Your Ultimate Guide to Sourcing Colorway Shoes

Guide to Colorway Shoes

- Introduction: Navigating the Global Market for colorway shoes

- Understanding colorway shoes Types and Variations

- Key Industrial Applications of colorway shoes

- Strategic Material Selection Guide for colorway shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for colorway shoes

- Comprehensive Cost and Pricing Analysis for colorway shoes Sourcing

- Spotlight on Potential colorway shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for colorway shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the colorway shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of colorway shoes

- Strategic Sourcing Conclusion and Outlook for colorway shoes

Introduction: Navigating the Global Market for colorway shoes

In today’s highly competitive footwear industry, colorway shoes have emerged as a pivotal factor in capturing consumer attention and driving sales. For international B2B buyers, understanding the nuances of this segment is essential to meet diverse market demands and stay ahead of trends. Whether sourcing for retail, wholesale, or private label brands, selecting the right colorways can significantly influence product appeal, brand differentiation, and customer loyalty.

This comprehensive guide offers a strategic overview of the entire value chain—covering key aspects such as types of colorway shoes, material considerations, manufacturing and quality control processes, and trusted suppliers. It also delves into critical factors like cost optimization, market dynamics, and regulatory compliance, empowering buyers from Africa, South America, the Middle East, and Europe to make informed sourcing decisions.

By navigating this guide, B2B buyers will gain actionable insights into identifying reliable manufacturers, managing quality standards, and understanding regional market preferences. Whether you’re expanding into new territories or optimizing existing supply chains, this resource aims to enhance your ability to source high-quality, innovative colorway shoes that resonate with local consumers. Ultimately, mastering these facets will enable you to differentiate your offerings and succeed in the ever-evolving global footwear marketplace.

Understanding colorway shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Monochrome Colorways | Single, uniform color scheme across the entire shoe | Retail, wholesale distribution, brand collaborations | Easy to produce, consistent branding; limited appeal for diverse markets, potential oversaturation |

| Limited Edition / Special Releases | Unique, often seasonal or event-specific color schemes, limited quantities | High-end boutiques, exclusive collaborations | Creates buzz and exclusivity; higher procurement costs and inventory risks |

| Custom / Personalized Colorways | Customizable colors and patterns tailored to client specifications | Corporate gifting, promotional campaigns, niche markets | Enhances brand identity; longer lead times and higher costs, requires flexible manufacturing |

| Gradient / Ombre Effects | Shoes featuring color transitions or blending techniques | Trend-focused retail, specialty boutiques | Visually striking; complex manufacturing process may increase costs and production time |

| Multi-Color / Multi-Pattern | Shoes with multiple contrasting colors or patterns integrated into design | Youth markets, streetwear, fashion-forward segments | Wide appeal; potential complexity in quality control and color matching, higher material costs |

Monochrome Colorways

Monochrome shoes feature a single, consistent color across the entire surface, offering a clean and versatile aesthetic. This variation is highly suitable for mass production, making it ideal for wholesale buyers seeking reliable, scalable options. They are easier and more cost-effective to produce, with minimal color matching concerns. However, their simplicity may limit differentiation in highly competitive markets. For B2B buyers, choosing monochrome options allows for predictable inventory planning and straightforward branding opportunities, especially when partnering with brands emphasizing minimalism or uniformity.

Limited Edition / Special Releases

Limited edition colorways are crafted for exclusivity, often tied to seasonal trends, collaborations, or special events. These shoes appeal to premium retail segments and collectors, enabling brands to command higher prices. For international buyers, sourcing these requires careful planning around lead times, as production runs are smaller and more complex. The higher procurement cost and risk of unsold inventory should be balanced against the potential for higher margins and brand prestige. They are ideal for exclusive partnerships or marketing campaigns targeting niche markets.

Custom / Personalized Colorways

Custom colorways allow brands and buyers to tailor shoes precisely to their specifications, including unique color combinations, patterns, or branding elements. This flexibility is especially valuable for corporate gifting, promotional events, or niche markets where brand identity is paramount. The main considerations for B2B buyers include longer lead times, increased costs, and the need for flexible manufacturing processes. Building strong communication channels with manufacturers ensures quality and timely delivery, maximizing the value of personalized offerings.

Gradient / Ombre Effects

Gradient or ombre shoes feature smooth color transitions that create visually dynamic effects. These are popular in trend-driven markets such as streetwear and fashion boutiques. The manufacturing process involves advanced dyeing or printing techniques, which can elevate production costs and extend lead times. For B2B buyers, sourcing gradient shoes offers differentiation in crowded markets but requires careful quality control to ensure consistency across batches. They are best suited for brands seeking to position themselves at the forefront of fashion innovation.

Multi-Color / Multi-Pattern

Multi-color or patterned shoes incorporate contrasting hues and intricate designs, appealing to youthful, streetwear, or avant-garde segments. These shoes provide high visual impact, making them attractive for limited editions or fashion-forward collections. However, their complexity demands meticulous quality control, especially in color matching and pattern alignment, which can increase manufacturing costs. B2B buyers should evaluate supplier capabilities thoroughly and consider higher inventory risks due to rapid trend changes. When managed well, they can significantly enhance brand visibility and consumer appeal.

Key Industrial Applications of colorway shoes

| Industry/Sector | Specific Application of colorway shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports & Athletic Wear | Customizable performance footwear for team sports and events | Enhances brand visibility, customer engagement, and product differentiation | Ability to produce large volume custom designs, durable materials, colorfastness, and compliance with international sports standards |

| Fashion & Lifestyle | Limited edition or seasonal collections targeting youth markets | Drives brand exclusivity, appeals to trend-conscious consumers, boosts sales | Flexibility in design, quick turnaround times, high-quality finishes, and sourcing from trend-responsive suppliers |

| Work & Safety Footwear | High-visibility safety shoes with color-coded features | Improves workplace safety, easy identification, and compliance with safety standards | Material durability, color consistency, adherence to safety certifications, and availability in bulk quantities |

| Military & Tactical Gear | Camouflage or color-specific tactical footwear | Provides operational effectiveness, concealment, and durability in rugged environments | Rugged construction, colorfast and fade-resistant materials, and compliance with military specifications |

| Hospitality & Service Industry | Uniform footwear with specific color codes for staff roles | Facilitates easy staff identification, promotes uniformity, enhances professional appearance | Consistent color matching, comfort, slip resistance, and supply chain reliability for large deployments |

Sports & Athletic Wear

Colorway shoes in the sports industry are often customized to represent teams, sponsors, or specific events, making them a powerful branding tool. B2B buyers, especially from regions like South Africa or Brazil, can leverage these shoes to meet demand for high-performance, visually striking footwear that withstands rigorous use. The key is sourcing suppliers capable of producing large volumes with consistent colorfastness and durability, ensuring the shoes perform under extreme conditions while maintaining vibrant designs. This application enhances brand visibility and customer loyalty, particularly in competitive markets.

Fashion & Lifestyle

In the fashion sector, limited edition and seasonal collections utilize colorway shoes to attract trend-conscious consumers across Europe and the Middle East. These shoes serve as statement pieces that boost brand prestige and exclusivity. For international B2B buyers, sourcing flexible manufacturers who can deliver high-quality, innovative designs quickly is crucial. Emphasizing quick turnaround times, reliable color matching, and premium finishes will meet the dynamic demands of fashion cycles and regional preferences, ensuring market relevance and consumer appeal.

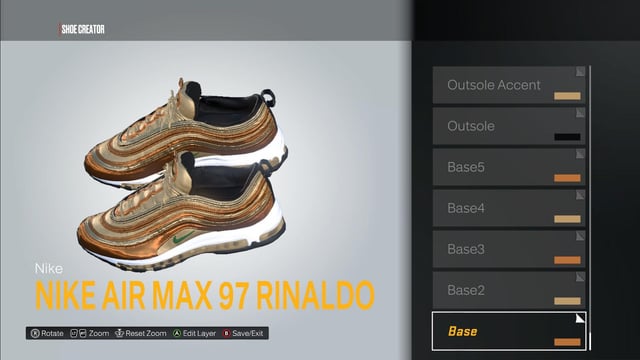

Illustrative Image (Source: Google Search)

Work & Safety Footwear

Colorway shoes are integral to safety footwear, where color coding enhances visibility and safety compliance. For industries such as construction, manufacturing, and logistics in Africa and South America, these shoes improve operational safety by enabling quick identification of personnel roles or hazard zones. Sourcing considerations include selecting suppliers who offer durable, slip-resistant, and colorfast materials that meet international safety standards (e.g., OSHA, EN ISO). Consistent quality and bulk availability are essential for large-scale deployment across multiple sites.

Military & Tactical Gear

Tactical footwear with specific colorways, such as camouflage or earth tones, supports military and law enforcement operations in regions like the Middle East and Europe. These shoes must be rugged, fade-resistant, and compliant with military specifications to withstand harsh environments. B2B buyers should prioritize suppliers with proven expertise in producing military-grade footwear, ensuring high durability, consistent colorfastness, and the ability to customize colors for different operational needs. Reliable supply chains are vital for ongoing procurement.

Hospitality & Service Industry

Uniform footwear featuring distinct colorways helps streamline staff identification and enhances professionalism within hospitality and service sectors across Africa and South America. These shoes need to combine comfort, slip resistance, and consistent color matching to maintain a uniform appearance. Sourcing considerations include sourcing from manufacturers capable of large-volume production with reliable quality control, ensuring that color consistency and durability meet industry standards. This application supports brand coherence and operational efficiency in large hospitality groups or service providers.

Strategic Material Selection Guide for colorway shoes

Material Analysis for Colorway Shoes

Selecting the appropriate materials for colorway shoes is critical for ensuring product performance, durability, and compliance with international standards. Different materials offer unique advantages and limitations, influencing manufacturing processes, cost, and end-user satisfaction. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding these nuances is essential for making informed procurement decisions.

Leather (Full-Grain, Top-Grain, or Synthetic)

Leather remains a traditional and highly favored material in the footwear industry due to its natural aesthetic and breathability. Full-grain leather offers exceptional durability and develops a unique patina over time, making it suitable for premium colorway shoes. Top-grain leather, slightly processed, balances cost and durability, while synthetic leather (PU or PVC) provides a more affordable alternative with easier manufacturing.

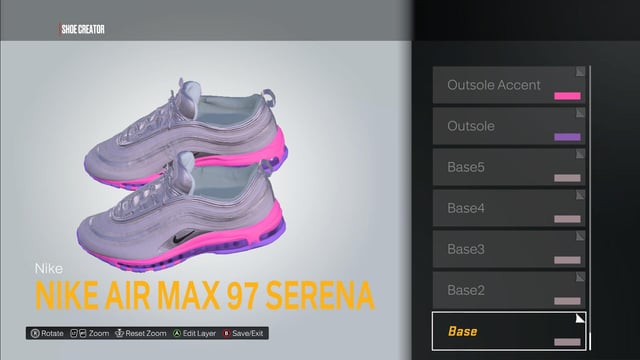

Illustrative Image (Source: Google Search)

Key Properties:

– Excellent durability and abrasion resistance

– Breathability and natural flexibility

– Varies in water resistance depending on treatment

– Meets standards like ASTM D2099 for flexibility and aging

Pros & Cons:

– Pros: Long-lasting, high-end appearance, good color retention, and customizable finishes

– Cons: Higher cost, complex manufacturing, potential environmental concerns (especially with synthetic options), and susceptibility to water damage if untreated

Impact on Application:

Leather’s natural properties make it suitable for high-end, fashion-forward colorways. However, it requires proper dyeing and finishing processes to ensure colorfastness, especially in humid or hot climates common in Africa and the Middle East.

International Considerations:

Buyers must ensure leather suppliers comply with regional environmental standards such as REACH in Europe or local regulations in South America. Certification of sustainable sourcing (e.g., Leather Working Group) can influence procurement decisions.

Thermoplastic Polyurethane (TPU)

TPU is a versatile synthetic material increasingly used in colorway shoes for components like overlays, logos, and decorative accents. Its excellent elasticity, abrasion resistance, and ease of coloring make it ideal for vibrant, customizable designs.

Key Properties:

– High flexibility and elasticity

– Good UV and weather resistance

– Chemical resistance, including oils and greases

– Meets standards like ISO 18088 for durability

Pros & Cons:

– Pros: Cost-effective, lightweight, easy to process, and offers excellent colorfastness

– Cons: Less breathable, can be prone to cracking over extended UV exposure if not formulated properly, and may have limited eco-friendliness depending on formulation

Impact on Application:

TPU’s adaptability allows for complex, colorful designs that withstand daily wear and environmental stressors. It is especially suitable for regions with high UV exposure, such as Middle Eastern markets.

International Considerations:

Manufacturers should verify compliance with environmental standards like REACH or RoHS. Buyers from Europe and South America often prefer eco-friendly formulations, so sourcing biodegradable or recycled TPU variants can be advantageous.

Rubber (Natural and Synthetic)

Rubber is fundamental in outsole construction but also plays a role in midsole and decorative elements of colorway shoes. Its elasticity and grip are unmatched, making it essential for functional and aesthetic purposes.

Key Properties:

– Excellent abrasion and slip resistance

– High flexibility and shock absorption

– Varies in chemical composition (natural vs. synthetic)

– Meets standards like ASTM D2000 for elastomeric properties

Pros & Cons:

– Pros: Durable, cost-effective, excellent weather resistance, and versatile in design

– Cons: Heavier than other materials, potential environmental concerns (especially with synthetic rubber), and limited color options once vulcanized

Impact on Application:

Rubber’s robustness makes it suitable for outdoor and rugged environments typical in Africa and South America. Its colorability is often limited to surface treatments or overlays, which must be compatible with the base material.

International Considerations:

Compliance with environmental regulations like the EU’s REACH or local standards is critical. Buyers should prefer suppliers that use natural rubber or recycled synthetic rubber to align with sustainability goals.

Summary Table

| Material | Typical Use Case for colorway shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Upper overlays, premium finishes | Durability, aesthetic appeal, breathability | High cost, complex processing, environmental concerns | High |

| Thermoplastic Polyurethane (TPU) | Decorative overlays, logos, accents | Flexibility, vibrant color options, weather resistance | Limited breathability, UV cracking risk | Med |

| Rubber | Outsole, midsole accents | Slip resistance, durability, weatherproof | Heavy weight, limited color options | Low |

| Synthetic Leather | Budget-friendly upper materials | Cost-effective, easy to dye, customizable | Less breathable, environmental impact | Med |

This analysis provides a strategic overview for international B2B buyers, emphasizing regional standards, environmental considerations, and application-specific properties. Selecting the right materials aligned with regional climates, compliance standards, and market preferences can significantly influence product success in diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for colorway shoes

Manufacturing Processes for Colorway Shoes

The production of colorway shoes involves a complex sequence of meticulously coordinated stages, each critical to ensuring the final product meets quality, aesthetic, and safety standards. For international B2B buyers, understanding these stages helps in assessing supplier capabilities and ensuring product consistency across different markets.

Material Preparation and Selection

The process begins with sourcing high-quality raw materials tailored to specific design and performance requirements. These include various leathers, synthetic leathers, textiles, rubber, EVA foam, and specialized adhesives. Suppliers often work with certified vendors to ensure materials comply with international standards such as REACH or CPSIA, especially for markets with strict chemical regulations like Europe and North America.

Key Insights for Buyers:

– Verify suppliers’ material certifications (e.g., OEKO-TEX, ISO 9001).

– Request detailed Material Safety Data Sheets (MSDS) for chemical compliance.

– For markets like Africa and South America, prioritize suppliers with local or regional sourcing to reduce logistics costs and lead times.

Forming and Component Manufacturing

This stage involves cutting, molding, and shaping components—such as uppers, insoles, and midsoles—using techniques like injection molding, stamping, and die-cutting. Automated machinery ensures precision, but manual processes may still be prevalent for certain high-end or customized colorways.

Key Insights for Buyers:

– Confirm the use of advanced machinery for consistent quality.

– Evaluate the supplier’s capacity for rapid prototyping and customization, essential for limited edition or seasonal colorways.

Assembly and Stitching

Assembly combines all components—upper, lining, sole, and embellishments—into a finished shoe. Stitching quality is paramount, with double and reinforced stitching used for durability, especially in performance or outdoor footwear.

Key Insights for Buyers:

– Ensure assembly lines follow standardized processes such as ISO 9001.

– Inspect for stitching consistency and seam strength, critical for product longevity and customer satisfaction.

Finishing and Coloring

Colorway shoes are distinguished by their vibrant and precise color schemes. This stage involves dyeing, painting, printing, and applying surface finishes like matte, gloss, or textured coatings. Techniques such as digital printing, screen printing, and heat transfer are commonly employed.

Key Insights for Buyers:

– Request detailed process documentation to verify colorfastness and adhesion.

– For complex designs, inquire about the use of eco-friendly dyes and finishes aligning with international environmental standards.

Quality Control (QC) Framework for Colorway Shoes

Robust QC systems are essential to meet international standards and ensure product reliability across diverse markets. B2B buyers should understand the key checkpoints and testing methods, as well as how to verify supplier compliance.

International and Industry Standards

- ISO 9001: The foundational quality management system standard. Suppliers certified under ISO 9001 demonstrate a structured approach to quality across manufacturing processes.

- CE Marking: For footwear sold in Europe, compliance with safety, chemical, and environmental directives is mandatory. Suppliers should provide CE certificates and technical documentation.

- Other Certifications: API (American Petroleum Institute) for materials used in specific components, and REACH compliance for chemical substances, are relevant depending on the target market.

Actionable Tip:

– Always request copies of relevant certifications and ensure they are current and applicable to the specific product batch.

QC Checkpoints and Inspection Types

- Incoming Quality Control (IQC): Verifies raw materials against specifications before production begins. Testing includes chemical analysis, physical property testing, and visual inspection.

- In-Process Quality Control (IPQC): Conducted throughout manufacturing, focusing on stitching quality, dimensional accuracy, color consistency, and surface defects.

- Final Quality Control (FQC): Performed on finished shoes before packaging. Checks include overall appearance, structural integrity, sole adhesion, and compliance with size standards.

Common Testing Methods:

– Colorfastness Tests: To ensure color does not bleed or fade after washing or exposure to sunlight.

– Adhesion Tests: To verify sole-to-upper bonding strength.

– Flex Testing: To assess durability under repeated bending or wear.

– Chemical Tests: To detect harmful substances like heavy metals or phthalates.

Verifying Supplier QC Capabilities

B2B buyers should adopt proactive measures to validate supplier QC systems:

– Audits: Conduct on-site audits or hire third-party inspection agencies familiar with footwear manufacturing standards.

– Inspection Reports: Review detailed QC reports and test results for each batch.

– Third-Party Inspection: Engage recognized agencies (e.g., SGS, Bureau Veritas) for independent verification, particularly when entering new markets or sourcing from emerging suppliers.

Additional Considerations for International Buyers:

– Understand regional differences in quality expectations; for example, European markets may have stricter chemical and safety standards than some African or South American markets.

– Negotiate clear quality warranties and return policies based on inspection results.

Navigating QC Nuances for Different Markets

International B2B buyers from Africa, South America, the Middle East, and Europe face unique challenges and opportunities in quality assurance.

- Africa & South America: Local infrastructure may limit access to advanced testing facilities. Buyers should prioritize suppliers with established third-party certifications and consider engaging inspection agencies during production runs to mitigate risks.

- Middle East: Market-specific standards, such as Gulf Standards (GSO), may require additional testing or certifications. Suppliers with experience exporting to these regions are preferable.

- Europe: Strict compliance with REACH, CE, and environmental directives is non-negotiable. Buyers should verify supplier certifications through official portals and consider comprehensive audits for continuous compliance.

Final Actionable Advice:

Establish clear communication channels with suppliers about quality expectations, and incorporate detailed inspection clauses into purchase agreements. Regularly review QC reports, conduct periodic audits, and stay updated on regional regulatory changes to ensure ongoing compliance and product excellence.

By understanding the detailed manufacturing stages and rigorous quality assurance protocols, B2B buyers can make informed decisions, foster stronger supplier relationships, and ensure the consistent delivery of high-quality colorway shoes tailored to their target markets.

Comprehensive Cost and Pricing Analysis for colorway shoes Sourcing

Understanding Cost Components in Colorway Shoes Sourcing

A thorough cost analysis begins with dissecting the primary components influencing the final price of colorway shoes. The material costs—including upper fabrics, soles, laces, and dyes—vary significantly based on quality, source country, and customization levels. High-quality or specialty materials (e.g., eco-friendly or innovative textiles) tend to increase costs but can justify premium pricing. Labor costs are highly dependent on the manufacturing country; factories in Asia typically offer lower wages, while suppliers in Europe or the Middle East may charge a premium for specialized craftsmanship or shorter lead times.

Manufacturing overheads encompass factory utilities, equipment depreciation, and management expenses, which scale with production volume. Tooling and development costs are usually upfront investments for molds and prototypes, amortized over large production runs. Quality control (QC) is essential for ensuring consistency and compliance with certifications, particularly for markets demanding high standards like Europe and South Africa, adding to per-unit costs when performed rigorously.

Logistics and shipping represent a substantial portion of total costs, especially with international sourcing. Factors such as freight mode (sea, air, or land), fuel prices, customs duties, and insurance influence final landed costs. Finally, profit margins are negotiated based on volume, exclusivity, and supplier relationships, but typically range from 10% to 30% for bulk orders.

Factors Influencing Pricing for International Buyers

Volume and Minimum Order Quantities (MOQs): Larger orders generally benefit from lower unit costs due to economies of scale, making bulk purchasing attractive for buyers from Africa, South America, or Europe. Smaller MOQs may incur higher per-unit prices, especially from premium suppliers or when customization is involved.

Customization and Specifications: Customized colorways, special finishes, or branding increase costs due to additional design work, tooling adjustments, and longer lead times. Standardized colorways tend to be more cost-effective, but market trends often demand unique designs, impacting pricing strategies.

Material Choices: Premium or imported materials, such as Italian leathers or specialized synthetic fabrics, elevate costs but can enhance brand positioning. Conversely, locally sourced or synthetic alternatives may reduce expenses but could influence quality perceptions.

Certifications and Quality Standards: Suppliers compliant with international standards (ISO, REACH, or local certifications) may charge higher prices to meet rigorous quality and safety benchmarks, especially relevant for European or Middle Eastern markets.

Supplier Factors: Established suppliers with strong reputations or those offering integrated services (design, manufacturing, logistics) often command higher prices but provide reliability and shorter lead times. Conversely, emerging manufacturers might offer competitive rates but pose risks related to quality consistency.

Incoterms and Delivery Terms: The choice of Incoterms (FOB, CIF, DDP, etc.) significantly impacts costs. Buyers should understand that FOB prices exclude freight and insurance, which they will need to arrange or negotiate separately. DDP (Delivered Duty Paid) provides convenience but often carries a premium due to added logistics handling.

Buyer Tips for Cost Optimization and Negotiation

Leverage Volume for Better Pricing: Engage in negotiations that reward larger orders with discounts or flexible payment terms. Building long-term relationships can lead to preferential pricing and priority production slots.

Assess Total Cost of Ownership (TCO): Beyond unit price, consider shipping costs, customs duties, compliance costs, and potential tariffs. An ostensibly cheaper supplier may incur higher overall costs due to freight or delays.

Negotiate Flexible Terms: Clarify lead times, payment conditions, and quality guarantees upfront. Request samples and conduct quality audits before committing to large orders, especially when sourcing from new suppliers.

Understand Pricing Nuances: Be aware of hidden costs such as tooling fees, mold charges, or late delivery penalties. Transparent communication and detailed quotations help avoid surprises.

Market-specific Considerations: Buyers from Africa or South America should consider regional tariffs, import restrictions, and local standards. European buyers often face strict compliance requirements, influencing costs and supplier selection.

Stay Informed on Price Fluctuations: Raw material prices fluctuate due to global supply chain disruptions, geopolitical tensions, or seasonal demand. Regularly review market trends to time procurement optimally.

Disclaimer

Prices for colorway shoes can vary widely based on specifications, order size, supplier relationships, and market conditions. As such, the figures provided are indicative and should be validated through direct supplier quotes and market research tailored to your specific requirements.

By understanding these cost components and influencing factors, international buyers can make more informed sourcing decisions, negotiate effectively, and optimize their overall procurement strategy for colorway shoes.

Spotlight on Potential colorway shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for colorway shoes.)*

Essential Technical Properties and Trade Terminology for colorway shoes

Key Technical Properties for Colorway Shoes

1. Material Grade and Composition

The quality and type of materials used in colorway shoes—such as leather, mesh, or synthetic fabrics—are fundamental to product durability and aesthetic appeal. Material grades (e.g., premium, standard, economy) influence the shoe’s lifespan, comfort, and suitability for different markets. B2B buyers should specify grade standards to ensure consistency across production batches, reducing defect rates and returns.

2. Colorfastness and Pigmentation Tolerance

Colorfastness refers to a shoe’s ability to retain its color after exposure to washing, sweating, or environmental factors. Tolerance levels indicate how much variation in shade or hue is acceptable during manufacturing. These properties are critical for maintaining brand integrity and customer satisfaction, especially in markets where vibrant or specific colorways are a key selling point.

3. Dimensional Tolerance and Fit

Precision in sizing is vital for customer comfort and reducing returns. Dimensional tolerances specify the allowable variation in shoe length, width, and height during production. Clear specifications help manufacturers maintain consistency, especially important when producing multiple colorways or styles based on the same pattern.

4. Sole and Stitching Strength

Durability hinges on the strength of outsole adhesion and stitching quality. Specifications should include tensile strength and seam integrity standards, ensuring shoes withstand daily wear. For international buyers, these properties impact product longevity, warranty claims, and brand reputation.

5. Finish and Surface Treatment

Surface properties such as matte, gloss, or textured finishes affect aesthetic appeal and market positioning. Tolerance levels for surface uniformity and defect rates in paint or coating applications are crucial to meet brand standards and consumer expectations across different regions.

Essential Trade Terms in the Colorway Shoe Industry

1. OEM (Original Equipment Manufacturer)

Refers to manufacturers producing shoes based on a brand’s design specifications. Understanding OEM relationships helps buyers negotiate pricing, lead times, and quality control measures. It is common for brands to outsource manufacturing to OEMs in countries like China, Vietnam, or India.

2. MOQ (Minimum Order Quantity)

The smallest quantity of shoes or components a supplier will accept per order. Knowing the MOQ helps buyers plan production schedules and negotiate better terms, especially when entering new markets or launching limited editions with specific colorways.

3. RFQ (Request for Quotation)

A formal request from buyers to suppliers for price, lead time, and technical details. An RFQ ensures clarity on costs and specifications before committing to large orders, reducing misunderstandings and facilitating competitive bidding.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities between buyer and seller regarding shipping, risk, and costs. Common Incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) influence logistics planning, especially when importing shoes across continents.

5. Lead Time

The period from order confirmation to product delivery. Precise knowledge of lead times allows buyers to synchronize production and marketing activities, particularly critical when managing seasonal colorway launches or avoiding stockouts in international markets.

6. Quality Control (QC) Standards

Predefined benchmarks for assessing finished shoes, including inspection for color consistency, stitching, material defects, and overall finish. Adhering to rigorous QC standards minimizes the risk of receiving non-compliant products, which is especially important for maintaining brand reputation in diverse markets.

By understanding these technical properties and trade terms, international B2B buyers from Africa, South America, the Middle East, and Europe can make more informed purchasing decisions, negotiate effectively, and establish reliable supply chains for colorway shoes. This knowledge ensures product quality, consistency, and alignment with market expectations across different regions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the colorway shoes Sector

Market Overview & Key Trends

The global market for colorway shoes is experiencing dynamic shifts driven by technological innovation, evolving consumer preferences, and supply chain globalization. For international B2B buyers from Africa, South America, the Middle East, and Europe, understanding these drivers is crucial to capitalizing on emerging opportunities.

Technological advancements such as digital design tools, 3D printing, and AI-driven customization are revolutionizing product development, enabling brands to offer highly personalized colorways efficiently. Moreover, e-commerce platforms and direct-to-consumer models are expanding market reach, reducing reliance on traditional retail channels. This shift is especially relevant for regions like South Africa and Saudi Arabia, where digital infrastructure is rapidly improving.

Sourcing trends are increasingly focused on agility and sustainability. Many brands are moving toward shorter, more transparent supply chains that incorporate local or regional suppliers to reduce lead times and mitigate geopolitical risks. The rise of nearshoring and regional manufacturing hubs benefits buyers from Africa and South America, offering opportunities for faster delivery and lower costs.

Market dynamics are also influenced by consumer demand for exclusivity and limited-edition releases, pushing brands to adopt agile production methods and innovative colorway offerings. For B2B buyers, staying attuned to these trends means fostering relationships with suppliers who can adapt quickly and provide high-quality, customizable options at competitive prices. Leveraging digital sourcing platforms and trade shows focused on footwear innovations can enhance sourcing efficiency and market intelligence.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a core consideration in the colorway shoes sector, impacting sourcing decisions and brand reputation globally. Environmental impacts of footwear manufacturing—such as water consumption, chemical use, and carbon emissions—are under increased scrutiny from consumers and regulators alike. B2B buyers from regions like Europe and the Middle East are prioritizing suppliers with robust sustainability credentials, seeking to align with global eco-conscious trends.

Ethical sourcing practices are equally vital, encompassing fair labor conditions, transparent supply chains, and adherence to international labor standards. Certifications such as Fair Trade, SA8000, and B Corp serve as indicators of responsible manufacturing, providing assurance that products are made ethically. For buyers, partnering with suppliers holding these credentials minimizes reputational risks and enhances brand credibility.

In terms of materials, there is a growing demand for ‘green’ components—such as recycled plastics, organic dyes, and bio-based leathers—that reduce environmental impact. Innovations like waterless dyeing, biodegradable adhesives, and low-impact synthetic materials are gaining traction. Incorporating these sustainable practices not only aligns with global environmental goals but can also unlock market advantages, as consumers increasingly favor eco-friendly products.

For B2B buyers, establishing clear sustainability criteria during sourcing negotiations, conducting supplier audits, and engaging in long-term partnerships with eco-certified manufacturers are essential steps toward building resilient, sustainable supply chains.

Brief Evolution/History

The colorway shoes sector has evolved significantly over the past few decades, transitioning from basic monochrome designs to highly expressive, customizable footwear. Initially driven by limited technology and mass production, the industry now thrives on innovation, personalization, and sustainability. This evolution offers B2B buyers opportunities to differentiate their offerings through exclusive colorways and innovative materials.

Understanding this history underscores the importance of agility and forward-looking sourcing strategies. As consumer preferences shift toward more personalized and sustainable products, suppliers who have adapted early—embracing digital design, sustainable materials, and ethical practices—are better positioned to serve global markets. For buyers, leveraging this evolution means partnering with manufacturers who can deliver cutting-edge, responsible products that meet the demands of modern consumers across diverse regions.

Frequently Asked Questions (FAQs) for B2B Buyers of colorway shoes

1. How can I effectively vet and verify international suppliers of colorway shoes?

To ensure supplier credibility, start with comprehensive background checks, including reviewing their business licenses, certifications, and references from existing clients. Request samples to assess quality firsthand and verify consistency. Utilize third-party verification services or trade platforms with verified supplier badges. Engage in video calls to evaluate communication professionalism and production facilities if possible. Additionally, check for compliance with international standards (e.g., ISO, ethical sourcing certifications). Establish clear communication channels and draft detailed contracts to mitigate risks. Regular audits and establishing long-term relationships help maintain quality and reliability.

2. What customization options are typically available for colorway shoes, and how can I communicate my requirements effectively?

Most suppliers offer customization in colors, materials, branding (logos, tags), and design elements. To communicate your needs clearly, provide detailed specifications, including color codes (Pantone), material types, and design sketches or prototypes. Use visual references and specify production standards to avoid misunderstandings. Clarify lead times for custom orders and request samples before bulk production. Consider working with suppliers experienced in your target markets to ensure they understand regional preferences and standards. Establishing a detailed purchase agreement with agreed-upon specifications, timelines, and quality benchmarks minimizes errors and delays.

3. What are typical minimum order quantities (MOQs), lead times, and payment terms for bulk colorway shoe orders?

MOQs vary based on supplier size and production capacity but generally range from 300 to 1,000 pairs for customized shoes. Lead times typically span 4 to 12 weeks, depending on complexity and order size. Payment terms often include a 30-50% deposit upfront, with the balance payable upon shipment or delivery. Some suppliers may offer flexible terms for repeat business or larger orders. To optimize cash flow, negotiate payment schedules aligned with your sales cycle, and consider letters of credit or secure escrow payments for added protection. Always clarify these terms before confirming orders to avoid delays or misunderstandings.

4. What quality assurance measures and certifications should I look for when sourcing colorway shoes internationally?

Ensure suppliers adhere to recognized quality standards such as ISO 9001 for quality management and comply with safety standards relevant to your market (e.g., REACH, CPSIA). Request quality assurance protocols, including inspection reports, testing certificates (e.g., slip resistance, durability), and factory audit reports. Consider third-party inspection services during production and pre-shipment to verify compliance with agreed standards. Certifications like ethical sourcing (Fair Trade, SA8000) can also add credibility. Establish clear quality benchmarks in your contracts and insist on detailed testing reports to ensure product safety, durability, and compliance, reducing the risk of returns or market rejection.

5. How can I manage logistics effectively when importing colorway shoes to different regions?

Start by choosing suppliers experienced in international shipping and familiar with your destination country’s import regulations. Negotiate Incoterms (e.g., FOB, CIF) that define responsibility and cost-sharing points. Engage reputable freight forwarders to handle customs clearance, documentation, and transportation. Maintain a detailed schedule, including production lead times, shipping, and customs processing, to forecast delivery accurately. Consider local warehousing options or distribution centers to reduce transit times and costs. Stay updated on import tariffs, taxes, and compliance requirements in your target markets to avoid delays or additional costs.

6. What are the common dispute resolution methods with international suppliers, and how can I protect my interests?

Disputes often arise over quality, delivery delays, or payment issues. To mitigate risks, include clear dispute resolution clauses in contracts, specifying preferred methods such as arbitration (preferably in a neutral jurisdiction) or mediation. Use international arbitration bodies like ICC or UNCITRAL for binding resolutions. Maintain detailed records of communications, agreements, and inspections to support claims. Consider purchasing trade credit insurance or escrow services for payments. Building strong, transparent relationships with suppliers and maintaining open communication channels helps prevent misunderstandings and facilitates quicker resolution when issues occur.

Illustrative Image (Source: Google Search)

7. How do I ensure compliance with regional regulations and standards for colorway shoes in my target markets?

Research specific regional standards—such as REACH and CE marking in Europe, SABS standards in South Africa, or GCC compliance in the Middle East. Communicate these requirements clearly to your suppliers and request compliance certificates or test reports. Engage local compliance consultants or third-party testing labs to verify products before shipment. Incorporate compliance clauses into contracts and conduct periodic audits. Staying informed about evolving regulations ensures your products meet safety, environmental, and labeling standards, reducing the risk of legal penalties, product recalls, or market bans.

8. What steps should I take to build a sustainable and long-term relationship with my international supplier?

Start by establishing transparent communication and setting mutual expectations from the outset. Offer consistent volume orders and timely payments to build trust. Provide constructive feedback and collaborate on product development to meet market demands. Visit suppliers’ facilities when possible or engage local agents to oversee quality and production processes. Invest in understanding their challenges and capabilities, and share market insights to foster partnership growth. Regularly review performance metrics, conduct audits, and negotiate favorable terms for repeat business. A strategic, collaborative approach ensures supply chain stability, quality consistency, and mutual growth over the long term.

Strategic Sourcing Conclusion and Outlook for colorway shoes

Conclusion and Future Outlook

Effective strategic sourcing remains essential for international buyers seeking to capitalize on the vibrant and dynamic colorway shoe market. By establishing reliable supplier relationships, leveraging regional manufacturing hubs, and prioritizing quality and innovation, buyers can secure competitive advantages and meet diverse consumer demands across Africa, South America, the Middle East, and Europe.

As consumer preferences continue to evolve toward personalized and sustainable products, sourcing strategies must adapt accordingly. Embracing technological tools such as digital procurement platforms and data-driven insights will enhance supply chain agility and transparency. Additionally, fostering long-term partnerships with manufacturers committed to quality, ethical practices, and innovation will drive sustained growth.

Looking ahead, international B2B buyers should proactively explore emerging sourcing regions and innovative materials to diversify their supply chains and reduce risks. Strategic investments in supplier relationships and market intelligence will be crucial to staying ahead in a rapidly changing industry. By adopting a forward-thinking approach, buyers from regions like South Africa, Saudi Arabia, and beyond can position themselves as leaders in the global colorway shoe market, ensuring resilience and continued success.