Master Global Sourcing Strategies for Tennis Shoes on Sale

Guide to Tennis Shoes On Sale

- Introduction: Navigating the Global Market for tennis shoes on sale

- Understanding tennis shoes on sale Types and Variations

- Key Industrial Applications of tennis shoes on sale

- Strategic Material Selection Guide for tennis shoes on sale

- In-depth Look: Manufacturing Processes and Quality Assurance for tennis shoes on sale

- Comprehensive Cost and Pricing Analysis for tennis shoes on sale Sourcing

- Spotlight on Potential tennis shoes on sale Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for tennis shoes on sale

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the tennis shoes on sale Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of tennis shoes on sale

- Strategic Sourcing Conclusion and Outlook for tennis shoes on sale

Introduction: Navigating the Global Market for tennis shoes on sale

In the highly competitive and dynamic landscape of global footwear trade, tennis shoes on sale represent a lucrative opportunity for B2B buyers seeking quality products at optimal prices. For importers and distributors across Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Egypt—understanding the nuances of this sector is vital for securing a competitive edge. Sourcing the right tennis shoes not only enhances your product portfolio but also drives customer satisfaction and brand loyalty in diverse markets.

This comprehensive guide aims to empower international buyers with critical insights into the entire supply chain—covering product types, materials, manufacturing standards, quality control, supplier selection, and cost analysis. Additionally, it offers actionable strategies to navigate market fluctuations, identify reliable partners, and optimize procurement processes. Whether you are exploring bulk orders or seeking innovative designs, this resource equips you with the knowledge necessary for informed decision-making.

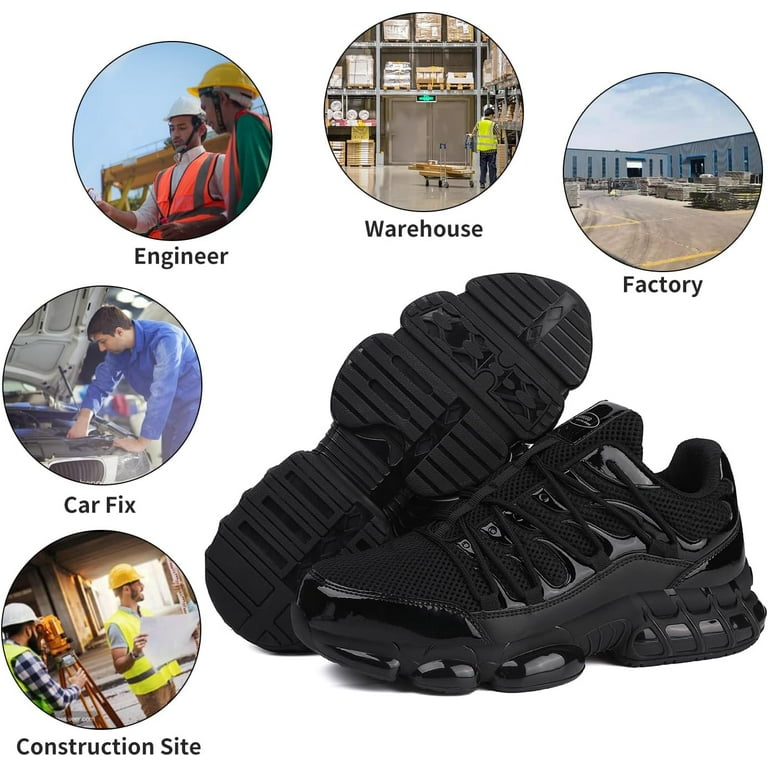

Illustrative Image (Source: Google Search)

By delving into market trends, supplier landscapes, and common FAQs, this guide ensures that B2B buyers can approach their sourcing with confidence and clarity. Understanding the complexities of global sourcing—especially in regions with varying regulations and market demands—is essential for maximizing value and establishing sustainable supply relationships. Ultimately, this guide is your strategic partner in unlocking the full potential of tennis shoes on sale in the international marketplace.

Understanding tennis shoes on sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Performance Tennis Shoes | Lightweight, breathable materials with advanced cushioning | Sporting goods, sportswear retailers | Pros: High demand among athletes, margin potential; Cons: Rapid obsolescence, high R&D costs |

| Court-Specific Shoes | Designed for specific surfaces (clay, grass, hard court) | Specialty sports stores, tennis clubs | Pros: Niche market appeal, premium pricing; Cons: Inventory complexity, limited versatility |

| Casual/Hybrid Tennis Shoes | Stylish, versatile with casual aesthetics | Fashion retailers, multi-sport outlets | Pros: Broader market appeal, year-round sales; Cons: Lower performance features |

| Eco-Friendly Tennis Shoes | Made from sustainable or recycled materials | Green-focused retailers, eco-conscious brands | Pros: Growing demand, brand differentiation; Cons: Higher manufacturing costs, limited supplier options |

| Customizable Tennis Shoes | Allow personalization (colors, logos) | Sports teams, promotional product suppliers | Pros: High customer engagement, premium pricing; Cons: Increased production complexity, longer lead times |

Performance Tennis Shoes

Performance tennis shoes are engineered for athletes, emphasizing lightweight construction, superior cushioning, and enhanced stability. They typically incorporate advanced materials such as mesh uppers for breathability and specialized outsoles for grip on various court surfaces. For B2B buyers, these shoes are ideal for sports retailers targeting competitive players or sports clubs. The main consideration is balancing quality with cost, as high-performance features can elevate manufacturing expenses. Additionally, rapid technological advancements mean inventory can quickly become outdated, necessitating close supplier relationships and agile supply chains.

Court-Specific Shoes

Designed for optimal play on specific surfaces—clay, grass, or hard courts—these shoes feature specialized outsoles and tread patterns to maximize traction and durability. B2B buyers in niche markets such as tennis clubs or specialty sports stores benefit from stocking these shoes as premium offerings. Their key advantage is catering to dedicated players willing to pay a premium for surface-specific performance. However, inventory management becomes complex due to multiple variants, and the limited versatility may restrict sales volume. Effective supplier partnerships are crucial to ensure consistent quality and timely delivery.

Illustrative Image (Source: Google Search)

Casual/Hybrid Tennis Shoes

Blending tennis shoe aesthetics with casual or fashion-oriented designs, these shoes appeal to a broader consumer base beyond serious athletes. They often feature trendy colors, stylish materials, and comfort-focused features suitable for everyday wear. For B2B buyers, these shoes offer opportunities for year-round sales in fashion retail outlets or multi-sport stores. The main advantage is higher sales volume due to wider appeal, though they may lack the advanced performance features demanded by professional players. Pricing strategies should reflect their hybrid nature to maximize margins.

Eco-Friendly Tennis Shoes

With increasing environmental consciousness, eco-friendly tennis shoes made from recycled or sustainable materials are gaining traction. These shoes appeal to eco-conscious consumers and brands aiming to enhance sustainability credentials. B2B buyers in green retail sectors or those targeting eco-focused markets can leverage this trend for differentiation. Challenges include higher manufacturing costs and limited supplier options, which can impact pricing and supply chain stability. Clear communication of environmental benefits can enhance market acceptance and brand loyalty.

Customizable Tennis Shoes

Offering personalization options such as color schemes, logos, or even bespoke designs, customizable tennis shoes serve niche markets like sports teams or promotional campaigns. B2B buyers can capitalize on premium pricing and high customer engagement. The main considerations include longer lead times, increased production complexity, and the need for flexible manufacturing processes. Establishing reliable customization partners and ensuring quality control are vital to meet client expectations and maintain brand reputation.

Key Industrial Applications of tennis shoes on sale

| Industry/Sector | Specific Application of tennis shoes on sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports & Recreation | Athletic footwear for sports academies, gyms, and recreational centers | Supports athlete performance and safety, enhances brand reputation | Durability, comfort, branding options, and compliance with sports standards |

| Manufacturing & Logistics | Work footwear for warehouse staff and delivery personnel | Improves worker safety and comfort, reduces injury-related costs | Slip resistance, lightweight design, cost-effectiveness, and bulk sourcing |

| Hospitality & Tourism | Staff uniforms for hotels, resorts, and tour operators | Ensures staff comfort, promotes a professional image | Style consistency, durability, ease of cleaning, and supply chain reliability |

| Healthcare & Wellness | Footwear for hospital staff, physiotherapy clinics, and wellness centers | Promotes hygiene, comfort, and injury prevention | Hygiene standards, non-slip soles, ergonomic design, and sourcing flexibility |

| Retail & Wholesale | Retail distribution of tennis shoes for end consumers | Expands product offerings, enhances sales volume | Competitive pricing, variety in sizes and styles, reliable logistics |

Athletic Footwear for Sports & Recreation

Tennis shoes on sale are extensively used in sports academies, gyms, and recreational centers across Africa, South America, the Middle East, and Europe. These shoes support athletic performance, offering cushioning, stability, and traction essential for diverse sports activities. B2B buyers should prioritize sourcing options that emphasize durability and comfort, especially for high-usage environments. Custom branding opportunities can also add value for sports teams or academies, making the shoes a promotional asset. Ensuring compliance with international sports standards enhances product credibility and appeal in competitive markets.

Work Footwear in Manufacturing & Logistics

In manufacturing plants and logistics hubs, tennis shoes serve as reliable work footwear for warehouse staff and delivery personnel. These shoes help mitigate workplace hazards by providing slip resistance and ergonomic support, reducing injury risks and associated costs. For international buyers, sourcing lightweight, durable, and cost-effective shoes in bulk is crucial. Suppliers offering customizable features such as reinforced toes or slip-resistant soles aligned with safety standards can significantly enhance operational efficiency and worker satisfaction.

Hospitality & Tourism Staff Uniforms

Hotels, resorts, and tour operators in regions like Egypt, Saudi Arabia, and South America utilize tennis shoes as part of staff uniforms. These shoes ensure staff members remain comfortable during long shifts while maintaining a professional appearance. B2B buyers should focus on sourcing shoes that are stylish yet durable, easy to clean, and suitable for various climates. Consistent supply chains and options for branding or color matching can help hospitality providers reinforce their brand identity and improve guest experiences.

Healthcare & Wellness Sector

Healthcare facilities and wellness centers increasingly adopt tennis shoes for staff due to their hygiene, comfort, and injury prevention features. Non-slip soles, ergonomic design, and breathable materials are critical for maintaining safety standards and staff wellbeing. International buyers should seek suppliers compliant with medical safety standards, with options for custom sizing and styles that meet institutional branding requirements. Reliable sourcing ensures continuous supply to meet the high demands of healthcare environments.

Retail & Wholesale Distribution

Retailers and wholesalers play a key role in distributing tennis shoes to end consumers across diverse markets. Offering a broad range of styles, sizes, and price points helps meet varied consumer preferences in Africa, South America, and Europe. Sourcing strategies should focus on competitive pricing, quality consistency, and dependable logistics to ensure timely delivery. Building strong relationships with manufacturers can facilitate customization and volume discounts, boosting sales and market share in competitive retail landscapes.

Strategic Material Selection Guide for tennis shoes on sale

Material Analysis for Tennis Shoes on Sale

Selecting the appropriate materials for tennis shoes is critical for ensuring product performance, durability, and compliance with regional standards. For international B2B buyers from Africa, South America, the Middle East, and Europe, understanding the properties and limitations of common materials can facilitate better sourcing decisions, cost management, and market suitability.

Synthetic Leather (Polyurethane-based)

Key Properties:

Synthetic leather, primarily made from polyurethane (PU), offers a lightweight, flexible, and cost-effective alternative to genuine leather. It provides decent breathability and can be engineered to resist moisture and abrasion. Its surface can be textured or smooth, allowing for aesthetic versatility.

Pros & Cons:

Advantages include lower cost, easier manufacturing, and consistent quality. It is also more environmentally friendly than animal leather, aligning with certain regional preferences. However, synthetic leather tends to have lower durability under extreme conditions and may crack or peel over time, especially when exposed to UV radiation or high humidity.

Impact on Application:

Synthetic leather performs well in indoor courts and dry climates but may degrade faster in humid or salty environments, such as coastal regions of Africa or the Middle East. It also responds well to standard manufacturing processes, making it suitable for mass production.

Regional Considerations:

Buyers should verify compliance with regional standards like ASTM or EN ISO for material safety and environmental impact. For markets like Egypt or Saudi Arabia, where consumers favor durable and stylish footwear, sourcing high-quality synthetic leather that resists cracking and fading is essential. Additionally, manufacturers should consider eco-labeling and sustainability certifications to meet regional consumer expectations.

Mesh Fabric (Nylon, Polyester)

Key Properties:

Mesh fabrics are lightweight, highly breathable, and moisture-wicking, making them ideal for uppers in tennis shoes. They can be engineered with varying pore sizes for enhanced airflow and can incorporate moisture barriers or anti-microbial treatments.

Pros & Cons:

The primary advantage is breathability, which enhances comfort during extended play. Mesh fabrics are also flexible and easy to mold into different shoe designs. However, they are less resistant to tearing and may require reinforcement in high-stress areas, increasing manufacturing complexity and cost.

Impact on Application:

Mesh is suitable for hot and humid climates common in many African and South American regions, providing ventilation and reducing sweat accumulation. It performs well in dry environments but may absorb dust and dirt, requiring additional cleaning or protective coatings.

Regional Considerations:

Buyers should ensure mesh materials meet local standards for safety and environmental impact, such as REACH in Europe or local chemical regulations. For Middle Eastern markets, UV-resistant coatings can extend lifespan. Suppliers should also consider sourcing from regions with reliable quality control to prevent issues like fraying or premature wear.

Rubber and Thermoplastic Elastomers (TPE)

Key Properties:

Rubber and TPE are widely used for outsoles due to their excellent grip, flexibility, and shock absorption. They can be formulated for specific hardness levels, impacting traction and durability.

Pros & Cons:

Rubber offers high durability, chemical resistance, and slip resistance, making it ideal for outsole applications. TPE provides similar benefits with easier processing and potential cost savings. The main limitations include higher weight and possible manufacturing complexity for custom tread patterns.

Impact on Application:

These materials are suitable for various terrains, including courts, outdoor paths, and uneven surfaces. Their resistance to temperature fluctuations makes them suitable for diverse climates, from the hot Middle East to cooler European regions.

Regional Considerations:

Buyers should confirm that rubber compounds comply with local environmental and safety standards, such as RoHS or REACH. For African and South American markets, sourcing from suppliers with proven resistance to heat and UV exposure ensures longer-lasting soles. Additionally, the choice of eco-friendly or recycled rubber can appeal to environmentally conscious consumers in these regions.

Summary Table of Material Characteristics

| Material | Typical Use Case for tennis shoes on sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Synthetic Leather | Shoe uppers, overlays | Cost-effective, consistent quality | Lower durability, prone to cracking in UV | Med |

| Mesh Fabric | Uppers, ventilation panels | Breathability, lightweight | Less resistant to tearing, dirt absorption | Low |

| Rubber/TPE Outsoles | Outsoles and tread patterns | High durability, slip resistance | Heavier, manufacturing complexity | Med |

| Thermoplastic Elastomers | Outsole components, flexible zones | Flexibility, shock absorption | Higher cost, processing complexity | High |

This comprehensive understanding of material properties, regional considerations, and compliance standards will enable B2B buyers to select optimal materials that balance performance, cost, and market expectations across diverse regions.

In-depth Look: Manufacturing Processes and Quality Assurance for tennis shoes on sale

Manufacturing Processes of Tennis Shoes

The production of tennis shoes involves a complex series of stages designed to ensure durability, performance, and comfort. For B2B buyers, understanding these processes helps evaluate supplier capabilities and product quality.

1. Material Preparation

The process begins with sourcing and preparing raw materials such as synthetic leathers, mesh fabrics, rubber compounds, EVA foam, and thermoplastics. Suppliers often source these materials from reputable vendors that meet international standards like ISO 9001. Material inspection at this stage (Incoming Quality Control, IQC) verifies conformity to specifications, ensuring consistency and quality.

2. Forming and Molding

The midsole and outsole are typically molded using injection or compression molding techniques. High-precision molds are used to shape components with tight tolerances. Thermoplastic components and rubber compounds are heated and injected into molds under controlled conditions, ensuring uniformity and dimensional stability.

3. Assembly

The various components—upper, midsole, outsole, insole, and laces—are assembled through a combination of stitching, gluing, and heat bonding. Automated machinery often performs stitching with computerized control for consistency, while gluing processes utilize industrial adhesives tested for durability and flexibility. Assembly lines incorporate ergonomic and safety standards aligned with industry best practices.

4. Finishing and Quality Checks

Final steps include trimming excess material, applying branding (logos, tags), and surface treatments like polishing or coating. Shoes undergo multiple inspections to detect visual defects, structural issues, or inconsistencies. Finishing ensures that each pair meets functional and aesthetic standards before packaging.

Quality Assurance (QA) and Control Measures

Quality assurance in tennis shoe manufacturing is critical for international trade, especially for B2B buyers from diverse regions. Adherence to internationally recognized standards and rigorous QC checkpoints are essential.

1. International Standards and Certifications

– ISO 9001: Most reputable manufacturers operate under ISO 9001 certification, ensuring a systematic approach to quality management. This includes documented procedures, process controls, and continuous improvement mechanisms.

– CE Marking: For European markets, compliance with CE requirements confirms conformity to safety, health, and environmental protection standards.

– Other Certifications: Depending on the target market, certifications like ASTM, REACH (for chemical safety), and ISO 14001 (environmental management) may also be relevant.

2. QC Checkpoints in Manufacturing

– Incoming Quality Control (IQC): Inspection of raw materials and components upon arrival to verify specifications, batch consistency, and absence of defects.

– In-Process Quality Control (IPQC): Continuous monitoring during production stages such as molding, assembly, and finishing. Techniques include dimensional checks, weight measurements, and process parameter audits.

– Final Quality Control (FQC): Thorough inspection of finished shoes for visual defects, structural integrity, and compliance with specifications. This includes testing for sole adhesion, stitching strength, and surface finish.

3. Testing Methods

– Physical Testing: Flexibility, tensile strength, abrasion resistance, and shock absorption tests ensure durability.

– Environmental Testing: Resistance to moisture, temperature variations, and UV exposure prolongs product lifespan in diverse climates.

– Performance Testing: Traction, grip, and stability are assessed, especially crucial for tennis shoes designed for specific court surfaces.

4. Third-Party Inspections and Audits

B2B buyers should engage third-party inspection agencies (e.g., SGS, Bureau Veritas, Intertek) to validate factory QC processes and product compliance before shipment. Regular audits of manufacturing facilities help verify adherence to contractual quality standards, environmental practices, and labor laws.

Verifying Supplier Quality for International Buyers

For buyers from Africa, South America, the Middle East, and Europe, verifying supplier QC is vital to mitigate risks and ensure product conformity.

- Factory Audits: Conduct comprehensive on-site audits focusing on process controls, worker safety, environmental compliance, and record-keeping. Audits can be facilitated directly or through third-party agencies familiar with local manufacturing landscapes.

- Review of QC Reports: Request detailed QC reports, batch testing results, and certification documents. These should include test methods, pass/fail criteria, and traceability data.

- Sample Testing: Prior to large orders, request and test samples under relevant conditions to confirm quality attributes and performance specifications.

- Supply Chain Transparency: Ensure that the manufacturer maintains clear documentation of materials, processes, and inspections to facilitate traceability and accountability.

Special Considerations for Diverse Markets

Different regions impose varying standards and expectations. For example:

- European Market (e.g., Saudi Arabia, Egypt): Emphasize compliance with CE marking, chemical safety (REACH), and environmental standards. Buyers should prioritize manufacturers with ISO 9001 and ISO 14001 certifications and conduct periodic audits to verify ongoing compliance.

- African and South American Markets: Focus on durability and resistance to local environmental conditions like high humidity, heat, or rough terrain. Suppliers should provide detailed testing data related to environmental resilience, and buyers should verify factory adherence through audits or third-party inspections.

- Middle Eastern Markets: Consider climatic factors such as extreme heat and dust. Manufacturers should demonstrate environmental testing results and supply shoes with appropriate surface treatments and materials suited for these conditions.

Final Recommendations for B2B Buyers

- Establish Clear Quality Specifications: Define detailed product standards, testing requirements, and certification needs upfront in procurement agreements.

- Conduct Due Diligence: Leverage third-party inspection agencies and audit reports to verify supplier claims and capabilities.

- Implement Sampling and Testing Protocols: Test samples from initial batches to validate quality before committing to large-scale orders.

- Maintain Continuous Communication: Regularly engage with suppliers regarding QC processes, improvements, and compliance updates, especially when entering new markets or working with new manufacturers.

By understanding the detailed manufacturing processes and implementing rigorous quality assurance measures, international B2B buyers can confidently source high-quality tennis shoes that meet their regional standards and customer expectations.

Comprehensive Cost and Pricing Analysis for tennis shoes on sale Sourcing

Cost Structure Breakdown

Understanding the detailed cost components involved in sourcing tennis shoes on sale is essential for international B2B buyers aiming to optimize procurement strategies. The primary cost elements include:

-

Materials: The choice of upper fabrics (mesh, synthetic leather, knit), midsoles (EVA, rubber), outsoles, and laces significantly impacts the base cost. Higher-quality, durable materials or eco-friendly options tend to command premium prices but may appeal to specific markets.

-

Labor: Manufacturing labor costs vary widely, influenced by the sourcing country. For example, Asian countries like Vietnam and China typically offer lower labor costs, whereas factories in Europe or the Middle East might have higher wages, affecting overall price points.

-

Manufacturing Overhead: This encompasses factory operation expenses, equipment depreciation, and utility costs. Efficient, automated factories can reduce overhead, but initial investments or complex customization can increase it.

-

Tooling and Development: Custom molds, patterns, and prototype development are often one-time costs but can significantly influence initial pricing, especially for bespoke or branded shoes.

-

Quality Control & Certifications: Ensuring consistent quality through QC processes and obtaining certifications (e.g., ISO, environmental standards) may add to costs but reduce downstream issues like returns or reputational damage.

-

Logistics & Incoterms: Freight, customs duties, taxes, and insurance are pivotal. FOB (Free on Board) terms transfer costs to the buyer at port, while CIF (Cost, Insurance, Freight) includes these in the price. Buyers from Africa and South America should account for longer transit times and higher freight costs, whereas European buyers might benefit from proximity to manufacturing hubs.

-

Profit Margin: Suppliers typically add a markup ranging from 10% to 30%, depending on volume, customization, and relationship strength. Larger orders often secure better margins.

Price Influencers and Market Dynamics

Several factors influence the final pricing and negotiations:

-

Order Volume & MOQ: Larger orders generally attract discounts due to economies of scale. Buyers should negotiate for favorable MOQs aligned with their demand forecasts to reduce per-unit costs.

-

Customization & Specifications: Customized designs, branding, or specialized features (e.g., enhanced grip, eco-materials) increase costs. Clear communication about specifications helps avoid hidden charges.

-

Material Choices: Premium or sustainable materials elevate costs but can be leveraged as unique selling points in target markets, especially in Europe and Middle Eastern countries emphasizing eco-conscious products.

-

Quality Certifications: Certifications like ISO, environmental standards, or fair labor practices may add to costs but are increasingly demanded by consumers and regulators, especially in Europe and the Middle East.

-

Supplier Factors: Factory reputation, production capacity, lead times, and reliability influence pricing. Established suppliers may command higher prices but offer better quality assurance and consistency.

-

Incoterms & Shipping Terms: Buyers should analyze shipping costs and responsibilities. For example, FOB terms are preferable for buyers capable of managing logistics, whereas CIF may simplify procurement but could be costlier.

Strategic Tips for International B2B Buyers

-

Negotiate for Volume Discounts: Larger orders can significantly reduce per-unit costs. Establish long-term relationships to secure better terms over multiple transactions.

-

Focus on Total Cost of Ownership (TCO): Consider all costs—product price, shipping, customs duties, warehousing, and after-sales support—to accurately evaluate affordability.

-

Leverage Multiple Suppliers: Diversify sourcing to mitigate risks related to geopolitical issues, supply chain disruptions, or quality inconsistencies.

-

Understand Pricing Nuances: Be aware of hidden costs such as currency fluctuations, import taxes, or additional charges for expedited shipping.

-

Market-Specific Considerations: For African and South American buyers, prioritize suppliers with experience exporting to your region to minimize customs delays and ensure compliance with local standards. European buyers should consider sustainability certifications and quality standards favored in the EU.

Indicative Price Ranges (Disclaimer)

While prices vary based on specifications and supplier relationships, typical FOB prices for standard tennis shoes on sale range from $10 to $25 per pair for bulk orders (e.g., 1,000+ units). Premium or customized models can range from $25 to $50+ per pair. Freight, duties, and taxes can add approximately 15-30% to the landed cost depending on the destination.

In summary, successful sourcing involves balancing material quality, manufacturing costs, logistics, and strategic negotiations. Tailoring your approach to regional market demands and supply chain nuances will help achieve optimal pricing and reliable supply.

Spotlight on Potential tennis shoes on sale Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for tennis shoes on sale.)*

Essential Technical Properties and Trade Terminology for tennis shoes on sale

Critical Technical Properties of Tennis Shoes for B2B Buyers

1. Material Composition and Grade

The choice of materials—such as synthetic leather, mesh fabrics, or rubber compounds—directly impacts durability, breathability, and overall performance. High-grade materials ensure longer product life and better customer satisfaction, especially in markets with diverse climate conditions like Africa, South America, or the Middle East. B2B buyers should verify material certifications and supplier specifications to ensure consistency and compliance with industry standards.

2. Sole Construction and Tread Pattern

The outsole’s design determines grip, stability, and wear resistance. Features such as non-slip tread patterns and reinforced areas for lateral movements are critical for performance and safety. For international buyers, understanding the sole’s construction helps assess suitability for various court surfaces—clay, grass, or hard courts—and ensures the product aligns with local customer preferences.

3. Cushioning and Support Technologies

Advanced cushioning systems (e.g., EVA foam, gel inserts) and support structures (arch support, heel counters) influence comfort during prolonged use. These technical properties are essential selling points, especially in markets where players demand high-performance shoes. Buyers should request detailed specifications and testing reports to confirm product claims.

4. Tolerance Levels and Quality Control

Tolerance refers to the permissible variation in dimensions and weight, ensuring batch-to-batch consistency. Tight tolerances indicate high manufacturing precision, reducing returns and customer complaints. B2B buyers should specify acceptable tolerance ranges in their purchase agreements and request quality assurance documentation.

5. Weight and Flexibility

Lightweight shoes enhance agility, while flexibility affects movement comfort. These properties are crucial for athletes and recreational players alike. Suppliers should provide technical sheets detailing weight per pair and flex rating to enable informed procurement decisions.

Industry and Trade Terms for Tennis Shoe Transactions

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce tennis shoes branded and sold by other companies. Understanding OEM relationships helps buyers negotiate pricing, customization, and exclusivity rights, especially important for regional brands seeking differentiation.

2. MOQ (Minimum Order Quantity)

The smallest quantity of shoes a supplier will accept per order. This term impacts inventory planning and cash flow management. Buyers from emerging markets should negotiate flexible MOQs to mitigate risk and adapt to fluctuating demand.

3. RFQ (Request for Quotation)

A formal process where buyers solicit detailed price and product specifications from multiple suppliers. Effective RFQs enable comparative analysis and better price negotiations, crucial in price-sensitive markets like Egypt or regional Middle Eastern countries.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and tariffs (e.g., FOB, CIF). A clear understanding of Incoterms helps buyers optimize logistics costs and mitigate risks during international transit, especially when dealing with suppliers across continents.

5. Lead Time

The duration from order placement to product delivery. Knowledge of lead times allows buyers to plan inventory and marketing strategies effectively, particularly vital for seasonal tennis markets or promotional sales.

6. Certification and Compliance Terms

Includes certifications such as ISO, CE, or local safety standards. Verifying compliance ensures legal market entry and safety assurance, reducing potential liabilities in diverse regions like Africa or South America.

By mastering these technical properties and trade terms, B2B buyers from diverse regions can make informed purchasing decisions, negotiate effectively, and establish reliable supply chains for tennis shoes that meet their market needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the tennis shoes on sale Sector

Market Overview & Key Trends

The global tennis shoe market is experiencing dynamic shifts driven by technological advancements, evolving consumer preferences, and supply chain innovations. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding these drivers is crucial for strategic sourcing and competitive positioning.

Emerging trends include the adoption of smart manufacturing technologies, such as 3D printing and automation, which reduce lead times and costs while enhancing customization capabilities. Digital platforms and B2B marketplaces are increasingly vital, providing streamlined access to a diverse supplier base and enabling real-time negotiations and order tracking. Additionally, the rise of direct-to-consumer (DTC) models has prompted brands to seek closer supplier relationships, influencing sourcing strategies.

Market dynamics are also shaped by fluctuating raw material costs—particularly rubber, synthetic textiles, and foam—affecting pricing and supplier selection. Geopolitical factors, such as trade tariffs and regional trade agreements, influence sourcing decisions, especially for buyers in Africa and South America seeking to minimize costs and logistical complexities.

For buyers in the Middle East and Europe, proximity to manufacturing hubs in Asia offers logistical advantages, but regional sourcing is gaining traction due to supply chain resilience concerns. Sustainability concerns are prompting shifts toward eco-friendly materials and ethical manufacturing practices, which are increasingly demanded by consumers and regulatory bodies alike.

Overall, B2B buyers should prioritize flexible, transparent, and technologically integrated sourcing channels to navigate these market dynamics effectively. Building strong supplier relationships and leveraging data-driven insights will be key to maintaining competitiveness in this evolving landscape.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a central criterion in the sourcing of tennis shoes, driven by consumer demand, regulatory pressures, and environmental imperatives. For B2B buyers, integrating ethical sourcing practices not only mitigates risks but also enhances brand reputation and market access, especially in regions like Europe and the Middle East where consumer awareness is high.

Illustrative Image (Source: Google Search)

Environmental impacts of tennis shoe manufacturing include high water consumption, chemical use, and waste generation. Eco-conscious buyers are increasingly seeking suppliers that utilize ‘green’ certifications such as ISO 14001 (Environmental Management) and OEKO-TEX (textile safety), which demonstrate adherence to sustainable practices. Additionally, the use of recycled materials—such as recycled rubber, PET textiles, and bio-based foams—reduces reliance on virgin resources and lowers carbon footprints.

Ethical sourcing extends beyond materials to encompass fair labor practices, safe working conditions, and transparent supply chains. Certifications like Fair Trade and SA8000 provide assurance of social compliance, which is vital for maintaining trust across international markets. For buyers from Africa and South America, establishing direct relationships with suppliers holding such credentials can ensure adherence to labor standards and facilitate capacity-building initiatives.

Incorporating sustainability into procurement strategies also involves evaluating supply chain resilience, promoting local sourcing where feasible, and encouraging innovation in biodegradable or low-impact materials. As regulations tighten globally, proactive engagement in sustainable sourcing not only complies with emerging standards but also positions buyers favorably in a competitive landscape increasingly driven by environmental and social governance (ESG) criteria.

Brief Evolution/History (Optional)

The tennis shoe industry has evolved from basic functional footwear to a highly innovative and fashion-driven sector, driven by technological advances and consumer demand for performance and style. Historically, manufacturing was concentrated in regions like East Asia, with mass production focused on cost efficiency. Over time, the industry has shifted toward integrating sustainability and ethical considerations, reflecting broader societal values.

For B2B buyers, understanding this evolution underscores the importance of supplier adaptability and innovation. Early focus on price has shifted to quality, customization, and sustainability, requiring more sophisticated sourcing and vetting processes. The transition also highlights the growing importance of regional manufacturing hubs that can offer agility and compliance with local regulations.

This historical context informs current sourcing strategies, emphasizing the need for transparency, technological integration, and sustainable practices to meet the demands of modern markets. As the industry continues to evolve, forward-looking buyers will benefit from partnerships that prioritize innovation, resilience, and ethical standards, ensuring long-term competitiveness.

Frequently Asked Questions (FAQs) for B2B Buyers of tennis shoes on sale

1. How can I effectively vet tennis shoe suppliers to ensure quality and reliability?

To vet international suppliers thoroughly, start by requesting comprehensive company documentation, including business licenses, export licenses, and certifications (ISO, CE, etc.). Review their product samples for quality, and inquire about their manufacturing processes and quality control procedures. Check references and seek feedback from other buyers, especially those in your region or industry. Utilize third-party verification services or trade associations for supplier audits. Establish clear communication channels and request detailed product specifications, certifications, and compliance documents before committing. A well-vetted supplier reduces risks of substandard quality, delays, and non-compliance issues.

2. What are the best practices for customizing tennis shoes for different markets?

Understand regional preferences, sports standards, and branding requirements before customization. Collaborate closely with suppliers to specify design elements, branding logos, color schemes, and packaging preferences. Confirm the supplier’s capability to handle customized orders, including minimum order quantities (MOQs) and lead times. Ensure clear agreements on intellectual property rights and approval processes for prototypes and samples. Consider local market regulations, such as safety standards and labeling laws. A transparent customization process minimizes errors, accelerates approval, and ensures your product aligns with regional consumer expectations, boosting market acceptance.

3. How do I determine the appropriate MOQ, lead times, and payment terms for international tennis shoe orders?

Discuss these parameters upfront with potential suppliers. MOQs often depend on production scale, customization complexity, and supplier policies; negotiate to find a balance that meets your inventory needs without excessive costs. Lead times vary based on order size, manufacturing capacity, and shipping logistics—confirm these details early to plan your inventory and marketing. Payment terms typically include options like 30% upfront with the balance upon delivery or letter of credit arrangements—choose terms that minimize risk and provide flexibility. Building strong relationships and clear communication fosters smoother transactions and reduces operational uncertainties.

4. What certifications and quality assurance measures should I require from international tennis shoe suppliers?

Request certifications relevant to your target markets, such as ISO 9001 for quality management, environmental standards like ISO 14001, and safety certifications like CE or ASTM. Verify supplier adherence to these standards through audit reports or third-party inspections. Ask for detailed QA procedures, including raw material testing, in-process inspections, and final product audits. Consider requesting third-party lab test reports for durability, slip resistance, and toxicity compliance. These measures ensure your products meet international safety and quality standards, reducing the risk of recalls, legal issues, and damage to brand reputation.

5. How can I optimize logistics and shipping when importing tennis shoes from overseas?

Start by selecting reliable freight forwarders with experience in international B2B shipments, especially to your region. Evaluate different shipping modes—sea freight for cost efficiency on large volumes, air freight for faster delivery, or multimodal options. Clarify Incoterms (e.g., FOB, CIF) with your supplier to define responsibilities and costs. Consolidate shipments to reduce costs and improve tracking. Ensure proper packaging to prevent damage during transit. Stay updated on customs regulations, tariffs, and import duties in your country to avoid delays. Establish a clear logistics plan that balances cost, speed, and reliability for seamless supply chain operations.

6. What should I do if there is a dispute or quality issue with the supplier’s tennis shoes?

Establish clear contractual terms covering quality standards, inspection rights, and dispute resolution procedures before ordering. If issues arise, document the problem thoroughly with photos, samples, and inspection reports. Communicate promptly with the supplier, providing detailed evidence and referencing contractual clauses. Negotiate amicably to seek solutions such as replacements, refunds, or discounts. If unresolved, consider arbitration or mediation through international trade organizations or legal channels based on agreed jurisdiction. Building strong, transparent communication channels and maintaining detailed records help resolve disputes efficiently and protect your business interests.

7. How do I ensure compliance with regional import regulations and standards?

Research your country’s import regulations, including tariffs, taxes, labeling requirements, and safety standards specific to footwear and sports equipment. Work with customs brokers or trade consultants familiar with your region to navigate complex procedures. Ensure your supplier provides necessary documentation such as commercial invoices, packing lists, certificates of origin, and compliance certificates. Implement quality checks aligned with regional standards, and verify that labels meet legal language and informational requirements. Staying compliant minimizes customs delays, fines, and legal risks, ensuring a smooth flow of goods into your market.

8. What are key factors to consider when negotiating price and payment terms with international suppliers?

Focus on establishing transparent pricing that includes all costs—unit price, shipping, customs, and potential surcharges. Negotiate flexible payment terms that balance your cash flow and supplier confidence, such as letters of credit or installment payments. Consider volume discounts, early payment discounts, or long-term partnership incentives. Clarify conditions for price adjustments related to raw material fluctuations or exchange rate changes. Building trust through consistent communication and demonstrating commitment encourages favorable terms. Well-negotiated agreements reduce costs, mitigate risks, and foster mutually beneficial long-term relationships essential for sustainable sourcing.

Strategic Sourcing Conclusion and Outlook for tennis shoes on sale

Final Insights and Future Outlook

Effective strategic sourcing is essential for international B2B buyers seeking competitive advantages in the tennis shoe market. By diversifying supplier bases, leveraging regional manufacturing hubs, and embracing digital procurement tools, buyers from Africa, South America, the Middle East, and Europe can optimize cost, quality, and delivery timelines. Establishing strong supplier relationships and understanding local market dynamics further enhances resilience against supply chain disruptions.

Looking ahead, the global tennis shoe market is expected to continue evolving with innovations in sustainable materials and customization options. Buyers who proactively adapt their sourcing strategies will be better positioned to capitalize on emerging trends and consumer preferences.

Actionable takeaway: Stay informed about regional manufacturing capabilities, prioritize supplier transparency, and incorporate sustainable practices into procurement processes. This approach not only ensures competitive pricing but also builds long-term resilience and brand value.

For international buyers in dynamic regions like Saudi Arabia, Egypt, and beyond, embracing a strategic, forward-looking sourcing model will be key to seizing market opportunities and maintaining a competitive edge in the evolving landscape of tennis shoes on sale.