Your Ultimate Guide to Sourcing Neutral Running Shoes

Guide to Neutral Running Shoes

- Introduction: Navigating the Global Market for neutral running shoes

- Understanding neutral running shoes Types and Variations

- Key Industrial Applications of neutral running shoes

- Strategic Material Selection Guide for neutral running shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for neutral running shoes

- Comprehensive Cost and Pricing Analysis for neutral running shoes Sourcing

- Spotlight on Potential neutral running shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for neutral running shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the neutral running shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of neutral running shoes

- Strategic Sourcing Conclusion and Outlook for neutral running shoes

Introduction: Navigating the Global Market for neutral running shoes

Understanding the nuances of the global market for neutral running shoes is essential for B2B buyers seeking reliable and competitive sourcing options. As the demand for high-quality athletic footwear continues to grow across Africa, South America, the Middle East, and Europe, sourcing the right product requires a strategic approach informed by market insights, manufacturing standards, and supplier capabilities.

Neutral running shoes, characterized by their versatile design suitable for a wide range of foot types and running styles, represent a significant segment within the athletic footwear industry. Their universal appeal makes them a key product for importers, distributors, and retailers aiming to meet diverse consumer needs. However, navigating the complexities of sourcing—ranging from material selection and manufacturing quality to cost management and supplier reliability—can be challenging without comprehensive industry knowledge.

This guide offers a detailed roadmap for international B2B buyers, covering critical aspects such as product types, manufacturing processes, quality control practices, supplier sourcing strategies, cost considerations, and market dynamics. It also addresses frequently asked questions to clarify common uncertainties faced during procurement.

Empowering your sourcing decisions with these insights ensures you can identify reputable suppliers, optimize costs, and deliver high-quality neutral running shoes tailored to your target markets. Whether you’re sourcing from Asia, Europe, or emerging manufacturing hubs, this guide provides actionable intelligence to help you succeed in a competitive global landscape.

Illustrative Image (Source: Google Search)

Understanding neutral running shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Neutral Running Shoes | Lightweight, flexible, minimal stability features | Retail, sports stores, online marketplaces | Pros: Wide consumer appeal, versatile; Cons: Lower stability for some users |

| Max Cushioning Shoes | Enhanced midsole padding, plush feel, higher shock absorption | Specialty stores, high-performance segments | Pros: Attracts comfort-focused consumers; Cons: Higher cost, bulkier design |

| Minimalist Neutral Shoes | Thin, flexible sole, minimal structure, close to barefoot feel | Niche markets, fitness boutiques, eco-conscious outlets | Pros: Trendy, appeals to minimalist consumers; Cons: Limited durability, niche appeal |

| Stability-Neutral Hybrid | Combines neutral design with slight stability features | Multi-purpose retail, sports outlets | Pros: Broader market reach, adaptable; Cons: Slightly complex inventory management |

| Customizable Neutral Shoes | Modular components, adjustable fit, personalized options | Specialty sports stores, OEM partnerships | Pros: Differentiates brand, high consumer engagement; Cons: Higher manufacturing complexity |

Characteristics and Suitability

Classic Neutral Running Shoes are the most prevalent type, characterized by their lightweight construction and flexible design. They cater to a broad demographic, including casual runners and those seeking everyday comfort. For B2B buyers, these shoes offer high-volume potential with consistent demand across diverse markets, especially in regions like Africa and South America where affordability and versatility are valued. Procurement considerations include sourcing reliable suppliers with consistent quality and competitive pricing.

Max Cushioning Shoes emphasize superior shock absorption through thick midsoles and plush materials. They are suitable for long-distance runners, recovery users, or consumers with joint concerns. B2B buyers should focus on sourcing from manufacturers with proven durability and consistent cushioning performance. These shoes often command a higher retail price, making them attractive for premium segments but requiring careful inventory management to balance stock turnover.

Minimalist Neutral Shoes mimic barefoot running, featuring thin soles and minimal structure. They appeal to niche markets, eco-conscious consumers, and fitness enthusiasts interested in natural movement. For B2B buyers, sourcing these shoes involves identifying manufacturers with expertise in lightweight, sustainable materials. They typically have lower margins but can differentiate a product lineup in competitive markets.

Stability-Neutral Hybrid Shoes blend features of neutral and stability models, offering moderate support without sacrificing lightweight comfort. They are versatile, suitable for a wide range of runners who need some support but prefer a neutral feel. These shoes are ideal for retailers aiming to serve both casual and serious runners, requiring diverse supplier relationships to ensure quality across varied product lines.

Customizable Neutral Shoes incorporate modular designs allowing consumers to adjust fit and features. They target high-end markets and specialty sports stores seeking personalized solutions. For B2B buyers, establishing partnerships with OEMs capable of producing customizable options at scale is crucial. These shoes often involve higher production costs but can command premium pricing and foster brand loyalty.

Understanding these variations enables B2B buyers to tailor their inventory to regional preferences, consumer needs, and market trends. By selecting appropriate types and establishing reliable supply chains, buyers can enhance their competitiveness and meet diverse customer expectations effectively.

Key Industrial Applications of neutral running shoes

| Industry/Sector | Specific Application of neutral running shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports and Athletic Wear | Manufacturing of specialized neutral running shoes for athletes | Enhances product differentiation, meets diverse customer needs, boosts sales | Material durability, comfort, lightweight design, compliance with international safety standards |

| Medical and Rehabilitation | Use in physiotherapy clinics and orthopedics for gait correction | Supports patient recovery, reduces injury risk, improves comfort | Biocompatibility, ergonomic design, consistent quality control, availability of customization options |

| Corporate & Uniform Footwear | Provision of neutral shoes for employee wellness programs | Promotes health and safety, reduces workplace injuries, enhances corporate image | Bulk sourcing capabilities, cost efficiency, consistent sizing, compliance with safety regulations |

| Logistics & Warehouse Operations | Durable footwear for workers on long shifts in warehouses | Increases worker comfort, reduces fatigue, minimizes injury-related downtime | Slip resistance, high durability, cost-effectiveness, adaptability to various climates |

| Tourism & Hospitality | Footwear solutions for staff and guests in resorts or tour operations | Enhances comfort, supports active staff roles, improves guest experience | Comfort for extended wear, aesthetic appeal, ease of maintenance, reliable supply chain |

Applications in Detail

Sports and Athletic Wear:

Neutral running shoes are central to the manufacturing of athletic footwear designed for diverse running styles. For international B2B buyers, especially in regions like Africa and South America, sourcing high-quality neutral shoes can differentiate their product lines, appealing to a broad customer base from casual runners to serious athletes. These shoes help meet demand for lightweight, durable, and comfortable footwear that caters to various terrains and climates, making them ideal for local markets with diverse running environments.

Medical and Rehabilitation:

In physiotherapy and orthopedics, neutral running shoes are used as part of gait correction and injury prevention programs. B2B buyers such as medical suppliers or clinics in the Middle East and Europe require shoes that support proper biomechanics, are biocompatible, and can be customized for individual needs. Ensuring consistent quality and availability of these shoes helps healthcare providers deliver effective treatment, while buyers benefit from reliable supply chains and compliance with international health standards.

Corporate & Uniform Footwear:

Many organizations are adopting neutral shoes as part of employee wellness initiatives, particularly in sectors like logistics, retail, and hospitality. These shoes reduce fatigue and injury among staff working long shifts, thus decreasing downtime and insurance costs. International buyers from regions like Kenya and Argentina should prioritize sourcing shoes that are cost-effective, durable, and available in bulk, with certifications for workplace safety and comfort to meet local labor regulations.

Logistics & Warehouse Operations:

Workers in warehouses and logistics centers require footwear that withstands rigorous daily activity. Neutral running shoes with high durability, slip resistance, and ergonomic support are essential to reduce fatigue and prevent injuries. For B2B buyers, sourcing shoes that are adaptable to different climatic conditions and compliant with safety standards (such as anti-slip or puncture-resistant features) ensures operational efficiency and worker safety across diverse regions.

Tourism & Hospitality:

Neutral shoes are increasingly used in the tourism sector for staff in resorts, tour guides, and active hospitality roles. Comfort and aesthetic appeal are critical, especially for employees on their feet for extended periods. International buyers should focus on sourcing shoes that combine style with functionality, are easy to clean, and meet health and safety standards, thereby enhancing guest experience and supporting staff well-being in competitive markets like Europe and South America.

Strategic Material Selection Guide for neutral running shoes

Material Analysis for Neutral Running Shoes

Selecting the appropriate materials for neutral running shoes is critical for ensuring product performance, durability, and compliance with international standards. B2B buyers from regions such as Africa, South America, the Middle East, and Europe must consider not only the material properties but also regional manufacturing capabilities, import regulations, and end-user preferences.

EVA (Ethylene Vinyl Acetate)

EVA is one of the most common materials used in the midsole of neutral running shoes due to its excellent cushioning properties. It offers lightweight comfort, good shock absorption, and flexibility, making it ideal for neutral runners who prioritize comfort and responsiveness.

- Key Properties: Lightweight, excellent cushioning, good flexibility, and moderate durability. It performs well across a range of temperatures but can degrade under prolonged UV exposure.

- Pros & Cons: EVA is cost-effective and easy to mold during manufacturing, which benefits large-scale production. However, it tends to compress over time, leading to reduced cushioning and shorter lifespan. Its susceptibility to UV and environmental degradation can be a concern in regions with high sun exposure.

- Impact on Application: Suitable for use in regions with moderate climate conditions. For hotter climates like Kenya or Argentina, UV-resistant formulations or overlays are advisable.

- International Considerations: EVA complies with ASTM and EN standards, but buyers should verify supplier certifications for environmental compliance (e.g., REACH, RoHS). Its low cost makes it attractive for mass production, especially in emerging markets, but quality consistency is essential.

Thermoplastic Polyurethane (TPU)

TPU is frequently used in outsoles, overlays, and heel counters in neutral running shoes due to its high abrasion resistance and flexibility.

- Key Properties: High durability, excellent abrasion and tear resistance, good elasticity, and resistance to oils and chemicals. It maintains performance across a wide temperature range.

- Pros & Cons: TPU offers superior longevity and structural support, which enhances shoe lifespan. It is more expensive than EVA and requires more complex manufacturing processes, potentially increasing costs.

- Impact on Application: Ideal for regions with rugged terrains or high wear conditions, such as in parts of Africa and South America. Its chemical resistance makes it suitable for humid or corrosive environments.

- International Considerations: TPU materials must meet regional standards like DIN, ASTM, or JIS depending on the market. For export, compliance with environmental regulations (e.g., REACH in Europe) is crucial. The higher cost can be offset by longer product life and reduced warranty claims.

Mesh Fabrics (Synthetic and Natural Fibers)

Mesh fabrics are predominantly used in the upper part of neutral running shoes to provide breathability and lightweight comfort.

- Key Properties: High breathability, moderate durability, and flexibility. Synthetic meshes (nylon, polyester) are resistant to moisture and UV, while natural fibers (cotton) are less so.

- Pros & Cons: Synthetic meshes are cost-effective, easy to produce, and suitable for humid climates. Natural fibers offer eco-friendly appeal but are less resistant to environmental factors, which could lead to quicker deterioration in humid or salty environments.

- Impact on Application: For regions like the Middle East or coastal South America, synthetic meshes with UV and salt resistance are recommended. Buyers should consider local washing and maintenance standards.

- International Considerations: Mesh fabrics should meet regional standards for textile safety (OEKO-TEX, REACH). Suppliers with certifications for sustainable sourcing are increasingly preferred, especially in European markets.

Summary Table

| Material | Typical Use Case for neutral running shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| EVA (Ethylene Vinyl Acetate) | Midsole cushioning | Lightweight, cost-effective, good shock absorption | Compresses over time, UV degradation risk | Low |

| TPU (Thermoplastic Polyurethane) | Outsole, overlays, heel counters | High durability, chemical and abrasion resistance | Higher cost, complex manufacturing | High |

| Mesh Fabrics (Synthetic/Natural) | Upper part for breathability | Breathable, lightweight, moisture resistant | Less durable in harsh environments, possible environmental degradation | Low to Med |

| Carbon Fiber Reinforcement | Structural support in midsoles | High strength-to-weight ratio, enhances responsiveness | Costly, complex manufacturing, brittle if not properly integrated | High |

Final Insights for B2B Buyers

When selecting materials, consider regional climate and environmental conditions, regulatory standards, and end-user preferences. For African and South American markets, durability and cost are often key drivers, while European buyers may emphasize sustainability and compliance. Middle Eastern markets may prioritize UV and heat resistance, influencing material choices like UV-stabilized EVA or high-performance synthetics. Establishing reliable supplier partnerships with verified certifications ensures product quality, compliance, and market acceptance across diverse regions.

In-depth Look: Manufacturing Processes and Quality Assurance for neutral running shoes

Manufacturing Processes for Neutral Running Shoes

The production of neutral running shoes involves a complex, multi-stage process designed to ensure durability, comfort, and performance. For B2B buyers, understanding these stages helps in evaluating supplier capabilities and ensuring consistent product quality.

1. Material Preparation

The process begins with sourcing high-quality raw materials tailored for neutral running shoes. Key components include:

– Midsole materials: EVA (ethylene-vinyl acetate) or foam compounds for cushioning.

– Outsole materials: Rubber or synthetic compounds for durability and grip.

– Upper materials: Mesh, synthetic leather, or knit fabrics for breathability and comfort.

Suppliers often pre-condition and test raw materials to meet specified standards, ensuring consistency before production.

2. Forming and Molding

This stage involves shaping the shoe components:

– Midsole and outsole molding: Using injection or compression molding techniques, heated molds shape the cushioning and outsole parts.

– Upper fabrication: Cutting, stitching, and bonding fabric or synthetic upper parts through automated or semi-automated processes.

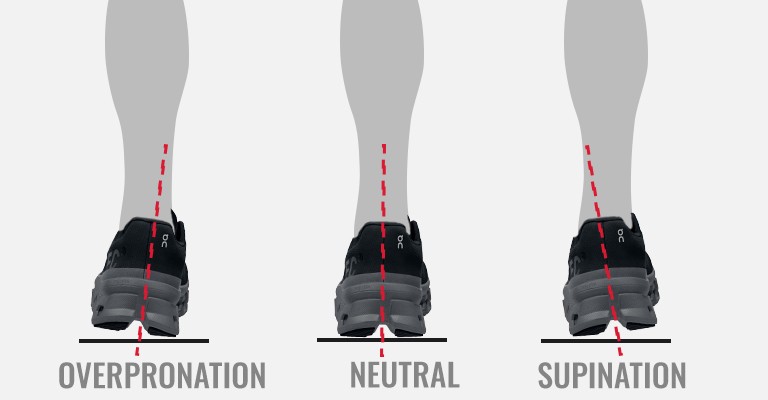

Precision in molding ensures the neutral profile—neither pronation nor supination correction—aligns with design specifications.

3. Assembly

Assembly integrates all components:

– Attaching the midsole to the upper: Often through adhesive bonding and sometimes mechanical fastening.

– Lacing systems, insoles, and linings: Installed in this phase, with attention to ergonomic fit.

– Quality of bonding and stitching: Critical to prevent delamination and ensure longevity, especially under diverse environmental conditions.

4. Finishing

Final touches include:

– Surface treatment: Cleaning, polishing, and applying protective coatings.

– Quality checks: Visual inspections for defects, proper fit, and finish.

– Packaging: Final products are packed in environmentally friendly packaging, ready for shipment.

Quality Assurance (QA) and Control Measures

Robust QA protocols are vital for consistent product quality, especially in international markets with diverse regulatory requirements.

1. International Standards and Certifications

- ISO 9001: Most manufacturers adhere to ISO 9001 standards for quality management systems, ensuring consistent process control and continuous improvement.

- Product-specific certifications: Depending on target markets, compliance with standards like CE (Europe), ASTM, or ISO 14001 (environmental management) may be necessary.

- Material certifications: For example, REACH compliance in Europe for chemical safety or eco-labels in South America and Africa.

2. Quality Control Checkpoints

- Incoming Quality Control (IQC): Inspection of raw materials upon receipt to verify conformity with specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing to identify deviations early. Techniques include dimensional checks, weight measurement, and visual inspections.

- Final Quality Control (FQC): Complete inspection of finished shoes for defects, consistency in color, stitching, and overall appearance. Functional testing, such as flexibility and adhesion tests, are also performed.

Illustrative Image (Source: Google Search)

3. Testing Methods

- Mechanical testing: Compression, tensile strength, and abrasion tests to assess durability.

- Performance testing: Cushioning resilience, energy return, and slip resistance.

- Environmental testing: Exposure to temperature, humidity, and UV light to ensure longevity under different climatic conditions.

Verifying Supplier QC for International Buyers

B2B buyers from Africa, South America, the Middle East, and Europe should adopt rigorous verification strategies:

– Supplier Audits: Conduct on-site audits to review manufacturing practices, quality systems, and compliance documentation.

– Third-party Inspections: Engage independent inspection agencies to perform random sampling, pre-shipment inspections, and factory audits.

– Review of Quality Reports: Request detailed QC reports, test certificates, and production records to verify adherence to standards.

– Product Testing: Perform independent lab testing on samples to validate claims and ensure compliance with local regulations.

QC Nuances for International B2B Buyers

Different regions impose specific requirements and expectations:

– Africa (e.g., Kenya): Emphasis on durability and environmental compliance due to climate and market conditions. Suppliers should demonstrate adherence to both international standards and local import regulations.

– South America (e.g., Argentina): Focus on chemical safety and eco-certifications, aligning with regional environmental policies.

– Middle East: Requirements often include high-temperature resistance and dustproof features; suppliers should provide relevant testing data.

– Europe: Strict compliance with CE marking, chemical safety, and environmental standards; suppliers must demonstrate traceability and certification.

Actionable Insights for B2B Buyers

- Establish clear quality specifications: Define material standards, performance benchmarks, and certification requirements upfront.

- Develop a supplier qualification process: Combine audits, test reports, and sample testing to validate supplier capabilities.

- Implement ongoing QC monitoring: Use a combination of third-party inspections and in-house testing to maintain quality consistency.

- Leverage technology: Utilize digital platforms for real-time quality reporting, traceability, and compliance documentation.

- Build supplier relationships: Foster transparent communication and long-term partnerships to ensure continuous quality improvement.

By understanding and rigorously managing manufacturing and quality assurance processes, B2B buyers from diverse regions can mitigate risks, ensure product consistency, and meet international standards—ultimately enhancing brand reputation and customer satisfaction in the global market for neutral running shoes.

Comprehensive Cost and Pricing Analysis for neutral running shoes Sourcing

Cost Structure Breakdown for Neutral Running Shoes

Understanding the detailed cost components is essential for effective pricing and sourcing strategies. The primary cost elements include:

-

Materials: The bulk of the cost is attributed to high-quality synthetic or mesh upper fabrics, EVA or foam midsoles, rubber outsoles, and other components like laces and insoles. Material costs can vary significantly depending on the quality, sourcing country, and certifications (e.g., eco-labels). For budget models, material costs might be around 20-30% of FOB price, while premium models may see higher material costs due to advanced fabrics or technologies.

-

Labor: Manufacturing labor costs are highly variable, influenced by the country of production. For example, Asian manufacturers (China, Vietnam) typically offer lower labor costs, whereas factories in Europe or the Middle East may have higher wages. Efficient factories with high labor productivity can reduce per-unit labor costs, often constituting 15-25% of the FOB price.

-

Manufacturing Overhead: This includes factory utilities, machinery maintenance, and administrative expenses. Overhead costs tend to be stable but can vary based on factory scale and automation levels. Higher automation can reduce overhead per unit, impacting overall pricing.

-

Tooling and Development: Initial tooling costs for molds, dies, and prototypes are usually amortized over large production volumes. For small MOQ orders, tooling costs can significantly inflate unit prices, sometimes adding 10-15% to the FOB price.

-

Quality Control (QC): Rigorous QC processes are critical for ensuring product consistency, especially for international markets with strict standards. QC costs can be around 5-10% of manufacturing costs, depending on complexity and certification requirements.

-

Logistics and Shipping: Shipping costs are influenced by order volume, destination country, mode (sea, air), and Incoterms. Bulk shipments via sea freight are more economical but have longer lead times, whereas air freight offers speed at a premium. Customs duties, taxes, and import tariffs also significantly impact landed costs, especially for African, South American, and Middle Eastern buyers.

-

Profit Margin: Suppliers typically aim for a gross margin of 10-25%, depending on competitive pressure, order volume, and relationship maturity. Larger, repeat orders often secure better margins through negotiations.

Price Influencers and Their Impact

Several factors influence the final pricing and sourcing decisions:

-

Order Volume & MOQ: Higher volumes reduce per-unit costs due to economies of scale. Many manufacturers offer tiered pricing, with significant discounts at volume thresholds, making large orders more cost-effective for buyers.

-

Specifications & Customization: Custom colors, branding, or specialized technologies (e.g., specific cushioning systems) increase costs due to additional tooling, design, and certification requirements.

-

Materials & Certifications: Premium or eco-friendly materials, along with certifications like ISO or environmental standards, can elevate costs but may also command higher retail prices and consumer demand.

-

Quality & Certifications: Meeting international standards (e.g., ISO, ASTM, or specific market certifications) can increase costs but are often necessary for market acceptance, especially in Europe and the Middle East.

-

Supplier Factors: Factory reputation, production capacity, lead times, and payment terms influence pricing negotiations. Reliable, established suppliers may command higher prices but provide better quality assurance.

-

Incoterms & Delivery Terms: FOB (Free On Board) is common, but CIF (Cost, Insurance, Freight) or DDP (Delivered Duty Paid) might be preferred for simplified logistics. Buyers should evaluate the total landed cost, including freight, duties, and taxes.

Strategic Tips for International B2B Buyers

-

Negotiate for Volume Discounts: Larger orders reduce unit costs. Engage suppliers early to lock in favorable pricing, especially for predictable, ongoing demand.

-

Focus on Total Cost of Ownership (TCO): Beyond FOB price, consider logistics, customs duties, quality assurance, and post-sales support. A slightly higher initial cost might lead to better profitability through lower defect rates or faster lead times.

-

Leverage Long-term Relationships: Building trust can unlock better pricing, flexible payment terms, and priority production slots, crucial for markets with volatile currency or political climates.

-

Understand Pricing Nuances: Prices can fluctuate based on raw material costs, currency exchange rates, and geopolitical factors. Regular market analysis helps anticipate cost changes.

-

Certifications & Compliance: Investing in suppliers with international quality and environmental certifications can mitigate risks and facilitate market entry, especially in Europe and the Middle East.

Indicative Price Range (Disclaimers Applied)

For a standard neutral running shoe, FOB prices generally range from $8 to $15 per pair for mid-tier products in large volumes (e.g., 10,000+ units). Premium models with advanced features or eco-certifications can reach $20 or more. Smaller MOQ orders or customized designs often see prices at the higher end of this spectrum.

By carefully analyzing these cost components and price influencers, international B2B buyers from Africa, South America, the Middle East, and Europe can optimize their sourcing strategies—balancing cost, quality, and delivery to maximize competitiveness in their respective markets.

Spotlight on Potential neutral running shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for neutral running shoes.)*

Essential Technical Properties and Trade Terminology for neutral running shoes

Key Technical Properties of Neutral Running Shoes

Understanding the technical specifications of neutral running shoes is essential for international B2B buyers to ensure product quality, performance, and market suitability. Here are the critical properties to consider:

1. Material Grade and Composition

The choice of materials—such as EVA foam, TPU, mesh, and rubber—directly impacts durability, weight, and comfort. Higher-grade materials typically offer better longevity and performance but may come at a higher cost. Buyers should verify material certifications and compliance with regional safety standards to ensure suitability for target markets.

2. Cushioning and Midsole Technology

Neutral shoes rely heavily on effective cushioning to absorb impact and provide comfort. Key specifications include the type of foam used (e.g., EVA, EVA blends, or specialized proprietary foams), thickness, and density. Advanced midsole technologies like gel inserts or air capsules can differentiate products, offering better shock absorption and energy return, which are attractive features in competitive markets.

3. Outsole Tread Pattern and Rubber Quality

The outsole’s design influences grip, flexibility, and durability. Tread patterns should be optimized for different terrains, especially if targeting markets with diverse running surfaces. The rubber compound’s hardness and abrasion resistance are vital for longevity, particularly in regions with rugged or variable terrains.

4. Tolerance and Manufacturing Precision

Tolerance levels refer to the allowable deviation in dimensions during manufacturing. Tight tolerances ensure consistency in fit and performance, reducing returns and dissatisfaction. For B2B buyers, sourcing from manufacturers with strict quality control processes minimizes risk and ensures the product meets specified standards.

5. Weight Specifications

Lightweight shoes are preferred in many markets for their comfort and performance benefits. Precise weight measurements (per shoe or pair) help buyers assess suitability for specific customer segments, such as competitive runners or casual users.

6. Breathability and Ventilation

Materials with high breathability improve comfort, especially in hot climates common in Africa, South America, and the Middle East. Mesh uppers with moisture-wicking properties are standard; verifying material breathability ratings ensures suitability for regional climates.

Common Trade Terminology in the Neutral Running Shoe Industry

Familiarity with industry jargon enhances communication and negotiation efficiency. Here are key terms every B2B buyer should know:

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce products under another brand’s label. In footwear, OEMs often manufacture shoes based on specifications provided by brands or distributors. Understanding OEM capabilities helps buyers evaluate manufacturing quality, lead times, and customization options.

2. MOQ (Minimum Order Quantity)

The smallest quantity a manufacturer will accept for a production run. MOQs vary widely and directly impact initial investment and inventory planning. Buyers should negotiate MOQs that align with their market size and storage capacity, especially in regions with fluctuating demand.

3. RFQ (Request for Quotation)

A formal document sent to suppliers requesting price quotes, lead times, and terms for specific product specifications. Effective RFQs help compare suppliers objectively and ensure clarity on costs, quality, and delivery expectations.

4. Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce that define responsibilities, risks, and costs during shipping. Common terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) influence pricing structures and logistics planning, crucial for international trade.

5. Lead Time

The period from order placement to product delivery. Understanding lead times helps in inventory management and aligning production schedules, especially when dealing with international shipping and customs procedures.

6. Quality Certification and Standards

Certifications such as ISO, CE, or regional standards ensure compliance with safety, environmental, and quality requirements. Verifying these certifications is critical when entering new markets, as non-compliance can lead to delays or rejection.

Strategic Insights for International B2B Buyers

Grasping these technical properties and trade terms enables buyers to make informed decisions, negotiate effectively, and establish reliable supply chains. Emphasize quality control, transparent communication on specifications, and clear contractual terms to mitigate risks and foster long-term supplier relationships. Tailoring product specifications and understanding regional standards can also significantly enhance market acceptance and customer satisfaction.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the neutral running shoes Sector

Market Overview & Key Trends

The global neutral running shoes market is experiencing robust growth driven by increasing health consciousness, rising participation in fitness activities, and expanding urban lifestyles. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for effective sourcing and market positioning. Emerging trends include the integration of advanced materials like lightweight foams, responsive cushioning, and breathable textiles, which enhance comfort and performance for consumers.

Technological innovations such as 3D printing and digitized supply chains are reshaping sourcing strategies, enabling faster prototyping and customization. Sustainability is increasingly influencing product development, with brands prioritizing eco-friendly materials and ethical manufacturing practices. Moreover, the rise of direct-to-consumer (DTC) channels and e-commerce platforms has shifted traditional distribution models, creating new opportunities for B2B partnerships.

Regionally, markets like Europe and the Middle East show high demand for premium, performance-oriented shoes, often emphasizing brand heritage and innovation. Conversely, African and South American markets are witnessing rapid growth in affordable, durable models driven by local athletic trends and increasing disposable income. For B2B buyers, staying abreast of these regional preferences, technological advances, and sourcing innovations—such as nearshoring or local manufacturing—can provide competitive advantages in meeting diverse consumer needs.

Furthermore, sourcing strategies are increasingly focused on agility and resilience, with many buyers exploring diversified supplier networks across Asia, Europe, and emerging markets. The adoption of digital sourcing platforms and supply chain analytics is enabling better risk management and inventory optimization, vital for navigating fluctuating demand and geopolitical uncertainties.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a central pillar in the neutral running shoes sector, influencing both product development and supply chain practices. Consumers and regulatory bodies worldwide are demanding greater transparency and accountability, prompting brands to adopt environmentally responsible sourcing. For B2B buyers, this means prioritizing partnerships with manufacturers that hold credible green certifications—such as Global Organic Textile Standard (GOTS), Fair Trade, or LEED—and utilize sustainable materials.

Eco-friendly materials like recycled polyester, natural rubber, and plant-based foams are gaining prominence as substitutes for conventional synthetics. Brands are also exploring innovative solutions such as biodegradable midsoles and water-based adhesives to reduce environmental impact. Ethical sourcing extends beyond materials to encompass fair labor practices, safe working conditions, and fair wages, all of which are increasingly scrutinized by global consumers and stakeholders.

For international buyers, aligning with suppliers committed to sustainability not only mitigates reputational risks but also unlocks market access in regions with stringent environmental regulations, such as Europe. Implementing supplier audits, requiring transparent supply chain documentation, and fostering long-term partnerships with certified factories are practical steps to ensure compliance. Additionally, investing in traceability technologies like blockchain can enhance transparency, allowing buyers to verify the origin and ethical standards of their products.

Sustainable practices are also linked to cost efficiencies in the long term, as eco-friendly materials and processes often reduce waste and energy consumption. By embedding sustainability into sourcing strategies, B2B buyers can differentiate their offerings, appeal to environmentally conscious consumers, and future-proof their supply chains amid evolving global standards.

Brief Evolution/History

While the neutral running shoes market is relatively modern compared to traditional athletic footwear, its evolution reflects broader trends in sportswear innovation and consumer preferences. Initially driven by performance needs, the sector has shifted towards comfort, minimalism, and versatility, appealing to a broader demographic beyond serious athletes.

The advent of lightweight, cushioned midsoles and breathable uppers marked a significant turning point, enabling neutral shoes to cater to everyday runners and casual wearers alike. Over the past decade, technological advancements—such as the integration of sustainability features—have further shaped the landscape. For B2B buyers, understanding this evolution helps in sourcing products that align with current consumer expectations and technological standards, ensuring relevance and competitiveness in diverse markets.

This historical context underscores the importance of innovation, ethical practices, and regional adaptation in shaping the future of neutral running shoes. As consumer awareness grows, brands that emphasize sustainability and technological differentiation will likely lead the market, offering strategic advantages for proactive B2B sourcing and distribution.

Frequently Asked Questions (FAQs) for B2B Buyers of neutral running shoes

1. How can I verify the credibility and reliability of a neutral running shoe supplier?

To ensure supplier credibility, conduct thorough due diligence by requesting verifiable business licenses, certifications, and references from existing clients. Check for industry-specific quality standards such as ISO certifications or compliance with international footwear safety norms. Review their manufacturing facilities via virtual tours or third-party audits. Engage in direct communication to assess responsiveness and transparency. Additionally, analyze their track record on platforms like Alibaba or Global Sources, and seek samples to evaluate product quality before committing to larger orders. Reliable suppliers prioritize transparency, quality, and consistent communication.

2. What customization options are typically available for neutral running shoes in B2B sourcing?

Suppliers often offer customization in design, branding, and specifications. Common options include logo placement, color schemes, and packaging. Material adjustments such as sole firmness, upper fabric type, or additional cushioning can also be negotiated. For larger orders, some manufacturers provide bespoke molds or design modifications to meet regional preferences or brand identity. Clearly communicate your target market needs, and request samples of customized products to ensure alignment with your specifications. Establish clear agreements on minimum quantities for customization, lead times, and costs to avoid misunderstandings.

3. What are typical minimum order quantities (MOQs), lead times, and payment terms for international B2B purchases of neutral running shoes?

MOQs vary widely depending on the supplier but generally range from 500 to 5,000 pairs for new or OEM products. Lead times typically span 4 to 12 weeks, depending on order size, customization complexity, and production capacity. Payment terms are often negotiated; common options include 30% upfront with the balance prior to shipment, or letters of credit for larger transactions. Establish clear contractual terms covering payment deadlines, penalties for delays, and cancellation policies. Building strong relationships and negotiating flexible terms can improve supply chain stability, especially for smaller or regional buyers.

4. What quality assurance (QA) standards and certifications should I look for in neutral running shoes?

Look for suppliers with internationally recognized certifications such as ISO 9001 (quality management), OEKO-TEX (safe textiles), and sustainability certifications like BSCI or Fair Trade. These demonstrate adherence to strict manufacturing and environmental standards. Request detailed QA processes, including in-line inspections, pre-shipment audits, and third-party testing reports for durability, slip resistance, and material safety. Additionally, ensure the supplier can provide product testing certificates compliant with your target markets’ regulations, such as REACH in Europe or local safety standards in Africa and South America.

5. How do I manage logistics and shipping when sourcing neutral running shoes internationally?

Coordinate with suppliers to select reliable freight options—air freight for urgent, smaller shipments, or sea freight for bulk orders to optimize costs. Clarify Incoterms (e.g., FOB, CIF) early to define responsibilities for shipping, insurance, and customs clearance. Work with experienced freight forwarders familiar with your region’s import regulations, duty tariffs, and documentation requirements. Consider warehousing solutions near your target markets to reduce transit times. Regular communication with logistics providers ensures timely updates, and comprehensive insurance coverage protects against loss or damage during transit.

6. What common disputes might arise in international B2B transactions, and how can I prevent or resolve them?

Disputes often relate to product quality, delivery delays, payment issues, or contract ambiguities. To prevent these, establish clear contracts detailing specifications, inspection procedures, lead times, and payment terms. Use third-party inspections before shipment to verify quality. Maintain open communication channels and document all agreements. In case of disputes, consider arbitration clauses in contracts that specify neutral arbitration bodies familiar with international trade laws. Building trust through transparent communication and detailed contractual terms minimizes risks, while timely intervention can resolve disagreements efficiently.

7. How can I ensure compliance with local import regulations and standards in my target markets?

Research specific import requirements, safety standards, and labeling regulations for each country—such as CE marking in Europe, SABS certification in South Africa, or local customs duties in Argentina. Collaborate with local customs brokers and legal advisors to navigate complex procedures. Ensure your supplier provides all necessary documentation, including test reports, certificates of origin, and compliance declarations. Staying informed about evolving regulations and participating in industry trade associations can further streamline compliance, reducing the risk of shipment delays or rejections.

8. What strategies can I implement to build long-term relationships with reliable suppliers?

Focus on consistent communication, prompt payments, and constructive feedback to foster trust. Start with smaller, manageable orders to evaluate performance before scaling up. Offer transparent forecasts and collaborate on product development or customization to align offerings with market needs. Recognize supplier efforts and establish mutually beneficial terms, including flexible payment options or shared marketing initiatives. Regular audits and site visits, where feasible, reinforce commitment and ensure ongoing quality standards. Building a partnership based on reliability, transparency, and mutual growth creates a sustainable supply chain for neutral running shoes.

Strategic Sourcing Conclusion and Outlook for neutral running shoes

Strategic Sourcing Outlook for Neutral Running Shoes

Effective strategic sourcing is crucial for international buyers seeking to capitalize on the growing demand for neutral running shoes across diverse markets such as Africa, South America, the Middle East, and Europe. By establishing strong relationships with reputable manufacturers and leveraging global sourcing networks, buyers can secure high-quality products at competitive prices while maintaining supply chain resilience.

Key actions include conducting thorough supplier evaluations, prioritizing manufacturers with sustainable practices, and exploring emerging sourcing regions to diversify risk. Additionally, aligning sourcing strategies with market-specific consumer preferences—such as comfort, durability, and eco-friendliness—can create a competitive advantage.

Looking ahead, the neutral running shoe segment offers significant growth potential driven by increasing health awareness and athleisure trends worldwide. International buyers should proactively adapt their sourcing approaches, focusing on innovation, quality assurance, and sustainability. Embracing these strategies will position buyers to meet evolving market demands effectively, foster long-term partnerships, and achieve sustained success in the dynamic landscape of athletic footwear.

Illustrative Image (Source: Google Search)