Your Ultimate Guide to Sourcing Ionic Shoes Silhouette

Guide to Ionic Shoes Silhouette

- Introduction: Navigating the Global Market for ionic shoes silhouette

- Understanding ionic shoes silhouette Types and Variations

- Key Industrial Applications of ionic shoes silhouette

- Strategic Material Selection Guide for ionic shoes silhouette

- In-depth Look: Manufacturing Processes and Quality Assurance for ionic shoes silhouette

- Comprehensive Cost and Pricing Analysis for ionic shoes silhouette Sourcing

- Spotlight on Potential ionic shoes silhouette Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for ionic shoes silhouette

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ionic shoes silhouette Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of ionic shoes silhouette

- Strategic Sourcing Conclusion and Outlook for ionic shoes silhouette

Introduction: Navigating the Global Market for ionic shoes silhouette

In the highly competitive and dynamic landscape of global footwear manufacturing, the ionic shoes silhouette has emerged as a distinctive and sought-after style that combines innovation with consumer appeal. For international B2B buyers—particularly from regions such as Africa, South America, the Middle East, and Europe—understanding the nuances of this niche is essential to making strategic sourcing decisions. The ionic shoes silhouette not only embodies cutting-edge design but also offers opportunities for differentiation in crowded markets, making it a critical component of product portfolios seeking both trend relevance and functional appeal.

This comprehensive guide is designed to equip B2B buyers with in-depth insights into the ionic shoes silhouette—from its core design elements and material options to manufacturing processes, quality control standards, and supplier landscapes. It also explores cost considerations, market demand trends, and answers common FAQs, empowering buyers to navigate complexities with confidence. Whether sourcing from established manufacturing hubs in Europe or emerging suppliers in Africa, South America, or the Middle East, this guide provides actionable intelligence tailored to your regional context.

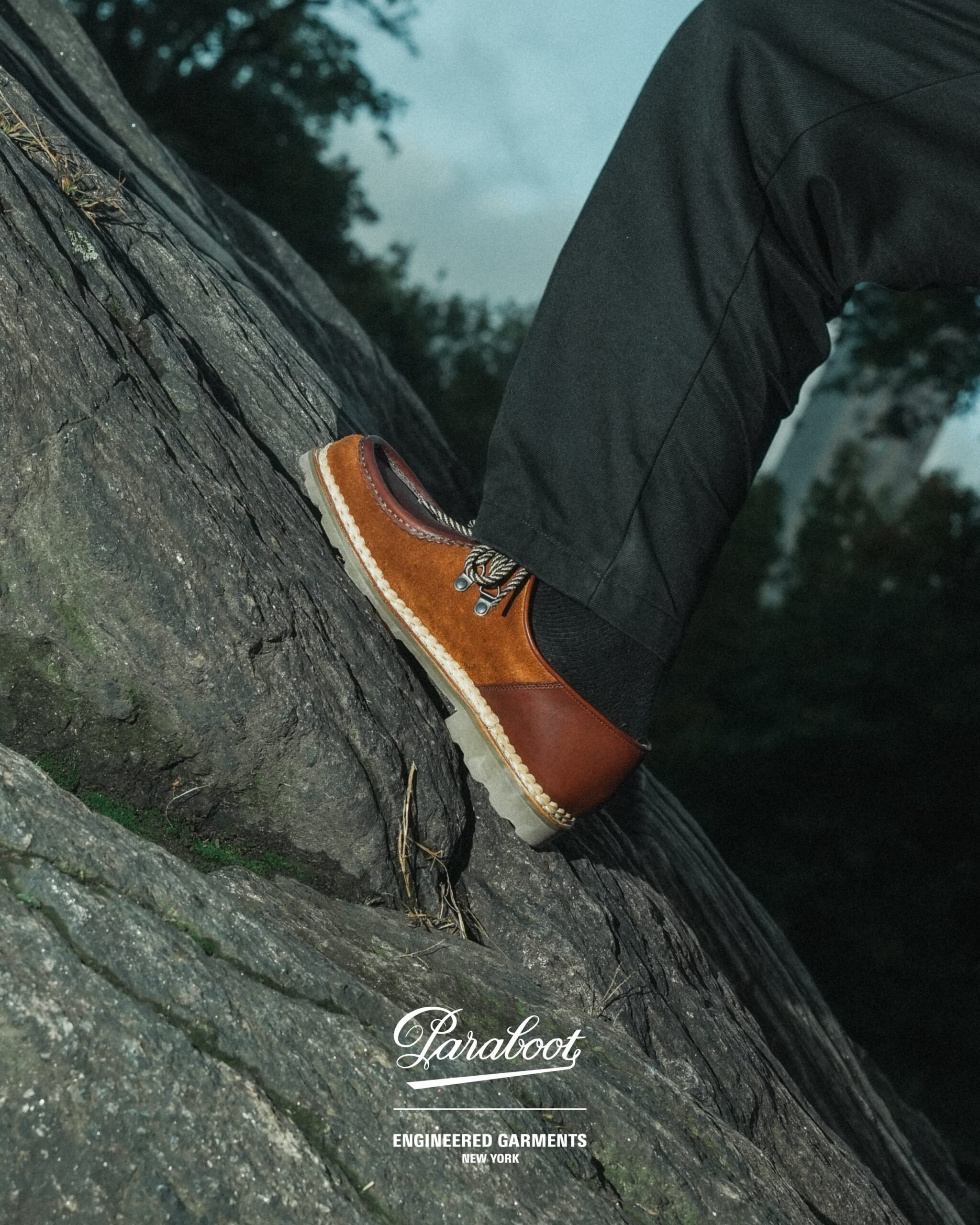

Illustrative Image (Source: Google Search)

By leveraging this knowledge, international buyers can optimize sourcing strategies, ensure product quality, and capitalize on market opportunities for ionic shoes silhouettes. In an era where innovation and authenticity drive consumer choices, mastering the intricacies of this footwear style is crucial for establishing a competitive edge in the global market.

Understanding ionic shoes silhouette Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Low-Top Ionic Shoes | Minimalist silhouette with low ankle profile, streamlined design | Athletic footwear, casual wear, retail chains | Pros: Versatile, widely accepted; Cons: Limited variation for niche markets |

| High-Top Ionic Shoes | Extended ankle support, more substantial silhouette | Sportswear, specialty sports stores, fashion retailers | Pros: Enhanced support appeal; Cons: Higher manufacturing costs, less universal appeal |

| Mid-Cut Ionic Shoes | Balance between low-top and high-top, moderate ankle coverage | Lifestyle markets, urban fashion, workwear | Pros: Versatile, appealing to multiple demographics; Cons: Moderate production complexity |

| Performance-Optimized Ionic Shoes | Designed with advanced cushioning and stability features | Performance sports, professional markets | Pros: High technical value, premium pricing; Cons: Limited mass-market appeal |

| Fashion-Forward Ionic Shoes | Trend-driven designs, bold aesthetics, unique silhouette features | Fashion boutiques, luxury segments, designer collaborations | Pros: High margin potential, brand differentiation; Cons: Niche market, higher risk |

Characteristics and Suitability

Classic Low-Top Ionic Shoes are characterized by their sleek, minimal ankle coverage, making them a popular choice across diverse markets. Their straightforward design facilitates large-scale manufacturing and broad distribution, especially suitable for mass-market retail channels. B2B buyers should consider their target demographic’s preferences—these shoes appeal to consumers seeking comfort and simplicity. They are ideal for volume orders, with a focus on consistent quality and cost-effective production.

High-Top Ionic Shoes feature extended ankle support, often with additional padding or structural elements. This silhouette caters to sports-specific markets like basketball or volleyball, and fashion-forward segments emphasizing streetwear. For B2B buyers, these shoes demand attention to durability and support features, which can increase manufacturing costs. They suit premium retail channels or specialty sports stores aiming to differentiate through technical attributes.

Mid-Cut Ionic Shoes offer a balanced approach with moderate ankle coverage, blending style and functionality. They are versatile, fitting urban fashion, casual wear, and workwear segments. B2B purchasers should evaluate production flexibility, as these shoes often require adaptable designs to meet varying consumer preferences. They are well-suited for markets seeking a middle ground—appealing to a broad audience while maintaining manageable manufacturing complexity.

Performance-Optimized Ionic Shoes are engineered with advanced cushioning, stability, and lightweight materials for athletic excellence. These are targeted at professional sports teams, high-performance retail outlets, and specialty sports distributors. B2B buyers need to prioritize technical specifications and quality assurance, as these shoes command higher prices and demand stringent quality control. Their niche appeal requires careful market analysis to ensure adequate demand.

Fashion-Forward Ionic Shoes emphasize bold aesthetics, unique silhouettes, and trend-driven details. They are primarily sold through boutique stores, designer collaborations, and luxury segments. For buyers, this category offers high margins but involves higher risks due to rapid fashion cycles and niche markets. Production considerations include flexibility for innovative designs and shorter lead times to capitalize on trends.

By understanding these silhouette variations, B2B buyers can tailor their sourcing strategies to align with target markets, optimize manufacturing processes, and maximize profitability across diverse regional demands.

Key Industrial Applications of ionic shoes silhouette

| Industry/Sector | Specific Application of ionic shoes silhouette | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Chemical Processing | Wear-resistant linings for corrosive fluid handling equipment | Enhances durability and reduces maintenance costs in aggressive environments | Material compatibility with chemicals, certification standards, supply chain reliability |

| Oil & Gas | Seals and gasket components in high-pressure, high-temperature environments | Ensures safety, leak prevention, and operational integrity | High-temperature resistance, pressure ratings, compliance with industry standards |

| Power Generation | Insulation components within electrical turbines and generators | Improves electrical performance and safety margins | Electrical insulating properties, thermal stability, certification requirements |

| Automotive & Heavy Machinery | Shock absorption and vibration damping components | Extends equipment lifespan and improves operational stability | Mechanical robustness, vibration damping efficiency, global supply capabilities |

| Healthcare & Biotech | Precision components in medical devices requiring sterile, reliable contact | Ensures safety and precision in sensitive applications | Biocompatibility, sterilization compatibility, quality assurance standards |

Chemical Processing

Ionic shoes silhouette components are critical in chemical processing for creating wear-resistant linings within reactors, pipes, and storage tanks. These applications require materials that withstand highly corrosive media, such as acids and solvents, while maintaining structural integrity. For international B2B buyers from regions like South America and Africa, sourcing materials with proven chemical resistance and compliance with global safety standards is vital. Suppliers must offer certifications and consistent quality to ensure long-term operational reliability and minimize downtime.

Oil & Gas

In the oil and gas industry, ionic shoes silhouette elements are used in seals, gaskets, and protective linings within high-pressure, high-temperature environments. These components are essential for preventing leaks and ensuring safety in pipelines, refineries, and offshore platforms. Buyers from the Middle East and Europe, especially Italy, seek suppliers capable of providing materials that meet strict API and ISO standards, with high thermal and pressure resistance. Reliable sourcing ensures compliance and operational continuity in complex, demanding environments.

Power Generation

Within power plants, ionic shoes silhouette components serve as insulation parts in turbines, generators, and switchgear. They contribute to electrical safety, thermal management, and efficiency. For European and Middle Eastern markets, sourcing high-quality, thermally stable, and electrically insulating materials is crucial. These components must withstand extreme operational conditions while adhering to international standards such as IEC and IEEE, ensuring reliability and safety in energy production.

Automotive & Heavy Machinery

In automotive manufacturing and heavy machinery, ionic shoes silhouette parts are used for shock absorption, vibration damping, and sealing applications. They improve machinery longevity and operational stability, especially in rugged environments. Buyers from Africa and South America prioritize sourcing robust, mechanically resilient components that can withstand harsh conditions. Ensuring global supply chain access and compliance with international quality standards is essential for seamless integration into manufacturing processes.

Healthcare & Biotech

In the healthcare sector, ionic shoes silhouette components are integrated into medical devices where precision, sterility, and biocompatibility are critical. These parts support applications such as surgical tools, diagnostic equipment, and implantable devices. For European and Middle Eastern medical device manufacturers, sourcing components that meet stringent biocompatibility, sterilization, and quality standards is vital. Reliable, certified suppliers help ensure patient safety and regulatory compliance across international markets.

Strategic Material Selection Guide for ionic shoes silhouette

Material Analysis for Ionic Shoes Silhouette

Selecting the appropriate materials for ionic shoes involves balancing performance, durability, cost, and compliance with international standards. For B2B buyers across diverse markets—Africa, South America, the Middle East, and Europe—understanding the specific properties and implications of each material is crucial for making informed procurement decisions.

1. Polyurethane (PU)

Key Properties:

Polyurethane is a versatile polymer known for its excellent flexibility, abrasion resistance, and shock absorption. It performs well across a wide temperature range (-40°C to 80°C) and offers good chemical resistance, especially against oils and greases. Its lightweight nature makes it suitable for footwear applications, providing comfort without adding excess weight.

Pros & Cons:

– Pros: Cost-effective, easy to mold, and offers good durability. It can be customized in terms of hardness and finish, making it adaptable for various shoe designs.

– Cons: Susceptible to degradation under prolonged UV exposure unless stabilized, and can be less environmentally friendly due to its synthetic origin. Manufacturing complexity is moderate, requiring specific molding processes.

Impact on Application:

Polyurethane’s chemical resistance makes it suitable for shoes exposed to diverse media, including oily or chemically contaminated environments. Its flexibility ensures comfort and durability in everyday wear.

International Buyer Considerations:

Polyurethane complies with many international standards, including ASTM and ISO. For markets like Europe (Italy) and South America (Colombia), eco-labels and sustainability certifications are increasingly important. Buyers should verify suppliers’ adherence to environmental standards and ensure material safety data sheets (MSDS) meet local regulations.

2. EVA (Ethylene Vinyl Acetate)

Key Properties:

EVA is a lightweight, elastic polymer with excellent cushioning properties. It withstands temperatures from -30°C to 70°C and exhibits good chemical resistance. Its closed-cell structure provides shock absorption, making it popular in footwear midsoles.

Pros & Cons:

– Pros: Very low cost, easy to process, and provides superior comfort and cushioning. It is also resistant to cracking and UV degradation.

– Cons: Less durable under heavy wear and tear, prone to compression set over time, and can degrade with prolonged exposure to certain solvents. Manufacturing requires precise extrusion or molding techniques.

Impact on Application:

Ideal for applications emphasizing comfort, EVA is often used in insoles and midsoles of ionic shoes. Its media compatibility is limited for chemically aggressive environments but suitable for casual or athletic footwear.

International Buyer Considerations:

EVA’s widespread use aligns with global standards; however, buyers should confirm supplier compliance with environmental directives like REACH (Europe) and local safety standards. Cost considerations are favorable for mass production, especially in regions with established EVA manufacturing facilities like China and Turkey.

3. Stainless Steel (e.g., 304, 316 grades)

Key Properties:

Stainless steel offers high corrosion resistance, strength, and temperature stability (-200°C to 800°C). It withstands harsh environments and is non-reactive, making it suitable for parts exposed to moisture or corrosive media.

Pros & Cons:

– Pros: Exceptional durability, corrosion resistance, and aesthetic appeal. It is also recyclable, aligning with sustainability goals.

– Cons: Heavy compared to polymers, more expensive, and requires specialized manufacturing processes like welding or machining. Its rigidity can impact comfort if used in structural shoe components.

Impact on Application:

Suitable for structural elements or protective features in ionic shoes, especially in environments with high humidity or chemical exposure. Its media compatibility is excellent for corrosive conditions, but overuse can increase overall product weight.

International Buyer Considerations:

Compliance with standards such as ASTM A240 or DIN 1.4301 is essential. Buyers in Europe and the Middle East should verify supplier certifications for quality and environmental management (ISO 9001, ISO 14001). Cost considerations are higher, but the longevity and performance benefits often justify the investment.

4. Aluminum Alloys (e.g., 6061, 7075)

Key Properties:

Aluminum alloys are lightweight, corrosion-resistant, and possess good strength-to-weight ratios. They operate effectively within a temperature range of -200°C to 250°C and are easy to machine and anodize for enhanced surface properties.

Pros & Cons:

– Pros: Light, durable, and highly customizable with surface treatments. Suitable for structural or aesthetic components.

– Cons: Less impact-resistant than steel, susceptible to fatigue over time, and more costly than polymers. Manufacturing involves extrusion, machining, or casting.

Impact on Application:

Ideal for components requiring strength without added weight, such as structural reinforcements or decorative elements in ionic shoes. Media compatibility is good, especially with anodized surfaces, but care must be taken to prevent galvanic corrosion when in contact with dissimilar metals.

International Buyer Considerations:

Compliance with aerospace or automotive standards (e.g., ASTM B209) is common. Buyers should ensure suppliers provide certifications for alloy composition and processing standards. Cost is moderate to high, but the benefits in weight reduction and aesthetics can be significant for high-end markets.

Summary Table

| Material | Typical Use Case for ionic shoes silhouette | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane (PU) | Outsoles, midsole components | Versatile, durable, customizable | UV degradation risk, environmental concerns | Med |

| EVA | Midsoles, insoles | Lightweight, excellent cushioning | Less durable under heavy wear, compression set | Low |

| Stainless Steel | Structural supports, protective elements | High strength, corrosion-resistant | Heavy, expensive, less flexible | High |

| Aluminum Alloys | Structural reinforcements, aesthetic accents | Lightweight, corrosion-resistant, customizable | Costlier, less impact-resistant | Med-High |

This detailed analysis enables international B2B buyers to select materials aligned with their specific application needs, environmental conditions, and market standards. Considering regional preferences, regulatory compliance, and cost implications ensures a strategic approach to sourcing ionic shoes components.

In-depth Look: Manufacturing Processes and Quality Assurance for ionic shoes silhouette

Manufacturing Processes for Ionic Shoes Silhouette

The production of ionic shoes silhouettes involves a series of meticulously controlled stages to ensure product consistency, durability, and aesthetic appeal. Understanding these processes allows B2B buyers to evaluate supplier capabilities and ensure compliance with international standards.

Material Preparation

The process begins with sourcing high-quality raw materials, primarily lightweight EVA or similar foams for the midsole, durable thermoplastics or textiles for the upper, and specialized adhesives. Suppliers often source materials from certified vendors adhering to ISO 9001 standards to guarantee quality and traceability. Material testing at this stage includes checking for tensile strength, dimensional stability, and chemical composition to prevent defects downstream.

Forming and Molding

The core of ionic shoe manufacturing involves forming the midsole and outsole through precision molding techniques such as injection molding or compression molding. These methods ensure dimensional accuracy and surface finish quality. For the upper components, cutting and thermoforming are common, often utilizing CNC cutting machines or automated cutting systems for consistency. Advanced manufacturers incorporate computer-aided design (CAD) and computer-aided manufacturing (CAM) systems to optimize fit and structural integrity.

Assembly

Assembly is a critical stage where upper components are attached to the midsole/outsole via high-performance adhesives or mechanical fastening, depending on the design. Automated robotic systems often handle precise placement, reducing variability. Additional steps include embedding reinforcement elements, inserting insoles, and attaching laces or fastening mechanisms. This stage requires strict control to prevent defects such as misalignment, weak bonds, or surface blemishes.

Finishing and Packaging

The finishing phase involves quality checks, surface cleaning, branding (e.g., logo stamping), and applying protective coatings if necessary. Final inspection ensures the shoes meet aesthetic standards and dimensional tolerances. Packaging is designed for international shipping, with considerations for protection against environmental factors and compliance with destination country regulations.

Quality Assurance (QA) and Control (QC) Framework

Implementing a robust QC system is essential for producing ionic shoes that meet global standards and satisfy B2B buyer expectations. Internationally recognized standards like ISO 9001 provide a foundation, while industry-specific certifications (e.g., CE for Europe, API for certain markets) add additional credibility.

Key QC Stages

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival. Tests include visual inspections, material property testing, and batch verification against specifications. Suppliers should provide comprehensive material test reports (MTRs) and certificates of conformity.

-

In-Process Quality Control (IPQC): During manufacturing, checkpoints verify dimensional accuracy, bonding strength, and assembly precision. Techniques such as 3D scanning, ultrasonic testing, and visual inspection are employed. Continuous monitoring ensures deviations are corrected promptly.

-

Final Quality Control (FQC): Before shipment, finished shoes undergo rigorous testing, including visual inspections, fit and finish assessments, and functional testing (e.g., flexibility, weight, and durability). Random sampling following standards like AQL (Acceptable Quality Level) ensures overall quality compliance.

Testing Methods and Industry Standards

- Physical Testing: Tensile strength, elongation, and adhesion tests confirm structural integrity. Drop tests and fatigue assessments evaluate durability under typical usage conditions.

- Environmental Testing: Resistance to UV, moisture, and temperature fluctuations ensures suitability for diverse climates.

- Certification Verification: B2B buyers should request test reports, certificates, and audit documentation from suppliers. Third-party inspection agencies (e.g., SGS, TÜV) can provide independent verification, especially critical for imports into Europe and the Middle East.

How B2B Buyers Can Verify Supplier QC

To mitigate risks and ensure supplier compliance, B2B buyers should adopt a multi-layered approach:

- Supplier Audits: Conduct on-site audits to review manufacturing facilities, quality management systems, and production processes. Focus on adherence to ISO standards, cleanliness, worker safety, and process control.

- Review QC Documentation: Request detailed QC reports, test certificates, and production batch records. These documents should include results of physical tests, environmental assessments, and compliance verifications.

- Third-party Inspections: Engage independent inspection agencies for pre-shipment inspections, especially when dealing with suppliers from regions with varying quality standards. This provides an unbiased assessment of product conformity.

- Sample Testing: Perform independent testing on sample units to verify key parameters, especially when importing into markets with stringent standards such as Europe or Colombia.

- Continuous Improvement Programs: Collaborate with suppliers to implement quality improvement initiatives, share feedback, and ensure ongoing compliance.

Considerations for International B2B Buyers from Different Regions

- Africa and South America: Suppliers may have varying levels of certification and infrastructure. Prioritize those with ISO 9001 or ISO 14001 certifications and request detailed compliance documentation. Establish clear quality benchmarks and perform periodic audits.

- Middle East: Focus on suppliers with CE certification and environmental compliance reports. Given regional import regulations, verify that products meet local standards and testing requirements.

- Europe (e.g., Italy): Suppliers should have CE certification, and products must pass EU-specific safety and environmental standards. Verify supplier adherence through third-party audits and certification validation.

- Colombia: Ensure suppliers comply with local standards and have proper export documentation. Certifications like ISO 9001 and compliance with ASTM or EN standards can facilitate smoother import processes.

Final Recommendations for B2B Buyers

- Develop detailed supplier qualification criteria emphasizing quality management systems, certification status, and transparency.

- Invest in regular supplier audits and establish long-term relationships with manufacturers committed to continuous quality improvement.

- Leverage third-party testing and inspection services to validate supplier claims and ensure product compliance before shipment.

- Stay informed about regional standards and adapt QC procedures accordingly to ensure seamless market entry and brand reputation.

By understanding and rigorously evaluating manufacturing and quality assurance processes, B2B buyers from Africa, South America, the Middle East, and Europe can mitigate risks, ensure product consistency, and foster mutually beneficial partnerships in the ionic shoes market.

Comprehensive Cost and Pricing Analysis for ionic shoes silhouette Sourcing

Cost Components in Ionic Shoes Silhouette Sourcing

Understanding the detailed cost structure is essential for effective pricing and negotiation. The primary components include:

- Materials: The choice of upper fabrics, sole compounds, and decorative elements significantly impacts cost. High-performance or eco-friendly materials tend to command higher prices but can be leveraged for premium positioning.

- Labor: Manufacturing labor costs vary widely depending on the sourcing country. For instance, Asian countries like Vietnam or China typically offer lower labor costs, whereas European suppliers may have higher wages but often provide faster turnaround and higher craftsmanship standards.

- Manufacturing Overheads: These include factory utilities, equipment depreciation, and quality control expenses. Efficient factories with advanced automation can reduce overhead costs, influencing overall pricing.

- Tooling & Setup: Initial mold creation and tooling can be a substantial upfront investment, especially for customized or complex designs. These costs are amortized over large order volumes.

- Quality Control & Certifications: Ensuring compliance with international standards (ISO, CE, etc.) adds to costs but is crucial for market access, especially in Europe and the Middle East.

- Logistics & Shipping: Freight costs depend on the destination, volume, and mode (sea, air, land). For Africa and South America, sea freight is generally more economical but slower, while air freight is faster but more expensive.

- Margins: Suppliers typically add a markup to cover risks, currency fluctuations, and profit margins. Negotiating favorable terms can help optimize this component.

Price Influencers and Their Impact

Several factors influence the final price of ionic shoes:

- Order Volume & MOQ: Larger orders often benefit from volume discounts, reducing per-unit costs. Conversely, low MOQs tend to have higher unit prices due to fixed setup costs.

- Specifications & Customization: Customized designs, unique materials, or special features increase costs. Standard models are more cost-efficient but may limit differentiation.

- Material Selection: Premium or specialized materials elevate costs, but they can justify higher retail pricing and margins.

- Quality & Certifications: Higher quality standards and international certifications can increase costs but are often necessary for access to regulated markets like Europe and the Middle East.

- Supplier Factors: Reputation, production capacity, and geographic location influence pricing. Suppliers with advanced automation or proximity to key markets may offer competitive advantages.

- Incoterms & Shipping Terms: The choice of Incoterms (e.g., FOB, CIF, DDP) impacts who bears transportation costs and risks, affecting the total landed cost for the buyer.

Strategic Tips for International B2B Buyers

- Negotiate Based on Volume: Leverage larger orders to secure better unit prices. Establish long-term relationships to benefit from ongoing discounts.

- Focus on Total Cost of Ownership (TCO): Consider not just manufacturing costs but also shipping, customs, tariffs, and potential delays. For example, sourcing from Asia might be cheaper upfront but could incur higher logistics costs and longer lead times for African or South American markets.

- Optimize Specifications: Balance customization with cost-efficiency. Standardized designs can reduce tooling and setup costs, enabling more competitive pricing.

- Certifications & Compliance: Prioritize suppliers with relevant certifications to avoid costly compliance issues in Europe or the Middle East.

- Currency & Payment Terms: Be aware of currency fluctuations and seek favorable payment terms to mitigate financial risks.

Pricing Nuances for Key Markets

- Africa & South America: Typically, buyers should expect lower manufacturing costs but higher logistics and customs expenses. Negotiating FOB terms can help control costs, but consider the total landed cost.

- Middle East: Market access often requires specific certifications and quality standards, which can add to costs. Suppliers with local or regional presence might offer faster delivery and better terms.

- Europe (e.g., Italy, Colombia): High standards for quality and certifications influence pricing. Premium materials and compliance increase costs but can enable access to lucrative retail channels. Buyers should also factor in import duties, VAT, and other tariffs.

Indicative Price Range (Disclaimer)

While prices vary widely based on specifications, order volume, and supplier location, typical manufacturing costs for ionic shoes silhouette range from $10 to $25 per pair at the factory gate. Retail prices can be significantly higher, often 2-3 times the production cost, depending on branding, quality, and market positioning.

In summary, a thorough understanding of the cost components, influencing factors, and market-specific nuances enables international B2B buyers to negotiate effectively, optimize their total costs, and develop competitive pricing strategies for ionic shoes silhouette sourcing.

Spotlight on Potential ionic shoes silhouette Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for ionic shoes silhouette.)*

Essential Technical Properties and Trade Terminology for ionic shoes silhouette

Critical Technical Properties

1. Material Grade and Composition

The material used in ionic shoes silhouettes significantly impacts durability, comfort, and aesthetic appeal. Common materials include high-grade thermoplastics, lightweight EVA foams, and advanced composites. For B2B buyers, specifying the exact grade ensures consistency across batches, reduces defects, and aligns with sustainability standards, especially important for markets emphasizing eco-friendly products.

2. Tolerance and Precision

Tolerance refers to the permissible deviation in manufacturing dimensions, typically measured in millimeters or microns. Tight tolerances (e.g., ±0.2mm) are crucial for ensuring proper fit, compatibility with other components, and overall quality. For international buyers, understanding tolerances helps in assessing product reliability and reduces the risk of returns or complaints.

3. Weight Specifications

The weight of ionic shoes influences end-user comfort and performance, especially for sports or activewear segments. Lighter shoes (measured in grams or ounces) appeal to consumers seeking mobility, while heavier variants may offer enhanced support. B2B buyers should specify target weight ranges based on their market needs to optimize product positioning.

4. Flexibility and Resilience

Properties such as bend radius, elasticity, and shock absorption determine how the shoe performs under stress. These technical properties are vital for footwear that promises durability and comfort. Suppliers should provide test data on flexibility and resilience to ensure the shoes meet the functional demands of target markets.

5. Finish and Surface Quality

Surface smoothness, adhesion quality, and finishing details (e.g., gloss, matte) affect the visual appeal and branding options. High-quality surface finishes prevent premature wear and facilitate branding techniques like embossing or printing. For international markets with specific aesthetic standards, this property is a key differentiator.

6. Compliance with Industry Standards

Certifications such as ISO, ASTM, or local regulatory standards (e.g., REACH in Europe, SABS in South Africa) verify that the product meets safety, environmental, and quality benchmarks. B2B buyers should verify compliance to avoid legal issues and facilitate easier customs clearance in different regions.

Common Trade Terms

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce shoes under a buyer’s brand name. Understanding OEM relationships allows buyers to customize designs, specifications, and packaging, ensuring brand consistency across markets. It also impacts lead times and production costs.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce or sell per order. Knowing MOQ helps buyers plan inventory and negotiate pricing. Larger MOQs often reduce unit costs but require more upfront investment, critical for market entry strategies.

3. RFQ (Request for Quotation)

A formal process where buyers solicit pricing, lead times, and terms from multiple suppliers. Using RFQs enables comparative analysis, cost optimization, and clearer communication of technical requirements, especially for complex or customized ionic shoe silhouettes.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs clearance (e.g., FOB, CIF, DDP). Familiarity with Incoterms ensures clarity on who bears costs and risks at each shipping stage, which is crucial for international transactions across diverse regions like Africa, South America, the Middle East, and Europe.

5. Lead Time

The duration from order placement to product delivery. Shorter lead times facilitate faster market response and inventory management, especially in dynamic fashion or sportswear segments. B2B buyers should confirm lead times to align with their supply chain schedules.

6. Quality Control (QC)

Processes and standards for inspecting and ensuring product quality before shipment. Clear QC protocols—such as third-party audits or in-house inspections—reduce the risk of defective products reaching markets, safeguarding brand reputation and customer satisfaction.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions, optimize procurement processes, and establish reliable supply chains for ionic shoes silhouettes tailored to diverse markets.

Illustrative Image (Source: Google Search)

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ionic shoes silhouette Sector

Market Overview & Key Trends

The ionic shoes silhouette sector is experiencing dynamic growth driven by evolving consumer preferences, technological innovation, and global supply chain shifts. As a lightweight, ergonomic footwear style, ionic shoes appeal to health-conscious consumers and athletes, creating significant B2B opportunities across markets.

Emerging trends include the integration of smart materials, customization options, and direct-to-consumer digital platforms that streamline sourcing and distribution. For international B2B buyers from regions like Africa, South America, the Middle East, and Europe—especially countries such as Italy and Colombia—there is a rising demand for high-quality, innovative products that balance performance with style.

Market dynamics are influenced by several factors: technological advancements in manufacturing (e.g., 3D printing, sustainable textiles), trade policies affecting import/export tariffs, and consumer awareness regarding health and sustainability. European buyers, particularly in Italy, focus on premium craftsmanship and design, often seeking partnerships with established or innovative manufacturers. Meanwhile, African and South American markets are rapidly expanding their distribution channels, driven by urbanization and increasing disposable incomes.

For B2B buyers, staying ahead involves monitoring sourcing trends such as near-shoring and diversification of supply chains to mitigate disruptions. Digital procurement platforms and industry expos are vital for discovering new suppliers and establishing strategic alliances. Given the sector’s rapid evolution, maintaining agility and fostering innovation are crucial for capitalizing on emerging opportunities.

Sustainability & Ethical Sourcing

Sustainability has become a pivotal criterion in sourcing ionic shoes, especially as global consumers grow more environmentally conscious. B2B buyers must prioritize suppliers committed to reducing environmental impact through the use of eco-friendly materials and transparent supply chains.

Key environmental considerations include the adoption of biodegradable or recyclable components, such as natural rubber, organic textiles, and low-impact dyes. The production process should minimize carbon footprints, water usage, and waste generation. Suppliers with green certifications—such as ISO 14001, Fair Trade, or Global Organic Textile Standard (GOTS)—offer added assurance of ethical practices and environmental responsibility.

Ethical sourcing extends beyond environmental concerns to social responsibility. It involves ensuring fair labor practices, safe working conditions, and community engagement within supply chains. B2B buyers from Africa, South America, the Middle East, and Europe should establish clear standards and conduct regular audits to verify compliance.

Collaborating with suppliers who hold sustainability certifications not only aligns with global ESG goals but also enhances brand reputation and consumer trust. Additionally, investing in traceability technologies like blockchain can provide transparent documentation of ethical practices and environmental impact, strengthening long-term supplier relationships and market positioning.

Brief Evolution/History

The ionic shoes silhouette originated from advancements in sports footwear technology aimed at optimizing comfort, support, and weight reduction. Initially developed for athletes, these shoes have transitioned into mainstream fashion and lifestyle markets, driven by innovations in materials and design.

For B2B stakeholders, understanding this evolution underscores the importance of technological adaptability and consumer-centric design. Early developments focused on shock absorption and ergonomic benefits, which now integrate smart textiles and sustainable materials. Recognizing this trajectory helps buyers identify suppliers with a proven track record of innovation and quality, essential for maintaining competitive advantage in a fast-changing market.

As the sector continues to evolve, embracing the historical emphasis on performance and health benefits can be leveraged to position ionic shoes as both functional and fashionable products—an appealing proposition for international markets seeking value-added footwear solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of ionic shoes silhouette

1. How can I effectively vet suppliers of ionic shoes silhouette to ensure product quality and reliability?

To ensure supplier credibility, start by requesting comprehensive company credentials, including business licenses, export licenses, and manufacturing certifications such as ISO or CE. Review their product samples and request references from previous international clients, especially from your region. Conduct virtual factory audits or third-party inspections if possible, to verify production capacity and quality control processes. Additionally, assess their communication responsiveness and transparency. Partnering with suppliers who have a strong track record and verifiable certifications minimizes risks and guarantees product consistency for your market.

2. What customization options are typically available for ionic shoes silhouette, and how do they impact lead times and costs?

Most suppliers offer customization in areas such as branding (logos, packaging), color schemes, sole design, and material blends. Advanced customization, like specialized ergonomic features or unique silhouette modifications, may increase both costs and lead times. Generally, standard customizations can be fulfilled within 2-4 weeks, while complex designs may extend to 6-8 weeks or more. Clear communication of your specifications upfront helps in accurate quoting and timeline planning. Negotiating minimum order quantities (MOQs) for customized products is common; ensure these align with your market demand to optimize costs.

3. What are typical minimum order quantities (MOQs) and lead times for ionic shoes silhouette, and how can I negotiate better terms?

MOQs for ionic shoes silhouette often range from 500 to 2,000 pairs, depending on the manufacturer and customization level. Lead times typically span 4-8 weeks from order confirmation to shipment. To negotiate better terms, consider building long-term relationships, which can lead to reduced MOQs or faster production cycles. Consolidate orders to meet minimums efficiently, and discuss flexible payment terms or batch production to improve cash flow. Establishing clear timelines and quality expectations upfront minimizes delays and fosters smoother procurement processes.

4. What payment methods are accepted, and what are best practices for secure transactions in international sourcing?

Common payment methods include letters of credit (LC), telegraphic transfers (T/T), PayPal, and escrow services. For large orders, LCs and T/T are standard and offer security for both parties. Always verify the supplier’s banking details through official channels before transferring funds. To mitigate risks, consider staged payments—pay a deposit upfront and the balance upon shipment or after quality inspection. Using reputable financial institutions and requiring contractual terms that specify penalties for delays or non-compliance further safeguard your investments.

5. What certifications and quality assurance documents should I request from ionic shoes silhouette suppliers?

Essential certifications include ISO 9001 (quality management), CE marking (European safety standards), and any regional compliance certificates relevant to your market (e.g., SABS for South Africa, INMETRO for Brazil). Request detailed Quality Assurance (QA) reports, test certificates for materials, and durability testing results. A reputable supplier should provide a comprehensive Certificate of Compliance (CoC) and be transparent about their QA processes. These documents ensure the product meets your country’s safety and quality standards, reducing regulatory risks and enhancing consumer confidence.

6. How do I manage logistics and shipping for international orders of ionic shoes silhouette, especially to remote regions?

Partner with experienced freight forwarders who understand your target markets’ import regulations, customs procedures, and preferred shipping routes. For cost-efficiency, consider sea freight for large volumes and air freight for urgent deliveries. Ensure your supplier provides detailed shipping documentation, including commercial invoices, packing lists, and certificates of origin. Clarify responsibilities for customs clearance and duties, and explore options like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) terms to allocate risks appropriately. Tracking systems and regular communication help prevent delays and facilitate smooth delivery.

7. What should I do if there is a dispute over product quality or delivery terms?

First, review your contract to understand dispute resolution clauses, including jurisdiction and arbitration options. Document all communications, inspection reports, and photos of any issues promptly. Engage in open dialogue with the supplier to identify the root cause—whether it’s quality, timing, or documentation. Negotiating a mutually agreeable solution, such as product rework, replacement, or financial compensation, is often effective. If resolution stalls, consider involving third-party mediators or legal counsel familiar with international trade laws. Having clear contractual terms and thorough documentation from the start reduces the likelihood of disputes escalating.

8. How can I build a sustainable and trustworthy partnership with ionic shoes silhouette suppliers across different regions?

Start by establishing transparent communication channels and setting clear expectations regarding quality, lead times, and compliance. Regular visits (virtual or physical) and ongoing audits help maintain standards. Invest in building personal relationships and understanding cultural nuances, especially when dealing with suppliers from diverse regions like Africa, South America, the Middle East, or Europe. Long-term partnerships are reinforced through consistent orders, timely payments, and feedback on product performance. Additionally, aligning on sustainability practices—such as eco-friendly materials or ethical labor standards—can enhance trust and brand reputation in your target markets.

This comprehensive FAQ aims to empower international B2B buyers with practical insights, fostering informed decision-making and fostering successful sourcing relationships for ionic shoes silhouette.

Strategic Sourcing Conclusion and Outlook for ionic shoes silhouette

Conclusion and Future Outlook

Effective strategic sourcing of the ionic shoes silhouette offers significant competitive advantages for international B2B buyers across Africa, South America, the Middle East, and Europe. By prioritizing reliable supply chains, quality assurance, and cost optimization, buyers can better meet evolving market demands and consumer preferences. Emphasizing supplier diversification and fostering strong partnerships will mitigate risks associated with global disruptions and raw material shortages.

Illustrative Image (Source: Google Search)

Looking ahead, technological advancements and sustainability initiatives will play a pivotal role in shaping sourcing strategies. Buyers should leverage digital tools for real-time supply chain visibility and pursue eco-friendly manufacturing practices to align with global trends and consumer expectations.

To capitalize on emerging opportunities, international buyers must adopt a proactive approach—building strategic relationships, engaging with innovative suppliers, and continuously monitoring market developments. Embracing these practices will ensure resilience, cost-efficiency, and product differentiation in the competitive ionic shoes market.

Actionable Step: Initiate comprehensive supplier evaluations and foster collaborations that support sustainable and innovative sourcing solutions to secure a competitive edge in this dynamic industry.