Your Ultimate Guide to Sourcing Maroon Shoes

Guide to Maroon Shoes

- Introduction: Navigating the Global Market for maroon shoes

- Understanding maroon shoes Types and Variations

- Key Industrial Applications of maroon shoes

- Strategic Material Selection Guide for maroon shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for maroon shoes

- Comprehensive Cost and Pricing Analysis for maroon shoes Sourcing

- Spotlight on Potential maroon shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for maroon shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the maroon shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of maroon shoes

- Strategic Sourcing Conclusion and Outlook for maroon shoes

Introduction: Navigating the Global Market for maroon shoes

In today’s competitive global footwear landscape, maroon shoes stand out as a versatile and sophisticated option for retailers, wholesalers, and corporate buyers worldwide. Their rich, distinctive hue offers a unique aesthetic that appeals across diverse markets—from the vibrant streets of Africa and South America to the refined fashion scenes of Europe and the Middle East. For B2B buyers, understanding the nuances of sourcing maroon shoes—from material selection to manufacturing quality—is crucial for maintaining product excellence and meeting consumer expectations.

This comprehensive guide is designed to equip international buyers with essential insights into the maroon shoe market. It covers various styles, including formal, casual, and athletic options, and dives deep into material options such as leather, synthetic fibers, and eco-friendly alternatives. Additionally, the guide provides practical advice on evaluating manufacturing and quality control processes, identifying reliable suppliers across key regions, and managing costs without compromising quality.

By navigating the complexities of global sourcing—factoring in tariffs, shipping logistics, and regional market preferences—buyers can make informed decisions that optimize their supply chain. Whether you’re sourcing from established manufacturing hubs in Europe or emerging markets in South America and Africa, this guide offers actionable strategies to enhance your procurement process. Ultimately, it empowers B2B buyers to confidently seize market opportunities, strengthen supplier relationships, and deliver high-quality maroon shoes tailored to diverse consumer demands worldwide.

Understanding maroon shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Leather Maroon Shoes | Smooth, high-quality leather with a uniform maroon finish | Formal wear, corporate uniforms, luxury retail | Pros: Durable, timeless appeal; Cons: Higher initial cost, limited style variations |

| Suede Maroon Shoes | Soft, textured suede material with a matte finish | Casual, semi-formal events, boutique fashion | Pros: Unique texture, premium look; Cons: Less resistant to moisture, higher maintenance |

| Patent Maroon Shoes | Glossy, high-shine patent leather with a reflective surface | Special occasions, fashion-forward retail | Pros: Eye-catching, premium appearance; Cons: Prone to scratches, less breathable |

| Athletic Maroon Shoes | Lightweight, breathable materials with supportive soles | Sports, activewear, casual retail | Pros: Comfort, performance-oriented; Cons: Limited formal appeal, shorter lifespan if overused |

| Vintage-Style Maroon Shoes | Retro designs with detailed stitching, brogue patterns, or decorative elements | Niche fashion markets, costume production | Pros: Distinctive aesthetic, high demand in niche markets; Cons: Limited mass-market appeal, higher production costs |

Classic Leather Maroon Shoes

This category epitomizes traditional elegance, crafted from high-quality leather with a smooth, polished finish. They are ideal for formal settings such as corporate offices, diplomatic events, and luxury retail outlets. B2B buyers should prioritize sourcing from reputable manufacturers who offer consistent leather quality and reliable supply chains. Consider factors like leather tanning processes and finishing techniques, which influence durability and appearance. Although they entail higher procurement costs, their longevity and classic appeal make them a sound investment for premium markets.

Suede Maroon Shoes

Suede shoes feature a soft, textured surface that offers a sophisticated, understated look. They are well-suited for semi-formal events, boutique fashion stores, and niche markets seeking premium, unique footwear. When sourcing suede shoes, buyers should evaluate the quality of the suede, including its nap consistency and tanning process, to ensure durability and aesthetic appeal. Suede requires careful handling and protective treatments, making maintenance a consideration for end-users. From a procurement perspective, suppliers offering high-grade suede with consistent color and finish are preferable to meet quality standards.

Patent Maroon Shoes

Known for their high-gloss, reflective surface, patent shoes are often chosen for special occasions, fashion shows, or high-end retail segments aiming for a bold statement. B2B buyers should focus on sourcing from manufacturers with expertise in patent leather processing to avoid issues like cracking or peeling over time. These shoes are less breathable and more susceptible to scratches, so they are best suited for short-term or occasional use. Pricing may vary based on the quality of the patent finish, and bulk purchasing should include considerations for maintenance and storage to preserve their shine.

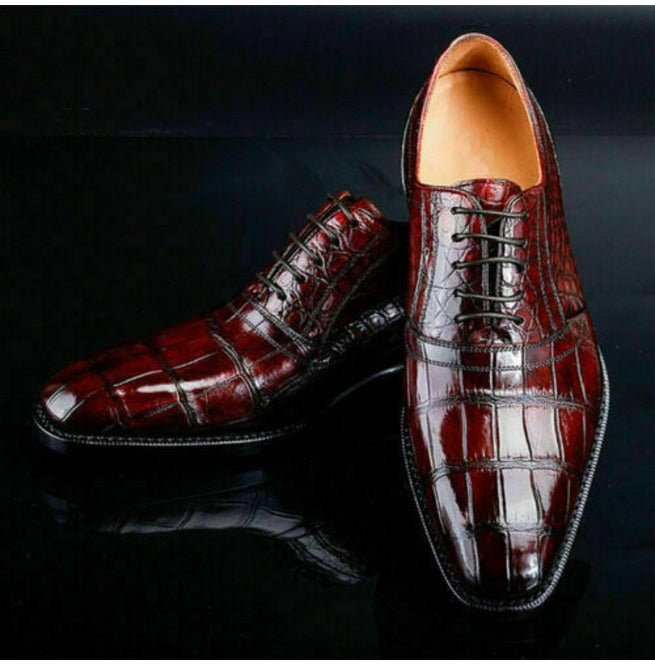

Illustrative Image (Source: Google Search)

Athletic Maroon Shoes

Designed for comfort and performance, athletic maroon shoes incorporate lightweight, breathable materials with cushioned soles. They are ideal for sports retailers, casual wear markets, and active lifestyle segments across regions like Africa and South America. Buyers should assess the quality of support features, sole durability, and breathability, especially when sourcing for large quantities. While they may lack formal appeal, their demand in the growing sports and casual sectors makes them a lucrative B2B product. Suppliers with reliable quality control and consistent material sourcing are critical for long-term supply stability.

Vintage-Style Maroon Shoes

This niche category captures retro aesthetics with detailed stitching, brogue patterns, or decorative elements. They appeal to fashion boutiques, costume producers, and specialty markets in Europe and Latin America. B2B buyers should seek manufacturers with expertise in artisanal craftsmanship and authentic vintage designs. Due to their specialized nature, production costs can be higher, and lead times longer. However, their distinctive appeal allows for premium pricing in targeted segments, making them a valuable addition to curated collections or boutique inventories.

Key Industrial Applications of maroon shoes

| Industry/Sector | Specific Application of maroon shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Heavy Industry | Protective footwear for construction workers on-site | Ensures safety compliance, reduces injury risk, enhances worker productivity | Durability, slip resistance, compliance with international safety standards (ISO, ASTM) |

| Oil & Gas | Specialized safety shoes for offshore and onshore operations | Protects against chemical, oil, and fire hazards; supports demanding environments | Resistance to chemicals and hydrocarbons, high heat resistance, certification for explosive atmospheres |

| Agriculture & Forestry | Durable, slip-resistant shoes for fieldwork | Enhances safety and comfort during prolonged outdoor activities | Weather resistance, lightweight design, abrasion resistance, adaptability to rugged terrains |

| Manufacturing & Warehousing | Industrial shoes for factory and warehouse staff | Improves safety, reduces accidents, and increases operational efficiency | Comfort for extended wear, slip resistance, compatibility with safety standards (EN ISO 20345) |

| Hospitality & Service | Uniform shoes for hospitality staff | Maintains a professional appearance while providing comfort and safety | Aesthetic appeal, comfort for long shifts, ease of cleaning, and slip resistance |

Construction & Heavy Industry

Maroon shoes are vital in construction and heavy industry environments where safety and durability are paramount. These shoes typically feature reinforced toe caps, slip-resistant soles, and durable uppers to withstand harsh conditions. International B2B buyers from regions like Africa and South America seek suppliers offering footwear that complies with global safety standards such as ISO and ASTM. Reliable sourcing ensures consistent quality, especially for large-scale projects, and helps mitigate risks associated with worker injuries, legal liabilities, and project delays.

Oil & Gas

In the oil and gas sector, maroon shoes serve as essential protective gear for personnel working in potentially explosive or chemically hazardous environments. These specialized safety shoes are designed with resistance to hydrocarbons, chemicals, and high temperatures, making them suitable for offshore platforms and refineries. B2B buyers in the Middle East and Europe prioritize footwear that meets stringent certifications (e.g., ATEX) and durability under extreme conditions. Sourcing from reputable manufacturers guarantees compliance and longevity, critical for operational safety and cost-efficiency.

Agriculture & Forestry

For agricultural and forestry operations, maroon shoes provide a combination of safety, comfort, and weather resistance. These shoes are designed to endure rugged terrains, mud, and moisture common in outdoor environments. Buyers from South America and Africa value lightweight, abrasion-resistant footwear that minimizes fatigue during long working hours. International sourcing considerations include material quality, slip resistance, and ease of cleaning, ensuring footwear remains functional and safe across diverse climatic conditions.

Manufacturing & Warehousing

In manufacturing and warehousing, workers require reliable, comfortable shoes that can withstand extended periods of standing and walking while providing protection against industrial hazards. Maroon shoes equipped with slip-resistant soles and protective toe caps reduce workplace accidents and improve operational efficiency. European and Argentine buyers often seek footwear that complies with EN ISO 20345 standards, emphasizing comfort, durability, and safety. Sourcing from established suppliers ensures consistent quality and adherence to safety regulations.

Hospitality & Service

Maroon shoes are increasingly used in the hospitality sector, where staff need footwear that balances professionalism with safety. These shoes often feature slip-resistant soles, easy-to-clean surfaces, and a polished appearance suitable for front-of-house roles. For international B2B buyers in Spain and the Middle East, sourcing high-quality, aesthetically appealing footwear ensures staff safety and enhances brand image. Considerations include material quality, comfort for long shifts, and compatibility with uniform standards to meet industry expectations.

Strategic Material Selection Guide for maroon shoes

Material Analysis for Maroon Shoes

Selecting the appropriate materials for maroon shoes requires a nuanced understanding of their physical properties, manufacturing considerations, and regional compliance standards. Below is a detailed analysis of four common materials used in the production of high-quality maroon footwear, emphasizing their suitability for international B2B buyers from Africa, South America, the Middle East, and Europe.

Leather (Full-Grain and Top-Grain)

Key Properties:

Leather remains the most traditional and preferred material for high-end maroon shoes due to its excellent durability, breathability, and aesthetic appeal. Full-grain leather offers superior strength and develops a patina over time, while top-grain leather provides a smoother finish with enhanced uniformity.

Pros & Cons:

Advantages include exceptional durability, comfort, and a premium appearance that aligns with luxury branding. However, leather production involves complex tanning processes, which can be costly and environmentally regulated. It is sensitive to moisture and requires proper maintenance.

Impact on Application:

Leather performs well across various media, including moisture and temperature fluctuations, making it suitable for formal and casual footwear. It also conforms well to custom molds, enhancing design flexibility.

International Considerations:

For buyers in Africa, South America, the Middle East, and Europe, sourcing leather involves ensuring compliance with environmental and animal welfare standards such as the EU’s REACH regulation or local regulations. Certification like LWG (Leather Working Group) can serve as quality assurance. Leather’s natural origin may pose challenges in humid climates unless treated appropriately.

Synthetic Leather (PU and PVC)

Key Properties:

Synthetic leather mimics natural leather but is produced from polyurethane (PU) or polyvinyl chloride (PVC). It offers consistent quality, lower cost, and easier manufacturing processes.

Pros & Cons:

Synthetic options are generally more affordable and resistant to moisture, making them suitable for regions with high humidity. They are lighter and easier to clean. However, synthetic leather tends to be less breathable, may crack over time, and generally has a shorter lifespan compared to genuine leather.

Impact on Application:

Ideal for mass-produced, cost-sensitive markets, synthetic leather suits casual and semi-formal maroon shoes. Its resistance to environmental factors makes it suitable for regions with variable climates.

International Considerations:

Buyers should verify compliance with local import regulations and standards such as REACH in Europe or similar standards in South America and Africa. Preference for eco-friendly or non-phthalate PVC formulations can influence market acceptance, especially in Europe where environmental standards are strict.

Microfiber and Engineered Fabrics

Key Properties:

Microfiber materials are engineered textiles with fine fibers that offer high durability, breathability, and water resistance. They can be engineered to mimic leather or other traditional materials.

Pros & Cons:

These materials are lightweight, resistant to staining, and generally less expensive. They also provide excellent flexibility and comfort. However, they may lack the premium feel of genuine leather and can be less durable under heavy abrasion.

Impact on Application:

Microfiber is suitable for casual or sporty maroon shoes, especially in markets emphasizing sustainability and innovation. Its water-resistant properties make it advantageous in humid or rainy climates.

International Considerations:

Buyers should ensure microfiber materials meet safety standards like OEKO-TEX or ISO certifications. Additionally, environmental concerns related to microfiber shedding and synthetic production may influence procurement decisions, especially in environmentally conscious European markets.

Rubber and Thermoplastic Polyurethane (TPU)

Key Properties:

Rubber and TPU are primarily used for soles and decorative elements but can also be incorporated into the upper design. They offer excellent shock absorption, flexibility, and weather resistance.

Pros & Cons:

Rubber and TPU are highly durable, resistant to water, and cost-effective. They are also easy to mold into complex shapes. However, their aesthetic appeal is limited compared to leather or synthetic alternatives, and they are less suitable for formal footwear.

Impact on Application:

Ideal for casual, outdoor, or work-oriented maroon shoes, especially in regions with rugged terrains or high moisture levels. They are also favored for their ease of manufacturing and recyclability.

International Considerations:

Compliance with environmental regulations regarding chemical content (e.g., REACH, RoHS) is essential. Buyers should prefer suppliers with certifications ensuring non-toxicity and sustainable manufacturing practices.

Summary Table

| Material | Typical Use Case for maroon shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather (Full/Top-Grain) | Formal, luxury, high-end casual shoes | Durable, breathable, premium appearance | Costly, environmentally sensitive, maintenance needed | High |

| Synthetic Leather (PU/PVC) | Mass-market casual and semi-formal shoes | Cost-effective, moisture-resistant, consistent quality | Less breathable, shorter lifespan, environmental concerns | Med |

| Microfiber and Engineered Fabrics | Sports, casual, eco-conscious markets | Lightweight, water-resistant, eco-friendly options | Less luxurious feel, potentially lower durability | Low to Med |

| Rubber & TPU | Outdoor, workwear, casual soles | Highly durable, weather-resistant, versatile | Limited aesthetic appeal, less formal | Low |

This comprehensive analysis enables international B2B buyers to make informed decisions aligned with regional standards, climate conditions, and market preferences. By understanding each material’s properties and limitations, buyers can optimize their supply chain, meet compliance requirements, and deliver products tailored to their target markets.

In-depth Look: Manufacturing Processes and Quality Assurance for maroon shoes

Manufacturing Processes for Maroon Shoes

The production of maroon shoes involves a series of carefully orchestrated stages that ensure both aesthetic appeal and durability. For B2B buyers, understanding these processes helps in assessing supplier capabilities and aligning quality expectations.

1. Material Preparation

The process begins with sourcing high-quality raw materials, primarily leather, synthetic leathers, or fabric uppers, and suitable sole materials such as rubber, EVA, or thermoplastic polyurethanes (TPU). Leather suppliers typically provide tanned hides with specific color treatments to achieve the distinctive maroon hue. Material inspection at this stage ensures conformity to specifications, including color consistency, thickness, and flexibility.

2. Forming and Cutting

The prepared materials are cut into pattern pieces using automated or manual cutting techniques. Computer Numerical Control (CNC) cutting machines are increasingly prevalent, offering precision and consistency. For custom or small-batch productions, manual cutting remains common. This stage emphasizes minimizing waste and ensuring pattern accuracy to prevent defects downstream.

3. Assembly and Stitching

The cut components are assembled through stitching, bonding, or adhesion. High-quality stitching, often reinforced with double or triple seams, enhances durability. For maroon shoes, special attention is paid to color-matched threads and seamless joining of upper parts to prevent fraying or peeling. Modern assembly lines may incorporate automated sewing machines, but skilled artisans often oversee complex details.

4. Lasting and Shaping

The assembled uppers are stretched over lasts—molds representing foot shapes—to give the shoe its final form. This process, often involving mechanical or manual lasting, ensures proper fit and aesthetics. Heat and moisture conditioning may be used to set the shape, especially for leather shoes.

5. Finishing

The final stage involves applying surface treatments, polishing, and adding decorative elements. For maroon shoes, finishing includes dyeing, buffing, and protective coatings to enhance color richness and resistance to environmental factors. Quality control during finishing ensures uniform coloration and surface smoothness.

Quality Assurance and Testing Standards

Effective quality assurance (QA) is vital to meet international standards and satisfy B2B buyer expectations. The manufacturing process is typically governed by a combination of international standards, industry-specific certifications, and rigorous internal protocols.

1. International Standards and Certifications

– ISO 9001: Most reputable manufacturers operate under ISO 9001, which mandates a quality management system focusing on continuous improvement and customer satisfaction.

– CE Marking (for European markets): Ensures compliance with safety, health, and environmental protection standards applicable within the European Economic Area (EEA).

– Industry-Specific Standards: For safety and environmental compliance, certifications such as REACH (chemical safety), and ASTM standards for material testing, may be relevant.

2. Quality Control Checkpoints

– Incoming Quality Control (IQC): Raw materials are inspected for color consistency, defect-free surfaces, and compliance with specifications before entering production.

– In-Process Quality Control (IPQC): Continuous monitoring during manufacturing ensures adherence to dimensions, stitching quality, and color uniformity. Techniques include visual inspections, measurement checks, and non-destructive testing methods.

– Final Quality Control (FQC): Completed shoes undergo comprehensive inspection for overall appearance, structural integrity, color uniformity, and functional testing such as flexibility and sole adhesion.

3. Testing Methods

– Color Fastness Tests: Assess resistance to rubbing, light, and washing, ensuring maroon color remains vibrant over time.

– Dimensional Stability: Checks for shrinkage or deformation after finishing processes.

– Flexibility and Durability Tests: Bending and wear tests simulate real-world usage, confirming longevity.

– Chemical Tests: Verify absence of harmful substances, complying with regulations like REACH or CPSIA.

Verifying Supplier Quality for International B2B Buyers

B2B buyers should adopt a proactive approach to validate supplier quality systems and compliance.

- Supplier Audits: Conduct on-site audits or third-party inspections to evaluate manufacturing practices, equipment, and quality management systems. Focus on documentation, cleanliness, and adherence to standards like ISO 9001.

- Review Quality Reports: Request detailed QC reports, test certificates, and batch samples. This documentation provides transparency on defect rates, testing outcomes, and process controls.

- Third-Party Inspection Services: Engage independent inspection agencies (e.g., SGS, Bureau Veritas) for pre-shipment quality checks, especially for high-volume orders or new suppliers.

- Sample Testing: Perform independent testing on samples, particularly for critical attributes like color fastness and sole adhesion, to verify compliance before large orders.

Special Considerations for Buyers from Africa, South America, the Middle East, and Europe

International buyers from diverse regions should recognize that manufacturing standards and quality expectations may vary based on local regulations and market preferences.

- Regional Certification Recognition: For European buyers, CE certification and REACH compliance are non-negotiable indicators of quality and safety. South American and Middle Eastern markets may emphasize local standards, but aligning with international certifications enhances credibility.

- Language and Documentation: Ensure suppliers provide documentation in accessible languages and that quality reports clearly specify testing methods and results.

- Customization and Compliance: Buyers should specify colorfastness levels, environmental standards, and packaging requirements upfront to ensure suppliers meet regional regulations and consumer expectations.

- Capacity for Certification and Traceability: Choose suppliers with transparent traceability systems, enabling verification of raw material origin and compliance with regional regulations.

Conclusion

For B2B buyers sourcing maroon shoes internationally, understanding the detailed manufacturing processes and rigorous quality assurance protocols is essential. Establishing clear specifications, conducting thorough supplier evaluations, and insisting on certified testing and documentation will mitigate risks and ensure product quality aligns with market standards. By partnering with manufacturers committed to international standards like ISO 9001 and industry-specific certifications, buyers can confidently navigate global markets, whether in Africa, South America, the Middle East, or Europe.

Comprehensive Cost and Pricing Analysis for maroon shoes Sourcing

Cost Structure Breakdown for Maroon Shoes Sourcing

Understanding the comprehensive cost structure is essential for international buyers aiming to optimize procurement and negotiate effectively. The primary components include:

-

Materials: The choice of raw materials significantly impacts costs. High-quality leathers or synthetic alternatives vary in price, with genuine leather typically costing between $15-$30 per pair, depending on grade. For maroon shoes, the dyeing process adds an extra layer of expense, especially if premium colorfast dyes are used to ensure vibrancy and longevity.

-

Labor: Manufacturing costs fluctuate based on country and labor standards. For instance, factories in South America or Africa might offer lower wages, reducing per-unit costs by 20-40% compared to European suppliers. However, quality consistency and labor regulations should be considered to avoid delays or compliance issues.

-

Manufacturing Overhead: This encompasses factory operations, machinery depreciation, and energy costs. Efficient factories with advanced equipment tend to have higher upfront costs but can offer better quality and shorter lead times.

-

Tooling & Development: Initial tooling for molds and patterns can range from $2,000 to $10,000, depending on complexity. This is a one-time expense, amortized over the production volume.

-

Quality Control & Certifications: Achieving certifications (e.g., ISO, REACH) or adhering to specific quality standards can add to costs but are crucial for entering certain markets, notably Europe and North America.

-

Logistics & Customs: Shipping costs depend on volume, weight, and destination. For Africa and South America, freight can range from $3-$8 per pair for sea freight, with additional costs for customs clearance, duties, and taxes which can add 10-25% to the landed cost.

-

Margins & Markup: Distributors typically add a markup of 20-50%, depending on the market and exclusivity agreements. Retail margins can further inflate the final retail price.

Price Influencers and Market Dynamics

Several factors influence the final price of maroon shoes in international markets:

-

Order Volume & MOQ: Larger orders often attract volume discounts, reducing unit costs by up to 15-20%. Many Asian manufacturers require MOQs between 500-1,000 pairs, but some suppliers in Africa or South America may accept smaller quantities, albeit at a premium.

-

Customization & Specifications: Custom colors, specific branding, or unique design features increase manufacturing complexity and costs. Standardized models are more cost-effective and suitable for bulk orders.

-

Material Choices: Opting for genuine leather versus synthetic options affects costs and market positioning. Premium markets (Europe, North America) often demand high-quality materials and certifications, impacting price.

-

Quality & Certification Standards: Meeting strict standards (e.g., REACH compliance in Europe) involves additional testing and documentation, adding approximately 5-10% to the cost but ensuring market acceptance.

-

Supplier Reputation & Capabilities: Established suppliers with proven track records may command higher prices but offer better reliability and quality assurances, reducing risks associated with delays or defects.

-

Incoterms & Shipping Terms: FOB (Free on Board) is common, but CIF (Cost, Insurance, Freight) is often preferred by buyers to simplify logistics. Shipping terms influence total landed costs and should be negotiated carefully.

Strategic Tips for International B2B Buyers

-

Negotiate Total Cost of Ownership (TCO): Focus not only on unit price but also on logistics, customs, and after-sales support. A slightly higher manufacturing cost may be offset by lower logistics or compliance expenses.

-

Leverage Volume & Flexibility: Larger, flexible orders can unlock discounts and better payment terms. Engage with suppliers willing to accept smaller batches with clear quality standards to balance cash flow and inventory.

-

Prioritize Quality & Certification: Investing in suppliers with recognized certifications can streamline market entry, especially into Europe and North America, reducing the risk of customs delays or rejections.

-

Understand Pricing Nuances: Be aware of hidden costs such as inspection fees, packaging, and export duties. Clarify all cost components upfront to avoid surprises.

-

Market-specific Strategies: For buyers from Africa, South America, the Middle East, or Europe, tailor negotiations to regional logistics challenges, currency fluctuations, and local compliance requirements.

Disclaimer

Indicative prices provided are estimates based on current market data and can vary significantly depending on supplier location, order volume, and specifications. Engaging in detailed negotiations and requesting samples and quotations are essential steps to accurately determine costs for your specific needs.

By understanding these detailed cost components and influencing factors, B2B buyers can better strategize their sourcing approach, achieve cost efficiencies, and establish reliable supply chains for maroon shoes in diverse international markets.

Spotlight on Potential maroon shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for maroon shoes.)*

Essential Technical Properties and Trade Terminology for maroon shoes

Critical Technical Properties for Maroon Shoes

1. Material Grade and Composition

The quality of materials used in manufacturing maroon shoes significantly impacts durability, comfort, and aesthetic appeal. Common upper materials include full-grain leather, suede, or high-quality synthetics, each with specified grades that denote their strength and finish. For B2B buyers, understanding material grades ensures consistency across production batches and aligns with end-user expectations. Higher-grade leathers, for example, offer better longevity and a premium look, which can command higher market prices.

2. Sole Material and Tolerance

The sole, typically made from rubber, polyurethane, or leather, must meet specific industry standards for flexibility, slip resistance, and wear resistance. Tolerance levels specify acceptable deviations in thickness and firmness, critical for manufacturing precision and safety standards. Precise sole specifications prevent issues like delamination or uneven wear, reducing after-sales complaints and warranty claims.

3. Colorfastness and Finish

Maroon shoes require colorfastness, meaning the dye must resist fading or bleeding during cleaning and exposure to elements. Technical specifications include lightfastness ratings and color consistency, which are crucial for maintaining product quality over time. For international buyers, verifying these properties ensures the shoes retain their aesthetic appeal in diverse climates and handling conditions.

4. Stitching and Assembly Tolerances

Manufacturing tolerances in stitching, such as stitch length and spacing, directly impact the shoe’s structural integrity and visual quality. Tight tolerances reduce the risk of seam separation or loose threads, which can compromise durability. Clear specifications in this area enable consistent production quality, essential for branding and customer satisfaction.

5. Compliance with Safety and Environmental Standards

Materials and manufacturing processes must meet specific safety standards, such as REACH compliance in Europe or environmental certifications in South America. These standards influence market access and consumer trust, especially in regions with strict regulatory frameworks. Ensuring these properties are met reduces legal risks and facilitates smoother customs clearance.

Common Trade Terms Relevant to Maroon Shoe B2B Transactions

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce shoes based on the buyer’s specifications, branding, and design. Understanding OEM arrangements is vital for buyers seeking custom branding or proprietary designs, ensuring clear communication of design and quality expectations.

2. MOQ (Minimum Order Quantity)

The smallest quantity a manufacturer will accept for an order. Knowledge of MOQ helps buyers plan procurement strategies, negotiate better terms, and avoid overstocking or under-ordering, particularly important when entering new markets or testing new designs.

3. RFQ (Request for Quotation)

A formal request from buyers to suppliers for price, lead time, and terms based on specific product specifications. Effective RFQs streamline sourcing processes and ensure competitive pricing, especially when dealing with international suppliers with varying pricing standards.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs clearance. Familiarity with Incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) helps buyers manage logistics costs and risks, crucial for cross-border transactions.

5. Lead Time

The period from order placement to delivery. Accurate understanding of lead times allows buyers to synchronize production schedules and inventory management, reducing stockouts or excess inventory, especially in regions with complex customs procedures.

6. Quality Assurance (QA) and Inspection Terms

Refers to standards and procedures for verifying product quality before shipment. Clear QA protocols, including third-party inspections, are essential for mitigating risks of receiving non-conforming products, particularly when dealing with multiple suppliers across different regions.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions, negotiate effectively, and ensure the consistent quality of maroon shoes across diverse markets. This knowledge also facilitates smoother communication and minimizes misunderstandings in complex global supply chains.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the maroon shoes Sector

Market Overview & Key Trends

The global market for maroon shoes is experiencing steady growth driven by evolving consumer preferences, fashion trends, and increasing demand for versatile footwear. In particular, markets in Europe—such as Spain—and South America—like Argentina—are showing a rising affinity for rich, earthy tones like maroon, which are perceived as both stylish and adaptable across formal and casual settings. Meanwhile, emerging markets in Africa and the Middle East are expanding their footwear sectors, with a focus on quality craftsmanship and regional design influences.

For international B2B buyers, understanding sourcing trends is crucial. Digital platforms and e-commerce solutions are transforming procurement, enabling real-time communication, transparent supplier evaluations, and streamlined order management. Technology-driven innovations such as 3D prototyping and virtual sampling are reducing lead times and costs, making it easier to customize designs and meet diverse regional preferences.

Key drivers include sustainability concerns, premium branding, and the rise of local craftsmanship. As consumer awareness grows, buyers increasingly seek suppliers who can provide reliable, high-quality maroon shoes with traceable supply chains. Additionally, regional trade agreements and tariff policies influence sourcing strategies—European buyers, for example, benefit from trade frameworks like the EU’s trade agreements, while African and Middle Eastern buyers must navigate regional import regulations and potential tariffs.

Emerging sourcing trends also point toward a shift from traditional manufacturing hubs to diversified supply chains, emphasizing near-shoring and regional production to reduce logistics costs and improve responsiveness. B2B buyers should leverage data analytics and supply chain management tools to identify resilient suppliers, monitor market shifts, and optimize inventory management in this dynamic sector.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly shaping procurement strategies within the maroon shoes sector. Environmental impacts, such as water consumption during leather tanning and the carbon footprint of transportation, are under scrutiny from both consumers and regulators. B2B buyers from Africa, South America, the Middle East, and Europe are prioritizing suppliers who adhere to eco-friendly practices, including the use of vegetable-tanned leather, water-efficient processing, and biodegradable materials.

Ethical sourcing extends beyond environmental concerns to include fair labor practices and supply chain transparency. Certification schemes such as Fair Trade, Leather Working Group (LWG), and Global Organic Textile Standard (GOTS) are becoming standard benchmarks, signaling responsible production. For instance, sourcing from suppliers with LWG certification assures buyers of environmentally responsible leather processing, while Fair Trade certifications confirm ethical labor conditions.

Green materials are gaining traction in the maroon shoes segment. Plant-based dyes, recycled textiles, and innovative eco-friendly alternatives to traditional leather—such as mushroom or cork leather—offer sustainable options that appeal to environmentally conscious markets. Incorporating these materials can enhance brand reputation and meet stringent regulations, especially in European markets where sustainability standards are increasingly mandatory.

For B2B buyers, establishing strong partnerships with certified suppliers and demanding transparency through detailed supply chain audits are essential. Integrating sustainability criteria into procurement processes not only mitigates reputational risks but also aligns with global trends toward circular economy principles, ensuring long-term viability in a competitive market.

Brief Evolution/History (Optional)

While the focus is primarily on current trends, understanding the evolution of maroon shoes can inform sourcing and design strategies. Historically, maroon has been associated with luxury and tradition, often used in formal footwear and ceremonial attire. As fashion evolved, the color transitioned into casual and contemporary styles, driven by the rise of streetwear and customization.

The shift towards sustainable and ethically sourced maroon shoes is relatively recent but significant. It reflects a broader industry movement emphasizing environmental responsibility and social accountability. This evolution underscores the importance for B2B buyers to stay ahead of market preferences, sourcing from suppliers who have adapted to these changing standards and consumer expectations, ensuring their offerings remain relevant and competitive in diverse regional markets.

Illustrative Image (Source: Google Search)

Frequently Asked Questions (FAQs) for B2B Buyers of maroon shoes

1. How can I verify the credibility and reliability of a maroon shoe supplier?

To ensure supplier credibility, conduct thorough due diligence by requesting business licenses, certifications, and references from previous clients. Use online platforms like Alibaba, Global Sources, or industry-specific directories to review supplier ratings and feedback. Request samples to assess product quality firsthand. Additionally, consider visiting the supplier’s manufacturing facilities if feasible or engaging third-party inspection services before committing. Building relationships with suppliers who have transparent communication, clear payment terms, and proven track records reduces risks and fosters long-term partnerships.

2. What customization options are typically available for bulk maroon shoe orders?

Most suppliers offer a range of customization options, including color shades, materials (leather, synthetic, fabric), branding (logos, tags, packaging), and design modifications like sole patterns or embellishments. Clarify minimum order quantities (MOQs) for each customization to avoid surprises. Communicate your specifications clearly and request prototypes before mass production. Ensure the supplier understands your target market’s preferences, especially regarding style, comfort, and durability, to optimize product appeal across different regions.

3. What are typical MOQs, lead times, and payment terms for international maroon shoe orders?

MOQs vary widely but generally range from 500 to 5,000 pairs depending on the supplier and complexity of customization. Lead times typically span 4 to 12 weeks, influenced by order size and manufacturing capacity. Payment terms commonly include a 30% deposit upfront, with the balance payable before shipment or upon delivery. Some suppliers may offer flexible terms for large or repeat orders. Establish clear agreements on payment methods (wire transfer, letter of credit, etc.) and timelines to ensure smooth transactions.

4. What quality assurance measures and certifications should I look for in maroon shoe suppliers?

Reliable suppliers should adhere to recognized quality standards such as ISO 9001, and provide relevant certifications like CE marking (for European markets) or ASTM standards (for North America). Request detailed quality control reports and documentation of compliance with safety and environmental regulations. Conduct or commission third-party inspections during production and before shipment. These measures help ensure product consistency, safety, and adherence to your target market’s legal requirements, reducing the risk of returns or legal issues.

5. How can I optimize logistics and shipping when importing maroon shoes internationally?

Start by selecting suppliers who have experience exporting to your region and can provide detailed shipping options. Use Incoterms (e.g., FOB, CIF) to clarify responsibilities and costs. Partner with reputable freight forwarders experienced in handling footwear exports to ensure timely delivery. Consider customs clearance procedures, import duties, and taxes specific to your country. Consolidate shipments when possible to reduce costs, and track shipments actively. Establish clear communication channels with suppliers and logistics providers to promptly address any delays or issues.

Illustrative Image (Source: Google Search)

6. What are common dispute resolution methods in international B2B transactions for shoes?

Disputes often arise over product quality, delivery delays, or payment issues. To mitigate risks, include clear dispute resolution clauses in contracts, specifying arbitration or mediation in neutral jurisdictions familiar with international trade laws. Preferably, opt for arbitration centers like ICC or LCIA, which offer enforceable rulings. Maintain detailed documentation of all communications, agreements, and transaction records. Establishing a good relationship and open communication channels with your supplier also helps resolve issues amicably before escalating to formal dispute resolution.

7. How do I ensure compliance with regional standards and regulations for maroon shoes?

Research the specific standards applicable in your target markets—such as REACH and CE in Europe, ASTM standards in North America, or local safety and environmental regulations in Africa, South America, and the Middle East. Request compliance certificates and testing reports from your supplier. Incorporate quality and safety requirements into your purchase agreements. Consider engaging local consultants or testing agencies to verify compliance upon arrival. This proactive approach minimizes legal risks and ensures your products meet consumer safety expectations.

8. What strategies can I use to build long-term relationships with reliable maroon shoe suppliers?

Focus on transparent communication, timely payments, and consistent quality standards. Start with smaller orders to build trust and gradually increase order volumes as the relationship matures. Offer feedback and collaborate on product development to align offerings with market trends. Attend trade shows and industry events to meet potential suppliers face-to-face. Regular performance evaluations and prompt issue resolution demonstrate professionalism and foster loyalty. Building mutual trust and understanding is key to securing favorable terms and priority during peak demand periods.

Strategic Sourcing Conclusion and Outlook for maroon shoes

Strategic Sourcing Outlook for Maroon Shoes

Effective sourcing of maroon shoes presents significant opportunities for international B2B buyers seeking quality, cost efficiency, and sustainable partnerships. Key takeaways include the importance of diversifying supplier bases across regions such as Asia, Africa, and Europe to mitigate risks and capitalize on regional strengths, whether it’s craftsmanship, raw material availability, or competitive pricing. Leveraging strategic sourcing practices—such as thorough supplier vetting, quality assurance, and fostering long-term relationships—can lead to improved product consistency and supply chain resilience.

For buyers in Africa, South America, the Middle East, and Europe, understanding regional market dynamics is essential. This involves staying informed about emerging trends, tariffs, trade agreements, and sustainability standards, which are increasingly influencing sourcing decisions. Additionally, embracing innovations like digital procurement platforms and supplier collaboration tools can streamline operations and enhance transparency.

Looking ahead, the demand for stylish, durable, and ethically produced maroon shoes is set to grow, driven by evolving consumer preferences and global fashion trends. B2B buyers should prioritize strategic sourcing as a competitive advantage—building flexible, ethical, and resilient supply chains that can adapt to changing market conditions. Proactively engaging with diverse suppliers now positions your business to meet future demand and strengthen your market presence internationally.