Your Ultimate Guide to Sourcing Timberland Boat Shoes

Guide to Timberland Boat Shoes

- Introduction: Navigating the Global Market for timberland boat shoes

- Understanding timberland boat shoes Types and Variations

- Key Industrial Applications of timberland boat shoes

- Strategic Material Selection Guide for timberland boat shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for timberland boat shoes

- Comprehensive Cost and Pricing Analysis for timberland boat shoes Sourcing

- Spotlight on Potential timberland boat shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for timberland boat shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the timberland boat shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of timberland boat shoes

- Strategic Sourcing Conclusion and Outlook for timberland boat shoes

Introduction: Navigating the Global Market for timberland boat shoes

In the competitive landscape of international footwear sourcing, Timberland boat shoes have emerged as a premium product with significant market demand across diverse regions. For B2B buyers in Africa, South America, the Middle East, and Europe—such as Nigeria and Egypt—understanding the nuances of this niche is crucial to securing quality products at optimal costs. These shoes, renowned for their durability, style, and maritime heritage, serve a broad spectrum of consumers from coastal communities to fashion-conscious markets, making them a strategic addition to global footwear portfolios.

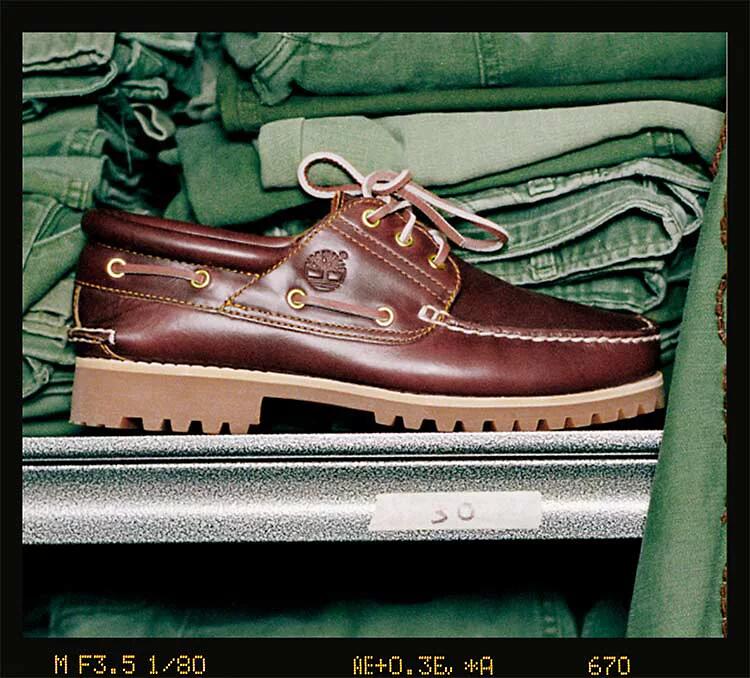

Illustrative Image (Source: Google Search)

This comprehensive guide is designed to equip international B2B buyers with critical insights into every facet of the Timberland boat shoes supply chain. It covers key topics including product varieties, materials used, manufacturing and quality control standards, sourcing options from global suppliers, and cost considerations. Additionally, it addresses market trends, regional import regulations, and common FAQs to streamline decision-making processes.

By leveraging this guide, buyers will gain the knowledge necessary to identify reliable suppliers, negotiate favorable terms, and navigate logistical challenges effectively. Whether sourcing for retail chains, distributors, or private labels, this resource aims to empower you with actionable intelligence—helping you make informed, strategic sourcing decisions that enhance your competitive edge in the global marketplace for timberland boat shoes.

Understanding timberland boat shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Leather Boat Shoes | Premium full-grain leather, non-marking rubber sole, traditional moc-toe design | Retail, wholesale distribution, luxury brands | Pros: Timeless appeal, high durability; Cons: Higher initial cost, limited color options |

| Synthetic Marine Shoes | Water-resistant synthetic uppers, lightweight, quick-drying soles | Mass retail, outdoor gear suppliers, budget markets | Pros: Cost-effective, versatile; Cons: Less breathable, lower luxury perception |

| Eco-Friendly/Recycled Models | Made from sustainable materials, biodegradable components | Eco-conscious brands, specialty boutiques | Pros: Aligns with sustainability trends, differentiates product line; Cons: Limited supply options, higher procurement complexity |

| Fashion-Forward Variants | Trend-driven designs, varied colors, decorative elements | Fashion retailers, boutique importers | Pros: Meets current fashion trends, attracts niche markets; Cons: Shorter product lifecycle, higher turnover risk |

| Heavy-Duty Commercial Types | Reinforced stitching, rugged soles, reinforced toe caps | Workwear suppliers, industrial distributors | Pros: High durability, suitable for demanding environments; Cons: Heavier, less fashionable |

Classic Leather Boat Shoes

This traditional variation features high-quality full-grain leather with a moccasin-style construction and non-marking rubber soles. They are highly durable and offer a classic aesthetic that appeals to premium retailers and luxury brands worldwide. For B2B buyers, sourcing authentic leather models requires attention to quality standards and supplier certifications, especially when importing to regions like Nigeria or Egypt. Pricing is generally higher, but the longevity and brand reputation can justify premium positioning.

Synthetic Marine Shoes

Designed with water-resistant synthetic uppers and lightweight, quick-drying soles, these shoes are ideal for mass-market retail and outdoor gear suppliers. They are cost-effective and easier to produce at scale, making them attractive for buyers seeking affordable options for large distribution channels in regions such as South America or the Middle East. However, buyers should consider trade-offs in breathability and perceived quality, which may affect branding strategies targeting luxury segments.

Eco-Friendly/Recycled Models

These boat shoes are made from sustainable or recycled materials, aligning with global environmental trends. They appeal to eco-conscious brands and specialty boutiques aiming to differentiate their offerings. B2B buyers should evaluate suppliers’ certifications and material sourcing transparency. While these models often command premium prices, they can open access to niche markets and enhance brand reputation, especially in regions with growing environmental awareness.

Fashion-Forward Variants

This category includes trendy designs with vibrant colors, decorative laces, or embellishments, catering to fashion retailers and boutique importers. They are suitable for markets with high fashion turnover, such as Europe or urban centers in Africa. Buyers should consider the shorter lifecycle of fashion-focused shoes and ensure supply chain agility to meet seasonal demands. These variants can command higher margins but require careful inventory management.

Heavy-Duty Commercial Types

Built with reinforced stitching, rugged soles, and reinforced toe caps, these shoes are tailored for industrial, maritime, or demanding work environments. They are favored by industrial distributors and workwear suppliers in regions with active maritime or construction industries. While offering superior durability, these models tend to be heavier and less stylish, which should be balanced against customer requirements for safety and longevity. B2B buyers should verify certifications for safety standards and material compliance in their target markets.

Key Industrial Applications of timberland boat shoes

| Industry/Sector | Specific Application of timberland boat shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine & Maritime | Crew footwear for ship maintenance and port operations | Enhanced safety, slip resistance, and durability in wet environments | Material quality, slip-resistant sole design, compliance with maritime safety standards |

| Construction & Infrastructure | Site workers operating in coastal or water-adjacent projects | Waterproof features reduce foot fatigue and protect against moisture | Water resistance, comfort for prolonged wear, availability in bulk quantities |

| Hospitality & Tourism | Staff uniforms for waterfront resorts and cruise lines | Professional appearance combined with slip-resistant comfort | Aesthetic consistency, comfort, durability, and ease of cleaning |

| Outdoor & Recreation | Boating, sailing, and water sports activities | Grip and comfort in wet conditions, reducing fall risk | Non-slip sole quality, durability, and suitability for active use |

| Industrial Supply & Logistics | Uniform footwear for workers in ports, warehouses, and logistics hubs | Safety and durability in demanding environments | Heavy-duty construction, slip resistance, and ease of maintenance |

Marine & Maritime

Timberland boat shoes are widely used by crew members and maintenance staff aboard ships and in port facilities. Their slip-resistant soles and water-resistant materials address the critical safety requirements of wet, slippery decks and docks. For international buyers from regions like Nigeria or Egypt, sourcing shoes that meet maritime safety standards (e.g., ISO certifications) ensures compliance and reduces liability. Durable, high-quality materials help extend product lifespan, minimizing replacement costs and ensuring operational continuity in demanding environments.

Construction & Infrastructure

In coastal construction projects, timberland boat shoes serve as reliable footwear for workers exposed to water, mud, and uneven terrains. Their waterproof features prevent foot fatigue and protect workers from moisture-related issues, which is especially important in humid climates common in South America and Africa. For B2B buyers, sourcing shoes with reinforced soles and high durability ensures safety and longevity, reducing overall operational costs. Bulk procurement from trusted suppliers guarantees consistent quality and availability for large-scale projects.

Hospitality & Tourism

Waterfront resorts, cruise lines, and related hospitality sectors rely on timberland boat shoes for their staff uniforms. These shoes provide a professional yet practical look, combining aesthetic appeal with slip-resistant soles for staff working on wet surfaces. For buyers in the Middle East or Europe, sourcing shoes that are easy to clean and maintain is essential to uphold hygiene standards and guest experience. Bulk orders from reliable suppliers ensure uniformity, cost efficiency, and consistent quality across multiple properties.

Illustrative Image (Source: Google Search)

Outdoor & Recreation

Water sports operators, sailing clubs, and recreational boaters utilize timberland boat shoes for their grip and comfort in wet conditions. These shoes help reduce the risk of slips and falls during active water-based activities. International buyers should focus on sourcing shoes with superior non-slip soles, high durability, and comfort to meet safety standards and customer expectations. Ensuring product availability in various sizes and styles supports diverse recreational needs and enhances customer satisfaction.

Industrial Supply & Logistics

Workers in ports, warehouses, and logistics hubs often operate in environments with water exposure, oil spills, or slippery surfaces. Timberland boat shoes provide a robust solution with slip-resistant soles and durable construction, enhancing worker safety and reducing accident-related costs. For B2B buyers from regions like Egypt or South America, sourcing shoes that meet industrial safety standards (such as ANSI or EN standards) and can withstand tough conditions is vital. Reliable supply chains and bulk purchasing options help maintain operational efficiency and workforce safety.

Strategic Material Selection Guide for timberland boat shoes

Analysis of Common Materials for Timberland Boat Shoes

Leather

Leather remains the most traditional and preferred material for timberland boat shoes due to its excellent durability, breathability, and aesthetic appeal. Full-grain leather offers superior resistance to wear and tear, making it suitable for frequent use in maritime environments. It also provides natural water resistance when properly treated, which is critical for boat footwear.

Pros:

– High durability and longevity

– Natural breathability and comfort

– Good water resistance when treated

– Aesthetic versatility

Cons:

– Higher cost compared to synthetic alternatives

– Requires maintenance (conditioning, waterproofing)

– Manufacturing complexity, especially for premium grades

– Sensitive to extreme humidity and temperature variations, which can affect leather quality over time

Impact on Application:

Leather performs well in saltwater and freshwater environments if properly maintained. However, untreated or poorly maintained leather can degrade faster in high humidity or salty conditions, common in regions like Nigeria or Egypt.

International Considerations:

Buyers should ensure leather complies with regional standards such as ASTM D2099 for leather durability or local environmental regulations. For markets with strict import standards, sourcing vegetable-tanned or chrome-free leather can enhance compliance and appeal to eco-conscious consumers.

Synthetic Materials (e.g., PU, PVC)

Synthetic materials like polyurethane (PU) or polyvinyl chloride (PVC) are increasingly used in boat shoes due to their cost-effectiveness and ease of manufacturing. These materials can be engineered to mimic leather while offering enhanced resistance to water, chemicals, and UV exposure.

Pros:

– Lower cost and consistent quality

– Excellent water and chemical resistance

– Less maintenance required

– Easier to produce in various colors and finishes

Cons:

– Generally less breathable, potentially reducing comfort

– Lower durability over long-term use compared to leather

– Environmental concerns related to production and disposal

– Possible degradation under prolonged UV exposure

Impact on Application:

Synthetic materials excel in salt-heavy environments, such as Middle Eastern or North African climates, where chemical resistance is advantageous. They are also suitable for mass production, making them ideal for large-scale exports.

International Considerations:

Buyers should verify that synthetic materials meet regional standards such as REACH (European Union) or other chemical safety regulations. Additionally, eco-labels or certifications can enhance market acceptance, especially in Europe.

Rubber and EVA (Ethylene Vinyl Acetate)

Rubber and EVA are primarily used for outsoles and midsoles in timberland boat shoes. Rubber provides excellent grip, slip resistance, and durability, while EVA offers lightweight cushioning and shock absorption.

Pros:

– Superior slip resistance and traction

– High durability and wear resistance

– Flexibility and lightweight properties (EVA)

– Good chemical and saltwater resistance

Cons:

– Rubber can be heavy and less flexible if not formulated properly

– EVA may degrade under prolonged UV exposure unless stabilized

– Cost varies depending on grade and formulation

– Manufacturing complexity for specialized formulations

Impact on Application:

Rubber and EVA are well-suited for maritime environments, especially in regions with rough terrains or slippery surfaces. They are also compatible with various outsole designs to meet regional safety standards.

International Considerations:

Buyers should ensure that rubber and EVA meet standards such as ASTM D2240 (hardness testing) or ISO specifications. For markets with strict environmental regulations, sourcing eco-friendly or recyclable formulations is advisable.

Summary Table

| Material | Typical Use Case for timberland boat shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Upper material, especially for premium, durable boat shoes | High durability, aesthetic appeal, breathability | Higher cost, maintenance needs, sensitive to humidity | High |

| Synthetic (PU, PVC) | Upper material for cost-effective, water-resistant designs | Cost-effective, water/chemical resistance | Less breathable, environmental concerns | Low to Med |

| Rubber/EVA | Outsoles and midsoles for grip, cushioning | Slip resistance, durability, lightweight | EVA UV degradation, rubber weight | Med |

This comprehensive analysis helps international B2B buyers understand the material choices that best suit regional conditions, compliance standards, and end-user preferences. Selecting the appropriate materials ensures product longevity, compliance, and market competitiveness across diverse regions such as Africa, South America, the Middle East, and Europe.

In-depth Look: Manufacturing Processes and Quality Assurance for timberland boat shoes

Manufacturing Processes of Timberland Boat Shoes

The production of Timberland boat shoes involves a series of meticulously coordinated stages designed to ensure durability, comfort, and aesthetic appeal. Understanding these processes enables B2B buyers to evaluate supplier capabilities and maintain quality standards across international markets.

1. Material Preparation

The process begins with sourcing high-quality raw materials, primarily premium leathers, textiles, and rubber outsoles. Leather selection is critical, often involving vegetable-tanned or chrome-tanned leathers that meet sustainability and durability standards. Suppliers typically perform initial inspections for defects and consistency, adhering to ISO 9001 standards for quality management. Additionally, eco-certifications like OEKO-TEX may be relevant for markets emphasizing sustainability.

2. Cutting and Forming

Leather and textile components are cut using computer-controlled cutting machines to ensure precision and minimize waste. Modern manufacturers often employ CAD/CAM systems for pattern accuracy, which is vital for maintaining consistency across batches. The cut pieces are then conditioned and prepped for assembly, with attention to grain orientation and material stretch properties to optimize shoe fit and longevity.

3. Assembly and Stitching

This stage involves stitching the upper components, attaching eyelets, and securing the lining. Industrial sewing machines, often with reinforced stitches, are used to meet strength requirements. Adhesives are applied strategically to bond components, especially around the sole attachment area. For waterproof features, seam sealing techniques may be employed, requiring specific adhesives and stitching patterns to prevent water ingress.

4. Lasting and Shaping

The assembled uppers are stretched over lasts—molds that define the shoe’s shape—and secured for shaping. This step ensures uniformity in size and form. Heat-setting or mechanical pressing may be used to fix the shape, with some manufacturers incorporating eco-friendly materials in this stage to meet regional sustainability standards.

5. Finishing and Quality Checks

Final touches include polishing, branding, adding insoles, and attaching outsoles. Outsoles are typically vulcanized or glued onto the upper, depending on design specifications. The shoes undergo detailed inspection for surface defects, stitching integrity, and fit. The application of branding elements like logos is verified for consistency.

Quality Assurance (QA) and Control for Timberland Boat Shoes

Robust quality assurance protocols are essential for B2B buyers to mitigate risks associated with international sourcing. Manufacturers often align with international standards and employ multiple inspection checkpoints to ensure product consistency and safety.

1. International Standards Compliance

Most reputable manufacturers adhere to ISO 9001 certification, which emphasizes quality management systems. ISO 9001 ensures that suppliers maintain consistent quality, document processes, and continuously improve. For footwear, additional certifications like CE marking (European conformity) are crucial for markets in Europe, ensuring compliance with safety, health, and environmental directives. In North America, adherence to ASTM standards for footwear safety may also be relevant.

2. Industry-Specific Certifications

Depending on target markets, manufacturers might also comply with standards such as API (American Petroleum Institute) for specific testing or environmental standards like REACH in Europe for chemical safety. Certifications related to sustainability, such as Leather Working Group (LWG) certification, demonstrate environmentally responsible manufacturing.

3. Quality Control Checkpoints

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival for defects, consistency, and compliance with specifications. Leather is checked for grain integrity, color uniformity, and absence of defects like scars or cracks.

– In-Process Quality Control (IPQC): During manufacturing, inspections are conducted at key stages—cutting, stitching, assembly—to detect defects early. Visual inspections, dimensional checks, and stitching strength tests are standard procedures.

– Final Quality Control (FQC): Before packaging, shoes undergo comprehensive checks including visual inspection, fit testing, sole adhesion tests, and durability assessments. Random sampling ensures batch consistency.

4. Testing Methods

Manufacturers employ various testing methods to validate product performance:

– Tensile and stitch pull tests for seam strength.

– Flex tests to assess sole durability.

– Waterproofing tests involving immersion or spray methods.

– Colorfastness and abrasion resistance testing to ensure longevity.

5. Verification for B2B Buyers

International buyers should request detailed QC reports, certifications, and third-party inspection reports. Conducting audits—either remotely or on-site—can verify adherence to quality standards. Engaging third-party inspection agencies (e.g., SGS, Bureau Veritas) provides unbiased assessments, especially critical for buyers from regions with less manufacturing oversight such as Nigeria, Egypt, or other emerging markets.

Nuances and Best Practices for International B2B Engagement

Understanding Local Regulations and Standards:

Buyers from Africa, South America, the Middle East, and Europe should verify that suppliers comply with regional standards like CE (Europe), ASTM (North America), or local certifications required for import/export. Some countries enforce strict chemical regulations, demanding detailed chemical composition reports and safety certifications.

Supplier Audits and Quality Documentation:

Establishing a routine audit schedule helps ensure ongoing compliance. Request comprehensive quality manuals, inspection records, and test reports. Many buyers opt for third-party audits, especially when engaging with new suppliers or in regions with variable manufacturing oversight.

Building Long-term Quality Partnerships:

Collaborating with suppliers committed to continuous improvement—evidenced by ISO 9001 recertifications, sustainability certifications, and transparent QC processes—can reduce risks. Incorporating quality clauses into purchase agreements and conducting periodic reviews ensures standards are maintained.

Addressing Supply Chain Risks:

In regions prone to political or logistical disruptions, diversify sourcing options and specify contingency plans within contracts. Verify that suppliers have robust QC systems capable of handling scale and complexity.

Final Insights for B2B Buyers

A thorough understanding of manufacturing and QC processes enhances the ability to select reliable suppliers of Timberland boat shoes. Emphasizing certifications, inspection protocols, and transparent documentation minimizes risks and ensures product quality aligns with international standards. For buyers from emerging markets like Nigeria, Egypt, or South America, leveraging third-party audits and fostering long-term supplier relationships can significantly improve quality outcomes and supply chain resilience.

Comprehensive Cost and Pricing Analysis for timberland boat shoes Sourcing

Cost Structure Breakdown for Timberland Boat Shoes

Understanding the cost components involved in sourcing timberland boat shoes is essential for international B2B buyers aiming to optimize procurement strategies. The primary cost drivers include:

-

Materials: High-quality leather, rubber soles, and durable laces are standard. Premium materials or eco-certified inputs can significantly influence costs, often ranging from 30% to 50% of the FOB (Free on Board) price.

-

Labor: Manufacturing labor costs vary greatly by region. For example, factories in Southeast Asia or North Africa may offer lower wages, reducing overall costs, whereas European or Middle Eastern producers might have higher labor expenses, impacting the final price.

-

Manufacturing Overhead: This includes factory utilities, machinery maintenance, and equipment amortization. Overhead costs are typically embedded within the FOB price but can fluctuate based on factory scale and efficiency.

-

Tooling & Setup: Initial tooling for molds and patterns constitutes a one-time cost that is amortized over production runs. Larger orders justify this expense, lowering per-unit costs.

-

Quality Control (QC): Rigorous inspection, certifications (e.g., ISO, REACH compliance), and testing add to production costs but are crucial for meeting international standards.

-

Logistics & Shipping: Freight costs depend on shipment volume, destination port, and mode (sea, air). Buyers from Nigeria or Egypt, for instance, should consider the impact of port congestion and inland transportation.

-

Margins: Suppliers typically add a markup (10-30%) to cover their operational costs and profit margin, influencing the final purchase price.

Key Factors Influencing Pricing

Several factors can cause price variations and should be carefully negotiated:

-

Order Volume & MOQ: Larger orders reduce per-unit costs due to economies of scale. Many suppliers offer discounts for high-volume commitments, which is advantageous for bulk buyers.

-

Specifications & Customization: Custom features such as unique branding, specific colorways, or special materials increase costs. Clear specifications upfront can prevent unexpected expenses.

-

Material Choices: Premium or eco-friendly materials often come with higher price tags but can add value and appeal in certain markets.

-

Quality Certifications: Meeting international standards (e.g., ISO, environmental certifications) can elevate costs but enhance marketability and compliance.

-

Supplier Factors: The reputation, production capacity, and reliability of the supplier influence pricing. Established manufacturers may charge higher but offer better quality assurance.

-

Incoterms & Delivery Terms: FOB prices are common, but terms like CIF (Cost, Insurance, Freight) include shipping costs, impacting the final price paid by the buyer. Buyers should evaluate these carefully to understand total landed costs.

Strategic Tips for International B2B Buyers

-

Negotiate Effectively: Leverage volume commitments to negotiate better prices or favorable payment terms. Building long-term relationships can yield discounts and priority access.

-

Focus on Total Cost of Ownership (TCO): Beyond FOB prices, consider shipping, customs duties, taxes, storage, and potential tariffs. For example, import duties in Nigeria or Egypt can significantly affect overall costs.

-

Understand Pricing Nuances: Prices can fluctuate based on raw material costs, currency exchange rates, and geopolitical factors. Regular market monitoring helps anticipate price changes.

-

Optimize Logistics: Consolidate shipments where possible to reduce freight costs. Explore different shipping modes and routes to find the most cost-effective options.

-

Certify and Standardize: Ensuring products meet regional standards can prevent costly rejections or modifications later, saving time and money.

Price Range and Disclaimer

Indicative FOB prices for timberland boat shoes generally range from $10 to $25 per pair, depending on order size, specifications, and supplier location. Larger, customized, or premium-quality orders tend toward the higher end of this spectrum. However, prices are subject to fluctuations due to raw material costs, currency exchange rates, and global supply chain dynamics.

Note: These figures are approximate and should be used as a guide. Engaging directly with suppliers for detailed quotations tailored to specific requirements is essential for accurate budgeting and planning.

Spotlight on Potential timberland boat shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for timberland boat shoes.)*

Essential Technical Properties and Trade Terminology for timberland boat shoes

Critical Technical Properties for Timberland Boat Shoes

1. Material Quality and Grade

The primary material used in timberland boat shoes is typically leather, rubber, or a combination of both. The material grade (e.g., full-grain, top-grain, or bonded leather) directly impacts durability, appearance, and comfort. High-grade materials are preferred for premium markets, ensuring longevity and a premium finish. For B2B buyers, specifying the material grade helps align product quality with market expectations and customer demands.

2. Sole Composition and Traction Properties

The outsole material—often rubber—must provide adequate slip resistance, especially for maritime or outdoor use. The tread pattern and traction coefficient are critical technical specs that determine safety and performance. Suppliers should provide detailed traction ratings, especially for clients in regions with varied climates or terrains, such as Africa or South America, where slip hazards are prevalent.

3. Dimensional Tolerances

Consistent sizing is vital for customer satisfaction and brand reputation. Dimensional tolerances specify acceptable deviations in length, width, and height during manufacturing. Precise tolerances ensure the shoes fit correctly, reducing returns and complaints. For international trade, understanding and verifying tolerances can prevent logistical issues related to sizing discrepancies.

4. Water Resistance and Breathability

Many timberland boat shoes are marketed as water-resistant or waterproof. Technical specifications should include water resistance ratings (e.g., IPX standards or hydrostatic head measurements) and breathability levels. These properties are especially relevant for buyers in humid or rainy regions, impacting product performance and customer satisfaction.

5. Manufacturing Certifications and Compliance

Certifications such as ISO standards, environmental sustainability labels, or fair labor practices (e.g., Fair Trade) add value and credibility. They assure buyers that the products meet specific quality, safety, and ethical benchmarks, which can be a decisive factor in procurement decisions across diverse markets.

Essential Industry and Trade Terms

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce timberland boat shoes based on the buyer’s specifications or branding. Understanding OEM relationships helps buyers negotiate customization options, branding rights, and production timelines, crucial for market differentiation.

2. MOQ (Minimum Order Quantity)

The smallest number of units a manufacturer will accept per order. MOQs impact inventory planning, especially for buyers in emerging markets with fluctuating demand. Negotiating favorable MOQs can enable smaller businesses to access quality products without excessive upfront investment.

3. RFQ (Request for Quotation)

A formal process where buyers solicit price and lead-time estimates from multiple suppliers. Efficient RFQ procedures streamline procurement, allowing buyers from Africa, South America, or the Middle East to compare offers, assess supplier responsiveness, and negotiate better terms.

4. Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce (ICC) define responsibilities for shipping, insurance, and tariffs. Familiarity with Incoterms (e.g., FOB, CIF, DDP) helps buyers clarify cost responsibilities, reduce misunderstandings, and optimize logistics strategies across borders.

5. Lead Time

The duration from order placement to product delivery. Lead times influence inventory management and sales planning, especially in regions with logistical challenges. Clear understanding of supplier lead times allows buyers to align procurement schedules with seasonal demand cycles.

6. Quality Assurance (QA) & Inspection Terms

Refers to procedures ensuring products meet specified standards before shipment. Knowledge of QA processes, such as third-party inspections or factory audits, helps mitigate risks of receiving substandard goods, crucial for maintaining brand reputation in diverse markets.

By understanding these technical properties and trade terms, international B2B buyers can make more informed decisions, negotiate effectively, and ensure the timberland boat shoes they procure meet quality standards and market expectations across Africa, South America, the Middle East, and Europe.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the timberland boat shoes Sector

Market Overview & Key Trends

The global market for timberland boat shoes is experiencing a dynamic evolution driven by shifting consumer preferences, technological advancements, and supply chain innovations. Historically associated with casual and outdoor lifestyles, these shoes are now increasingly recognized for their durability, eco-friendly materials, and versatile design, appealing to a broad spectrum of international markets. For B2B buyers from Africa, South America, the Middle East, and Europe—such as Nigeria, Egypt, Brazil, and Spain—understanding these trends is crucial to securing competitive sourcing channels and establishing sustainable supply partnerships.

Emerging sourcing trends include the integration of digital platforms for supplier discovery, real-time inventory management, and quality assurance. Blockchain technology, for example, is gaining traction to enhance transparency and traceability across supply chains, ensuring authenticity and ethical compliance. Additionally, the adoption of lean manufacturing and just-in-time inventory systems allows buyers to reduce lead times and inventory costs, which is especially advantageous in volatile markets.

Market dynamics are also influenced by fluctuating raw material costs, geopolitical considerations, and trade policies. For instance, tariffs on imported leather and synthetic materials can impact pricing, prompting buyers to explore alternative, locally-sourced, or innovative sustainable materials. Environmental regulations in key sourcing regions are tightening, pushing manufacturers toward greener practices, which in turn influences global supply chains.

For international B2B buyers, particularly in emerging markets, establishing direct relationships with manufacturers and leveraging trade fairs or digital marketplaces can mitigate risks and improve negotiating power. Understanding regional preferences, import regulations, and logistics options will further optimize sourcing strategies and ensure resilience amid market fluctuations.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a fundamental criterion for sourcing timberland boat shoes, driven by both consumer demand and regulatory pressures. The environmental footprint of footwear production—particularly the sourcing of leather, synthetic materials, and adhesives—raises concerns about deforestation, water consumption, and chemical pollution. B2B buyers from Africa, South America, the Middle East, and Europe must prioritize suppliers committed to environmentally responsible practices to mitigate risks and align with global standards.

Illustrative Image (Source: Google Search)

Ethical sourcing involves ensuring fair labor practices, transparent supply chains, and adherence to certifications such as Forest Stewardship Council (FSC), Leather Working Group (LWG), and Global Organic Textile Standard (GOTS). These certifications signal compliance with environmental and social standards, providing assurance that materials are sourced sustainably and workers are protected.

Innovative ‘green’ materials are gaining prominence in the timberland boat shoes sector. These include recycled rubber soles, organic cotton linings, and vegetable-tanned leathers, which reduce reliance on environmentally damaging processes. Suppliers investing in eco-friendly manufacturing technologies not only reduce their ecological footprint but also offer B2B buyers a competitive advantage through premium branding and compliance with international sustainability mandates.

Furthermore, traceability systems enable buyers to verify the origin of raw materials, ensuring that supply chains are free from illegal logging or unethical labor practices. Engaging with suppliers committed to continuous improvement in sustainability practices can foster long-term relationships, reduce regulatory risks, and meet the increasing demand from end consumers for ethically produced footwear.

Brief Evolution/History (Optional)

The timberland boat shoes sector has evolved significantly over the past few decades, transitioning from traditional handcrafted footwear to highly mechanized, globally integrated supply chains. Initially rooted in maritime and casual outdoor wear, the design and manufacturing processes have become more sophisticated, incorporating eco-friendly materials and sustainable practices driven by consumer awareness and regulatory pressures.

This evolution reflects broader industry shifts toward sustainability, transparency, and technological integration. For B2B buyers, understanding this history underscores the importance of partnering with suppliers who have adapted to these changes—those who invest in sustainable raw materials, fair labor practices, and innovative manufacturing processes. Such strategic alignments not only ensure compliance but also position buyers to capitalize on market growth driven by environmentally conscious consumers worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of timberland boat shoes

-

How can I verify the credibility and reliability of a timberland boat shoe supplier?

To ensure supplier credibility, conduct thorough due diligence by requesting industry references, reviewing their business licenses, and verifying certifications such as ISO or other quality standards. Request samples to evaluate product quality firsthand. Engage in detailed communication to assess responsiveness and transparency. Additionally, consider visiting supplier facilities if feasible or utilizing third-party inspection services. Platforms like Alibaba’s Verified Suppliers or trade associations can also provide vetted supplier lists. Establish clear communication channels and ask for references from other international buyers, especially from your region, to gauge their reputation in your target market. -

What customization options are typically available, and how do they impact lead times and costs?

Most suppliers offer customization in design, color, branding, and sole materials to meet specific market preferences. Customization can include logo embossing, special stitching, or unique packaging. While customization enhances brand differentiation, it may extend lead times by 2–4 weeks and increase initial costs due to setup fees or minimum order requirements. Communicate your exact specifications early and request detailed quotations. Ensure the supplier can accommodate your desired customizations within your production schedule and budget. Establish clear timelines and review prototypes before mass production to avoid delays and additional costs. -

What are typical minimum order quantities (MOQs), lead times, and payment terms for international B2B purchases?

MOQ requirements for timberland boat shoes generally range from 500 to 2,000 pairs, depending on the supplier and customization level. Lead times vary between 4 to 12 weeks, influenced by order size and complexity. Common payment terms include 30% upfront deposit with the balance paid before shipment or upon receipt of goods, often via wire transfer or letter of credit. Negotiate flexible terms that align with your cash flow and inventory needs. Building a strong relationship can facilitate better terms over time, especially for larger or repeat orders. -

What quality assurance processes and certifications should I look for in suppliers?

Reliable suppliers should adhere to strict QA processes, including pre-production sample approvals, in-line inspections, and final quality checks before shipment. Certifications such as ISO 9001, SGS, or OEKO-TEX demonstrate compliance with international safety and environmental standards. Request recent audit reports and product testing certificates, especially for footwear safety, chemical use, and environmental impact. Insist on transparent QA documentation and consider engaging third-party inspection agencies for on-site audits, particularly when importing in large volumes or for high-end markets. -

How can I manage logistics effectively when importing timberland boat shoes to my country?

Collaborate with experienced freight forwarders familiar with your region’s import regulations to streamline customs clearance and reduce delays. Choose shipping methods based on your urgency and budget—sea freight for large volumes or air freight for quicker delivery. Clarify Incoterms (e.g., FOB, CIF) upfront to delineate responsibilities and costs. Ensure the supplier provides accurate shipping documentation, including commercial invoices, packing lists, and certificates of origin. Consider warehousing options near ports if you require flexible inventory management. Regular communication with logistics partners ensures smooth transit and timely delivery. -

What are common dispute resolution mechanisms when dealing with international suppliers?

Establish clear contractual terms covering quality standards, delivery timelines, payment conditions, and dispute resolution procedures. Favor arbitration clauses under internationally recognized bodies like the International Chamber of Commerce (ICC). This approach provides a neutral forum outside your jurisdiction, reducing bias. Maintain detailed records of all communications, inspections, and transactions to support dispute claims. Engage legal counsel familiar with international trade laws to draft or review contracts. Proactive communication and transparency are vital; addressing issues early can prevent escalation and preserve supplier relationships. -

How do I ensure compliance with import regulations and standards in my country?

Research your country’s import tariffs, customs procedures, and product standards for footwear. Obtain necessary import licenses or permits beforehand. Verify if your target market has specific standards, such as chemical safety or labeling requirements, and confirm that the supplier’s products meet these standards. Collaborate with local customs brokers or trade consultants to facilitate smooth clearance. Maintaining proper documentation, including certificates of origin and compliance certificates, is essential for avoiding delays or penalties. Staying updated on regulatory changes ensures ongoing compliance and market access. -

What steps should I take to build a sustainable and long-term relationship with my supplier?

Start by establishing clear, transparent communication and sharing your long-term vision. Make consistent timely payments and provide constructive feedback to improve product quality and service. Consider visiting supplier facilities or participating in joint development projects to foster trust. Engage in regular performance reviews and discuss future order forecasts to align expectations. Building cultural understanding and respecting local business practices enhances collaboration. Long-term relationships often lead to better pricing, priority in production, and preferential treatment, especially when expanding your market presence in regions like Africa, South America, the Middle East, or Europe.

Strategic Sourcing Conclusion and Outlook for timberland boat shoes

Conclusion and Future Outlook

Effective strategic sourcing for timberland boat shoes offers international B2B buyers a competitive edge through cost optimization, quality assurance, and supply chain resilience. By establishing relationships with reputable manufacturers and leveraging global sourcing networks, buyers from regions such as Africa, South America, the Middle East, and Europe can secure reliable access to premium products while managing risks associated with geopolitical and logistical challenges.

As global markets continue to evolve, embracing innovation in sourcing—such as digital procurement platforms and sustainable supply chain practices—will be crucial. Buyers should prioritize partnerships with suppliers committed to environmental standards and ethical labor practices, aligning procurement strategies with growing consumer and regulatory expectations.

Looking ahead, proactive engagement and diversified sourcing strategies will enable buyers to adapt swiftly to market fluctuations and emerging trends. Now is the opportune moment for international buyers to deepen supplier collaborations, explore new sourcing regions, and leverage technological advancements. By doing so, they can ensure a resilient, sustainable, and competitive supply of timberland boat shoes well into the future.