Your Ultimate Guide to Sourcing Jds Shoes

Guide to Jds Shoes

- Introduction: Navigating the Global Market for jds shoes

- Understanding jds shoes Types and Variations

- Key Industrial Applications of jds shoes

- Strategic Material Selection Guide for jds shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for jds shoes

- Comprehensive Cost and Pricing Analysis for jds shoes Sourcing

- Spotlight on Potential jds shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for jds shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the jds shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of jds shoes

- Strategic Sourcing Conclusion and Outlook for jds shoes

Introduction: Navigating the Global Market for jds shoes

In today’s dynamic global marketplace, sourcing high-quality footwear like JDS Shoes requires strategic insight and a thorough understanding of international supply chains. As a trusted brand recognized for durability, comfort, and style, JDS Shoes presents a compelling opportunity for B2B buyers across Africa, South America, the Middle East, and Europe—regions eager to meet rising consumer demand with reliable, competitively priced footwear solutions.

This comprehensive guide is designed to empower you with critical knowledge on every aspect of JDS Shoes sourcing—from product varieties and materials to manufacturing standards, quality control, and supplier selection. Understanding these factors enables you to optimize your procurement process, minimize risks, and negotiate effectively in a competitive landscape.

Key topics covered include the different types of JDS Shoes suitable for diverse markets, material innovations, manufacturing practices, and quality assurance protocols. Additionally, the guide offers actionable insights into cost considerations, supplier evaluation, and navigating market trends specific to your region.

By leveraging this knowledge, B2B buyers can make informed sourcing decisions that enhance product quality, reduce lead times, and improve profitability. Whether you’re expanding retail offerings in Nigeria, Colombia, or neighboring markets, or establishing strategic partnerships, this guide equips you with the tools needed to succeed in the evolving global footwear industry.

Understanding jds shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Leather Shoes | Genuine leather uppers, traditional design, standard soles | Retail, wholesale, uniform supply chains | Pros: Durable, premium appeal; Cons: Higher cost, longer lead times |

| Casual Sneakers | Lightweight, flexible, often with synthetic or mesh uppers | Corporate casual wear, bulk orders for uniforms | Pros: Cost-effective, versatile; Cons: Less formal, limited durability |

| Formal Dress Shoes | Sleek, polished finish, often with brogue or oxford styles | Executive apparel, corporate gifting | Pros: High-end appearance, consistent quality; Cons: Higher price point |

| Work & Safety Shoes | Reinforced toe caps, slip-resistant soles, heavy-duty materials | Industrial, construction, logistics | Pros: Safety compliance, long-lasting; Cons: Heavier, less stylish |

| Eco-friendly & Sustainable Shoes | Made from recycled or organic materials, eco-conscious manufacturing | Green procurement, CSR initiatives | Pros: Market differentiation, aligns with sustainability goals; Cons: Limited supply options |

Classic Leather Shoes

Classic leather shoes are the cornerstone of formal footwear, characterized by genuine leather uppers and traditional craftsmanship. They are highly durable and exude a premium image, making them ideal for executive offices, formal events, and uniform supplies for corporate staff. B2B buyers should consider lead times, as high-quality leather shoes often require longer manufacturing periods. Price points tend to be higher, but the investment is justified by longevity and brand perception. Bulk purchasing from reputable manufacturers ensures consistent quality and better negotiation leverage.

Casual Sneakers

Casual sneakers are versatile, lightweight, and designed for comfort, often featuring synthetic or mesh uppers for breathability. They are suitable for corporate casual settings, promotional giveaways, or uniform components for industries with a relaxed dress code. For B2B buyers, cost-effectiveness and quick turnaround times are key advantages. However, their less formal appearance and reduced durability compared to formal shoes mean they are better suited for short-term or casual use. Sourcing from manufacturers with scalable production capabilities ensures timely delivery and competitive pricing.

Formal Dress Shoes

Formal dress shoes include oxford, brogue, or derby styles, polished to a high sheen. They are predominantly used in executive settings, corporate gifting, or uniform programs targeting professional environments. Buyers should focus on suppliers with a proven track record of consistent finishing and sizing accuracy. While these shoes command premium prices, they offer high aesthetic appeal and can enhance corporate branding efforts. Volume discounts and quality certifications are critical for large B2B orders, especially when maintaining uniformity across a workforce.

Work & Safety Shoes

Designed for industrial environments, work and safety shoes feature reinforced toes, slip-resistant soles, and heavy-duty materials to meet safety standards. They are essential for logistics, construction, and manufacturing sectors. B2B buyers must prioritize certifications (e.g., ISO, ANSI), durability, and comfort for end-users. Bulk procurement benefits from establishing long-term relationships with manufacturers who can provide consistent stock and customization options. Though heavier and less fashionable, these shoes are crucial for compliance and safety, making them a necessary investment for industrial clients.

Eco-friendly & Sustainable Shoes

This category encompasses shoes made from recycled, organic, or biodegradable materials, aligning with global sustainability trends. They are increasingly sought after by companies aiming to enhance their CSR profiles or meet environmental standards. For B2B buyers, sourcing reliable suppliers with certified eco-friendly processes is vital. Although these shoes may have limited styles or higher costs initially, they open opportunities for brand differentiation and access to niche markets. Long-term partnerships with eco-conscious manufacturers can ensure supply stability and support sustainability commitments.

Key Industrial Applications of jds shoes

| Industry/Sector | Specific Application of jds shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Downhole tools and wellhead equipment | Ensures reliable sealing and high-pressure resistance, reducing downtime | Material compatibility with hydrocarbons, API certification, durability under extreme conditions |

| Chemical Processing | Seals and gaskets in aggressive chemical environments | Provides chemical resistance, preventing leaks and corrosion | Compatibility with aggressive media, compliance with international safety standards |

| Power Generation | Turbine and valve seals | Maintains operational integrity in high-temperature, high-pressure settings | Heat resistance, long service life, ease of installation |

| Mining & Heavy Industry | Conveyor belt and machinery seals | Enhances equipment lifespan, reduces maintenance costs | Abrasion resistance, robustness in rugged environments, supply chain reliability |

| Construction & Infrastructure | Waterproofing and sealing solutions for infrastructure projects | Ensures longevity and safety of structures, especially in harsh climates | Weather resistance, adaptability to diverse substrates, cost-effectiveness |

Oil & Gas

JDS shoes are extensively used in oil and gas exploration and production, particularly in downhole tools and wellhead equipment. Their primary role is to provide a reliable seal under extreme pressure and temperature conditions, preventing leaks that could lead to costly downtime or environmental hazards. For international B2B buyers from regions like Nigeria or Colombia, sourcing JDS shoes with API certification and proven chemical compatibility is crucial. These applications demand high durability and precise manufacturing standards to withstand corrosive media and mechanical stresses, ensuring operational safety and efficiency.

Chemical Processing

In chemical processing plants, JDS shoes serve as critical components in seals and gaskets exposed to aggressive chemicals. Their resistance to corrosive media minimizes the risk of leaks, spills, and equipment failure, which is vital for maintaining safety and regulatory compliance. Buyers from the Middle East or South America should prioritize sourcing JDS shoes made from chemically resistant materials, with certifications confirming compliance with international safety standards. This ensures long-term performance and reduces maintenance costs in demanding environments.

Power Generation

JDS shoes are used in turbines and valves within power plants to maintain high-pressure and high-temperature integrity. Their ability to withstand thermal stresses and chemical exposure makes them ideal for ensuring the continuous and safe operation of energy infrastructure. For European or Middle Eastern buyers, sourcing JDS shoes with excellent heat resistance and proven longevity is essential. These applications require components that can endure operational stresses over extended periods, reducing downtime and maintenance expenses.

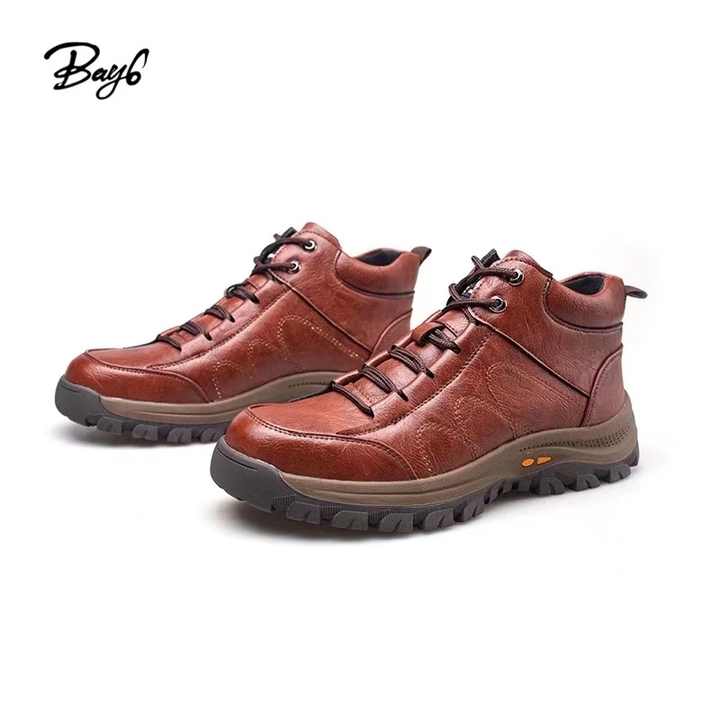

Illustrative Image (Source: Google Search)

Mining & Heavy Industry

In mining and heavy industries, JDS shoes function as seals for conveyor belts, crushers, and other machinery. Their robustness in rugged environments helps prevent dust ingress, contamination, and mechanical wear, thereby extending equipment lifespan. International buyers from Africa or South America should focus on sourcing JDS shoes with high abrasion resistance and proven durability in harsh conditions. Reliable supply chains and consistent quality are critical to minimizing operational disruptions and optimizing maintenance schedules.

Construction & Infrastructure

JDS shoes are integral to waterproofing and sealing in large-scale infrastructure projects, especially in regions prone to extreme weather conditions. They help ensure the longevity and safety of bridges, tunnels, and other structures by providing effective sealing against water ingress and environmental stressors. Buyers from Europe or the Middle East should select JDS shoes with proven weather resistance, adaptability to different substrates, and competitive pricing. Proper sourcing guarantees structural integrity and reduces long-term maintenance costs in challenging climates.

Strategic Material Selection Guide for jds shoes

Analysis of Common Materials for jds Shoes from a B2B Perspective

Selecting the appropriate materials for jds shoes is critical for ensuring product performance, durability, and compliance with international standards. For B2B buyers across Africa, South America, the Middle East, and Europe, understanding the properties, advantages, and limitations of key materials can facilitate better procurement decisions and optimize supply chain outcomes.

Leather (Full-Grain and Genuine Leather)

Key Properties:

Leather remains a primary material in high-quality footwear, valued for its breathability, flexibility, and aesthetic appeal. It offers moderate water resistance when properly treated and can withstand considerable wear and tear. Leather’s natural properties allow it to conform to foot shape over time, enhancing comfort.

Pros & Cons:

* Pros:*

– Excellent durability and aging characteristics

– Breathability reduces foot odor and moisture buildup

– Aesthetic versatility, suitable for premium branding

- Cons:*

- Higher cost compared to synthetic alternatives

- Requires specialized tanning and finishing processes, increasing manufacturing complexity

- Sensitive to environmental conditions such as humidity and extreme temperatures, which can cause cracking or mold

Impact on Application:

Leather is suitable for dress shoes, casual footwear, and premium jds shoes. It performs well in dry to moderately humid environments but may require additional treatment for water resistance in wet climates.

International Considerations:

Buyers from regions like Nigeria, Colombia, or Middle Eastern markets should ensure leather suppliers comply with environmental and ethical standards such as the Leather Working Group (LWG) certification. European markets often demand high-quality, sustainably sourced leather, influencing procurement choices.

Synthetic Polymers (EVA, PU, and PVC)

Key Properties:

Synthetic materials like Ethylene Vinyl Acetate (EVA), Polyurethane (PU), and Polyvinyl Chloride (PVC) are widely used for midsoles, outsoles, and sometimes uppers. They are lightweight, flexible, and can be manufactured with consistent quality. These materials often offer good shock absorption and water resistance.

Pros & Cons:

* Pros:*

– Cost-effective and suitable for mass production

– Lightweight, reducing overall shoe weight and enhancing comfort

– Resistant to water, chemicals, and environmental degradation

- Cons:*

- Generally less durable than natural materials, especially in high-wear zones

- May degrade under UV exposure over time

- Environmental concerns regarding non-biodegradability and recycling challenges

Impact on Application:

Ideal for casual, athletic, or work shoes where cost and weight are critical. They are less suitable for high-end fashion or premium applications requiring natural aesthetics.

International Considerations:

Buyers should verify compliance with local safety standards, such as REACH in Europe or ASTM standards in the US. For markets with strict environmental regulations, sourcing from manufacturers with eco-friendly certifications (e.g., GreenScreen) can be advantageous.

Rubber (Natural and Synthetic)

Key Properties:

Rubber offers excellent elasticity, grip, and water resistance. Natural rubber provides superior resilience and flexibility, while synthetic variants like SBR (Styrene-Butadiene Rubber) are tailored for specific performance needs.

Pros & Cons:

* Pros:*

– Exceptional durability and slip resistance

– Good weather resistance, especially in waterproof applications

– Suitable for outsoles and waterproof components

- Cons:*

- Natural rubber can be susceptible to ozone and UV degradation if not properly treated

- Synthetic rubbers may have inconsistent quality depending on manufacturing standards

- Cost varies depending on grade and source

Impact on Application:

Primarily used for outsoles, waterproof linings, and protective components. Its properties make it suitable for outdoor or work shoes in harsh climates.

International Considerations:

Buyers should ensure compliance with environmental regulations, especially concerning latex allergies and sustainable sourcing. Certifications like ISO 9001 and ISO 14001 can indicate quality and environmental management standards.

Summary Table

| Material | Typical Use Case for jds shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Dress shoes, casual footwear, premium collections | Durability, aesthetic appeal, breathability | Higher cost, sensitive to environmental conditions | High |

| Synthetic Polymers | Midsoles, outsoles, casual and athletic shoes | Cost-effective, lightweight, water-resistant | Less durable, environmental concerns | Low |

| Rubber | Outsoles, waterproof components | Excellent grip, durability, weather resistance | Cost varies, susceptible to ozone/UV degradation | Med |

| Textile (N/A) | Linings, uppers in casual or sport shoes | Breathability, lightweight, variety in design | Less durable, susceptible to wear and tear | Low to Med |

This comprehensive understanding of material properties enables international B2B buyers to make informed procurement decisions aligned with regional market demands, environmental standards, and product performance expectations. Tailoring material choices to specific applications and regional conditions will optimize product quality, compliance, and customer satisfaction across diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for jds shoes

Manufacturing Processes of JDS Shoes

Understanding the manufacturing workflow of JDS shoes is essential for B2B buyers aiming to establish reliable supply chains. The process typically unfolds in several critical stages, each demanding precision and adherence to quality standards.

1. Material Preparation

The journey begins with sourcing high-quality raw materials, including leather, synthetic textiles, rubber, and adhesives. Suppliers often select materials based on durability, comfort, and compliance with international standards such as ISO 9001. For buyers in regions like Africa, South America, the Middle East, and Europe, verifying the authenticity and quality certifications of these materials is vital to prevent counterfeit or substandard inputs.

2. Forming and Cutting

In this stage, raw materials are cut into patterns using automated cutting machines or manual templates, depending on the factory’s sophistication. Laser cutting and computer-aided design (CAD) systems are increasingly prevalent, ensuring precision and reducing waste. Properly cut components are crucial for fitting and durability, so B2B buyers should inquire about machine calibration and operator expertise.

3. Assembly and Stitching

Components such as uppers, linings, and insoles are assembled through sewing, bonding, or a combination of both. Advanced stitching techniques like double-stitched seams enhance durability, especially for footwear intended for rigorous use. Factories may employ automated sewing robots or skilled artisans, with the choice impacting consistency and quality.

4. Finishing and Quality Control

Finally, the shoes undergo finishing processes—applying polish, attaching soles, and adding decorative elements. This phase also includes inspection for aesthetic and structural flaws. The use of automated finishing equipment ensures uniformity, while manual touch-ups allow for detailed quality checks. Packaging is then carried out according to international standards, with attention to branding and protection during transit.

Quality Assurance (QA) and Quality Control (QC) Frameworks

Robust quality assurance is fundamental to ensuring that JDS shoes meet both international standards and specific buyer requirements. An effective QC system involves multiple checkpoints and compliance with recognized certifications.

1. International Standards Compliance

- ISO 9001: Most reputable JDS manufacturing facilities operate under ISO 9001 certification, demonstrating commitment to quality management systems. For B2B buyers, verifying ISO certificates during supplier audits provides confidence in consistent product quality.

- Additional Certifications: Depending on the target market, certifications such as CE (European conformity), ASTM standards, or API (for specific industrial applications) may be relevant. Confirming these certifications ensures compliance with local regulations and reduces market entry risks.

2. QC Checkpoints

- Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival. Tests include visual inspection, material testing (e.g., leather tannin levels, rubber elasticity), and dimensional checks.

- In-Process Quality Control (IPQC): Conducted during manufacturing, IPQC ensures each production stage adheres to specifications. For example, stitching quality, sole attachment strength, and structural integrity are monitored regularly.

- Final Quality Control (FQC): Before shipment, finished shoes undergo comprehensive inspection, including visual checks for defects, measurement verification, and functional tests like flexing and adhesion strength.

3. Testing Methods

- Durability Tests: Simulate wear conditions, including flexing, abrasion, and water resistance tests, to ensure longevity.

- Comfort and Fit: Assessed through ergonomic testing and, where applicable, biomechanical analysis.

- Environmental Testing: Resistance to temperature variations, UV exposure, and moisture, particularly important for shoes destined for diverse climatic zones.

Verifying Supplier Quality for International B2B Buyers

Given the variability in manufacturing capabilities, B2B buyers must implement rigorous verification processes to ensure supplier reliability.

1. Conduct Supplier Audits

- On-site Inspections: Visiting manufacturing facilities allows buyers to evaluate equipment, working conditions, and quality processes firsthand.

- Third-party Audits: Engaging reputable inspection agencies (e.g., SGS, Bureau Veritas) provides unbiased assessments of compliance and quality systems.

2. Review Quality Reports and Certifications

- Request detailed QA/QC reports, test certificates, and ISO or other relevant certifications.

- Verify the authenticity of certificates through issuing bodies or online verification portals.

3. Sample Testing

- Prior to bulk orders, procure samples for independent testing based on agreed specifications.

- Use local testing labs or third-party agencies familiar with regional standards to assess product conformity.

4. Ongoing Quality Monitoring

- Implement regular audits and quality reviews during production runs.

- Establish clear communication channels for defect reporting and corrective actions.

Nuances of QC and Certification for Buyers from Different Regions

International B2B transactions require sensitivity to regional standards, customs, and expectations.

- Africa (e.g., Nigeria): Emphasize compliance with local import regulations, which may include specific safety standards or customs certifications. Engage with local inspection agencies for pre-shipment verification.

- South America (e.g., Colombia): Ensure products meet regional environmental standards and labeling requirements. Certification of eco-friendly materials may also be advantageous.

- Middle East: Focus on certifications like CE or Gulf Standards (GSO). Water resistance and thermal insulation qualities are often scrutinized.

- Europe: Strict adherence to CE standards, REACH regulations, and sustainability certifications (e.g., OEKO-TEX) is essential. European buyers often demand detailed documentation and traceability.

Final Recommendations for B2B Buyers

- Establish Clear Quality Agreements: Define specifications, testing procedures, and acceptance criteria upfront.

- Leverage Technology: Use digital platforms for real-time quality monitoring and documentation sharing.

- Partner with Reputable Inspection Agencies: Ensure unbiased third-party verification, especially when dealing with new or unverified suppliers.

- Maintain Flexibility: Be prepared for regional variations in standards and adapt quality expectations accordingly.

- Build Long-term Relationships: Regular audits and open communication foster trust, leading to improved quality and reliability over time.

By understanding and rigorously managing manufacturing and quality assurance processes, international buyers from Africa, South America, the Middle East, and Europe can secure high-quality JDS shoes that meet their market demands and regulatory requirements.

Comprehensive Cost and Pricing Analysis for jds shoes Sourcing

Cost Structure Overview for JDS Shoes Sourcing

Understanding the comprehensive cost structure of JDS Shoes is crucial for international buyers aiming to optimize procurement strategies. The primary components include raw materials, labor, manufacturing overheads, tooling, quality control, logistics, and profit margins.

Materials typically constitute 40-50% of the total production cost, with the choice of synthetic or genuine leather, textiles, and rubber influencing both price and quality. Sourcing high-quality, certified materials might increase costs but can significantly enhance product durability and brand reputation.

Labor costs in manufacturing countries like China or Vietnam (common JDS production hubs) are relatively low compared to Europe or the Middle East, often ranging from $2 to $5 per pair for assembly. However, labor costs are impacted by skill level, labor laws, and minimum wage regulations.

Manufacturing overheads encompass factory utilities, machinery depreciation, and indirect labor, typically adding 10-15% to the base costs. Tooling and setup fees are usually one-time expenses that can range from $500 to $2,000 per model, depending on complexity, and should be amortized over large order volumes.

Quality control (QC) processes—especially if certification standards like ISO or specific regional standards are required—can add 5-10% to the cost but are vital for compliance and reducing returns or rework.

Logistics costs include shipping, customs duties, and insurance, which vary depending on destination country, shipping method, and incoterms. For example, FOB (Free on Board) terms shift responsibility to the buyer after loading at origin port, while CIF (Cost, Insurance, Freight) includes shipping costs in the price, affecting upfront costs but offering more predictability.

Profit margins for suppliers typically range between 10-20%, depending on order volume and negotiation. Larger, consistent orders often secure better margins and priority treatment.

Price Influencers and Their Impact

Several factors significantly influence the final pricing of JDS shoes:

-

Order Volume & MOQ: Larger orders reduce per-unit costs due to economies of scale. Many suppliers prefer MOQs of 500–1,000 pairs, but flexible negotiations can lower this threshold, especially for emerging markets.

-

Specifications & Customization: Custom designs, branding, or specialized materials increase costs. Detailed specifications require additional tooling or adjustments, impacting both setup and unit costs.

-

Materials & Certifications: Using premium or certified materials (e.g., eco-friendly, vegan, or region-specific standards) raises material costs but can command higher retail prices and meet market expectations.

-

Quality & Certifications: Higher quality standards and certifications (ISO, environmental standards, safety certifications) often entail additional testing and compliance costs, but they are critical for market acceptance in regions like Europe and the Middle East.

-

Supplier Factors: Supplier reputation, production capacity, and proximity influence pricing. Established factories with reliable quality often charge a premium but offer consistency and compliance.

-

Incoterms & Logistics: The choice of incoterms impacts cost and risk distribution. Buyers should weigh FOB options for cost control against CIF options for logistical convenience, especially when dealing with complex import regulations.

Tips for International B2B Buyers

-

Negotiate for Better Terms: Leverage order volume and long-term partnerships to negotiate discounts, flexible MOQs, or inclusive logistics services. Building rapport can also lead to better payment terms and priority production.

-

Focus on Total Cost of Ownership (TCO): Don’t just compare unit prices; consider shipping, duties, customs clearance, and potential rework costs. A slightly higher unit price with lower logistics costs can be more economical overall.

-

Understand Pricing Nuances: Prices can vary based on regional demand, currency fluctuations, and regional tariffs. Stay informed about import duties in your country—Africa, South America, the Middle East, and Europe often have different tariffs that impact landed cost.

-

Leverage Volume & Lead Time: Larger, consistent orders and shorter lead times can unlock discounts and priority manufacturing slots, reducing overall procurement costs.

Disclaimer

Indicative prices and cost components provided here are averages based on current industry data and may vary depending on specific supplier negotiations, order size, and regional factors. Buyers should conduct detailed due diligence and request formal quotations tailored to their exact requirements to obtain accurate pricing.

By thoroughly understanding these cost components and influencing factors, international B2B buyers from regions like Nigeria, Colombia, or the Middle East can make informed sourcing decisions that optimize both cost efficiency and product quality.

Spotlight on Potential jds shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for jds shoes.)*

Essential Technical Properties and Trade Terminology for jds shoes

Critical Technical Properties for JDS Shoes

1. Material Grade and Composition

The quality and durability of JDS shoes heavily depend on the grade of materials used, such as leather, synthetic fabrics, and rubber soles. Higher-grade materials typically offer better longevity, comfort, and aesthetic appeal. For B2B buyers, specifying material grades ensures consistency across batches and aligns with end-user expectations, especially in markets demanding premium quality like Europe or South America.

2. Sole Thickness and Flexibility

The thickness and flexibility of the sole influence comfort, grip, and overall product performance. Thicker soles often provide better shock absorption, suitable for outdoor or industrial use, while flexibility is critical for casual or dress shoes. Understanding these specifications helps buyers select products tailored to regional preferences and usage conditions.

3. Tolerance and Size Accuracy

Tolerance refers to the allowable variation in shoe dimensions during manufacturing. Precise tolerances (e.g., ±1 mm) ensure proper fit, reduce returns, and enhance customer satisfaction. For international trade, clear tolerance standards facilitate quality control and consistency across production lots, especially when manufacturing in different regions.

4. Finish and Surface Treatment

Surface properties such as polish, embossing, or waterproofing impact the shoe’s appearance and functionality. High-quality surface finishes increase the product’s visual appeal and durability, essential for premium markets. Buyers should specify finish standards to maintain brand consistency and meet regional climate demands.

5. Weight and Balance

The weight of the shoe affects comfort, especially for work or travel footwear. Balanced weight distribution enhances wearability, reducing fatigue over extended use. Understanding weight specifications helps buyers recommend suitable options for their target demographic.

Common Industry and Trade Terms

1. OEM (Original Equipment Manufacturer)

Refers to manufacturers that produce shoes based on a buyer’s design and specifications. Engaging with OEMs allows buyers to customize products, ensuring branding and design align with regional market preferences. For international buyers, establishing OEM relationships can also enable better control over quality and exclusivity.

2. MOQ (Minimum Order Quantity)

The smallest number of units a supplier is willing to produce or sell in a single order. MOQs impact procurement planning, especially for buyers with limited storage or initial market testing. Negotiating MOQs is crucial to balance cost efficiency with market entry strategies.

3. RFQ (Request for Quotation)

A formal process where buyers solicit price and lead-time estimates from multiple suppliers. Sending a detailed RFQ helps compare offers on price, quality, and delivery terms, enabling informed purchasing decisions. For international trade, clear RFQs reduce misunderstandings and streamline negotiations.

4. Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce, defining responsibilities for shipping, insurance, and tariffs. Common Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) clarify who bears costs and risks at each stage, critical for international buyers managing logistics across borders.

5. Lead Time

The duration from order placement to product delivery. Understanding lead times helps buyers plan inventory and align production schedules, especially in markets with seasonal demand or tight delivery windows.

6. Quality Certification

Standards such as ISO, CE, or local compliance marks indicate adherence to safety, environmental, or quality standards. Confirming certification ensures products meet regional regulations, reducing customs delays and enhancing market credibility.

Strategic Insights for International B2B Buyers

For buyers from Africa, South America, the Middle East, and Europe, understanding these technical properties and trade terms is essential for effective sourcing and risk mitigation. Clear communication of specifications ensures product consistency, while familiarity with trade terminology facilitates smoother negotiations and logistics planning. Establishing relationships with reliable OEMs, negotiating favorable MOQs, and understanding Incoterms will optimize supply chains and improve market competitiveness. Prioritize detailed RFQs and quality certifications to safeguard quality and compliance across diverse markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the jds shoes Sector

Market Overview & Key Trends

The global footwear industry is experiencing robust growth driven by evolving consumer preferences, technological innovations, and shifting supply chain dynamics. For B2B buyers in Africa, South America, the Middle East, and Europe, understanding these drivers is essential to capitalize on emerging opportunities within the jds shoes sector.

Emerging trends include the integration of digital technologies such as AI-driven inventory management, 3D printing for prototyping, and e-commerce platforms that facilitate direct sourcing and bulk purchasing. These advancements enable more agile and cost-effective procurement processes, especially critical for buyers navigating diverse markets. Additionally, the rise of fast fashion and mass customization demands more flexible sourcing arrangements, encouraging brands like jds shoes to adopt shorter lead times and localized manufacturing partnerships.

Market dynamics are influenced by fluctuating raw material costs—particularly leather, synthetic fabrics, and rubber—and geopolitical factors affecting trade policies and tariffs. For African buyers, local sourcing options are expanding, but reliance on imports remains prevalent, necessitating strategic supplier relationships. South American and Middle Eastern buyers should monitor regional trade agreements and logistics infrastructure improvements, which can reduce costs and delivery times.

European buyers, often driven by sustainability standards and quality assurance, seek suppliers with proven compliance and technological capabilities. International B2B buyers must stay attuned to market shifts such as the growing demand for athleisure and eco-friendly footwear, which are shaping sourcing strategies. Building diversified supplier networks across regions can mitigate risks associated with supply chain disruptions and currency fluctuations, ensuring resilience and competitive advantage.

Sustainability & Ethical Sourcing in B2B

Sustainability has transitioned from a corporate social responsibility (CSR) initiative to a core requirement in B2B sourcing for jds shoes. Buyers across Africa, South America, the Middle East, and Europe are increasingly prioritizing suppliers with transparent, ethical supply chains that adhere to environmental and social standards.

Environmental impacts of footwear production—such as water consumption, chemical use, and waste generation—are under scrutiny. Sourcing from suppliers with eco-friendly certifications like ISO 14001, OEKO-TEX, or GOTS helps mitigate reputational risks and aligns with consumer expectations for greener products. The adoption of sustainable materials, such as recycled fabrics, bio-based leathers, and biodegradable soles, is gaining momentum among manufacturers aiming to reduce carbon footprints.

For B2B buyers, establishing partnerships with suppliers committed to ethical practices involves verifying labor conditions, fair wages, and workers’ rights. Certifications like Fair Trade and Sedex are valuable indicators of ethical compliance. Incorporating sustainability clauses into contracts and conducting regular audits can ensure ongoing adherence. Additionally, transparency in sourcing—such as traceability of raw materials—fosters trust and aligns with global standards, especially for European buyers who face strict regulatory environments.

Investing in sustainability not only enhances brand reputation but also opens access to premium markets willing to pay a premium for ethically produced footwear. As consumer awareness grows, integrating ‘green’ certifications and sustainable practices into procurement strategies becomes a strategic differentiator for international B2B buyers.

Illustrative Image (Source: Google Search)

Brief Evolution/History (Optional)

The jds shoes sector has evolved from traditional craftsmanship to a modern, technology-driven industry. Initially rooted in local artisanal manufacturing, the brand has expanded globally by adopting innovative production techniques and quality standards. This evolution reflects a broader industry shift toward scalability, sustainability, and compliance with international regulations. For B2B buyers, understanding this history underscores the importance of partnering with manufacturers committed to continuous improvement, technological adoption, and ethical practices—key factors influencing supply chain stability and product quality today.

Frequently Asked Questions (FAQs) for B2B Buyers of jds shoes

1. How can I verify the legitimacy and reliability of JDS Shoes suppliers?

Verifying supplier legitimacy is crucial for minimizing risks. Start by requesting business licenses, certifications, and trade references. Conduct online research to check for company registration details, reviews, and reputation in the industry. Request samples to assess product quality firsthand. Consider visiting the supplier’s factory if feasible or engaging third-party inspection services for factory audits. Additionally, ensure the supplier is responsive and transparent in communication, and confirm their compliance with international trade standards. Using platforms like Alibaba’s verified supplier program or industry-specific directories can also help identify reputable partners.

2. What customization options are available, and how do they impact lead times and costs?

JDS Shoes often offers various customization options, including branding (logos, tags), colorways, sole designs, and packaging. The extent of customization can influence both production lead times and costs—more complex designs or large branding orders typically require longer lead times and higher minimum order quantities (MOQs). To optimize planning, clearly communicate your specifications early and request detailed quotes with estimated lead times. Establishing a strong relationship with your supplier can also facilitate smoother customization processes and negotiate better terms, especially for recurring orders or large volume projects.

3. What are typical minimum order quantities (MOQs), lead times, and payment terms for international B2B orders?

MOQs for JDS Shoes generally range from 500 to 1,000 pairs, depending on the style and customization level. Lead times vary from 4 to 12 weeks, influenced by order complexity, customization, and supplier capacity. Payment terms often include a 30% upfront deposit with the balance paid before shipment, though terms can be negotiated based on order size and buyer-supplier relationship. Establish clear contractual agreements, and consider trade financing options like letters of credit or escrow services to secure payments and mitigate risks. Early planning and consistent communication help align expectations and ensure timely delivery.

4. What quality assurance and certification standards should I look for when sourcing JDS Shoes internationally?

Ensure the supplier adheres to international quality standards such as ISO 9001 for quality management. Request certificates of compliance, including CE marking for European markets, or other relevant safety and environmental certifications depending on your target region. Conduct or commission third-party inspections during production and before shipment to verify adherence to agreed specifications. Quality assurance should cover material authenticity, durability, comfort, and safety standards. Maintaining detailed inspection reports and certification documentation is vital for customs clearance and building trust with your customers.

5. How can I manage logistics and shipping effectively for international orders of JDS Shoes?

Effective logistics management involves selecting reliable freight forwarders experienced in international trade. Consider options such as sea freight for cost efficiency on large shipments or air freight for urgent deliveries. Work with your supplier to coordinate packaging, labeling, and documentation to meet import regulations. Use Incoterms (e.g., FOB, CIF) to clearly define responsibilities and costs. Establish tracking systems for shipments and maintain open communication with logistics providers. Planning ahead for customs clearance, tariffs, and duties specific to your country will help prevent delays and unexpected expenses.

6. How should I handle disputes or quality issues with JDS Shoes suppliers?

Disputes are best addressed through clear, written contractual terms covering quality standards, inspection rights, and dispute resolution processes. Maintain detailed records of all communications, inspections, and shipment documents. If issues arise, communicate promptly with your supplier to seek a mutually agreeable solution, such as product replacement or refund. Consider including arbitration clauses or choosing dispute resolution centers familiar with international trade. Building a strong, transparent relationship from the outset can prevent many conflicts, but always have a contingency plan, such as engaging third-party mediators or legal counsel familiar with international trade laws.

Illustrative Image (Source: Google Search)

7. What are the key considerations for ensuring compliance with import regulations in my country?

Familiarize yourself with your country’s import regulations, tariffs, and product standards specific to footwear. Ensure your supplier provides accurate and complete commercial invoices, packing lists, and certificates of origin to facilitate customs clearance. Verify if any specific labeling, safety, or environmental standards apply to footwear imports. Working with experienced customs brokers or trade consultants can streamline the process and prevent delays. Staying updated on regulatory changes and maintaining good documentation will also protect your business from potential penalties or shipment holds.

8. What strategies can I adopt to build long-term, mutually beneficial relationships with JDS Shoes suppliers?

Developing long-term partnerships requires consistent communication, timely payments, and collaborative planning. Invest in building trust by providing clear forecasts and feedback, and consider ordering in larger quantities to secure better pricing and priority service. Regular visits, whether virtual or physical, can strengthen relationships and facilitate better understanding of each other’s capabilities. Be transparent about your business needs and growth plans, and explore opportunities for joint development or exclusive designs. Recognizing supplier efforts and maintaining professionalism will foster loyalty, ensuring reliable supply chains and priority access to new collections.

Strategic Sourcing Conclusion and Outlook for jds shoes

Conclusion and Forward Outlook

Effective strategic sourcing is pivotal for international buyers seeking to capitalize on JDS Shoes’ competitive advantages, including quality craftsmanship and cost efficiency. By establishing strong supplier relationships, leveraging local sourcing options, and continuously monitoring global market trends, B2B buyers from Africa, South America, the Middle East, and Europe can secure reliable supply chains and negotiate better terms.

In today’s dynamic global landscape, proactive sourcing strategies not only mitigate risks but also unlock opportunities for innovation and differentiation in competitive markets. Embracing digital tools, such as supplier analytics and e-procurement platforms, can further streamline procurement processes and enhance decision-making.

Looking ahead, the key to success lies in building resilient, adaptable supply networks that align with evolving market demands. International buyers should prioritize due diligence, foster transparent partnerships, and explore emerging sourcing hubs to maintain a competitive edge. Now is the moment to forge strategic alliances with JDS Shoes, unlocking sustainable growth and ensuring long-term supply chain stability across diverse regions.