Master Global Sourcing of Drag Queen Shoes: The Ultimate

Guide to Drag Queen Shoes

- Introduction: Navigating the Global Market for drag queen shoes

- Understanding drag queen shoes Types and Variations

- Key Industrial Applications of drag queen shoes

- Strategic Material Selection Guide for drag queen shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for drag queen shoes

- Comprehensive Cost and Pricing Analysis for drag queen shoes Sourcing

- Spotlight on Potential drag queen shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for drag queen shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the drag queen shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of drag queen shoes

- Strategic Sourcing Conclusion and Outlook for drag queen shoes

Introduction: Navigating the Global Market for drag queen shoes

In the vibrant and rapidly expanding world of drag performance, drag queen shoes have become an essential element of self-expression, performance, and brand identity. For B2B buyers, sourcing high-quality, innovative, and reliable footwear options is critical to meet the diverse demands of performers, boutiques, and entertainment venues across the globe. As this niche market gains prominence, understanding its nuances—ranging from design trends to manufacturing standards—becomes essential for making informed procurement decisions.

This comprehensive guide offers valuable insights into the types of drag queen shoes, the materials and craftsmanship behind them, and the quality control processes that ensure durability and style. It also explores the landscape of global suppliers, highlighting key sourcing regions including Africa, South America, the Middle East, and Europe—such as France and Colombia—where craftsmanship and innovation converge.

For international B2B buyers, this resource is designed to facilitate strategic sourcing, cost analysis, and supplier evaluation. Whether you are expanding your product portfolio, entering new markets, or establishing partnerships, understanding the market dynamics and supply chain intricacies will empower you to make confident, profitable decisions. From navigating tariffs and regulations to assessing supplier reliability, this guide aims to be your essential tool in successfully navigating the global market for drag queen shoes.

Understanding drag queen shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

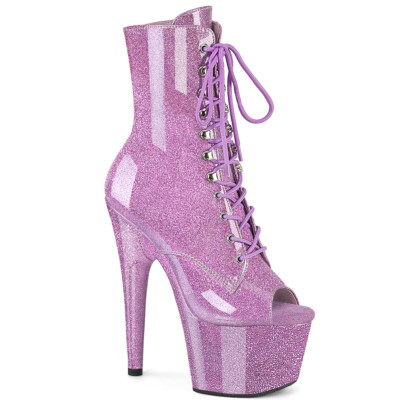

| Classic Platform Heels | Elevated platform sole with stiletto or chunky heel, often adorned | Costumes, stage performances, fashion shows | Pros: High visual impact, wide variety of styles. Cons: Higher manufacturing costs, limited comfort for prolonged wear. |

| Ankle Boot Heels | Heeled shoes covering the ankle, often with decorative elements | Retail boutiques, costume suppliers | Pros: Versatile styling, easier to produce in bulk. Cons: Less dramatic height increase compared to traditional heels. |

| Over-the-Top Costume Shoes | Extravagant, often oversized or uniquely shaped shoes, with bold embellishments | Specialty costume shops, theatrical productions | Pros: Unique selling point, high customization. Cons: Niche market, higher complexity in manufacturing and shipping. |

| Flared or Platform Boots | Tall boots with flared soles or chunky platforms, often with decorative laces | Drag shows, themed events, fashion brands | Pros: Durable, statement-making, suitable for various weather conditions. Cons: Bulkier, higher shipping costs. |

| Customizable Heels | Modular shoes with interchangeable parts or customizable embellishments | High-end boutiques, custom orders | Pros: High margin potential, tailored to customer preferences. Cons: Longer lead times, complex inventory management. |

Classic Platform Heels

Classic platform heels are characterized by a thick sole under the front part of the foot and a tall, slender or chunky heel. They are often decorated with sequins, rhinestones, or metallic finishes, making them a staple in drag performance and high fashion. For B2B buyers, these shoes are widely available in various sizes and designs, suitable for mass production or bespoke orders. When sourcing, consider material quality and manufacturing complexity, as these impact both cost and delivery timelines. Bulk purchasing from established manufacturers can ensure consistency and reliability, especially for large retail or theatrical clients.

Ankle Boot Heels

Ankle boots with heels are a versatile option, combining practicality with flamboyance. They typically feature a sturdy heel and decorative elements like glitter, feathers, or embroidery. These shoes are ideal for boutique retailers and costume suppliers looking to offer a wider range of styles at competitive prices. B2B buyers should evaluate the manufacturing process for durability and comfort, especially if they plan to customize or add embellishments. Bulk orders can benefit from modular designs that facilitate easier production and inventory management, while also allowing for regional style adaptations.

Over-the-Top Costume Shoes

This category encompasses shoes with exaggerated shapes, oversized features, or elaborate embellishments such as feathers, rhinestones, or metallic accents. These shoes are often custom-made for specific performances or events, making them suitable for niche markets. For B2B buyers, establishing relationships with specialized artisans or manufacturers is essential to ensure quality and customization options. Due to their bespoke nature, these shoes typically involve longer lead times and higher costs, but they can command premium pricing and attract high-end clients seeking unique, show-stopping footwear.

Flared or Platform Boots

Tall, sturdy boots with flared soles or chunky platforms are designed for durability and visual impact. They often feature decorative laces, buckles, or painted finishes, making them suitable for both performance and fashion retail. For international buyers, sourcing these boots from manufacturers with experience in footwear durability and comfort is crucial. Bulk procurement can leverage economies of scale, but attention must be paid to shipping costs and customs regulations, especially for heavier items. These boots appeal to clients seeking statement pieces that balance style with practicality.

Customizable Heels

These shoes are designed with modular components or interchangeable embellishments, allowing for personalized designs. They are particularly attractive to high-end boutiques and clients who want exclusive, bespoke footwear. B2B buyers should focus on establishing reliable supply chains for high-quality materials and components, as well as managing longer lead times. Offering customization options can significantly boost profit margins, but requires careful inventory management and clear communication with clients regarding lead times and design options. These shoes are ideal for premium markets and can differentiate a retailer in competitive landscapes.

Key Industrial Applications of drag queen shoes

| Industry/Sector | Specific Application of drag queen shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Entertainment & Performing Arts | Stage costumes and performance outfits for drag shows and theatrical productions | Enhances visual impact, supports brand differentiation, and attracts audiences | Customization options, durability, comfort, and high-quality embellishments |

| Fashion & Costume Design | High-concept runway shows, fashion editorials, and costume manufacturing | Creates bold, innovative designs that set trends and attract media attention | Material versatility, sourcing sustainable materials, and flexibility in design |

| Event & Festival Production | Special events, pride parades, themed festivals, and cultural celebrations | Boosts event visibility, promotes inclusivity, and enhances attendee engagement | Bulk procurement, vibrant color options, and ease of transport and storage |

| Retail & Wholesale Distribution | Selling to boutiques, costume stores, and online platforms | Expands product portfolio, caters to niche markets, and increases sales | Consistent quality, scalable manufacturing, and competitive pricing |

| Film & Media Production | Costuming for movies, commercials, and digital content creation | Adds authenticity and visual appeal, supporting storytelling and branding | Authenticity in design, adherence to costume specifications, and quick turnaround times |

Entertainment & Performing Arts

Drag queen shoes are pivotal in the entertainment industry, particularly for stage performances, drag shows, and theatrical productions. They serve not only as costume accessories but also as tools to enhance the performer’s charisma and stage presence. International B2B buyers, especially from regions like Europe and South America, prioritize shoes that combine visual impact with comfort and durability. Customization with embellishments or unique designs can elevate a show’s aesthetic. Sourcing considerations include high-quality craftsmanship, reliable suppliers for bespoke designs, and materials that withstand frequent use and stage conditions, ensuring long-term value and performance.

Fashion & Costume Design

In the fashion sector, drag queen shoes are increasingly integrated into avant-garde runway collections, editorial shoots, and bespoke costume designs. They enable designers to push boundaries with bold, unconventional styles that command attention and influence trends. For international buyers from Africa and the Middle East, sourcing options that offer sustainable or locally produced materials can align with regional sustainability initiatives and reduce logistics costs. Flexibility in design, along with high-quality finishes, is essential to meet the demands of high-profile fashion events and ensure the shoes’ durability in repeated use.

Event & Festival Production

Drag queen shoes are vital for large-scale cultural and pride events across the globe. They contribute to the vibrant, inclusive atmosphere that these festivals aim to promote. For B2B buyers from Latin America and Europe, bulk procurement of colorful, eye-catching designs facilitates consistent branding and visual cohesion. These shoes should be lightweight for ease of transport and storage, with vibrant color options and quick customization capabilities. Sourcing considerations include scalable manufacturing, reliable supply chains, and adherence to safety standards for outdoor and large crowd events.

Retail & Wholesale Distribution

Retailers and distributors targeting niche markets such as drag performers, costume shops, and online marketplaces rely heavily on quality and variety. Drag queen shoes with consistent quality, competitive pricing, and a broad selection of styles can significantly expand a distributor’s product offerings. For international buyers, establishing relationships with manufacturers that offer scalable production and reliable logistics ensures timely delivery and stock availability. Emphasizing product authenticity and unique designs can help retailers differentiate themselves in competitive markets.

Film & Media Production

Costuming for media productions demands high fidelity and authenticity, especially for characters that emphasize flamboyance and personality. Drag queen shoes are used in movies, commercials, and digital content to add depth and visual storytelling elements. B2B buyers from regions like Europe and the Middle East seek shoes that meet specific costume specifications while offering quick turnaround times for project deadlines. Sourcing considerations include authentic design replication, high-quality materials for camera clarity, and reliable suppliers capable of fulfilling short-notice orders to meet production schedules.

Strategic Material Selection Guide for drag queen shoes

Analysis of Common Materials for Drag Queen Shoes

Leather

Leather remains a top choice for high-end drag queen shoes due to its superior aesthetic appeal and flexibility. It offers excellent durability, conforming to the wearer’s foot over time, which enhances comfort and fit. Leather’s natural properties provide good breathability, reducing moisture buildup during prolonged wear. However, genuine leather can be costly and requires careful maintenance to prevent cracking and deterioration, especially in humid or harsh environments.

From a manufacturing perspective, leather is relatively straightforward to work with but demands skilled craftsmanship, which can influence production costs. For international buyers, especially from regions like Africa or South America, sourcing quality leather may involve navigating import tariffs and ensuring compliance with local environmental standards, such as the EU’s REACH regulations or similar regional directives. Leather also tends to meet various international standards (e.g., ASTM D2097 for leather testing), making it a versatile choice for global markets.

Synthetic Materials (PVC, PU)

Synthetic materials like PVC and PU are popular alternatives to leather due to their affordability and wide availability. These materials are lightweight, easy to mold, and offer a broad range of colors and finishes, enabling creative and vibrant designs suited for drag performances. They are resistant to water and most chemicals, making them suitable for various environments and climates.

However, synthetic materials often lack the breathability of natural leather, which can lead to discomfort during extended wear. Durability varies depending on the quality of the synthetic, with cheaper options prone to cracking or peeling over time. From an international trade perspective, synthetic materials generally comply with global safety standards, but buyers should verify that products meet specific regional regulations regarding chemical content (e.g., REACH in Europe, CPSIA in the US). Cost-wise, synthetics are generally low to medium, making them attractive for mass production.

Wood and Cork

Wood and cork are less conventional but increasingly popular for statement or platform drag shoes due to their unique aesthetic and lightweight properties. Cork, in particular, offers excellent shock absorption and flexibility, making it comfortable for wear. Wood provides a sturdy, high-fashion look and can be finished with various coatings for durability.

The main challenge with these materials is manufacturing complexity; shaping and finishing require specialized skills and equipment, which can increase production costs. Additionally, wood and cork are susceptible to moisture damage, necessitating proper sealing and treatment—especially critical for international markets with humid climates like Colombia or Middle Eastern countries. Compliance with environmental standards (e.g., FSC certification for sustainable cork) is also a consideration for European buyers seeking eco-friendly options.

Metal Components

While not a primary material for the entire shoe, metal components such as decorative embellishments, buckles, or heel supports are integral to many drag shoe designs. Metals like stainless steel, brass, or aluminum are chosen for their strength, corrosion resistance, and aesthetic appeal.

Metals can add weight and complexity to manufacturing but significantly enhance the visual impact and durability of the shoe. For international buyers, ensuring that metal parts meet safety standards (e.g., RoHS compliance in Europe) and are free from harmful substances is essential. Metal components also require corrosion-resistant coatings if used in humid environments, which is particularly relevant for regions like South America or the Middle East.

Summary Table of Materials for Drag Queen Shoes

| Material | Typical Use Case for drag queen shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | High-end, custom, luxury drag shoes | Excellent durability, aesthetic appeal, conforming fit | High cost, maintenance required, environmental concerns | High |

| Synthetic (PVC, PU) | Budget-friendly, vibrant, mass-produced designs | Affordable, lightweight, versatile color options | Less breathable, potential for cracking, variable quality | Low to Medium |

| Cork/Wood | Artistic, statement shoes, platform designs | Lightweight, eco-friendly options, unique aesthetic | Manufacturing complexity, moisture sensitivity | Medium |

| Metal Components | Decorative elements, heel supports | Durable, aesthetic enhancement, corrosion-resistant | Adds weight, manufacturing complexity, potential corrosion | Medium to High |

This comprehensive analysis provides B2B buyers with critical insights into material selection, emphasizing regional considerations, compliance standards, and cost implications. By aligning material choices with market demands, environmental standards, and manufacturing capabilities, buyers can optimize product quality and market competitiveness across Africa, South America, the Middle East, and Europe.

In-depth Look: Manufacturing Processes and Quality Assurance for drag queen shoes

Manufacturing Processes for Drag Queen Shoes

The production of drag queen shoes involves a series of carefully orchestrated stages, each critical to achieving the desired aesthetic, comfort, and durability.

1. Material Preparation

The process begins with selecting high-quality raw materials tailored to the design specifications. Common materials include synthetic leathers, patent finishes, glitter fabrics, and embellishments like rhinestones or sequins. Suppliers often pre-treat or pre-cut these materials to ensure consistency and ease of assembly. For B2B buyers, establishing supplier capabilities in sourcing sustainable or specialty materials can be a differentiator, especially in regions like Africa and South America where raw material availability varies.

2. Forming and Shaping

Forming involves creating the shoe’s structure, typically through injection molding, thermoforming, or traditional last-based shaping. For platforms, stiletto heels, and ornate designs common in drag queen footwear, precision molds are essential. Advanced manufacturing facilities utilize CAD/CAM technologies to produce detailed molds that accommodate complex shapes and intricate embellishments. Ensuring proper fit and comfort during this stage is vital, as it impacts the final product’s performance.

3. Assembly

Assembly encompasses attaching the upper to the sole, installing heel components, and adding decorative elements. Techniques such as cementing, stitching, and mechanical fastening are employed, often in combination. For embellished shoes, hand-finishing is common to ensure quality and aesthetic appeal. B2B buyers should verify that suppliers have skilled artisans or automated systems capable of handling complex designs without compromising quality.

4. Finishing

The finishing stage includes polishing, painting, applying protective coatings, and attaching embellishments. Special attention is paid to achieve a flawless surface, vibrant color, and secure attachment of decorative elements. Techniques such as airbrushing or electroplating may be used for metallic accents. Final inspections involve checking for defects, color consistency, and overall appearance.

Quality Assurance in Drag Queen Shoe Manufacturing

Given the importance of aesthetics, durability, and comfort, rigorous quality assurance (QA) processes are integral to manufacturing.

International Standards Compliance

– ISO 9001: Most reputable manufacturers adhere to ISO 9001 standards for quality management systems, ensuring consistent product quality and continuous improvement.

– Other Certifications: Depending on the target market, additional certifications such as CE marking (European Economic Area), API (American Petroleum Institute for certain materials), or regional standards may be required.

Industry-Specific Certifications and Testing

– Safety and Durability: Testing for slip resistance (sole grip), tensile strength (stitching, adhesives), and impact resistance (heel stability) is common.

– Material Safety: Compliance with REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) in Europe or similar regulations ensures non-toxic materials, crucial for international markets.

QC Checkpoints and Methods

– Incoming Quality Control (IQC): Raw materials are inspected upon receipt for defects, consistency, and compliance with specifications. This step prevents substandard inputs from progressing through production.

– In-Process Quality Control (IPQC): During manufacturing, checkpoints monitor dimensional accuracy, assembly precision, and adherence to design specifications. Techniques include visual inspections, measurement tools, and functional testing of prototypes.

– Final Quality Control (FQC): Before shipment, finished shoes undergo comprehensive inspections for aesthetic flaws, structural integrity, and functional performance. Random sampling and detailed audits help maintain standards.

Common Testing Methods

– Visual Inspection: Checks for surface defects, color mismatches, and embellishment security.

– Mechanical Testing: Assesses flexibility, heel stability, and sole adhesion through standardized tests like ASTM or ISO methods.

– Environmental Testing: Simulates wear conditions, such as exposure to moisture, heat, or UV light, to ensure durability in various climates.

How B2B Buyers Can Verify Supplier Quality

Supplier Audits

Conduct on-site or virtual audits to evaluate manufacturing facilities, quality systems, and adherence to standards. A thorough audit covers production processes, personnel training, equipment calibration, and record-keeping.

Review of Quality Reports and Certifications

Request and review detailed quality reports, test certificates, and compliance documentation. Ensure certifications like ISO 9001, CE, or regional safety standards are valid and current.

Third-Party Inspection and Certification

Engage independent inspection agencies to verify product quality before shipment. These agencies can perform random sampling, detailed testing, and certification, providing an unbiased assessment crucial for international trade.

Sample Testing and Pilot Orders

Place initial small-volume orders to evaluate product quality firsthand. Conduct independent testing or third-party inspections on these samples to confirm they meet specifications and standards.

Special Considerations for International B2B Buyers

From Africa and South America

Manufacturers in these regions may face challenges related to raw material sourcing and infrastructure. B2B buyers should prioritize suppliers with robust quality management systems and transparent supply chains. Building long-term relationships can improve consistency and facilitate compliance with international standards.

From the Middle East

Manufacturers often emphasize luxury finishes and high-end embellishments. Buyers should verify certifications related to chemical safety and durability, especially if products are intended for export to Europe or North America.

From Europe (e.g., France, Colombia)

European manufacturers typically adhere to stringent environmental and safety regulations. B2B buyers should ensure suppliers maintain ISO certifications and comply with REACH or similar directives. Additionally, European suppliers may offer advanced testing capabilities, providing higher assurance levels.

Final Tips for B2B Buyers

- Establish clear quality specifications upfront, including materials, craftsmanship, and safety standards.

- Request detailed documentation and certifications with each order.

- Perform regular audits and inspections to maintain consistent quality.

- Foster transparent communication with manufacturers about quality expectations and compliance requirements.

- Consider partnering with third-party inspection agencies for ongoing quality verification, especially when dealing with new or unfamiliar suppliers from diverse regions.

By understanding and rigorously managing manufacturing processes and quality assurance protocols, international B2B buyers can mitigate risks, ensure product excellence, and foster long-term supplier relationships in the competitive drag queen shoe market.

Comprehensive Cost and Pricing Analysis for drag queen shoes Sourcing

Cost Structure Breakdown for Drag Queen Shoes Sourcing

Understanding the comprehensive cost structure is vital for international buyers aiming to optimize procurement strategies. The primary cost components include:

-

Materials: High-quality synthetic leathers, sequins, glitter fabrics, and embellishments are standard. Premium finishes or custom fabrics significantly increase material costs. Material prices vary regionally, with suppliers in Asia typically offering competitive rates, while European and Middle Eastern suppliers may charge a premium for luxury-grade materials.

-

Labor: Manufacturing costs are predominantly influenced by the complexity of the design and the skill level required. Countries like China, Vietnam, and India offer lower labor rates, often ranging from $1 to $5 per pair, whereas European factories may charge $10 to $30 per pair due to higher wages and stricter labor standards.

-

Manufacturing Overheads: These include equipment depreciation, factory utilities, and management expenses. Overheads tend to be embedded in unit costs and vary based on factory size, automation level, and location.

-

Tooling and Development: Initial mold creation, pattern making, and prototype development can range from $200 to $1,000 depending on complexity. These costs are typically amortized over large production runs, making larger MOQs more cost-efficient.

-

Quality Control (QC): Rigorous QC processes are critical for ensuring consistent quality, especially for performance and stage shoes. QC costs might add 5-10% to manufacturing expenses but are essential for maintaining brand reputation.

-

Logistics and Shipping: Costs depend on volume, destination, shipping mode (air vs. sea), and Incoterms. Air freight ensures faster delivery but at a premium, whereas sea freight offers significant savings for bulk orders. Buyers should also consider customs duties, taxes, and import fees, which vary by country.

-

Profit Margin: Suppliers typically add a markup of 15-30%, influenced by the order volume, customization requirements, and relationship strength.

Key Price Influencers

Several factors significantly impact the final unit price:

-

Order Volume and MOQ: Larger quantities reduce per-unit costs due to economies of scale. Suppliers often set MOQs between 50-200 pairs, with discounts increasing at higher volumes.

-

Customization and Specifications: Unique designs, special materials, or custom branding increase costs. Custom molds or intricate embellishments require additional tooling and labor, raising the price.

-

Material Choices: Premium materials or eco-friendly options tend to be more expensive, affecting both initial costs and retail pricing.

-

Quality Certifications: Certifications like ISO, CE, or compliance with local safety standards can elevate costs but are vital for international markets, especially in Europe and the Middle East.

-

Supplier Factors: Factory reputation, production capacity, and lead times influence pricing. Established manufacturers with reliable quality may charge higher but provide better consistency.

-

Incoterms and Shipping Terms: FOB (Free On Board) prices are common, but buyers should negotiate terms that include insurance and freight, especially for distant markets.

Strategic Tips for International B2B Buyers

-

Negotiate for Better Terms: Leverage volume commitments to negotiate discounts, especially for large or repeat orders. Clarify all costs upfront to avoid unexpected charges.

-

Focus on Total Cost of Ownership (TCO): Beyond unit price, consider shipping, customs, taxes, and potential quality-related costs. A cheaper unit price may not always translate to lower overall expenses if logistics or QC issues arise.

-

Assess Customization Costs Carefully: Balance design uniqueness with manufacturing feasibility. Simplified designs or limited customization can significantly reduce costs without compromising brand appeal.

-

Understand Pricing Nuances by Region: Suppliers in Africa or South America might offer lower labor costs but face higher logistics or import tariffs. European suppliers may charge premium but offer higher quality and faster delivery.

-

Build Strong Supplier Relationships: Long-term partnerships can lead to better pricing, priority production, and more flexible terms. Regular communication and quality audits help mitigate risks.

Disclaimer

Prices for drag queen shoes can vary widely based on design complexity, order volume, and regional factors. As a rough guideline, unit prices generally range from $15 to $50 per pair for standard designs in moderate quantities, with premium or highly customized shoes costing upwards of $60 or more. Always request detailed quotes and conduct a thorough cost analysis aligned with your specific requirements.

By understanding these cost components and influencing factors, international B2B buyers from Africa, South America, the Middle East, and Europe can better strategize their sourcing, negotiate effectively, and optimize their total procurement costs for drag queen shoes.

Spotlight on Potential drag queen shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for drag queen shoes.)*

Essential Technical Properties and Trade Terminology for drag queen shoes

Key Technical Properties for Drag Queen Shoes

Material Grade

The quality of materials used directly impacts durability, comfort, and aesthetic appeal. Common materials include synthetic leathers, genuine leather, and high-quality fabrics. For B2B transactions, specifying material grade (e.g., full-grain leather vs. bonded leather) ensures clarity on product longevity and price point, especially important for buyers in regions like Africa or South America where sourcing quality materials locally may vary.

Heel Height and Stability

Heel height is a critical factor affecting both design and safety. Typically ranging from 4 to 8 inches for drag queen shoes, precise measurements ensure the shoes meet performance and comfort expectations. Stability features such as reinforced heel counters and anti-slip soles are essential, particularly for international markets where uneven terrain or different usage contexts are common.

Sole Composition and Tread Pattern

The sole’s material—such as rubber, leather, or synthetic composites—affects grip, wear resistance, and overall comfort. A well-designed tread pattern enhances slip resistance, which is vital for safety during performances or events. Clear specifications allow buyers to select shoes suitable for various climates and usage environments, from tropical regions to colder European markets.

Tolerances and Fit Precision

Manufacturing tolerances refer to the permissible deviations in size and shape. Tight tolerances (e.g., ±0.5mm) ensure consistent quality, which is crucial for international orders to prevent returns and dissatisfaction. Accurate fit is especially important for high-heeled footwear, where comfort and safety are paramount, influencing customer satisfaction and brand reputation.

Colorfastness and Finish Durability

Colors must resist fading and transfer, particularly under stage lighting or exposure to sweat and moisture. Finish durability measures how well the shoe maintains its appearance over time. These properties are essential for maintaining a premium look, especially for performance-oriented footwear used in diverse environmental conditions.

Common Industry and Trade Terms

OEM (Original Equipment Manufacturer)

Refers to manufacturers producing shoes based on the buyer’s specifications and branding. Understanding OEM allows B2B buyers to customize designs, select reliable factories, and ensure product consistency, which is vital when sourcing unique styles or collaborating with regional artisans.

MOQ (Minimum Order Quantity)

The smallest batch size a manufacturer accepts per order. Knowing MOQ helps buyers plan inventory and negotiate terms, especially when entering new markets like Europe or South America where demand may vary. Lower MOQs are often advantageous for testing new markets or styles.

RFQ (Request for Quotation)

A formal process where buyers solicit price and lead-time estimates from multiple suppliers. An RFQ enables comparison of manufacturing costs, quality standards, and delivery schedules, empowering buyers from Africa or the Middle East to make informed sourcing decisions.

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs duties. Familiarity with Incoterms (e.g., FOB, CIF, DDP) helps buyers clarify costs and logistics, ensuring smoother international transactions and compliance with regional import/export regulations.

Sample Lead Time

The period required to produce and deliver sample products for quality evaluation. This metric influences project timelines and helps buyers plan product launches or market entry strategies across diverse regions.

Quality Certifications

Standards such as ISO, CE, or local compliance marks assure product safety and quality. For international buyers, especially in regulated markets like Europe, verifying certifications reduces risk and facilitates smoother customs clearance.

By understanding these technical properties and trade terms, international B2B buyers can optimize sourcing strategies, negotiate effectively, and ensure the delivery of high-quality drag queen shoes tailored to their regional markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the drag queen shoes Sector

Market Overview & Key Trends

The global market for drag queen shoes is experiencing notable growth driven by increased acceptance of gender diversity, rising demand from niche entertainment sectors, and expanding online retail channels. Major markets such as North America and Europe continue to lead in innovation, but emerging regions like Africa, South America, and the Middle East are becoming increasingly significant due to shifting cultural attitudes and rising disposable incomes. For international B2B buyers from these regions, understanding local consumer preferences—such as vibrant designs, customizations, and comfort—is crucial for sourcing success.

Current sourcing trends are heavily influenced by technological advancements, including 3D printing and digital design platforms, which enable faster prototyping and customization. E-commerce platforms and global marketplaces streamline procurement, making it easier for buyers to access diverse manufacturers and artisans. Sustainability and ethical sourcing are gaining momentum, with buyers increasingly prioritizing suppliers who adhere to fair labor practices and environmentally friendly processes. For B2B buyers, establishing transparent supply chains and leveraging certifications like Fair Trade or EcoVadis can serve as differentiators in competitive markets.

Illustrative Image (Source: Google Search)

Market dynamics are also shaped by fluctuating raw material costs, trade policies, and regional manufacturing capabilities. Buyers from Africa and South America should explore local or regional manufacturers to reduce logistics costs and support local economies, while European and Middle Eastern buyers may focus on premium, bespoke products that cater to high-end markets. Building strong supplier relationships and staying attuned to emerging fashion trends—such as platform heels and sustainable materials—are essential for maintaining competitive advantage in this evolving sector.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical factor influencing B2B procurement decisions within the drag queen shoes sector. Manufacturers are increasingly adopting eco-friendly materials such as recycled plastics, organic leathers, and biodegradable components to reduce environmental impact. For buyers in regions like Africa, South America, and the Middle East, sourcing from suppliers committed to green practices not only enhances brand reputation but also aligns with global consumer demand for ethically produced products.

Illustrative Image (Source: Google Search)

Ethical sourcing extends beyond environmental concerns to include fair labor practices, safe working conditions, and fair wages. B2B buyers should prioritize suppliers with verifiable certifications such as Fair Trade, SA8000, or B Corp status. Implementing rigorous supplier audits and fostering long-term partnerships can help mitigate risks related to labor violations or environmental violations.

Additionally, “green” certifications and transparency in the supply chain serve as valuable markers of credibility. Using sustainable materials and certifying eco-labels can also open access to niche markets willing to pay premium prices for environmentally responsible products. For regions like Europe and the Middle East, where consumers and regulators are increasingly scrutinizing supply chain ethics, integrating sustainability into sourcing strategies is not just ethical but also economically advantageous.

Brief Evolution/History

The evolution of drag queen shoes reflects broader shifts in fashion, culture, and social acceptance. Originally rooted in underground performance scenes, these shoes have transitioned into mainstream fashion and entertainment, driven by the rise of drag culture and social media visibility. For B2B buyers, understanding this history underscores the importance of innovation and cultural relevance in product offerings.

Historically, drag shoes were characterized by exaggerated features, platform heels, and flamboyant designs. Today, manufacturers incorporate modern materials, ergonomic designs, and sustainable elements, broadening appeal across diverse markets. This evolution presents opportunities for buyers to source innovative, culturally resonant products that cater to both niche and mass markets. Recognizing these trends can inform strategic sourcing decisions, enabling buyers to stay ahead of consumer preferences and capitalize on the sector’s dynamic growth.

Frequently Asked Questions (FAQs) for B2B Buyers of drag queen shoes

1. How can I effectively vet suppliers to ensure product quality and reliability?

To vet suppliers effectively, start by requesting detailed product samples and certifications such as ISO, CE, or relevant safety standards. Review their company credentials, including business licenses and manufacturing licenses, and verify their reputation through references or industry networks. Conduct virtual factory audits or third-party inspections when possible, especially for international suppliers. Also, check online reviews, trade association memberships, and previous client feedback. Establish clear communication channels to assess responsiveness and transparency. Building strong, verified relationships minimizes risks and ensures consistent quality for your drag queen shoe orders.

Illustrative Image (Source: Google Search)

2. What customization options are typically available, and how do they impact MOQ and lead times?

Most suppliers offer customization in design, color, embellishments, and packaging. Highly customized orders generally require higher MOQs—often 200-500 pairs—to justify production setup costs. Lead times for customized shoes can range from 4 to 12 weeks, depending on complexity and supplier capacity. To optimize, specify your customization needs early and negotiate flexible MOQs or phased production runs. Some suppliers provide ready-made designs with minor customization, which can reduce lead times and MOQ requirements. Clear communication about your specifications and timelines ensures smoother production and delivery.

3. What are typical MOQ, lead times, and payment terms for international B2B orders?

MOQ for drag queen shoes usually ranges between 100-300 pairs for standard models and higher for customized designs. Lead times generally span 4-8 weeks post-order confirmation, but this varies by supplier and order complexity. Payment terms often include 30% upfront as a deposit, with the balance payable before shipment or upon delivery. Some suppliers may offer letter of credit (L/C) options or net terms for trusted buyers. Establish clear contractual terms upfront to safeguard payments and ensure timely production, especially when dealing with international transactions.

4. What certifications and quality assurance processes should I look for?

Reliable suppliers should provide certifications such as CE, ISO 9001, or other relevant safety and quality standards. Request documentation on material safety, environmental compliance, and manufacturing practices. Quality assurance should include pre-production samples, in-line inspections, and final quality checks before shipment. Ask if they have a dedicated QA team and whether they perform third-party audits. Implementing a rigorous QA process reduces defects, returns, and disputes, ensuring your drag queen shoes meet both safety standards and your customer expectations.

5. How should I handle logistics and shipping for international orders?

Coordinate with suppliers to choose the most efficient shipping method—air freight for urgent orders or sea freight for larger volumes to reduce costs. Clarify Incoterms (e.g., FOB, CIF, DDP) to define responsibilities and costs clearly. Work with experienced freight forwarders familiar with customs regulations in your region to streamline clearance. Ensure proper packaging to prevent damage during transit. Consider insurance options for high-value shipments. Regular communication with your logistics partners ensures transparency and helps address delays proactively, minimizing supply chain disruptions.

6. How can I resolve disputes or quality issues with international suppliers?

Establish clear contractual agreements covering product specifications, quality standards, and dispute resolution mechanisms before placing orders. Maintain detailed records of communications, inspections, and photographs of shipped products. If issues arise, communicate promptly with the supplier, providing evidence and referencing contractual terms. Negotiate amicably to reach a resolution, whether through rework, replacement, or refunds. If necessary, engage third-party mediators or arbitration services familiar with international trade laws. Building strong, transparent relationships and detailed contracts reduces the risk of unresolved disputes.

7. What are best practices for maintaining long-term supplier relationships across borders?

Develop mutual trust through consistent communication, timely payments, and transparent feedback. Regularly visit suppliers if feasible or conduct virtual audits to assess ongoing capabilities. Share forecasts and collaborate on new designs or innovations to foster partnership. Establish clear performance metrics and review supplier performance periodically. Offering volume incentives or early payments can strengthen loyalty. Cultural sensitivity and understanding local business practices also enhance collaboration. Long-term relationships reduce sourcing risks, improve product quality, and may lead to better pricing and priority production.

8. How do I ensure compliance with local import regulations and standards?

Research import regulations, tariffs, and customs procedures in your country before ordering. Work with suppliers familiar with export documentation like commercial invoices, packing lists, and certificates of origin. Ensure products meet local safety and environmental standards—e.g., footwear safety standards, labeling laws, or import bans. Engage local customs brokers to facilitate smooth clearance. Staying updated on regulatory changes and maintaining accurate documentation minimizes delays and penalties. Implementing compliance checks as part of your supplier onboarding process ensures consistent adherence to legal requirements across markets.

Strategic Sourcing Conclusion and Outlook for drag queen shoes

Strategic Sourcing Outlook for Drag Queen Shoes

Effective strategic sourcing is crucial for international B2B buyers seeking to capitalize on the growing demand for drag queen shoes across diverse markets. By establishing strong relationships with reliable manufacturers and suppliers—particularly in regions known for innovative design and quality craftsmanship such as Europe and South America—buyers can secure competitive pricing, ensure product authenticity, and maintain consistent supply chains.

For buyers in Africa, the Middle East, and emerging markets like Colombia, leveraging regional trade agreements and exploring local manufacturing options can reduce costs and enhance agility. Embracing a multi-sourcing approach mitigates risks associated with supply disruptions and fosters flexibility to respond to shifting consumer preferences.

Looking ahead, the industry’s evolution will be driven by increased demand for custom, high-quality, and sustainable footwear options. International buyers are encouraged to invest in supplier vetting processes, foster long-term partnerships, and stay informed about emerging trends to maintain a competitive edge. Proactive, strategic sourcing will be instrumental in unlocking new market opportunities, strengthening brand positioning, and ensuring sustainable growth in the vibrant world of drag queen footwear.