Master Global Sourcing of Unisa Shoes: The Essential B2B

Guide to Unisa Shoes

- Introduction: Navigating the Global Market for unisa shoes

- Understanding unisa shoes Types and Variations

- Key Industrial Applications of unisa shoes

- Strategic Material Selection Guide for unisa shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for unisa shoes

- Comprehensive Cost and Pricing Analysis for unisa shoes Sourcing

- Spotlight on Potential unisa shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for unisa shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the unisa shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of unisa shoes

- Strategic Sourcing Conclusion and Outlook for unisa shoes

Introduction: Navigating the Global Market for unisa shoes

In today’s highly interconnected global footwear market, Unisa shoes have emerged as a distinctive and highly sought-after brand, recognized for their craftsmanship, innovative designs, and quality materials. For international B2B buyers—particularly from Africa, South America, the Middle East, and Europe—understanding the nuances of sourcing Unisa shoes is crucial to gaining a competitive edge and meeting diverse consumer demands. This guide offers a comprehensive overview of the brand’s product range, manufacturing standards, supplier landscape, and cost considerations, empowering buyers to make informed procurement decisions.

Navigating the complexities of global sourcing involves more than just identifying a supplier; it requires a strategic approach to quality assurance, cost efficiency, and market-specific preferences. Whether sourcing for retail, wholesale, or private label distribution, this guide covers critical aspects such as material selection, manufacturing processes, quality control protocols, and supplier evaluation. Additionally, it addresses common questions related to shipping, customs, and compliance in key regions like Italy, Saudi Arabia, and beyond.

By leveraging these insights, B2B buyers can optimize their sourcing strategies, reduce risks, and unlock new growth opportunities in expanding markets. This guide is designed to serve as an authoritative resource—transforming the challenge of global procurement into a strategic advantage—ensuring your business stays ahead in the competitive world of fashion footwear.

Understanding unisa shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Loafers | Slip-on design, smooth leather finish, minimal embellishments | Fashion retail, luxury boutiques, corporate gifting | Pros: Timeless appeal, versatile for various markets. Cons: Higher price point, limited seasonal variation. |

| Formal Oxfords | Closed lacing system, sleek silhouette, fine craftsmanship | Formalwear markets, corporate clients, luxury segments | Pros: Premium look, high demand in professional sectors. Cons: Longer lead times, delicate materials. |

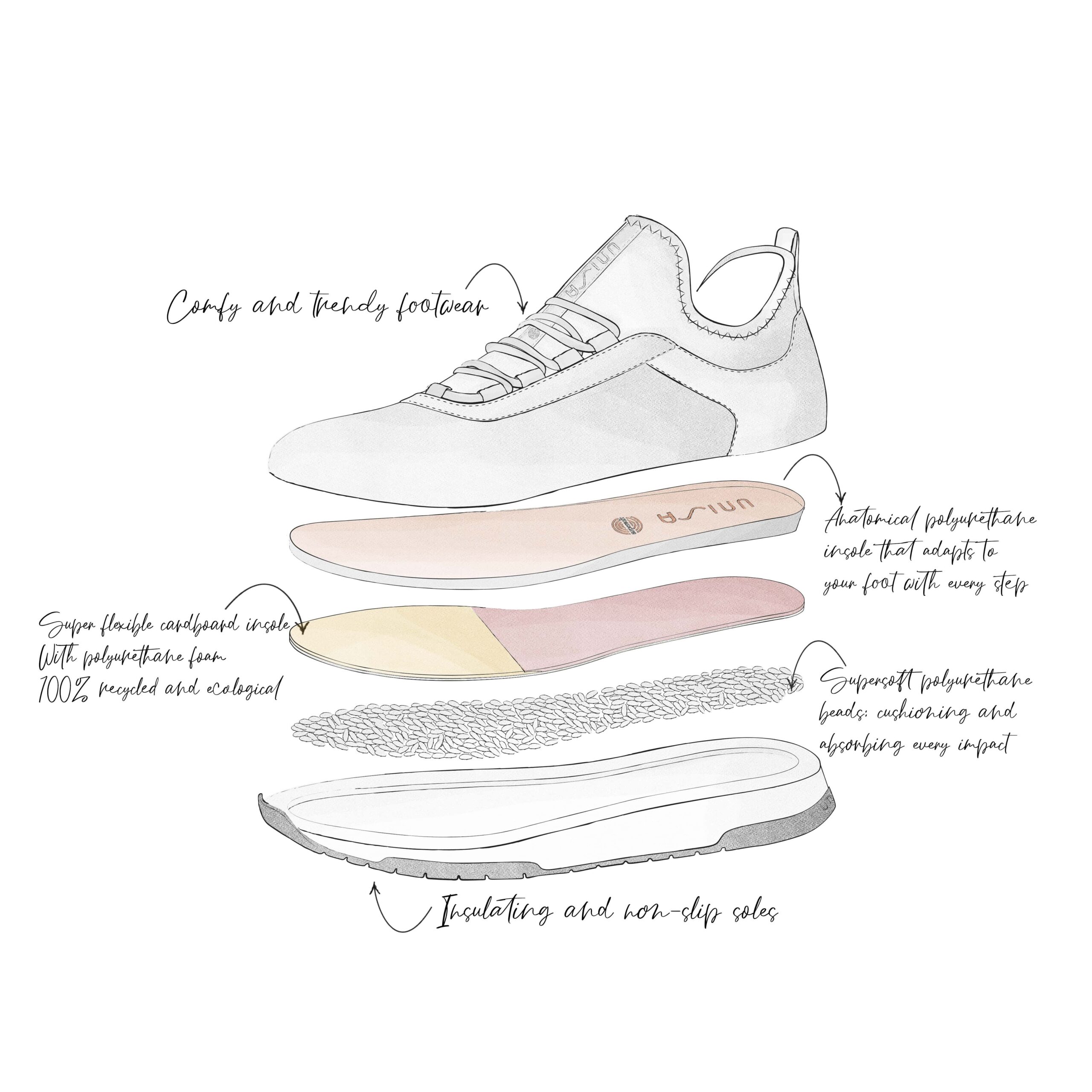

| Casual Sneakers | Comfortable, lightweight, often with sporty detailing | Youth markets, casual wear, lifestyle brands | Pros: High volume sales, broad appeal. Cons: Lower margin, fast fashion cycles require frequent updates. |

| Sandals & Open-Toe Shoes | Open design, breathable materials, often with decorative elements | Summer collections, resort markets, warm climates | Pros: Seasonal demand, niche markets. Cons: Limited year-round sales, durability concerns. |

| Boot Variants | Ankle to knee-high, sturdy construction, often waterproof | Outdoor, workwear, fashion statements | Pros: Durable, high perceived value. Cons: Bulkier logistics, higher import costs, seasonal fluctuations. |

Classic Loafers

Unisa’s classic loafers are characterized by their slip-on design and smooth leather finishes, often with minimal embellishments. These shoes are highly versatile, fitting both formal and casual settings, making them ideal for markets seeking timeless footwear options. For B2B buyers, especially in regions like Europe and the Middle East, sourcing high-quality loafers can cater to luxury retail and corporate gifting segments. Consider lead times and quality assurance, as premium craftsmanship influences customer satisfaction and brand reputation. High-quality leather and craftsmanship demand higher initial investment but often result in better margins and repeat orders.

Formal Oxfords

Oxfords are distinguished by their closed lacing system, sleek silhouette, and meticulous detailing. They are predominantly targeted at formalwear markets, including corporate clients and luxury boutiques across Africa and Europe. B2B buyers should prioritize sourcing Oxfords with durable materials and precise craftsmanship to meet the expectations of high-end markets. These shoes tend to have longer production cycles and higher price points, so establishing reliable supply chains and quality control is crucial. Their premium appeal makes them suitable for bulk orders aimed at professional sectors or seasonal collections.

Casual Sneakers

Unisa’s casual sneakers feature comfortable, lightweight designs often with sporty or trendy detailing. They are particularly popular among youth and lifestyle markets in South America and Africa, where casual and athleisure wear are growing rapidly. For B2B buyers, these shoes offer high-volume sales opportunities but require quick turnaround times and frequent product updates to stay aligned with fashion trends. Margins can be lower, so bulk purchasing and efficient logistics are essential to optimize profitability. They are ideal for brands looking to expand their casual footwear lines or tap into fast fashion cycles.

Sandals & Open-Toe Shoes

Designed for warm climates and summer seasons, Unisa’s sandals and open-toe shoes feature breathable materials and decorative elements. These are suitable for resort markets, summer collections, and seasonal sales in regions like the Middle East and South America. B2B buyers should consider seasonal demand fluctuations and durability, especially for outdoor use. Sourcing quality materials ensures customer satisfaction and reduces return rates. These shoes often have niche appeal but can generate significant seasonal revenue when positioned correctly within a diversified product portfolio.

Boot Variants

Unisa’s range of boots includes ankle boots and knee-high styles, often with sturdy construction and waterproof features. These shoes are favored in outdoor, workwear, and fashion markets across Europe and Africa. For B2B buyers, the focus should be on sourcing durable, high-perceived-value boots suitable for seasonal and year-round sales. Logistics considerations include bulk packaging and shipping costs due to their size and weight. Their higher price point and durability make them attractive for wholesale buyers aiming at premium or rugged market segments, especially during colder months or in outdoor-focused regions.

Key Industrial Applications of unisa shoes

| Industry/Sector | Specific Application of unisa shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive & Manufacturing | Protective footwear for assembly line workers | Ensures safety compliance, reduces injury risk, enhances productivity | Certification standards (EN, ASTM), durability, slip resistance |

| Construction & Infrastructure | Heavy-duty safety shoes for construction sites | Provides impact and puncture resistance, complies with safety norms | Robust materials, slip resistance, adaptability to rugged environments |

| Oil & Gas & Petrochemical | Specialized footwear for hazardous environments | Chemical and heat resistance, slip prevention, safety assurance | Material compatibility with chemicals, high-temperature resilience |

| Hospitality & Logistics | Comfort-oriented shoes for warehouse and delivery personnel | Improves worker comfort, reduces fatigue, supports extended shifts | Ergonomic design, lightweight materials, breathability |

| Healthcare & Cleanroom | Sterile, slip-resistant shoes for healthcare staff | Infection control, slip prevention, comfort in demanding settings | Easy cleaning, antimicrobial properties, compliance with hygiene standards |

Automotive & Manufacturing

Unisa shoes are widely used in the automotive and manufacturing sectors as protective footwear for assembly line workers. These shoes are designed to meet stringent safety standards, offering features such as anti-slip soles, impact resistance, and electrical hazard protection. For international buyers from regions like Europe and the Middle East, sourcing unisa shoes ensures compliance with local safety regulations while maintaining high durability in demanding environments. This application reduces workplace injuries, minimizes downtime, and enhances overall productivity, making it a critical component of industrial safety protocols.

Construction & Infrastructure

In construction and infrastructure projects, unisa shoes serve as essential safety gear for workers exposed to hazards like falling objects, sharp debris, and uneven surfaces. These shoes typically feature reinforced toe caps, puncture-resistant soles, and slip-proof treads, addressing the core safety concerns in rugged environments. Buyers from Africa and South America benefit from sourcing durable, reliable footwear that withstands harsh conditions and complies with regional safety standards. This application not only protects workers but also helps companies avoid costly legal liabilities and project delays.

Oil & Gas & Petrochemical

The oil, gas, and petrochemical industries demand specialized footwear capable of withstanding extreme conditions such as chemical exposure, high temperatures, and slippery surfaces. Unisa shoes designed for these environments incorporate chemical-resistant materials, heat-resistant soles, and secure grip features. For international buyers, particularly in the Middle East and South America, sourcing such footwear ensures safety compliance and operational efficiency in hazardous zones. These shoes mitigate risk, prevent accidents, and support compliance with industry-specific safety certifications.

Hospitality & Logistics

In the hospitality and logistics sectors, unisa shoes emphasize comfort without compromising safety. Warehouse staff, delivery drivers, and porters require footwear that supports long hours of standing and movement. Features like ergonomic insoles, lightweight construction, and breathable materials improve worker comfort and reduce fatigue. For European and African buyers, sourcing these shoes enhances workforce efficiency and morale, particularly in high-temperature or humid climates. The focus on comfort and safety aligns with operational needs for extended shifts and demanding environments.

Healthcare & Cleanroom

Healthcare professionals and cleanroom personnel need footwear that ensures hygiene and slip resistance. Unisa shoes designed for these applications often feature antimicrobial properties, easy-to-clean surfaces, and non-slip soles. They are essential in preventing infections and maintaining a sterile environment. International buyers from Europe and the Middle East value these shoes for their compliance with health standards and their ability to withstand frequent cleaning. Proper footwear reduces workplace accidents and supports overall hygiene protocols, critical in healthcare settings.

Strategic Material Selection Guide for unisa shoes

Analysis of Common Materials for unisa Shoes from a B2B Perspective

Leather

Leather remains the most traditional and preferred material for high-quality unisa shoes, especially in luxury and formal segments. Its key properties include excellent durability, breathability, and a premium aesthetic. Leather performs well under various temperature conditions, providing comfort in both hot and cold climates, which is advantageous for international markets such as Africa, South America, Europe, and the Middle East.

Illustrative Image (Source: Google Search)

Pros & Cons:

– Pros: Long-lasting, develops a unique patina over time, offers a high-end appearance, and is relatively easy to repair.

– Cons: Higher initial cost, requires specialized manufacturing processes, and sensitive to moisture and humidity, which can lead to deterioration if not properly treated.

Impact on Application:

Leather’s flexibility and breathability make it suitable for various shoe styles, from formal to casual. However, in humid or wet environments common in tropical regions, additional waterproofing treatments are necessary.

International Considerations:

Buyers should ensure leather complies with regional standards such as the EU REACH regulations or ASTM standards for chemical safety. Tanning methods (vegetable vs. chrome) may influence environmental compliance and consumer preferences, especially in eco-conscious markets like Europe.

Synthetic Materials (e.g., PU, PVC)

Synthetic materials such as polyurethane (PU) and polyvinyl chloride (PVC) are increasingly used in unisa shoes for cost-effective production and consistent quality. These materials can mimic leather’s appearance while offering enhanced resistance to environmental factors.

Pros & Cons:

– Pros: Lower cost, resistant to water and humidity, lightweight, and easier to manufacture at scale.

– Cons: Generally less durable than genuine leather, can crack or degrade over time, and may lack breathability, impacting comfort.

Impact on Application:

Synthetic materials are ideal for casual or fashion-forward unisa shoes intended for markets with high humidity or frequent exposure to water, such as in parts of Africa and South America. They also facilitate rapid manufacturing cycles, which benefit buyers seeking quick turnaround.

International Considerations:

Compliance with chemical safety standards like REACH, JIS, or ASTM is critical, especially since some synthetic materials may contain plasticizers or other chemicals scrutinized in certain markets. Buyers should verify eco-label certifications if sustainability is a priority.

Rubber and Thermoplastic Elastomers (TPE)

Rubber and TPE are often used in soles and specific shoe components for their flexibility and durability. These materials are essential for providing grip, shock absorption, and weather resistance.

Illustrative Image (Source: Google Search)

Pros & Cons:

– Pros: Excellent wear resistance, high flexibility, good weatherproofing, and cost-effective for sole manufacturing.

– Cons: Limited aesthetic appeal for upper parts, potential environmental concerns depending on formulation, and possible degradation under UV exposure.

Impact on Application:

Ideal for outsole components in unisa shoes designed for outdoor or rugged use, especially in regions with diverse terrains. Their resistance to temperature fluctuations makes them suitable for markets with extreme climates, such as the Middle East.

International Considerations:

Buyers should confirm compliance with environmental standards like VOC emissions and recyclability directives. Compatibility with regional safety standards for slip resistance and durability (e.g., ASTM F489) is also vital.

Summary Table

| Material | Typical Use Case for unisa shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Formal, luxury, casual shoes | Durable, premium appearance, develops character over time | High cost, sensitive to moisture, requires maintenance | High |

| Synthetic Materials (PU, PVC) | Fashion, casual, cost-sensitive models | Cost-effective, water-resistant, lightweight | Less durable, less breathable, environmental concerns | Medium |

| Rubber & TPE | Outsole, weatherproof components | Excellent wear resistance, weatherproofing, flexibility | Limited aesthetic for upper parts, environmental impact | Low |

Final Insights for International B2B Buyers

When selecting materials for unisa shoes, buyers should consider regional climate, regulatory standards, and consumer preferences. Leather offers a premium, durable option suitable for markets valuing luxury and longevity, especially in Europe and affluent Middle Eastern segments. Synthetic alternatives provide cost-effective, weather-resistant solutions ideal for emerging markets in Africa and South America. Rubber and TPE are essential for functional outsoles, particularly in outdoor or rugged applications across diverse climates.

Buyers must verify compliance with local safety and environmental standards, such as REACH in Europe or JIS in Japan, and consider eco-label certifications to meet increasing consumer demand for sustainable products. Establishing strong supplier relationships that prioritize quality control and transparency will ensure material consistency, ultimately supporting the production of high-quality unisa shoes tailored to each regional market.

In-depth Look: Manufacturing Processes and Quality Assurance for unisa shoes

Manufacturing Processes of Unisa Shoes

Unisa shoes are renowned for their craftsmanship, blending traditional artisanal techniques with modern manufacturing practices to ensure consistency, durability, and aesthetic appeal. The manufacturing process generally comprises four main stages: material preparation, forming, assembly, and finishing.

Material Preparation:

The process begins with sourcing high-quality leathers, textiles, and synthetic materials, often adhering to international standards such as ISO 9001 for quality management. Raw materials undergo inspection upon receipt, including visual assessment, thickness measurement, and testing for defects or contaminants. Suppliers may also provide certification reports (e.g., REACH compliance, Leather Working Group certifications) to demonstrate material safety and sustainability.

Forming (Cutting and Shaping):

In this stage, patterns are precisely cut from the prepared materials using automated CNC cutting machines or traditional hand-cutting, depending on the production scale. Advanced CAD/CAM systems optimize material usage and ensure pattern accuracy. The cut components are then shaped or molded—especially for leather upper parts—using heat presses or vacuum forming techniques to achieve the desired contours.

Assembly:

Components such as insoles, outsoles, linings, and decorative elements are assembled. This involves multiple techniques:

– Stitching: High-precision sewing machines, including lockstitch and double-stitched seams, ensure durability.

– Adhesive Bonding: Specialized adhesives (e.g., polyurethane-based) are used for bonding components, especially in areas requiring flexibility.

– Lasting: The upper is stretched and shaped over a mold (last) using manual or mechanical lasting machines, ensuring a perfect fit and form.

– Outsole Attachment: Outsoles are attached via cementing, heat vulcanization, or mechanical fasteners, with attention to alignment and adhesion quality.

Finishing:

The final stage involves surface treatments, polishing, and quality checks. Processes include dyeing, embossing, buffing, and applying protective coatings. Skilled artisans may also add decorative elements or branding. This stage ensures that each pair meets aesthetic and functional standards before passing QC.

Quality Control (QC) in Unisa Shoes Manufacturing

Ensuring consistent quality in Unisa shoes relies on a multi-layered QC system aligned with international standards such as ISO 9001, which emphasizes process control, documentation, and continuous improvement.

Key Quality Control Stages:

-

Incoming Quality Control (IQC):

Raw materials and components are inspected upon arrival. Tests include visual checks for defects, dimensional verification, and chemical testing for colorfastness and chemical residues. Certification documents, such as eco-labels or safety certificates, are verified at this stage. -

In-Process Quality Control (IPQC):

Throughout manufacturing, checkpoints are established to monitor critical parameters. For example: - Stitching consistency and seam strength are verified using tensile testing.

- Adhesive application is checked for uniformity.

- Dimensional accuracy of cut patterns is measured regularly.

-

Lasting and shaping processes are monitored to prevent deformation or defects.

-

Final Quality Control (FQC):

Before shipment, completed shoes undergo comprehensive inspection, including visual assessment for blemishes, color consistency, and structural integrity. Tests such as flex testing, slip resistance, and outsole adhesion are conducted. Random sampling ensures batch consistency.

Testing Methods:

- Mechanical Tests: Tensile strength, elongation, and abrasion resistance tests are conducted per ASTM or ISO standards.

- Environmental Tests: Shoes are subjected to temperature, humidity, and UV exposure tests to evaluate durability in different climates.

- Chemical Tests: Leathers and textiles are tested for harmful substances, complying with regulations such as REACH or OEKO-TEX.

Verifying Supplier QC for International B2B Buyers

For international buyers, especially from regions with strict regulatory environments like Europe and the Middle East, verifying supplier quality is crucial. Actions include:

-

Supplier Audits:

Engage third-party inspection agencies or conduct on-site audits to review manufacturing processes, QC documentation, and working conditions. Audits assess compliance with ISO 9001, SA8000, or other relevant standards. -

Review of Quality Reports and Certifications:

Request detailed QC reports, test certificates, and compliance documents. Confirm that these are current and aligned with international standards. -

Third-Party Inspection and Certification:

Utilize independent inspection companies (e.g., SGS, Bureau Veritas) to perform pre-shipment inspections, ensuring product conformity to specifications. Some buyers also require third-party laboratory testing for chemical and physical properties. -

Sample Testing:

Conduct or commission independent testing on samples from production batches to verify quality claims, especially for critical parameters such as sole adhesion, leather quality, and colorfastness.

Special Considerations for Different Regions

Africa and South America:

Buyers should focus on verifying that suppliers adhere to local and international labor laws and environmental standards, as these regions may have varying enforcement levels. Certifications such as ISO 14001 for environmental management can be valuable indicators of responsible manufacturing.

Middle East (e.g., Saudi Arabia):

Given the importance of compliance with safety and quality standards, verifying CE marking (for footwear with electrical components or special features) and chemical safety tests is essential. Ensuring suppliers follow strict QC protocols reduces risks associated with import bans or compliance issues.

Europe (e.g., Italy):

European buyers prioritize certifications such as REACH, OEKO-TEX, and adherence to the EU’s General Product Safety Directive. Detailed documentation, traceability, and third-party lab testing are often prerequisites. Regular audits and ongoing QC reviews help maintain high standards required by the European market.

Actionable Insights for B2B Buyers

-

Establish Clear Quality Specifications:

Communicate detailed product specifications and required certifications upfront. Include specific testing standards and acceptable tolerances. -

Build a Robust Supplier Evaluation Program:

Combine on-site audits, review of QC documentation, and third-party testing to validate supplier claims. -

Leverage Technology for Transparency:

Request digital QC reports, real-time inspection data, and traceability systems to monitor manufacturing quality continuously. -

Foster Long-term Partnerships:

Collaborate with suppliers committed to continuous improvement and compliance with international standards, reducing risks and ensuring consistent quality. -

Stay Updated on Regional Regulations:

Understand regional import requirements and standards to tailor QC checks accordingly, minimizing customs delays and compliance issues.

By integrating these manufacturing and QC insights, international B2B buyers from Africa, South America, the Middle East, and Europe can make informed sourcing decisions, mitigate risks, and establish resilient supply chains for Unisa shoes.

Comprehensive Cost and Pricing Analysis for unisa shoes Sourcing

Cost Structure Breakdown for Unisa Shoes

Understanding the detailed cost composition of Unisa shoes is essential for international B2B buyers aiming to optimize procurement strategies. The primary cost components include:

- Materials: High-quality leathers, textiles, and embellishments form the bulk of material costs. Premium materials tend to increase per-unit costs but can enhance product value and appeal in high-end markets like Europe and Italy.

- Labor: Labor costs vary significantly by sourcing country, with African and South American factories often offering competitive rates, while Middle Eastern and European manufacturers may have higher wage standards but also stricter labor regulations.

- Manufacturing Overhead: This includes factory utilities, machinery depreciation, and operational expenses. Overheads are influenced by factory automation levels and energy costs, which differ regionally.

- Tooling & Development: Initial tooling costs are typically amortized over large production runs but can be substantial for customized or limited-edition models.

- Quality Control & Certifications: Rigorous QC processes and certifications (e.g., ISO, environmental standards) add to costs but are crucial for accessing premium markets, especially in Europe and the Middle East.

- Logistics & Shipping: International shipping costs depend on shipment volume, destination port, and chosen Incoterms. Buyers should account for customs duties, tariffs, and potential delays.

- Profit Margin: Manufacturers typically target margins of 10-30%, but this varies based on order volume, customization complexity, and relationship strength.

Price Influencers in Unisa Shoes Sourcing

Several factors directly impact the final unit price and negotiating leverage:

- Order Volume & MOQ: Larger orders usually enable better unit pricing due to economies of scale. Buyers from Africa and South America should aim to negotiate volume discounts, especially for sustained partnerships.

- Customization & Specs: Customized designs, branding, or special materials increase costs. Clear specifications and early engagement can help control these expenses.

- Material Choices: Opting for standard materials reduces costs, but premium leathers or eco-friendly options may command higher prices, impacting the total cost structure.

- Quality Certifications: Higher quality standards and certifications increase manufacturing costs but are often necessary for export to Europe and Middle Eastern markets where compliance is strict.

- Supplier Factors: Factory reputation, production capacity, and lead times influence pricing. Established suppliers with reliable quality often charge premium prices but mitigate risks.

- Incoterms & Logistics: Shipping terms like FOB, CIF, or DDP significantly affect landed costs. Buyers should evaluate their logistics capabilities and consider local warehousing options to optimize costs.

Strategic Tips for International B2B Buyers

- Negotiate for Volume & Long-Term Contracts: Leverage bulk purchasing power to negotiate better prices, especially in markets like Africa and South America where suppliers seek consistent demand.

- Focus on Total Cost of Ownership (TCO): Beyond unit price, consider logistics, customs, tariffs, and potential rework costs. A slightly higher manufacturing cost might be offset by lower logistics or faster delivery.

- Understand Pricing Nuances: Be aware of regional cost structures—European markets may demand higher quality standards, which can elevate prices, while African and South American suppliers might offer more competitive base prices but with longer lead times.

- Request Detailed Cost Breakdowns: Always ask suppliers for itemized quotes to identify cost drivers and negotiate effectively.

- Prioritize Certifiable Quality & Compliance: Ensuring supplier adherence to international standards reduces risk and can facilitate market entry in strict regulatory environments.

Disclaimer

The pricing and cost insights provided are indicative and can vary significantly based on specific product configurations, supplier relationships, order quantities, and regional economic factors. Engaging in direct negotiations and requesting detailed quotes from multiple suppliers is essential for accurate cost assessments tailored to your sourcing needs.

Spotlight on Potential unisa shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for unisa shoes.)*

Essential Technical Properties and Trade Terminology for unisa shoes

Critical Technical Properties for Unisa Shoes

1. Material Grade and Composition

The quality of materials used in Unisa shoes—such as leather, synthetic fabrics, or rubber soles—is fundamental. High-grade genuine leather, for example, should meet industry standards like full-grain or top-grain classifications, ensuring durability and aesthetic appeal. For B2B buyers, understanding material grades helps assess product longevity, comfort, and compliance with regional regulations (e.g., import standards in Europe or the Middle East).

2. Manufacturing Tolerance and Precision

Tolerance levels refer to the acceptable variation in dimensions during production, such as shoe length, width, or heel height. Tight tolerances (e.g., ±0.5 mm) indicate consistent quality and ease of fitting, which are crucial for maintaining brand reputation across markets. Precise manufacturing reduces returns and enhances customer satisfaction, especially in markets with high quality expectations like Italy or Saudi Arabia.

3. Sole and Heel Specifications

The composition and design of soles and heels—such as rubber, leather, or synthetic materials—impact durability and traction. Specifications like slip resistance, wear resistance, and flexibility are critical for shoes intended for professional or formal use. B2B buyers should verify these properties align with end-user needs and regional safety standards.

4. Finishing and Stitching Quality

High-quality finishing, including even stitching and smooth edges, reflects craftsmanship and affects product durability. Uniform stitching minimizes seam failure, which is vital for premium markets in Europe and South America. Suppliers should provide detailed quality assurance reports to assure compliance with international standards.

5. Weight and Comfort Specifications

Lightweight shoes with ergonomic design features enhance comfort for end-users, especially in markets where consumers wear shoes for extended periods. Technical data on weight per pair and cushioning materials can influence purchasing decisions, particularly for corporate or uniform shoe programs.

Essential Trade Terminology for Unisa Shoes

1. OEM (Original Equipment Manufacturer)

An OEM produces shoes based on the buyer’s specifications and branding. Understanding OEM relationships helps B2B buyers negotiate customization, branding, and private label options, which are common in international markets seeking unique product differentiation.

2. MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity a supplier is willing to produce or sell in a single order. Awareness of MOQ levels helps buyers plan inventory and negotiate terms, especially when entering new markets or testing product acceptance.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent by buyers to suppliers requesting detailed pricing, lead times, and terms for specific shoe models. Efficient RFQ processes facilitate competitive bidding and ensure timely decision-making, vital for managing international supply chains.

4. Incoterms (International Commercial Terms)

Incoterms specify the responsibilities of buyers and sellers regarding shipping, risk transfer, and customs clearance. Common terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) clarify cost-sharing and delivery obligations, enabling smooth cross-border transactions.

5. Lead Time

This refers to the duration from order placement to product delivery. Understanding lead times is crucial for inventory planning and meeting regional market demands, especially in countries with varying logistical infrastructures.

6. Quality Certification and Compliance

Certificates such as ISO standards, CE marking, or regional safety certifications verify product quality and compliance with legal requirements. B2B buyers should verify these certifications to ensure seamless import processes and adherence to regional regulations.

In summary, understanding these technical properties and trade terms enables international B2B buyers to make informed purchasing decisions, negotiate effectively, and ensure compliance with regional standards. This knowledge is essential for establishing reliable supply chains and maintaining competitive advantage in diverse global markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the unisa shoes Sector

Market Overview & Key Trends

The global footwear industry is experiencing rapid evolution driven by technological advancements, changing consumer preferences, and supply chain innovations. For Unisa shoes, a brand renowned for its craftsmanship and style, these dynamics present both opportunities and challenges for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe.

Emerging sourcing trends emphasize digital integration, with blockchain technology enhancing transparency and traceability across supply chains. Buyers are increasingly prioritizing suppliers that offer real-time data on materials and production processes, facilitating compliance with regional regulations and consumer expectations. Additionally, automation and smart manufacturing are reducing lead times and costs, making it easier for international buyers to access premium quality at competitive prices.

Market drivers include the rising demand for sustainable and ethically produced footwear, especially in Europe and the Middle East, where consumers and regulators are scrutinizing supply chain practices. In Africa and South America, growth is fueled by expanding retail infrastructure and a burgeoning middle class eager for stylish yet affordable footwear. For B2B buyers, understanding regional market preferences—such as the preference for eco-friendly materials in Europe or durability suited to diverse climates in Africa—is crucial for tailoring procurement strategies.

Furthermore, geopolitical factors and trade agreements influence sourcing options. Regions with preferential trade terms or reduced tariffs can offer cost advantages, but buyers must also weigh supply chain resilience amid global disruptions. Strategic diversification of sourcing partners, coupled with investments in local supplier development, can mitigate risks and foster long-term partnerships.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical criterion for B2B buyers engaging with brands like Unisa shoes. The environmental impact of footwear production encompasses resource consumption, waste generation, and carbon emissions. Buyers in Europe and the Middle East are particularly attentive to eco-labels and certifications, such as Global Organic Textile Standard (GOTS), Leather Working Group (LWG), and ISO 14001, which verify sustainable practices.

Ethical sourcing extends beyond environmental considerations to include fair labor practices, transparent supply chains, and social responsibility. Many international buyers are now requiring suppliers to adhere to rigorous standards, such as the Fair Labor Association (FLA) or SA8000, to ensure workers’ rights are protected throughout the manufacturing process.

Adopting ‘green’ materials—such as recycled leathers, organic textiles, and biodegradable components—can not only meet regulatory requirements but also serve as a unique selling point in competitive markets. For instance, Unisa’s move toward using environmentally friendly materials aligns with global trends, providing B2B buyers with opportunities to differentiate their offerings.

Investing in sustainable supply chain infrastructure, including energy-efficient factories and waste management systems, enhances brand reputation and customer loyalty. B2B buyers should prioritize partnerships with suppliers committed to continuous sustainability improvement, leveraging certifications and audits as proof of compliance. This approach ensures long-term viability, mitigates risks associated with regulatory changes, and aligns with the growing consumer demand for responsible products.

Brief Evolution/History (Optional)

Unisa shoes, founded in the early 20th century in Spain, has evolved from a traditional shoemaking enterprise to a globally recognized brand known for its artisanal craftsmanship and contemporary designs. Over decades, the company has integrated innovative manufacturing processes and expanded its footprint across Europe, the Middle East, and Latin America.

For B2B buyers, understanding this heritage underscores the brand’s commitment to quality and authenticity—key differentiators in competitive markets. The evolution reflects a strategic shift towards sustainable practices and digital integration, positioning Unisa as a forward-thinking partner capable of meeting modern sourcing and sustainability demands. Recognizing this history can facilitate stronger collaborations, emphasizing the brand’s stability and long-term vision in sourcing negotiations.

Frequently Asked Questions (FAQs) for B2B Buyers of unisa shoes

1. How can I verify the legitimacy and reliability of a Unisa Shoes supplier?

To ensure supplier credibility, start by requesting official business licenses, export certificates, and references from existing international clients. Check if they are listed on recognized trade directories or industry associations. Conduct virtual audits or factory visits if feasible, or hire third-party inspection services to verify manufacturing capabilities and quality standards. Additionally, review online reviews, testimonials, and their responsiveness to inquiries. Reliable suppliers should provide transparent communication, detailed product catalogs, and compliance documentation. Establish clear terms of trade early to minimize risks associated with counterfeit or non-compliant products.

2. Can Unisa Shoes be customized for my market, and what is the process?

Yes, Unisa Shoes offers customization options including branding, color schemes, packaging, and even specific design modifications to suit regional preferences. The process typically involves initial consultation to understand your target market and branding requirements. Provide detailed specifications and samples if available. The supplier will then share prototypes or samples for approval before mass production. Be aware that customization may extend lead times and increase minimum order quantities (MOQs). Clear communication and detailed agreements are essential to ensure the final product aligns with your market needs and quality expectations.

3. What are the typical minimum order quantities (MOQs) and lead times for international orders?

Most Unisa Shoes suppliers have MOQs ranging from 300 to 1,000 pairs per style, depending on the complexity of the product and customization requirements. Lead times generally vary from 4 to 12 weeks after order confirmation, influenced by production schedules, customization, and logistics. Advanced planning and early engagement help mitigate delays. Establishing a reliable supply chain and maintaining regular communication with the supplier can help you optimize inventory levels and meet your market demands efficiently.

4. What payment terms are commonly accepted, and how can I mitigate financial risks?

Common payment terms include a 30% upfront deposit with the balance paid before shipment, or letter of credit (L/C) arrangements for larger orders. Negotiating flexible terms is possible, especially for repeat orders or trusted suppliers. To mitigate risks, conduct due diligence on the supplier’s financial stability, request trade references, and consider escrow services or trade insurance. Always insist on a detailed contract specifying payment milestones, quality standards, and dispute resolution procedures to safeguard your investment.

5. What quality assurance and certification standards should I look for?

Ensure the supplier complies with international quality standards such as ISO 9001, and adheres to safety and environmental regulations relevant to your market (e.g., REACH compliance in Europe, CA Prop 65 in the US). Request quality control reports, sample approvals, and third-party inspection certificates. For markets with specific standards, verify the supplier’s ability to provide necessary certifications and test reports. Establish quality checkpoints during production and pre-shipment inspections to ensure consistency and reduce the risk of defective products reaching your customers.

6. How should I handle logistics and shipping from Unisa Shoes suppliers?

Coordinate with suppliers to select the most suitable shipping method—air freight for faster delivery or sea freight for cost efficiency on large orders. Clarify Incoterms (e.g., FOB, CIF) to define responsibilities and costs clearly. Use reputable freight forwarders with experience in international trade to manage customs clearance, taxes, and duties specific to your country (e.g., import VAT in Europe, customs duties in Africa or the Middle East). Regular tracking and transparent communication with logistics partners help prevent delays and ensure timely delivery to your distribution centers.

7. What common disputes might arise, and how can I resolve them effectively?

Disputes often relate to quality issues, late deliveries, or payment disagreements. To prevent these, establish detailed contracts outlining product specifications, inspection procedures, and penalty clauses for non-compliance. Maintain thorough documentation of all communications, orders, and inspections. In case of disputes, engage in amicable negotiations first; if unresolved, escalate to arbitration or legal channels specified in your contract. Working with local legal experts familiar with international trade laws can expedite dispute resolution and protect your interests.

8. How can I build a long-term partnership with Unisa Shoes suppliers?

Develop trust through consistent communication, timely payments, and constructive feedback. Invest in understanding their production capabilities and limitations, and share market insights to foster collaboration. Consider visiting their facilities periodically to strengthen relationships and ensure quality standards are maintained. Offering volume commitments and exploring joint marketing initiatives can incentivize suppliers to prioritize your orders. Building a reliable partnership reduces supply chain risks, improves pricing terms, and facilitates smoother customization and logistics processes, ultimately supporting your long-term market success.

Strategic Sourcing Conclusion and Outlook for unisa shoes

Strategic Sourcing Conclusion and Outlook for unisa shoes

Effective strategic sourcing is essential for international B2B buyers seeking to capitalize on unisa shoes’ unique value proposition. By establishing strong supplier relationships, focusing on quality assurance, and leveraging cost efficiencies, buyers can ensure a reliable supply chain that meets diverse market demands across Africa, South America, the Middle East, and Europe.

Illustrative Image (Source: Google Search)

Understanding the nuances of regional sourcing options—such as local manufacturing hubs or global supply networks—enables buyers to optimize lead times, mitigate risks, and adapt swiftly to market changes. Emphasizing sustainable practices and ethical sourcing further enhances brand reputation and aligns with global consumer expectations.

Looking ahead, the evolving landscape of global trade offers significant opportunities for strategic partnerships with unisa shoes. Proactive engagement and tailored sourcing strategies will position buyers to secure competitive advantages, foster innovation, and expand market reach.

International B2B buyers from emerging markets and established regions alike are encouraged to prioritize strategic sourcing as a core component of their procurement approach. Embrace these insights to build resilient, efficient supply chains that support long-term growth and success in the global footwear industry.