlook for suede shoe cleaner

Effective strategic sourcing is essential for B2B buyers seeking high-quality suede shoe cleaners that meet diverse market needs. By prioritizing supplier reliability, product innovation, and sustainable practices, buyers can secure competitive advantages and build resilient supply chains. Recognizing regional sourcing options—from Asia to Europe—allows for better cost management, quality assurance, and compliance with local regulations.

Illustrative Image (Source: Google Search)

For buyers in Africa, South America, the Middle East, and Europe, leveraging global supplier networks offers opportunities to access innovative formulations, eco-friendly products, and scalable manufacturing solutions. Establishing strong supplier relationships and conducting thorough market research will enable more agile responses to evolving consumer preferences and regulatory standards.

Looking ahead, the demand for premium, sustainable suede shoe cleaners is poised to grow as consumers become more environmentally conscious. International buyers should capitalize on emerging sourcing trends, diversify supplier bases, and invest in strategic partnerships. Proactive sourcing decisions today will position your business for long-term success in a competitive global marketplace—driving growth, innovation, and sustainability in the suede care industry.