Your Ultimate Guide to Sourcing Best Shoe Inserts For Flat

Guide to Best Shoe Inserts For Flat Feet

- Introduction: Navigating the Global Market for best shoe inserts for flat feet

- Understanding best shoe inserts for flat feet Types and Variations

- Key Industrial Applications of best shoe inserts for flat feet

- Strategic Material Selection Guide for best shoe inserts for flat feet

- In-depth Look: Manufacturing Processes and Quality Assurance for best shoe inserts for flat feet

- Comprehensive Cost and Pricing Analysis for best shoe inserts for flat feet Sourcing

- Spotlight on Potential best shoe inserts for flat feet Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for best shoe inserts for flat feet

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the best shoe inserts for flat feet Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of best shoe inserts for flat feet

- Strategic Sourcing Conclusion and Outlook for best shoe inserts for flat feet

Introduction: Navigating the Global Market for best shoe inserts for flat feet

In the increasingly competitive global healthcare and footwear markets, sourcing the best shoe inserts for flat feet is more than a logistical challenge—it’s a strategic imperative. Flat feet, or fallen arches, affect millions worldwide, leading to discomfort, mobility issues, and long-term musculoskeletal problems. For B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, understanding how to identify high-quality, effective solutions can significantly impact product offerings, customer satisfaction, and market competitiveness.

This comprehensive guide is designed to empower international buyers with critical insights into the flat feet insert market. It covers essential aspects such as the various types of inserts—orthopedic, gel-based, foam, and custom solutions—and the materials that influence durability, comfort, and cost. Additionally, it provides actionable guidance on evaluating manufacturing standards, quality control processes, and sourcing from reliable suppliers worldwide.

By understanding market dynamics, cost considerations, and regulatory nuances across different regions—including emerging markets like Argentina or Australia—buyers can make informed decisions that optimize value and product quality. This guide aims to streamline your sourcing process, mitigate risks, and unlock opportunities for sustainable growth in the global footwear accessories sector. Ultimately, it positions you to meet growing consumer demand for effective, comfortable, and durable shoe inserts tailored for flat-footed customers worldwide.

Understanding best shoe inserts for flat feet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Arch Support Insoles | Contoured design providing targeted arch elevation and stabilization | Medical, orthotic clinics, sports footwear suppliers | High customization potential; durable materials; may require fitting services but can be pricier to stock |

| Cushioned Insoles | Soft, shock-absorbing materials offering overall comfort | Casual, everyday footwear brands, retailers | Widely versatile; lower cost; less targeted support, which may limit effectiveness for severe flat feet |

| Rigid Orthotic Inserts | Firm, semi-rigid structures with reinforced arch support | Specialist orthopedics, high-end footwear brands | Long-lasting and highly supportive; higher manufacturing complexity and cost |

| Gel-Based Insoles | Gel-filled layers providing shock absorption and flexible support | Athletic footwear, casual shoe manufacturers | Excellent impact absorption; bulkier; may degrade faster under heavy use |

| Semi-Rigid Inserts | Combination of flexible and firm components for moderate support | Multi-purpose footwear brands, custom-fit providers | Balanced support; adaptable to various shoe types; may require specific manufacturing expertise |

Characteristics and Suitability

Arch Support Insoles are designed specifically to mimic the natural arch of the foot, making them ideal for severe flat feet. They are often made from firm materials like EVA or thermoplastics, allowing for precise contouring and long-term support. These insoles are suitable for medical applications and high-performance footwear, where customized orthotic solutions are necessary. B2B buyers should prioritize sourcing from manufacturers capable of offering various sizes and customizable options, ensuring they meet diverse client needs.

Cushioned Insoles focus on comfort through soft, shock-absorbing materials such as foam or gel. While they provide general support and comfort, they may lack the structural reinforcement needed for severe flat feet. These are well-suited for mass-market retail, casual shoes, and footwear targeting everyday comfort. Buyers should consider the balance between cost and durability, ensuring the insoles maintain their cushioning over extended use.

Rigid Orthotic Inserts are crafted from semi-rigid plastics or carbon fiber, offering high durability and precise support. They are typically used in specialized orthotic applications and high-end footwear where maximum support and longevity are required. For B2B buyers, sourcing from reputable orthotic manufacturers with certification and quality assurance is critical, especially for healthcare providers and premium footwear brands.

Gel-Based Insoles incorporate gel layers to absorb shock and provide flexible support, making them popular in athletic and casual shoes. They are especially beneficial in reducing impact stress for flat-footed individuals engaged in high-impact activities. However, gel insoles may be bulkier and susceptible to wear over time. Buyers should evaluate the quality of gel materials and consider the insoles’ lifespan relative to their target market’s needs.

Semi-Rigid Inserts blend features of both rigid and cushioned insoles, offering moderate support that adapts to various footwear styles. They are suitable for brands seeking versatile solutions that can cater to a broad customer base. These inserts require careful manufacturing to balance flexibility and support, making supplier selection crucial for consistent quality.

B2B Purchasing Insights

For international buyers, understanding the specific support requirements of their target markets is essential. Customization options, material quality, and manufacturing standards significantly influence product performance and customer satisfaction. Sourcing from suppliers with proven expertise in orthotic solutions can reduce returns and warranty claims. Additionally, considering the logistics of shipping, compliance with regional standards, and the potential for private labeling are vital factors for expanding market reach in regions like Africa, South America, the Middle East, and Europe.

Key Industrial Applications of best shoe inserts for flat feet

| Industry/Sector | Specific Application of best shoe inserts for flat feet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare & Orthopedics | Custom orthotic solutions for clinics and hospitals treating flat-footed patients | Enhances patient outcomes, broadens service offerings, and boosts reputation | Certification standards (ISO, CE), biocompatibility, customization options, lead times |

| Sports & Performance Gear | Athletic shoes and insoles for sports teams, gyms, and individual athletes | Improves athletic performance, reduces injury risk, and increases product appeal | Material durability, shock absorption capabilities, compliance with sports safety standards |

| Footwear Manufacturing | OEM supply of flat-foot supportive insoles for footwear brands and retailers | Expands product portfolio, reduces manufacturing costs, and ensures consistent quality | Bulk sourcing options, quality control, compliance with international footwear standards |

| Rehabilitation & Wellness | Supportive inserts for physiotherapy clinics, rehabilitation centers, and wellness programs | Accelerates recovery, alleviates pain, and enhances client satisfaction | Flexibility in sizing, ease of insertion, antimicrobial properties, cost-effectiveness |

| Corporate & Workwear | Ergonomic insoles for work shoes in industries with prolonged standing (e.g., retail, manufacturing) | Reduces worker fatigue, enhances comfort, and decreases absenteeism | Heavy-duty durability, slip resistance, ergonomic design, supply chain reliability |

Healthcare & Orthopedics

In the healthcare sector, especially within orthopedics, best shoe inserts for flat feet are integral to treatment plans for patients suffering from foot deformities, chronic pain, or gait issues. B2B buyers such as medical device distributors, orthopedists, and clinics in regions like Africa, South America, and the Middle East seek inserts that are customizable, biocompatible, and compliant with international health standards. These inserts help improve patient mobility and reduce the need for invasive procedures, making them a valuable addition to medical offerings. International buyers should prioritize sourcing from manufacturers with proven certification and quality assurance processes to ensure safety and efficacy.

Sports & Performance Gear

Athletic performance is heavily influenced by footwear support, especially for individuals with flat feet prone to injuries like plantar fasciitis or overpronation. Suppliers providing best shoe inserts tailored for sports applications can tap into markets across Europe, Australia, and Latin America by offering durable, shock-absorbing insoles that enhance athletic output and prevent injuries. B2B buyers such as sports brands, gyms, and sports teams look for products with high resilience, moisture-wicking properties, and compliance with sports safety standards. Sourcing high-quality, impact-resistant materials and ensuring consistent supply are key considerations.

Footwear Manufacturing

For footwear brands and OEMs, integrating high-quality insoles designed for flat feet broadens product appeal and supports market differentiation. These inserts can be supplied in bulk, enabling manufacturers in Argentina, Europe, or Africa to produce supportive shoes at scale while maintaining cost efficiency. Key sourcing factors include consistent quality control, scalability, and adherence to international manufacturing standards. This approach allows brands to meet the growing demand for comfortable, health-oriented footwear in diverse markets.

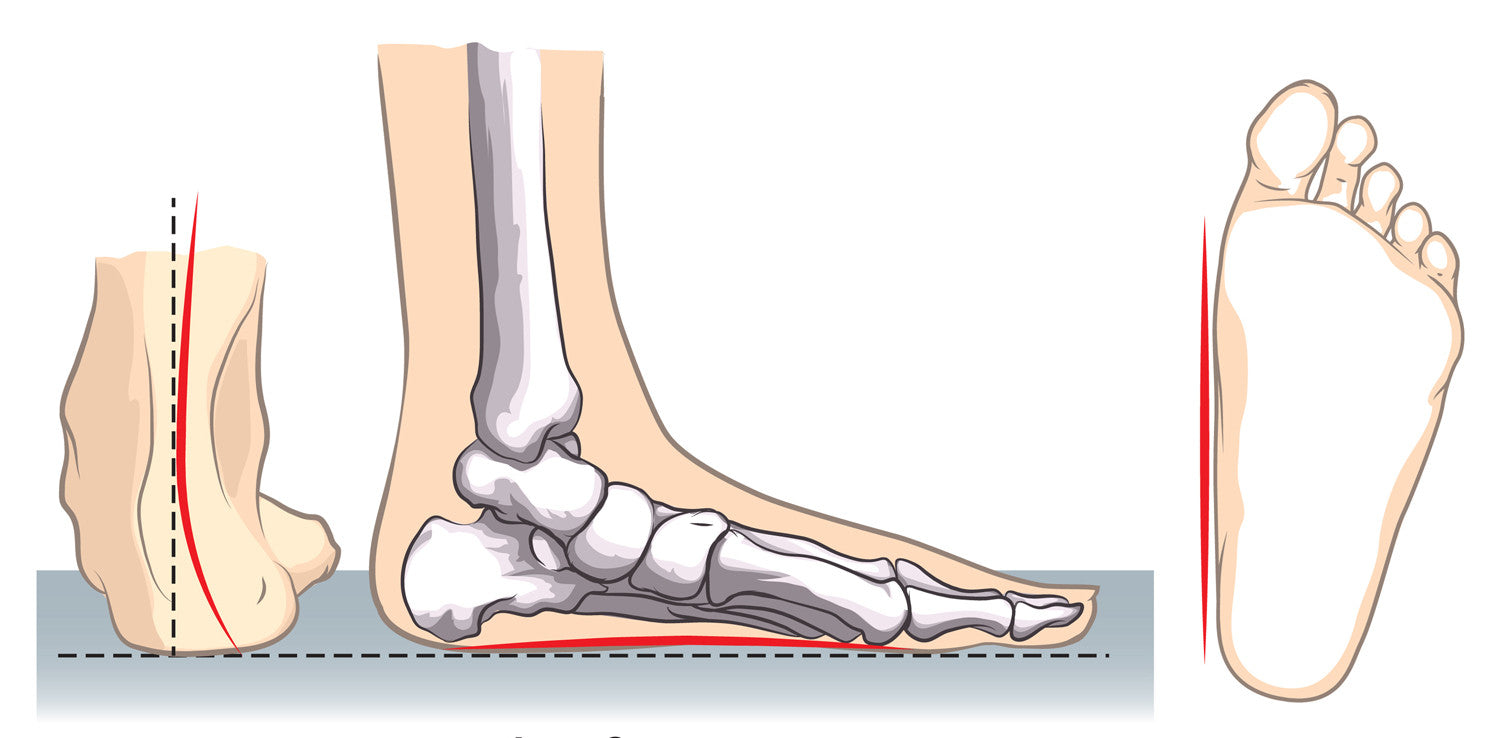

Illustrative Image (Source: Google Search)

Rehabilitation & Wellness

Rehabilitation centers and physiotherapy clinics increasingly incorporate supportive inserts for patients recovering from foot injuries or surgeries. These inserts provide stabilization, reduce pain, and facilitate faster recovery. B2B buyers in this segment prioritize sourcing flexible, antimicrobial, and easy-to-insert products that cater to various foot sizes and conditions. Cost-effective, reliable supply chains are essential to ensure consistent availability and to support large-scale wellness programs, particularly in regions with expanding healthcare infrastructure like South America and the Middle East.

Corporate & Workwear

Industries with physically demanding roles, such as manufacturing, retail, and logistics, benefit from ergonomic insoles that alleviate fatigue and prevent work-related foot ailments. Suppliers offering durable, slip-resistant, and ergonomically designed inserts can serve B2B buyers across Europe, Australia, and Africa, helping companies improve employee well-being and reduce absenteeism. Key sourcing considerations include product robustness, compliance with occupational safety standards, and reliable logistics to meet large-volume demands efficiently.

Strategic Material Selection Guide for best shoe inserts for flat feet

Material Analysis for Shoe Inserts for Flat Feet

Selecting the appropriate materials for shoe inserts designed for flat feet is crucial for ensuring product performance, durability, and compliance across diverse markets. Different materials offer unique properties that influence comfort, longevity, manufacturing complexity, and cost. For international B2B buyers, understanding these nuances helps optimize sourcing, manufacturing, and distribution strategies, especially when navigating regional standards and preferences.

Thermoplastics (e.g., EVA, PE, polypropylene)

Key Properties:

Thermoplastics like Ethylene Vinyl Acetate (EVA), Polyethylene (PE), and polypropylene are widely used in shoe inserts due to their lightweight, flexible, and cushioning qualities. They exhibit good energy absorption and resilience, making them suitable for supporting flat feet. These materials are temperature-sensitive but generally maintain performance within typical footwear manufacturing ranges.

Pros & Cons:

Thermoplastics are cost-effective, easy to mold, and offer consistent quality at scale, making them attractive for mass production. They are resistant to moisture and corrosion, which enhances product lifespan. However, their durability can vary based on formulation; some EVA grades may degrade under prolonged UV exposure or extreme temperatures. Manufacturing complexity is moderate, requiring precise molding processes.

Impact on Application:

Thermoplastics are compatible with standard injection molding media, facilitating high-volume production. They can be customized with surface textures or embedded with additional materials for enhanced support.

International Considerations:

For buyers in Africa, South America, the Middle East, and Europe, compliance with regional standards such as ASTM, DIN, or JIS is essential. Thermoplastics generally meet these standards if sourced from reputable suppliers. Additionally, eco-friendly formulations with recyclable content are increasingly favored, aligning with environmental regulations in Europe and Australia.

EVA Foam

Key Properties:

EVA foam combines softness with flexibility, providing excellent shock absorption and comfort—key for flat foot support. It has good resilience and can be formulated with varying densities to tailor support levels. Its thermal insulation properties also help in temperature regulation.

Pros & Cons:

EVA foam is lightweight and easy to cut or mold, reducing manufacturing complexity. It offers excellent cushioning, which enhances wearer comfort. The downside includes potential compression over time, which might reduce support efficacy. Cost varies depending on density and formulation but generally remains moderate.

Impact on Application:

EVA foam is compatible with adhesive bonding and lamination processes, allowing for layered constructions. It performs well in applications requiring flexible, cushioning inserts but may require reinforcement for high-stress areas.

International Considerations:

EVA foam is widely accepted globally, but buyers should verify compliance with local health and safety standards, especially concerning off-gassing and VOC emissions. In Europe, adherence to REACH regulations is vital, and suppliers should provide relevant certifications.

Thermoplastic Elastomers (TPE)

Key Properties:

TPEs combine the elastic properties of rubber with the processing advantages of plastics. They offer excellent flexibility, durability, and resistance to environmental factors such as moisture, temperature fluctuations, and chemicals. TPEs can mimic the feel of rubber but are easier to process.

Pros & Cons:

TPEs provide high durability and consistent performance over time, making them suitable for long-term flat foot support. They are resistant to cracking and deformation. Manufacturing can be more complex and costly than simpler thermoplastics, and sourcing high-quality TPEs may involve higher costs.

Impact on Application:

TPEs are compatible with injection molding and extrusion, enabling complex geometries and layered designs. Their elastic nature allows for dynamic support, which can enhance comfort and biomechanical correction.

International Considerations:

TPEs often meet stringent environmental and safety standards, including REACH and RoHS. For markets like Europe and Australia, suppliers should provide compliance documentation. Additionally, the recyclability of TPEs aligns with sustainability trends prevalent in these regions.

Summary Table

| Material | Typical Use Case for best shoe inserts for flat feet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastics (EVA, PE, polypropylene) | Support and cushioning in mass-produced insoles | Cost-effective, easy to mold, moisture and corrosion resistant | Variable durability depending on formulation, UV sensitivity | Low |

| EVA Foam | Shock absorption and comfort | Lightweight, flexible, easy to cut/mold | May compress over time, less durable in high-stress areas | Medium |

| Thermoplastic Elastomers (TPE) | Durable, elastic support with long-term resilience | High durability, chemical and temperature resistant | Higher manufacturing complexity and cost | High |

This comprehensive understanding of material properties and regional considerations enables B2B buyers to make informed sourcing decisions. Prioritizing compliance, environmental standards, and application-specific performance ensures the successful integration of shoe inserts for flat feet into diverse markets worldwide.

In-depth Look: Manufacturing Processes and Quality Assurance for best shoe inserts for flat feet

Manufacturing Processes for Shoe Inserts for Flat Feet

The production of high-quality shoe inserts tailored for flat feet involves a series of meticulously controlled stages, each critical to ensuring product consistency, durability, and therapeutic effectiveness.

1. Material Preparation

The process begins with sourcing and preparing raw materials, which typically include EVA (ethylene-vinyl acetate), polyurethane foams, gel pads, and specialized arch support materials. Suppliers must ensure raw materials meet specific standards for elasticity, density, and biocompatibility. For B2B buyers, verifying supplier certifications for raw material quality—such as ISO 9001 or ISO 13485—is essential, especially when importing into regions with strict regulatory regimes like Europe or Australia.

2. Forming and Molding

The core of manufacturing involves shaping the insert to match ergonomic and biomechanical requirements for flat feet. Techniques include:

- Thermoforming: Heating EVA or similar materials to a pliable state, then molding them over precision forms that replicate foot anatomy.

- Injection Molding: For complex, multi-layered inserts, this method allows high precision and repeatability.

- 3D Printing: Emerging as an innovative approach, 3D printing enables rapid prototyping and customization, especially for orthotic inserts with personalized arch support.

Throughout this stage, strict temperature and pressure controls are maintained to ensure dimensional stability and material integrity.

3. Assembly

In multi-component inserts, assembly involves integrating different layers—such as gel pads, cushioning foams, and rigid supports—using adhesive bonding or heat welding. Adhesives should be medical-grade, complying with ISO 10993 standards to ensure biocompatibility. Assembly lines should be designed for minimal contamination and precise alignment, with operators trained in hygiene protocols.

4. Finishing and Packaging

Final steps include trimming excess material, surface smoothing, and applying surface treatments like anti-slip coatings or antimicrobial finishes. Packaging must protect the product during transit, especially for international shipments, and should include detailed labeling compliant with destination country regulations.

Quality Control (QC) in Manufacturing Shoe Inserts for Flat Feet

Robust QC processes are vital for delivering products that meet international standards and fulfill therapeutic claims. The following practices are standard across reputable manufacturers:

1. Incoming Quality Control (IQC)

Raw materials undergo IQC checks upon arrival, verifying parameters such as:

- Material density and elasticity

- Biocompatibility certifications

- Absence of contaminants or defects

This step ensures only compliant materials enter the production line, reducing downstream defects.

2. In-Process Quality Control (IPQC)

During manufacturing, continuous monitoring ensures conformity. Key checkpoints include:

- Dimensional accuracy using coordinate measuring machines (CMM)

- Thickness and firmness tests for foam layers

- Adhesion strength for bonded components

- Visual inspections for surface defects or inconsistencies

Automated inspection systems are increasingly employed for rapid, objective assessments.

3. Final Quality Control (FQC)

Before shipment, finished inserts undergo comprehensive testing:

- Functional Testing: Simulating load and stress conditions to assess durability.

- Biomechanical Validation: Ensuring arch support and cushioning meet ergonomic specifications.

- Surface and Finish Inspection: Confirming smoothness and defect-free surfaces.

4. Industry Standards and Certifications

Manufacturers often adhere to standards such as:

- ISO 9001: Quality management systems ensuring consistent process control.

- ISO 13485: For medical device manufacturing, covering design, production, and servicing.

- CE Marking: Demonstrates compliance with European health, safety, and environmental requirements.

- API and ASTM Standards: For specific testing methods related to cushioning and durability.

5. Verification for International Buyers

B2B buyers should request detailed quality reports, including test results, inspection reports, and certifications. Auditing suppliers through on-site visits or third-party inspections (e.g., SGS, TUV) can verify adherence to stated standards. Maintaining transparent documentation facilitates customs clearance and regulatory compliance in diverse markets.

Illustrative Image (Source: Google Search)

Special Considerations for International B2B Buyers

Buyers from regions like Africa, South America, the Middle East, and Europe face unique challenges and opportunities in verifying and managing QC:

- Regulatory Compliance: Ensure suppliers possess certifications aligned with local standards—e.g., CE for Europe, TGA approval for Australia, or ANVISA registration for Brazil.

- Language and Documentation: Request documentation in accessible languages or certified translations to facilitate understanding.

- Inspection and Auditing: Conduct periodic on-site audits or engage third-party inspectors familiar with regional regulations and manufacturing practices.

- Supply Chain Transparency: Favor manufacturers providing detailed traceability of materials and manufacturing processes, which is critical for warranty claims or product recalls.

- Cultural and Logistical Factors: Recognize regional differences in quality expectations and logistical constraints; establish clear communication channels to mitigate misunderstandings.

Final Insights for B2B Buyers

To ensure consistent quality and compliance, B2B buyers should establish rigorous supplier qualification protocols, including:

- Pre-qualification questionnaires assessing manufacturing capabilities and certifications.

- Regular audits and third-party inspections to verify ongoing compliance.

- Sample testing of incoming shipments against agreed specifications.

- Clear contractual clauses on quality standards, penalties for non-conformance, and procedures for corrective actions.

By understanding the intricacies of manufacturing processes and implementing stringent QC measures, international buyers can confidently source superior shoe inserts for flat feet, ensuring product efficacy and customer satisfaction across diverse markets.

Comprehensive Cost and Pricing Analysis for best shoe inserts for flat feet Sourcing

Cost Structure Breakdown for Shoe Inserts for Flat Feet

Understanding the comprehensive cost structure is essential for international B2B buyers seeking the best shoe inserts for flat feet. The main components include raw materials, manufacturing labor, overhead costs, tooling, quality control, logistics, and profit margins. Raw materials—such as EVA foam, gel inserts, or specialty orthotic plastics—constitute a significant portion, often ranging from 30% to 50% of the production cost, depending on quality and specifications. Labor costs vary widely based on the manufacturing country; for instance, Asian manufacturers might offer lower wages, whereas European or North American facilities typically have higher labor expenses but may provide advanced quality assurance.

Manufacturing overhead encompasses factory utilities, machinery depreciation, and administrative expenses, usually accounting for 10-20% of total costs. Tooling costs are often a one-time expense for molds and fixtures, which can range from a few hundred to several thousand USD depending on complexity. Quality control (QC) processes—certifications, testing, and inspections—add to costs but are vital for meeting international standards, especially for markets requiring CE, ISO, or other certifications.

Logistics costs are highly variable, influenced by shipment volume, destination, and chosen Incoterms. For bulk orders, freight becomes more economical per unit, whereas smaller shipments or urgent deliveries incur higher costs. Profit margins for manufacturers typically range from 10% to 30%, but this can fluctuate based on competitive pressures and buyer negotiation.

Price Influencers and Market Dynamics

Several factors influence the final pricing of shoe inserts in the B2B landscape. Order volume and MOQ (Minimum Order Quantity) play a crucial role: larger orders often secure better unit prices due to economies of scale. Conversely, low-volume or customized orders tend to carry premium pricing, reflecting higher per-unit costs.

Specifications and customization—such as bespoke sizes, orthotic features, or branding—also impact costs. Customization increases tooling expenses and requires more detailed QC, which can push prices upward. High-quality materials with certifications (e.g., medical-grade, eco-friendly) command premium prices but are essential for premium market segments or regulatory compliance.

Supplier factors such as production capacity, reputation, and country of origin influence pricing and reliability. Suppliers in regions like China, Vietnam, or India may offer more competitive rates, whereas European or North American manufacturers might emphasize quality, innovation, and compliance, resulting in higher prices.

Incoterms and shipping arrangements significantly affect landed costs. Buyers should evaluate whether to opt for FOB (free on board) or CIF (cost, insurance, freight) terms, considering customs duties, taxes, and import tariffs. Understanding local import policies is critical for accurate cost estimation.

Strategic Tips for International B2B Buyers

- Negotiate for volume discounts: Larger orders can significantly reduce per-unit costs. Establish long-term relationships to access better pricing tiers.

- Prioritize quality and certifications: While cheaper options may seem attractive, investing in certified, durable inserts reduces return rates and enhances brand reputation.

- Evaluate Total Cost of Ownership (TCO): Consider shipping, customs, storage, and potential rework costs rather than just unit price. A slightly higher initial cost might be offset by lower logistics or defect-related expenses.

- Leverage flexible Incoterms: FOB terms often provide more control over logistics and costs, but require buyer expertise. CIF can simplify import processes but might carry higher upfront costs.

- Stay informed on regional tariffs and import duties: For markets like Argentina, Australia, or Middle Eastern countries, understanding local tariffs can prevent unexpected expenses.

Indicative Price Ranges (Disclaimer)

For bulk orders of standard shoe inserts, prices typically range from USD 1.50 to USD 4.00 per pair, with premium or highly customized options exceeding USD 5.00. Small or trial orders may see higher unit prices due to setup costs. Always request detailed quotes based on your specific specifications and volume requirements to obtain accurate pricing tailored to your market.

This detailed analysis should serve as a strategic guide for international B2B buyers aiming to optimize costs while ensuring quality and compliance in sourcing shoe inserts for flat feet.

Spotlight on Potential best shoe inserts for flat feet Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for best shoe inserts for flat feet.)*

Essential Technical Properties and Trade Terminology for best shoe inserts for flat feet

Key Technical Properties for Shoe Inserts for Flat Feet

1. Material Grade and Composition

The quality of materials used in shoe inserts directly impacts durability, comfort, and support. High-grade EVA (ethylene-vinyl acetate), memory foam, or thermoplastic polyurethane (TPU) are common choices, with specifications indicating the density and resilience of the material. For B2B buyers, selecting inserts with premium materials ensures longer product lifespan and reduces returns due to early wear or failure.

2. Support and Arch Height

Effective inserts for flat feet must provide adequate arch support to correct overpronation and distribute pressure evenly. The support level is often measured in millimeters or categorized as low, medium, or high. Clear specifications enable buyers to match products with customer needs, ensuring the inserts deliver proper biomechanical correction.

3. Tolerance and Manufacturing Precision

Tolerance levels refer to the allowable deviation during manufacturing, typically expressed in millimeters. Tight tolerances (e.g., ±0.2mm) indicate high precision, crucial for ensuring consistent fit and performance across production batches. For international buyers, understanding tolerance standards helps in assessing product quality and compatibility with various footwear sizes and styles.

4. Flexibility and Compression Resistance

Inserts must strike a balance between flexibility for comfort and rigidity for support. The material’s ability to withstand compression without losing shape is vital for sustained support over time. This property is often evaluated through standardized testing, which B2B buyers can request to verify product durability.

5. Breathability and Hygienic Features

Materials with breathable fabrics or perforations enhance moisture control, reducing odor and fungal risks. These features are increasingly important in regions with hot or humid climates, such as Africa and South America. Selecting inserts with hygienic properties extends product usability and customer satisfaction.

6. Compatibility with Footwear Types

Certain technical properties, such as thickness and adhesion qualities, determine how well inserts fit into different shoe styles—from athletic to formal footwear. Clear specifications help buyers source inserts suitable for diverse markets and footwear categories across regions.

Common Industry and Trade Terms

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce shoe inserts under a brand name supplied by another company. B2B buyers often seek OEM options for custom branding or private labeling, which can enhance market differentiation and expand regional distribution.

2. MOQ (Minimum Order Quantity)

The smallest order size a manufacturer is willing to accept. Understanding MOQ is crucial for planning inventory levels, especially in regions with fluctuating demand like Europe or South America. Negotiating flexible MOQs can optimize cash flow and reduce excess stock.

3. RFQ (Request for Quotation)

A formal process where buyers solicit detailed price and product specifications from suppliers. Effective RFQs enable comparative analysis of technical properties, costs, and lead times, facilitating informed procurement decisions in international markets.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities between buyers and sellers for shipping, insurance, and customs clearance. Familiarity with Incoterms (e.g., FOB, CIF, DDP) helps B2B buyers manage logistics costs and streamline cross-border transactions across regions such as Africa and the Middle East.

5. Lead Time

The period from order placement to product delivery. Shorter lead times are often preferred in dynamic markets, but they may come at higher costs. Understanding lead times assists buyers in planning inventory and avoiding stockouts.

6. Quality Certifications

Standards such as ISO, CE, or specific regional certifications (e.g., EAC in Eurasia) verify product safety, quality, and compliance. These certifications are essential for entering regulated markets and building trust with end customers.

By understanding these technical properties and trade terms, international B2B buyers can make more strategic decisions, ensuring they select high-quality shoe inserts that meet regional demands and regulatory standards. This knowledge facilitates smoother negotiations, reduces risks, and supports long-term supplier relationships across diverse markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the best shoe inserts for flat feet Sector

Market Overview & Key Trends

The global market for shoe inserts targeting flat feet is experiencing robust growth driven by increasing awareness of foot health, aging populations, and a rising prevalence of flat foot conditions across diverse demographics. For international B2B buyers, understanding regional market nuances is essential. In Europe, mature markets such as Germany, France, and the UK are seeing heightened demand for innovative, personalized solutions, often emphasizing advanced orthotic technologies and customization. Conversely, emerging markets in Africa and South America are expanding rapidly, driven by rising disposable incomes and growing healthcare infrastructure that supports the adoption of specialized footcare products.

Current sourcing trends highlight a shift toward technologically advanced materials such as memory foam, gel inserts, and eco-friendly bioplastics, which enhance comfort and durability. Suppliers increasingly incorporate digital tools like 3D scanning and AI-driven customization, allowing for precise fitting and improved customer satisfaction. For B2B buyers from regions such as Argentina, Australia, or Middle Eastern countries, establishing partnerships with suppliers leveraging these innovations can provide a competitive edge.

Market dynamics are also shaped by regulatory environments and consumer preferences. In Europe, stringent health and safety standards necessitate compliance with CE marking and ISO certifications, while in Africa and South America, affordability and supply chain resilience are critical. The ongoing trend toward e-commerce and direct-to-consumer channels offers opportunities for bulk procurement and scalable distribution. B2B buyers should prioritize suppliers with flexible manufacturing capabilities, robust logistics networks, and a clear understanding of regional market demands to capitalize on these evolving dynamics.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal factor influencing procurement decisions within the footwear accessory sector, especially for shoe inserts designed for flat feet. Buyers from Africa, South America, the Middle East, and Europe are increasingly scrutinizing supply chains to ensure environmental responsibility and social ethics. Eco-conscious consumers and regulatory frameworks are pushing manufacturers to adopt greener practices, including the use of biodegradable, recycled, or renewable materials such as natural latex, cork, and organic cotton.

Certifications like Global Organic Textile Standard (GOTS), Forest Stewardship Council (FSC), and Fair Trade are gaining importance, signaling responsible sourcing and fair labor practices. For B2B buyers, partnering with suppliers holding these certifications not only mitigates reputational risks but also aligns with corporate sustainability goals. Additionally, transparent supply chains and traceability systems are becoming standard, enabling buyers to verify material origins and ethical labor conditions.

Implementing sustainability in sourcing also involves reducing carbon footprints through optimized logistics, local sourcing, and energy-efficient manufacturing processes. As regulations tighten and consumer awareness heightens, sustainable sourcing is no longer optional but essential for market competitiveness. For buyers from regions like Europe, where sustainability standards are highly developed, integrating these criteria into procurement policies can facilitate market access and brand loyalty. In emerging markets, fostering supplier relationships that prioritize eco-friendly practices can open avenues for innovation and long-term value creation.

Brief Evolution/History

The development of shoe inserts for flat feet has evolved significantly over the past few decades. Initially, simple arch supports made from basic foam or cork dominated the market, primarily focusing on affordability. Over time, technological advancements introduced materials like gel, memory foam, and thermoplastics, enhancing comfort and functional support. The trend toward customization gained momentum with the advent of 3D printing and digital scanning, allowing for tailored solutions that improve fit and efficacy.

In recent years, sustainability has become a core driver of innovation, prompting manufacturers to incorporate eco-friendly materials and transparent supply chains. The shift reflects a broader industry movement toward responsible manufacturing and consumer transparency. For B2B buyers, understanding this evolution helps in selecting suppliers capable of delivering innovative, compliant, and sustainable products that meet both regional standards and consumer expectations. Recognizing these trends ensures a strategic advantage in sourcing high-quality, future-ready shoe inserts for flat feet.

Frequently Asked Questions (FAQs) for B2B Buyers of best shoe inserts for flat feet

1. How can I effectively vet shoe insert suppliers to ensure product quality and reliability?

To vet suppliers effectively, start by requesting comprehensive product samples and detailed specifications, including materials and manufacturing processes. Verify their certifications such as ISO, CE, or FDA approvals to ensure compliance with international standards. Check references and seek feedback from other B2B clients, especially those from your region or similar markets. Conduct factory audits or virtual inspections when possible, and review their quality control procedures. Prioritize suppliers with transparent communication, consistent delivery records, and a proven track record of meeting international standards, reducing risks for your business.

2. What customization options are typically available for shoe inserts, and how can I communicate my specific requirements?

Most suppliers offer customization in terms of size, shape, arch support level, and material composition. Advanced options may include branding, packaging, and specific ergonomic features tailored to regional foot morphology. Clearly articulate your target customer demographics, including foot size ranges and common flat foot conditions, to ensure the supplier understands your needs. Provide detailed design specifications, sketches, or prototypes if possible. Establish open channels with the supplier’s R&D or technical team to discuss feasibility, lead times, and costs associated with customizations, ensuring your product aligns with your market demands.

3. What are typical minimum order quantities (MOQs), lead times, and payment terms I should expect for international bulk orders?

MOQs vary widely but generally range from 500 to 5,000 pairs, depending on supplier capacity and product complexity. Lead times are typically between 4 to 12 weeks, including manufacturing and shipping, but can extend during peak seasons or for large orders. Payment terms often include 30% upfront deposit with the balance payable before shipment, or letters of credit for larger transactions. Negotiate flexible payment terms that suit your cash flow, and consider establishing long-term relationships for better terms. Always confirm lead times upfront to plan your inventory and distribution effectively.

4. What certifications and quality assurance processes should I verify to ensure the safety and efficacy of the shoe inserts?

Ensure the supplier holds relevant certifications such as ISO 9001 for quality management, CE marking for European markets, or FDA approval for North American standards. Request documentation demonstrating compliance with regional safety and health regulations. Verify that the supplier conducts rigorous quality control checks at each production stage, including material testing, durability assessments, and ergonomic validation. Request test reports and third-party inspection certificates when possible. Establish quality assurance agreements and conduct periodic audits to maintain consistent product standards, thereby reducing liability and enhancing customer satisfaction.

5. How do I manage logistics, shipping, and customs clearance when importing shoe inserts to different regions?

Partner with freight forwarders experienced in international shipments to streamline logistics. Clarify Incoterms (e.g., FOB, CIF) with your supplier to define responsibilities and costs clearly. Ensure the supplier provides accurate commercial invoices, packing lists, and certificates of origin to facilitate customs clearance. Be aware of regional import tariffs, VAT, and regulatory requirements in your target markets such as Argentina, Australia, or Middle Eastern countries. Consider consolidating shipments to reduce costs and optimize delivery schedules. Regularly track shipments and maintain open communication with logistics providers for timely updates and issue resolution.

6. What should I do if I encounter disputes or quality issues with my supplier’s products?

Establish clear contractual terms outlining quality standards, inspection rights, and dispute resolution procedures before placing orders. If issues arise, document them thoroughly with photographs and detailed descriptions. Communicate promptly with your supplier, referencing contractual clauses or agreed-upon specifications. Negotiate corrective actions such as replacements, refunds, or partial refunds. If disputes cannot be resolved amicably, consider involving third-party arbitration or legal counsel familiar with international trade laws. Building strong relationships and maintaining transparent communication are key to resolving issues efficiently and preserving long-term partnerships.

7. How can I ensure my bulk orders are compliant with regional safety and regulatory standards?

Research the specific standards applicable in your target markets, such as European CE marking, Australian ACCC regulations, or South American regional standards. Share these requirements with your supplier early in the negotiation process. Request compliance documentation, test reports, and certifications that confirm adherence to regional regulations. Incorporate compliance clauses into your purchase agreements and consider engaging local regulatory consultants or third-party labs for independent verification. Regular audits and product testing post-production can further ensure ongoing compliance, reducing the risk of import delays or legal issues.

8. How can I build a sustainable and long-term sourcing relationship with reliable suppliers?

Start by establishing clear communication channels and mutual expectations from the outset. Prioritize suppliers with proven track records, strong certifications, and capacity for scalable production. Invest in developing rapport through consistent orders, timely payments, and constructive feedback. Consider offering volume commitments or long-term contracts to secure better pricing and priority service. Regularly visit factories or conduct virtual audits to monitor ongoing quality and capacity. Building trust and demonstrating commitment to quality and compliance will foster loyalty, enabling you to negotiate better terms, adapt to market changes, and secure a stable supply chain.

Strategic Sourcing Conclusion and Outlook for best shoe inserts for flat feet

Conclusion and Future Outlook

Effective strategic sourcing is pivotal for B2B buyers seeking the best shoe inserts for flat feet, especially in dynamic markets across Africa, South America, the Middle East, and Europe. By prioritizing suppliers with proven quality standards, innovative product offerings, and reliable logistics, companies can secure competitive advantages and meet growing consumer demand for comfortable, orthopedic footwear solutions.

In an increasingly globalized marketplace, diversifying sourcing channels and establishing strong supplier relationships will mitigate risks associated with supply chain disruptions and fluctuating raw material costs. Emphasizing sustainability and compliance also enhances brand reputation and aligns with evolving consumer preferences worldwide.

Looking ahead, international buyers should leverage emerging technologies—such as digital procurement platforms and data-driven supplier assessments—to optimize sourcing strategies further. Staying attuned to regional market trends and regulatory changes will enable proactive adaptation and sustained growth.

Actionable Tip: Engage with local industry experts and trade associations in your region to identify trusted suppliers and stay ahead of innovation trends. Embracing a strategic, forward-thinking approach will ensure your sourcing operations remain resilient, competitive, and aligned with global demand for high-quality, ergonomic shoe inserts.