Your Ultimate Guide to Sourcing Kobe Adidas Shoes

Guide to Kobe Adidas Shoes

- Introduction: Navigating the Global Market for kobe adidas shoes

- Understanding kobe adidas shoes Types and Variations

- Key Industrial Applications of kobe adidas shoes

- Strategic Material Selection Guide for kobe adidas shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for kobe adidas shoes

- Comprehensive Cost and Pricing Analysis for kobe adidas shoes Sourcing

- Spotlight on Potential kobe adidas shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for kobe adidas shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the kobe adidas shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of kobe adidas shoes

- Strategic Sourcing Conclusion and Outlook for kobe adidas shoes

Introduction: Navigating the Global Market for kobe adidas shoes

In today’s highly interconnected global marketplace, Kobe adidas shoes have emerged as a pivotal product for retailers, distributors, and corporate buyers seeking premium athletic footwear with a strong brand presence. Their popularity spans across diverse markets, from Africa’s burgeoning sportswear sector to Europe’s luxury sneaker boutiques, making them a strategic asset for expanding your product portfolio. For B2B buyers, understanding the nuances of sourcing Kobe adidas shoes—ranging from authentic supply channels to cost structures—is essential for maintaining competitive advantage and ensuring compliance with quality standards.

This comprehensive guide is designed to empower international buyers from regions including Africa, South America, the Middle East, and Europe—such as the UK and Nigeria—with actionable insights. It covers critical areas like product varieties, materials used, manufacturing and quality control processes, reliable supplier networks, and cost considerations. Additionally, it addresses common market challenges and provides answers to frequently asked questions to streamline decision-making.

By navigating the complexities of the global Kobe adidas shoes market with this guide, B2B buyers will be better equipped to identify trustworthy suppliers, optimize sourcing strategies, and mitigate risks associated with counterfeit products or supply chain disruptions. Whether you are seeking bulk imports or exploring new retail opportunities, this resource aims to facilitate informed, strategic decisions that drive growth and brand integrity in your local markets.

Understanding kobe adidas shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Performance Basketball Shoes | High ankle support, lightweight materials, advanced cushioning | Sporting goods retail, sports teams, gyms | Pros: High demand among athletes, premium branding. Cons: Higher procurement cost, limited bulk discounts. |

| Lifestyle/Casual Shoes | Trendy designs, versatile aesthetics, moderate cushioning | Fashion retailers, casual wear outlets | Pros: Broad consumer appeal, higher margins. Cons: Shorter product lifecycle, less technical appeal. |

| Signature/Collaborative Editions | Limited editions, unique design collaborations, premium materials | Specialty boutiques, collectors, premium markets | Pros: High exclusivity and markup potential. Cons: Limited availability, complex supply chain. |

| Youth/Junior Models | Smaller sizes, vibrant colors, durable yet flexible construction | Children’s apparel and footwear stores | Pros: Growing market segment, high volume potential. Cons: Smaller margins, seasonal demand fluctuations. |

| Eco-Friendly/Sustainable Lines | Use of recycled materials, eco-conscious branding | Green retail outlets, global sustainability initiatives | Pros: Growing consumer preference, regulatory advantages. Cons: Higher raw material costs, certification complexities. |

Performance Basketball Shoes

This category encompasses high-performance Kobe adidas shoes designed for athletes and sports teams. They feature advanced cushioning, ankle support, and lightweight materials to optimize athletic performance. B2B buyers should target sporting goods distributors, gyms, and sports teams seeking premium, high-demand products. These shoes often command higher margins but can involve higher procurement costs and limited bulk discounts due to their specialized nature. They are ideal for markets where sports performance footwear is a priority, such as Nigeria or South American countries with active basketball communities.

Lifestyle/Casual Shoes

Lifestyle Kobe adidas shoes emphasize trendy, versatile designs suitable for everyday wear. They combine fashion with comfort, appealing to a broad consumer base. B2B buyers in fashion retail or casual footwear markets should consider these for their high margin potential and strong consumer appeal. However, these models tend to have shorter product lifecycles due to fast-changing fashion trends. They are best suited for markets with a vibrant youth demographic, such as European urban centers or Middle Eastern retail outlets, where style and brand prestige drive sales.

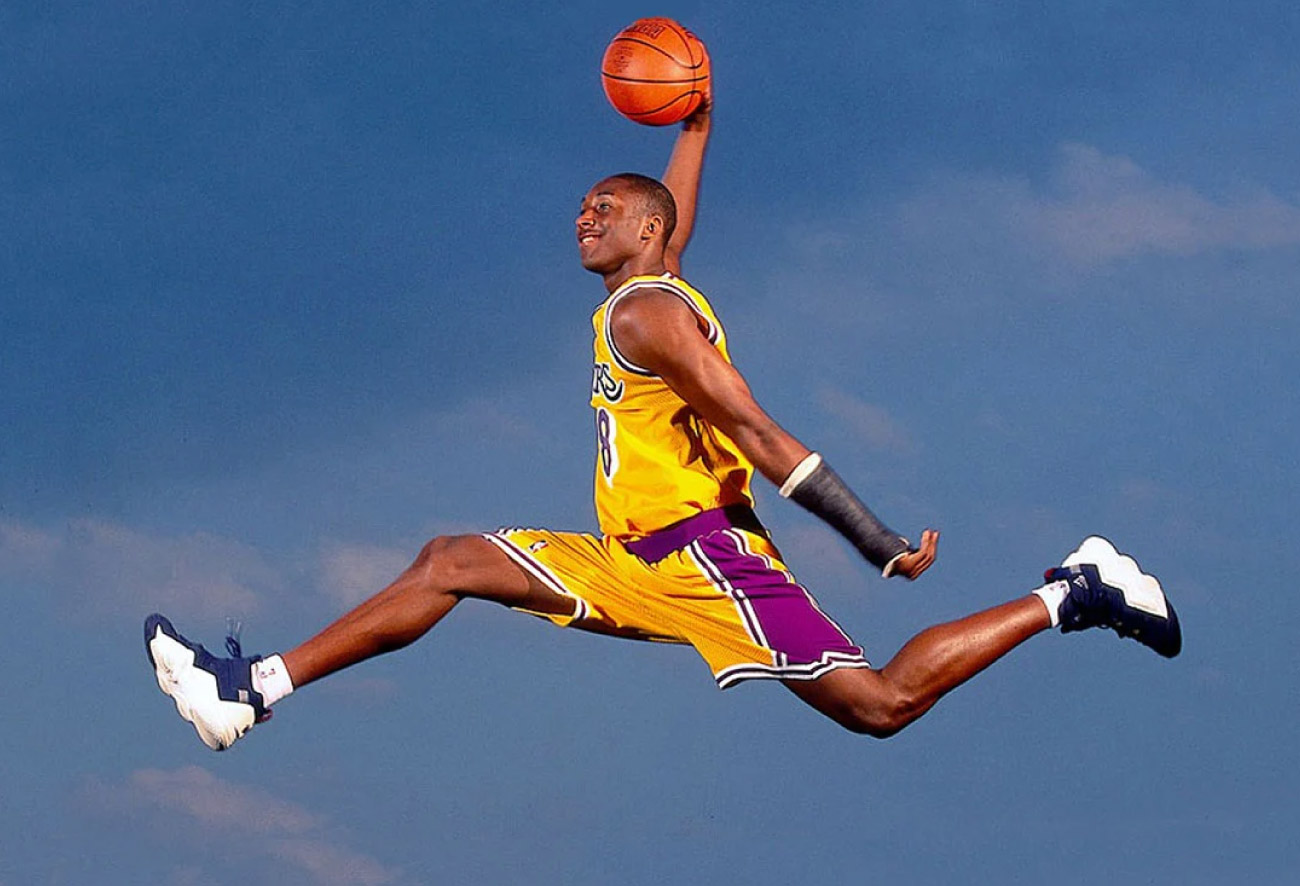

Illustrative Image (Source: Google Search)

Signature/Collaborative Editions

Limited-edition Kobe adidas shoes often feature exclusive collaborations with designers or celebrities. These models attract collectors and premium buyers, offering high markup opportunities. B2B buyers should focus on specialty boutiques, online exclusive channels, and premium retail outlets. The key considerations include limited supply, high demand, and the need for precise inventory management. These editions are suitable for markets with a strong culture of sneaker collecting or luxury branding, like Europe or affluent Middle Eastern markets, where exclusivity enhances brand value.

Youth/Junior Models

Designed for children and teenagers, these Kobe adidas shoes combine durability with vibrant aesthetics. They are positioned in the growing youth footwear segment, appealing to parents and schools. B2B buyers should target children’s apparel stores, school uniform suppliers, and online marketplaces. While the margins may be lower, the high volume potential and seasonal demand can offset this. These models are particularly relevant in emerging markets like Nigeria or South America, where youth sports participation is increasing.

Eco-Friendly/Sustainable Lines

These Kobe adidas shoes utilize recycled materials and sustainable manufacturing practices. They cater to environmentally conscious consumers and align with global sustainability initiatives. B2B buyers in green retail outlets or those seeking to enhance corporate social responsibility portfolios should prioritize these lines. While raw material costs may be higher, the growing consumer demand for sustainable products and favorable regulatory environments make them a strategic choice. Markets with progressive sustainability policies, such as parts of Europe and the Middle East, represent ideal distribution channels for these shoes.

Key Industrial Applications of kobe adidas shoes

| Industry/Sector | Specific Application of kobe adidas shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports & Athletic Apparel | Customization for sports teams and training facilities | Enhances brand recognition, boosts team morale, and supports athlete performance | Quality assurance, customization options, reliable supply chain |

| Retail & E-commerce | Wholesale distribution to sports retailers and specialty stores | Drives sales volume, expands market reach, and enhances product portfolio | Competitive pricing, consistent inventory, regional distribution capabilities |

| Corporate & Promotional Events | Branded promotional giveaways and corporate gifts | Increases brand visibility, fosters client loyalty, and enhances corporate image | Branding flexibility, bulk order discounts, timely delivery |

| Healthcare & Rehabilitation | Supportive footwear for injury prevention and recovery | Offers ergonomic benefits, reduces injury risk, and improves patient compliance | Compliance with medical standards, ergonomic design features |

| Construction & Industrial Safety | Durable footwear for workers in hazardous environments | Provides safety, durability, and comfort, reducing workplace accidents | Certification for safety standards, material durability, bulk sourcing |

Sports & Athletic Apparel

Kobe adidas shoes are extensively used in the sports industry for athlete performance and team branding. B2B buyers, such as sports apparel manufacturers or team sponsors, leverage these shoes for custom designs, team branding, and promotional events. Their high-performance features support athletes in training and competitions, making them attractive for resale or bulk procurement. For international buyers, especially in Africa and South America, sourcing reliable suppliers with consistent quality and customization options ensures brand integrity and athlete satisfaction.

Retail & E-commerce

Wholesale distribution of kobe adidas shoes to retail outlets and online platforms is a key B2B application. Distributors benefit from broad product ranges that appeal to diverse customer bases, boosting their sales and market presence. Buyers should prioritize sourcing from suppliers with strong logistics networks to ensure timely delivery across regions like Europe and Nigeria. Competitive pricing and stable inventory levels are critical to maintaining retailer confidence and expanding market share.

Corporate & Promotional Events

Kobe adidas shoes serve as effective promotional items for corporate branding and client engagement. B2B buyers, such as marketing agencies or corporate gift suppliers, utilize these shoes as giveaways during events, sponsorships, or employee incentives. The ability to customize branding on shoes adds value, making them memorable promotional tools. Ensuring quick turnaround times and bulk discounts is essential for international buyers managing large-scale campaigns across diverse markets.

Illustrative Image (Source: Google Search)

Healthcare & Rehabilitation

In the healthcare sector, specially designed kobe adidas shoes are used for injury prevention, orthotic support, and rehabilitation programs. B2B buyers such as medical supply distributors or rehabilitation centers source these shoes for their ergonomic features and compliance with medical standards. For international markets like Europe and Africa, sourcing shoes with certified safety and ergonomic standards ensures acceptance and efficacy, while bulk procurement reduces per-unit costs and streamlines supply.

Construction & Industrial Safety

Durable, protective footwear modeled after kobe adidas shoes is vital for workers in hazardous environments, including construction sites and industrial facilities. These shoes provide safety features such as slip resistance, impact protection, and long-lasting durability. B2B buyers in regions with high industrial activity, such as Nigeria or Middle Eastern countries, prioritize sourcing from suppliers with certification for safety standards and the ability to supply in bulk, ensuring worker safety and compliance with local regulations.

Strategic Material Selection Guide for kobe adidas shoes

Material Analysis for Kobe Adidas Shoes

Selecting the appropriate materials for Kobe Adidas shoes is crucial for ensuring product quality, durability, and compliance with international standards. Different materials offer distinct advantages and limitations, which must be carefully considered from a B2B perspective, especially for international buyers across Africa, South America, the Middle East, and Europe. Below is a detailed analysis of key materials commonly used in these shoes.

Leather (Full-Grain and Synthetic)

Key Properties:

Leather, especially full-grain, offers excellent durability, breathability, and a premium feel. Synthetic variants provide similar aesthetic qualities with lower costs and more consistent quality. Both types are resistant to abrasion but vary in moisture management.

Pros & Cons:

– Pros: High durability, good moisture regulation, and aesthetic appeal. Leather is often preferred for high-end models and branding.

– Cons: Leather can be expensive, requires significant manufacturing expertise, and may have environmental concerns related to tanning processes. Synthetic leather, while cheaper, may degrade faster and offer less breathability.

Impact on Application:

Leather materials are suitable for high-performance areas like the upper and overlays, providing support and style. Synthetic options are often used in mid-tier models for cost efficiency.

International Considerations:

– Compliance with environmental standards (e.g., REACH in Europe, ECHA regulations) is vital.

– Buyers should verify sourcing and tanning processes to meet local regulations.

– Leather imports may face tariffs and import restrictions in some African and Middle Eastern countries, necessitating careful logistics planning.

Mesh and Knit Fabrics

Key Properties:

Mesh and knit fabrics are lightweight, highly breathable, and flexible. They are often used in the upper sections for ventilation and comfort.

Pros & Cons:

– Pros: Excellent airflow, reduces weight, and allows for design flexibility.

– Cons: Less resistant to tearing and abrasion; may require reinforcement for durability.

Impact on Application:

Ideal for performance zones where breathability is critical, such as the tongue and side panels. They also facilitate rapid moisture wicking, enhancing athlete comfort.

International Considerations:

– Mesh fabrics must meet standards for flame retardancy and chemical safety, especially in markets with strict textile regulations.

– Buyers should confirm fabric certifications (e.g., OEKO-TEX) to ensure compliance across regions.

– Variability in quality can influence product lifespan, so sourcing from reputable suppliers is recommended.

EVA and Polyurethane (PU) Foam

Key Properties:

EVA (Ethylene Vinyl Acetate) and PU foams are used extensively in midsoles for cushioning and shock absorption. They offer a balance of weight, flexibility, and comfort.

Pros & Cons:

– Pros: Lightweight, good energy return, and cost-effective.

– Cons: EVA can degrade faster under UV exposure, while PU offers better longevity but is heavier and more expensive.

Impact on Application:

Critical for midsole construction, affecting overall comfort and performance. Proper selection impacts product durability and customer satisfaction.

International Considerations:

– Foam materials must meet safety standards for chemical emissions (e.g., VOC limits).

– In regions with high UV exposure, UV-resistant formulations are advantageous.

– Cost considerations are significant; EVA is generally preferred in lower-cost markets, while PU suits premium segments.

Summary Table

| Material | Typical Use Case for Kobe Adidas Shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather (Full-Grain/Synthetic) | Upper overlays, branding, support structures | Durability, premium feel, aesthetic appeal | Costly, environmental concerns, manufacturing complexity | High |

| Mesh and Knit Fabrics | Ventilation zones, uppers, tongue lining | Breathability, lightweight, flexible | Less abrasion resistance, potential for tearing | Low to Med |

| EVA and PU Foam | Midsoles for cushioning and shock absorption | Lightweight, cost-effective, good shock absorption | EVA degrades faster under UV, PU is heavier and costlier | Low to Med |

Final Remarks for International B2B Buyers

When sourcing materials for Kobe Adidas shoes, it is essential to prioritize suppliers who can demonstrate compliance with regional standards such as REACH (Europe), ASTM (North America), or JIS (Japan). For markets like Nigeria and other African countries, understanding import tariffs, environmental regulations, and quality certifications can influence material selection and overall product cost. Similarly, in the Middle East, adherence to chemical safety standards and durability under harsh conditions is critical. European buyers should focus on sustainability certifications, as European markets increasingly favor eco-friendly materials.

By aligning material choices with regional standards and market preferences, B2B buyers can optimize product quality, reduce compliance risks, and enhance their competitive edge in diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for kobe adidas shoes

Manufacturing Processes of Kobe adidas Shoes

The production of Kobe adidas shoes involves a complex, multi-stage process designed to ensure durability, performance, and aesthetic appeal. For B2B buyers, understanding these stages is crucial for assessing supplier capabilities and quality consistency.

Material Preparation

The process begins with sourcing high-quality raw materials aligned with industry standards. Upper components are typically made from engineered mesh, synthetic leather, or textile blends, selected for breathability and flexibility. Midsole and outsole materials often include EVA foam, Boost technology, or rubber compounds that offer shock absorption and durability. Suppliers must comply with international material safety standards, such as REACH or RoHS, especially when exporting to regions with strict regulations like the EU or UK.

Forming and Component Manufacturing

In this stage, components such as uppers, midsoles, and outsoles are manufactured separately. Cutting-edge techniques like automated CNC cutting and laser precision ensure consistency and minimal waste. For uppers, sewing and bonding processes—using heat, adhesives, or ultrasonic welding—are employed to assemble panels accurately. Midsole molding involves injection or compression molding, often utilizing computer-controlled equipment to ensure uniformity.

Assembly

The assembled components are brought together through a series of bonding, stitching, and fitting operations. Automated robotic systems are increasingly used for stitching, especially for high-volume production, ensuring tight tolerances. The footwear is then subjected to preliminary quality checks, such as dimensional accuracy and visual inspection, before moving to finishing.

Finishing

Final touches include adding branding elements, insoles, laces, and packaging. Quality control at this stage focuses on ensuring all components meet design specifications. Surface treatments like polishing or coating are applied to enhance appearance and protect against environmental factors. Packaging adheres to international standards to prevent damage during transit.

Quality Control (QC) Framework for Kobe adidas Shoes

Ensuring consistent quality in Kobe adidas shoes requires a rigorous, multi-layered QC process aligned with international standards and industry-specific certifications.

International Standards Compliance

Most reputable manufacturers operate under ISO 9001, which emphasizes quality management systems, process control, and continuous improvement. Adherence to ISO standards assures B2B buyers of a manufacturer’s commitment to quality consistency. For regions like the EU and UK, compliance with CE marking directives indicates conformity with safety, health, and environmental requirements.

Industry-Specific Certifications

Depending on the target market, additional certifications may be necessary:

– CE Certification: For European markets, confirming conformity with safety and environmental standards.

– ISO 14001: Environmental management, increasingly important for eco-conscious buyers.

– OEKO-TEX or Global Organic Textile Standard (GOTS): For environmentally friendly and non-toxic materials used in uppers and linings.

QC Checkpoints

To maintain quality throughout production, manufacturers implement multiple checkpoints:

-

Incoming Quality Control (IQC): Raw materials are inspected upon receipt for defects, compliance with specifications, and safety standards. Techniques include visual inspection, dimensional measurement, and material testing.

-

In-Process Quality Control (IPQC): Continuous monitoring during manufacturing ensures adherence to process parameters. Automated systems check stitching integrity, bonding strength, and dimensional tolerances. Statistical process control (SPC) tools are often used to detect deviations early.

-

Final Quality Control (FQC): Completed shoes undergo comprehensive inspection for visual defects, consistency, and functionality. Testing includes:

- Durability Tests: Flex, compression, and wear tests simulate real-world use.

- Environmental Tests: Resistance to water, UV, and temperature variations.

- Fit and Comfort Tests: Ensuring ergonomic standards are met.

Testing Methods

- Mechanical Testing: Tensile, shear, and adhesion tests verify bonding strength and structural integrity.

- Material Testing: Chemical composition, colorfastness, and toxicity are checked using spectroscopy and chemical analysis.

- Performance Testing: Laboratory simulations of impact, fatigue, and slip resistance ensure product reliability.

How B2B Buyers Can Verify Supplier QC

For international buyers, especially from Africa, South America, the Middle East, and Europe, verifying the integrity of a supplier’s QC processes is paramount to mitigate risks and ensure product consistency.

Supplier Audits

Engage third-party or in-house auditors to review manufacturing facilities, quality management systems, and documentation. Audits should verify:

– Compliance with ISO 9001 and other relevant standards.

– Implementation of QC checkpoints and testing procedures.

– Traceability of materials and components.

Inspection Reports and Certifications

Request detailed inspection reports, test certificates, and certifications for each batch or production run. Authentic documentation from accredited labs or certification bodies provides assurance of quality claims.

Third-Party Inspection Services

Utilize independent inspection agencies like SGS, Bureau Veritas, or TUV to conduct on-site inspections. These agencies can:

– Verify production processes.

– Conduct random sampling and testing.

– Confirm compliance with contractual specifications.

Continuous Monitoring and Feedback

Establish a system for ongoing quality monitoring, including:

– Regular site visits.

– Review of production metrics.

– Feedback loops for continuous improvement.

QC Nuances for International B2B Engagements

Different regions have distinct regulatory and market expectations that impact QC requirements:

- Africa and South America: Emphasize supplier traceability, compliance with local import regulations, and sustainable sourcing. Quality documentation must be clear and verifiable, given potential customs scrutiny.

- Middle East: Focus on compliance with safety standards like SASO (Saudi Standards) and environmental certifications, considering regional regulations.

- Europe (UK): Strict adherence to CE marking, REACH, and GOTS standards is essential. B2B buyers should verify that suppliers maintain up-to-date certifications and conduct periodic third-party audits.

Final Recommendations for B2B Buyers

- Develop clear, detailed specifications and quality expectations upfront.

- Establish a rigorous supplier qualification process, including audits and testing.

- Use third-party inspection agencies for unbiased verification.

- Maintain open communication channels to address QC issues promptly.

- Consider long-term partnerships with suppliers demonstrating consistent quality and transparency.

By understanding the detailed manufacturing stages and implementing a robust quality assurance framework, international B2B buyers can confidently source Kobe adidas shoes that meet their regional standards and consumer expectations.

Comprehensive Cost and Pricing Analysis for kobe adidas shoes Sourcing

Cost Structure Breakdown for Kobe Adidas Shoes Sourcing

Understanding the comprehensive cost components involved in sourcing Kobe Adidas shoes is vital for international B2B buyers. The primary expense categories include:

- Materials: High-quality synthetic uppers, rubber soles, foam insoles, and specialized textiles contribute significantly to costs. Premium materials with branding or performance-enhancing features can increase unit prices.

- Labor: Manufacturing costs vary based on the country of production. Factories in Asia (e.g., Vietnam, China) often offer lower labor rates, but buyers should consider the impact of labor standards and compliance costs.

- Manufacturing Overheads: These encompass equipment depreciation, factory utilities, and maintenance. Efficient factories with advanced machinery tend to have higher upfront costs but may reduce overall production time and defects.

- Tooling & Development: Initial mold creation and design adjustments represent fixed costs. Customization or limited editions can elevate these expenses, especially if multiple prototypes are involved.

- Quality Control & Certifications: Meeting international standards (ISO, CE, or ASTM) adds costs but ensures product reliability, reducing returns and warranty claims.

- Logistics & Shipping: FOB (Free on Board) prices typically cover factory delivery, but total landed costs depend on freight mode, volume, and destination port charges.

- Profit Margin: Manufacturers and suppliers add margins based on market conditions, volume commitments, and negotiation outcomes.

Price Influencers and Variability

Several factors influence the final pricing of Kobe Adidas shoes in B2B transactions:

- Order Volume & MOQ: Larger orders typically attract lower unit costs due to economies of scale. Minimum Order Quantities (MOQs) vary, but high-volume buyers can negotiate better prices.

- Product Specifications & Customization: Special features such as exclusive colorways, branding, or performance enhancements increase costs. Customization often incurs additional tooling and development fees.

- Material Choices: Using premium or sustainable materials raises costs but may appeal to specific markets or branding strategies.

- Certifications & Standards: Meeting regional safety, environmental, or quality certifications can add to manufacturing costs but improve market acceptance.

- Supplier Factors: Established suppliers with strong reputations might command higher prices but offer better reliability and quality assurance.

- Incoterms & Delivery Terms: The choice of Incoterms (e.g., FOB, CIF, DDP) significantly impacts total landed cost, affecting responsibilities and additional charges like insurance and customs duties.

Strategic Buyer Tips for Cost Optimization

Negotiation & Relationships: Building long-term relationships with suppliers can unlock better pricing, flexible MOQs, and priority during peak production times. Leverage your purchasing volume to negotiate discounts, especially for recurring orders.

Focus on Total Cost of Ownership (TCO): Consider not only unit price but also shipping, customs duties, taxes, and potential delays. For buyers in Nigeria, the UK, or South America, understanding import tariffs and local regulations is crucial to avoid unexpected expenses.

Customization & Specifications: Clearly define your product specifications upfront to minimize costly revisions. Opt for standard models when possible to benefit from existing economies of scale.

Pricing Nuances for International Buyers:

- Africa & South America: Tariffs, import duties, and logistical complexities often inflate costs. Working with suppliers familiar with regional customs can reduce delays and hidden fees.

- Middle East & Europe: Markets may demand higher quality certifications and sustainable materials, which can elevate costs but also enhance brand positioning.

Indicative Price Range: As a rough estimate, FOB prices for Kobe Adidas shoes typically range from $30 to $60 per pair for bulk orders (minimum 1,000 units). Final landed costs, including shipping and duties, can add 20-40%, depending on the destination country and logistics choices.

Final Remarks

While these insights provide a foundational understanding, actual prices vary based on market dynamics, supplier relationships, and specific product requirements. Conduct detailed quotations from multiple suppliers, and factor in all logistics, compliance, and regional costs to determine the most cost-effective sourcing strategy for your market. Building strong partnerships and thorough due diligence are key to optimizing costs and ensuring consistent product quality in your Kobe Adidas shoes procurement process.

Spotlight on Potential kobe adidas shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for kobe adidas shoes.)*

Essential Technical Properties and Trade Terminology for kobe adidas shoes

Critical Technical Properties for Kobe Adidas Shoes

1. Material Grade and Composition

The quality of materials used in Kobe Adidas shoes directly impacts durability, comfort, and brand perception. Common materials include premium synthetic leather, mesh fabrics, and specialized foam insoles. For B2B transactions, specifying material grades—such as ASTM or ISO standards—ensures consistency across batches. High-grade materials reduce return rates and enhance the product’s value proposition, making them crucial for international buyers aiming for premium positioning.

2. Manufacturing Tolerance Levels

Tolerance refers to the acceptable range of variation in dimensions and construction during production. For shoes, this includes sole thickness, upper stitching, and overall sizing. Tight tolerances (e.g., ±0.5 mm) indicate high precision, ensuring product uniformity and compatibility with international sizing standards. B2B buyers should specify tolerance levels to prevent defects and facilitate smooth distribution across markets.

3. Weight and Balance Specifications

Lightweight design enhances athlete performance and consumer appeal. Precise weight specifications—such as grams per pair—are vital for inventory planning and shipping logistics. Balanced weight distribution also affects comfort and athletic performance, which are key selling points in competitive markets.

4. Sole and Midsole Material Properties

The sole material’s grip, elasticity, and shock absorption are critical for performance shoes like Kobe Adidas models. Materials such as EVA foam or rubber compounds must meet specific hardness (Shore A scale) and rebound characteristics. These properties influence product lifespan and safety standards, making them essential for quality assurance and marketing claims.

5. Color and Finish Consistency

Colorfastness and finish quality are vital for brand uniformity, especially when exporting to diverse climates. Specifications should include Pantone color matching and resistance to UV or water exposure. Consistent color and finish reduce customer complaints and returns.

Essential Industry and Trade Terms

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce Kobe Adidas shoes based on the buyer’s specifications and branding. Understanding OEM arrangements allows buyers to customize product features, packaging, and branding, ensuring the final product aligns with local market preferences.

2. MOQ (Minimum Order Quantity)

The smallest order size a manufacturer accepts, often dictated by production costs and economies of scale. Knowing MOQ helps buyers plan procurement budgets, negotiate better terms, and manage inventory levels effectively, especially in markets with fluctuating demand.

3. RFQ (Request for Quotation)

A formal process where buyers solicit price and lead time estimates from suppliers. RFQs are critical for competitive sourcing, enabling buyers to compare offers, assess supplier reliability, and negotiate favorable terms before committing to large orders.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibility points between buyers and sellers for shipping, insurance, and tariffs. Common Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) clarify cost responsibilities, delivery timelines, and risk transfer—vital for international logistics planning.

5. Quality Assurance (QA) and Certification

Refers to standards and tests (e.g., ISO, ASTM, CE) that verify product safety, environmental compliance, and performance. Confirming QA processes and certifications ensures Kobe Adidas shoes meet regional import regulations, reducing customs delays and liability risks.

6. Lead Time

The duration from order placement to product shipment. Awareness of lead times allows B2B buyers to synchronize production schedules, manage inventory buffers, and meet retail deadlines across different markets.

Actionable Insights for International Buyers

- Clearly specify material grades and tolerance standards in purchase agreements to ensure consistent quality.

- Understand and negotiate MOQs to optimize procurement costs while maintaining flexibility.

- Use RFQs extensively to compare supplier offers, especially when entering new markets or dealing with unfamiliar manufacturers.

- Familiarize with Incoterms to structure logistics and minimize unexpected costs or responsibilities.

- Verify supplier certifications and QA processes to ensure compliance with local regulations and reduce supply chain disruptions.

- Incorporate lead time considerations into inventory planning to meet market demand efficiently and avoid stockouts.

By mastering these technical properties and trade terms, international B2B buyers can streamline procurement processes, reduce risks, and secure high-quality Kobe Adidas shoes tailored to their specific market needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the kobe adidas shoes Sector

Market Overview & Key Trends

The global market for Kobe adidas shoes is shaped by several dynamic drivers, including evolving consumer preferences, technological innovations, and supply chain globalization. As a premium athletic footwear segment, Kobe adidas shoes appeal to niche markets focused on performance, style, and brand loyalty. International B2B buyers from Africa, South America, the Middle East, and Europe are increasingly seeking reliable sourcing partners to meet rising demand for authentic, high-quality products.

Emerging trends such as digital supply chain management, blockchain-based authentication, and advanced manufacturing techniques are transforming sourcing strategies. For example, digital platforms enable real-time inventory tracking and transparent procurement processes, reducing counterfeiting risks and enhancing trust. Additionally, additive manufacturing and automation are improving production efficiency, allowing for faster turnaround times and customization options.

Market dynamics are influenced by fluctuating raw material costs, geopolitical factors, and regional trade policies. Buyers in Africa and South America, for instance, benefit from exploring local or regional suppliers to mitigate import tariffs and shipping delays. Meanwhile, European and Middle Eastern buyers are leveraging trade agreements and logistics hubs to optimize supply chain resilience.

Sourcing trends favor sustainable and ethical production, driven by increasing consumer awareness and regulatory standards. Buyers are now prioritizing partnerships with suppliers committed to transparency, fair labor practices, and environmental responsibility. The ability to adapt swiftly to market shifts—such as demand surges during sporting seasons or new product launches—is crucial for maintaining competitiveness.

For B2B buyers, understanding these market drivers and technological advancements enables strategic sourcing decisions. Building relationships with diversified suppliers, embracing digital tools for supply chain transparency, and staying attuned to regional trade developments will be key to navigating this complex landscape effectively.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

Sustainability has become a central pillar in the sourcing of Kobe adidas shoes, reflecting a broader shift within the athletic footwear industry toward reducing environmental impact and promoting ethical practices. For international B2B buyers, aligning procurement strategies with sustainability standards is not only ethically responsible but also commercially advantageous, as consumers increasingly favor brands with clear environmental commitments.

Environmental impacts of sneaker production include high water and energy consumption, waste generation, and the use of non-renewable materials. Kobe adidas shoes manufacturers are responding by integrating recycled materials, such as ocean plastics and agricultural waste, into their supply chains. The adoption of eco-friendly dyes and low-impact manufacturing processes further minimizes ecological footprints.

Certifications such as the Global Organic Textile Standard (GOTS), Leather Working Group (LWG) certification, and Fair Trade labels are vital indicators of a supplier’s commitment to sustainability and ethical sourcing. B2B buyers should prioritize partnerships with suppliers possessing these credentials, ensuring transparency and compliance with international standards.

Ethical sourcing also encompasses labor rights, fair wages, and safe working conditions. Buyers should conduct rigorous due diligence, including supplier audits and third-party verifications, to mitigate risks associated with child labor, forced labor, or unsafe environments. Establishing long-term relationships with certified suppliers can enhance supply chain resilience and reputation.

Investing in sustainable sourcing not only meets regulatory requirements across regions like Europe and the Middle East but also aligns with the growing consumer demand for ethically produced products. For B2B buyers, embedding sustainability criteria into supplier selection processes and fostering collaborative initiatives—such as joint eco-innovation projects—are actionable strategies to future-proof their sourcing operations.

Brief Evolution/History (Optional)

The Kobe adidas shoes segment has evolved significantly over the past two decades, transitioning from basic athletic footwear to a premium, technologically advanced product line. Early collaborations between Kobe Bryant and adidas focused on performance innovation, but recent years have seen a shift toward sustainability and ethical manufacturing, driven by global consumer and regulatory pressures.

This evolution influences B2B sourcing by emphasizing transparency, quality assurance, and adaptability. Suppliers now invest in eco-friendly materials and ethical labor practices, aligning with international standards and consumer expectations. For international buyers, understanding this trajectory helps in selecting partners who are committed to ongoing innovation and responsible practices, ensuring long-term supply chain stability.

By staying informed about the sector’s historical shifts, B2B buyers can better anticipate future trends, such as the integration of smart technology and increased regional manufacturing capabilities, enabling strategic planning and competitive advantage.

Frequently Asked Questions (FAQs) for B2B Buyers of kobe adidas shoes

1. How can I verify the legitimacy and reliability of Kobe Adidas shoe suppliers?

To ensure supplier legitimacy, start by requesting verified business licenses, certifications (such as ISO or factory audits), and references from existing clients. Utilize platforms like Alibaba Gold Supplier or Global Sources with verified profiles. Conduct virtual factory visits or third-party inspections when possible, especially for high-value orders. Reviewing supplier history, payment terms, and response time also provides insight into their reliability. Establish clear communication channels and request samples before bulk purchasing. Building relationships with suppliers who are transparent and compliant reduces risks of counterfeit products or fraud, safeguarding your brand reputation in international markets.

2. What customization options are available for Kobe Adidas shoes, and how do they impact order lead times?

Many reputable suppliers offer customization such as branding, colorways, packaging, and limited-edition designs. Customization typically involves additional setup costs and longer lead times—usually between 4 to 8 weeks—depending on complexity and order volume. For quick turnarounds, consider suppliers with in-house design teams or pre-approved templates. Clear communication of your specifications and early planning are critical to align production schedules. Be aware that extensive customization may also impact MOQ requirements and pricing. Establish a detailed contract to account for potential delays and ensure quality standards are met throughout the process.

3. What are typical minimum order quantities (MOQs), lead times, and payment terms for importing Kobe Adidas shoes?

MOQs for Kobe Adidas shoes generally range from 300 to 1,000 pairs, depending on the supplier and customization level. Lead times vary from 4 to 12 weeks, influenced by order size, customization, and factory capacity. Standard payment terms often include a 30% deposit upfront with the balance payable before shipment or on delivery. Some suppliers may offer flexible terms for repeat buyers or large orders, such as letter of credit or open account arrangements. Negotiating these terms early, along with clear delivery schedules, helps optimize cash flow and inventory planning, especially for buyers in Africa, South America, the Middle East, and Europe.

4. What quality assurance certifications should I look for in Kobe Adidas shoe suppliers?

Verify that suppliers hold relevant quality assurance certifications such as ISO 9001 for quality management and compliance with international safety standards like REACH (for chemicals) or CPSIA (for children’s products). For footwear, certifications related to sole adhesion, sole durability, and material safety are essential. Request detailed test reports or third-party inspection certificates to confirm product authenticity, durability, and safety. Suppliers with established quality control processes and transparent documentation reduce the risk of defective products reaching your market. This is especially critical when importing to regions with strict import regulations like Europe or the Middle East.

5. How can I manage international logistics effectively when importing Kobe Adidas shoes?

Effective logistics management involves selecting reliable freight forwarders experienced in footwear shipments, especially for bulk consignments. Consider options like sea freight for cost efficiency or air freight for urgent orders, balancing cost and delivery speed. Ensure suppliers provide comprehensive shipping documentation, including bills of lading, invoices, and certificates of origin, to streamline customs clearance. Partner with customs brokers familiar with import regulations in your country—Nigeria, UK, or Brazil—to avoid delays. Additionally, plan for warehousing and distribution, considering potential tariffs, taxes, and local compliance requirements to optimize the supply chain flow.

6. How do I handle disputes or quality issues with Kobe Adidas shoe suppliers?

Establish clear contractual terms covering quality standards, inspection rights, and dispute resolution procedures before placing orders. Conduct pre-shipment inspections through third-party agencies or on-site audits to verify product quality. If issues arise, communicate promptly with suppliers, providing documented evidence such as photos or inspection reports. Negotiating arbitration or mediation clauses in contracts can facilitate resolution without lengthy legal processes. Maintaining good supplier relationships and transparent communication often helps resolve disputes amicably. For persistent issues, consider legal counsel familiar with international trade laws to enforce contractual rights effectively.

7. What are the key considerations for ensuring product authenticity and preventing counterfeit Kobe Adidas shoes?

Verify supplier credentials and request official authorization from Adidas or Kobe brands, especially for branded products. Use traceability features like QR codes, holograms, or unique serial numbers embedded in the shoes. Request detailed product documentation, including factory audit reports and authenticity certificates. Work with suppliers who provide transparent supply chain traceability and have a track record of delivering genuine products. Conduct periodic quality checks and consider third-party authentication services for high-value shipments. Ensuring authenticity not only protects your brand reputation but also complies with international trademark laws, especially in markets like Europe and the Middle East.

8. How can I stay compliant with import regulations and tariffs in different regions?

Research specific import regulations, tariffs, and product standards in your target markets—such as Nigeria, the UK, or South America—prior to importing Kobe Adidas shoes. Work with customs brokers who understand regional compliance requirements, including labeling, packaging, and safety standards. Keep updated on trade agreements or tariffs that may impact costs, such as the UK-EU trade deal or regional trade blocs. Maintaining detailed documentation, including invoices, certificates of origin, and compliance certificates, simplifies customs clearance. Regularly reviewing regulatory changes and engaging with local trade authorities or industry associations enhances compliance and reduces the risk of shipment delays or fines.

This comprehensive FAQ section aims to empower international B2B buyers with actionable insights, helping them navigate the complexities of sourcing Kobe Adidas shoes efficiently and securely across diverse markets.

Strategic Sourcing Conclusion and Outlook for kobe adidas shoes

Strategic Sourcing Outlook for Kobe Adidas Shoes

Effective strategic sourcing is essential for international B2B buyers seeking to capitalize on the growing demand for Kobe Adidas shoes across diverse markets such as Africa, South America, the Middle East, and Europe. By prioritizing reliable supply chain partnerships, leveraging local manufacturing options, and maintaining a keen eye on quality standards, buyers can optimize costs while ensuring product authenticity and brand integrity.

Key takeaways include:

– Building strong relationships with authorized distributors and verified manufacturers to mitigate counterfeit risks.

– Exploring diversified sourcing channels to enhance supply resilience amidst global disruptions.

– Incorporating sustainable and ethical sourcing practices to meet increasing consumer and regulatory expectations.

Looking ahead, the evolving footwear market presents significant opportunities for strategic sourcing initiatives that foster innovation, cost efficiency, and brand differentiation. International buyers should continuously evaluate emerging suppliers and leverage technological tools to streamline procurement processes. Proactively adapting sourcing strategies will position buyers to meet market demands effectively, ensuring long-term growth and competitive advantage in the Kobe Adidas shoes segment. Now is the time to act—embrace strategic sourcing as a key driver of success in this dynamic industry landscape.