Master Sourcing High-Quality Jelly Shoes 80s for Global B2B

Guide to Jelly Shoes 80S

- Introduction: Navigating the Global Market for jelly shoes 80s

- Understanding jelly shoes 80s Types and Variations

- Key Industrial Applications of jelly shoes 80s

- Strategic Material Selection Guide for jelly shoes 80s

- In-depth Look: Manufacturing Processes and Quality Assurance for jelly shoes 80s

- Comprehensive Cost and Pricing Analysis for jelly shoes 80s Sourcing

- Spotlight on Potential jelly shoes 80s Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for jelly shoes 80s

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the jelly shoes 80s Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of jelly shoes 80s

- Strategic Sourcing Conclusion and Outlook for jelly shoes 80s

Introduction: Navigating the Global Market for jelly shoes 80s

In today’s dynamic global footwear market, jelly shoes from the 1980s have experienced a remarkable resurgence, capturing consumer interest across diverse regions. For international B2B buyers—especially from Africa, South America, the Middle East, and Europe—understanding the nuances of this niche offers a significant competitive advantage. These vibrant, versatile, and nostalgic products appeal to a broad demographic, from fashion-forward youth to lifestyle brands seeking retro-inspired collections.

This comprehensive guide is designed to empower you with critical insights into sourcing high-quality jelly shoes from the 80s era. It covers a wide spectrum of essential topics, including different types and materials used in manufacturing, quality control standards, reliable suppliers, and cost considerations. Additionally, it delves into current market trends, consumer preferences, and practical FAQs to facilitate confident decision-making.

By equipping you with this knowledge, the guide aims to streamline your sourcing process, reduce risks, and enhance your product offerings. Whether you are establishing new supply chains or expanding existing ones, understanding the intricacies of the jelly shoes 80s market enables you to capitalize on a growing niche. Ultimately, this resource helps you navigate the complexities of international sourcing, ensuring you make informed, strategic choices that drive your business success.

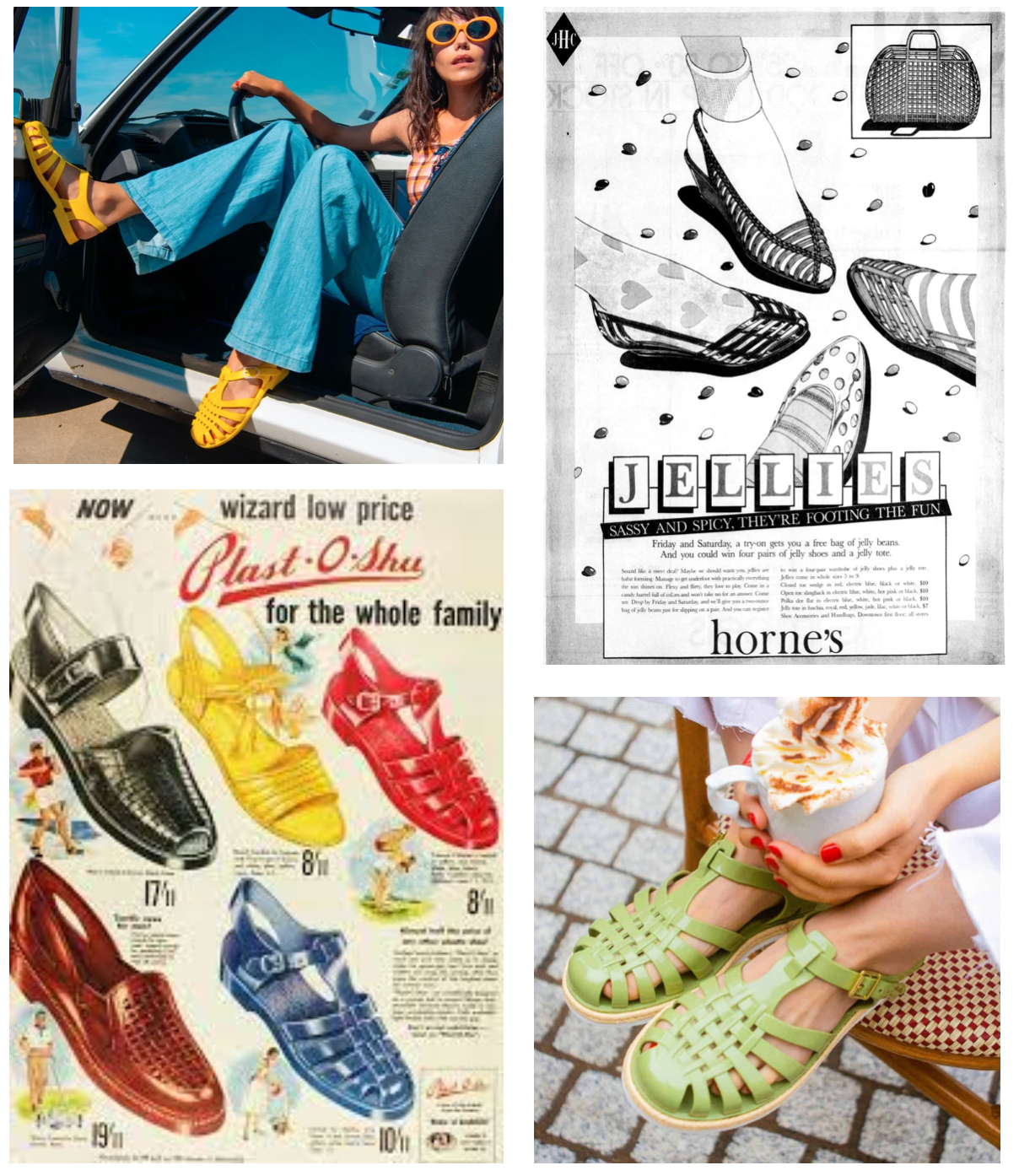

Illustrative Image (Source: Google Search)

Understanding jelly shoes 80s Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Transparent Jelly | Fully transparent, flexible PVC material, minimal embellishments | Retail footwear, fashion boutiques, promotional giveaways | Pros: High visual appeal, versatile styling options; Cons: Limited durability under heavy use |

| Embellished Jelly | Features added decorations like glitter, bows, or charms | Fashion-forward retail, seasonal collections | Pros: Attractive for niche markets, high-margin potential; Cons: Higher production costs, limited flexibility for mass production |

| Platform Jelly Shoes | Elevated soles with chunky or wedge designs | Trend-focused retail, youth markets | Pros: Trendy appeal, higher price points; Cons: Bulkier inventory, shipping considerations due to size |

| Children’s Jelly Shoes | Smaller sizes, playful colors, durable yet lightweight | Children’s apparel stores, gift markets | Pros: Consistent demand, durable for active use; Cons: Smaller size range, safety standards compliance needed |

| Customizable Jelly | Modular designs allowing for color or accessory swaps | Custom fashion brands, promotional products | Pros: High customization, brand engagement; Cons: Complex logistics, longer lead times |

Classic Transparent Jelly

This variation epitomizes the original 80s jelly shoe aesthetic—clear, flexible PVC that molds comfortably to the foot. It appeals broadly in retail markets, especially for fashion boutiques and promotional campaigns due to its visual versatility. For B2B buyers, sourcing reliable manufacturers capable of maintaining consistent transparency and quality is vital. While these shoes are cost-effective and popular for seasonal collections, they may face durability issues under heavy or prolonged use, making them suitable mainly for fashion or short-term promotional purposes.

Embellished Jelly

Embellished jelly shoes incorporate decorative elements like glitter, bows, or charms, elevating their fashion appeal. They are ideal for niche markets targeting consumers seeking unique, eye-catching footwear. For B2B buyers, this category offers higher margins but demands careful supplier vetting to ensure quality embellishments and consistent design execution. These shoes tend to be more expensive to produce, and their delicate decorations may limit their durability, requiring strategic inventory planning to avoid excess unsellable stock.

Platform Jelly Shoes

Characterized by thick, elevated soles—often wedge or chunky styles—platform jellies resonate with youth and trend-conscious consumers. They are suitable for retail outlets focusing on seasonal or statement footwear collections. For buyers, sourcing stable, high-quality sole materials is critical to prevent cracking or separation. These shoes command higher retail prices but involve larger, bulkier inventories, which impact shipping and storage logistics. Their distinctive style makes them a popular choice for fashion-forward markets in Africa, South America, and Europe.

Illustrative Image (Source: Google Search)

Children’s Jelly Shoes

Designed specifically for younger consumers, these shoes feature smaller sizes, playful colors, and durable yet lightweight PVC construction. They are a staple in children’s apparel stores and gift markets, with consistent demand driven by seasonal trends and school-related needs. B2B buyers should prioritize suppliers with safety certifications and non-toxic materials to meet regulatory standards. Their durability and affordability make them attractive for mass distribution, though inventory management must account for sizing variations and safety compliance.

Customizable Jelly

This innovative category offers modular designs that allow for easy swapping of colors or accessories, appealing to brands seeking high engagement and personalization. They are ideal for promotional products, corporate gifting, or fashion brands wanting to differentiate their offerings. B2B buyers should consider suppliers with flexible manufacturing capabilities and reliable lead times to meet custom order demands. While offering high margins and brand visibility, these shoes involve complex logistics and longer production cycles, requiring strategic planning for inventory and delivery schedules.

Key Industrial Applications of jelly shoes 80s

| Industry/Sector | Specific Application of jelly shoes 80s | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Footwear & Fashion Retail | Trend-driven fashion accessories and casual footwear | Capitalizes on nostalgic appeal, boosts sales, attracts youth markets | Material durability, colorfastness, compliance with safety standards |

| Tourism & Hospitality | Souvenir items and promotional merchandise | Enhances guest experience, promotes brand visibility | Customization options, quality consistency, competitive pricing |

| Healthcare & Wellness | Water-resistant footwear for medical and wellness facilities | Provides hygienic, easy-to-clean footwear solutions | Hygiene standards, non-slip properties, material safety compliance |

| Construction & Industrial | Protective footwear for workers in wet or chemical environments | Ensures safety, comfort, and moisture resistance | Slip resistance, chemical resistance, durability under harsh conditions |

| Event & Promotional Goods | Branded giveaways and event merchandise | Increases brand exposure, cost-effective promotional tool | Customization flexibility, bulk sourcing, quick turnaround |

Footwear & Fashion Retail

Jelly shoes from the 80s era are highly valued in the fashion industry as nostalgic, colorful, and versatile accessories. They are popular among youth and trend-conscious consumers, especially in regions like Africa and South America where retro styles are resurging. B2B buyers can source these shoes in bulk to supply retail chains, online platforms, and boutique stores. Emphasizing material quality—such as UV stability, colorfastness, and flexibility—is essential to meet consumer expectations and withstand regional climate conditions. Ensuring compliance with safety and material standards across markets enhances product credibility and reduces liability risks.

Tourism & Hospitality

In the tourism sector, especially in beach destinations and resorts across Europe, Brazil, and Kenya, jelly shoes serve as attractive souvenirs and promotional items. Hotels and travel companies can customize these shoes with logos or regional motifs, making them memorable keepsakes for guests. For B2B buyers, sourcing high-quality, customizable jelly shoes that resist fading and are comfortable for extended wear is critical. Bulk procurement from reliable manufacturers ensures consistent quality, timely delivery, and cost efficiency, enabling brands to capitalize on the souvenir market while boosting brand visibility.

Healthcare & Wellness

Water-resistant and hygienic, jelly shoes are increasingly used in healthcare and wellness environments such as spas, gyms, and hospitals. Their non-porous material prevents bacterial buildup, facilitating easy cleaning and sanitization—crucial for infection control. B2B buyers from regions like the Middle East and South America should prioritize sourcing shoes with non-slip soles, chemical resistance, and medical-grade safety certifications. These features ensure safety and hygiene standards are met, making jelly shoes suitable for staff uniforms or patient use, while offering durable, low-maintenance footwear solutions.

Construction & Industrial

In construction and industrial sectors, particularly in wet or chemically exposed environments, jelly shoes are used as protective footwear for workers. They provide moisture resistance, slip resistance, and lightweight comfort, reducing fatigue during long shifts. Sourcing considerations include selecting shoes with high durability, resistance to industrial chemicals, and compliance with safety regulations such as ANSI or EN standards. For international buyers, establishing reliable supply chains with consistent quality and competitive pricing is vital to meet project timelines and safety requirements.

Event & Promotional Goods

Jelly shoes are cost-effective promotional items and branded giveaways at events, festivals, and corporate campaigns. Their vibrant colors and customizable surfaces make them ideal for brand exposure. B2B buyers should focus on sourcing manufacturers capable of rapid customization, bulk production, and adherence to branding specifications. Ensuring consistent quality and timely delivery allows companies in regions like Africa, South America, and Europe to maximize marketing impact while maintaining budget efficiency. These shoes also serve as memorable, functional souvenirs that reinforce brand loyalty.

This strategic overview highlights how jelly shoes from the 80s era serve diverse industrial applications worldwide. By understanding specific sector needs and sourcing considerations, international B2B buyers can effectively leverage this nostalgic yet functional product to expand their market offerings and enhance operational efficiency.

Strategic Material Selection Guide for jelly shoes 80s

Material Analysis for Jelly Shoes 80s

Selecting the appropriate materials for jelly shoes is critical for ensuring product quality, durability, safety, and compliance across diverse international markets. Here, we analyze four common materials used in the production of jelly shoes, focusing on their properties, advantages, limitations, and considerations for B2B buyers from Africa, South America, the Middle East, and Europe.

Thermoplastic Polyurethane (TPU)

Key Properties:

TPU is a versatile, semi-elastic thermoplastic that offers excellent flexibility, transparency, and resistance to abrasion. It performs well across a wide temperature range (-40°C to +80°C), with good chemical and oil resistance. Its low permeability makes it resistant to water ingress, ideal for footwear exposed to moisture.

Pros & Cons:

TPU’s primary advantage is its durability and flexibility, which translate into longer-lasting jelly shoes that maintain their shape and comfort over time. It is relatively easy to mold during manufacturing, enabling high-volume production with consistent quality. However, TPU can be more costly than simpler plastics, and its processing requires specialized equipment, which may increase initial setup costs.

Impact on Application:

TPU’s chemical resistance makes it suitable for various environments, including humid or salty conditions common in coastal regions of Brazil or West Africa. Its transparency allows for vibrant, colorful designs, appealing to fashion-conscious consumers.

International Buyer Considerations:

TPU complies with many international standards, including ASTM and REACH, facilitating export to Europe and other regions with strict chemical regulations. For African and Middle Eastern markets, suppliers should verify local import standards and ensure the material’s safety data sheets (SDS) meet regional requirements.

PVC (Polyvinyl Chloride)

Key Properties:

PVC is a widely used thermoplastic known for its affordability, chemical resistance, and ease of processing. It can be formulated as rigid or flexible, with flexible PVC often used in jelly shoes for its soft, pliable nature.

Pros & Cons:

PVC’s low cost makes it attractive for mass-market footwear, especially in price-sensitive markets like parts of Africa and South America. Its chemical resistance and water-proof qualities enhance product longevity. However, PVC can become brittle over time, especially under UV exposure, and may emit plasticizers that raise health and environmental concerns.

Impact on Application:

PVC’s versatility allows for a broad spectrum of designs and colors, but its environmental footprint and potential health issues (e.g., phthalates) may limit its acceptance in markets with strict regulations, such as Europe.

International Buyer Considerations:

European buyers should prioritize phthalate-free formulations to meet EU standards. In Africa and the Middle East, compliance with local chemical safety regulations and environmental standards is essential. PVC’s recyclability can be a selling point if suppliers can demonstrate environmentally responsible disposal or recycling programs.

Thermoplastic Elastomers (TPE)

Key Properties:

TPEs combine the processing ease of plastics with the flexibility and elasticity of rubbers. They are resistant to UV, chemicals, and aging, with good tactile feel and slip resistance.

Pros & Cons:

TPE offers excellent comfort and durability, making it ideal for trendy, flexible jelly shoes. It is generally considered environmentally safer than PVC, with fewer health concerns related to plasticizers. However, TPE can be more expensive than PVC or standard plastics, and its processing may require specific equipment.

Impact on Application:

TPE’s softness and elasticity make it suitable for fashionable, comfortable footwear that appeals to a broad demographic. Its resistance to environmental factors ensures longevity in outdoor or humid conditions, common in tropical regions.

International Buyer Considerations:

TPE complies with many international safety standards, including REACH and ASTM, easing export processes. For markets with strict environmental policies, TPE’s eco-friendliness can be a competitive advantage.

Rubber (Natural and Synthetic)

Key Properties:

Rubber provides high elasticity, excellent grip, and impact absorption. Natural rubber offers biodegradability, while synthetic variants like SBR or EPDM are designed for enhanced weather resistance.

Pros & Cons:

Rubber’s durability and comfort are significant benefits, especially in rugged or outdoor environments. Synthetic rubbers tend to be more resistant to weathering and ozone. However, natural rubber can be susceptible to degradation from ozone and UV, and both types can be more expensive than plastics. Processing rubber also involves vulcanization, which can be complex and costly.

Impact on Application:

Rubber’s high grip and cushioning make it ideal for outdoor or active use, especially in regions with uneven terrain or where slip resistance is critical. Its natural properties may appeal to eco-conscious markets but require careful sourcing to ensure sustainability.

International Buyer Considerations:

Compliance with environmental standards like REACH and EU regulations on natural rubber is vital for European markets. Buyers in Africa and South America should verify the source and sustainability certifications to meet local regulations and consumer expectations.

Summary Table

| Material | Typical Use Case for jelly shoes 80s | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic Polyurethane (TPU) | Durable, flexible, transparent jelly shoes | Excellent durability, chemical resistance | Higher cost, specialized processing equipment needed | High |

| PVC (Polyvinyl Chloride) | Cost-effective, water-proof jelly shoes | Low cost, versatile, easy to process | Environmental concerns, potential health issues (phthalates) | Low |

| Thermoplastic Elastomers (TPE) | Flexible, comfortable, trendy jelly shoes | Eco-friendly, UV and chemical resistant | Higher price point, specific processing requirements | Medium |

| Rubber (Natural/Synthetic) | Outdoor, active, impact-absorbing jelly shoes | High elasticity, slip-resistant | Costly, complex processing, environmental concerns | Medium to High |

This comprehensive analysis provides B2B buyers with critical insights into material selection, enabling informed decisions aligned with regional standards, market preferences, and product performance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for jelly shoes 80s

Manufacturing Processes of Jelly Shoes 80s

The production of jelly shoes, especially those inspired by the iconic 80s style, involves a series of carefully controlled manufacturing stages to ensure product quality, durability, and safety. Understanding these processes enables B2B buyers to better evaluate potential suppliers and ensure compliance with international standards.

Material Preparation

The core material used in jelly shoes is thermoplastic elastomer (TPE), a flexible, transparent, and water-resistant polymer. Suppliers typically source TPE resins from reputable chemical providers to ensure consistency. Material preparation involves blending, heating, and extrusion to produce uniform sheets or pellets, which form the basis for shoe components. For international buyers, verifying the chemical composition and sourcing of raw materials is crucial, especially given regional environmental and safety regulations.

Forming and Molding

The primary shaping process is injection molding or compression molding, where heated TPE is injected into molds that shape the soles, uppers, and decorative elements. High-precision molds are essential for achieving consistent dimensions, fit, and aesthetic appeal. Advanced manufacturing facilities often incorporate automation to reduce variability and improve efficiency. For buyers from regions like Africa, South America, the Middle East, or Europe, inspecting the mold maintenance records and equipment calibration can offer insights into manufacturing consistency.

Assembly

Post-molding, shoe components are assembled through techniques such as heat welding, adhesive bonding, or mechanical fastening. The assembly process must ensure strong joints and uniform construction to withstand daily wear and exposure to water. Additional features like straps, embellishments, or logo inserts are added during this stage, often using heat presses or ultrasonic welding. Suppliers with modern, automated assembly lines tend to produce more consistent quality, which is vital for B2B buyers seeking reliable supply chains.

Finishing and Packaging

Final finishing involves trimming excess material, surface smoothing, and applying decorative or branding elements. Quality control at this stage ensures no surface defects, such as bubbles, warping, or discoloration. Packaging must comply with international shipping standards to prevent damage during transit. For international buyers, especially those importing in bulk, assessing the supplier’s finishing processes and packaging quality is key to reducing returns and complaints.

Quality Assurance (QA) and Control Measures

Robust quality assurance protocols are integral to manufacturing jelly shoes that meet international safety, durability, and aesthetic standards. B2B buyers should prioritize suppliers with established QA systems aligned with recognized standards.

International Standards and Certifications

- ISO 9001: The cornerstone of quality management systems globally. Suppliers certified under ISO 9001 demonstrate a structured approach to process control, continuous improvement, and customer satisfaction.

- CE Marking: For European markets, CE certification indicates compliance with health, safety, and environmental directives, especially relevant for products with direct skin contact.

- API and Other Industry Standards: While API standards are more relevant for petrochemical industries, similar standards like ASTM or EN certifications may apply for materials and testing methods.

Inspection and Testing Protocols

- Incoming Quality Control (IQC): Raw materials, especially TPE resins, are tested upon arrival for chemical composition, color consistency, and impurity levels. B2B buyers should request supplier test reports and third-party audits to verify material quality.

- In-Process Quality Control (IPQC): During manufacturing, checkpoints monitor parameters such as mold temperature, injection pressure, cycle times, and assembly accuracy. Real-time data collection ensures process stability.

- Final Quality Control (FQC): Before shipment, finished shoes undergo comprehensive inspections, including visual checks for surface defects, dimensional accuracy, and functional tests such as flexibility, water resistance, and colorfastness.

Common Testing Methods

- Visual Inspection: Detects surface blemishes, misalignments, or color inconsistencies.

- Dimensional Verification: Ensures size accuracy using calipers or coordinate measuring machines.

- Mechanical Testing: Tests for tensile strength, elongation, and tear resistance.

- Environmental Testing: Simulates exposure to UV light, water immersion, or temperature variations to assess durability.

- Chemical Testing: Ensures no harmful substances (like phthalates or heavy metals) are present, complying with REACH or CPSIA regulations.

Verifying Supplier Quality for International B2B Transactions

For buyers, particularly from regions with varying regulatory environments, verifying supplier quality is essential to mitigate risks and ensure product compliance.

Conducting Supplier Audits

- On-site Audits: Visiting manufacturing facilities allows direct assessment of equipment, cleanliness, worker conditions, and process controls. Engaging third-party inspection firms familiar with local manufacturing practices adds objectivity.

- Documentation Review: Request detailed quality manuals, inspection reports, process control records, and certification copies. Transparent documentation indicates a supplier’s commitment to quality.

- Sample Testing: Prior to large orders, request samples tested at accredited labs to verify material and product quality against specifications.

Third-party Inspection and Certification

- Engage recognized inspection agencies (e.g., SGS, Bureau Veritas, Intertek) for pre-shipment inspections.

- Certificates of compliance should be validated and cross-checked with issuing authorities.

- For regions like Africa or South America, where local standards may differ, ensure supplier adherence to international standards or obtain third-party verification.

Industry Nuances and Regional Considerations

B2B buyers from diverse regions face unique challenges in quality assurance:

- Africa (e.g., Kenya): Infrastructure and regulatory oversight may vary, making third-party audits and certifications even more critical. Establish clear quality benchmarks and insist on detailed inspection reports.

- South America (e.g., Brazil): Local regulations (like ANVISA standards) may influence material choices. Suppliers should demonstrate compliance with these standards, and buyers should verify certification validity.

- Middle East: Climate conditions demand durable, UV-resistant shoes. Suppliers should provide environmental testing reports to validate product resilience.

- Europe: Stringent regulations on chemicals and safety (REACH, EN standards) necessitate comprehensive chemical testing and certifications. B2B buyers should prioritize suppliers with proven compliance and traceability.

Conclusion

A thorough understanding of manufacturing processes and rigorous quality assurance practices are vital for B2B buyers sourcing jelly shoes inspired by the 80s. By scrutinizing supplier capabilities, certifications, and testing protocols, buyers can mitigate risks, ensure product compliance, and build reliable supply chains across diverse regions. Establishing clear communication, demanding transparency, and leveraging third-party inspections are essential strategies for successful international sourcing in this niche footwear market.

Comprehensive Cost and Pricing Analysis for jelly shoes 80s Sourcing

Cost Structure Overview

When evaluating the costs associated with sourcing ‘jelly shoes 80s’, it is essential to understand the key components that influence the final price. The primary cost drivers include raw materials, labor, manufacturing overheads, tooling, quality control, logistics, and profit margins.

Illustrative Image (Source: Google Search)

Materials: The core material—PVC or thermoplastic elastomers—constitutes a significant portion of the cost, typically accounting for 30-50% of the manufacturing expense. Variations in material quality, transparency, and sourcing country can affect pricing. Premium or certified eco-friendly materials often command higher prices but may appeal to specific markets.

Labor: Manufacturing labor costs vary greatly by region. Countries in Southeast Asia and parts of Eastern Europe tend to offer lower wages, reducing overall costs, whereas European or Middle Eastern suppliers may have higher labor expenses. Efficient production practices can mitigate these differences.

Manufacturing Overheads & Tooling: Overheads, including factory utilities and maintenance, contribute around 10-20% of costs. Initial tooling costs for molds can be substantial, often ranging from $5,000 to $20,000 depending on complexity and customization. These are typically amortized over large production volumes.

Quality Control & Certifications: Ensuring consistent quality and obtaining necessary safety or environmental certifications (e.g., REACH, ISO) can add to costs but are crucial for market acceptance, especially in Europe and the Middle East.

Logistics & Incoterms: Shipping costs depend on volume, destination, and chosen Incoterms. FOB (Free on Board) is common, where the supplier handles shipping to port, but buyers should account for freight, insurance, and customs clearance fees, which can significantly impact total landed cost.

Profit Margin: Suppliers typically aim for a markup of 15-30%, but this varies based on order volume, relationship, and market competitiveness.

Price Influencers and Variability

Several factors influence the final pricing, especially for international B2B buyers:

- Order Volume & MOQ: Larger orders usually benefit from lower unit prices due to economies of scale. Minimum order quantities (MOQs) can range from 500 to 5,000 pairs, with higher volumes reducing per-unit costs significantly.

- Specifications & Customization: Custom colors, logos, or unique designs increase tooling and development costs. Standard designs are more cost-effective, but customization can command premiums of 10-20%.

- Materials & Quality Standards: Higher-grade, eco-certified, or specialty materials increase material costs, impacting the final price.

- Certifications & Compliance: Market-specific standards, particularly in Europe and the Middle East, may necessitate additional testing and certification, raising costs.

- Supplier Factors: Larger, established manufacturers may offer better pricing and reliability but might have longer lead times or higher minimum order requirements. Smaller suppliers may be more flexible but could have variable quality standards.

Strategic Tips for B2B Buyers

- Negotiate Effectively: Leverage volume commitments and long-term partnerships to negotiate better prices or favorable payment terms.

- Focus on Total Cost of Ownership (TCO): Consider not just unit price but also shipping, customs, taxes, and potential rework costs. For instance, choosing FOB terms might reduce initial costs but could lead to unpredictable expenses at destination.

- Optimize Logistics: Consolidate shipments, choose cost-effective freight options, and understand Incoterms thoroughly to avoid unexpected charges.

- Assess Lead Times & Flexibility: Larger orders might require longer lead times; plan accordingly to prevent stockouts or delays.

- Market-Specific Pricing Nuances: Buyers from Africa (e.g., Kenya), South America (e.g., Brazil), or the Middle East should be aware of import tariffs, VAT, and local standards, which can add 10-30% to landed costs.

Indicative Price Range (Disclaimer)

Based on current market data, the FOB unit price for standard jelly shoes 80s ranges approximately from $2.50 to $6.00 per pair for bulk orders (minimum 1,000 pairs). Premium or customized options can push prices upward, especially with added certifications or special materials. Buyers should consider these figures as indicative, subject to variation based on supplier negotiations, order specifics, and market conditions.

By thoroughly analyzing these cost components and influencers, international B2B buyers can better strategize their sourcing approach, negotiate effectively, and optimize their total cost of ownership for jelly shoes 80s.

Spotlight on Potential jelly shoes 80s Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for jelly shoes 80s.)*

Essential Technical Properties and Trade Terminology for jelly shoes 80s

Critical Technical Properties for Jelly Shoes 80s

1. Material Grade and Composition

The primary material used in 80s-style jelly shoes is thermoplastic rubber (TPR) or PVC (polyvinyl chloride). High-quality TPR offers superior flexibility, durability, and resistance to cracking, which are essential for consumer satisfaction. For B2B buyers, specifying the material grade ensures the product meets safety standards and longevity expectations, especially important for markets with varying climate conditions.

2. Thickness and Tolerance

Jelly shoes typically range from 3mm to 8mm in thickness. Consistent thickness contributes to uniform comfort and structural integrity. Tolerance levels, often within ±0.2mm, guarantee production consistency across batches, reducing defects and returns. Precise control over thickness is vital for meeting both design specifications and functional durability.

3. Colorfastness and UV Resistance

Since jelly shoes are often used outdoors, the ability of the material to resist fading from sunlight (UV resistance) and maintain colorfastness after exposure to water and detergents is critical. Suppliers should provide testing reports confirming these properties, ensuring the shoes retain their aesthetic appeal over time, especially for markets with strong sunlight like Africa and South America.

4. Flexibility and Comfort

A key property for consumer satisfaction, flexibility affects how easily shoes conform to different foot shapes and how comfortable they feel during wear. Material elasticity tests and bend tests are standard to verify this property. B2B buyers should specify minimum flexibility standards to ensure the final product is both wearable and comfortable.

5. Non-Toxicity and Safety Compliance

All materials must comply with international safety standards such as REACH (Europe) or CPSIA (USA). Non-toxic, hypoallergenic components reduce liability risks and are often mandated by import regulations. Verification through third-party testing reports is essential for smooth customs clearance.

6. Resistance to Water and Environmental Stress

Jelly shoes are frequently exposed to water and humid environments. Resistance to water ingress, mold, and bacterial growth prolongs product life. Material testing for environmental stress cracking and water resistance ensures suitability for diverse climates.

Industry and Trade Terminology

1. OEM (Original Equipment Manufacturer)

Refers to factories that produce jelly shoes based on a buyer’s design or specifications. Understanding OEM relationships allows buyers to customize products or leverage existing designs, often at lower costs. Clarifying OEM capabilities helps in sourcing reliable partners with experience in jelly shoe manufacturing.

2. MOQ (Minimum Order Quantity)

The smallest batch size a manufacturer is willing to produce. For new markets or custom designs, MOQs can range from 500 to 10,000 pairs. Negotiating MOQ is vital for balancing inventory costs and market entry strategies, especially for emerging markets like Africa or South America.

3. RFQ (Request for Quotation)

A formal request sent to manufacturers seeking price, lead time, and technical details for a specific order. B2B buyers should prepare detailed RFQs to compare supplier offerings effectively, ensuring clarity on material specs, packaging, and delivery terms.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and tariffs between buyers and sellers. Common Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate cost-sharing and risk points during transit. Mastery of Incoterms minimizes misunderstandings and optimizes logistics planning.

5. Lead Time

The period from order confirmation to product delivery. Understanding lead times helps buyers plan inventory and market launches, especially in regions with long shipping routes like South America or Africa. Accurate lead time estimation reduces stockouts and delays.

6. Quality Control (QC)

Processes implemented to ensure products meet specified standards before shipment. Effective QC includes raw material inspection, in-process checks, and final audits. B2B buyers should specify QC procedures and required certifications to ensure consistent product quality.

By comprehending these technical properties and trade terms, international buyers can make informed decisions, optimize procurement strategies, and establish reliable supply chains for jelly shoes 80s in diverse markets worldwide.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the jelly shoes 80s Sector

Market Overview & Key Trends

The global jelly shoes market, rooted in the vibrant 1980s fashion scene, is experiencing renewed interest driven by nostalgia, eco-conscious consumer preferences, and innovative design. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding these dynamics is vital for sourcing competitive, trend-aligned products.

Emerging trends include the integration of sustainable materials, customization options, and innovative manufacturing processes that reduce environmental impact. Countries like Brazil and Kenya are increasingly becoming hubs for eco-friendly manufacturing, leveraging local resources and skilled labor to produce high-quality jelly shoes. Meanwhile, technological advances in injection molding and 3D printing are enabling smaller batches, rapid prototyping, and flexible production, ideal for regional markets with diverse consumer preferences.

Market drivers include the rising demand for affordable yet stylish footwear, driven by urbanization and youth culture across emerging economies. European markets are pivoting towards premium, ethically produced jelly shoes, while African and Middle Eastern markets focus on affordability and durability. B2B buyers should consider sourcing from regions with strong local manufacturing capabilities and compliance with international quality standards, ensuring products meet both regional tastes and global quality benchmarks.

Furthermore, digital platforms and supply chain transparency tools are transforming sourcing strategies. Buyers now favor suppliers who offer real-time tracking, sustainable certifications, and traceability, aligning with global standards. As e-commerce continues to grow, establishing reliable relationships with regional manufacturers can provide a competitive edge in fast-moving markets.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly central to sourcing decisions in the jelly shoes sector, especially given the environmental footprint associated with traditional PVC and other plastic materials. For B2B buyers, prioritizing suppliers committed to ethical and eco-friendly practices not only aligns with global consumer trends but also mitigates regulatory and reputational risks.

Eco-conscious sourcing involves selecting manufacturers that utilize biodegradable or recycled plastics, such as post-consumer PET or bio-based polymers. Certifications like ISO 14001 (Environmental Management) and GRS (Global Recycled Standard) are valuable indicators of genuine sustainability efforts. For instance, some suppliers in South America and Europe are pioneering the use of plant-based plastics derived from corn or sugarcane, reducing reliance on fossil fuels.

Ethical sourcing extends beyond materials to include fair labor practices, safe working conditions, and transparent supply chains. Buyers should seek suppliers who adhere to international labor standards and possess relevant certifications like SA8000 or Fair Trade. Establishing partnerships with certified suppliers can enhance brand credibility and appeal to environmentally conscious consumers.

Investing in sustainable packaging, such as biodegradable wrapping or minimal plastic use, further supports environmental goals. Additionally, engaging with suppliers who participate in environmental audits or possess third-party sustainability ratings can ensure accountability. Ultimately, integrating sustainability into sourcing strategies can differentiate products in competitive markets and foster long-term supplier relationships.

Brief Evolution/History (Optional)

Jelly shoes originated in the 1980s as a playful, fashionable footwear made from PVC and other plastics, embodying the era’s bold and colorful aesthetic. Initially popular among children and teenagers, they became a global trend driven by vibrant designs and affordability. Over the decades, the sector experienced fluctuations, with a decline in the late 1990s and early 2000s due to concerns over plastic pollution.

Recently, the resurgence of interest in nostalgic fashion, combined with increasing environmental awareness, has revitalized the sector. Modern reinterpretations focus on sustainable materials, comfort, and customization. This historical evolution informs B2B buyers about the importance of balancing aesthetic appeal with environmental responsibility, emphasizing the need for innovative sourcing solutions that align with contemporary values.

Understanding this evolution helps buyers identify reliable manufacturers with a heritage of quality and innovation, ensuring long-term supply stability. It also highlights opportunities for differentiation through eco-friendly and design-forward products, catering to both nostalgic consumers and environmentally conscious markets.

Frequently Asked Questions (FAQs) for B2B Buyers of jelly shoes 80s

1. How can I effectively vet jelly shoe suppliers to ensure product quality and reliability?

To vet suppliers effectively, start by requesting comprehensive company credentials, including business licenses, manufacturing certifications (e.g., ISO, SGS), and references from existing clients. Conduct virtual factory audits or visit in person if feasible, focusing on production capacity, quality control processes, and hygiene standards. Request samples to assess material quality, comfort, and durability before placing bulk orders. Additionally, review online reviews, trade association memberships, and payment history to gauge reliability. Building a strong communication channel and setting clear expectations early can help establish trust and reduce risks in your supply chain.

2. What are the typical customization options available for jelly shoes, and how do they impact lead times and costs?

Most suppliers offer customization options including colorways, branding (logos or tags), packaging, and sometimes design modifications like sole patterns or embellishments. Customization usually involves higher upfront costs and extended lead times—expect an additional 2-4 weeks depending on complexity. To manage costs, prioritize essential custom features and request detailed quotations upfront. Clear communication about your specifications, minimum order quantities (MOQs), and deadlines is crucial. Working with suppliers experienced in OEM/ODM processes can streamline customization, ensuring your branded jelly shoes meet quality standards without significant delays.

3. What are the typical MOQs, lead times, and payment terms for international orders of jelly shoes 80s?

Most manufacturers set MOQs ranging from 1,000 to 5,000 pairs, depending on the supplier’s capacity and customization level. Lead times generally range from 4 to 8 weeks after order confirmation, including sample approval, production, and shipping. Payment terms commonly include a 30% deposit upfront with the balance payable before shipment or upon arrival. Some suppliers may offer flexible terms for large or repeat orders, such as letters of credit or open accounts. Negotiating payment terms that align with your cash flow, and planning orders well in advance, helps mitigate delays and financial risks.

4. What certifications or quality assurance documents should I request to ensure compliance with international standards?

Request certifications such as CE, RoHS, or ASTM, especially if targeting European or North American markets. For regions like Africa, South America, or the Middle East, ensure compliance with local import regulations, including safety, chemical, and labeling standards. Quality assurance documentation should include factory inspection reports, SGS or BV testing results, and batch sampling records. Establish clear quality benchmarks in your purchase agreement, and consider engaging third-party inspectors for pre-shipment inspections. This proactive approach reduces the risk of non-compliance, product recalls, or customs clearance issues.

5. How can I optimize logistics and shipping to minimize costs and ensure timely delivery?

Start by selecting suppliers with established logistics networks or partnerships with reliable freight forwarders. Consolidate shipments when possible to benefit from bulk shipping rates. Consider port-to-port shipping for cost efficiency and arrange for local customs clearance services at destination countries. Use incoterms like FOB (Free on Board) to clarify responsibilities and reduce surprises. Track shipments actively and maintain open communication with logistics providers. Planning for potential delays (e.g., customs, weather) and securing appropriate insurance coverage ensures smoother delivery, especially for time-sensitive markets like Europe or South America.

6. What common disputes arise in international jelly shoe trade, and how can they be proactively managed?

Common disputes include quality discrepancies, delayed shipments, payment issues, and intellectual property concerns. To mitigate these, establish clear contractual terms covering specifications, inspection rights, and dispute resolution procedures (preferably arbitration). Use detailed purchase agreements and enforceable warranties. Maintain transparent communication throughout the process and document all agreements and changes in writing. Engaging third-party inspection agencies before shipment can verify product quality. Building a strong, mutually respectful relationship with your supplier also helps resolve issues amicably and swiftly, reducing the risk of costly legal disputes.

7. How do I ensure the sustainability and ethical standards of jelly shoe suppliers?

Request detailed information about the supplier’s sourcing and manufacturing practices, including the use of eco-friendly materials, waste management, and labor conditions. Look for suppliers with certifications like SA8000, BSCI, or Fair Trade, which indicate compliance with social and environmental standards. Conduct supplier audits or engage third-party inspection firms to verify adherence. Favor suppliers who demonstrate transparency about their supply chain, use recyclable or non-toxic materials, and implement fair labor policies. This not only aligns with global sustainability trends but also enhances your brand’s reputation in eco-conscious markets.

8. What are best practices for handling disputes or quality issues after shipment?

Establish a structured process for addressing post-shipment issues, including clear communication channels with the supplier. Upon receiving the goods, perform thorough inspections—preferably with third-party inspectors—to identify defects or non-compliance. Document all issues with photos and detailed reports. Refer to your purchase agreement to invoke warranty clauses or defect liabilities. Negotiate corrective actions such as replacements, refunds, or discounts. Maintaining a professional, solution-oriented approach and fostering ongoing relationships with suppliers can facilitate quicker resolutions, safeguarding your market reputation and customer satisfaction in international markets.

Strategic Sourcing Conclusion and Outlook for jelly shoes 80s

Conclusion and Future Outlook

Effective strategic sourcing is vital for B2B buyers seeking to capitalize on the nostalgic appeal and growing demand for 80s-style jelly shoes. By establishing strong relationships with reliable manufacturers—particularly in regions known for cost-effective production such as Asia, or exploring local suppliers in Africa, South America, the Middle East, and Europe—buyers can secure quality products at competitive prices. Emphasizing quality control, sustainable sourcing practices, and flexible lead times will enhance your market position.

Looking ahead, the global footwear market’s shift toward eco-friendly and innovative materials presents an opportunity to differentiate your offerings. As consumer preferences evolve, integrating sustainable practices into your sourcing strategy will be crucial for long-term success.

International B2B buyers from regions like Kenya, Brazil, and the Middle East should prioritize building resilient supply chains and leveraging regional trade agreements to reduce costs and streamline logistics. Staying attuned to emerging trends and fostering strategic partnerships will position you to meet increasing demand for retro-inspired fashion. Act now to refine your sourcing approach—your ability to adapt will determine your competitive edge in this vibrant market.