The Ultimate B2B Guide to Sourcing High-Quality Drip Shoes

Guide to Drip Shoes

- Introduction: Navigating the Global Market for drip shoes

- Understanding drip shoes Types and Variations

- Key Industrial Applications of drip shoes

- Strategic Material Selection Guide for drip shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for drip shoes

- Comprehensive Cost and Pricing Analysis for drip shoes Sourcing

- Spotlight on Potential drip shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for drip shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the drip shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of drip shoes

- Strategic Sourcing Conclusion and Outlook for drip shoes

Introduction: Navigating the Global Market for drip shoes

In today’s dynamic global footwear landscape, drip shoes have emerged as a critical product category, blending innovative design with cultural expression and streetwear appeal. For B2B buyers across Africa, South America, the Middle East, and Europe—particularly in markets like Saudi Arabia and the UAE—sourcing high-quality drip shoes offers significant growth opportunities. These products are not just fashion statements; they represent a lucrative segment driven by youth culture, social media influence, and evolving consumer preferences.

This comprehensive guide is designed to equip international B2B buyers with the essential knowledge needed to navigate the complex market for drip shoes confidently. It covers a wide range of topics, including the different types of drip shoes, the materials used, manufacturing processes, quality control standards, and reliable supplier networks. Additionally, it provides actionable insights into cost considerations, market trends, and key FAQs to streamline sourcing decisions.

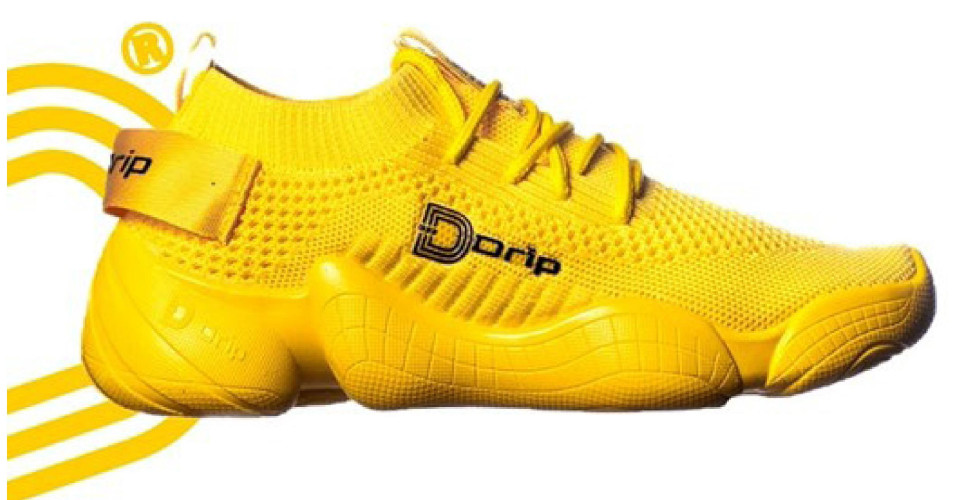

Illustrative Image (Source: Google Search)

By understanding these critical aspects, buyers can identify reputable manufacturers, negotiate better pricing, and ensure product quality—ultimately strengthening their competitive edge in local and regional markets. Whether you’re expanding your product portfolio or entering new markets, this guide aims to empower you with the tools to make informed, strategic sourcing choices for drip shoes in the global marketplace.

Understanding drip shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Drip Shoes | Basic design with simple drainage channels and open structure | Chemical processing, wastewater treatment | Cost-effective, easy to maintain; limited customization options |

| Heavy-Duty Drip Shoes | Reinforced materials, thicker construction, corrosion-resistant | Heavy industrial environments, mining | Durable, long lifespan; higher initial investment but reduced replacement costs |

| Custom-Designed Drip Shoes | Tailored shapes and features to specific process needs | Specialized chemical handling, pharmaceuticals | Precise fit for complex systems; higher lead times and costs |

| Modular Drip Shoes | Interchangeable sections, adaptable to various setups | Food processing, manufacturing lines | Flexibility in installation; potential complexity in assembly |

| Insulated Drip Shoes | Incorporate thermal insulation for temperature-sensitive fluids | Petrochemical, cryogenic applications | Minimize heat loss, protect personnel; higher manufacturing costs |

Characteristics and Suitability

Standard Drip Shoes are the most common type, characterized by their simple, open-channel design that facilitates drainage and vapor removal. They are suitable for general industrial applications where cost efficiency and straightforward maintenance are priorities. For B2B buyers, these shoes offer a reliable, low-cost solution, especially in environments with moderate chemical exposure and temperature fluctuations.

Heavy-Duty Drip Shoes are constructed with reinforced materials such as stainless steel or specialized alloys, making them ideal for harsh environments like mining, chemical processing, or heavy industrial setups. They provide increased durability and resistance to corrosion, which is crucial for minimizing downtime and replacement costs. Buyers should consider the initial higher investment against long-term operational savings.

Custom-Designed Drip Shoes are tailored to meet specific process requirements, including unique geometries, material compositions, or integration features. They are essential for complex systems where standard solutions may not suffice. While they offer precise fit and optimized performance, lead times and costs are higher, demanding careful planning and supplier collaboration.

Modular Drip Shoes feature interchangeable sections that can be reconfigured or expanded as process needs evolve. This flexibility is advantageous for growing or changing production lines, reducing the need for complete system overhauls. However, they may involve more complex installation procedures and require detailed planning to ensure compatibility.

Insulated Drip Shoes incorporate thermal insulation to manage temperature-sensitive fluids, preventing heat loss and protecting personnel from extreme temperatures. They are essential in petrochemical or cryogenic applications. Although they come at a premium price, their ability to maintain process integrity and safety can justify the investment.

B2B Purchasing Considerations

When sourcing drip shoes internationally, buyers should evaluate material compatibility with their fluids, operational environment, and budget constraints. Custom and modular options often involve longer lead times and higher upfront costs but provide tailored performance advantages. Heavy-duty and insulated variants, while more expensive initially, offer significant savings through durability and safety benefits. Engaging with reputable suppliers who understand regional standards and logistics is crucial for timely delivery and compliance, especially for buyers in regions like Africa, South America, the Middle East, and Europe.

Key Industrial Applications of drip shoes

| Industry/Sector | Specific Application of drip shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Pipeline leak containment and isolation | Ensures secure sealing, reduces environmental risks, and prevents leaks | Material resistance to hydrocarbons, high-pressure tolerance, API certifications |

| Chemical Processing | Containment of corrosive or hazardous fluids | Protects equipment and personnel, minimizes contamination risk | Chemical compatibility, durability under corrosive conditions, compliance standards |

| Mining | Sealing of slurry and wastewater systems | Prevents leaks, reduces environmental impact, and enhances safety | Abrasion resistance, sealing integrity under abrasive conditions, robust construction |

| Power Generation | Cooling system and turbine sealing | Maintains system efficiency, prevents fluid leaks, reduces downtime | Thermal stability, pressure resistance, compatibility with cooling media |

| Water Treatment | Sealing in filtration and piping systems | Ensures leak-proof operation, prolongs equipment lifespan | Resistance to water and chemical exposure, compliance with water industry standards |

Oil & Gas

In the oil and gas industry, drip shoes are critical for pipeline leak containment and isolation. They are used to create reliable seals around pipelines, especially in high-pressure and high-temperature environments common in offshore platforms and refineries. For international B2B buyers from regions like the Middle East or West Africa, sourcing drip shoes with high chemical and pressure resistance—certified to API standards—is essential to ensure safety and regulatory compliance. Properly selected drip shoes reduce environmental risks and costly downtime, making them an investment in operational integrity.

Chemical Processing

Chemical processing facilities require drip shoes for containment of hazardous or corrosive fluids within piping and vessel connections. These applications demand materials that are chemically resistant and capable of withstanding aggressive media. B2B buyers in South America or Europe should prioritize drip shoes with proven chemical compatibility and compliance with industry standards like ASTM or ISO. High-quality drip shoes help prevent leaks, protect personnel, and maintain process integrity, especially in environments handling aggressive chemicals.

Mining

In mining operations, drip shoes are vital for sealing slurry lines and wastewater systems. The abrasive nature of mining slurries necessitates drip shoes with excellent wear resistance and sealing performance under rugged conditions. For buyers in Africa or Latin America, sourcing drip shoes with robust construction and abrasion-resistant materials ensures long service life and minimizes environmental hazards. Proper sealing reduces water wastage and prevents contamination, supporting sustainable and compliant mining practices.

Power Generation

Power plants rely on drip shoes to seal cooling systems and turbines, preventing fluid leaks that could impair efficiency or cause damage. These applications require drip shoes that can withstand high temperatures and pressures, often in demanding environments like thermal or nuclear plants. B2B buyers from Europe or the Middle East should seek products with thermal stability, pressure resistance, and compatibility with cooling media. Reliable sealing enhances system uptime and reduces maintenance costs, crucial for continuous power supply.

Water Treatment

In water treatment facilities, drip shoes are used to ensure leak-proof operation in filtration units and piping systems. They must resist water exposure and chemicals used in treatment processes, maintaining integrity over extended periods. Buyers from regions such as South America or Africa should prioritize drip shoes with high chemical and water resistance, meeting industry standards for safety and durability. Effective sealing prolongs equipment lifespan, reduces operational disruptions, and ensures environmental compliance.

Strategic Material Selection Guide for drip shoes

Material Analysis for Drip Shoes

Selecting the appropriate materials for drip shoes is critical for ensuring durability, chemical compatibility, and compliance with international standards. Different industries and regions have unique requirements, influencing material choice based on environmental conditions, regulatory standards, and cost considerations. Here, we analyze four common materials—Carbon Steel, Stainless Steel, Elastomers (like Viton or EPDM), and PTFE—to guide international B2B buyers in making informed decisions.

Carbon Steel

Key Properties:

Carbon steel is known for its high strength, moderate corrosion resistance (when coated or treated), and excellent machinability. It can withstand high pressures and temperatures, making it suitable for demanding industrial environments. However, it is susceptible to rust and corrosion if not properly protected.

Pros & Cons:

* Pros: Cost-effective, widely available, easy to fabricate, and offers good mechanical strength.

* Cons: Prone to corrosion without protective coatings, requiring maintenance or additional surface treatments like galvanization or painting. Manufacturing complexity is moderate, but surface preparation adds to costs.

Impact on Application:

Ideal for applications involving non-corrosive media or where protective coatings are feasible. Suitable for industries handling water, oil, or non-aggressive chemicals.

International Considerations:

Compliance with standards such as ASTM A216 or ASME B16.34 is common. Buyers from regions like Africa, South America, and the Middle East should verify local standards and compatibility with corrosion protection practices. Cost considerations make it attractive for large-scale projects, but maintenance costs should be factored in.

Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance, high strength, and good temperature tolerance. Grades like 304 and 316 are prevalent, with 316 providing superior resistance in harsh environments, including saline or acidic media.

Pros & Cons:

* Pros: Highly durable, corrosion-resistant, low maintenance, and compliant with many international standards.

* Cons: Higher initial cost compared to carbon steel, and manufacturing complexity is increased due to its hardness and workability challenges.

Impact on Application:

Preferred in aggressive chemical environments, marine applications, or regions with high humidity and salinity, such as Middle East coastal zones. Suitable for applications requiring longevity and minimal maintenance.

International Considerations:

Buyers should verify compliance with standards like ASTM A240 or EN 10088. For regions like Europe and the Middle East, adherence to local standards and certifications (e.g., CE marking) enhances market acceptance. The higher cost is offset by longer service life and reduced maintenance.

Elastomers (Viton, EPDM)

Key Properties:

Elastomers like Viton and EPDM are used for sealing and lining applications within drip shoes. Viton offers excellent chemical resistance and high-temperature tolerance, while EPDM provides good weather and ozone resistance, suitable for outdoor applications.

Pros & Cons:

* Pros: Flexibility, chemical resistance, and ease of installation.

* Cons: Limited mechanical strength compared to metals, potential degradation under extreme conditions, and higher costs for specialty grades like Viton.

Impact on Application:

Primarily used for lining or sealing components exposed to aggressive media or weather conditions. Elastomer choice depends on the specific media and temperature ranges.

International Considerations:

Buyers should ensure compliance with relevant standards such as FDA, ISO, or ASTM for chemical resistance and safety. Regional preferences may favor certain elastomers based on environmental exposure—e.g., EPDM for outdoor or humid climates in Africa and South America, Viton for high-temperature or chemical-intensive environments in Europe and the Middle East.

PTFE (Polytetrafluoroethylene)

Key Properties:

PTFE is renowned for its exceptional chemical inertness, low friction, and high-temperature resistance. It performs well in highly corrosive environments and maintains integrity over a wide temperature range.

Pros & Cons:

* Pros: Superior chemical resistance, non-stick properties, and minimal maintenance.

* Cons: Costlier than metals and elastomers, and manufacturing complexity is high. Mechanical strength is lower, making it less suitable for load-bearing applications.

Impact on Application:

Ideal for highly corrosive media, such as acids or aggressive chemicals, especially in chemical processing industries. Suitable for applications requiring minimal media interaction.

International Considerations:

Compliance with standards like ASTM D1457 or ISO 10933 is essential. Buyers should verify certifications for purity and safety, especially in regions with strict chemical handling regulations like Europe. Cost considerations are significant, but long-term durability justifies the investment in critical applications.

Summary Table

| Material | Typical Use Case for drip shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General industrial media, non-corrosive fluids | Cost-effective, good strength | Susceptible to corrosion without protection | Low |

| Stainless Steel | Corrosive or saline environments, chemical plants, marine applications | Excellent corrosion resistance, durable | Higher initial cost, more complex fabrication | High |

| Elastomers (Viton, EPDM) | Sealing, lining in chemically aggressive or outdoor environments | Flexibility, chemical resistance | Limited mechanical strength, costlier for specialty grades | Med |

| PTFE | Highly corrosive media, chemical processing, lining applications | Superior chemical inertness, low friction | Expensive, lower mechanical strength | High |

This comprehensive analysis helps B2B buyers from diverse regions evaluate material choices based on environmental conditions, compliance standards, and budget constraints. Proper material selection ensures optimized performance, longevity, and regulatory adherence in international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for drip shoes

Manufacturing Processes for Drip Shoes

The manufacturing of drip shoes involves a series of carefully controlled stages designed to ensure product integrity, functional performance, and compliance with international standards. Understanding these stages allows B2B buyers to better evaluate supplier capabilities and ensure quality consistency across batches.

1. Material Preparation

The process begins with sourcing high-quality raw materials, typically including specialized plastics, rubbers, or composites depending on the design specifications. Raw materials are inspected upon arrival through Incoming Quality Control (IQC) to verify compliance with supplier specifications, including chemical composition, tensile strength, and flexibility. Suppliers adhering to ISO 9001 standards often maintain detailed documentation and testing reports for these materials, facilitating transparency for international buyers.

2. Forming and Molding

This stage involves shaping the drip shoes through processes like injection molding, blow molding, or rotational molding. Precision tooling and molds are critical here, ensuring dimensional accuracy and consistency. Advanced manufacturing facilities employ Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems to optimize mold design and reduce defects. Consistent process parameters—temperature, pressure, cycle time—are monitored through automated systems to ensure uniformity.

3. Assembly

Post-molding, components such as soles, straps, or decorative elements are assembled. This may involve ultrasonic welding, adhesive bonding, or mechanical fastening, depending on the design and material compatibility. The assembly process often incorporates semi-automated or robotic systems to enhance precision and repeatability, especially for complex or high-volume orders.

4. Finishing and Surface Treatment

Final touches include trimming excess material, surface smoothing, painting, or coating. Surface treatments—such as anti-slip coatings or UV stabilizers—are applied to enhance durability and safety, especially for outdoor or industrial applications. Quality checks at this stage verify surface integrity, adhesion, and visual quality before packaging.

Quality Assurance (QA) and Control in Drip Shoe Manufacturing

Ensuring the quality of drip shoes for international markets requires adherence to strict standards and rigorous testing at multiple checkpoints. B2B buyers should focus on the supplier’s certification, testing protocols, and quality management practices.

1. International Standards and Certifications

– ISO 9001: The cornerstone for quality management systems, ISO 9001 certification indicates a supplier’s commitment to consistent quality and continuous improvement. It mandates documented processes, regular audits, and customer satisfaction tracking.

– Product-specific certifications: Depending on the target market, additional certifications such as CE marking (European Economic Area), UL (for safety in North America), API (for industrial applications), or ISO 14001 (environmental management) may be required.

2. Quality Control Checkpoints

– Incoming Quality Control (IQC): Verifies raw materials and components upon arrival, ensuring they meet specifications before entering production.

– In-Process Quality Control (IPQC): Conducted during manufacturing, this involves random sampling, dimensional inspections, and process parameter verification. Automated systems can track temperature, pressure, and cycle times, reducing human error.

– Final Quality Control (FQC): The last inspection stage assesses finished products for visual defects, dimensional accuracy, and functional performance, including slip resistance and durability testing.

3. Testing Methods and Validation

– Mechanical testing: Tensile, compression, and bend tests ensure material robustness.

– Environmental testing: Resistance to UV, moisture, and temperature fluctuations simulates real-world conditions, vital for outdoor or industrial drip shoes.

– Safety testing: Slip resistance tests (e.g., ASTM C1028 or oil-slip tests) verify anti-slip properties, crucial for safety-critical applications.

4. Verification and Auditing for B2B Buyers

International buyers should request detailed QC reports, test certificates, and process documentation. On-site audits or third-party inspections (by agencies such as SGS, Bureau Veritas, or Intertek) are highly recommended for verifying supplier claims. These inspections assess production facilities, review quality documentation, and perform sample testing to confirm compliance.

Considerations for Buyers from Africa, South America, the Middle East, and Europe

Regional Standards and Market Expectations

Buyers should be aware of specific regulatory requirements, such as the CE marking for European markets or local standards in Middle Eastern countries like Saudi Arabia or UAE. Many suppliers in these regions have obtained relevant certifications, but due diligence is essential.

Supplier Audits and Due Diligence

Given the variability in manufacturing maturity across regions, international buyers should prioritize suppliers with ISO 9001 certification and proven compliance with local standards. Conducting comprehensive audits—either physically or via third-party inspectors—helps verify quality systems, traceability, and production capacity.

Quality Documentation and Transparency

Request detailed Quality Control Plans, test reports, and certification documents. Suppliers who maintain transparent records and readily share documentation facilitate smoother compliance processes and reduce risks associated with non-conformance.

Final Thoughts

By understanding the detailed manufacturing and quality assurance processes, B2B buyers can better assess potential suppliers’ capabilities and reliability. Emphasizing certifications, rigorous QC checkpoints, and third-party validation ensures that drip shoes meet safety, durability, and compliance standards across diverse international markets. This proactive approach minimizes risks, fosters trust, and supports long-term supply chain stability in the global marketplace.

Comprehensive Cost and Pricing Analysis for drip shoes Sourcing

Understanding Cost Components in Drip Shoe Sourcing

A thorough cost analysis begins with dissecting the primary components that influence the unit price of drip shoes. Materials typically account for 30-50% of total costs, with high-quality synthetic or genuine leather, specialized soles, and unique decorative elements being key price drivers. Labor costs vary significantly depending on the manufacturing country—factories in Asia (e.g., China, Vietnam) often offer lower wages compared to Eastern Europe or Middle Eastern facilities. Manufacturing overheads, including factory utilities, equipment depreciation, and administrative expenses, can range from 10-20% of total costs.

Tooling and setup costs are upfront expenses critical for customized or limited-edition designs, often amortized over the production run. Quality control (QC) is vital, especially for markets demanding certifications such as ISO or environmental standards; this can add 5-10% to manufacturing costs. Logistics and shipping represent a significant variable, influenced by distance, shipping mode, and Incoterms. For example, FOB (Free on Board) terms shift logistical costs to the buyer, whereas DDP (Delivered Duty Paid) includes all shipping and customs fees.

Finally, a sustainable profit margin—generally 10-30%—must be factored into the final pricing to ensure supplier viability and flexibility for negotiations.

Price Influencers for Drip Shoes

Several factors shape the final pricing structure:

- Order Volume and MOQ: Larger orders often attract discounts, with MOQs ranging from 500 to 5,000 pairs depending on the supplier. Buyers from Africa or South America should negotiate volume-based discounts to lower unit costs.

- Customization and Specifications: Unique designs, special materials, or added features (e.g., branding, eco-friendly materials) increase costs. Suppliers may charge setup fees or premiums for bespoke options.

- Material Choices: Premium materials (e.g., genuine leather, specialized soles) elevate prices. Consider balancing quality with cost efficiency, especially for competitive markets.

- Certifications and Quality Standards: Meeting international standards (ISO, REACH, environmental certifications) can add 5-15% to costs but may be necessary for access to certain markets, such as the EU or UAE.

- Supplier Factors: Factory reputation, production capacity, lead times, and geographic location influence prices. Suppliers in regions with lower labor costs often provide more competitive quotes but assess quality and compliance rigorously.

- Incoterms and Shipping Conditions: FOB terms reduce initial costs but transfer logistics responsibility to the buyer. DDP simplifies import processes but increases the upfront cost. Buyers should evaluate total landed costs to determine the most economical approach.

Strategic Tips for International Buyers

- Negotiate for Volume Discounts: Leverage larger orders to secure better unit prices, especially when sourcing from Asian manufacturers. For smaller markets, consider pooling orders with regional partners.

- Focus on Total Cost of Ownership (TCO): Don’t fixate solely on unit price. Factor in logistics, customs duties, taxes, and after-sales support to understand the complete financial impact.

- Understand Pricing Nuances: Prices are dynamic and can fluctuate based on raw material costs, currency exchange rates, and geopolitical factors. Maintain ongoing communication with suppliers to stay informed.

- Leverage Certification and Quality Standards: While certifications may increase initial costs, they facilitate market access, reduce import barriers, and enhance brand credibility.

- Evaluate Incoterm Options Carefully: Choose terms that optimize logistics control and cost-efficiency based on your capacity to handle customs clearance and freight arrangements.

Indicative Price Range (Disclaimer)

Based on current market trends, the estimated FOB unit price for standard drip shoes ranges from $10 to $25 per pair for bulk orders of 1,000+ units. Custom designs or premium materials can push prices upward of $30 to $50 per pair. Shipping and customs duties can add 10-30% to the final landed cost, depending on destination and shipping mode.

This comprehensive analysis highlights the importance of strategic sourcing, negotiation, and understanding of total costs for international buyers. By scrutinizing each component and leveraging market-specific insights, buyers from Africa, South America, the Middle East, and Europe can optimize their procurement process, ensuring competitive pricing and reliable quality.

Spotlight on Potential drip shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for drip shoes.)*

Essential Technical Properties and Trade Terminology for drip shoes

Critical Technical Properties of Drip Shoes

1. Material Grade and Composition

The choice of materials directly impacts durability, chemical resistance, and suitability for specific industrial environments. Common materials include high-grade stainless steel, polypropylene, or specialized polymers. For B2B buyers, specifying the material grade ensures the product withstands operational stresses and meets safety standards, reducing the risk of failure or costly replacements.

2. Dimensional Tolerance

Tolerance refers to the permissible deviation from specified dimensions, which is crucial for ensuring proper fit and function within existing equipment or systems. Tight tolerances (e.g., ±0.1 mm) are often required for precision applications, while looser tolerances may suffice for general use. Clear communication of tolerance levels helps prevent assembly issues and minimizes rework costs.

3. Thickness and Wall Integrity

The thickness of the drip shoes affects their strength and lifespan. Thicker walls generally provide better wear resistance but may increase weight and cost. B2B buyers should consider the operating environment—harsh or abrasive conditions demand thicker, more robust designs to ensure longevity.

4. Surface Finish and Coating

A smooth, corrosion-resistant surface finish is vital for preventing buildup of residues and facilitating easy cleaning. Coatings such as epoxy or galvanization can enhance corrosion resistance, especially in humid or chemically aggressive environments. Proper surface treatment extends product life and reduces maintenance expenses.

5. Compatibility and Interchangeability

Drip shoes must often align with existing equipment specifications or industry standards. Ensuring compatibility simplifies procurement and installation, reducing downtime. Buyers should verify dimensions, mounting interfaces, and material compatibility to facilitate seamless integration.

6. Load Capacity and Stress Tolerance

Understanding the maximum load and stress the drip shoes can handle ensures safety and performance. This property is especially important in high-flow or high-pressure applications. Accurate load specifications prevent unexpected failures, safeguarding operational continuity.

Essential Industry and Trade Terms

1. OEM (Original Equipment Manufacturer)

Refers to the company that produces the drip shoes designed to meet the specifications of a particular brand or client. B2B buyers often source OEM products for consistency, quality assurance, and brand-specific requirements.

2. MOQ (Minimum Order Quantity)

The smallest quantity of products that a supplier is willing to produce or sell in a single order. Understanding MOQ helps buyers plan procurement budgets and timelines, especially when sourcing from international suppliers with varying production capacities.

3. RFQ (Request for Quotation)

A formal process where buyers solicit price, lead time, and technical details from multiple suppliers. An RFQ streamlines negotiations and ensures transparent comparison of offers, which is critical for making informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce, defining responsibilities for shipping, insurance, and customs clearance. Familiarity with Incoterms (e.g., FOB, CIF, DDP) helps buyers clarify costs, delivery points, and risk transfer points in international transactions.

5. Lead Time

The period between placing an order and receiving the shipment. B2B buyers need to factor in lead times to align procurement schedules with production cycles, especially in regions with logistical delays like Africa or remote Middle Eastern locations.

6. Certification and Compliance Terms

Terms such as ISO, CE, or other regional certifications indicate that the drip shoes meet specific safety, quality, and environmental standards. Verifying these ensures products are compliant with local regulations, preventing customs issues or product recalls.

Summary:

Understanding these technical properties and trade terms empowers international B2B buyers to make informed decisions, negotiate effectively, and establish reliable supply chains. Clear specifications and familiarity with industry jargon minimize risks, optimize procurement processes, and ensure the delivery of high-quality drip shoes tailored to diverse operational needs across different regions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the drip shoes Sector

Market Overview & Key Trends

The global drip shoes market is experiencing significant growth driven by increased demand for innovative footwear solutions that combine style, comfort, and performance. Key drivers include rising urbanization, evolving fashion trends, and a growing emphasis on functional footwear in both casual and professional settings. For international B2B buyers from Africa, South America, the Middle East, and Europe, understanding regional consumer preferences is crucial, as these markets are increasingly adopting global trends while maintaining local nuances.

Emerging sourcing trends are centered around digital transformation, with suppliers leveraging e-commerce platforms, AI-driven inventory management, and blockchain for transparency. This shift enables more efficient sourcing and quality assurance, especially important for buyers seeking reliable supply chains across continents. Additionally, the adoption of nearshoring and regional manufacturing hubs—particularly in Europe and the Middle East—reduces lead times and mitigates geopolitical risks.

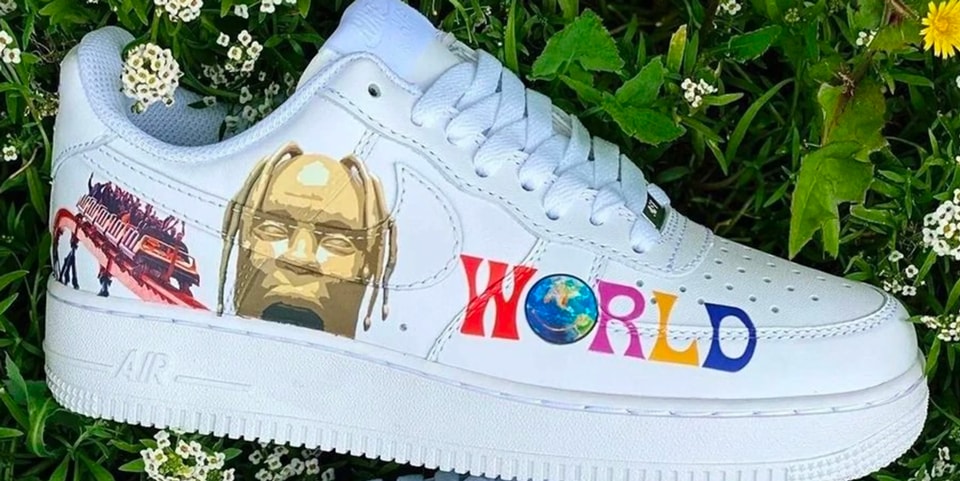

Illustrative Image (Source: Google Search)

Market dynamics for B2B buyers are also influenced by tariffs, trade agreements, and currency fluctuations, which can impact pricing and procurement strategies. For instance, African and South American buyers should monitor regional trade policies and explore partnerships with local manufacturers to reduce costs and enhance supply chain resilience. Conversely, European and Middle Eastern buyers benefit from established logistics networks and stringent quality standards, enabling quicker deployment of product lines.

Sustainability is increasingly shaping market dynamics, with brands and consumers demanding eco-friendly products. As a result, the sector is witnessing innovation in materials and manufacturing processes, emphasizing the importance of early supplier engagement and diversification to stay ahead in this competitive landscape.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer optional but a core criterion for B2B engagement in the drip shoes sector. Environmental impacts of traditional manufacturing—such as water consumption, chemical use, and waste generation—are under scrutiny, prompting brands and buyers to prioritize sustainable practices. For international buyers, especially from regions with strict environmental regulations like Europe and the Middle East, sourcing from suppliers with verified green credentials is essential.

Ethical sourcing is equally critical, encompassing fair labor practices, transparent supply chains, and adherence to human rights standards. Certifications like Fair Trade, SA8000, and B Corporation serve as benchmarks for responsible sourcing. Incorporating these standards into procurement criteria not only mitigates reputational risks but also aligns with consumer expectations for ethical products.

Adopting environmentally friendly materials—such as recycled plastics, organic textiles, and bio-based adhesives—can significantly reduce the carbon footprint of drip shoes. Suppliers offering ‘green’ certifications and traceability tools enable B2B buyers to verify claims and ensure compliance. For buyers in emerging markets, establishing direct partnerships with certified manufacturers can facilitate better oversight and foster sustainable growth.

Furthermore, integrating sustainability into the supply chain can lead to operational efficiencies, such as reduced waste and energy consumption, translating into cost savings. As the market evolves, proactive engagement with suppliers committed to sustainability will be pivotal for maintaining competitive advantage and meeting regulatory standards.

Brief Evolution/History (Optional)

Understanding the evolution of drip shoes can provide context for B2B buyers seeking reliable, innovative partners. Originally designed as specialized footwear for technical or industrial applications, drip shoes have transitioned into mainstream fashion and performance markets over the past decade. This shift has been driven by technological advancements in materials, manufacturing, and design, making drip shoes more versatile and appealing globally.

The increasing demand for lightweight, durable, and eco-friendly footwear has propelled innovation, with brands investing heavily in R&D. For B2B buyers, partnering with suppliers that have a proven track record of technological innovation and adherence to quality standards ensures access to cutting-edge products. Recognizing this evolution helps in negotiating terms, setting quality benchmarks, and aligning sourcing strategies with future market trends.

Frequently Asked Questions (FAQs) for B2B Buyers of drip shoes

1. How can I effectively vet and verify drip shoe suppliers to ensure product quality and reliability?

To ensure supplier credibility, start with thorough research using platforms like Alibaba, Global Sources, or industry-specific trade directories. Request detailed company profiles, certifications (e.g., ISO, CE), and references from previous clients. Conduct virtual or in-person factory audits when possible, focusing on production capacity, quality control processes, and compliance standards. Request product samples for inspection before committing to large orders. Establish clear communication channels to assess responsiveness and transparency. Building relationships with verified suppliers reduces risks, ensures consistent quality, and fosters long-term partnerships vital for international trade success.

2. What customization options are typically available for drip shoes, and how can I communicate my specifications effectively?

Most drip shoe manufacturers offer a range of customization options including branding (logos, tags), colorways, materials, and packaging. To communicate your specifications effectively, provide detailed technical drawings, color swatches, and sample references. Clearly specify size ranges, design features, and any unique features needed for your target market. Engage with suppliers early to discuss feasibility, lead times, and costs associated with customization. Establishing a detailed product specification sheet and maintaining open dialogue ensures your custom drip shoes meet market preferences and regulatory requirements across different regions.

Illustrative Image (Source: Google Search)

3. What are typical minimum order quantities (MOQs) and lead times for drip shoes, and how can I plan my procurement schedule accordingly?

MOQs for drip shoes vary depending on the manufacturer, generally ranging from 500 to 2,000 pairs for initial orders. Lead times usually span 4 to 8 weeks, including sample approval, production, and shipping. To optimize procurement, establish clear timelines with your supplier upfront and consider incremental ordering for testing markets. Build flexibility into your schedule to accommodate potential delays caused by raw material shortages or customs procedures. Maintaining ongoing communication and forecasting demand accurately helps ensure timely replenishment and minimizes inventory disruptions.

4. What payment terms and methods are standard in international drip shoe trade, and how can I negotiate favorable conditions?

Standard payment terms often include a 30% deposit upfront with the balance paid before shipment or upon delivery. Common payment methods are bank wire transfers, letters of credit, or secure escrow services. To negotiate favorable terms, leverage your purchase volume, establish trust through smaller trial orders, and demonstrate reliable payment history. Consider requesting flexible payment options like letter of credit guarantees or installment plans for larger orders. Clear contractual agreements on payment schedules and penalties for late payments help mitigate risks and ensure smooth financial transactions across borders.

5. What certifications and quality assurance measures should I look for in drip shoe suppliers to meet international standards?

Suppliers should possess relevant certifications such as ISO 9001 for quality management, CE marking for European markets, and other regional compliance standards like SGS or ASTM. Request detailed quality assurance protocols, including inspection reports, pre-shipment testing, and third-party audits. Verify that suppliers follow strict raw material sourcing, manufacturing processes, and packaging standards. For regions like the Middle East and Europe, compliance with local safety and environmental regulations is critical. Incorporating contractual clauses for quality guarantees and post-sale support ensures product reliability and regulatory adherence.

6. How can I optimize logistics and shipping to minimize costs and ensure timely delivery of drip shoes?

Partner with freight forwarders experienced in international trade, focusing on routes that balance cost and speed. Consolidate shipments when possible to reduce logistics expenses, and choose reliable carriers with track-and-trace capabilities. Understand customs procedures and documentation requirements for each destination—such as invoices, certificates of origin, and compliance certificates—to prevent delays. Negotiate Incoterms (e.g., FOB, CIF) that clearly define responsibilities and costs. Consider warehousing options in strategic locations to buffer against transit disruptions. Regular communication with logistics providers ensures proactive management of potential delays, safeguarding your supply chain.

7. What are common dispute resolution mechanisms in international drip shoe trade, and how can I protect myself legally?

Disputes are best managed through clear contractual terms specifying dispute resolution procedures, such as arbitration under recognized bodies like ICC or LCIA. Incorporate choice of law clauses favoring your jurisdiction or neutral arbitration venues to reduce legal complexity. Maintain comprehensive documentation of all communications, agreements, and transaction records. Employ escrow services or letters of credit to secure payments during disputes. Working with legal advisors familiar with international trade laws and regional regulations enhances your ability to navigate conflicts efficiently, minimizing financial and reputational risks.

8. How do I adapt my sourcing strategy for drip shoes to different regional markets, considering cultural, regulatory, and logistical factors?

Research regional preferences, including design, sizing standards, and branding preferences, to tailor your offerings. Stay updated on local import regulations, tariffs, and product certifications to ensure compliance. Establish regional partnerships or agents who understand local market dynamics, language, and business etiquette. Consider regional logistics solutions such as local warehousing or distribution centers to reduce transit times and costs. Engage with local trade chambers or industry associations for insights and support. Adapting your sourcing approach to regional nuances enhances market acceptance, reduces compliance risks, and strengthens your global supply chain resilience.

Strategic Sourcing Conclusion and Outlook for drip shoes

Conclusion and Future Outlook

Effective strategic sourcing of drip shoes offers international B2B buyers a competitive edge by enabling access to high-quality products, cost efficiencies, and reliable supply chains. Emphasizing relationships with trusted manufacturers, leveraging regional trade agreements, and prioritizing quality assurance are essential steps toward optimizing procurement processes.

As market dynamics evolve—with increasing demand for innovative designs and sustainable materials—buyers must adopt agile sourcing strategies that accommodate shifting consumer preferences and regulatory landscapes. Embracing digital sourcing platforms and supplier diversification can mitigate risks and enhance resilience.

Looking ahead, buyers from Africa, South America, the Middle East, and Europe should prioritize building strategic partnerships that foster transparency and long-term value. Staying informed about emerging trends, technological advancements, and regional trade policies will be crucial for maintaining competitive advantage.

Act now to refine your sourcing approach, leverage global networks, and capitalize on the growing opportunities within the drip shoe market. A proactive, strategic stance will ensure sustainable growth and market relevance in an increasingly interconnected world.