Master Sourcing Authentic Earth Shoes 1970s for Global

Guide to Earth Shoes 1970S

- Introduction: Navigating the Global Market for earth shoes 1970s

- Understanding earth shoes 1970s Types and Variations

- Key Industrial Applications of earth shoes 1970s

- Strategic Material Selection Guide for earth shoes 1970s

- In-depth Look: Manufacturing Processes and Quality Assurance for earth shoes 1970s

- Comprehensive Cost and Pricing Analysis for earth shoes 1970s Sourcing

- Spotlight on Potential earth shoes 1970s Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for earth shoes 1970s

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the earth shoes 1970s Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of earth shoes 1970s

- Strategic Sourcing Conclusion and Outlook for earth shoes 1970s

Introduction: Navigating the Global Market for earth shoes 1970s

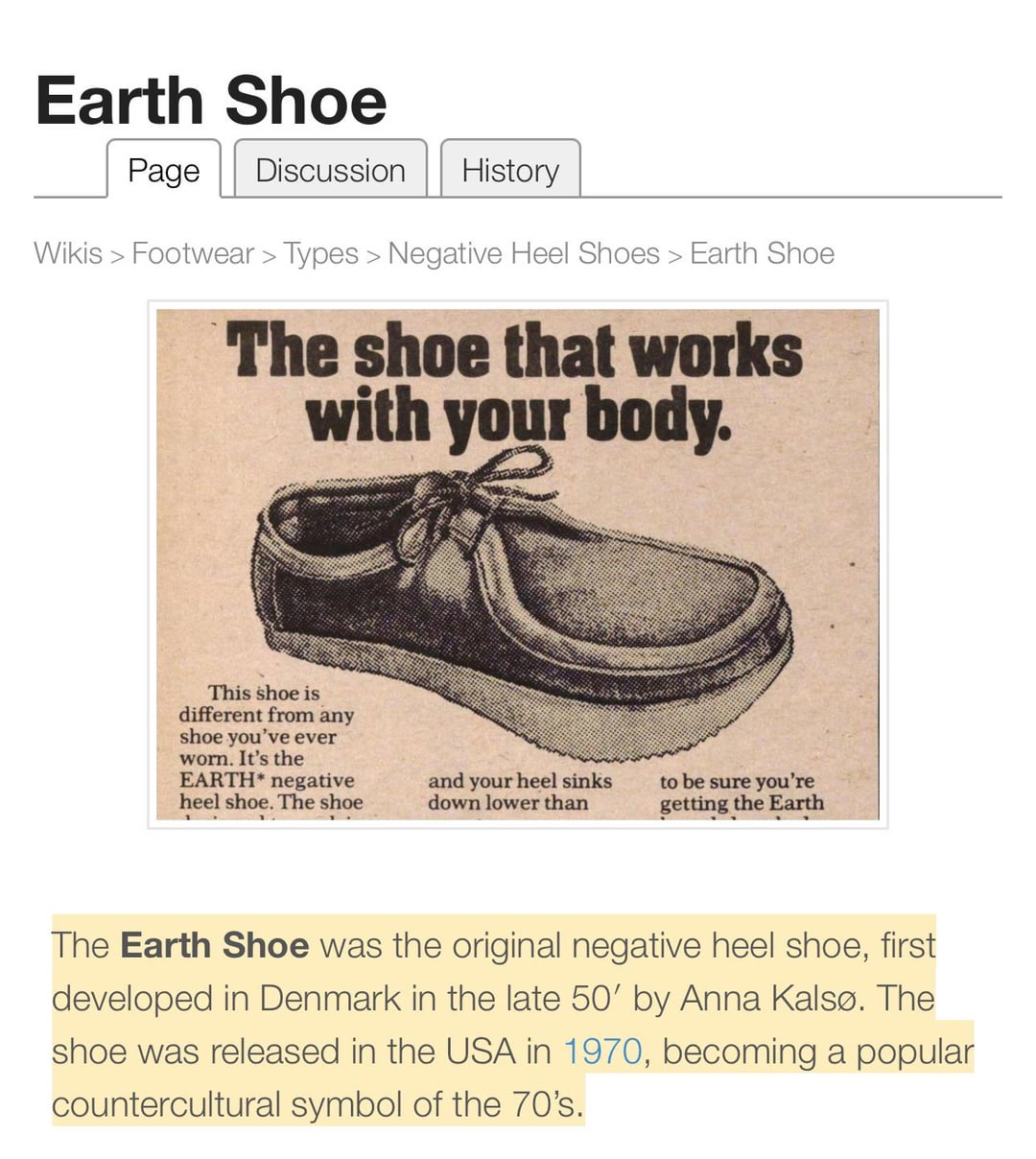

In the dynamic landscape of global footwear manufacturing, understanding the unique appeal and production nuances of Earth Shoes from the 1970s is essential for forward-thinking B2B buyers. These iconic shoes, characterized by their distinctive design and eco-conscious ethos, continue to influence contemporary footwear trends and present significant market opportunities worldwide. For importers and distributors in regions such as Africa, South America, the Middle East, and Europe—including key markets like Colombia and Italy—grasping the historical significance and current sourcing options of these vintage-inspired shoes is vital for competitive positioning.

Illustrative Image (Source: Google Search)

This comprehensive guide equips international buyers with critical insights into the various types of Earth Shoes from the 1970s, their authentic materials, and manufacturing standards. It covers essential topics such as sourcing reliable suppliers, quality control measures, cost considerations, and market demand dynamics. Additionally, it addresses frequently asked questions to streamline decision-making processes and mitigate risks associated with international procurement.

By leveraging this guide, B2B buyers can make well-informed sourcing decisions, ensuring product authenticity, quality, and cost-efficiency. Whether expanding a boutique footwear line or tapping into niche markets emphasizing retro and eco-friendly products, understanding the intricacies of 1970s Earth Shoes empowers buyers to capitalize on a distinctive segment with enduring appeal. This strategic knowledge ultimately facilitates smarter investments and sustainable growth in the global footwear industry.

Understanding earth shoes 1970s Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic 1970s Earth Shoe | Elevated heel with a negative heel design, organic materials | Footwear retail, vintage collections, niche markets | Authentic vintage appeal; moderate demand; sourcing vintage stock may be limited |

| Platform Earth Shoe | Thick sole with platform design, exaggerated negative heel | Fashion boutiques, costume design, retro-themed stores | Eye-catching; appeals to niche markets; higher manufacturing costs and limited modern production |

| Casual Earth Shoe | Simpler design, lower profile, softer sole, versatile styling | Everyday wear, casual retail outlets | Wide appeal; easier to source; potential for high-volume sales but less exclusivity |

| Limited Edition/Reissue | Reproductions of original 1970s styles, often with modern updates | Collector markets, specialty retailers | High demand among collectors; premium pricing; requires careful sourcing to authenticate |

| Custom/Collaborative Variations | Special editions or designer collaborations, unique materials | High-end boutiques, fashion collaborations | Adds exclusivity; higher margins; limited production runs may impact supply chain stability |

Characteristics and Suitability

Classic 1970s Earth Shoes are characterized by their distinctive negative heel design, which was revolutionary at the time. Made from natural materials like leather and cork, these shoes emphasize comfort and a bohemian aesthetic. They are suitable for retailers targeting vintage enthusiasts or niche markets seeking authentic retro products. B2B buyers should consider sourcing from specialized vintage suppliers or manufacturers capable of replicating original designs with quality assurance.

Platform Earth Shoes feature an exaggerated sole with a pronounced heel, often used to make bold fashion statements. They appeal to trend-driven boutiques, costume designers, and retro-themed stores. While visually striking, their manufacturing complexity and higher production costs mean buyers should evaluate demand carefully. They are best suited for limited editions or seasonal collections to optimize margins.

Casual Earth Shoes offer a more subdued, versatile design that can appeal to a broader consumer base. Their lower profile makes them easier to produce and source, often from contemporary manufacturers that replicate 1970s styles. These are ideal for high-volume sales channels, such as general footwear retailers or online marketplaces, providing a balance between authenticity and practicality.

Limited Edition/Reissue models are reproductions of original 1970s designs, often with modern updates for comfort or durability. These are highly sought after by collectors and specialty retailers. B2B buyers should prioritize authentic sourcing channels, ensuring product provenance to meet collector expectations. Premium pricing can be justified by the product’s exclusivity.

Custom/Collaborative Variations involve unique designs created through collaborations with designers or brands, sometimes incorporating modern materials or reinterpretations. These editions appeal to high-end boutiques and fashion-forward retailers aiming to offer exclusive items. Limited production runs require careful supply chain planning but can command higher margins due to their exclusivity.

B2B Purchasing Insights

For international buyers, understanding the specific characteristics of each type is crucial for aligning inventory with target markets. Authentic vintage styles may require partnerships with specialized suppliers or vintage archives, especially for markets like Italy or Colombia where vintage fashion has strong appeal. Modern reproductions or limited editions can be sourced from contemporary manufacturers with experience in retro footwear, ensuring quality and consistency. Additionally, establishing relationships with regional distributors or agents familiar with the vintage and niche footwear markets will facilitate smoother procurement processes and help navigate potential import/export regulations.

Key Industrial Applications of earth shoes 1970s

| Industry/Sector | Specific Application of earth shoes 1970s | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Civil Engineering | Heavy-duty footwear for construction workers operating on uneven or rugged terrains | Enhanced safety, stability, and durability for workers in challenging environments | Material robustness, slip resistance, compliance with safety standards |

| Agriculture & Farming | Footwear designed for long hours in muddy, uneven fields | Improved comfort, slip resistance, and reduced fatigue for field workers | Weather resistance, comfort, and availability in bulk quantities |

| Industrial Manufacturing | Protective footwear for factory or warehouse staff | Protection against industrial hazards while maintaining mobility | Certification for impact and compression resistance, sourcing flexible sole materials |

| Oil & Gas | Footwear for personnel working on offshore rigs or remote sites | Reliable safety and stability in high-risk, slippery environments | Chemical and oil resistance, durability under extreme conditions |

| Logistics & Warehousing | Durable shoes for warehouse staff handling heavy loads | Increased safety, reduced injury risk, and long-lasting wear | High abrasion resistance, comfort for extended use, supply chain reliability |

Construction & Civil Engineering

Earth shoes of the 1970s were widely used as safety footwear for construction workers, especially those operating in rugged, uneven terrains. Their sturdy build and slip-resistant soles helped mitigate the risk of falls and injuries, crucial for projects in developing regions across Africa, South America, and the Middle East. For international buyers, sourcing from reliable manufacturers with certifications in safety standards (e.g., ISO, OSHA) is essential. These shoes also offered durability against harsh environmental conditions, making them a cost-effective choice for large-scale infrastructure projects.

Agriculture & Farming

In agricultural sectors, earth shoes from the 1970s provided essential support for workers in muddy, uneven fields common in Colombia, Italy, and other rural regions. Their design helped reduce fatigue during long hours, while slip-resistant soles prevented accidents in wet, slippery conditions. For B2B buyers, sourcing options should prioritize weather-resistant materials and bulk procurement capabilities to meet large-scale farm needs. These shoes improve worker safety and productivity, especially in regions with challenging climates.

Industrial Manufacturing

Factories and warehouses in Europe, South America, and the Middle East relied on earth shoes to protect workers from industrial hazards such as falling objects, sharp materials, and heavy equipment. The shoes’ reinforced soles and impact-resistant features provided necessary safety without compromising mobility. Buyers should focus on sourcing shoes with certifications for impact and compression resistance, ensuring compliance with local safety regulations. Consistent supply and quality assurance are critical for maintaining safety standards over time.

Oil & Gas

Offshore rigs and remote oil extraction sites demanded footwear that could withstand extreme conditions. Earth shoes from the 1970s offered slip resistance, durability, and chemical resistance vital for personnel working in high-risk environments. International buyers from Middle Eastern and South American regions should prioritize sourcing shoes with proven resistance to oils, chemicals, and extreme temperatures. Reliable supply chains and adherence to industry safety standards are key to operational safety and efficiency.

Logistics & Warehousing

In fast-paced logistics environments across Europe, Africa, and South America, earth shoes provided warehouse staff with durable, slip-resistant footwear capable of handling heavy loads and prolonged standing. Their robustness minimized injury risks, while comfort features helped sustain productivity. B2B buyers should consider sourcing shoes with high abrasion resistance, ergonomic design, and consistent availability to support large workforce needs. Ensuring compatibility with safety regulations across different regions enhances operational compliance.

Strategic Material Selection Guide for earth shoes 1970s

Material Analysis for Earth Shoes 1970s

When selecting materials for manufacturing earth shoes in the 1970s, B2B buyers must prioritize properties that influence durability, comfort, manufacturing complexity, and compliance with international standards. The following analysis covers key materials historically used in this context, emphasizing their suitability for different markets such as Africa, South America, the Middle East, and Europe.

Leather

Leather was the predominant material for the upper and lining of earth shoes in the 1970s due to its natural breathability and comfort. Its key properties include excellent flexibility, durability, and a natural resistance to wear when properly treated. Leather also offers good thermal regulation, making it suitable for varied climates, from the hot Middle East to cooler European regions.

Pros & Cons:

Leather’s primary advantage is its durability and aesthetic appeal, which aligns with consumer preferences for high-quality footwear. However, it can be expensive, especially premium grades, and manufacturing requires specialized skills, increasing production costs. Leather is also sensitive to moisture and requires proper treatment to prevent degradation, which can be a concern in humid environments like parts of South America and Africa.

Impact on Application:

Leather’s breathability and flexibility make it ideal for everyday wear, but its susceptibility to water damage necessitates water-resistant treatments for markets with high humidity or frequent rain.

International Considerations:

Buyers from regions with strict import standards, such as the European Union, must ensure leather complies with regulations like REACH. Additionally, sourcing ethically tanned leather can be a competitive advantage, especially in markets emphasizing sustainability.

Rubber

Rubber was commonly used for outsoles and sometimes for midsole components in earth shoes, owing to its excellent grip and shock absorption properties. Natural rubber, derived from latex, offers high elasticity and resilience, making it suitable for footwear that demands comfort and durability.

Pros & Cons:

Rubber provides excellent wear resistance and traction, which is critical for outdoor use in rugged terrains typical of many African and South American regions. Its resistance to environmental factors like water and mud enhances shoe longevity. However, natural rubber can be sensitive to temperature extremes—becoming brittle in cold climates or overly soft in high heat—potentially affecting performance.

Impact on Application:

Rubber’s chemical inertness makes it compatible with various media, including oily or muddy terrains, common in developing regions. Its flexibility also supports ergonomic design.

International Considerations:

Buyers should verify compliance with standards such as ASTM D2000 or ISO 4649 for rubber properties. Sourcing sustainably produced rubber aligns with increasing environmental standards globally, especially in Europe.

Synthetic Polymers (e.g., PVC, Polyurethane)

Synthetic materials like PVC and polyurethane gained popularity in the 1970s for their versatility and cost-effectiveness. These materials are used for components such as insoles, linings, and decorative elements.

Pros & Cons:

Synthetic polymers are generally cheaper and easier to manufacture at scale, offering consistent quality. They are resistant to moisture, chemicals, and UV exposure, making them suitable for diverse climates. However, they often lack the breathability of natural materials, potentially leading to discomfort or odor issues in hot and humid environments.

Impact on Application:

For regions with high humidity, synthetic materials may require additional ventilation or treatment to improve comfort. Their chemical inertness can be advantageous in industrial or harsh environments.

International Considerations:

Buyers should ensure that synthetic materials meet local safety standards, such as JIS or DIN, and are free from harmful phthalates or other additives. Certifications for eco-friendly or non-toxic plastics can be a market differentiator.

Summary Table

| Material | Typical Use Case for earth shoes 1970s | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Upper, lining, and decorative elements | Durable, breathable, aesthetically appealing | Expensive, sensitive to moisture, requires maintenance | High |

| Rubber | Outsoles and shock absorption components | Excellent grip, water resistance, durability | Temperature sensitivity, environmental degradation risk | Med |

| Synthetic Polymers (PVC, Polyurethane) | Insoles, linings, decorative trims | Cost-effective, moisture resistant, versatile | Less breathable, potential chemical concerns | Low |

| Natural Rubber | Outsoles and midsole components | Resilient, flexible, high traction | Temperature-dependent performance, environmental concerns | Med |

This comprehensive analysis enables international B2B buyers to make informed decisions tailored to their target markets, balancing material properties, costs, and compliance requirements to optimize product performance and market acceptance.

In-depth Look: Manufacturing Processes and Quality Assurance for earth shoes 1970s

Manufacturing Processes of Earth Shoes 1970s: An In-Depth Overview for B2B Buyers

Understanding the manufacturing processes behind Earth Shoes of the 1970s is vital for international B2B buyers aiming to ensure product quality, compliance, and consistent supply. The typical manufacturing cycle encompasses four main stages: material preparation, forming, assembly, and finishing. Each stage involves specific techniques and quality controls to meet both industry standards and regional requirements.

Main Manufacturing Stages

1. Material Preparation

The foundation of Earth Shoes’ distinctive look and comfort in the 1970s was based on high-quality raw materials. These included leather, suede, and innovative sole compounds like crepe rubber. Suppliers often sourced these materials locally or imported from established vendors, ensuring they met durability and comfort standards.

Key Techniques:

– Material Inspection: Raw materials undergo initial visual and tactile inspections to identify defects.

– Pre-treatment: Leather and textiles are conditioned and treated to enhance flexibility, water resistance, and colorfastness.

– Cutting Patterns: Precise cutting using templates or automated cutters ensures consistency and minimizes waste.

2. Forming

In this stage, components are shaped into the footwear’s structural elements. Leather uppers are molded or cut into panels, while soles are molded or assembled from rubber or crepe materials.

Key Techniques:

– Stitching and Bonding: Leather panels are stitched using industrial sewing machines, often employing reinforced stitches for durability.

– Molding: Rubber soles are molded via compression or injection techniques, with some manufacturers utilizing vulcanization to enhance strength and elasticity.

– Lining and Reinforcement: Internal components such as insoles and reinforcements are inserted to improve comfort and support.

3. Assembly

Assembly combines all components into a finished shoe. This process involves attaching the upper to the sole, inserting insoles, and adding hardware or decorative elements.

Key Techniques:

– Lasting: The upper is stretched over a mold (last) and secured, ensuring shape retention.

– Adhesive Bonding: Industrial adhesives, often polyurethane-based, are used to attach the sole to the upper securely.

– Stitching and Riveting: Additional reinforcement is added where necessary, especially around high-stress areas.

4. Finishing

Final touches include quality checks, surface treatments, and packaging. The goal is to deliver a product that meets aesthetic and functional standards.

Key Techniques:

– Surface Treatment: Polishing, dyeing, and protective coatings enhance appearance and durability.

– Labeling and Packaging: Branding, size markings, and safety labels are applied, followed by packaging suitable for international shipping.

Quality Control (QC) Framework

Implementing rigorous QC is crucial to meet international standards and satisfy regional market requirements. The typical QC framework includes several checkpoints:

1. Incoming Quality Control (IQC)

- Objective: Verify raw materials and components before production.

- Methods: Visual inspection, material testing (e.g., tensile strength, colorfastness), and supplier certification review.

- Standards Referenced: ISO 9001, ASTM, and regional certifications like REACH (Europe) or SABS (South Africa).

2. In-Process Quality Control (IPQC)

- Objective: Monitor manufacturing consistency and detect defects early.

- Methods: Dimensional checks, stitching quality, adhesion strength tests, and functional assessments.

- Common Techniques: Use of gauges, microscopes for stitching accuracy, and pull tests for adhesives.

3. Final Quality Control (FQC)

- Objective: Ensure finished products meet specifications before shipment.

- Methods: Visual inspection for surface defects, measurement verification, flexibility tests, and durability assessments.

- Testing Methods: Accelerated wear tests, bend tests, and water resistance evaluations.

International Standards and Certification

B2B buyers should verify that suppliers adhere to recognized standards to ensure product safety, compliance, and market acceptance:

- ISO 9001: Ensures quality management systems are in place, covering process control, documentation, and continual improvement.

- CE Marking (Europe): Indicates compliance with health, safety, and environmental standards.

- API (American Petroleum Institute): Less relevant for footwear but may apply if the manufacturing involves specific industrial components.

- Regional Certifications:

- Europe: REACH compliance for chemical safety.

- South America: INMETRO certification (Brazil) or similar regional standards.

- Middle East: GSO certifications for safety and quality.

How B2B Buyers Can Verify Supplier QC

- Audits and Site Visits: Conduct comprehensive audits focusing on QC processes, equipment, and personnel training.

- Inspection Reports: Request detailed third-party inspection reports and test certificates, ideally from accredited labs.

- Third-Party Inspection Services: Engage independent inspection firms (e.g., SGS, Bureau Veritas) for unbiased quality verification.

- Sample Testing: Perform pre-shipment sampling and testing aligned with regional standards to validate supplier claims.

Regional Nuances in Quality Assurance for International Buyers

Africa & Middle East:

– Emphasis on durability and resistance to local environmental conditions (e.g., high humidity, rough terrains).

– Verify if suppliers meet local safety standards and chemical restrictions.

South America (e.g., Colombia):

– Focus on compliance with regional certifications like INMETRO.

– Ensure suppliers can provide traceability documentation for raw materials.

Europe (e.g., Italy):

– Strict adherence to REACH and CE standards.

– Preference for suppliers with ISO 9001 and additional certifications such as ISO 14001 (environmental management).

Actionable Recommendations for B2B Buyers

- Develop Clear Specifications: Define quality standards, testing protocols, and certification requirements upfront.

- Select Certified Suppliers: Prioritize suppliers with recognized certifications and proven quality management systems.

- Implement Regular Audits: Schedule periodic audits and inspections to ensure ongoing compliance.

- Leverage Third-Party Testing: Use independent labs to verify product quality, especially for critical attributes.

- Foster Long-Term Relationships: Collaborate with suppliers committed to continuous improvement and quality excellence.

By understanding and rigorously managing manufacturing and quality assurance processes, international B2B buyers from Africa, South America, the Middle East, and Europe can mitigate risks, ensure product consistency, and build strong supply chain partnerships for Earth Shoes of the 1970s.

Comprehensive Cost and Pricing Analysis for earth shoes 1970s Sourcing

Cost Structure Breakdown

Understanding the comprehensive cost components involved in sourcing Earth Shoes from the 1970s style manufacturers is essential for effective negotiation and pricing strategy. The primary cost drivers include:

-

Materials: Authentic 1970s Earth Shoes often utilized natural, eco-friendly materials such as leather, suede, and cork. Material costs can vary significantly based on quality, sourcing region, and certification standards. For example, European buyers might face higher material costs due to stricter environmental regulations, whereas suppliers in Asia may offer more competitive rates.

-

Labor: Labor costs are highly dependent on the sourcing country. Manufacturers in regions like Southeast Asia or North Africa tend to have lower wages, enabling more competitive pricing. Conversely, European or Middle Eastern suppliers may have higher labor costs but can sometimes offer superior craftsmanship or compliance with strict labor standards.

-

Manufacturing Overhead: This includes factory utilities, equipment depreciation, and compliance costs. Suppliers with modernized facilities or those adhering to international standards (e.g., ISO, BSCI) may incur higher overheads, which are reflected in their quotes.

-

Tooling & Setup: For custom designs or specific sizes, initial tooling costs can be significant but are amortized over larger volume orders. Buyers planning long-term or bulk sourcing should negotiate these costs upfront.

-

Quality Control (QC): Rigorous QC processes ensure product consistency and compliance with buyer specifications. Premium QC services increase costs but reduce risks of returns or rejections.

-

Logistics & Incoterms: Shipping costs depend on destination, order volume, and chosen Incoterms (e.g., FOB, CIF). Buyers in remote regions like parts of Africa or South America should factor in higher freight and insurance costs, especially for smaller shipments.

-

Margins: Suppliers incorporate their profit margins into the unit price. Transparent negotiations and bulk orders can help secure better margins for buyers.

Factors Influencing Pricing

Several key factors can influence the final price of Earth Shoes:

-

Order Volume & MOQ: Larger orders typically attract volume discounts. Many suppliers have minimum order quantities (MOQs), often ranging from 300 to 1,000 pairs. For smaller buyers or niche markets, unit prices may be higher due to fixed costs.

-

Customization & Specs: Unique designs, specific colorways, or custom branding increase manufacturing complexity and costs. Standard models are generally more cost-effective.

-

Material Choices: Higher-quality or certified eco-friendly materials command premium prices. Buyers seeking sustainable credentials should expect to pay more but can leverage these features for branding.

-

Certifications & Standards: Compliance with regional standards (e.g., REACH in Europe, ISO certifications) can add to costs but are essential for market entry, especially in Europe and the Middle East.

-

Supplier Location & Capabilities: Suppliers with proven experience in vintage or eco-friendly footwear, especially those with established export channels, might charge premiums but offer better reliability and quality.

Buyer Tips for Cost Optimization

-

Negotiate Volume & Payment Terms: Leverage larger orders to negotiate better unit prices and flexible payment terms. Early payments or bulk commitments can incentivize suppliers.

-

Focus on Total Cost of Ownership (TCO): Beyond unit price, consider shipping, customs duties, taxes, and potential rework or QC costs. For buyers in Africa or South America, these can significantly impact overall expenditure.

-

Understand Pricing Nuances: Prices can vary due to currency fluctuations, regional tariffs, or seasonal demand. Keep abreast of geopolitical or economic shifts affecting supply chains.

-

Request Detailed Quotes: Ensure quotes specify all cost components, including shipping, taxes, and incidental charges, to accurately compare offers.

-

Build Long-term Relationships: Developing trust with reliable suppliers can lead to preferential pricing, priority production, and better terms over time.

Disclaimer on Price Estimates

Indicative prices for vintage-style Earth Shoes sourced from Asia or Eastern Europe generally range from $10 to $25 per pair, depending on volume, customization, and quality standards. European suppliers may quote slightly higher, often between $15 to $30 per pair, reflecting higher labor and material costs. Always request detailed quotations tailored to your specific requirements and consider the entire cost ecosystem for accurate budgeting.

By understanding these cost components and influencing factors, international B2B buyers from Africa, South America, the Middle East, and Europe can strategically plan their sourcing, negotiate effectively, and optimize their total procurement costs for Earth Shoes from the 1970s style manufacturers.

Spotlight on Potential earth shoes 1970s Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for earth shoes 1970s.)*

Essential Technical Properties and Trade Terminology for earth shoes 1970s

Critical Technical Properties of Earth Shoes (1970s)

1. Material Composition and Grade

The primary materials used in 1970s earth shoes typically included natural leather, rubber, and canvas. The grade of these materials directly impacts durability, comfort, and aesthetic appeal. High-grade leather, for instance, ensures longevity and a premium look, which is vital for brand positioning and customer satisfaction. B2B buyers should specify material grades during procurement to maintain consistency and meet quality standards across batches.

2. Sole Construction and Flexibility

The sole design is crucial for the signature negative heel and ergonomic support characteristic of earth shoes. The construction involves specific layering and rubber composition to provide flexibility and shock absorption. Understanding the technical specifications of sole materials helps buyers assess comfort and durability, especially for markets with diverse terrains such as Africa and South America.

3. Tolerance Levels and Manufacturing Precision

Tolerance refers to permissible deviations in dimensions like shoe length, width, and heel height. Tight tolerances (e.g., ±1mm) ensure product consistency, which is essential for brand reputation and customer satisfaction. B2B buyers should verify tolerance standards with suppliers, particularly when importing for retail chains or large distributors.

4. Colorfastness and Finishing Standards

Colorfastness indicates how well the shoe’s dyes withstand exposure to light, water, and wear. High standards prevent premature fading, which is especially important for export markets where durability influences brand loyalty. Suppliers should provide documentation on finishing standards to ensure compliance with local environmental and quality regulations.

5. Compliance with Safety and Environmental Standards

Earth shoes from the 1970s often emphasize eco-friendly materials and manufacturing processes. Certifications such as ISO or local environmental standards are vital for market access, especially in Europe and the Middle East. Buyers should request compliance certificates and detailed material safety data sheets (MSDS) to mitigate regulatory risks.

6. Packaging and Labeling Specifications

Proper packaging ensures product integrity during transit, while accurate labeling facilitates customs clearance and meets local regulations. Specifications should include material for boxes, protective fillers, and label language to cater to regional markets like Colombia or Italy.

Essential Industry and Trade Terms

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce shoes based on the buyer’s design and specifications. Understanding OEM relationships allows buyers to customize products, control quality, and potentially reduce costs through direct manufacturing agreements.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce or sell in a single order. Awareness of MOQ helps buyers plan inventory and negotiate better terms, especially when entering new markets with limited initial demand.

3. RFQ (Request for Quotation)

A formal document sent to suppliers requesting price estimates, lead times, and terms for specific products. Using RFQs ensures transparent pricing and helps compare offers from multiple manufacturers, which is critical in price-sensitive markets like Africa and South America.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs clearance. Familiarity with Incoterms (e.g., FOB, CIF, DDP) enables buyers to accurately calculate total landed costs and negotiate logistics terms suitable for regional infrastructure.

5. Lead Time

The period from order placement to product delivery. Accurate knowledge of lead times helps in planning inventory and avoiding stockouts, especially when dealing with international shipping complexities.

6. Quality Assurance (QA) and Inspection Terms

Processes and standards used to verify product compliance with specifications. Understanding QA protocols, such as third-party inspections or in-house testing, ensures that imported earth shoes meet the desired quality benchmarks, reducing return rates and fostering brand trust.

This comprehensive understanding of technical properties and trade terminology equips international B2B buyers with the knowledge to navigate sourcing, quality control, and logistics effectively. Mastery of these elements ensures smoother transactions, better pricing negotiations, and successful market entry in diverse regions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the earth shoes 1970s Sector

Market Overview & Key Trends

The global market for earth shoes inspired by the 1970s aesthetic is experiencing a notable resurgence driven by increasing consumer demand for sustainable, retro-inspired footwear. Key drivers include heightened environmental consciousness, the rise of ethical consumerism, and a growing preference for unique, heritage-rich brands. For international B2B buyers in regions such as Africa, South America, the Middle East, and Europe—particularly countries like Colombia and Italy—there are significant opportunities to capitalize on these trends through strategic sourcing and distribution.

Emerging sourcing trends focus on integrating advanced manufacturing technologies such as 3D printing and automation, which enable faster prototyping and reduced waste. Digital platforms facilitate direct communication with manufacturers, promoting transparency and streamlined supply chains. Sustainability is a core component, with buyers increasingly seeking suppliers who can offer eco-friendly materials—such as organic cotton, hemp, cork, and recycled rubber—and adhere to fair labor practices.

Market dynamics are influenced by geopolitical factors, tariffs, and trade agreements, which can impact sourcing costs and lead times. For example, European buyers benefit from proximity to Mediterranean manufacturing hubs, allowing for quicker turnaround times and reduced logistical complexities. Conversely, African and South American buyers might leverage regional manufacturing capabilities and benefit from lower production costs, provided quality standards are maintained. Overall, success in this sector hinges on balancing cost efficiency with sustainability commitments and rapid market responsiveness.

Sustainability & Ethical Sourcing in B2B

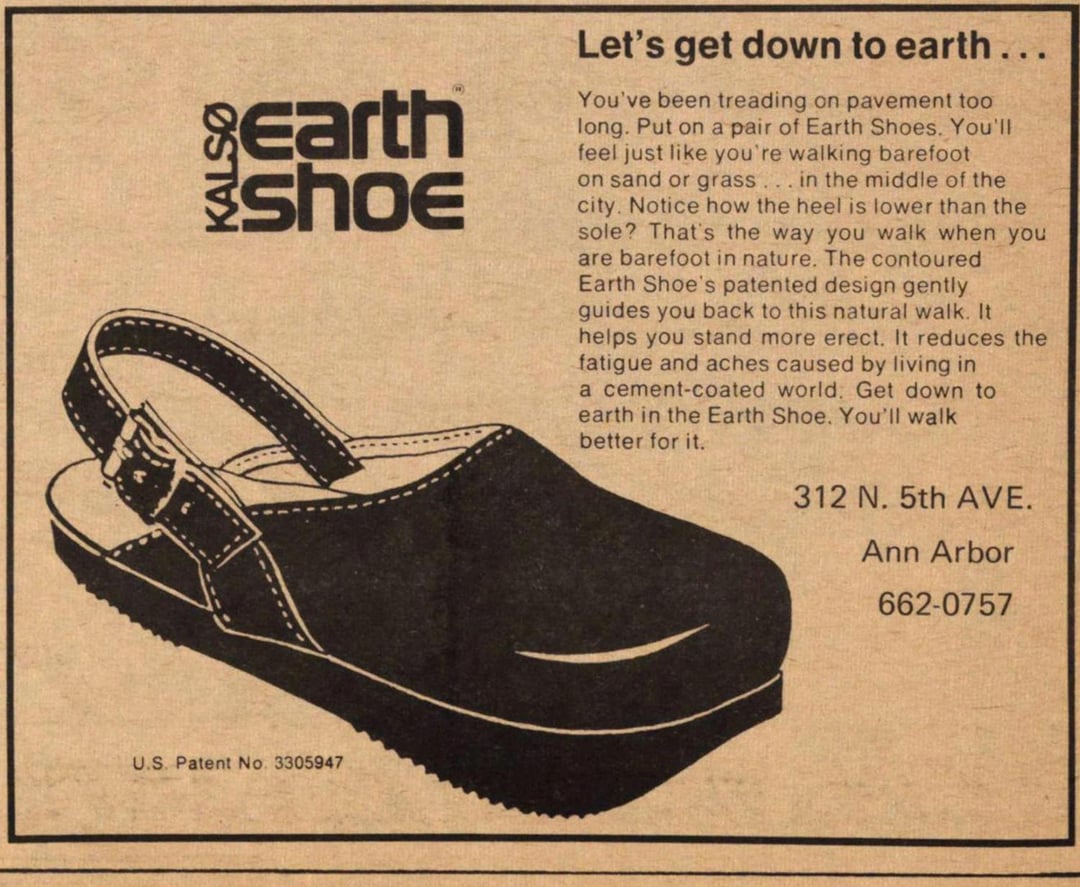

Sustainability is no longer optional; it is a fundamental criterion for B2B engagement in the earth shoes 1970s sector. Buyers are increasingly demanding supply chains that minimize environmental impact, driven by consumer preferences and regulatory frameworks. This includes sourcing from suppliers who utilize environmentally friendly materials such as organic textiles, biodegradable adhesives, and recycled components.

Illustrative Image (Source: Google Search)

Certifications like Global Organic Textile Standard (GOTS), Fair Trade, and Forest Stewardship Council (FSC) play a crucial role in validating ethical practices. For B2B buyers from regions like Italy and Colombia, establishing partnerships with certified suppliers ensures compliance with local and international sustainability standards, reducing reputational risks.

Implementing transparent supply chain practices—such as blockchain traceability and third-party audits—enhances trust and demonstrates a commitment to ethical sourcing. Moreover, adopting eco-design principles and circular economy models can significantly reduce waste and encourage product lifecycle management. For markets in Africa and South America, investing in local capacity building and fair labor practices can foster resilient supply chains aligned with global sustainability goals.

Brief Evolution/History (Optional)

The earth shoes trend of the 1970s was rooted in the counterculture movement, emphasizing comfort, natural materials, and a rejection of mass-produced fashion. Over the decades, this ethos has evolved into a sophisticated sector where sustainability and ethical sourcing are integral. For B2B buyers today, understanding this historical context underscores the importance of authenticity and heritage-driven branding, which resonate strongly with environmentally conscious consumers worldwide.

The shift from simple, organic-inspired footwear to technologically advanced, sustainable products reflects broader industry trends. Modern earth shoes incorporate innovative eco-materials and manufacturing processes, making them attractive to global markets seeking eco-friendly alternatives. Recognizing this evolution helps B2B buyers position themselves as leaders in sustainable footwear, ensuring long-term competitiveness in a rapidly changing landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of earth shoes 1970s

1. How can I verify the reliability and quality standards of suppliers offering Earth Shoes from the 1970s?

To ensure supplier credibility, prioritize those with comprehensive certifications such as ISO, CE, or other relevant industry standards. Request detailed product catalogs, production certificates, and references from previous international clients. Conduct virtual factory audits or arrange third-party inspections when feasible. Additionally, review supplier history, years in operation, and client testimonials. Engaging with reputable trade platforms or chambers of commerce can also help validate credentials. Establish clear quality expectations upfront, including sample approval processes, to mitigate risks and ensure the authenticity of vintage Earth Shoes.

2. What customization options are typically available for Earth Shoes from the 1970s, and how can I communicate specific requirements?

Many suppliers offer customization in branding, packaging, and minor design tweaks to cater to regional preferences. Clearly specify your desired modifications—such as color, logo placement, or packaging materials—in your purchase agreement. Use detailed specifications and visual references to avoid misunderstandings. Communicate through trusted channels like verified email, video calls, or dedicated B2B platforms. Negotiating lead times for customization and requesting sample prototypes before bulk production can help ensure the final product aligns with your market needs.

Illustrative Image (Source: Google Search)

3. What are the typical minimum order quantities (MOQs), lead times, and payment terms for sourcing vintage Earth Shoes from international suppliers?

MOQs for vintage or specialized footwear like Earth Shoes from the 1970s often range from 50 to 300 pairs, depending on supplier capacity and customization needs. Lead times can vary from 4 to 12 weeks, influenced by order complexity and shipping logistics. Common payment terms include 30% upfront deposit with the balance payable before shipment, or letters of credit for larger orders. Establish clear contractual agreements emphasizing these terms, and consider negotiating flexible payment options based on your purchase volume and relationship with the supplier.

4. What quality assurance measures and certifications should I request to ensure authenticity and safety?

Request suppliers to provide authenticity certificates proving the vintage nature of the shoes, along with safety standards compliance such as non-toxic adhesives and materials suitable for your target markets. Ask for detailed product testing reports, especially for European and Middle Eastern markets with strict safety regulations. Consider third-party inspection services during production and prior to shipment to verify quality, authenticity, and packaging standards. Maintaining detailed records and photographs of inspected samples can also help resolve disputes swiftly and uphold product integrity.

5. How can I efficiently manage international logistics, customs, and delivery of Earth Shoes from the 1970s to my country?

Partner with experienced freight forwarders familiar with your region’s import regulations. Choose shipping methods based on urgency and cost—air freight for faster delivery or sea freight for larger volumes. Ensure all documentation, including commercial invoices, packing lists, certificates of origin, and any applicable import licenses, are accurate and complete. Work closely with customs brokers to facilitate smooth clearance, and factor in potential delays or tariffs. Establish clear communication channels with your supplier and logistics partners to track shipments and handle any issues proactively.

6. What strategies can I use to resolve disputes related to quality, delivery, or payment issues with international suppliers?

Develop a clear dispute resolution process outlined in your contract, emphasizing negotiation, mediation, or arbitration options. Maintain detailed records of all communications, agreements, and inspection reports to support your case. Engage local legal counsel familiar with international trade laws in your region. Building strong relationships and transparent communication can often prevent misunderstandings. If disputes arise, aim for amicable solutions, but be prepared with contractual remedies such as penalties or order cancellations if necessary, to protect your business interests.

7. How can I stay informed about market trends and vintage footwear demand in my region to optimize my sourcing strategy?

Regularly monitor industry publications, trade shows, and online marketplaces specializing in vintage footwear. Engage with local distributors and retailers to understand consumer preferences and seasonal demand shifts. Join international B2B platforms and forums dedicated to vintage or sustainable footwear to access market insights. Conduct periodic market research and competitor analysis to identify gaps and opportunities. Building a network of trusted suppliers and industry contacts across your region can also provide real-time intelligence, enabling you to adapt your sourcing and inventory strategies effectively.

8. What are best practices for building long-term relationships with international Earth Shoes suppliers?

Establish clear communication channels and maintain transparency regarding your needs and expectations. Pay invoices promptly and provide constructive feedback after each order to foster trust. Consider visiting supplier facilities when possible to strengthen rapport and understand their operations better. Diversify your supplier base to mitigate risks and negotiate favorable terms for repeat orders. Investing in cultural understanding and language support can enhance collaboration. Long-term partnerships often lead to better pricing, priority production, and customized service, giving you a competitive edge in your target markets.

Strategic Sourcing Conclusion and Outlook for earth shoes 1970s

Strategic Sourcing Conclusion and Outlook for earth shoes 1970s

Effective strategic sourcing remains a critical factor for B2B buyers seeking to capitalize on the nostalgic appeal and unique design elements of earth shoes from the 1970s. By establishing strong relationships with reliable suppliers, leveraging local manufacturing capabilities, and prioritizing quality assurance, international buyers can secure authentic products while optimizing costs. Diversifying sourcing channels across regions such as Africa, South America, the Middle East, and Europe can also mitigate risks and enhance supply chain resilience.

Looking ahead, the growing global demand for vintage and eco-conscious footwear presents significant opportunities for forward-thinking buyers. Embracing sustainable sourcing practices and fostering long-term partnerships will be essential in maintaining competitive advantage. As markets evolve, strategic agility and due diligence will enable buyers from Colombia, Italy, and beyond to meet consumer preferences efficiently and responsibly.

Actionable takeaway: Start engaging with regional suppliers today, conduct comprehensive supplier assessments, and develop flexible sourcing strategies to unlock the full potential of earth shoes from the 1970s. Proactively adapting to market trends will position your business for sustained growth in this niche segment.