Your Ultimate Guide to Sourcing Moonstar Shoes By Antonio

Guide to Moonstar Shoes By Antonio Vietri

- Introduction: Navigating the Global Market for moonstar shoes by antonio vietri

- Understanding moonstar shoes by antonio vietri Types and Variations

- Key Industrial Applications of moonstar shoes by antonio vietri

- Strategic Material Selection Guide for moonstar shoes by antonio vietri

- In-depth Look: Manufacturing Processes and Quality Assurance for moonstar shoes by antonio vietri

- Comprehensive Cost and Pricing Analysis for moonstar shoes by antonio vietri Sourcing

- Spotlight on Potential moonstar shoes by antonio vietri Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for moonstar shoes by antonio vietri

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the moonstar shoes by antonio vietri Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of moonstar shoes by antonio vietri

- Strategic Sourcing Conclusion and Outlook for moonstar shoes by antonio vietri

Introduction: Navigating the Global Market for moonstar shoes by antonio vietri

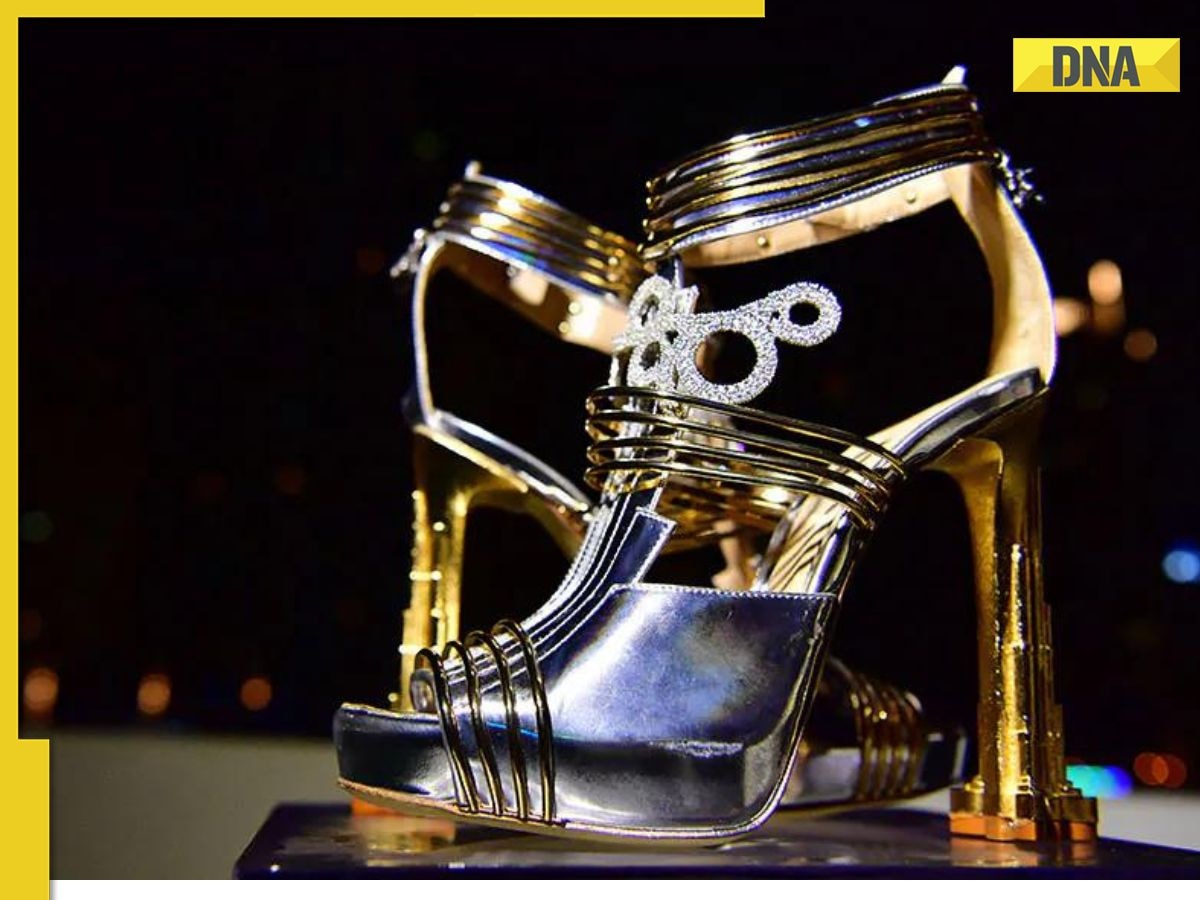

In the fiercely competitive landscape of global footwear sourcing, Moonstar Shoes by Antonio Vietri stands out as a brand synonymous with innovation, quality, and cultural authenticity. For international B2B buyers—especially those from Africa, South America, the Middle East, and Europe—understanding the nuances of sourcing this esteemed brand is vital for gaining a competitive edge. As markets evolve and consumer preferences shift towards sustainable, durable, and stylish footwear, Moonstar’s diverse product offerings have become increasingly sought after.

Illustrative Image (Source: Google Search)

This comprehensive guide is designed to equip you with actionable insights, covering everything from product types and materials to manufacturing processes, quality control, and supplier networks. It aims to demystify critical factors such as pricing structures, logistics considerations, and market demand, enabling you to make informed sourcing decisions. Whether you are looking to import for retail, wholesale, or private label branding, understanding these elements will help optimize your supply chain and maximize profitability.

By providing a detailed overview tailored to your regional market, this guide empowers B2B buyers to navigate the complexities of international footwear procurement with confidence. From assessing supplier reliability to understanding market trends, you will gain the strategic knowledge needed to establish successful partnerships with Moonstar or its authorized distributors. Ultimately, this resource is your roadmap to unlocking the full potential of Moonstar Shoes by Antonio Vietri in your local market.

Understanding moonstar shoes by antonio vietri Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Canvas Sneakers | Durable canvas upper, rubber sole, minimalist design | Retail, wholesale, promotional campaigns | Pros: Widely accepted, versatile, attractive pricing; Cons: Limited technical features for specialized markets |

| Eco-Friendly Line | Made with sustainable materials, biodegradable components | Eco-conscious retail, corporate gifting | Pros: Appeals to sustainability-focused clients; Cons: Higher material costs, limited color options |

| Limited Edition Collaborations | Unique designs, exclusive collaborations with artists or brands | Premium retail, collector markets | Pros: High profit margins, brand prestige; Cons: Limited stock, longer lead times |

| Customizable Shoes | Options for personalized colors, logos, and materials | Corporate branding, bulk orders for events | Pros: High customer engagement, added value; Cons: Increased production complexity and costs |

| Industrial & Workwear Models | Reinforced soles, slip-resistant, heavy-duty materials | Industrial sectors, safety gear suppliers | Pros: High durability, meets safety standards; Cons: Higher upfront costs, limited fashion appeal |

Classic Canvas Sneakers

This variation is the most recognizable and versatile, featuring a durable canvas upper paired with a rubber sole. Ideal for retail distribution and wholesale bulk sales, these shoes appeal to a broad demographic due to their affordability and timeless style. B2B buyers should consider volume discounts and consistent supply chains to meet large orders efficiently. While they lack advanced technical features, their simplicity makes them suitable for promotional campaigns and mass-market retail. Ensuring reliable sourcing of quality canvas and rubber is crucial for maintaining product consistency.

Eco-Friendly Line

Moonstar’s eco-friendly shoes utilize sustainable, biodegradable materials, aligning with global trends toward environmental responsibility. These shoes are particularly attractive to clients in eco-conscious markets like Europe and parts of South America and Africa where sustainability is a purchasing criterion. B2B buyers should evaluate the cost premium against the growing consumer demand for green products. Effective marketing and clear communication of environmental benefits can enhance sales, but sourcing reliable eco-materials and managing higher production costs are key considerations.

Limited Edition Collaborations

These shoes are produced in partnership with artists or brands, resulting in exclusive, high-demand designs. They are ideal for premium retail outlets and collectors, offering significant profit margins and brand prestige. B2B buyers should plan for longer lead times and limited stock availability, emphasizing the importance of inventory management. Such collaborations are best suited for markets with a high appreciation for exclusivity, such as Europe and Argentina, where consumers seek unique, collectible items.

Customizable Shoes

Offering personalization options, these shoes enable bulk orders for corporate branding, events, or promotional campaigns. They cater well to B2B buyers looking to enhance client engagement or reinforce brand identity. The main advantage lies in added value and customer loyalty, but customization increases complexity in production and logistics. Buyers should establish clear specifications and reliable manufacturing partners to meet quality standards and delivery timelines, especially for large orders.

Industrial & Workwear Models

Designed for durability and safety, these shoes feature reinforced soles, slip resistance, and heavy-duty materials. They serve industrial sectors, construction, and safety equipment suppliers, fulfilling strict safety standards. B2B buyers should focus on sourcing models that meet local safety regulations and certifications. While these models have higher upfront costs, their longevity and compliance reduce long-term expenses and liability risks. Their limited appeal in fashion-focused markets makes them more suitable for targeted industrial clients.

Key Industrial Applications of moonstar shoes by antonio vietri

| Industry/Sector | Specific Application of moonstar shoes by antonio vietri | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Heavy Industry | Protective footwear for on-site workers in hazardous environments | Enhances worker safety, reduces injury-related downtime, and complies with international safety standards | Certification for safety standards (e.g., EN, OSHA), durability under tough conditions, reliable supply chain management |

| Logistics & Warehouse Operations | Durable, slip-resistant shoes for warehouse staff | Improves safety and efficiency, minimizes accidents, and supports long-term cost savings | Comfort for extended wear, slip resistance, availability in bulk, and adaptability to various climates |

| Oil & Gas Exploration & Production | Specialized boots with reinforced soles for field technicians | Provides protection against heavy equipment, rough terrain, and chemical exposure | Resistance to chemicals, high durability, and compliance with industry-specific safety certifications |

| Agriculture & Farming | Robust footwear for field workers exposed to uneven terrain and weather | Ensures safety and comfort during long working hours, reduces fatigue | Weather resistance, ease of cleaning, and availability in sizes suitable for diverse workforce demographics |

| Manufacturing & Industrial Plants | Anti-static, slip-resistant shoes for factory personnel | Reduces risk of static buildup, prevents slips, and adheres to industrial safety regulations | Anti-static properties, comfort for prolonged use, and compatibility with industrial PPE standards |

Construction & Heavy Industry

In construction and heavy industries, safety footwear must meet rigorous standards to protect workers from falling objects, punctures, and slips. moonstar shoes by antonio vietri are engineered with reinforced soles, steel toe caps, and slip-resistant outsoles, making them ideal for demanding environments. International B2B buyers from Africa, South America, and the Middle East should prioritize sourcing shoes with certified safety standards such as EN or OSHA compliance to ensure legal and safety adherence. Reliable sourcing ensures continuous supply, especially critical in remote or developing regions where logistics can be challenging.

Logistics & Warehouse Operations

For logistics hubs and warehouses across Europe, South America, and Africa, durable footwear that offers slip resistance and comfort is essential for maintaining operational efficiency and safety. moonstar shoes by antonio vietri provide high-traction soles and ergonomic designs that reduce fatigue during long shifts. B2B buyers should consider bulk procurement options and confirm the shoes’ compliance with local safety regulations. Additionally, sourcing shoes with moisture-wicking and breathable materials can improve worker comfort, reducing turnover and enhancing productivity.

Oil & Gas Exploration & Production

Field technicians and workers in the oil and gas sector require footwear that withstands extreme conditions, including chemical exposure, rough terrain, and heavy equipment. moonstar shoes by antonio vietri feature reinforced soles, chemical-resistant materials, and high durability, making them suitable for such environments. For international buyers, especially in the Middle East and South America, ensuring the shoes meet industry-specific certifications and standards (e.g., ASTM, ISO) is vital. Consistent quality and supply chain transparency are key to maintaining operational safety and compliance.

Agriculture & Farming

Agricultural workers operating in diverse climatic zones need footwear that combines durability with comfort and weather resistance. moonstar shoes by antonio vietri are designed to withstand mud, water, and uneven terrain while offering slip resistance. Sourcing considerations for buyers in Africa and South America include availability in various sizes, ease of cleaning, and adaptability to local conditions. Durable, weather-resistant shoes help reduce injury risks and improve worker productivity during long outdoor hours.

Manufacturing & Industrial Plants

In manufacturing environments, static buildup and slip hazards are common concerns. moonstar shoes by antonio vietri incorporate anti-static properties and slip-resistant soles, aligning with industrial safety standards. For European and Middle Eastern buyers, compliance with local industrial safety regulations is crucial. Sourcing reliable, certified footwear in bulk ensures consistent safety standards, minimizes downtime due to injuries, and supports sustainable industrial operations.

Strategic Material Selection Guide for moonstar shoes by antonio vietri

Material Analysis for moonstar shoes by antonio vietri

Selecting appropriate materials for moonstar shoes by Antonio Vietri is crucial for ensuring product quality, durability, and compliance across diverse international markets. Different regions impose varying standards and preferences, which influence material choice. Here, we analyze four common materials—leather, synthetic fabrics, rubber, and EVA foam—focusing on their properties, advantages, limitations, and considerations for global B2B buyers.

Leather

Key Properties:

Leather is renowned for its durability, breathability, and aesthetic appeal. It offers excellent resistance to wear and tear and can be treated for water resistance. Depending on the grade, leather can withstand moderate to high mechanical stresses, making it suitable for high-end footwear.

Pros & Cons:

Leather’s primary advantage is its longevity and premium feel, which appeals to consumers in Europe and affluent markets. However, it is relatively costly, requires complex manufacturing processes, and involves significant environmental considerations due to tanning processes. Leather also demands proper maintenance to retain its qualities over time.

Impact on Application:

Leather performs well in applications requiring flexibility and breathability, such as uppers. It is compatible with various dyes and finishes, allowing customization. However, its susceptibility to water damage necessitates additional waterproofing treatments, especially relevant in regions with high humidity like parts of South America and Africa.

International Considerations:

For markets like France and Argentina, compliance with environmental standards such as REACH (EU) or local regulations on animal-derived products is essential. Buyers should verify leather sourcing to ensure ethical and sustainable practices. Additionally, leather’s weight and maintenance requirements may influence consumer preferences in different regions.

Synthetic Fabrics (e.g., Polyester, Nylon)

Key Properties:

Synthetic fabrics are lightweight, moisture-wicking, and resistant to environmental factors such as UV radiation and chemicals. They can be engineered for specific properties like enhanced elasticity or water resistance.

Pros & Cons:

These materials are generally cost-effective, easy to manufacture, and versatile. They enable rapid production cycles and consistent quality. However, synthetic fabrics may lack the breathability of natural materials, potentially impacting comfort in hot climates, and may degrade under prolonged UV exposure.

Impact on Application:

Ideal for mesh panels, linings, or lightweight uppers, synthetic fabrics contribute to breathable and flexible shoe designs. They are suitable for regions with hot climates, such as parts of Africa and South America. Their resistance to moisture makes them advantageous in humid environments.

International Considerations:

Synthetic materials often meet global standards like ASTM or JIS, simplifying compliance for international buyers. However, environmental concerns regarding microplastics and sustainability are increasingly influential; buyers should seek suppliers with eco-friendly certifications or recycled content. In markets with strict import regulations, proper labeling and documentation are vital.

Rubber (Natural and Synthetic)

Key Properties:

Rubber provides excellent elasticity, slip resistance, and impact absorption. Natural rubber offers superior resilience, while synthetic variants like SBR or EPDM are tailored for specific weather and chemical resistance.

Pros & Cons:

Rubber’s durability and grip make it ideal for outsoles and protective elements. Natural rubber is biodegradable but can be more expensive and susceptible to environmental degradation if not properly treated. Synthetic rubbers are more stable but may involve higher processing costs.

Impact on Application:

Rubber is essential for outsoles, providing traction and durability. Its chemical resistance makes it suitable for outdoor and industrial applications. However, in regions with high temperatures or exposure to oils and chemicals, selecting the appropriate rubber type is crucial.

International Considerations:

Compliance with standards such as ASTM D2000 or DIN EN 1400 ensures quality consistency. Buyers from regions like Europe and the Middle East should verify that rubber components meet environmental and safety standards, especially concerning volatile organic compounds (VOCs). Cost considerations vary based on rubber type, influencing overall shoe pricing.

EVA Foam

Key Properties:

EVA (Ethylene Vinyl Acetate) foam is lightweight, flexible, and provides excellent cushioning. It has good shock absorption and is resistant to cracking and UV degradation.

Pros & Cons:

EVA foam is cost-effective and easy to mold, making it popular for midsoles and insoles. Its main limitations include lower durability under heavy wear and potential compression over time, which can affect comfort.

Impact on Application:

Primarily used in midsoles and insoles, EVA enhances comfort and absorbs impact, especially in casual and athletic footwear. It is suitable for markets demanding lightweight shoes, such as in Europe and South America.

International Considerations:

EVA foam generally complies with global standards like ASTM and EN. Buyers should ensure that foam formulations are free from harmful additives, especially in regions with strict chemical safety regulations. Cost-wise, EVA is typically low to medium, making it attractive for mass-market applications.

Summary Table of Material Considerations

| Material | Typical Use Case for moonstar shoes by antonio vietri | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Shoe uppers, premium designs | Durability, aesthetic appeal | Costly, environmental concerns, maintenance | High |

| Synthetic Fabrics | Mesh panels, linings, lightweight uppers | Cost-effective, moisture-wicking | Less breathable, environmental impact | Low to Med |

| Rubber | Outsoles, protective elements | Slip resistance, impact absorption | Environmental degradation (natural rubber) | Med |

| EVA Foam | Midsoles, insoles | Lightweight, cushioning | Lower durability under heavy wear | Low |

This detailed analysis equips international B2B buyers with the insights necessary to select materials aligned with regional preferences, compliance standards, and market demands. Proper material choice not only enhances product performance but also ensures regulatory adherence and consumer satisfaction across diverse global markets.

In-depth Look: Manufacturing Processes and Quality Assurance for moonstar shoes by antonio vietri

Manufacturing Processes of Moonstar Shoes by Antonio Vietri

The manufacturing of Moonstar shoes by Antonio Vietri involves a meticulous process that emphasizes craftsmanship, material quality, and adherence to international standards. Understanding these stages enables B2B buyers to assess supplier capabilities and ensure product consistency.

Illustrative Image (Source: Google Search)

Material Preparation and Selection

The process begins with sourcing high-quality raw materials, which include premium leather, textiles, and eco-friendly synthetics. Suppliers often establish long-term relationships with trusted material vendors to guarantee consistency. For buyers, verifying material certifications (e.g., REACH, OEKO-TEX) is essential, especially for markets with strict import regulations like Europe or Argentina.

Forming and Component Manufacturing

The next stage involves cutting, molding, and shaping components. Advanced techniques such as computer-aided design (CAD) and CNC cutting are employed for precision. For mid- to high-end shoes, injection molding for soles and thermoforming for uppers are common. B2B buyers should inquire about the equipment used and the calibration processes to ensure dimensional accuracy and material integrity.

Assembly and Stitching

Assembling combines various components—uppers, insoles, outsoles—using both manual craftsmanship and automated machinery. Key techniques include direct sewing, heat bonding, and adhesive bonding, depending on the product line. For consistency, suppliers should follow standardized assembly procedures, often documented in operational manuals.

Finishing and Quality Checks

Final steps include polishing, labeling, and quality finishing. This stage may also involve adding branding details and packaging. The focus here is on aesthetic quality and durability, with inspection for defects like uneven stitching, material blemishes, or improper adhesion.

Quality Assurance Framework for Moonstar Shoes by Antonio Vietri

Ensuring product quality is vital for B2B buyers, especially when importing for diverse markets. The quality assurance (QA) processes align with international standards, primarily ISO 9001, and adhere to industry-specific certifications.

International and Industry Standards

- ISO 9001: The primary benchmark for quality management systems, emphasizing process consistency, customer satisfaction, and continuous improvement.

- CE Marking: For shoes destined for the European market, CE compliance ensures conformity with safety, health, and environmental directives.

- Other Certifications: API (American Petroleum Institute) standards are less relevant here but may be applicable if specific materials or manufacturing processes demand it. For markets like Argentina or South Africa, local standards (e.g., IRAM, SABS) should also be considered.

Key Quality Control Checkpoints

- Incoming Quality Control (IQC): Raw materials are inspected upon receipt for defects, correct specifications, and compliance with certifications.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing, including dimensional checks, stitching quality, and bonding strength. Use of statistical process control (SPC) techniques helps detect deviations early.

- Final Quality Control (FQC): Before shipment, products undergo comprehensive inspections for visual defects, structural integrity, and functional performance. This includes testing for colorfastness, sole adhesion, and flexibility.

Testing Methods

- Mechanical Tests: Flexibility, abrasion resistance, and tensile strength tests ensure durability.

- Chemical Tests: Testing for harmful substances (e.g., heavy metals, VOC emissions) to meet REACH and other regulations.

- Environmental Tests: Simulating conditions like humidity, temperature fluctuations, and UV exposure to ensure product resilience.

How B2B Buyers Can Verify Supplier Quality

B2B buyers should adopt rigorous verification methods to ensure supplier quality standards are maintained and meet their market requirements.

Conducting Audits

- Factory Audits: Regular on-site inspections focusing on manufacturing processes, cleanliness, worker safety, and environmental compliance.

- Process Audits: Reviewing quality control procedures, testing records, and certification validity.

- Product Sampling: Requesting random samples for independent testing to verify compliance with agreed specifications.

Reviewing Documentation and Reports

- Quality Certificates: Certificates of compliance, test reports, and material certifications must be reviewed and authenticated.

- Inspection Reports: Suppliers should provide detailed inspection records, including defect rates, corrective actions, and non-conformance reports.

- Third-party Inspection Reports: Engaging accredited third-party inspectors (e.g., SGS, Bureau Veritas) adds an impartial layer of verification.

Engaging Third-party Inspection Services

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, third-party inspections are invaluable. They provide unbiased assessments of product quality, compliance, and manufacturing practices before shipment.

Special Considerations for International B2B Buyers

Navigating Diverse Regulatory Landscapes

Buyers from regions with stringent standards, such as Europe and France, should prioritize suppliers with ISO 9001 certification and CE compliance. For markets like Argentina or South Africa, verifying adherence to local standards (IRAM, SABS) is crucial to avoid customs delays or rejection.

Addressing Cultural and Logistical Factors

Understanding local inspection and certification requirements can streamline import processes. For example, African and Middle Eastern markets may have specific import regulations regarding chemical substances or labeling, necessitating clear documentation from suppliers.

Building Long-term Quality Partnerships

Establishing ongoing audits and quality reviews fosters trust and ensures continuous compliance. B2B buyers should consider integrating supplier development programs to improve quality standards aligned with evolving market demands.

Final Thoughts

A comprehensive understanding of the manufacturing and quality assurance processes of Moonstar shoes by Antonio Vietri empowers international buyers to make informed sourcing decisions. Emphasizing transparent communication, rigorous verification, and adherence to global standards ensures product quality, reduces risks, and facilitates successful market entry across diverse regions.

Comprehensive Cost and Pricing Analysis for moonstar shoes by antonio vietri Sourcing

Cost Structure Breakdown

Understanding the comprehensive cost structure for Moonstar Shoes by Antonio Vietri is essential for international B2B buyers aiming to optimize procurement strategies. The main cost components include:

-

Materials: The choice of materials significantly influences the unit cost. High-quality leathers, sustainable fabrics, or innovative composites can increase prices but also add value through durability and brand positioning. Suppliers in Asia, particularly Japan and China, offer a range of options, with prices varying based on grade and sourcing origin.

-

Labor: Manufacturing costs are typically lower in Asian factories, especially in countries like Vietnam, China, and Indonesia. However, for premium or customized designs, labor costs may increase proportionally with complexity and craftsmanship requirements.

-

Manufacturing Overheads: These include factory utilities, machinery depreciation, and quality assurance processes. Overheads are generally embedded within the unit cost but can vary depending on factory efficiency and scale.

-

Tooling and Setup: Initial tooling costs for molds or specialized equipment can be substantial but are amortized over large production runs. For small orders or prototypes, these costs represent a significant portion of the unit price.

-

Quality Control and Certifications: Ensuring compliance with international standards (ISO, REACH, etc.) and obtaining certifications can add to costs but are crucial for market access, especially in Europe and the Middle East.

-

Logistics and Shipping: Freight costs depend heavily on order volume, destination, and shipping method (air vs. sea). Buyers from Africa and South America should plan for higher shipping costs and longer lead times, while European and Middle Eastern buyers might benefit from proximity to manufacturing hubs.

-

Margins: Manufacturers typically add a markup to cover risks and profit margins. For large, repeat orders, buyers can negotiate better margins, especially if they commit to long-term partnerships.

Influencing Price Factors

Several factors influence the final pricing of Moonstar Shoes:

-

Order Volume & MOQ: Larger orders generally lead to lower unit prices due to economies of scale. Many suppliers offer tiered discounts for volume, with MOQs starting from 500 pairs for standard models, and higher for customized products.

-

Customization & Specifications: Customized designs, unique branding, or specialized materials increase costs. Detailed specifications, colorways, and packaging requirements also impact pricing.

-

Material Choice: Premium or eco-friendly materials carry higher costs but can command higher retail prices in your target markets, enhancing overall profitability.

-

Quality & Certifications: Higher quality standards and certifications required for European or Middle Eastern markets increase costs but are often necessary for market acceptance and compliance.

-

Supplier Factors: Factory reputation, production capacity, and reliability influence pricing. Established suppliers with strong quality records might charge premium but offer greater assurance.

-

Incoterms & Logistics: Shipping terms like FOB, CIF, or DDP affect the overall landed cost. Buyers should evaluate these carefully to understand true cost implications and negotiate accordingly.

Strategic Tips for B2B Buyers

-

Negotiate for Volume & Long-term Contracts: Leverage larger order volumes to secure better pricing and flexible payment terms. Building long-term relationships can also lead to priority production and better margins.

-

Focus on Total Cost of Ownership (TCO): Beyond unit price, consider customs duties, taxes, import fees, and logistical expenses. For example, importing to Europe or Argentina may involve higher tariffs, influencing the final landed cost.

-

Explore Certification and Quality Standards: Ensure the supplier can meet your market’s certifications to avoid costly delays or rejections. European buyers should prioritize compliance with REACH and CE standards, while Middle Eastern buyers may require specific GCC certifications.

-

Balance Cost and Quality: While lower-cost suppliers may seem attractive, compromised quality can lead to higher returns, rework, or brand damage. Select suppliers with proven track records and transparent quality assurance processes.

-

Understand Pricing Nuances: Prices vary based on regional factors. For instance, Asian suppliers might offer more competitive prices, but longer shipping times and higher freight costs can offset savings. European suppliers may have higher prices but shorter lead times and easier compliance.

Disclaimer on Price Estimates

Indicative prices for Moonstar Shoes by Antonio Vietri typically range from $20 to $50 per pair for standard models, depending on specifications, order volume, and customization. Premium or heavily customized shoes can exceed $60 per pair. These figures are approximate and subject to change based on market conditions, supplier negotiations, and specific order details.

By thoroughly analyzing these cost components and influencing factors, international B2B buyers can develop more accurate budgets, negotiate effectively, and optimize the total value of their procurement investments in Moonstar Shoes.

Spotlight on Potential moonstar shoes by antonio vietri Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for moonstar shoes by antonio vietri.)*

Essential Technical Properties and Trade Terminology for moonstar shoes by antonio vietri

Critical Technical Properties for Moonstar Shoes by Antonio Vietri

1. Material Grade and Composition

The quality of materials used in manufacturing Moonstar shoes directly impacts durability, comfort, and brand reputation. Key materials include leather, synthetic fabrics, rubber, and specialized insoles. High-grade materials (e.g., full-grain leather, premium rubber) ensure longevity and meet international safety standards. B2B buyers should verify material certifications to confirm compliance with regional regulations, especially for export markets with strict import standards.

2. Manufacturing Tolerance and Precision

Tolerance refers to the acceptable variation in shoe dimensions during production, such as length, width, and sole thickness. Tight tolerances (e.g., ±0.5 mm) are crucial for consistent sizing, reducing returns, and ensuring customer satisfaction. Suppliers with precise manufacturing controls demonstrate reliability, especially important when fulfilling large or recurring orders across different markets.

3. Stitching and Seaming Quality

Stitching durability impacts the shoe’s lifespan and resistance to wear. Uniform, reinforced seams prevent early breakdowns and ensure product integrity, which is vital for wholesale buyers. High-quality stitching also signifies adherence to international manufacturing standards, reducing the risk of defects upon delivery.

4. Sole Composition and Traction

The outsole material, often rubber or specialized polymers, determines grip, flexibility, and slip resistance. For diverse climates—such as humid regions in Africa or icy conditions in Europe—selecting soles with appropriate traction properties is essential. B2B buyers should request technical datasheets to verify slip resistance ratings and compatibility with regional terrains.

5. Weight and Flexibility

Lightweight shoes enhance comfort, especially for active consumers, while flexibility ensures ease of movement. These properties influence customer satisfaction and can be tailored for specific markets, such as lightweight casual shoes for urban European markets or more robust designs for outdoor use in South America.

6. Compliance and Certification Standards

Shoes must meet regional safety and quality standards, such as ISO certifications, CE markings in Europe, or local safety regulations in Africa and South America. Confirming these certifications during procurement reduces legal risks and facilitates smoother customs clearance.

Essential Trade Terminology for Moonstar Shoes by Antonio Vietri

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce shoes based on the buyer’s specifications or brand. Understanding OEM relationships helps B2B buyers negotiate customization, branding, and quality control directly with manufacturers, ensuring product alignment with market expectations.

2. MOQ (Minimum Order Quantity)

The smallest quantity of shoes a supplier is willing to produce per order. For new market entry or testing demand, buyers should negotiate flexible MOQs. Larger MOQs often lead to better unit prices but require careful market analysis to avoid excess inventory.

3. RFQ (Request for Quotation)

A formal document sent by buyers to suppliers requesting price, lead time, and technical details. Efficient RFQ processes facilitate competitive pricing and enable buyers to compare multiple suppliers’ offerings systematically.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs duties. Familiarity with Incoterms (e.g., FOB, CIF, DDP) allows buyers to accurately calculate landed costs and plan logistics, especially when importing into regions with complex customs procedures like Africa or South America.

5. Lead Time

The period from order confirmation to delivery. Understanding lead times helps buyers plan inventory and avoid stockouts, particularly crucial when dealing with seasonal demand or promotional campaigns.

6. Quality Assurance (QA) and Inspection

Processes to verify that shipped shoes meet specified standards. Conducting pre-shipment inspections minimizes defects, reduces returns, and ensures compliance with regional standards. Buyers should establish clear QA protocols aligned with industry benchmarks.

Actionable Insights for International B2B Buyers

- Prioritize Material Certification: Always request detailed material specifications and certifications to ensure compliance with local import regulations and quality expectations.

- Negotiate Tolerances and Lead Times: Clear communication on tolerances and production timelines helps prevent costly delays and quality issues.

- Leverage Trade Terms: Fully understand Incoterms to manage logistics costs and responsibilities effectively, especially when dealing with multiple regions.

- Assess MOQ Flexibility: For new markets, negotiate flexible MOQs to minimize inventory risk and adapt to demand fluctuations.

- Implement Robust QA Protocols: Establish inspection routines aligned with industry standards to guarantee product quality upon arrival.

- Build Strong OEM Relationships: Collaborate closely with manufacturers to customize products that meet regional preferences and standards, enhancing market competitiveness.

By mastering these technical properties and trade terms, B2B buyers can streamline procurement processes, optimize costs, and ensure the consistent delivery of high-quality Moonstar shoes tailored to diverse regional markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the moonstar shoes by antonio vietri Sector

Market Overview & Key Trends

The global footwear industry is experiencing rapid transformation driven by technological innovation, shifting consumer preferences, and increased emphasis on sustainability. For Moonstar Shoes by Antonio Vietri, the current landscape presents numerous opportunities and challenges for international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe.

Emerging sourcing trends include the adoption of digital platforms for supplier discovery, real-time supply chain tracking, and AI-driven demand forecasting. These tools enable buyers to optimize inventory, reduce lead times, and improve cost efficiencies. Additionally, regional sourcing is gaining prominence, with buyers seeking to diversify supply chains to mitigate geopolitical risks and currency fluctuations.

Market dynamics are also influenced by rising consumer demand for unique, handcrafted, and eco-friendly footwear. European markets, particularly France, are increasingly favoring premium, artisanal products, while South American and African markets show growth potential in affordable, durable footwear. Middle Eastern markets are shifting toward luxury and innovative designs, driven by a growing affluent demographic.

For B2B buyers from these regions, understanding local market preferences and leveraging technology-driven sourcing platforms are crucial. Establishing strong relationships with suppliers that demonstrate agility, transparency, and compliance with international standards can significantly enhance supply chain resilience. Moreover, embracing data analytics and supply chain digitization can provide a competitive edge in navigating fluctuating demand and supply conditions.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a central pillar of strategic sourcing in the footwear sector, particularly for brands like Moonstar Shoes by Antonio Vietri that appeal to eco-conscious consumers. B2B buyers must prioritize suppliers committed to environmentally responsible practices, including the use of sustainable raw materials, ethical labor standards, and transparent supply chains.

Implementing green sourcing strategies involves selecting materials that reduce environmental impact, such as recycled plastics, organic textiles, and natural dyes. Certifications like Global Organic Textile Standard (GOTS), Forest Stewardship Council (FSC), and Fair Trade are increasingly recognized as benchmarks of ethical compliance and environmental stewardship. These certifications not only enhance brand reputation but also meet the growing demand from European and Middle Eastern markets for ethically produced footwear.

Furthermore, adopting a circular economy approach—such as designing for recyclability or incorporating biodegradable components—can reduce waste and lower lifecycle emissions. B2B buyers should also engage with suppliers that demonstrate traceability and transparency, ensuring that every step of the supply chain adheres to environmental and social standards.

Investing in sustainability is not merely a compliance measure but a strategic advantage. It can lead to cost savings through resource efficiency, open access to premium markets, and foster long-term supplier relationships rooted in shared values. For Moonstar Shoes by Antonio Vietri, integrating sustainability into sourcing practices can differentiate products in competitive markets and meet the increasing consumer and regulatory expectations worldwide.

Brief Evolution/History (Optional)

Moonstar Shoes by Antonio Vietri has evolved from a niche artisanal footwear producer to a recognized name in eco-friendly, handcrafted shoes. This evolution reflects broader industry trends emphasizing craftsmanship, sustainability, and innovation. For B2B buyers, understanding this trajectory can inform sourcing strategies—highlighting the brand’s commitment to quality and responsible manufacturing.

Historically, Moonstar’s emphasis on sustainable materials and ethical production has positioned it favorably in markets with rising environmental awareness, such as Europe and parts of South America. Its adaptive approach—integrating modern design with traditional techniques—offers opportunities for international buyers seeking authentic, premium products that align with global sustainability standards.

Recognizing this evolution helps B2B buyers identify partnership opportunities rooted in shared values of craftsmanship and environmental responsibility, fostering long-term collaborations that can meet the demands of increasingly conscious consumers worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of moonstar shoes by antonio vietri

1. How can I verify the credibility and reliability of Moonstar Shoes by Antonio Vietri as a supplier?

To ensure supplier credibility, start by requesting comprehensive company documentation such as business licenses, export certificates, and factory audits. Check for industry certifications related to quality standards (ISO, CE, etc.) and request references from existing international clients. Conduct virtual factory visits or third-party inspections when possible. Additionally, review their track record on B2B platforms like Alibaba, Global Sources, or industry-specific directories. Establish clear communication channels and negotiate trial orders to assess responsiveness and product quality before scaling your partnership.

2. What customization options are available for Moonstar Shoes, and how do they impact lead times and costs?

Moonstar Shoes by Antonio Vietri typically offers customization in areas like branding (logos, packaging), colorways, and minor design tweaks. For larger or complex customizations, production timelines may extend by 4–8 weeks, and costs will increase accordingly due to setup fees and tooling. Early engagement with the supplier’s design and R&D teams is essential to align expectations. Clarify minimum order quantities (MOQs) for customized products and request detailed quotations that include lead times, additional costs, and potential sample development periods to plan your procurement schedule effectively.

3. What are the typical minimum order quantities (MOQs) and lead times for international shipments?

MOQs for Moonstar Shoes generally range from 200 to 1,000 pairs, depending on the product line and customization level. Lead times can vary from 4 to 12 weeks, influenced by order complexity, current production schedules, and destination logistics. To mitigate risks, consider ordering in smaller batches initially and establishing a reliable forecast with the supplier. Always confirm lead times before committing, and build buffer periods into your supply chain to accommodate customs clearance, shipping delays, or unforeseen disruptions, especially when sourcing from Asia or other distant regions.

4. What payment terms are standard for B2B transactions, and how can I mitigate financial risks?

Common payment terms include 30% advance payment with the remaining 70% upon shipment, or letter of credit (L/C) arrangements for larger orders. Negotiate payment terms that align with your cash flow, and consider using escrow services or trade finance options for added security. To mitigate risks, conduct thorough credit checks on the supplier, request references, and start with smaller trial orders. Establish clear contractual agreements covering quality standards, delivery schedules, and dispute resolution clauses to protect your investments.

Illustrative Image (Source: Google Search)

5. What quality assurance measures and certifications should I look for in Moonstar Shoes products?

Ensure the supplier adheres to internationally recognized quality standards such as ISO 9001, and check for specific certifications related to footwear safety and environmental compliance (e.g., REACH, OEKO-TEX). Request detailed quality control procedures, including inspection reports and third-party testing results. Implement your own quality checks upon receipt or engage third-party inspection agencies at the factory. Establish clear quality benchmarks in your contract, and consider requesting pre-shipment samples for approval to avoid costly returns or rework post-arrival.

6. How are logistics and shipping typically managed, and what should I consider for international deliveries?

Most Moonstar Shoes shipments are managed via sea freight for cost efficiency or air freight for urgent deliveries. Coordinate with freight forwarders experienced in international footwear logistics to optimize routes, customs clearance, and documentation (commercial invoices, packing lists, certificates of origin). Be aware of import duties, taxes, and local regulations in your country—these can significantly impact total landed cost. Negotiate Incoterms (e.g., FOB, CIF) upfront to clearly define responsibilities and liabilities. Establish reliable tracking and communication channels to stay informed throughout transit.

7. How should I handle potential disputes or product quality issues with my supplier?

Develop a clear dispute resolution process within your contract, specifying methods such as negotiation, mediation, or arbitration in a neutral jurisdiction. Maintain detailed records of communications, inspection reports, and photographs of any quality issues. If problems arise, communicate promptly with the supplier, providing documented evidence. Consider including penalty clauses or quality warranties to incentivize adherence to agreed standards. Building a good relationship with open, transparent communication can often resolve issues more efficiently than formal legal routes.

8. What are the best practices for building long-term, reliable B2B partnerships with Moonstar Shoes by Antonio Vietri?

Establish consistent communication and mutual understanding of expectations from the outset. Regularly review performance metrics, such as quality, delivery times, and responsiveness. Invest in building trust through transparent dealings, timely payments, and constructive feedback. Consider visiting the supplier’s facilities periodically and participating in joint planning to align on future product development and capacity expansion. Diversify your supplier base to mitigate risks and ensure supply continuity. Long-term relationships often yield better pricing, priority treatment, and collaborative innovation, especially in dynamic international markets.

Strategic Sourcing Conclusion and Outlook for moonstar shoes by antonio vietri

Conclusion and Future Perspective

Effective strategic sourcing of Moonstar shoes by Antonio Vietri offers international B2B buyers a compelling opportunity to align with a brand renowned for quality, innovation, and cultural authenticity. By leveraging strong supplier relationships, understanding regional market nuances, and prioritizing sustainability, buyers from Africa, South America, the Middle East, and Europe can secure a competitive edge in their footwear offerings.

As global demand for authentic and ethically produced footwear continues to grow, establishing resilient sourcing channels becomes essential. Embracing a strategic approach not only mitigates supply chain risks but also enhances brand reputation and customer loyalty across diverse markets.

Looking ahead, proactive engagement with Moonstar’s production network and staying abreast of industry trends will position buyers to capitalize on emerging opportunities. We encourage international B2B partners to explore tailored sourcing strategies that align with their market needs, fostering mutually beneficial collaborations that drive sustainable growth. Now is the time to forge strategic partnerships that can adapt to evolving global demands and establish a strong foothold in the competitive footwear industry.