Master Sourcing and Trading Merino Shoes for Global Markets

Guide to Merino Shoes

- Introduction: Navigating the Global Market for merino shoes

- Understanding merino shoes Types and Variations

- Key Industrial Applications of merino shoes

- Strategic Material Selection Guide for merino shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for merino shoes

- Comprehensive Cost and Pricing Analysis for merino shoes Sourcing

- Spotlight on Potential merino shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for merino shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the merino shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of merino shoes

- Strategic Sourcing Conclusion and Outlook for merino shoes

Introduction: Navigating the Global Market for merino shoes

In today’s highly interconnected global economy, sourcing high-quality merino shoes has become a strategic imperative for B2B buyers across diverse markets. Recognized for their exceptional comfort, durability, and sustainable appeal, merino shoes are increasingly sought after by consumers and retailers worldwide. For international buyers—particularly from Africa, South America, the Middle East, and Europe—understanding the nuances of this niche market is essential to securing competitive advantages, optimizing supply chains, and meeting evolving consumer demands.

This comprehensive guide is designed to empower B2B buyers with critical insights into every facet of the merino shoe industry. From exploring different types of merino footwear and materials used to detailed manufacturing and quality control processes, it provides a holistic view necessary for informed decision-making. Additionally, it offers practical guidance on sourcing reliable suppliers, evaluating costs, and navigating market trends.

Given the diverse economic and logistical landscapes of regions such as Nigeria, Saudi Arabia, Brazil, and European markets, tailored strategies are crucial. This guide aims to equip international buyers with actionable knowledge, enabling them to select the right partners, ensure product quality, and capitalize on market opportunities. Whether you are establishing new supplier relationships or optimizing existing ones, this resource is your essential partner in navigating the complex, dynamic world of merino shoes.

Understanding merino shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Merino Running Shoes | Lightweight, flexible, high-performance merino wool upper | Sportswear, outdoor retail, fitness centers | Pros: High moisture-wicking, odor control; Cons: Higher price point, limited color options |

| Merino Casual Shoes | Stylish designs with merino wool blends, versatile for daily wear | Fashion retailers, casual footwear markets | Pros: Comfortable, sustainable; Cons: Less durability for heavy use, moderate pricing |

| Merino Hiking & Outdoor Shoes | Rugged construction, reinforced soles, waterproof merino wool | Outdoor gear suppliers, adventure tourism | Pros: Superior insulation, moisture management; Cons: Heavier, higher manufacturing costs |

| Merino Work Shoes | Durable, slip-resistant soles, merino wool interior for comfort | Workwear suppliers, industrial markets | Pros: Comfort for long shifts, odor control; Cons: Slightly bulkier, higher procurement costs |

| Merino Dress Shoes | Formal styles with merino wool linings, elegant finishes | Luxury retailers, corporate apparel | Pros: Breathable, luxurious feel; Cons: Premium pricing, limited styles |

Classic Merino Running Shoes

This type emphasizes performance, featuring a lightweight, flexible design with a merino wool upper that provides excellent moisture-wicking and odor control. They are ideal for sports retailers, outdoor enthusiasts, and fitness centers seeking high-performance footwear. B2B buyers should consider sourcing from manufacturers with proven quality control to ensure consistency, especially since demand for premium performance shoes is rising globally. Pricing may be higher but can be offset by the product’s durability and customer satisfaction.

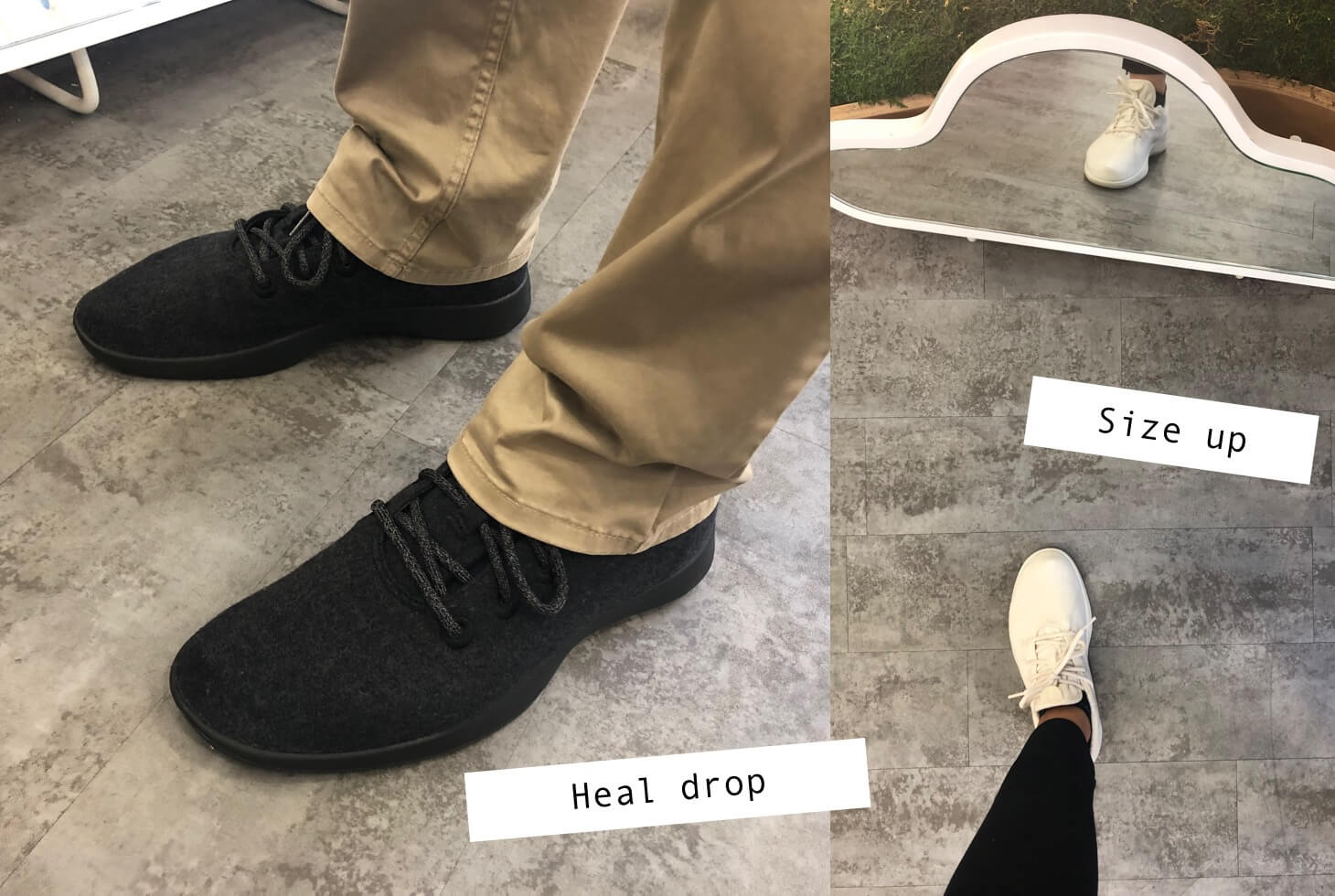

Illustrative Image (Source: Google Search)

Merino Casual Shoes

Designed for everyday comfort and style, merino casual shoes blend fashion with function. They often incorporate merino wool blends into versatile, trendy designs suitable for urban markets or casual wear segments. For B2B buyers, focus on sourcing from suppliers offering sustainable and ethically produced options, which appeal to environmentally conscious consumers. These shoes generally have moderate margins but require careful quality assurance to meet diverse customer expectations.

Merino Hiking & Outdoor Shoes

Built for rugged outdoor use, these shoes feature reinforced soles, waterproof merino wool linings, and durable construction materials. They are popular in outdoor retail channels, adventure tourism, and specialty outdoor stores. B2B buyers should evaluate suppliers’ expertise in outdoor gear manufacturing, ensuring product quality, waterproofing, and durability. The higher manufacturing costs can be justified by the premium market segment willing to pay for performance and longevity.

Merino Work Shoes

Targeted at industrial and work environments, these shoes combine durability with comfort, featuring slip-resistant soles and merino wool linings that manage foot odor and moisture over extended wear. They are suitable for industrial suppliers and corporate uniform providers. Buyers should prioritize sourcing from manufacturers with certifications for safety standards and consistent supply to meet the demands of industrial clients, balancing cost and quality.

Merino Dress Shoes

This category offers formal footwear with luxurious merino wool linings and elegant designs, appealing to premium markets and corporate clients. They are suitable for luxury retailers, executive apparel, and specialty boutiques. B2B buyers should focus on premium sourcing channels that ensure high-quality craftsmanship and sustainable sourcing practices, as these shoes command a higher price point and are often used as statement pieces in professional settings.

Key Industrial Applications of merino shoes

| Industry/Sector | Specific Application of merino shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture & Farming | Footwear for farmworkers operating in varied terrains | Enhanced comfort and moisture management, reducing fatigue and blisters | Durability in rugged environments, supply chain reliability, and cost-effectiveness |

| Outdoor & Adventure Sports | Hiking, trekking, and expedition footwear | Superior thermal regulation and odor control, improving athlete performance | High-quality merino wool integration, compliance with safety standards, and seasonal adaptability |

| Healthcare & Wellness | Therapeutic and rehabilitation footwear | Moisture-wicking and antimicrobial properties promote hygiene and skin health | Consistent quality, certifications for medical use, and customization options |

| Military & Security | Combat and operational footwear | Lightweight, temperature regulation, and odor control for prolonged wear | Military-grade durability, compliance with safety standards, and bulk sourcing capabilities |

| Hospitality & Tourism | Staff uniforms and guest footwear | Comfort and moisture management for long shifts, enhancing staff well-being | Scalability, consistent supply, and customization to branding requirements |

Agriculture & Farming

Merino shoes designed for agricultural workers are crafted to withstand rugged terrains and prolonged exposure to outdoor elements. Their moisture-wicking properties help keep feet dry in muddy or humid environments, reducing the risk of blisters and infections. For international buyers, especially from Africa and South America, sourcing durable, weather-resistant merino footwear ensures worker safety and productivity. Consider suppliers with proven track records in rugged environments and flexible logistics to maintain consistent supply chains.

Outdoor & Adventure Sports

In the outdoor sports industry, merino shoes are valued for their thermal regulation, odor resistance, and lightweight comfort—crucial for hikers, trekkers, and expedition teams operating in extreme conditions. European and Middle Eastern markets, with a high demand for premium outdoor gear, benefit from sourcing merino footwear that combines performance with durability. Buyers should prioritize suppliers offering technical specifications aligned with safety standards and seasonal performance, ensuring athlete comfort and safety.

Healthcare & Wellness

Merino shoes serve in therapeutic applications where hygiene and skin health are paramount. Their antimicrobial and moisture-wicking features make them ideal for rehabilitation centers, hospitals, and wellness clinics. For B2B buyers in Europe and the Middle East, sourcing medical-grade merino footwear requires strict adherence to health certifications and customization options for different patient needs. Reliable, high-quality supply chains are essential to meet the regulatory standards of healthcare sectors globally.

Illustrative Image (Source: Google Search)

Military & Security

Military and security personnel benefit from merino shoes that offer lightweight comfort, temperature regulation, and odor control, crucial for prolonged wear in diverse climates. Countries like Saudi Arabia and Nigeria demand footwear that combines durability with performance, ensuring operational readiness. Sourcing considerations include military-grade certifications, bulk procurement capabilities, and suppliers with experience in rugged, high-performance footwear to meet strict safety and durability standards.

Hospitality & Tourism

In the hospitality sector, staff footwear made from merino wool enhances comfort during long shifts, especially in hot or humid environments. Merino shoes help maintain foot hygiene and reduce fatigue, improving staff well-being and guest service quality. For international buyers, sourcing scalable, customizable solutions that align with branding and comfort standards is key. Reliable supply chains and the ability to deliver consistent quality are vital for maintaining operational efficiency across hospitality establishments in Europe, Africa, and the Middle East.

Strategic Material Selection Guide for merino shoes

Analysis of Common Materials for Merino Shoes

1. Leather (Full-Grain and Nubuck)

Leather remains a traditional and highly valued material in merino shoes, especially for premium and luxury segments. Its key properties include excellent durability, natural breathability, and a comfortable fit once broken in. Leather also offers good resistance to abrasion and can be treated for water resistance, making it suitable for diverse climates.

Pros:

– High durability and longevity, suitable for daily wear.

– Natural breathability enhances comfort, especially in hot or humid environments.

– Can be aesthetically refined, aligning with luxury market demands.

Cons:

– Manufacturing complexity is higher due to tanning and finishing processes.

– Cost tends to be high, especially for full-grain or exotic leathers.

– Sensitive to moisture and requires maintenance to prevent cracking or deterioration.

Impact on Application:

Leather’s breathability and natural properties make it suitable for indoor and outdoor footwear, but it may require additional waterproofing treatments for wet climates.

International Buyer Considerations:

Leather sourcing must comply with environmental standards like the Leather Working Group (LWG) certifications. Buyers from regions like Europe and the Middle East should prioritize eco-friendly tanning methods. In Africa and South America, local tanneries may offer cost advantages but need verification for quality standards and compliance with international regulations such as REACH or ASTM.

2. Synthetic Polymers (EVA, PU)

Synthetic materials such as Ethylene Vinyl Acetate (EVA) and Polyurethane (PU) are popular for midsoles and sometimes uppers in merino shoes due to their lightweight and versatile nature. They are engineered for specific performance attributes like shock absorption and flexibility.

Pros:

– Cost-effective with lower manufacturing complexity.

– Lightweight, improving overall shoe comfort and reducing fatigue.

– Easily molded into various shapes, allowing design flexibility.

Cons:

– Lower durability compared to natural materials; prone to cracking or degradation over time.

– Environmental concerns due to non-biodegradability and chemical emissions during manufacturing.

– Limited breathability, which can affect comfort in hot climates.

Impact on Application:

Ideal for casual or athletic merino shoes where comfort and cost are priorities. Less suitable for high-end or formal footwear demanding premium aesthetics.

International Buyer Considerations:

Synthetic materials generally meet global standards such as ASTM or ISO. Buyers from regions like Nigeria or South America should verify supplier certifications for chemical safety and environmental compliance. In Europe, adherence to REACH regulations is critical, and buyers should prefer suppliers with documented eco-friendly manufacturing processes.

3. Merino Wool (Natural Fiber)

Merino wool itself is a core component of merino shoes, especially in linings, insoles, or upper overlays. Its natural properties include excellent moisture-wicking, thermal regulation, and odor resistance.

Pros:

– Superior moisture management, ideal for humid or hot climates.

– Naturally antimicrobial, reducing odor buildup.

– Eco-friendly, biodegradable, and renewable.

Cons:

– Less resistant to environmental factors like moisture unless treated.

– Manufacturing processes for blending or integrating wool into footwear can be complex.

– Cost can be higher relative to synthetic alternatives.

Impact on Application:

Best suited for performance-oriented, outdoor, or luxury merino shoes. In regions with high humidity or temperature extremes, merino wool enhances comfort significantly.

International Buyer Considerations:

Buyers should ensure wool sourcing complies with sustainable practices such as Responsible Wool Standard (RWS). In markets like Europe and South America, eco-labeling and traceability are valued. In Africa and the Middle East, durability against local environmental conditions and supply chain reliability are key considerations.

4. Rubber (Outsoles)

Rubber is a critical component for outsoles, providing grip, flexibility, and impact absorption. Its properties are well-suited for outdoor and casual merino shoes.

Pros:

– Excellent slip resistance and durability.

– Good shock absorption, enhancing comfort.

– Resistant to water and many chemicals.

Cons:

– Can be heavy, affecting overall shoe weight.

– Environmental concerns due to non-biodegradability.

– Manufacturing quality varies, impacting performance.

Impact on Application:

Ideal for outdoor, hiking, or casual merino shoes requiring traction and durability. For formal shoes, rubber outsoles may be less desirable aesthetically.

International Buyer Considerations:

Compliance with standards like ASTM D2240 (hardness testing) is advisable. Buyers should select suppliers with environmentally friendly rubber formulations, especially in regions with strict regulations like Europe. In emerging markets, cost and supply chain reliability are primary factors.

Summary Table

| Material | Typical Use Case for merino shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather (Full-Grain/Nubuck) | Premium, outdoor, luxury footwear | Durable, breathable, aesthetically refined | High cost, sensitive to moisture, complex manufacturing | High |

| Synthetic Polymers (EVA, PU) | Casual, athletic, cost-sensitive shoes | Lightweight, versatile, low cost | Less durable, environmental concerns, limited breathability | Low |

| Merino Wool | Linings, insoles, upper overlays | Moisture-wicking, odor-resistant, eco-friendly | Higher cost, less resistant to environmental factors | Med |

| Rubber (Outsoles) | Outsoles for outdoor, casual, hiking shoes | Slip-resistant, durable, impact-absorbing | Heavy, environmental concerns | Med |

This comprehensive analysis enables international B2B buyers from diverse regions to make informed decisions aligned with their market needs, environmental standards, and cost considerations. Prioritizing materials based on application, climate, and compliance will optimize product performance and market acceptance.

In-depth Look: Manufacturing Processes and Quality Assurance for merino shoes

Manufacturing Processes for Merino Shoes

The production of merino shoes involves a series of carefully orchestrated stages, each critical to ensuring high-quality output that meets international standards. For B2B buyers, understanding these stages helps in assessing supplier capabilities and ensuring product consistency.

1. Material Preparation

The process begins with sourcing premium merino wool, renowned for its softness, breathability, and moisture-wicking properties. Suppliers typically pre-treat the wool through cleaning, carding, and sometimes blending with synthetic fibers to enhance durability. Material certification—such as OEKO-TEX or GOTS—serves as a vital indicator of compliance with safety and environmental standards, especially relevant for markets like Europe and North America.

2. Forming and Molding

The shoe upper and sole are formed through various techniques. For the upper, cutting-edge CNC machines or manual cutting are employed, depending on order volume and complexity. The merino wool is often molded into the desired shape using heat-pressing or thermoforming, which ensures precise contours and a snug fit. The sole, frequently made from rubber or EVA foam, is prepared separately, with some manufacturers integrating merino wool linings or insoles during this stage.

3. Assembly

This phase involves stitching, attaching the upper to the sole, and finishing details such as eyelets, laces, or decorative elements. Advanced assembly lines incorporate automated sewing machines for consistency, alongside skilled artisans for intricate designs. Adhesives used must comply with health and safety standards, especially for international markets with strict chemical regulations.

4. Finishing

Final touches include trimming excess materials, applying waterproofing treatments, and quality checks for aesthetic and functional defects. For merino shoes, finishing also involves gentle brushing to enhance the wool’s natural softness and appearance. Some suppliers perform laser etching or branding at this stage, ensuring brand consistency and quality.

Quality Assurance (QA) and Control (QC) Protocols

Ensuring consistent quality in merino shoes requires adherence to international standards and industry-specific certifications, along with rigorous internal QC processes.

1. International Standards and Certifications

– ISO 9001: Most reputable manufacturers operate under ISO 9001, which emphasizes a systematic approach to quality management, process control, and continual improvement.

– CE Marking (European Conformity): For markets in Europe, compliance with CE directives ensures the product meets safety, health, and environmental protection standards.

– Other Industry Certifications: Depending on the target market, certifications such as OEKO-TEX Standard 100 (chemical safety), GOTS (organic textiles), or ASTM standards (North America) may be required.

2. QC Checkpoints and Procedures

– Incoming Quality Control (IQC): Raw materials, especially merino wool, are inspected upon arrival. Tests include fiber content verification, color consistency, chemical residue analysis, and physical properties like tensile strength.

– In-Process Quality Control (IPQC): During manufacturing, checkpoints monitor dimensions, stitching quality, adhesive application, and mold accuracy. Operators may perform visual inspections and dimensional measurements at key stages.

– Final Quality Control (FQC): Before shipment, shoes undergo comprehensive testing, including visual inspection for defects, measurement checks, and functionality tests such as sole adhesion and flexibility.

3. Testing Methods

– Physical Tests: Tensile strength, elongation, and abrasion resistance tests for materials and assembled shoes.

– Chemical Tests: Ensuring no harmful substances (like formaldehyde, heavy metals) are present, complying with REACH or CPSIA regulations.

– Durability Tests: Simulating wear conditions to verify longevity, including bending, compression, and moisture exposure.

– Fit and Comfort Assessments: Involving ergonomic testing and pressure mapping to ensure product performance aligns with consumer expectations.

How B2B Buyers Can Verify Supplier QC

For international buyers, especially from regions like Nigeria, Saudi Arabia, or South America, verifying a supplier’s QC capabilities is crucial to mitigate risks and ensure product reliability.

- Third-Party Audits: Engage accredited auditing firms (e.g., SGS, BV, Intertek) to conduct comprehensive factory audits focusing on quality management systems, environmental compliance, and social responsibility.

- Request QC Reports and Documentation: Suppliers should provide detailed inspection reports, test certificates, and batch tracking data. Review these documents for consistency, compliance, and traceability.

- Factory Visits and On-site Inspections: When feasible, visiting manufacturing facilities allows direct assessment of processes, cleanliness, worker conditions, and QC practices.

- Sample Testing: Prior to large orders, B2B buyers should request samples for independent testing against specified standards, especially for critical attributes like wool quality and chemical safety.

- Establish Clear Quality Agreements: Define acceptance criteria, inspection frequency, and corrective action protocols within contractual agreements to maintain oversight and accountability.

Nuances of QC for International B2B Transactions

Different markets have distinct quality expectations and regulatory requirements. For instance:

- European Markets: Emphasize chemical safety, environmental sustainability, and social responsibility. Suppliers must demonstrate compliance with REACH, OEKO-TEX, and GOTS standards.

- Middle East and African Markets: May prioritize durability and climatic suitability, requiring testing for heat resistance, moisture management, and abrasion.

- South American Markets: Often demand certifications related to fair labor practices and eco-friendly materials, with an increasing focus on traceability and transparency.

B2B buyers should communicate these specific requirements upfront and select suppliers with proven compliance records. Using internationally recognized certifications and third-party inspection reports will facilitate smoother market entry and consumer trust.

Conclusion

Manufacturing merino shoes involves meticulous material handling, precise forming techniques, and stringent QC protocols to ensure product excellence. For international buyers, understanding these processes and verifying supplier capabilities through audits, certifications, and testing is essential. By aligning manufacturing and QC expectations with regional market standards, B2B buyers can confidently source high-quality merino shoes that meet their customers’ demands across Africa, South America, the Middle East, and Europe.

Comprehensive Cost and Pricing Analysis for merino shoes Sourcing

Cost Structure Breakdown for Merino Shoes

Understanding the comprehensive cost structure is crucial for international buyers aiming to optimize procurement. The primary cost components include:

-

Materials: High-quality merino wool for uppers and linings, combined with durable outsole materials such as rubber, EVA, or leather. Material costs fluctuate based on quality, source region, and supplier volume. Organic or sustainably sourced merino wool typically commands a premium—often 10-20% higher than conventional wool.

-

Labor: Manufacturing costs depend heavily on the country of production. For example, Asian factories (China, Vietnam) often offer lower labor rates, while European or Middle Eastern producers may have higher wages but potentially better craftsmanship. Labor costs generally range from $3 to $10 per pair, influenced by complexity and labor standards.

-

Manufacturing Overhead: Includes factory utilities, machinery depreciation, and quality control expenses. Higher automation can reduce overhead per unit, but quality-focused producers may invest more, impacting costs.

-

Tooling & Setup Fees: Initial tooling costs for molds or specialized equipment can range from $500 to $2,000, amortized over production runs. These are fixed costs but should be factored into the unit price for small or custom orders.

-

Quality Control & Certifications: International standards (ISO, OEKO-TEX, GOTS) may add costs but are vital for accessing premium markets. Certification expenses vary but typically range from a few hundred to a few thousand dollars annually.

-

Logistics & Shipping: Freight costs are a significant variable, influenced by shipment volume, destination port, and mode (sea, air). Bulk sea freight offers lower per-unit costs, often $1-$4 per pair for large shipments to Europe or Africa. Air freight, while faster, can double or triple costs.

-

Margins: Suppliers typically target a markup of 20-50%, depending on order size, brand positioning, and market demand. Larger orders often attract better margins due to economies of scale.

Price Influencers and Their Impact

Several factors influence the final FOB (Free on Board) or CIF (Cost, Insurance, and Freight) prices:

-

Order Volume & MOQ: Larger orders reduce per-unit costs, incentivizing buyers to negotiate volume discounts. MOQs can range from 500 to 2,000 pairs, depending on the supplier.

-

Customization & Specifications: Custom colors, branding, or design modifications increase tooling and setup costs, raising the unit price by 10-30%. Standard models are more economical.

-

Material Choices: Organic merino or specialty wool adds 15-25% to material costs. Similarly, premium outsole materials or eco-friendly packaging elevate the final price.

-

Quality & Certifications: Meeting international standards incurs certification fees but can open access to high-end markets in Europe and North America, justifying higher price points.

-

Supplier Factors: Experience, reputation, production capacity, and proximity influence pricing. Established suppliers with reliable quality often command higher prices but reduce risk for buyers.

-

Incoterms & Shipping Terms: FOB terms favor buyers who manage logistics, potentially reducing overall costs. DDP (Delivered Duty Paid) offers convenience but includes additional fees for customs clearance and delivery.

Strategic Tips for International B2B Buyers

-

Negotiate for Better Terms: Leverage larger order volumes to secure discounts, reduced MOQs, or better payment terms. Clear communication about future order potential can motivate suppliers to offer favorable pricing.

-

Focus on Total Cost of Ownership (TCO): Consider not just unit price but also shipping, customs duties, taxes, and after-sales support. For example, sourcing from regions with favorable trade agreements can significantly lower tariffs.

-

Assess Quality & Certifications: Prioritize suppliers with certifications aligned to your target markets. While these add upfront costs, they can facilitate market entry and premium pricing.

-

Understand Pricing Nuances: Prices vary based on order specifics, supplier location, and market conditions. Always request detailed quotations that break down costs for transparency.

-

Plan for Currency & Payment Risks: Fluctuations in exchange rates can impact costs. Consider forward contracts or currency hedging where applicable.

Disclaimer

Indicative prices for merino shoes generally range from $15 to $40 per pair FOB, depending on order size, customization, and supplier origin. Shipping, certification, and import duties will add to these costs. Buyers should conduct due diligence and obtain multiple quotations to ensure competitive pricing tailored to their specific requirements.

In summary, a strategic approach combining volume negotiations, quality assurance, and comprehensive cost analysis will enable international buyers from Africa, South America, the Middle East, and Europe to optimize their sourcing of merino shoes, balancing quality with cost-efficiency.

Spotlight on Potential merino shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for merino shoes.)*

Essential Technical Properties and Trade Terminology for merino shoes

Critical Technical Properties of Merino Shoes

1. Material Grade and Composition

The quality of merino wool used in shoes significantly impacts durability, comfort, and performance. High-grade merino wool typically features finer micron counts (e.g., 18.5 microns or lower), offering superior softness and reduced irritation. For B2B buyers, specifying the wool’s micron range and whether it’s 100% merino or blended with synthetic fibers helps ensure product consistency and meets end-user expectations.

2. Wool Density and Thickness

Wool density, measured in grams per square meter (GSM), influences the shoe’s insulation, breathability, and flexibility. For instance, shoes with a GSM of 150-200 are lightweight and suitable for warm climates, while higher GSM offers better insulation for colder regions. Precise control over density ensures the shoes perform reliably across different environmental conditions.

3. Tolerance Levels and Manufacturing Precision

Dimensional tolerances refer to acceptable variations in shoe size, shape, and component fit. Tight tolerances (e.g., ±1 mm) ensure consistent quality, reducing issues like discomfort or premature wear. For international buyers, clear specifications on tolerances are crucial to avoid costly rework or returns.

4. Finishing and Dyeing Quality

Surface finishing, including dye fastness and uniformity, affects the aesthetic appeal and longevity of merino shoes. High-quality dyeing processes prevent color fading and bleeding, especially important for regions with high humidity or frequent washing. B2B buyers should verify certifications and standards related to environmental and colorfastness testing.

5. Sole Compatibility and Attachment

Since merino wool is often used in upper or lining components, understanding how these are integrated with the sole is vital. The durability of attachment methods (e.g., cementing, stitching) impacts overall shoe lifespan. Suppliers should provide detailed technical sheets on sole attachment techniques to ensure compatibility with regional footwear standards.

6. Moisture and Odor Control Properties

Merino wool naturally resists odor and manages moisture effectively. Technical specifications should include tests for moisture-wicking capacity and odor retention. These properties are especially valued in hot or humid climates, making them a key selling point for international markets.

Common Trade Terms Relevant to Merino Shoes

1. OEM (Original Equipment Manufacturer)

Refers to manufacturers producing products based on a buyer’s design and specifications. Understanding OEM relationships helps buyers leverage custom design options and control branding, critical for differentiated products in competitive markets.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce per order. Clear MOQ terms assist buyers in planning inventory and negotiating production costs, especially important when entering new markets or testing new designs.

3. RFQ (Request for Quotation)

A formal process where buyers solicit price and lead time estimates from multiple suppliers. Efficient RFQ processes streamline sourcing, enabling buyers to compare options quickly and select the most competitive offers.

4. Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce that define responsibilities for shipping, insurance, and customs clearance. Familiarity with Incoterms (e.g., FOB, CIF, DDP) helps buyers accurately calculate landed costs and negotiate delivery terms suited to regional logistics.

5. Lead Time

The period between order confirmation and product delivery. Understanding lead times allows buyers to coordinate production schedules, inventory management, and market launches, particularly in regions with logistical challenges.

6. Certification Standards

Industry certifications such as ISO, OEKO-TEX, or environmental standards verify product safety, quality, and sustainability. Ensuring suppliers meet relevant certifications enhances credibility and compliance in diverse markets like Nigeria, Saudi Arabia, or Brazil.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, ensure product quality, and optimize supply chain efficiency when sourcing merino shoes for diverse markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the merino shoes Sector

Market Overview & Key Trends

The global merino shoes market is experiencing significant growth driven by increasing consumer demand for sustainable, high-performance footwear. Key drivers include rising awareness around natural fibers, technological innovations in sourcing, and shifting consumer preferences toward eco-friendly products. For international B2B buyers from Africa, South America, the Middle East, and Europe, understanding these dynamics is essential to capitalize on emerging opportunities.

Emerging sourcing trends focus on integrating advanced textile technologies such as moisture-wicking, odor-resistant, and temperature-regulating merino wool, which appeal to active and luxury markets alike. Digital transformation plays a pivotal role, with blockchain and traceability platforms enhancing transparency across supply chains, thus reducing counterfeiting and ethical concerns. E-commerce platforms and direct-to-consumer models are also reshaping sourcing strategies, enabling buyers to connect more directly with manufacturers and producers.

Market dynamics are influenced by fluctuating raw material costs, geopolitical factors, and trade policies. For example, South American producers, particularly in Argentina and Uruguay, are gaining prominence due to their high-quality wool and competitive pricing. Meanwhile, European brands are increasingly investing in sustainable certifications to differentiate their offerings. For buyers in Nigeria, Saudi Arabia, and other regions, establishing reliable supply chains and understanding regional trade regulations are critical for successful market entry and expansion.

Furthermore, the rise of niche markets, such as luxury merino footwear and performance-oriented shoes for outdoor activities, presents lucrative opportunities. Strategic partnerships with certified suppliers and adopting flexible sourcing models are vital to navigate these evolving market conditions effectively.

Sustainability & Ethical Sourcing in B2B

Sustainability and ethical sourcing are at the forefront of the merino shoes industry, driven by consumer demand, regulatory pressures, and environmental imperatives. Merino wool is inherently biodegradable and renewable, making it an attractive eco-friendly material. However, to meet the expectations of discerning buyers, suppliers must demonstrate transparency and adherence to rigorous environmental standards.

Implementing traceability systems, such as blockchain-based certification, ensures that merino wool is ethically sourced, free from animal cruelty, and produced under humane conditions. Certifications like Responsible Wool Standard (RWS), ZQ Merino, and OEKO-TEX® are crucial indicators of commitment to sustainability. These certifications verify sustainable land management, animal welfare, and chemical safety, which are essential for brand credibility in global markets.

Environmental impacts of wool sourcing include water consumption, land use, and carbon emissions. Suppliers adopting regenerative grazing practices and water conservation measures significantly reduce their ecological footprint. For B2B buyers, partnering with certified suppliers not only enhances brand reputation but also aligns with corporate social responsibility (CSR) goals.

In regions like Africa and South America, ethical sourcing is increasingly tied to community development initiatives. Supporting local farmers and cooperatives ensures fair wages and sustainable livelihoods, creating a resilient supply chain. Emphasizing sustainability and ethics in sourcing strategies can provide competitive advantages, open access to premium markets, and future-proof operations amid tightening regulations and shifting consumer preferences.

Illustrative Image (Source: Google Search)

Brief Evolution/History (Optional)

The merino wool industry has evolved from traditional sheep farming to a sophisticated segment of the high-performance textiles market. Originally valued for its warmth and durability, merino wool’s versatility has led to innovations in lightweight, breathable footwear materials. Over the past two decades, increased focus on sustainability and ethical practices has transformed sourcing paradigms, with certifications and traceability becoming standard expectations. For B2B buyers, understanding this evolution helps in selecting suppliers committed to quality and sustainability, ensuring long-term partnerships aligned with global market trends.

Frequently Asked Questions (FAQs) for B2B Buyers of merino shoes

-

How can I verify the credibility and reliability of a merino shoe supplier?

To ensure supplier credibility, conduct thorough due diligence including checking business licenses, certifications, and references from previous international clients. Request samples to assess quality firsthand and verify their production capabilities. Additionally, review their export history, compliance with international standards (such as ISO or OEKO-TEX), and seek feedback through industry networks or trade associations. Using third-party verification services or visiting supplier facilities (if feasible) can further mitigate risks. Building strong communication channels and requesting detailed documentation helps confirm their reliability before committing to large orders. -

What customization options are typically available for merino shoes, and how do they impact lead times and costs?

Most suppliers offer a range of customization options including branding (logos, tags), colorways, sole designs, and packaging. Advanced customization like specific sizing or material blends may require longer lead times and higher minimum order quantities (MOQs). Clear communication of your specifications upfront helps in accurate quoting and timeline planning. Customization can increase costs due to setup fees or tooling, but it enhances brand differentiation. To optimize lead times, collaborate closely with suppliers on feasible options and consider ordering smaller batches initially to test market response. -

What are common minimum order quantities (MOQs), lead times, and payment terms for international merino shoe orders?

MOQs for merino shoes typically range from 500 to 2,000 pairs, depending on the supplier’s production capacity and customization level. Lead times generally span 4 to 12 weeks, influenced by order complexity and destination logistics. Standard payment terms often include 30% upfront payment with the balance payable before shipment, but these can be negotiated—especially for large or repeat orders. Establishing clear contractual terms, including payment schedules and penalties for delays, helps ensure smooth transactions and aligns expectations across borders. -

What quality assurance measures and certifications should I look for in merino shoe suppliers?

Prioritize suppliers with certifications such as ISO 9001 (quality management), OEKO-TEX Standard 100 (safe textiles), or Fair Trade (ethical sourcing). Request detailed QA procedures, including raw material testing, in-process inspections, and pre-shipment audits. Some suppliers offer third-party inspection reports or factory audits—these are valuable for verifying quality standards. Implementing sample approvals and pilot orders can further reduce risks. Ensuring compliance with your target market’s standards (e.g., CE marking for Europe) is crucial for seamless distribution and avoiding customs delays. -

How can I effectively manage international logistics and customs clearance for merino shoes?

Partner with experienced freight forwarders familiar with your destination markets to optimize shipping routes and costs. Choose reliable carriers offering tracking, insurance, and flexible delivery options. Understand customs requirements—such as import duties, VAT, and product classification codes—to prevent delays. Prepare complete documentation including commercial invoices, packing lists, certificates of origin, and any necessary certifications. Establish clear communication with your supplier and logistics partners to coordinate timelines, and consider using freight consolidators for cost efficiency when shipping smaller volumes. -

What strategies can I use to resolve disputes or quality issues with international merino shoe suppliers?

Develop clear contractual agreements outlining quality standards, inspection procedures, and dispute resolution processes. Maintain open, documented communication channels to address concerns promptly. If issues arise, conduct joint inspections and request detailed reports from the supplier. Mediation or arbitration clauses in contracts can facilitate neutral resolution without lengthy legal procedures. Building strong relationships and setting mutual expectations early reduces misunderstandings. Consider working with suppliers who have a track record of resolving issues amicably and offer guarantees or warranties on their products. -

What are the key considerations for ensuring ethical and sustainable sourcing of merino shoes?

Prioritize suppliers with transparent supply chains, certifications like Fair Trade, and adherence to environmental standards. Ask for documentation on raw material sourcing—especially for merino wool—to confirm animal welfare practices and sustainable harvesting. Evaluate the supplier’s labor practices and adherence to international labor laws. Incorporate sustainability clauses into your contracts and consider partnering with suppliers actively involved in eco-friendly initiatives. Ethical sourcing not only aligns with global consumer preferences but also mitigates reputational and legal risks. -

How can I stay updated on market trends and new innovations in merino footwear for B2B procurement?

Subscribe to industry publications, trade shows, and online B2B marketplaces focused on footwear and sustainable textiles. Join industry associations and participate in international trade missions to network with manufacturers and learn about new materials, technologies, and design trends. Engage with innovation hubs or research institutions working on eco-friendly footwear solutions. Regularly communicate with your suppliers about product development and emerging trends to stay competitive. Investing in continuous market intelligence enables you to adapt quickly and offer cutting-edge merino shoe products to your customers.

Strategic Sourcing Conclusion and Outlook for merino shoes

Conclusion and Future Outlook

Effective strategic sourcing is vital for B2B buyers seeking to capitalize on the unique qualities of merino shoes, including premium comfort, durability, and sustainability. By establishing strong partnerships with reputable suppliers—especially those committed to ethical sourcing and quality assurance—buyers can secure competitive advantages in their markets. Diversifying sourcing channels across regions such as Africa, South America, the Middle East, and Europe ensures resilience against supply chain disruptions and fosters innovation.

Looking ahead, the growing global demand for sustainable and high-performance footwear positions merino shoes as a strategic asset for forward-thinking buyers. Embracing digital tools, transparent supply chains, and sustainable practices will be essential in maintaining a competitive edge.

Actionable takeaway: International B2B buyers, particularly from Nigeria, Saudi Arabia, and emerging markets across Africa and South America, should prioritize building long-term, collaborative relationships with trusted suppliers. By doing so, they can unlock the full potential of merino shoes, driving growth and differentiation in their respective markets. The future of sourcing lies in agility, sustainability, and strategic partnerships—seize these opportunities now.