Your Ultimate Guide to Sourcing Black Hoka Shoes

Guide to Black Hoka Shoes

- Introduction: Navigating the Global Market for black hoka shoes

- Understanding black hoka shoes Types and Variations

- Key Industrial Applications of black hoka shoes

- Strategic Material Selection Guide for black hoka shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for black hoka shoes

- Comprehensive Cost and Pricing Analysis for black hoka shoes Sourcing

- Spotlight on Potential black hoka shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for black hoka shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the black hoka shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of black hoka shoes

- Strategic Sourcing Conclusion and Outlook for black hoka shoes

Introduction: Navigating the Global Market for black hoka shoes

In today’s highly competitive global footwear market, black HOKA shoes have emerged as a vital product category for retailers, distributors, and importers seeking premium athletic and lifestyle footwear. Their distinctive design, superior cushioning, and reputation for quality make them a sought-after choice across diverse markets, from Africa and South America to the Middle East and Europe. For B2B buyers, understanding the nuances of sourcing these shoes—ranging from product varieties to manufacturing standards—is crucial for gaining a competitive edge and ensuring customer satisfaction.

This comprehensive guide aims to equip international buyers with actionable insights into the entire supply chain of black HOKA shoes. It covers essential aspects such as product types, materials used, manufacturing processes, quality control standards, and reliable supplier networks. Additionally, it addresses key considerations like cost optimization, market demand trends, and regulatory compliance, helping buyers make informed sourcing decisions.

Whether you are sourcing from established manufacturing hubs like Indonesia and Thailand or exploring emerging suppliers in South America and Africa, this guide offers strategic guidance tailored to your regional context. By understanding the critical factors that influence quality, pricing, and supply chain stability, B2B buyers can confidently navigate the complex global market—maximizing profitability while meeting the evolving demands of their target markets.

Understanding black hoka shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Running Shoes | Lightweight, cushioned, with responsive midsoles | Athletic retail, sports stores, wholesale importers | Pros: High demand, versatile; Cons: High competition, rapid fashion shifts |

| Trail Shoes | Durable, aggressive tread patterns, water-resistant uppers | Outdoor gear suppliers, specialty sports distributors | Pros: Growing outdoor market; Cons: Niche appeal, higher manufacturing costs |

| Lifestyle/Casual Shoes | Sleek design, minimal branding, versatile for daily wear | Fashion retailers, boutiques, online marketplaces | Pros: Broad consumer base; Cons: Price sensitivity, trend dependence |

| Performance/Training Shoes | Enhanced stability, specialized support for gym and cross-training | Fitness centers, sports teams, specialty retailers | Pros: Niche market with premium margins; Cons: Requires technical specifications |

| Orthopedic/Comfort Shoes | Extra support, cushioned insoles, ergonomic design | Medical supply distributors, health-focused outlets | Pros: Stable demand in health sector; Cons: Higher production costs, certification requirements |

Running Shoes

Running shoes are among the most popular black Hoka shoes, characterized by lightweight construction, ample cushioning, and responsive midsoles designed for high performance. They appeal widely to both casual runners and professional athletes, making them highly suitable for bulk purchasing by sports stores and wholesale distributors. When sourcing, B2B buyers should evaluate the durability of materials, brand reputation, and whether the design aligns with regional preferences. Volume discounts and brand partnerships can enhance competitiveness in markets like Europe or emerging markets in Africa and South America.

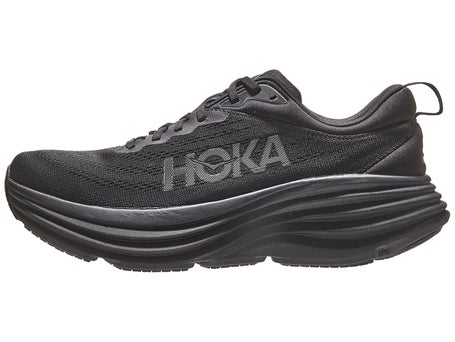

Illustrative Image (Source: Google Search)

Trail Shoes

Trail Hoka shoes feature rugged soles with aggressive tread patterns and water-resistant or breathable uppers, making them ideal for outdoor activities and rough terrains. These shoes are increasingly sought after by outdoor gear suppliers and specialty sports distributors, especially in regions with active outdoor lifestyles such as the Middle East or South America. Buyers should consider the product’s durability and resistance to environmental factors, as well as potential seasonal demand fluctuations. Bulk procurement should also focus on stock variety to meet diverse outdoor activity needs.

Illustrative Image (Source: Google Search)

Lifestyle/Casual Shoes

Black Hoka lifestyle shoes emphasize sleek, minimalistic designs suitable for everyday wear. They often combine comfort with contemporary aesthetics, appealing to fashion-conscious consumers across various markets. For B2B buyers, especially in fashion retail or online marketplaces, understanding regional style preferences and price points is critical. These shoes tend to have high turnover but also face rapid trend changes, so flexible inventory planning and quick turnaround are essential for maximizing margins.

Performance/Training Shoes

Designed for gym workouts, cross-training, and sports-specific activities, these shoes offer enhanced stability and support. They are targeted at fitness centers, sports teams, and specialty sports retailers. B2B buyers should focus on technical specifications, certifications, and the ability to meet high-quality standards. These shoes often command higher margins due to their specialized nature, but require careful supplier vetting to ensure consistent product performance and compliance with regional safety standards.

Orthopedic/Comfort Shoes

Black Hoka orthopedic or comfort shoes prioritize ergonomic design, extra cushioning, and support, catering to health-conscious consumers and those with specific medical needs. They are often distributed through medical supply channels or health-focused retail outlets. For international buyers, compliance with medical device regulations and certification standards is crucial. These shoes tend to have stable demand, especially in aging populations, but sourcing should emphasize quality control and certification to avoid compliance issues in different markets.

Key Industrial Applications of black hoka shoes

| Industry/Sector | Specific Application of black hoka shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Heavy Industry | Safety footwear for workers on construction sites | Enhanced safety, slip resistance, durability reduces injury risk and downtime | Certification standards (e.g., EN ISO, ASTM), durability, slip resistance, availability of bulk quantities |

| Logistics & Warehousing | Indoor and outdoor footwear for warehouse staff | Comfort for long shifts, slip resistance on varied surfaces, durability | Ergonomic design, slip resistance, supply chain reliability, size range options |

| Sports & Outdoor Activities | Performance shoes for outdoor workers and athletes | Superior grip, shock absorption, comfort improves productivity and safety | Performance features, material quality, weather resistance, compliance with safety standards |

| Manufacturing & Industrial Maintenance | Protective footwear for plant workers | Chemical and impact resistance, high durability, comfort for extended wear | Chemical resistance, impact protection, compliance with industrial safety standards |

| Retail & Commercial Spaces | Staff uniform shoes for retail, hospitality, and service sectors | Professional appearance, comfort, durability enhances customer experience | Aesthetic consistency, comfort, ease of maintenance, supply flexibility |

Construction & Heavy Industry

Black Hoka shoes are extensively used as safety footwear in construction and heavy industry sectors. They provide critical slip resistance, impact protection, and durability essential for challenging environments. B2B buyers from Africa, South America, the Middle East, and Europe should prioritize sourcing shoes with relevant safety certifications (such as EN ISO or ASTM standards). Bulk purchasing from reliable suppliers ensures consistent quality, reducing workplace injuries and associated costs. International buyers should also verify material specifications for heat, chemical, or oil resistance, especially in regions with extreme climates or industrial pollutants.

Logistics & Warehousing

In logistics and warehousing, black Hoka shoes serve as essential footwear for staff operating on varied surfaces, both indoors and outdoors. Their slip-resistant soles and ergonomic design help prevent accidents during long shifts, while durability minimizes replacement costs. For international B2B buyers, sourcing should focus on shoes that meet specific safety standards, offer comfort for extended wear, and are available in diverse sizes to accommodate diverse workforces. Reliable supply chains are crucial to avoid disruptions, especially in regions with logistical challenges like remote parts of Africa or South America.

Sports & Outdoor Activities

Black Hoka shoes are favored in outdoor work environments, including maintenance crews, agricultural workers, and outdoor athletes. Their performance features—such as superior grip, shock absorption, and weather resistance—enhance safety and productivity. B2B buyers should seek suppliers offering shoes with high-performance materials that withstand diverse climatic conditions, from humid tropical regions to arid Middle Eastern deserts. Ensuring compliance with regional safety standards and availability of customized options can provide a competitive advantage in serving local markets.

Manufacturing & Industrial Maintenance

In manufacturing plants and industrial maintenance operations, black Hoka shoes are valued for their chemical resistance, impact protection, and long-lasting comfort. These shoes help prevent injuries caused by falling objects, chemical spills, or slips on oily surfaces. International buyers should look for shoes with certifications aligned with industrial safety norms, and consider sourcing from suppliers with proven expertise in industrial-grade footwear. Ensuring consistent supply and customization options can help meet specific industry needs across different regions.

Retail & Commercial Spaces

Black Hoka shoes are increasingly used as staff uniforms in retail, hospitality, and service sectors, offering a balance of professionalism, comfort, and durability. They contribute to a cohesive brand image while ensuring staff safety and comfort during long working hours. For B2B buyers, sourcing should focus on shoes that maintain aesthetic appeal, are easy to clean, and are available in large quantities with consistent quality. Regional considerations include style preferences, sizing standards, and supply chain reliability to serve diverse markets efficiently.

Strategic Material Selection Guide for black hoka shoes

Analysis of Common Materials for Black Hoka Shoes

When selecting materials for black Hoka shoes, B2B buyers must consider a range of factors including durability, cost, manufacturing complexity, and compliance with international standards. Below is an in-depth review of four common materials used in the production of these shoes, with actionable insights tailored for global markets such as Africa, South America, the Middle East, and Europe.

1. EVA (Ethylene Vinyl Acetate) Foam

Key Properties:

EVA foam is lightweight, flexible, and offers excellent cushioning. It possesses good shock absorption qualities, making it ideal for midsole applications. Its thermal insulation properties also help maintain comfort across diverse climates.

Pros & Cons:

* Pros: Cost-effective, easy to mold, and provides high comfort levels.

* Cons: Less durable under prolonged stress or exposure to UV radiation; can degrade over time, especially in hot environments.

Impact on Application:

EVA is suitable for midsole components but less ideal for outsole or structural elements where higher wear resistance is required. Its compatibility with various dyes makes it easy to produce in black.

International Considerations:

EVA foam generally complies with ASTM and EN standards but may vary in VOC emissions depending on manufacturing processes. Buyers in regions with strict chemical regulations (e.g., Europe’s REACH) should verify supplier compliance. For markets like Africa and South America, cost and availability are primary considerations, but ensuring eco-friendly formulations can enhance market acceptance.

2. Rubber (Natural and Synthetic)

Key Properties:

Rubber offers excellent abrasion resistance, flexibility, and weatherproofing. Natural rubber provides superior elasticity, while synthetic variants like SBR (Styrene-Butadiene Rubber) are more resistant to aging and environmental factors.

Pros & Cons:

* Pros: High durability, good grip, and resistance to environmental elements.

* Cons: Heavier than foam materials, potentially higher cost depending on grade, and complex manufacturing processes.

Impact on Application:

Rubber is predominantly used for outsoles, providing traction and durability. Its black coloration is naturally achievable, reducing dyeing costs. Compatibility with various adhesives and bonding agents is well-established.

International Considerations:

Rubber production and quality standards vary globally. European buyers often prefer synthetic rubber with certified environmental and safety standards (e.g., DIN, JIS). In regions like Africa and South America, sourcing sustainable or recycled rubber can be advantageous, aligning with local environmental policies and consumer preferences.

3. Polyurethane (PU)

Key Properties:

Polyurethane offers high resilience, excellent load-bearing capacity, and good abrasion resistance. It can be formulated as foam or solid, depending on application needs.

Pros & Cons:

* Pros: Durable, versatile, and capable of producing high-quality black finishes.

* Cons: More expensive than EVA or rubber, with complex manufacturing requirements. It can also be less breathable, impacting comfort.

Impact on Application:

PU is often used for insoles, midsoles, and structural components requiring durability. Its chemical stability makes it suitable for diverse climates, including hot and humid regions.

International Considerations:

Manufacturers must ensure PU formulations meet local chemical safety standards. For export markets like Europe, compliance with REACH and other chemical safety directives is critical. In developing regions, cost considerations may limit the use of PU to premium segments or specialized applications.

4. Leather (Synthetic and Genuine)

Key Properties:

Leather provides a premium aesthetic, breathability, and flexibility. Synthetic leather (PU or PVC-based) offers similar visual appeal with potentially lower cost and easier maintenance.

Pros & Cons:

* Pros: High-end appearance, good durability, and comfort.

* Cons: Higher cost, variable environmental impact, and potential issues with water resistance (especially for genuine leather without treatment).

Impact on Application:

Leather is primarily used for upper components, especially in fashion-forward or high-end models. Synthetic options are often preferred for cost-sensitive markets and can be produced in black with consistent quality.

International Considerations:

European markets emphasize eco-friendly and ethically sourced leather, requiring certifications such as LWG or ISO standards. In regions like Africa and South America, availability and cost are dominant factors, but increasing consumer demand for sustainable materials is influencing procurement choices.

Summary Table

| Material | Typical Use Case for black Hoka shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| EVA Foam | Midsole cushioning | Lightweight, cost-effective, high comfort | Less durable under UV and heat exposure | Low |

| Rubber | Outsole | Excellent durability, grip, weatherproofing | Heavier, higher cost depending on grade | Med |

| Polyurethane (PU) | Insoles, midsoles, structural parts | Durable, versatile, high resilience | Higher cost, complex manufacturing | High |

| Leather (Synthetic & Genuine) | Upper components | Premium appearance, breathable | Costly, environmental concerns, maintenance | Med-High |

This detailed analysis provides B2B buyers with a strategic understanding of material choices, enabling informed procurement decisions aligned with regional standards, cost considerations, and product performance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for black hoka shoes

Manufacturing Processes of Black Hoka Shoes

The production of black Hoka shoes involves a series of meticulously coordinated stages, each critical to ensuring product quality and consistency. For international B2B buyers, understanding these stages helps in assessing supplier capabilities and ensuring compliance with quality standards.

1. Material Preparation and Procurement

The process begins with sourcing high-quality raw materials, including synthetic or leather uppers, specialized midsole foams, rubber outsoles, and reinforcing components. Reputable manufacturers prioritize suppliers with certifications such as ISO 9001 or environmental standards like ISO 14001. Buyers should verify supplier credentials and request material test reports (MTRs) to ensure compliance with durability, safety, and environmental norms.

2. Forming and Cutting

The upper components are cut from fabric or leather using computer-controlled cutting machines to ensure precision and minimal waste. In some factories, laser cutting technology is employed to achieve clean edges and intricate designs, especially for customized orders. Proper handling during this stage reduces defects and rework.

3. Assembly and Stitching

Assembling involves attaching the upper to the midsole and outsole. Skilled workers or automated sewing machines stitch the upper panels, reinforce stress points, and install eyelets or other hardware. The midsole, often made from EVA or polyurethane foam, is molded using compression or injection techniques to achieve optimal cushioning. The assembly process is crucial for ensuring structural integrity and comfort, especially in high-performance models like Hoka shoes.

4. Finishing and Quality Checks

Finishing includes applying surface treatments such as polishing, coloring, or coating to achieve the desired black aesthetic. This stage also involves attaching the outsole, adding insoles, and branding elements. Visual inspections and tactile assessments are performed to verify uniformity, color consistency, and absence of defects. Automated inspection systems may also be employed for high-volume production.

Quality Control (QC) in Manufacturing

Effective QC practices are essential for maintaining the high standards associated with Hoka shoes, especially for B2B buyers seeking reliable suppliers across diverse markets.

1. International Standards and Certifications

Manufacturers typically adhere to ISO 9001 standards for quality management systems, which emphasize process consistency and continuous improvement. For footwear, additional certifications such as CE (European conformity), ASTM standards (for safety testing), or API certifications (for material safety) may be relevant. Buyers should request documented certifications to validate compliance.

2. QC Checkpoints and Inspection Types

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specifications. Tests include tensile strength, colorfastness, and chemical safety.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing detects deviations early. This includes dimensional checks, seam strength tests, and surface inspections.

- Final Quality Control (FQC): Before shipment, finished shoes undergo comprehensive inspections—visual checks for defects, fit tests, and durability assessments. Random sampling and statistical process control (SPC) methods are often used.

3. Testing Methods

Manufacturers utilize various testing techniques, such as:

– Pull Tests: To assess seam strength and bonding integrity.

– Flex Tests: To evaluate durability under repeated bending.

– Colorfastness Tests: Ensuring black coloration remains stable after exposure to light, water, and abrasion.

– Slip Resistance Tests: Particularly relevant for outsole performance, aligning with industry standards like ASTM or ISO.

Verifying Supplier QC for International Buyers

B2B buyers should implement robust verification mechanisms to ensure supplier compliance with quality standards:

- Audits: Conduct on-site audits, preferably with third-party inspection agencies familiar with regional manufacturing practices. Focus on production processes, QC procedures, and documentation.

- Inspection Reports: Require detailed inspection reports, test certificates, and batch traceability documentation for each shipment.

- Third-party Inspection: Engage independent inspection firms (e.g., SGS, Bureau Veritas) to perform pre-shipment inspections, especially when dealing with suppliers from regions like Indonesia, Thailand, or other emerging manufacturing hubs.

Nuances in QC for Different Regions

Different regions may have varying adherence levels to international standards, influenced by local regulations, infrastructure, and industry maturity. For instance:

- Africa and South America: Buyers should be cautious of inconsistent QC practices. Prioritize suppliers with recognized certifications and conduct regular audits.

- Middle East: Often emphasizes compliance with CE and safety standards; verifying certification authenticity is crucial.

- Europe (e.g., Indonesia, Thailand): Many suppliers are experienced with international markets and hold ISO 9001 or similar certifications. Nonetheless, due diligence remains essential.

Actionable Insights for B2B Buyers

- Supplier Qualification: Always verify certifications, audit reports, and test certificates before engagement.

- Sample Testing: Request pre-production samples for independent testing, especially for critical performance attributes like durability and slip resistance.

- Ongoing Monitoring: Establish long-term quality monitoring through periodic audits and third-party inspections to ensure continuous compliance.

- Customization and Certification: For custom orders, specify exact QC standards and request documented proof of compliance to facilitate smoother international trade, particularly in regions with strict import regulations.

By understanding these manufacturing and QC processes, B2B buyers can make informed decisions, select reliable partners, and ensure that black Hoka shoes meet their quality expectations across diverse markets.

Comprehensive Cost and Pricing Analysis for black hoka shoes Sourcing

Cost Structure Breakdown for Black Hoka Shoes

Understanding the comprehensive cost structure is vital for international buyers aiming to optimize procurement strategies. The primary cost components include:

- Materials: High-quality synthetic or mesh uppers, foam midsoles, rubber outsoles, and specialized cushioning contribute significantly to the base cost. Premium materials or eco-friendly options may increase costs but can also add value.

- Labor: Manufacturing labor costs vary widely depending on the country. For instance, Asian countries like Vietnam or China typically offer lower wages, whereas European or Middle Eastern factories may charge higher rates but often provide stricter quality controls.

- Manufacturing Overheads: This encompasses factory utilities, machinery maintenance, and administrative expenses. Efficient factories with advanced automation tend to have lower overheads, reducing overall costs.

- Tooling and Setup: Initial mold creation and tooling can be a substantial upfront expense, especially for custom designs or limited editions. These costs are amortized over larger production runs.

- Quality Control (QC): Rigorous QC processes, including testing for durability, fit, and safety certifications, add to the cost but are essential for brand reputation and compliance in certain markets.

- Logistics and Shipping: Freight costs depend on shipment volume, mode (air or sea), and destination country. For Africa, South America, and the Middle East, inland distribution and customs clearance can also influence final landed costs.

- Profit Margin: Suppliers typically mark up prices to ensure profitability, with margins influenced by order volume, exclusivity, and relationship strength.

Price Influencers in Sourcing Black Hoka Shoes

Several factors shape the final pricing for B2B buyers:

- Order Volume and Minimum Order Quantities (MOQs): Higher volumes generally lead to lower unit costs due to economies of scale. Buyers from emerging markets should negotiate for favorable MOQs that align with their demand.

- Product Specifications and Customization: Customized designs, specific colorways, or unique features (e.g., enhanced cushioning or specific certifications) increase costs. Standard models are more cost-effective.

- Materials and Quality Standards: Using higher-grade materials or obtaining certifications (e.g., ISO, environmental standards) can elevate costs but also improve marketability.

- Supplier Capabilities and Reputation: Established manufacturers with proven quality records might command higher prices but reduce risks of defects or delays.

- Incoterms and Delivery Terms: FOB (Free On Board), CIF (Cost, Insurance, Freight), or DDP (Delivered Duty Paid) terms influence landed costs. DDP, for instance, includes all logistics and customs fees, providing clarity but often at a premium.

Strategic Buyer Tips for Cost Optimization

- Negotiate Effectively: Leverage order volume, long-term relationships, or exclusivity agreements to secure better pricing. Highlight potential future orders to incentivize suppliers.

- Focus on Total Cost of Ownership (TCO): Consider not only the unit price but also shipping, customs, tariffs, and after-sales support. For instance, sourcing from countries with favorable trade agreements can reduce tariffs.

- Optimize Logistics: Explore shipping modes—sea freight for large volumes typically offers cost savings over air freight. Group shipments and consolidate orders to minimize logistics expenses.

- Understand Pricing Nuances: Prices can vary based on exchange rates, political stability, and market demand. It’s advisable to request detailed quotes that specify all cost components to avoid hidden charges.

- Market-Specific Considerations: Buyers from Africa, South America, the Middle East, and Southeast Asia should be aware of local import duties, taxes, and compliance requirements, which can significantly impact the final landed cost.

Indicative Price Range (Disclaimer)

For bulk orders of standard black Hoka shoes, factory prices typically range from $40 to $70 per pair, depending on specifications, order volume, and supplier location. Final landed costs, including logistics and tariffs, may increase the total expenditure by 10-30%. Customized or premium models can command higher prices, potentially exceeding $80 per pair.

This comprehensive analysis underscores the importance of strategic sourcing, thorough cost evaluation, and proactive negotiation to optimize procurement of black Hoka shoes in international markets. Buyers should tailor their approach based on specific market conditions, supplier capabilities, and logistical considerations to achieve the best value.

Spotlight on Potential black hoka shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for black hoka shoes.)*

Essential Technical Properties and Trade Terminology for black hoka shoes

Critical Technical Properties of Black Hoka Shoes

1. Material Grade and Composition

The quality of materials used in black Hoka shoes directly impacts durability, comfort, and overall product performance. Commonly used upper materials include engineered mesh or synthetic textiles, which should meet industry standards for breathability and strength. Outsole compounds often utilize durable rubber blends, with specific grades that resist wear and provide grip. For B2B transactions, sourcing shoes with certified material grades ensures consistency and aligns with your quality standards, reducing the risk of returns or warranty issues.

2. Cushioning and Midsole Technology

Hoka shoes are renowned for their maximalist cushioning, which involves specialized midsole foam compositions like EVA or RMAT. The density and resilience of these foams influence shock absorption and energy return. When evaluating suppliers, verify the technical specifications of midsole materials to ensure they meet your target comfort levels and durability expectations, especially for high-mileage or specialty use cases.

3. Tolerance and Manufacturing Precision

Tolerance refers to the permissible variation in shoe dimensions (length, width, heel height, etc.) during manufacturing. Tight tolerances—typically within ±1 mm—are crucial for consistent fit and customer satisfaction. For bulk orders, confirming manufacturer adherence to specified tolerances ensures that the shoes meet your quality and sizing requirements, minimizing customer complaints and returns.

4. Weight and Flexibility

Weight influences user comfort, especially for athletic or everyday footwear. Lighter shoes tend to enhance performance but must not compromise durability. Flexibility, often measured through bending tests, indicates how well the shoe accommodates natural foot movement. B2B buyers should specify target weight ranges and flexibility standards aligned with the shoe’s intended use, facilitating better market positioning.

5. Color Fastness and Finish Quality

For black Hoka shoes, the dye’s resistance to fading, especially in various climates, is vital. High-quality finishing ensures the color remains consistent over time and under different conditions, which is crucial for branding and customer satisfaction. When sourcing, request certification of color fastness tests and finish quality to ensure longevity and visual appeal.

Essential Industry and Trade Terms

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce footwear based on the buyer’s specifications and branding. Understanding whether a supplier offers OEM services helps B2B buyers customize designs, logos, and packaging, creating a unique product line for their market.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity a manufacturer is willing to produce per order. Recognizing MOQ limits is essential for planning inventory, managing costs, and negotiating better terms, especially when entering new markets or testing demand.

3. RFQ (Request for Quotation)

An RFQ is a formal request sent by buyers to suppliers seeking detailed pricing, lead times, and terms for specific product specifications. Issuing clear RFQs streamlines the procurement process and enables accurate cost comparisons across multiple suppliers.

4. Incoterms (International Commercial Terms)

Incoterms define responsibilities and risks between buyers and sellers during shipping and delivery. Familiarity with terms such as FOB (Free on Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid) helps in negotiating shipping costs, customs clearance, and delivery timelines, especially critical for international trade across diverse regions.

5. Lead Time

Lead time refers to the period between order confirmation and product delivery. Understanding and negotiating realistic lead times ensures inventory planning aligns with market demand, avoiding stockouts or excess inventory.

6. Quality Certification Standards

Standards such as ISO, CE, or local compliance certifications verify product safety, environmental impact, and manufacturing processes. B2B buyers should verify these certifications to ensure regulatory compliance in their target markets, reducing legal and logistical risks.

By mastering these technical properties and trade terminologies, B2B buyers from Africa, South America, the Middle East, and Europe can streamline procurement, improve supplier negotiations, and ensure product quality aligns with market expectations. Clear understanding fosters better communication, reduces misunderstandings, and enhances overall supply chain efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the black hoka shoes Sector

Market Overview & Key Trends

The global market for black Hoka shoes is experiencing significant shifts driven by technological advancements, evolving consumer preferences, and supply chain innovations. As a niche within the broader athletic and lifestyle footwear segments, Hoka’s emphasis on maximal cushioning and comfort has fostered rapid brand loyalty, especially among health-conscious and performance-driven consumers. For international B2B buyers from Africa, South America, the Middle East, and Asia (notably Indonesia and Thailand), understanding these dynamics is crucial to leveraging growth opportunities.

Emerging sourcing trends include increased adoption of digital procurement platforms, which streamline supplier vetting, order management, and logistics coordination. Blockchain technology is increasingly used to enhance transparency and traceability within the supply chain, addressing concerns around authenticity and ethical sourcing. Additionally, there is a noticeable shift towards nearshoring and regional manufacturing hubs to reduce lead times and mitigate geopolitical risks, especially amid global disruptions like COVID-19.

Market dynamics are also influenced by sustainability pressures and consumer demand for eco-friendly products. Buyers are prioritizing suppliers who demonstrate agility in adopting sustainable practices, including the use of recycled materials and environmentally conscious manufacturing processes. Importantly, competitive pricing remains critical, but it increasingly coexists with quality and sustainability credentials, compelling suppliers to innovate while maintaining affordability.

For B2B buyers, strategic sourcing involves building relationships with suppliers committed to technological integration, flexible production capacities, and transparent supply chains. Embracing data-driven decision-making and diversifying sourcing portfolios can mitigate risks associated with market volatility, ensuring a steady supply of black Hoka shoes tailored to regional consumer preferences.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a central pillar in the B2B procurement of black Hoka shoes. Environmental impacts of footwear production—ranging from water consumption and carbon emissions to waste generation—necessitate a shift towards greener practices. For international buyers, sourcing from suppliers with verified environmental credentials not only aligns with global ESG standards but also enhances brand reputation in their local markets.

Ethical sourcing is equally vital. The footwear industry has faced scrutiny over labor practices, fair wages, and working conditions. B2B buyers should prioritize suppliers with certifications such as Fair Trade, SA8000, or B Corp, which verify adherence to ethical standards. Transparent supply chains, traceability of raw materials, and regular audits are essential to mitigate risks associated with unethical practices.

In terms of materials, eco-conscious innovations include the use of recycled plastics, natural rubber, organic cotton, and biodegradable components. Suppliers offering ‘green’ certifications—such as GRS (Global Recycled Standard) or OEKO-TEX—provide added assurance of environmentally responsible production. For buyers, establishing partnerships with certified suppliers not only ensures compliance with international sustainability standards but also appeals to eco-aware consumers, enhancing market competitiveness.

Furthermore, integrating sustainability into procurement strategies can unlock benefits like cost savings through resource efficiency, reduced waste management expenses, and access to preferential trade terms in markets with stringent environmental regulations. Building a sustainable supply chain requires ongoing dialogue, capacity building, and adherence to emerging global standards.

Brief Evolution/History (Optional)

The evolution of black Hoka shoes reflects broader trends in athletic footwear, emphasizing innovation, comfort, and sustainability. Originally launched as trail-running shoes, Hoka gained popularity for its maximalist cushioning, which differentiated it from traditional athletic brands. Over time, the brand expanded into lifestyle and everyday wear segments, appealing to a broader demographic.

For B2B buyers, understanding this evolution aids in predicting future product developments and aligning sourcing strategies accordingly. As sustainability gains prominence, Hoka and similar brands are increasingly integrating eco-friendly materials and ethical manufacturing practices, aligning with global consumer trends. Recognizing these shifts enables buyers to foster long-term partnerships with suppliers committed to innovation and responsible production, ensuring relevance in dynamic markets.

This comprehensive overview equips international B2B buyers with critical insights to navigate the evolving landscape of black Hoka shoes, emphasizing strategic sourcing, sustainability, and market adaptation to seize global opportunities effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of black hoka shoes

1. How can I verify the credibility and reliability of a black Hoka shoes supplier?

To ensure supplier credibility, start by checking their business licenses, certifications (such as ISO, BSCI), and references from previous international clients. Request samples and conduct quality inspections before placing large orders. Utilize third-party inspection agencies for factory audits and product verification, especially if dealing with suppliers from emerging markets. Additionally, review online platforms like Alibaba, Global Sources, or industry-specific trade directories for supplier ratings and reviews. Establish clear communication channels and ask for detailed product catalogs, production capacity, and export history to assess long-term reliability.

2. What customization options are typically available for bulk orders of black Hoka shoes?

Most suppliers offer customization in areas such as logo placement, color shades, materials, and packaging. Some may provide design modifications, including sole patterns or fabric types, especially for large orders. Clearly communicate your branding requirements and desired specifications upfront. Confirm whether customization incurs additional costs or lead times. For larger, recurring orders, negotiate for dedicated OEM/ODM services, which can streamline the process and ensure product differentiation in competitive markets. Always request samples of customized designs before mass production to verify quality and accuracy.

3. What are typical minimum order quantities (MOQs) and lead times for black Hoka shoes?

MOQs for bulk orders usually range from 200 to 1,000 pairs, depending on the supplier and customization level. Standard lead times are generally between 4 to 8 weeks, but can extend during peak seasons or for complex customizations. To optimize supply chain planning, confirm MOQs and lead times early in negotiations. Consider establishing long-term relationships with suppliers who offer flexible MOQs or partial shipments, especially if you are entering new markets or testing demand. Always include buffer time for quality inspections, logistics delays, and customs clearance.

4. What payment terms and methods are common in international transactions for bulk shoe orders?

Common payment terms include 30% upfront deposit with 70% balance before shipment, letter of credit (L/C), or bank transfers. For trusted suppliers, some buyers negotiate payment upon delivery or documentary collections. Use secure payment methods such as international bank transfers, PayPal, or escrow services for smaller orders. Establish clear contractual agreements detailing payment milestones, penalties for delays, and dispute resolution mechanisms. For high-value orders, L/Cs provide added security, but they require compliance with strict documentation standards, so work closely with your bank and supplier.

5. What quality assurance measures and certifications should I look for in suppliers?

Ensure your supplier complies with international quality standards such as ISO 9001 or BSCI, which demonstrate consistent quality management. Request recent quality inspection reports, factory audit certificates, and test reports for materials (e.g., sole adhesion, colorfastness). Certifications like CE (Europe), SGS, or OEKO-TEX (for non-toxic materials) enhance product credibility. Incorporate quality checks at multiple stages—raw materials, in-process, and pre-shipment—to minimize defects. Establish clear quality specifications in your contracts and consider third-party inspections before shipment to avoid costly returns or reputational damage.

6. How can I manage logistics and customs clearance for importing black Hoka shoes?

Collaborate with experienced freight forwarders familiar with your target markets to streamline shipping and customs clearance. Choose reliable shipping methods—sea freight for bulk orders, air freight for urgent needs—based on cost and delivery timelines. Provide suppliers with accurate shipping documentation, including commercial invoices, packing lists, certificates of origin, and any required import permits. Research tariffs and import duties applicable in your country (e.g., Africa, South America, Middle East, Europe) to accurately calculate landed costs. Establish clear communication channels for tracking shipments and resolving customs issues promptly to avoid delays.

7. What strategies can I use to resolve disputes or quality issues with international suppliers?

Develop a clear dispute resolution process in your contract, including mediation, arbitration, or legal action under applicable jurisdiction. Maintain detailed records of all communications, agreements, and quality inspection reports. If quality issues arise, document defects thoroughly with photos and reports, and communicate promptly with your supplier. Negotiate corrective actions such as rework, refunds, or replacements. Building long-term relationships based on transparency and mutual trust can reduce conflicts. When possible, include clauses for dispute resolution and penalties to protect your interests, and consider involving third-party mediators if disagreements escalate.

8. How can I ensure sustainable and ethical sourcing of black Hoka shoes?

Prioritize suppliers with verified social compliance certifications like BSCI, SA8000, or WRAP, which demonstrate adherence to labor rights and ethical practices. Request transparency reports on sourcing materials, especially if using environmentally sensitive components. Engage with suppliers committed to reducing environmental impact through eco-friendly materials, waste management, and energy efficiency. Conduct periodic audits and site visits, even remotely, to verify compliance. Establish clear sustainability standards in your procurement policies and communicate these expectations to suppliers. This approach not only aligns with global consumer trends but also mitigates risks related to unethical practices that could damage your brand reputation.

Strategic Sourcing Conclusion and Outlook for black hoka shoes

Strategic Sourcing Conclusion and Outlook for black hoka shoes

Effective strategic sourcing is critical for international B2B buyers aiming to secure high-quality black Hoka shoes at competitive prices. By establishing strong relationships with reliable manufacturers, leveraging regional advantages, and prioritizing quality control, buyers can mitigate risks and ensure consistent product supply. Diversifying sourcing channels across regions such as Southeast Asia, Africa, and South America can also enhance resilience against market fluctuations and geopolitical uncertainties.

Illustrative Image (Source: Google Search)

Looking ahead, the evolving landscape of global trade presents opportunities for buyers to innovate their sourcing strategies—embracing sustainability initiatives, digital procurement tools, and supply chain transparency. As demand for performance footwear like black Hoka shoes continues to grow, proactive engagement with suppliers and continuous market analysis will be vital for maintaining a competitive edge.

For buyers in Africa, South America, the Middle East, and Europe, strategic sourcing is not just about cost savings but about building sustainable, scalable partnerships that support long-term growth. Now is the time to strengthen your sourcing frameworks, explore emerging markets, and leverage industry insights to secure a reliable supply chain that meets your evolving needs.