Your Ultimate Guide to Sourcing Comfortable Steel Toe Shoes

Guide to Comfortable Steel Toe Shoes

- Introduction: Navigating the Global Market for comfortable steel toe shoes

- Understanding comfortable steel toe shoes Types and Variations

- Key Industrial Applications of comfortable steel toe shoes

- Strategic Material Selection Guide for comfortable steel toe shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for comfortable steel toe shoes

- Comprehensive Cost and Pricing Analysis for comfortable steel toe shoes Sourcing

- Spotlight on Potential comfortable steel toe shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for comfortable steel toe shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the comfortable steel toe shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of comfortable steel toe shoes

- Strategic Sourcing Conclusion and Outlook for comfortable steel toe shoes

Introduction: Navigating the Global Market for comfortable steel toe shoes

In the competitive landscape of industrial safety footwear, comfortable steel toe shoes have become a critical factor for ensuring worker safety, productivity, and overall satisfaction. For international B2B buyers—especially from regions such as Africa, South America, the Middle East, and Europe—understanding the nuances of sourcing high-quality, comfortable steel toe shoes is essential to meet market demands and regulatory standards. These markets are rapidly evolving, with increasing emphasis on ergonomic design, durability, and cost-efficiency, making informed sourcing decisions more vital than ever.

This comprehensive guide equips you with actionable insights into every facet of the global market—from the diverse types and materials of steel toe shoes, to manufacturing processes, quality control standards, and supplier landscapes. It also provides strategic guidance on cost considerations, market trends, and frequently asked questions, empowering you to navigate international procurement with confidence. Whether you are seeking reliable suppliers in Italy, Poland, or emerging markets across Africa and South America, this resource helps you identify optimal partners and mitigate risks.

By leveraging this guide, B2B buyers can streamline their sourcing strategies, ensure compliance with safety standards, and secure products that balance comfort, quality, and affordability. Ultimately, it serves as a vital tool to make well-informed decisions that enhance your competitive edge in the global marketplace for safety footwear.

Understanding comfortable steel toe shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Steel Toe Shoes | Traditional design with reinforced steel toe cap, basic comfort features | Manufacturing, construction, warehousing | Pros: Widely available, cost-effective; Cons: May lack advanced comfort features |

| Composite Toe Shoes | Toe cap made from non-metallic materials like Kevlar or carbon fiber | Food processing, logistics, environments with metal detectors | Pros: Lighter, non-conductive; Cons: Slightly higher initial cost |

| Ergonomic/Comfort-Focused Shoes | Designed with advanced cushioning, ergonomic insoles, and flexible outsoles | Long shifts in factories, logistics hubs | Pros: Enhanced comfort, reduced fatigue; Cons: Higher price point |

| Waterproof & Weather-Resistant Shoes | Incorporates waterproof membranes and weatherproof materials | Outdoor construction, agriculture, maritime | Pros: Durable in harsh conditions; Cons: Potentially heavier and less breathable |

| High-Performance Safety Shoes | Incorporate features like anti-slip soles, electrical hazard protection | Heavy-duty industrial environments, mining | Pros: Multi-protection; Cons: Often bulkier and more expensive |

Classic Steel Toe Shoes

This traditional type features a reinforced steel toe cap integrated into a basic yet durable shoe design. They are suitable for industries like manufacturing, construction, and warehousing, where impact protection is critical. B2B buyers benefit from their affordability and widespread availability, making large-volume procurement straightforward. However, these shoes may lack advanced comfort features, leading to fatigue during extended wear. They are ideal for environments prioritizing safety over comfort but should be paired with ergonomic insoles for better employee satisfaction.

Composite Toe Shoes

Constructed with non-metallic materials such as Kevlar, carbon fiber, or fiberglass, composite toe shoes are lightweight and non-conductive. They are increasingly popular in food processing, logistics, and environments with metal detectors, where metal-based shoes could cause delays or safety issues. For B2B buyers, these shoes offer a balance of protection and comfort, especially in roles requiring prolonged standing or walking. While initially more expensive than steel toe options, their reduced weight and non-conductivity can lower fatigue and safety compliance costs over time.

Ergonomic/Comfort-Focused Shoes

Designed specifically for prolonged wear, these shoes incorporate advanced cushioning, supportive insoles, and flexible outsoles. They are well-suited for industries with long shifts, such as assembly lines, warehouses, and logistics centers. B2B buyers should prioritize these options for roles where employee comfort directly impacts productivity and safety. Although they tend to be more costly upfront, the reduction in fatigue-related issues can lead to lower healthcare and turnover costs, making them a strategic investment for large-scale operations.

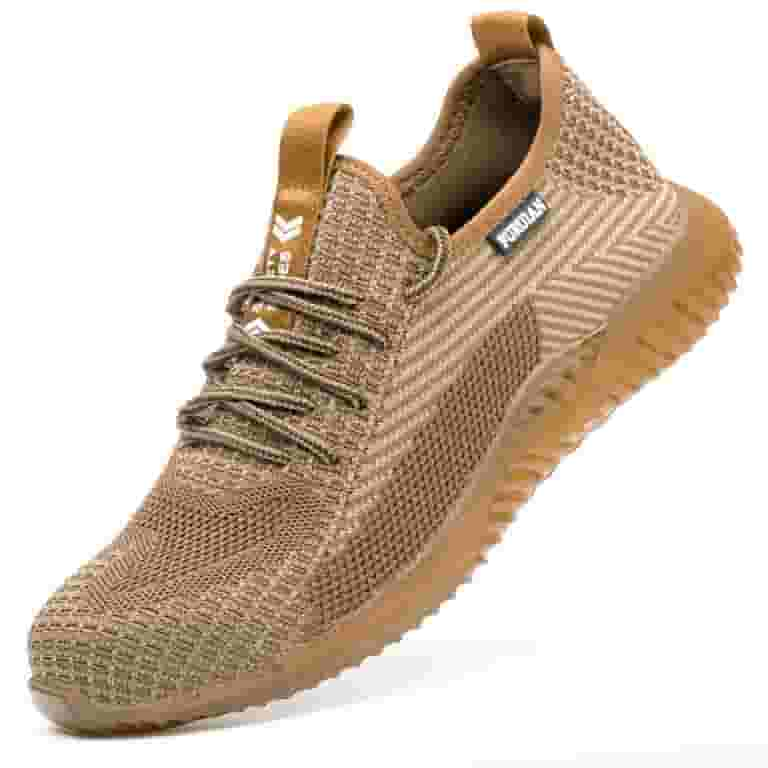

Illustrative Image (Source: Google Search)

Waterproof & Weather-Resistant Shoes

These shoes feature waterproof membranes, sealed seams, and weatherproof materials to withstand rain, mud, and other challenging outdoor conditions. They are essential in outdoor construction, agriculture, and maritime sectors. For B2B buyers, durability and environmental resistance are key purchasing considerations, especially for companies operating in harsh climates. These shoes tend to be heavier and less breathable, so balancing waterproof features with comfort is critical. Bulk procurement should focus on brands with proven longevity and maintenance support.

High-Performance Safety Shoes

Combining multiple protective features, these shoes offer anti-slip soles, electrical hazard protection, and reinforced toe caps. They are suitable for heavy-duty industrial environments, mining, and electrical work. B2B buyers should consider these shoes for roles demanding maximum safety and compliance with strict standards. While they are often more expensive and bulkier, their comprehensive protection can reduce workplace accidents and liability. Ensuring compatibility with existing safety protocols and comfort needs is essential for successful procurement.

Key Industrial Applications of comfortable steel toe shoes

| Industry/Sector | Specific Application of comfortable steel toe shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Infrastructure | Workers on-site, including heavy machinery operators and laborers | Enhanced safety and comfort reduce fatigue, leading to increased productivity and fewer injury-related downtime | Durability, slip resistance, compliance with local safety standards, and availability of sizes for diverse workforce needs |

| Manufacturing & Warehousing | Assembly line workers, forklift operators, and logistics personnel | Improved comfort minimizes fatigue during long shifts, decreasing absenteeism and increasing operational efficiency | Ergonomic design, lightweight construction, and reliable toe protection suitable for prolonged wear |

| Oil & Gas & Mining | Field workers, rig operators, and underground miners | Superior impact protection with comfort features reduces injury risk in hazardous environments | Material resistance to oils, chemicals, and extreme conditions; certification for rugged environments |

| Agriculture & Forestry | Farm workers, harvesters, and forestry personnel | Comfortable footwear supports prolonged outdoor activity, reducing foot fatigue and injury risk | Weather resistance, slip resistance, and adaptability to uneven terrain |

| Heavy Industry & Steelworks | Welders, metalworkers, and assembly line staff | Enhanced safety with comfort features enables longer shifts with reduced discomfort and injury risk | High durability, stability, and compliance with industrial safety standards |

Construction & Infrastructure

In the construction industry, workers often face physically demanding environments with heavy machinery, uneven surfaces, and prolonged standing. Comfortable steel toe shoes are essential to provide reliable impact and crush protection while reducing fatigue. International B2B buyers from regions like Europe and Africa need footwear that complies with local safety standards (e.g., EN ISO 20345 in Europe) and offers durability against rough conditions. Sourcing considerations include selecting models with slip-resistant soles, high-quality materials, and a range of sizes to accommodate diverse workforces, ensuring both safety and comfort over long shifts.

Manufacturing & Warehousing

Manufacturing plants and warehouses require footwear that supports long hours of standing and movement. Steel toe shoes with enhanced comfort features—such as cushioned insoles, ergonomic fit, and lightweight construction—help minimize foot fatigue, thereby improving worker productivity and reducing injury-related costs. For B2B buyers in South America and Europe, choosing suppliers that offer customizable options, quick lead times, and compliance with industry standards (like ASTM or EN standards) is vital. These factors ensure the shoes not only protect but also promote workforce well-being.

Oil & Gas & Mining

Operations in oil, gas, and mining sectors involve hazardous environments where impact resistance and durability are critical. Comfortable steel toe shoes designed for these sectors often feature chemical and oil-resistant soles, reinforced toe caps, and rugged construction to withstand extreme conditions. B2B buyers from the Middle East and South America should prioritize sourcing from manufacturers with certifications such as ANSI or ISO for safety and environmental resistance. Comfort features like moisture-wicking linings and ergonomic support reduce fatigue during extended shifts underground or offshore, enhancing safety and operational efficiency.

Agriculture & Forestry

Agricultural and forestry workers spend long hours outdoors on uneven terrain, often in variable weather conditions. Steel toe shoes that combine comfort with weather resistance—such as waterproofing and slip-resistant soles—are crucial for injury prevention and productivity. European and African buyers should look for footwear that offers durability against mud, water, and rough terrain, along with proper fit to prevent blisters and fatigue. Sourcing from suppliers with a focus on rugged outdoor performance ensures safety and comfort during demanding seasonal activities.

Heavy Industry & Steelworks

Workers in heavy industry and steel manufacturing face high-impact risks and exposure to extreme heat and materials. Comfortable steel toe shoes with high durability, thermal resistance, and stability are essential for maintaining safety during long shifts. B2B buyers from Poland, Italy, and other European countries should seek footwear that meets strict industrial safety standards (e.g., EN ISO 20345), with features like anti-slip soles and reinforced toes. Prioritizing ergonomic design and quality materials helps reduce discomfort, improve worker compliance, and lower injury rates in these high-risk environments.

Strategic Material Selection Guide for comfortable steel toe shoes

Material Analysis for Comfortable Steel Toe Shoes

Selecting the appropriate materials for the components of steel toe shoes is critical for ensuring comfort, durability, and compliance with international standards. Different markets—such as Africa, South America, the Middle East, and Europe—have unique requirements based on environmental conditions, regulatory standards, and industry preferences. Here, we analyze four common materials used in the manufacturing of steel toe shoes, focusing on their properties, advantages, limitations, and implications for international B2B buyers.

Steel (e.g., Carbon Steel, Alloy Steel)

Key Properties:

Steel is renowned for its high tensile strength, impact resistance, and structural stability. It can withstand high pressure and temperature variations, making it suitable for demanding industrial environments. Steel components are often compliant with standards such as ASTM, DIN, and JIS, facilitating international acceptance.

Pros & Cons:

Steel offers excellent durability and impact protection, essential for safety footwear. It is relatively cost-effective, especially in bulk manufacturing, and is widely available globally. However, steel is heavy, which can compromise overall shoe comfort, especially for prolonged wear. It is susceptible to corrosion if not properly treated or coated, necessitating additional protective layers.

Impact on Application:

Steel’s corrosion susceptibility requires consideration in humid or salty environments common in coastal regions of Africa and South America. For these markets, coated or stainless steel options enhance longevity. Steel also performs well in high-temperature environments typical of the Middle East, provided appropriate insulation is incorporated.

International Buyer Considerations:

Compliance with standards like ASTM F2413 (USA), EN ISO 20345 (Europe), and JIS T 8101 (Japan) is crucial. Buyers should verify steel grades and protective coatings to meet local safety regulations. Cost considerations are favorable for large orders, but weight and corrosion resistance should influence material choices for specific climates.

Thermoplastic Polyurethane (TPU)

Key Properties:

TPU is a versatile, lightweight polymer known for excellent abrasion resistance, flexibility, and impact absorption. It maintains performance over a wide temperature range and offers good chemical resistance, including oils and certain acids.

Pros & Cons:

TPU enhances comfort due to its flexibility and cushioning properties. It is resistant to cracking and tearing, extending the lifespan of shoe components such as toe caps and midsoles. However, TPU can be more expensive than traditional plastics or metals, and its manufacturing process can be complex, impacting overall cost.

Impact on Application:

Ideal for midsoles and reinforcement parts, TPU contributes to reducing shoe weight and improving shock absorption—key factors for comfort in long shifts. Its chemical resistance makes it suitable for environments with exposure to oils, solvents, or chemicals, common in manufacturing and agricultural sectors across Africa and South America.

International Buyer Considerations:

TPU components must meet relevant standards for impact and abrasion resistance, such as EN ISO 20345. Buyers should consider local environmental conditions—UV exposure, temperature extremes—and select grades accordingly. Cost might be higher, but the benefit of increased comfort and durability can justify the investment.

Thermoplastic Elastomers (TPE)

Key Properties:

TPEs combine the processing advantages of plastics with the elasticity of rubbers. They are lightweight, flexible, and resistant to wear, making them suitable for comfort-focused shoe components like insoles and flexible protective overlays.

Pros & Cons:

TPEs offer excellent comfort and shock absorption, contributing to overall shoe ergonomics. They are resistant to chemicals, UV, and weathering, which benefits outdoor or industrial applications. However, TPEs generally have lower structural strength compared to steel or TPU, limiting their use in load-bearing parts.

Impact on Application:

TPEs are primarily used in insoles, linings, and flexible protective overlays, enhancing overall comfort. They are especially beneficial in regions with high temperatures or humidity, such as the Middle East and tropical zones in Africa and South America, where breathability and flexibility are valued.

International Buyer Considerations:

Compliance with standards for impact resistance and chemical exposure is essential. Buyers should verify the specific TPE formulations used, as performance can vary. Cost is generally moderate, and their lightweight nature can reduce shipping and manufacturing costs.

Summary Table of Material Options

| Material | Typical Use Case for comfortable steel toe shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel (e.g., Carbon Steel, Alloy Steel) | Toe caps, reinforcement plates | High strength, impact resistance | Heavy, susceptible to corrosion without coating | Low |

| Thermoplastic Polyurethane (TPU) | Midsoles, reinforcement components | Lightweight, excellent impact absorption | Higher cost, complex manufacturing | Med |

| Thermoplastic Elastomers (TPE) | Insoles, flexible overlays | Superior comfort, weather resistance | Lower structural strength, limited load-bearing capacity | Med |

| Aluminum (e.g., Aerospace-grade) | Lightweight impact protection | Very lightweight, corrosion-resistant | Lower impact resistance compared to steel, higher cost | High |

This detailed analysis equips international B2B buyers with the insights needed to select optimal materials tailored to specific environmental conditions, safety standards, and cost considerations across diverse markets. Proper material choice not only enhances product performance but also aligns with regional compliance and consumer preferences, ensuring a competitive edge in the global safety footwear industry.

In-depth Look: Manufacturing Processes and Quality Assurance for comfortable steel toe shoes

Manufacturing Processes for Comfortable Steel Toe Shoes

The production of comfortable steel toe shoes involves a multi-stage process that emphasizes precision, material integrity, and ergonomic design. For international B2B buyers, understanding these stages is crucial to evaluate supplier capabilities and ensure product quality.

Material Preparation

The manufacturing process begins with sourcing high-quality raw materials, including durable leathers or synthetic uppers, resilient steel or composite toe caps, and shock-absorbing insoles. Suppliers often select materials compliant with international standards such as ISO 9001 to guarantee consistency. Additional focus is placed on selecting breathable fabrics and ergonomic insoles to enhance comfort, especially for prolonged wear.

Forming and Component Manufacturing

This stage involves cutting, molding, and shaping components. Cutting is performed with precision CNC machines or die-cutting techniques to ensure uniformity across batches. The toe caps are either stamped from steel sheets or molded from composites, with strict adherence to dimensional tolerances to guarantee safety and comfort. Uppers are shaped through heat pressing or stitching, integrating features like padding or ergonomic contours.

Assembly

The assembled shoes undergo multiple processes including attaching the upper to the sole, inserting insoles, and installing steel toe caps. Adhesives used must meet safety and environmental standards, such as REACH compliance in Europe. Stitching and bonding are performed with industrial-grade equipment to ensure durability. Some manufacturers incorporate advanced ergonomic features during assembly, such as padded collars or contoured insoles, to enhance comfort.

Finishing

Final stages include cleaning, polishing, and quality detailing. Additional features like anti-slip outsoles, abrasion-resistant layers, and reflective elements are added during this phase. The shoes are inspected for visual defects and functional integrity before packaging. Finishing also involves applying labels, certifications, and compliance markings tailored to target markets.

Quality Assurance Frameworks and Standards

Ensuring consistent quality in steel toe shoes is fundamental for B2B procurement. Manufacturers typically adopt internationally recognized standards alongside industry-specific certifications to meet diverse market requirements.

International Standards

- ISO 9001: Most reputable manufacturers operate under ISO 9001 quality management systems, emphasizing process control, continuous improvement, and customer satisfaction.

- ISO 20345: This is the primary standard for safety footwear, specifying requirements for impact resistance, compression, and other safety features pertinent to steel toe shoes.

- ISO 14001: Environmental management standards ensure eco-friendly manufacturing practices, increasingly valued in European and Middle Eastern markets.

Industry Certifications

- CE Marking (Europe): Indicates compliance with EU safety, health, and environmental requirements. For steel toe shoes, this involves testing impact resistance, sole anchorage, and overall durability.

- ANSI/ASTM Standards (North America): While not mandatory globally, some manufacturers align with these standards for impact and compression resistance.

- Other Regional Certifications: For markets in Africa and South America, certifications such as INMETRO (Brazil) or SABS (South Africa) may be relevant, often requiring local compliance testing.

Illustrative Image (Source: Google Search)

Quality Control (QC) Stages and Techniques

Robust QC processes are essential to validate that each batch of shoes meets safety, comfort, and durability criteria.

Incoming Quality Control (IQC)

- Raw Material Inspection: Verification of material certifications, physical tests for tensile strength, abrasion resistance, and chemical safety.

- Supplier Audits: Regular audits of supplier facilities and documentation ensure raw materials meet specified standards, especially critical when sourcing from regions with variable quality control practices.

In-Process Quality Control (IPQC)

- Dimensional Checks: Ensuring components like toe caps, soles, and uppers conform to design specifications.

- Functional Testing: Periodic testing during assembly, such as impact resistance of toe caps and adhesion strength of sole attachments.

- Process Monitoring: Real-time checks for stitching quality, bonding integrity, and ergonomic features.

Final Quality Control (FQC)

- Visual Inspection: Checks for surface defects, color consistency, and finishing quality.

- Mechanical Testing: Impact resistance tests, compression tests, and slip resistance evaluations are performed in accordance with ISO 20345.

- Comfort Evaluation: Some manufacturers incorporate ergonomic assessments, including insole flexibility and fit testing, to ensure comfort standards.

Testing Methods and Verification

Effective QC relies on standardized testing methods, often conducted in certified laboratories or in-house facilities:

- Impact Resistance Testing: Using drop tests or pendulum impact testers to verify compliance with impact resistance requirements.

- Compression Testing: Applying force to the steel toe cap to ensure it withstands specified impacts without deformation.

- Slip Resistance: Testing outsole materials on standardized surfaces to confirm anti-slip performance.

- Environmental Testing: Assessing resistance to temperature variations, water, and chemical exposure for durability assurance.

How B2B Buyers Can Verify Supplier QC

To ensure suppliers maintain high standards, B2B buyers should adopt comprehensive verification strategies:

- Third-Party Inspections: Engage accredited inspection agencies (e.g., SGS, Bureau Veritas) to audit manufacturing facilities and verify compliance with specified standards.

- Review Certification Documentation: Require up-to-date certificates for ISO standards, CE markings, and regional certifications.

- Factory Audits: Conduct on-site visits to assess manufacturing processes, QC protocols, and working conditions, especially crucial in regions with diverse manufacturing practices.

- Sample Testing: Request product samples for independent testing to validate safety and comfort claims.

- Quality Reports & Documentation: Insist on detailed QC reports, test results, and batch traceability records for transparency.

Nuances for International B2B Buyers from Africa, South America, the Middle East, and Europe

Different regions have specific expectations and regulatory requirements that influence QC procedures:

- Europe (e.g., Italy, Poland): Emphasis on CE compliance, environmental sustainability, and ergonomic standards. Suppliers should demonstrate adherence to REACH and RoHS directives, with detailed technical documentation.

- Middle East: Growing demand for high-impact safety features and durability under harsh conditions. Suppliers should provide certifications aligned with local safety regulations, along with testing for heat resistance and chemical exposure.

- Africa & South America: Certification standards may vary; local regulatory bodies often require compliance with regional standards like INMETRO or SABS. Buyers should verify that suppliers understand and meet these regional requirements, including appropriate testing and documentation.

Final Insights for B2B Buyers

Establishing clear communication of quality expectations and conducting rigorous supplier evaluations are vital. Incorporate clauses for periodic audits, sample testing, and certification verification into procurement agreements. Working with manufacturers who demonstrate transparency, invest in modern QC equipment, and adhere to international standards will significantly reduce risks and ensure the delivery of comfortable, safe, and compliant steel toe shoes for global markets.

Comprehensive Cost and Pricing Analysis for comfortable steel toe shoes Sourcing

Cost Structure Breakdown for Comfortable Steel Toe Shoes

Understanding the comprehensive cost structure is vital for international B2B buyers aiming to optimize procurement strategies. The primary cost components include:

- Materials: High-quality steel toe caps, durable uppers (leather or synthetic), insoles, and outsole materials. Premium materials, especially for comfort and safety, tend to increase costs but enhance product value and compliance with safety standards.

- Labor: Manufacturing costs vary significantly based on the sourcing country. Asian suppliers, especially in China and Vietnam, often offer competitive labor rates, whereas European and Middle Eastern producers might have higher labor costs but potentially better craftsmanship.

- Manufacturing Overhead: This includes factory maintenance, equipment depreciation, and utilities. Efficient factories with modern equipment may offset higher labor costs through productivity gains.

- Tooling & Setup Fees: Initial costs for molds, dies, and production setup can be substantial, especially for customized or specialized designs. These are typically amortized over large production runs.

- Quality Control (QC): Rigorous QC ensures compliance with safety standards like ASTM or EN ISO, which is crucial for steel toe shoes. Certification costs can add to the overall price but are essential for market acceptance.

- Logistics & Shipping: Freight costs depend on order volume, destination country, and shipping method (air vs. sea). FOB (Free on Board) pricing is common, but buyers should account for inland transportation, customs, and duties.

- Profit Margin: Suppliers typically include a margin to ensure profitability, which varies based on market competition, order volume, and supplier reputation.

Key Price Influencers for International Buyers

Several factors influence the final price of steel toe shoes in the global market:

- Order Volume & MOQ: Larger orders often secure better unit prices due to economies of scale. Many manufacturers offer discounts on MOQ, which can be advantageous for buyers with larger distribution networks.

- Specifications & Customization: Custom features—such as personalized branding, specific safety certifications, or unique comfort enhancements—will increase costs. Standard models tend to be more economical.

- Materials & Certifications: Premium materials and compliance with international safety standards (e.g., ASTM, CE, ISO) influence price. Certified products often command higher prices but are crucial for certain markets.

- Supplier Reputation & Location: Established manufacturers with a reputation for quality may charge premium prices but offer better reliability. Sourcing from countries with lower manufacturing costs (e.g., China, Vietnam, Pakistan) can reduce prices but requires due diligence on quality and compliance.

- Incoterms & Shipping Terms: FOB and CIF (Cost, Insurance, Freight) terms impact the overall cost structure. Buyers should evaluate the total landed cost, including customs duties and taxes in their country.

Buyer Tips for Cost Optimization

- Negotiate Effectively: Leverage larger order volumes to negotiate discounts or better payment terms. Building long-term relationships can also lead to preferential pricing.

- Focus on Total Cost of Ownership (TCO): Consider not only unit price but also shipping, customs, import duties, and after-sales support. Sometimes, sourcing from nearby countries (e.g., Poland or Italy for Europe) reduces logistics costs and lead times.

- Evaluate Quality & Certification Costs: Investing in certified, high-quality shoes may have higher upfront costs but can reduce returns, warranty claims, and market rejection.

- Understand Pricing Nuances: Prices can fluctuate based on raw material costs, exchange rates, and geopolitical factors. Regularly review supplier quotes and stay informed about market trends.

- Consider Lead Times & Flexibility: Shorter lead times often come at a premium. Balance the need for quick delivery against cost savings from bulk orders.

Price Range and Indicative Costs

As a reference, factory prices for standard, non-customized comfortable steel toe shoes typically range from $10 to $25 per pair, depending on quality, volume, and supplier location. For certified, customized, or premium models, prices can escalate to $30–$50 per pair or more. Shipping and import duties can add 10–30% to the landed cost, particularly for high-volume orders.

Disclaimer: These prices are indicative and subject to change based on market conditions, supplier negotiations, and specific product requirements. Buyers should conduct detailed supplier assessments and obtain multiple quotes for accurate budgeting.

Spotlight on Potential comfortable steel toe shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for comfortable steel toe shoes.)*

Essential Technical Properties and Trade Terminology for comfortable steel toe shoes

Critical Technical Properties for Comfortable Steel Toe Shoes

1. Material Grade and Composition

The quality of materials used in the shoe, particularly the steel toe cap and upper components, directly impacts durability and safety. Commonly, high-grade steel (such as ASTM or EN standards) ensures reliable impact resistance while maintaining lightweight characteristics. For B2B buyers, specifying the material grade guarantees compliance with safety standards and reduces the risk of product failure in demanding environments.

2. Impact and Compression Resistance

Steel toe shoes must withstand specific impact energies (measured in joules or foot-pounds) and compression forces. Typical requirements range from 200 to 300 joules, depending on industry standards. This property ensures worker safety without sacrificing comfort. Buyers should verify that the shoes meet or exceed local occupational safety regulations.

3. Fit Tolerance and Ergonomics

Precise fit tolerance—such as width, height, and arch support—is crucial for comfort during extended wear. Industry standards often specify allowable deviations (e.g., ±2 mm). Proper fit reduces fatigue and the risk of injury, making this a key consideration for procurement, especially in diverse markets where foot sizes vary widely.

4. Breathability and Material Flexibility

Comfortable shoes incorporate breathable materials (like mesh or perforated leather) and flexible components that promote airflow and reduce heat buildup. These properties are vital in hot climates prevalent in Africa, South America, and the Middle East. Ensuring flexibility and ventilation enhances worker compliance and reduces discomfort.

5. Sole Durability and Slip Resistance

The outsole’s composition, typically rubber or polyurethane, should provide high abrasion resistance and slip resistance (measured by slip coefficient). For industries with oily or wet surfaces, selecting shoes with proven slip ratings (e.g., R10 or higher in European standards) minimizes accidents. Durable soles also extend product lifespan, offering better ROI for buyers.

6. Weight and Balance

Lightweight construction, achieved through optimized material choices and design, enhances mobility and reduces fatigue. Proper weight distribution and balance are essential for comfort during prolonged shifts, especially in physically demanding jobs.

Essential Industry and Trade Terms

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce steel toe shoes according to the buyer’s specifications and branding. Understanding OEM relationships enables buyers to customize products for regional branding, compliance, and specific safety standards, often at lower costs for large orders.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce or sell in a single batch. For international buyers, negotiating MOQ is critical to balancing inventory costs with supply chain flexibility, especially when entering new markets or testing product acceptance.

3. RFQ (Request for Quotation)

A formal process where buyers solicit detailed price and lead time proposals from suppliers. Proper RFQs help international buyers compare options, clarify technical specifications, and ensure competitive pricing, particularly important in diverse markets with varying standards.

4. Incoterms (International Commercial Terms)

Standardized trade definitions published by the International Chamber of Commerce, specifying responsibilities for shipping, insurance, and tariffs. Familiarity with Incoterms (e.g., FOB, CIF, DDP) helps buyers determine cost responsibilities, streamline logistics, and avoid misunderstandings during cross-border transactions.

5. CE and EN Standards

European safety standards, such as CE marking and EN 20345, specify performance criteria for safety footwear. For buyers in Europe, compliance ensures legal sale and acceptance within the market, while in other regions, aligning with these standards can serve as a quality benchmark.

6. Lead Time

The duration from order placement to product delivery. Understanding lead times is vital for planning inventory, especially in markets with unpredictable logistics or customs delays. Negotiating shorter lead times can improve responsiveness to market demands.

Summary:

By understanding these technical properties and trade terms, B2B buyers from Africa, South America, the Middle East, and Europe can make informed procurement decisions. Clear specifications and familiarity with industry jargon facilitate smoother negotiations, ensure compliance, and optimize the value derived from their investments in comfortable steel toe footwear.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the comfortable steel toe shoes Sector

Market Overview & Key Trends

The global market for comfortable steel toe shoes is experiencing steady growth driven by increasing industrialization, infrastructure development, and a rising emphasis on worker safety and comfort. Key industries include construction, manufacturing, logistics, and energy, which demand durable yet comfortable protective footwear. For B2B buyers in regions like Africa, South America, the Middle East, and Europe, understanding regional demand nuances is crucial; for example, Europe’s stringent safety standards and eco regulations influence product specifications, while emerging markets in Africa and South America prioritize cost-effectiveness and durability.

Emerging sourcing trends are shaped by technological advancements such as 3D printing, AI-driven supply chain management, and digital marketplaces. These innovations facilitate faster, more transparent sourcing processes, enabling buyers to verify supplier credentials and ensure compliance with safety standards efficiently. Furthermore, the rise of regional manufacturing hubs—particularly in Eastern Europe (e.g., Poland) and Southern Europe (e.g., Italy)—offers strategic advantages like reduced lead times and adherence to local quality standards.

Global supply chains are increasingly influenced by geopolitical factors, tariffs, and trade agreements, necessitating adaptive sourcing strategies. Buyers are also shifting toward diversified sourcing to mitigate risks associated with disruptions, emphasizing partnerships with suppliers that demonstrate flexibility, scalability, and compliance with international safety and quality benchmarks. Sustainability considerations are becoming a core component, with buyers seeking suppliers committed to environmentally responsible manufacturing and ethical labor practices.

Sustainability & Ethical Sourcing in B2B

Sustainability in the comfortable steel toe shoes sector is gaining momentum as buyers and consumers alike become more conscious of environmental impacts. For international B2B buyers, integrating sustainability into sourcing practices offers competitive advantages, including compliance with regulations, brand differentiation, and long-term cost savings. Environmentally friendly materials—such as recycled rubber, organic cotton linings, and bio-based leather alternatives—are increasingly favored. These materials not only reduce carbon footprints but also appeal to end-users seeking eco-conscious products.

Ethical sourcing is equally vital, with a focus on supply chain transparency and fair labor practices. Suppliers that adhere to recognized standards like Fair Trade, SA8000, or ISO 26000 demonstrate commitment to worker safety, fair wages, and humane working conditions. For buyers in regions like Europe and the Middle East, certifications and audits provide assurance that products are ethically produced, mitigating reputational and legal risks.

Moreover, sustainability certifications such as LEED, Green Seal, and Global Organic Textile Standard (GOTS) are becoming benchmarks for suppliers. These certifications verify environmentally responsible manufacturing processes and sustainable material sourcing. Implementing robust supplier audits and fostering long-term partnerships with transparent supply chains enable buyers to meet their corporate social responsibility (CSR) goals effectively while responding to the growing market demand for sustainable footwear solutions.

Brief Evolution/History

The evolution of comfortable steel toe shoes reflects broader trends in safety footwear and sustainable manufacturing. Initially driven by industrial safety regulations, the sector has progressively incorporated ergonomic designs and lightweight materials to enhance comfort without compromising protection. Over recent decades, technological innovations—such as ergonomic footwear engineering and advanced impact-resistant materials—have significantly improved product quality.

In tandem, sustainability has become a central focus, with brands adopting eco-friendly materials and transparent supply chains to meet stricter environmental standards. The integration of digital sourcing platforms and certification systems has streamlined supplier vetting and compliance processes, enabling B2B buyers to make more informed decisions. This evolution underscores a shift from purely functional safety gear to sophisticated, sustainable, and comfortable solutions tailored to diverse regional market needs.

By understanding these market dynamics, sourcing trends, and sustainability imperatives, international B2B buyers can strategically navigate the evolving landscape of comfortable steel toe shoes, ensuring they secure high-quality, compliant, and ethically produced products that meet regional demands and global standards.

Frequently Asked Questions (FAQs) for B2B Buyers of comfortable steel toe shoes

1. How can I effectively vet steel toe shoe suppliers to ensure quality and reliability?

To vet suppliers effectively, start by requesting comprehensive company credentials, including business licenses, export licenses, and quality certifications (e.g., ISO, CE). Review their product catalogs and request samples to evaluate comfort, durability, and safety standards. Check references or customer testimonials, especially from clients in similar regions or industries. Conduct virtual factory audits or third-party inspections when feasible, focusing on manufacturing processes, quality control measures, and labor practices. Finally, consider visiting trade shows or engaging with local agents to build trust and verify supplier credibility before committing significant orders.

2. What customization options are typically available for steel toe shoes, and how do they impact lead times?

Most manufacturers offer customization such as branding (logos), color schemes, material preferences, and sole designs. Some can also customize features like padding, insoles, or specific safety standards. Customization usually increases lead times by 2-4 weeks due to design adjustments and production setup. To manage expectations, clearly communicate your specifications early and confirm lead times during negotiations. Establish a detailed product development schedule, and consider ordering prototypes first to validate customization before bulk production, reducing delays and ensuring alignment with your quality standards.

3. What are the typical minimum order quantities (MOQs) and lead times I should expect when sourcing from international suppliers?

MOQs for steel toe shoes generally range from 500 to 2,000 pairs, depending on the manufacturer and level of customization. Lead times vary from 4 to 12 weeks, influenced by order size, complexity, and factory capacity. For urgent needs, some suppliers offer expedited production options at a premium. To optimize supply chain planning, negotiate MOQs that align with your sales forecasts and establish clear timelines upfront. Building relationships with multiple suppliers can also provide flexibility in meeting fluctuating demand and reducing lead time risks.

4. What payment terms are standard in international B2B transactions for steel toe shoes?

Common payment terms include 30% upfront deposit with the remaining 70% payable before shipment, or letters of credit for larger orders. Some suppliers may accept T/T (telegraphic transfer), PayPal, or Alibaba Trade Assurance for smaller or initial orders. Establish clear payment terms early in negotiations, ensuring they align with your cash flow and risk management policies. For high-volume or long-term partnerships, negotiate discounts or flexible terms such as net 60 days. Always verify the credibility of payment methods and consider escrow services or trade assurance platforms to mitigate payment risks.

5. What certifications and quality assurance documents should I request from suppliers?

Ask for relevant safety and quality certifications such as CE, ASTM, ISO 9001, or local compliance marks applicable in your target markets. Request test reports for impact resistance, slip resistance, and material safety. Quality assurance documentation should include inspection reports, batch testing results, and factory audit reports. Confirm that suppliers follow standardized quality control procedures and are willing to provide ongoing QC reports for each batch. These documents ensure compliance with your local safety regulations and reduce the risk of product recalls or legal issues.

6. How can I streamline logistics and shipping when importing steel toe shoes from overseas?

Work with freight forwarders experienced in international trade, especially those familiar with your target regions. Consolidate shipments where possible to reduce costs and transit times. Opt for reliable shipping methods like sea freight for bulk orders or air freight for urgent deliveries, balancing cost and speed. Ensure proper documentation such as commercial invoices, packing lists, and certificates of origin are prepared accurately to avoid customs delays. Collaborate with customs brokers to understand import duties and VAT implications specific to your country. Establish clear communication channels with logistics providers for tracking and issue resolution.

7. What are common dispute resolution practices in international B2B transactions, and how can I protect my interests?

Disputes are often resolved through negotiation, mediation, or arbitration, with arbitration being the most common in international trade. Include clear dispute resolution clauses in your contracts specifying jurisdiction, arbitration venues, and governing laws. Use secure payment methods like letters of credit or escrow to safeguard financial transactions. Maintain detailed records of all communications, agreements, and inspections. Building strong relationships and maintaining transparency during negotiations can prevent misunderstandings. Engaging legal counsel familiar with international trade laws can help you navigate disputes efficiently and protect your interests.

8. How can I ensure ongoing product quality and supply consistency over multiple orders?

Establish a long-term relationship with trusted suppliers who have proven quality standards and reliable delivery records. Implement regular quality audits, including pre-shipment inspections and third-party testing, to verify batch consistency. Develop a quality management system that includes detailed specifications, quality control checkpoints, and feedback loops. Maintain open communication channels to address issues promptly and encourage supplier continuous improvement. Consider creating a shared quality agreement, and if possible, visit manufacturing facilities periodically to monitor processes. This proactive approach helps sustain product standards and ensures consistent supply for your market needs.

Strategic Sourcing Conclusion and Outlook for comfortable steel toe shoes

Conclusion and Future Outlook

Effective strategic sourcing is essential for international B2B buyers seeking high-quality, comfortable steel toe shoes that meet diverse market demands. Prioritizing suppliers with a proven track record in innovation, compliance, and sustainable practices ensures product reliability and aligns with global standards. Leveraging regional advantages—such as Italy’s craftsmanship, Poland’s manufacturing expertise, or emerging markets in Africa, South America, and the Middle East—can optimize cost-efficiency and supply chain resilience.

Looking ahead, the footwear industry is poised for continued innovation in comfort technology, materials, and customization. Buyers should focus on building strong, long-term partnerships with trusted manufacturers to stay ahead of evolving trends and regulatory requirements. Additionally, embracing digital sourcing platforms and supplier transparency will enhance decision-making and reduce risks.

Illustrative Image (Source: Google Search)

For international buyers from Africa, South America, the Middle East, and Europe, proactive engagement and strategic planning are vital. Seize opportunities to diversify your supplier base, foster sustainable practices, and adapt to changing market dynamics. Staying ahead in this competitive landscape requires a forward-thinking approach—position your organization now to capitalize on emerging trends and secure a reliable supply of comfortable, durable steel toe footwear.