Master Sourcing Gold Nike Shoes for Global Markets |

Guide to Gold Nike Shoes

- Introduction: Navigating the Global Market for gold nike shoes

- Understanding gold nike shoes Types and Variations

- Key Industrial Applications of gold nike shoes

- Strategic Material Selection Guide for gold nike shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for gold nike shoes

- Comprehensive Cost and Pricing Analysis for gold nike shoes Sourcing

- Spotlight on Potential gold nike shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for gold nike shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the gold nike shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of gold nike shoes

- Strategic Sourcing Conclusion and Outlook for gold nike shoes

Introduction: Navigating the Global Market for gold nike shoes

In the highly competitive and trend-driven world of athletic footwear, gold Nike shoes have emerged as a symbol of luxury, exclusivity, and innovative design. For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, sourcing these premium products offers lucrative opportunities to meet rising consumer demand for statement footwear and limited-edition collectibles. Understanding the nuances of this niche market is essential to making informed procurement decisions that maximize profitability and brand positioning.

This comprehensive guide aims to equip you with critical insights into the types, materials, manufacturing processes, quality control standards, and supplier landscapes associated with gold Nike shoes. It also provides a detailed analysis of cost considerations, market trends, and regulatory factors across key regions, ensuring you can navigate import/export complexities confidently. Additionally, the guide addresses frequently asked questions and best practices for establishing reliable supply chains, from sourcing authentic products to evaluating quality assurance protocols.

By leveraging this knowledge, B2B buyers can optimize sourcing strategies, mitigate risks of counterfeit or substandard products, and capitalize on emerging market opportunities. Whether you are seeking to stock retail outlets, supply luxury boutiques, or explore private label collaborations, this guide empowers you to make strategic, data-driven decisions that align with your regional market dynamics and consumer preferences.

Understanding gold nike shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Gold Nike Sneakers | Iconic design with a metallic gold finish, versatile silhouette | Retail, wholesale, promotional merchandise | Pros: High brand recognition, broad appeal; Cons: High demand may inflate prices |

| Limited Edition Gold Models | Special releases with unique design elements, often with premium materials | Collectors, premium retail, exclusive collaborations | Pros: Higher resale value, exclusivity; Cons: Limited supply, higher MOQ requirements |

| Customizable Gold Nike Shoes | Shoes with customizable elements like color accents or personalized engravings | Corporate gifting, promotional campaigns | Pros: Tailored branding, higher customer engagement; Cons: Longer lead times, setup costs |

| Performance-Oriented Gold Shoes | Designed for athletic use with lightweight materials and advanced cushioning | Sports teams, athletic retailers | Pros: High functionality, appeal to sports market; Cons: Higher technical standards, costlier production |

| Fashion-Forward Gold Nike Footwear | Trend-driven designs with innovative aesthetics, often limited runs | Fashion boutiques, luxury retailers | Pros: High margin potential, trendy appeal; Cons: Rapid obsolescence, niche market |

Classic Gold Nike Sneakers

These are the most recognizable and widely available gold Nike shoes, characterized by their iconic Nike design with a metallic gold finish. They are suitable for mass retail, wholesale distribution, and promotional merchandise due to their broad consumer appeal. For B2B buyers, these shoes offer a reliable demand stream, especially in markets with high brand loyalty, such as Europe and the Middle East. However, their popularity can lead to inflated procurement costs, and high demand may cause supply constraints. Buyers should consider establishing strong supplier relationships to ensure consistent stock availability.

Limited Edition Gold Models

Limited edition gold Nike shoes feature exclusive design elements, often collaborating with artists or designers. They use premium materials and are produced in restricted quantities, making them highly desirable for collectors and high-end retail outlets. B2B buyers in luxury markets or specialty stores can leverage these models for higher profit margins. The key considerations include higher minimum order quantities (MOQs), longer lead times, and premium pricing. These shoes are ideal for creating hype and exclusivity, but buyers must carefully plan inventory to avoid overstocking or missed opportunities.

Customizable Gold Nike Shoes

These shoes allow for personalization, such as adding logos, initials, or specific color accents, making them attractive for corporate gifting, promotional campaigns, and brand collaborations. They enable B2B buyers to offer tailored products that enhance brand visibility and customer engagement. However, customization processes often involve longer production times and setup costs, which require careful planning. Suitable for large-scale campaigns or corporate orders, these shoes provide a unique value proposition but demand reliable manufacturing partners to meet deadlines.

Performance-Oriented Gold Shoes

Designed primarily for athletes, these shoes incorporate lightweight materials, advanced cushioning, and stability features, often with gold accents to signify premium quality or sponsorship. They are suitable for sports teams, athletic retailers, and fitness brands seeking high-performance products with a luxurious twist. B2B buyers should evaluate technical specifications, durability, and manufacturing standards to meet athletic performance demands. While they typically command higher prices, their technical complexity can increase production costs and lead times.

Fashion-Forward Gold Nike Footwear

This category encompasses trend-driven designs that emphasize aesthetics and innovation, often released as limited runs or seasonal collections. They appeal to fashion boutiques, luxury retailers, and consumers seeking statement pieces. For B2B buyers, these shoes offer high-margin opportunities but require rapid inventory turnover due to fast-changing fashion trends. Establishing relationships with Nike’s fashion-focused lines and understanding seasonal cycles are crucial for optimizing stock levels and maximizing profitability in this segment.

Key Industrial Applications of gold nike shoes

| Industry/Sector | Specific Application of gold nike shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive & Transportation | Precision machinery assembly, especially in high-performance vehicle manufacturing | Enhances durability and precision in component alignment, reducing downtime and maintenance costs | Material quality, compatibility with industrial lubricants, certification standards (ISO, ASTM) |

| Aerospace & Defense | Critical component testing and calibration tools | Ensures high accuracy and reliability in aerospace applications, meeting strict safety standards | High purity, traceability, adherence to aerospace-grade specifications |

| Electronics & Semiconductor | Specialized manufacturing tools and wafer handling equipment | Provides conductive, corrosion-resistant properties essential for sensitive electronics | Electrical conductivity, corrosion resistance, cleanroom compatibility |

| Jewelry & Luxury Goods | Manufacturing of high-end, limited-edition footwear and accessories | Adds value through luxury branding, attracting premium B2B clients | Authenticity verification, consistent quality, supply chain transparency |

| Medical Devices & Instruments | Surgical tools and diagnostic equipment components | Ensures biocompatibility, corrosion resistance, and precision in medical applications | Medical-grade certification, biocompatibility, sterility standards |

Automotive & Transportation

Gold Nike shoes are increasingly used in precision machinery components within high-performance automotive manufacturing. Their unique properties—such as excellent wear resistance and electrical conductivity—help improve the accuracy of sensor systems and assembly tools. For international B2B buyers, especially in regions like Europe and the Middle East where automotive innovation is growing, sourcing high-quality gold components ensures operational reliability and reduces costly downtime. Buyers should prioritize suppliers with automotive-grade certifications and consistent purity standards to meet stringent industry demands.

Aerospace & Defense

In aerospace and defense sectors, gold Nike shoes are critical in calibration and testing equipment due to their exceptional electrical conductivity and corrosion resistance. These applications demand materials that can withstand extreme environmental conditions while maintaining precision. International buyers from Africa or South America working with aerospace manufacturers must ensure suppliers comply with aerospace industry certifications such as ISO 9100 or ASTM standards. Reliable sourcing guarantees safety, compliance, and operational integrity in sensitive aerospace applications.

Electronics & Semiconductor

Gold Nike shoes are vital in the manufacturing of semiconductor wafers and delicate electronic components, where their conductive and corrosion-resistant qualities are essential. They are used in contact points, connectors, and bonding wires, ensuring signal integrity and longevity. For B2B buyers in regions like Europe or the Middle East, sourcing from suppliers with strict quality controls and cleanroom-compatible products is crucial to prevent contamination and ensure device performance. Traceability and high purity levels are key considerations.

Jewelry & Luxury Goods

In the luxury footwear and accessories industry, gold Nike shoes serve as premium materials for limited-edition collections and bespoke collaborations. Their use enhances product exclusivity and brand prestige, attracting high-end B2B clients globally. Buyers from Africa, South America, or Europe should seek suppliers offering certified authenticity and consistent quality. Transparent supply chains and adherence to ethical sourcing standards add further value and mitigate reputational risks.

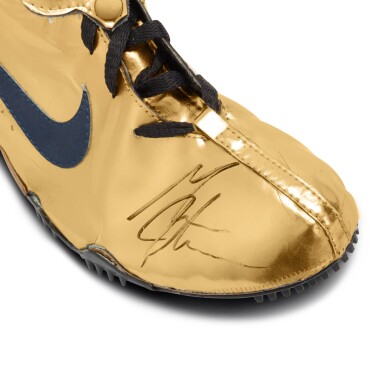

Illustrative Image (Source: Google Search)

Medical Devices & Instruments

Gold Nike shoes are increasingly employed in the production of surgical tools and diagnostic equipment components, thanks to their biocompatibility and resistance to corrosion. These properties are critical in medical environments where safety and reliability are paramount. International buyers, particularly in Europe and the Middle East, must ensure sourcing from suppliers with medical-grade certifications, sterile processing standards, and traceability to meet regulatory requirements. High-quality sourcing minimizes risks of contamination and ensures compliance with health standards.

Strategic Material Selection Guide for gold nike shoes

Material Analysis for Gold Nike Shoes

Selecting the appropriate materials for manufacturing gold Nike shoes requires careful consideration of performance, durability, cost, and compliance with international standards. Below is a detailed analysis of four common materials used in this context, tailored to meet the needs of international B2B buyers from Africa, South America, the Middle East, and Europe.

1. Synthetic Leather (PU or PVC-based)

Synthetic leather is a popular choice for modern athletic footwear, including gold Nike shoes, due to its versatility and aesthetic appeal.

-

Key Properties:

Lightweight, flexible, and capable of mimicking genuine leather. It offers decent resistance to water and stains but varies in breathability. Typically rated for moderate temperature ranges (-20°C to 60°C) and pressure conditions encountered during wear. -

Pros & Cons:

Pros: Cost-effective, easy to produce, and available in various finishes including metallic gold. It allows for intricate design details and color customization.

Cons: Less durable than genuine leather, prone to cracking over time, especially under harsh conditions. Environmental concerns are significant, as PVC and PU are non-biodegradable and may face regulatory restrictions. -

Impact on Application:

Suitable for fashion-forward, lightweight designs. Compatibility with adhesives and printing techniques is high, facilitating branding and decorative elements. -

International Considerations:

Buyers from regions with strict environmental regulations (e.g., Europe’s REACH standards) should verify supplier compliance. Synthetic leather often meets ASTM or EN standards for footwear materials but may require certification for chemical safety.

2. Genuine Leather (Full-Grain or Top-Grain)

Genuine leather remains a premium material for high-end footwear, including luxury or limited-edition gold Nike shoes.

-

Key Properties:

Known for exceptional durability, breathability, and aesthetic appeal. It withstands temperature variations (-30°C to 70°C) and pressure without significant degradation. Leather’s natural properties confer excellent aging characteristics. -

Pros & Cons:

Pros: Superior durability and a premium feel. It ages well, developing a unique patina. Suitable for metallic finishes if properly treated.

Cons: Higher cost and longer manufacturing times. Leather processing involves complex tannage procedures, increasing lead times and costs. Environmental concerns and compliance with animal welfare standards are critical, especially in Europe and North America. -

Impact on Application:

Ideal for premium segments and applications requiring high wear resistance. Compatibility with metallic finishes and dyes is high, but surface treatment must be carefully managed to retain flexibility. -

International Considerations:

Buyers should ensure supplier certifications such as ISO 9001 or animal welfare standards (e.g., LWG certification). Regional regulations (e.g., EU’s REACH) may restrict certain tanning agents, requiring due diligence.

3. Metallic Foils or Films (Gold-colored Aluminum or Stainless Steel)

For achieving the iconic gold finish, metallic foils or films are often used as overlays or accents.

-

Key Properties:

Thin, lightweight, and highly reflective. Aluminum foils are corrosion-resistant and can withstand moderate mechanical stresses, while stainless steel offers higher strength but is heavier. -

Pros & Cons:

Pros: Excellent visual appeal with high reflectivity; relatively easy to apply as overlays. Aluminum is cost-effective and lightweight.

Cons: Metallic films can be prone to scratching or peeling if not properly adhered. Aluminum may oxidize if improperly coated, affecting appearance. -

Impact on Application:

Best suited for decorative elements rather than structural parts. Compatibility with adhesives and protective coatings is essential to ensure longevity. -

International Considerations:

Buyers should verify supplier adherence to safety standards for metallic materials, such as ASTM F86 for aluminum alloys. For regions with high humidity or salt exposure (e.g., Middle East), corrosion-resistant coatings are vital.

4. Rubber or Thermoplastic Elastomers (TPE)

Used primarily for soles and decorative accents, rubber and TPE materials offer flexibility and resilience.

-

Key Properties:

TPEs are resistant to temperature extremes (-40°C to 80°C), chemicals, and abrasion. They provide excellent shock absorption and grip. -

Pros & Cons:

Pros: Cost-effective, highly durable, and easy to mold. Suitable for vibrant gold-colored finishes through pigmentation or coating.

Cons: Less suitable for upper parts exposed to UV degradation unless UV-stabilized. Some formulations may have limited breathability. -

Impact on Application:

Critical for outsole components and decorative overlays. Compatibility with adhesives and finishing processes is high, ensuring secure assembly. -

International Considerations:

Compliance with standards such as ISO 10993 (biocompatibility) and REACH is necessary for regions with strict chemical regulations. Buyers should confirm supplier certifications for safety and environmental compliance.

Summary Table

| Material | Typical Use Case for gold nike shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Synthetic Leather (PU/PVC) | Upper material, decorative overlays | Cost-effective, versatile, customizable | Less durable, environmental concerns | Low |

| Genuine Leather | Premium upper, luxury editions | Highly durable, develops patina, premium feel | Expensive, longer lead times, environmental/welfare issues | High |

| Metallic Foils/Films | Decorative accents, overlays | High reflectivity, lightweight | Susceptible to scratching/peeling | Medium |

| Rubber/TPE (Soling & accents) | Outsoles, decorative elements | Durable, flexible, shock-absorbing | UV degradation risk, limited breathability | Low |

This comprehensive analysis aims to guide international B2B buyers in selecting materials that balance performance, cost, and compliance, ensuring their gold Nike shoes meet regional standards and consumer expectations effectively.

In-depth Look: Manufacturing Processes and Quality Assurance for gold nike shoes

Manufacturing Processes for Gold Nike Shoes

The production of gold Nike shoes involves a series of meticulously controlled stages, each critical to ensuring product quality, aesthetic appeal, and durability. Understanding these stages allows B2B buyers to evaluate supplier capabilities and ensure compliance with international standards.

1. Material Preparation and Selection

The process begins with sourcing high-quality raw materials, including premium synthetic or genuine leather, textiles, and specialized metallic finishes for the gold effect. Suppliers often employ advanced coating techniques such as electroplating, PVD (Physical Vapor Deposition), or metallic foil lamination to achieve the distinctive gold appearance. Material verification involves certificates of conformity, lab testing for colorfastness, and adherence to environmental regulations like REACH or RoHS, especially for European markets.

2. Forming and Molding

This stage involves cutting, stamping, and molding the upper components and soles. Precision CNC cutting and automated stamping machines ensure consistency. For the gold finish, manufacturers may apply specialized metallic layers during this phase or post-assembly, demanding tight process controls to prevent defects like uneven coating or peeling.

3. Assembly and Stitching

Components are assembled using industrial stitching, adhesive bonding, and sometimes welding techniques for synthetic parts. The assembly line emphasizes seam strength, alignment, and surface finish. For gold shoes, additional care is taken to prevent scratching or tarnishing during handling, often involving protective films or gloves.

4. Finishing and Surface Treatment

The final stage involves applying protective coatings, polishing, and quality checks on the gold finish. Techniques such as UV curing or clear topcoats enhance durability and prevent oxidation. This stage may also include adding branding elements, insoles, and packaging preparations.

Quality Assurance Framework for Gold Nike Shoes

Effective quality assurance (QA) is vital for B2B buyers to mitigate risks, especially when importing from regions with varying manufacturing standards. Adherence to international standards and rigorous internal controls ensures consistent product quality.

1. International Standards Compliance

Most reputable manufacturers operate under ISO 9001, which emphasizes a quality management system (QMS) focusing on process control, continuous improvement, and customer satisfaction. For footwear, additional certifications like ISO 14001 (environmental management) are increasingly common. B2B buyers should verify certification validity through supplier documentation or third-party audits.

2. Industry-Specific Certifications

Depending on the target market, manufacturers may also hold certifications like CE marking for European compliance, ASTM standards for durability, or API standards if the shoes are used in specialized contexts. These certifications provide assurance of safety, environmental compliance, and product performance.

3. Quality Control (QC) Checks at Key Stages

– Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival for defects, color consistency, and compliance with specifications. Suppliers should provide detailed test reports and certificates.

– In-Process Quality Control (IPQC): Ongoing checks during manufacturing monitor parameters such as coating thickness, adhesion strength, dimensional accuracy, and stitching quality. Techniques include visual inspections, thickness gauges, and adhesion tests.

– Final Quality Control (FQC): Before shipment, finished shoes undergo comprehensive inspection for surface defects, color uniformity, finish quality, and packaging integrity. Random sampling and statistical process control (SPC) are standard practices.

4. Testing Methods for Gold Nike Shoes

– Visual Inspection: Ensures defect-free surfaces, uniform color, and branding accuracy.

– Adhesion Tests: Checks the durability of metallic coatings, often through tape tests or cross-hatch adhesion testing.

– Environmental Testing: Simulates conditions like humidity, UV exposure, and abrasion to assess coating stability and shoe durability.

– Mechanical Testing: Includes flex tests, tensile strength, and shock absorption evaluations to verify functional performance.

Verifying Supplier Quality and Ensuring Compliance

For B2B buyers, especially from Africa, South America, the Middle East, and Europe, verifying supplier quality is crucial to mitigate risks and ensure product standards.

1. Conduct Comprehensive Audits

On-site audits provide insights into manufacturing practices, worker conditions, and QC processes. Buyers should focus on assessing cleanliness, equipment calibration, and record-keeping. Engaging third-party inspection agencies with expertise in footwear manufacturing enhances objectivity.

2. Review Inspection Reports and Certification Documentation

Request detailed QC reports, test results, and certification copies. Cross-reference these with recognized standards such as ISO 9001, CE, or ASTM. Transparent documentation indicates a supplier’s commitment to quality.

3. Engage Third-Party Inspection Services

Third-party inspection firms like SGS, Bureau Veritas, or Intertek can perform pre-shipment inspections, random sampling tests, and factory audits. These inspections help validate the supplier’s claims and ensure compliance with buyer specifications.

4. Sample Testing and Certification Verification

B2B buyers should request pre-shipment samples for independent testing, especially for critical parameters like coating adhesion, colorfastness, and mechanical strength. Verifying certifications through issuing bodies or registries provides additional assurance.

Special Considerations for International B2B Buyers

Regional Standards and Customs Regulations:

Buyers from Europe and the UK must ensure products meet CE or REACH standards, including restrictions on hazardous substances. Middle Eastern buyers, like those in Saudi Arabia, should verify compliance with local standards and import regulations. African and South American buyers should prioritize suppliers with proven export experience and proper documentation to facilitate customs clearance.

Cultural and Market Expectations:

The aesthetic quality of gold finishes must align with regional preferences. Suppliers should provide detailed color and finish samples, along with certificates of conformity, to meet diverse market standards.

Logistics and Lead Times:

Manufacturing timelines and QC processes impact delivery schedules. Establish clear communication channels and quality checkpoints to synchronize production and shipping schedules, minimizing delays.

By understanding the detailed manufacturing stages and robust quality assurance protocols, B2B buyers can make informed decisions, select reliable suppliers, and ensure their gold Nike shoes meet both international standards and regional market expectations. This proactive approach reduces risks, enhances brand reputation, and fosters long-term supplier relationships across global markets.

Comprehensive Cost and Pricing Analysis for gold nike shoes Sourcing

Cost Structure Breakdown for Gold Nike Shoes

Understanding the comprehensive cost structure is vital for international buyers aiming to optimize procurement strategies. The primary components include:

-

Materials: The core material cost for gold Nike shoes typically involves premium synthetic or genuine leather, along with specialized gold-colored or metallic finishes. High-quality materials with certifications (e.g., eco-friendly, sustainable) can command higher prices but may also add perceived value.

-

Labor: Manufacturing costs vary significantly depending on the country of production. Factories in Southeast Asia or Eastern Europe often offer competitive labor rates, whereas facilities in regions like North Africa or Latin America might have different wage standards. Skilled labor for intricate designs or customization increases costs.

-

Manufacturing Overhead: This encompasses factory utilities, equipment depreciation, and management expenses. Overhead costs are influenced by factory size, technology level, and efficiency standards, impacting the unit price.

-

Tooling and Setup: Initial tooling costs for molds or dies, especially for custom or limited-edition designs, can be substantial. These are typically amortized over production volume, so higher MOQs reduce per-unit tooling costs.

-

Quality Control & Certification: Ensuring product consistency and compliance with international standards (e.g., ISO, sustainability certifications) adds to costs but is crucial for premium branding and market acceptance.

-

Logistics & Shipping: International shipping costs depend on shipment volume, mode (air vs. sea), and destination. Buyers from Africa or South America should consider the potential for higher freight charges and longer lead times, especially for smaller orders.

-

Margins & Profitability: Suppliers typically add a markup to cover their risks and desired profit margins, often ranging from 15% to 30% depending on order size, relationship, and market conditions.

Key Price Influencers

Several factors directly impact the final FOB (Free on Board) or CIF (Cost, Insurance, and Freight) prices:

-

Order Volume & MOQ: Larger orders benefit from economies of scale, significantly reducing per-unit costs. Many suppliers offer discounts for orders exceeding specific thresholds, making volume a critical negotiation lever.

-

Product Customization & Specifications: Unique designs, special finishes, or additional features (e.g., custom packaging, branding) increase costs. Clear communication of specifications can prevent costly revisions.

-

Material Choices: Opting for premium or certified materials elevates costs but can justify higher retail pricing and market positioning.

-

Quality & Certifications: Higher-quality standards and certifications (e.g., environmental, labor standards) often entail additional inspection costs but enhance brand credibility.

-

Supplier Factors: Supplier reputation, production capacity, and proximity influence pricing. Established manufacturers with reliable quality tend to command premium prices but offer better consistency.

-

Incoterms & Delivery Terms: FOB prices are common, but buyers should consider additional costs like freight, insurance, and customs duties. Choosing suitable Incoterms (e.g., DDP vs. FOB) impacts total landed costs.

Buyer Tips for Cost Optimization

-

Negotiate Volume Discounts: Emphasize long-term partnership potential to secure better prices, especially for large or repeat orders from Africa and South America where supplier competition may be limited.

-

Focus on Total Cost of Ownership (TCO): Beyond unit price, consider logistics, customs duties, tariffs, and potential delays. For instance, choosing suppliers closer to your market can reduce lead times and costs.

-

Leverage Customization & Quality Standards: Investing in higher quality or certifications may reduce post-sale costs related to returns or rebranding, thus improving overall profitability.

-

Understand Pricing Nuances: Be aware that initial quotes might exclude certain costs like freight or customs duties. Clarify what is included and plan accordingly for accurate budgeting.

-

Build Strong Supplier Relationships: Regular communication and transparent negotiations foster trust, enabling better terms and priority production scheduling.

Price Range and Market Considerations

Indicative prices for gold Nike shoes can vary widely based on specifications and order size. For standard models with basic customization, FOB prices generally range from $25 to $50 per pair for bulk orders (minimum order quantities typically start at 500 pairs). Premium or highly customized versions can reach $60 to $100+ per pair.

Disclaimer: These figures are approximate and influenced by fluctuating raw material costs, currency exchange rates, and market demand. Buyers should conduct due diligence and request detailed quotations tailored to their specific requirements.

By understanding these detailed cost and pricing dynamics, international B2B buyers from Africa, South America, the Middle East, and Europe can strategically negotiate, reduce total acquisition costs, and optimize their sourcing operations for gold Nike shoes.

Spotlight on Potential gold nike shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for gold nike shoes.)*

Essential Technical Properties and Trade Terminology for gold nike shoes

Critical Technical Properties for Gold Nike Shoes

1. Material Composition and Grade

The primary materials used in gold Nike shoes—such as synthetic leather, mesh fabrics, and metallic accents—must meet industry standards for durability and aesthetic quality. Material grade specifications ensure consistency across batches, which is vital for maintaining brand reputation. For B2B buyers, verifying supplier certifications (e.g., ISO standards) guarantees material authenticity and performance.

2. Finish and Plating Tolerance

The gold finish or plating on Nike shoes involves metallic coatings that give the product its distinctive appearance. Tolerance levels specify the allowable variation in thickness, adhesion, and uniformity of the plating. Strict adherence to these tolerances ensures a high-quality finish, minimizes defects, and reduces return rates, which is essential for large-scale distribution.

3. Dimensional Accuracy and Fit

Precise measurements of shoe components—such as sole thickness, upper size, and overall dimensions—are critical. Dimensional tolerances ensure that the shoes fit as intended and are compatible with standardized sizing systems. Consistency here affects consumer satisfaction and reduces logistical issues during packaging and shipping.

4. Weight and Load-Bearing Capacity

The weight of the shoe influences comfort and performance, especially for athletic models. B2B buyers should specify acceptable weight ranges and load capacities to meet end-user expectations. These properties also impact packaging requirements and transportation costs, making them key considerations in bulk procurement.

5. Compliance with Safety and Environmental Standards

Materials and manufacturing processes must comply with relevant regulations, such as REACH (Europe), CPSIA (US), or local standards in Africa and the Middle East. Ensuring compliance reduces legal risks, facilitates customs clearance, and aligns with sustainability goals, which are increasingly vital in global trade.

Common Industry and Trade Terms for Gold Nike Shoes

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce Nike shoes based on the brand’s specifications. B2B buyers often engage OEMs for bulk manufacturing, ensuring product consistency and brand integrity. Clarifying OEM capabilities helps buyers assess quality control and production capacity.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce or sell per order. Understanding MOQ is crucial for planning procurement budgets and inventory management, especially when entering new markets or testing product demand.

3. RFQ (Request for Quotation)

A formal document sent by buyers to suppliers requesting detailed pricing, lead times, and terms for specific products. Using RFQs allows buyers to compare offers accurately and negotiate better deals, particularly important in price-sensitive markets like Africa and South America.

4. Incoterms (International Commercial Terms)

Standardized trade terms published by the ICC that define responsibilities, risks, and costs between buyers and sellers during shipping. Common Incoterms for footwear include FOB (Free On Board) and CIF (Cost, Insurance, Freight). Proper understanding ensures clarity on who bears risks at each stage of transit, reducing disputes and unexpected costs.

5. QC (Quality Control)

Procedures implemented to ensure products meet specified standards before shipment. B2B buyers should specify QC protocols, such as third-party inspections or in-house testing, to guarantee product quality and reduce returns or rejections.

6. Lead Time

The duration from order placement to delivery. Accurate knowledge of lead times helps buyers plan inventory, align marketing strategies, and avoid stockouts, especially important when dealing with international logistics and customs procedures.

By understanding these technical properties and trade terms, B2B buyers from diverse regions can make informed decisions, streamline procurement processes, and establish reliable supply chains for gold Nike shoes. Mastery of industry-specific language and specifications enhances negotiation leverage and ensures product quality aligns with market expectations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the gold nike shoes Sector

Market Overview & Key Trends

The global market for premium athletic footwear, especially niche segments like gold Nike shoes, is experiencing dynamic shifts driven by consumer demand, technological innovation, and evolving sourcing strategies. As B2B buyers from Africa, South America, the Middle East, and Europe seek to secure high-quality, exclusive products, understanding these market drivers is essential.

Illustrative Image (Source: Google Search)

Emerging trends include the integration of advanced manufacturing techniques such as 3D printing and automated assembly, which reduce lead times and enable customization at scale. Digitalization of supply chains through blockchain and IoT enhances transparency, allowing buyers to verify authenticity and track ethical sourcing credentials—crucial factors in premium segments like gold Nike shoes. Additionally, the rise of direct-to-consumer (DTC) models and e-commerce platforms has shifted sourcing priorities towards more agile and responsive supply chains.

Market dynamics are also influenced by regional economic factors. For instance, the Middle East and Europe are witnessing increased demand for luxury and statement footwear, including gold accents, driven by fashion trends and consumer affluence. Conversely, African and South American markets are expanding their footprint through strategic partnerships with regional distributors and local manufacturers, seeking to balance quality with cost efficiency.

For international B2B buyers, particularly in these regions, staying ahead involves leveraging real-time data analytics for demand forecasting, engaging with suppliers utilizing Industry 4.0 technologies, and exploring flexible sourcing options. Diversifying supply sources—combining established manufacturing hubs in Asia with emerging local or regional suppliers—can mitigate risks associated with geopolitical tensions or supply chain disruptions.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical criterion for B2B buyers sourcing gold Nike shoes. Consumers globally are increasingly conscious of environmental and social impacts, prompting brands and suppliers to adopt greener practices. For buyers in Africa, South America, the Middle East, and Europe, this shift translates into a preference for suppliers committed to ethical sourcing and environmental stewardship.

Key environmental concerns include the extraction of raw materials, manufacturing waste, and carbon emissions. Incorporating recycled materials—such as recycled gold-tone finishes or eco-friendly synthetic leathers—can significantly reduce the environmental footprint. Certifications like ISO 14001 for environmental management, Fair Trade, and the Responsible Gold Certification (RG) are valuable indicators of a supplier’s commitment to sustainability.

Ethical sourcing extends beyond environmental factors to include labor rights, fair wages, and safe working conditions. B2B buyers should prioritize suppliers that adhere to internationally recognized labor standards, conduct regular audits, and provide transparency reports. Embracing ‘green’ certifications and traceability systems not only enhances brand reputation but also mitigates risks associated with supply chain scandals or compliance violations.

Furthermore, adopting sustainable practices in packaging—using biodegradable or recyclable materials—and reducing transportation emissions through regional sourcing can reinforce a company’s commitment to environmental responsibility. For buyers, establishing long-term partnerships with suppliers demonstrating measurable sustainability initiatives can lead to more resilient, ethically sound supply chains for gold Nike shoes.

Brief Evolution/History

The evolution of gold Nike shoes reflects broader trends in luxury athletic footwear, where innovation meets exclusivity. Initially, Nike’s focus was on performance and innovation, but over time, the brand introduced premium finishes—such as gold accents—to cater to the luxury market segment. Limited editions and collaborations with designers and celebrities have further elevated their status, transforming them into sought-after collectibles.

For B2B buyers, understanding this evolution underscores the importance of authenticity and exclusivity in sourcing. The rarity and desirability of gold Nike shoes mean that counterfeit prevention and supply chain integrity are paramount. As the market matured, technological advancements like RFID tagging and blockchain traceability have become standard tools to authenticate products and maintain brand integrity.

In a broader context, this evolution signifies a shift towards personalization and premiumization in athletic footwear, with a focus on craftsmanship, materials, and storytelling. For international buyers, especially in regions where luxury branding influences purchasing behavior, aligning sourcing strategies with these historical and market trends can enhance competitiveness and meet consumer expectations effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of gold nike shoes

1. How can I verify the legitimacy and reliability of a gold Nike shoes supplier?

Verifying supplier legitimacy is critical to avoid counterfeit products and ensure quality. Start by checking their business licenses, certifications (such as ISO, factory audits), and compliance with international trade standards. Request references from other B2B buyers, especially in your region, to assess their reputation. Conduct virtual or on-site audits if possible, focusing on production capabilities and quality control processes. Additionally, review their online presence, trade history on platforms like Alibaba or Global Sources, and seek third-party verification services. Establish clear communication channels to gauge transparency and responsiveness before committing to large orders.

Illustrative Image (Source: Google Search)

2. What customization options are available for bulk orders of gold Nike shoes, and how does that impact lead times?

Most B2B suppliers offer customization such as color variations, logo placement, packaging, and limited design modifications. Discuss your specific requirements upfront, including branding, size ranges, and packaging preferences. Customization generally extends lead times by 2-4 weeks, depending on complexity and supplier capacity. To ensure timely delivery, agree on a detailed production schedule, including prototypes and approval processes. Always factor in potential delays due to material sourcing or unforeseen production issues, especially when ordering large quantities or complex designs. Clear communication and early planning help mitigate risks.

3. What are typical MOQ (Minimum Order Quantities), lead times, and payment terms for international bulk orders?

MOQ for gold Nike shoes varies widely, typically ranging from 100 to 1,000 pairs depending on the supplier and customization level. Lead times generally span 4-8 weeks from order confirmation, contingent on order size, complexity, and current production schedules. Common payment terms include 30% upfront via bank transfer or letter of credit, with the balance payable before shipment or upon arrival. Negotiating flexible terms is possible for repeat buyers or large orders. Always ensure your payment terms align with your risk appetite and consider escrow services or trade assurance options for added security.

4. What certifications and quality assurance processes should I look for in my supplier?

Reliable suppliers should provide quality certifications such as ISO 9001, indicating adherence to quality management standards. Verify compliance with safety standards relevant to your region (e.g., CE for Europe, SASO for Saudi Arabia). Request detailed quality assurance procedures, including pre-shipment inspections, third-party testing, and batch sampling. Suppliers with transparent QA processes typically perform regular internal audits and maintain detailed records. Ensuring these certifications and procedures reduces the risk of receiving substandard or counterfeit products, safeguarding your brand reputation and customer satisfaction.

5. How do I manage logistics and shipping when importing gold Nike shoes internationally?

Effective logistics management involves selecting reliable freight forwarders experienced in handling apparel and footwear shipments. Consider options such as sea freight for cost efficiency or air freight for faster delivery, depending on your urgency. Clarify Incoterms (e.g., FOB, CIF) with your supplier to define responsibilities and costs. Factor in customs clearance procedures, import duties, taxes, and regional regulations—especially critical for markets like the UK, Saudi Arabia, or African nations. Establish strong communication with your logistics partner and ensure all necessary documentation (commercial invoices, packing lists, certificates) is accurate to prevent delays.

6. What are common dispute resolution mechanisms if product quality or delivery issues arise?

Disputes are best mitigated through clear contractual agreements outlining quality standards, delivery timelines, and penalties for non-compliance. Include arbitration clauses specifying a neutral jurisdiction—preferably in a region familiar to both parties (e.g., Dubai, London, or a designated trade hub). Maintain detailed records of all communications, inspections, and shipment documents to support claims. Engaging third-party inspection agencies before shipment can help verify quality and reduce disputes. Building a relationship of trust and open communication with your supplier also facilitates quicker resolution when issues occur.

7. How can I ensure the authenticity of gold Nike shoes and avoid counterfeit products?

Counterfeit products are a significant risk in the footwear industry, especially for branded items like Nike shoes. Work exclusively with verified, reputable suppliers who can provide authentic sourcing documentation, factory certifications, and traceability of their supply chain. Request detailed product specifications, original manufacturing tags, and consider third-party authentication services if available. Establish quality control checks upon receipt, including serial numbers or holograms verification. Building relationships with authorized distributors or authorized brand representatives can further assure authenticity and protect your brand integrity.

8. What strategies can I implement to build long-term partnerships with reliable suppliers?

Developing lasting supplier relationships hinges on transparency, consistent communication, and mutual benefit. Start with clear, detailed agreements covering quality standards, lead times, payment terms, and dispute resolution. Regularly review supplier performance through audits and feedback sessions. Consider volume-based incentives or long-term contracts to encourage supplier loyalty. Stay updated on market trends and share insights to foster collaboration. Building trust and demonstrating reliability over time will result in better pricing, priority production slots, and customized support, ultimately strengthening your supply chain resilience in international markets.

Strategic Sourcing Conclusion and Outlook for gold nike shoes

Conclusion and Future Outlook

Effective strategic sourcing is essential for international B2B buyers aiming to capitalize on the premium appeal of gold Nike shoes while managing risks and optimizing costs. Key takeaways include the importance of establishing reliable supplier networks, leveraging regional trade advantages, and prioritizing quality assurance to meet global standards. Embracing innovative sourcing strategies—such as digital procurement platforms and supplier diversification—can significantly enhance supply chain resilience and competitive positioning.

Looking ahead, the evolving landscape of global trade, coupled with increasing consumer demand for luxury athletic footwear, offers substantial growth opportunities. Buyers from Africa, South America, the Middle East, and Europe should focus on building strong, transparent supplier relationships and exploring emerging sourcing hubs to stay ahead of market trends.

Actionable Tip: Engage with local industry associations and trade facilitators to identify trustworthy partners and stay informed about regulatory developments. By adopting a proactive, strategic approach, international buyers can secure a sustainable supply of high-quality gold Nike shoes and unlock long-term value in this dynamic market.