Your Ultimate Guide to Sourcing Wide Toe Shoes

Guide to Wide Toe Shoes

- Introduction: Navigating the Global Market for wide toe shoes

- Understanding wide toe shoes Types and Variations

- Key Industrial Applications of wide toe shoes

- Strategic Material Selection Guide for wide toe shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for wide toe shoes

- Comprehensive Cost and Pricing Analysis for wide toe shoes Sourcing

- Spotlight on Potential wide toe shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for wide toe shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the wide toe shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of wide toe shoes

- Strategic Sourcing Conclusion and Outlook for wide toe shoes

Introduction: Navigating the Global Market for wide toe shoes

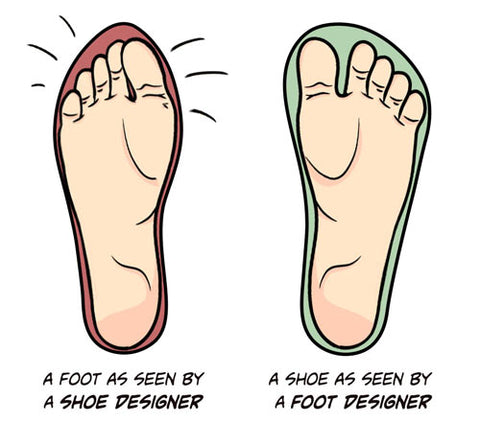

In today’s competitive global footwear market, wide toe shoes have emerged as a vital segment, driven by increasing awareness of foot health, comfort, and inclusive fashion. For international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe—including manufacturing hubs like Vietnam and Germany—understanding the nuances of this niche is essential for strategic sourcing and market expansion. Wide toe shoes not only cater to a growing demographic seeking comfort and orthotic support but also present significant opportunities for brands aiming to differentiate themselves through innovation and quality.

This comprehensive guide is designed to equip you with actionable insights across all critical facets of the wide toe shoe supply chain. It covers various types and styles, from casual to orthopedic footwear, alongside a detailed overview of sustainable and premium materials. We delve into manufacturing practices, quality control standards, and key supplier profiles to ensure you identify reliable partners. Additionally, the guide addresses cost considerations, market demand trends, and regulatory factors influencing global trade.

By providing clarity on sourcing strategies and market dynamics, this guide empowers international B2B buyers to make informed decisions that optimize quality, cost efficiency, and competitive advantage. Whether you are expanding into new markets or strengthening existing supply chains, understanding the intricacies of the wide toe shoe industry will enable you to meet consumer needs more effectively and seize emerging opportunities in a rapidly evolving marketplace.

Understanding wide toe shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Wide Toe Shoes | Traditional design with broad toe box, often leather or synthetic | Footwear retail, OEM manufacturing, bulk orders | Pros: Widely accepted, versatile; Cons: Less innovative, limited styles |

| Orthopedic Wide Toe Shoes | Enhanced support with ergonomic insoles, adjustable fittings | Medical footwear, specialized retail | Pros: High demand in health sector; Cons: Higher production costs |

| Fashion-forward Wide Toe Shoes | Trend-driven designs with bold aesthetics, varied materials | Boutique brands, fashion retailers | Pros: Attractive for niche markets; Cons: Shorter lifecycle, higher price |

| Eco-friendly Wide Toe Shoes | Made from sustainable materials, minimal environmental impact | Green product lines, eco-conscious markets | Pros: Growing demand, positive brand image; Cons: Material sourcing challenges |

| Industrial Wide Toe Shoes | Heavy-duty construction, reinforced toes, slip-resistant soles | Workwear, industrial sectors | Pros: Durable, safety-compliant; Cons: Less comfort for casual wear |

Classic Wide Toe Shoes

This category encompasses the traditional wide toe shoes, typically crafted from leather or synthetic materials with a broad toe box that accommodates wider feet comfortably. They are suitable for a broad consumer base, including those with foot deformities or general comfort needs. For B2B buyers, these shoes are ideal for large-scale retail or OEM manufacturing due to their proven design and broad appeal. Consider sourcing high-quality, durable materials to ensure longevity and customer satisfaction. Price points tend to be moderate, making them accessible for mass production, but innovation may be limited, impacting differentiation in competitive markets.

Orthopedic Wide Toe Shoes

Designed with a focus on foot health, orthopedic wide toe shoes feature ergonomic insoles, arch support, and adjustable fittings. They cater to medical retail outlets, clinics, and health-focused footwear brands. B2B buyers should evaluate the sourcing of certified supportive materials and consider customization options for different foot conditions. While these shoes command higher price points due to specialized features, they are in increasing demand across markets with aging populations or health-conscious consumers. Ensuring consistent quality and compliance with health standards is crucial for success in this segment.

Fashion-forward Wide Toe Shoes

This variation emphasizes contemporary styles with bold aesthetics, incorporating diverse materials like vegan leather, textiles, and innovative embellishments. They appeal to boutique brands and fashion retailers targeting trend-conscious consumers. B2B buyers should focus on sourcing fashionable designs that align with current market trends and seasonal demands. Although these shoes can command premium prices, their shorter lifecycle requires agility in inventory turnover. Partnering with innovative designers and reliable manufacturers can help maintain competitiveness in this dynamic segment.

Eco-friendly Wide Toe Shoes

Made from sustainable, biodegradable, or recycled materials, eco-friendly wide toe shoes target environmentally conscious markets. They are increasingly sought after by green brands and retail chains promoting sustainability. For B2B buyers, sourcing certified eco-materials and ensuring supply chain transparency are key considerations. While they may entail higher raw material costs, they offer branding advantages and access to a growing consumer base. Ensuring product durability and compliance with environmental standards is essential for long-term success.

Industrial Wide Toe Shoes

Built for durability and safety, industrial wide toe shoes feature reinforced toes, slip-resistant soles, and rugged construction. They are primarily used in workwear and industrial sectors, including construction, manufacturing, and logistics. B2B buyers should prioritize sourcing from reputable manufacturers with certifications for safety standards (e.g., ASTM, CE). These shoes tend to have longer lead times and bulk order requirements but provide steady demand due to ongoing industrial needs. Balancing cost, quality, and compliance is vital for maintaining profitability and customer trust.

Key Industrial Applications of wide toe shoes

| Industry/Sector | Specific Application of wide toe shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Heavy Industry | Worker safety footwear for prolonged standing and heavy loads | Enhanced comfort reduces fatigue, lowering injury risk and increasing productivity | Durable materials, slip-resistant soles, compliance with safety standards (ISO, EN) |

| Manufacturing & Assembly | Shoes designed for precision tasks requiring toe space | Improved worker dexterity and comfort, reducing errors and increasing efficiency | Custom sizing options, anti-fatigue features, availability of bulk sourcing |

| Logistics & Warehousing | Footwear for personnel handling heavy goods and equipment | Better stability and reduced foot strain during long shifts | Slip resistance, shock absorption, suitable for diverse work environments |

| Oil & Gas, Mining | Heavy-duty wide toe shoes for rugged environments | Protection against impact, crush hazards, and harsh conditions | High durability, oil-resistant soles, certification for hazardous environments |

| Healthcare & Sanitation | Shoes for staff in sterile or semi-sterile environments | Comfort for long shifts, ease of cleaning, and hygiene compliance | Non-porous materials, antimicrobial properties, compliance with health standards |

Construction & Heavy Industry

Wide toe shoes are essential in construction and heavy industry sectors where workers are exposed to prolonged standing, heavy loads, and potential impact hazards. These shoes provide extra space in the toe box, reducing pressure and discomfort during extended wear. For international buyers from regions like Africa and South America, sourcing footwear that complies with local safety standards (such as ISO or EN certifications) ensures legal compliance and worker safety. Durable, slip-resistant soles are critical to prevent accidents on uneven or slippery surfaces, making these shoes a vital investment in safety and productivity.

Manufacturing & Assembly

In manufacturing environments, especially those involving precision assembly or detailed work, wide toe shoes improve worker comfort and dexterity. The increased space allows for better foot movement, reducing fatigue during long shifts. For European and Asian markets like Germany or Vietnam, sourcing options that offer customization in sizing and anti-fatigue features can significantly enhance worker satisfaction and efficiency. Bulk procurement of high-quality, safety-compliant footwear also offers cost advantages and consistency across large teams.

Logistics & Warehousing

Personnel handling heavy goods benefit from wide toe shoes that provide stability and reduce foot strain during extended periods of walking and lifting. These shoes help mitigate fatigue-related injuries, which are common in high-volume logistics centers across regions such as the Middle East and South America. Sourcing slip-resistant, shock-absorbing footwear suitable for diverse environments—indoor, outdoor, cold or hot conditions—is crucial for maintaining safety standards and operational continuity in international supply chains.

Oil & Gas, Mining

In rugged environments like oil fields and mines, wide toe shoes are designed to withstand extreme conditions. They offer impact protection, crush resistance, and durability against harsh elements such as oil, dirt, and abrasive materials. For buyers in regions like Africa and South America, selecting footwear with high durability, oil-resistant soles, and certifications for hazardous environments (e.g., ATEX, ASTM) ensures safety compliance. These shoes are critical for minimizing injury risks and reducing replacement costs in demanding industries.

Healthcare & Sanitation

Healthcare workers and sanitation staff often spend long hours on their feet, requiring footwear that combines comfort with hygiene. Wide toe shoes accommodate foot swelling and provide additional comfort for staff working in hospitals, clinics, or sanitation facilities across Europe and the Middle East. Sourcing non-porous, antimicrobial shoes that meet health and safety standards ensures ease of cleaning and reduces infection risks. These features are particularly important for maintaining hygiene standards and worker well-being in sensitive environments.

Strategic Material Selection Guide for wide toe shoes

Material Analysis for Wide Toe Shoes

Selecting the appropriate materials for wide toe shoes is critical for ensuring product performance, durability, and compliance with international standards. Different regions have varying requirements, environmental conditions, and consumer preferences, which influence material choice. Here, we analyze four common materials—leather, EVA foam, thermoplastic polyurethane (TPU), and mesh fabric—focusing on their properties, advantages, limitations, and considerations for international B2B buyers from Africa, South America, the Middle East, and Europe.

Leather

Key Properties:

Leather is a natural material renowned for its durability, breathability, and aesthetic appeal. It offers moderate flexibility and conforms well over time, providing a comfortable fit for wide toe shoes. Leather exhibits good resistance to abrasion but varies in water resistance depending on treatment.

Pros & Cons:

Leather’s durability makes it suitable for long-term use, especially in high-wear areas. It also provides a premium look, appealing to consumers in Europe and Middle Eastern markets. However, leather manufacturing involves complex processing, which can increase costs. It is sensitive to water and humidity unless treated, which may be a concern in humid or rainy climates prevalent in parts of Africa and South America.

Impact on Application:

Leather’s breathability and natural properties make it ideal for casual and formal wide toe shoes. It can be treated for water resistance, but this adds cost and complexity. Leather also complies with many international standards, including ASTM and DIN, if sourced responsibly.

International Buyer Considerations:

Buyers should verify leather sourcing (e.g., vegetable-tanned vs. chrome-tanned) to meet environmental standards such as REACH in Europe or local regulations. Leather’s weight and care requirements may influence logistics and after-sales service, especially for markets with limited access to leather maintenance products.

EVA Foam

Key Properties:

EVA (ethylene-vinyl acetate) foam is a lightweight, flexible, and cushioning material. It offers excellent shock absorption and is resistant to cracking and UV degradation. EVA is also resistant to water and many chemicals.

Pros & Cons:

EVA’s low cost and ease of manufacturing make it popular for budget-conscious markets, especially in South America and parts of Africa. Its lightweight nature enhances comfort, but it may lack durability under heavy use or in rugged environments. EVA can degrade with prolonged exposure to high temperatures, which is relevant in Middle Eastern climates.

Impact on Application:

EVA is suitable for casual or fashion-oriented wide toe shoes, especially where cushioning and lightness are prioritized. It is compatible with various adhesives and manufacturing processes, facilitating mass production.

International Buyer Considerations:

Buyers should ensure EVA formulations meet safety and environmental standards, such as REACH or RoHS, especially for export to Europe. Cost-effective sourcing of EVA from Asian suppliers can be advantageous, but quality consistency must be verified to avoid issues like premature cracking.

Thermoplastic Polyurethane (TPU)

Key Properties:

TPU is a versatile thermoplastic elastomer known for its high abrasion resistance, elasticity, and chemical stability. It can be formulated to be rigid or flexible, making it suitable for structural components or overlays in footwear.

Pros & Cons:

TPU offers excellent durability and resistance to oils, greases, and weathering, which is beneficial for outdoor or work-related wide toe shoes. However, TPU is generally more expensive than EVA and may require specialized manufacturing equipment, increasing initial investment costs.

Impact on Application:

TPU is ideal for reinforcing wide toe shoes, especially in demanding environments or for safety footwear. Its resistance to environmental factors aligns well with markets in Africa and the Middle East, where exposure to harsh conditions is common.

International Buyer Considerations:

Buyers should ensure raw material compliance with local standards and verify that manufacturing processes meet ISO or equivalent certifications. TPU’s recyclability can also be a selling point in environmentally conscious markets, but sourcing from suppliers with sustainable practices is essential.

Mesh Fabric

Key Properties:

Mesh fabric is a lightweight, breathable textile material often used in the upper parts of wide toe shoes. It provides excellent ventilation, moisture management, and flexibility.

Pros & Cons:

Mesh is cost-effective and easy to incorporate into various shoe designs, making it popular in sports and casual footwear. Its main limitation is low resistance to abrasion and water, which can be problematic in wet or rugged environments common in parts of Africa and South America.

Impact on Application:

Ideal for summer or athletic wide toe shoes, mesh enhances comfort in hot climates. It can be combined with waterproof linings to improve weather resistance, although this adds complexity and cost.

International Buyer Considerations:

Buyers should consider fabric standards like JIS or OEKO-TEX to ensure safety and environmental compliance. Sourcing durable mesh that withstands regional environmental conditions is vital, especially in markets with high humidity or dust.

Summary Table of Material Selection

| Material | Typical Use Case for wide toe shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Formal, casual, high-end wide toe shoes | Durable, breathable, premium appearance | Sensitive to water, high manufacturing complexity | High |

| EVA Foam | Casual, fashion, lightweight comfort shoes | Low cost, lightweight, shock absorption | Less durable under heavy use, UV degradation in hot climates | Low |

| Thermoplastic Polyurethane (TPU) | Outdoor, safety, reinforced wide toe shoes | Highly durable, weather-resistant | Higher cost, requires specialized manufacturing | High |

| Mesh Fabric | Sports, casual summer shoes, ventilated wide toe shoes | Breathable, lightweight, cost-effective | Low abrasion resistance, water penetration | Low |

This comprehensive analysis equips international B2B buyers with actionable insights to select the most suitable materials based on regional environmental conditions, compliance standards, and market preferences. Proper material selection not only enhances product performance but also ensures compliance and competitiveness across diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for wide toe shoes

Manufacturing Processes for Wide Toe Shoes

The production of wide toe shoes involves a series of meticulously coordinated stages designed to ensure comfort, durability, and compliance with international standards. Understanding these stages allows B2B buyers from diverse regions to better evaluate supplier capabilities and product quality.

Material Preparation and Selection

The manufacturing process begins with selecting suitable raw materials that meet both functional and aesthetic requirements. Common materials include full-grain or corrected-grain leather, synthetic leathers, or specialized textiles, especially for the toe box area to accommodate a wider fit. Suppliers often source materials compliant with international standards like REACH or FDA regulations, especially for markets with strict import controls such as Europe and Germany.

Key considerations for B2B buyers:

– Verify material certifications (e.g., OEKO-TEX, ISO 9001).

– Confirm supplier traceability for raw materials.

– Ensure materials are suitable for the intended climate (e.g., breathable fabrics for warmer regions).

Forming and Cutting

This stage involves pattern making and cutting, typically done via computer-aided design (CAD) systems for precision and repeatability. The wide toe design requires specialized patterns to ensure the extra space does not compromise the shoe’s structural integrity. Cutting methods include die-cutting or laser cutting, which provide clean edges and consistent quality.

Insights for buyers:

– Confirm the supplier’s use of advanced CAD/CAM systems for pattern accuracy.

– Check for consistency in cutting tolerances, especially for large-volume orders.

Assembly and Construction

Assembly involves stitching, lasting, and attaching components such as soles, linings, and insoles. For wide toe shoes, particular attention is paid to the toe box area, which may require reinforced stitching or flexible overlays to maintain shape and support. Techniques like cementing, direct injection, or welt construction are common, depending on the quality tier.

Key points for B2B evaluation:

– Ensure assembly methods align with the target market’s durability expectations.

– Confirm that manufacturers employ skilled craftsmanship, especially for complex constructions like hand-stitched or Goodyear-welted soles.

Finishing

Finishing involves surface treatments, polishing, and quality checks before packaging. The focus here is on aesthetic appeal and functional durability, including waterproofing treatments or anti-slip coatings as needed.

For international buyers:

– Verify that finishing processes adhere to safety and environmental standards relevant to the destination market.

– Inspect sample products for surface uniformity and defect-free finishes.

Quality Assurance Protocols for Wide Toe Shoes

Robust quality assurance (QA) systems are critical to ensure that wide toe shoes meet international standards and specific market requirements. This is especially vital for B2B buyers from regions with stringent regulations like Europe and Germany, or emerging markets such as Africa, South America, and the Middle East.

Illustrative Image (Source: Google Search)

International and Industry Standards

The foundation of effective QA lies in adherence to recognized standards:

– ISO 9001: Ensures the overall quality management system (QMS) is implemented effectively, covering process control, documentation, and continual improvement.

– CE Marking (Europe): Indicates compliance with EU safety, health, and environmental requirements, especially relevant for footwear with specific safety features.

– Other Certifications: API (for certain industrial applications), REACH (chemical safety), and specific regional standards.

B2B buyers should:

– Request documented certifications and audit reports demonstrating compliance.

– Prefer suppliers with ISO 9001 certification, which indicates a mature QMS.

Quality Control Checkpoints

A comprehensive QC process involves multiple inspection stages:

– Incoming Quality Control (IQC): Verifies raw materials against specifications before production begins. Checks include visual inspection, material testing, and certification verification.

– In-Process Quality Control (IPQC): Conducted during manufacturing, focusing on stitching accuracy, dimensional tolerances, and assembly quality. Techniques include sampling, visual checks, and functional testing.

– Final Quality Control (FQC): Performed on finished shoes before shipment. Checks include overall appearance, fit, comfort, durability tests, and compliance with size standards.

Common testing methods include:

– Mechanical tests: Flexibility, abrasion resistance, and tensile strength.

– Environmental tests: Water resistance, UV stability, and temperature endurance.

– Dimensional checks: Toe width, length, and overall fit parameters, crucial for wide toe specifications.

Verification and Supplier Audits

B2B buyers should adopt proactive verification strategies:

– Third-Party Inspections: Engage independent inspection agencies (e.g., SGS, Bureau Veritas) to verify QC reports, conduct random sampling, and perform in-depth audits.

– Factory Audits: Conduct on-site visits or remote audits focusing on manufacturing practices, worker conditions, and adherence to quality protocols.

– Sample Testing: Request pre-production and production samples for independent testing, especially for critical parameters like dimensional accuracy and material safety.

Regional nuances:

– Africa & South America: Emphasize supplier transparency, certification authenticity, and adherence to local import regulations. Many regions have limited local inspection capacity; thus, third-party verification is essential.

– Middle East: Focus on compliance with regional safety standards and anti-counterfeiting measures.

– Europe & Germany: Prioritize suppliers with comprehensive certification portfolios and transparent QA documentation, as regulatory scrutiny is high.

Actionable Insights for B2B Buyers

- Develop a clear supplier qualification process: Include detailed audits, certification checks, and sample testing aligned with target market standards.

- Leverage third-party inspection services: Especially critical for emerging markets where quality control infrastructure may vary.

- Request detailed QC documentation: Certificates, test reports, inspection logs, and compliance declarations should be standard parts of supplier dossiers.

- Establish clear quality agreements: Define defect tolerances, inspection frequency, and corrective action protocols upfront to prevent misunderstandings.

- Monitor ongoing compliance: Maintain a system for periodic re-evaluation, especially if suppliers undergo process changes or new certifications are required.

By understanding and implementing rigorous manufacturing and QC standards, international B2B buyers can significantly reduce risks, ensure product consistency, and foster long-term supplier relationships that meet the specific needs of diverse markets.

Comprehensive Cost and Pricing Analysis for wide toe shoes Sourcing

Understanding the Cost Structure for Wide Toe Shoes

A thorough grasp of the cost components involved in manufacturing wide toe shoes is essential for effective sourcing and pricing strategies. The primary cost drivers include:

-

Materials: The choice of materials significantly impacts cost. Premium leathers, specialized insoles, or eco-friendly fabrics tend to elevate expenses. For wide toe shoes, extra material for the broader toe box can increase material costs by 10-20% compared to standard shoes.

-

Labor: Labor costs vary widely by country. Manufacturers in Vietnam and parts of Southeast Asia typically offer lower wages, contributing to more competitive pricing. European and German suppliers may have higher labor costs but often provide higher craftsmanship standards.

-

Manufacturing Overheads: These include factory expenses, machinery depreciation, and utilities. Efficient factories with high output volumes tend to amortize overheads more effectively, reducing per-unit costs.

-

Tooling and Setup: Initial tooling for molds, especially for custom or wide toe designs, can range from a few hundred to several thousand dollars. This is a fixed cost but becomes more economical with larger order volumes.

-

Quality Control: Stringent QC processes, especially for certifications like ISO or environmental standards, add to costs but are crucial for maintaining product consistency and meeting international standards.

-

Logistics & Shipping: Freight costs depend on shipment volume, mode (air vs. sea), and destination. For Africa and South America, sea freight is generally more economical but slower, whereas Europe and the Middle East may have access to faster, more reliable shipping options.

-

Profit Margin: Typically, suppliers aim for a margin of 10-30%, depending on the competitiveness of the market, order size, and customization levels.

Price Influencers and Variations

Several factors influence the final FOB (Free on Board) or CIF (Cost, Insurance, Freight) prices:

-

Order Volume & MOQ: Larger orders typically attract discounts, sometimes up to 15-20%, due to economies of scale. Many suppliers require MOQs ranging from 500 to 2,000 pairs for standard models, but custom wide toe designs might have higher minimums.

-

Specifications & Customization: Custom widths, unique colorways, or special insoles increase costs. Highly customized shoes may add 10-25% to the base price, especially if specialized tooling or materials are involved.

-

Materials & Certifications: Using eco-friendly or premium materials, or obtaining certifications like REACH or OEKO-TEX, can increase costs but add value for quality-conscious buyers.

-

Supplier Capabilities & Reliability: Established manufacturers with proven quality records often charge premium prices but offer better consistency and compliance, reducing downstream costs related to returns or rework.

-

Incoterms & Delivery Terms: FOB prices are common, but buyers should consider additional costs like insurance, customs duties, and taxes based on Incoterms chosen. Negotiating Incoterms can significantly influence total landed cost.

Strategic Tips for International B2B Buyers

-

Negotiate for Better Terms: Leverage order volume and long-term partnership potential to negotiate discounts or flexible payment terms. Clarify all costs upfront to avoid hidden charges.

-

Focus on Total Cost of Ownership (TCO): Beyond unit price, consider shipping, customs, quality assurance, and potential rework costs. A slightly higher product cost might be offset by lower logistics or QC expenses.

-

Understand Pricing Nuances: Prices in Vietnam or China may be lower, but consider factors like lead times, language barriers, and supplier reliability. European suppliers, while pricier, often provide faster turnaround and higher standards, reducing downstream costs.

-

Factor in Customs & Import Duties: Especially for buyers in Africa, South America, and the Middle East, customs duties can add 10-30% to landed costs. Ensure your sourcing strategy accounts for these expenses.

-

Order in Batches & Build Relationships: Larger, consistent orders can unlock volume discounts and priority production slots. Building long-term relationships with reliable suppliers can lead to better pricing and priority service.

Disclaimer on Price Estimates

Indicative prices for wide toe shoes typically range from $10 to $25 per pair FOB, depending on specifications, order volume, and supplier location. Premium or highly customized shoes may cost upwards of $30. Always request detailed quotations and sample costs tailored to your specific requirements, and factor in logistics, duties, and other landed costs for a comprehensive budget.

By understanding these cost components and pricing influencers, international B2B buyers can develop more strategic, cost-efficient sourcing plans for wide toe shoes, ensuring competitive pricing and quality assurance across diverse markets.

Spotlight on Potential wide toe shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for wide toe shoes.)*

Essential Technical Properties and Trade Terminology for wide toe shoes

Critical Technical Properties for Wide Toe Shoes

1. Material Grade and Composition

The quality and type of materials used—such as leather, synthetic fabrics, or specialized composites—directly influence durability, comfort, and compliance with safety standards. Higher-grade materials typically offer better wear resistance and longer lifespan, which is crucial for bulk procurement and brand reputation. B2B buyers should specify material specifications (e.g., full-grain leather vs. bonded leather) to ensure consistency across batches.

2. Width and Fit Tolerance

Wide toe shoes must adhere to precise width measurements, often classified as EE, 4E, or extra-wide, depending on regional standards. Tolerance levels indicate manufacturing accuracy, ensuring shoes meet specified dimensions within acceptable variance (e.g., ±2mm). Consistent fit is vital for customer satisfaction and reducing returns, especially when scaling production across different markets.

3. Sole and Footbed Specifications

The sole’s material (rubber, EVA, TPU) and design impact slip resistance, cushioning, and overall comfort. Footbed features like arch support and anti-microbial properties are also key, especially for specialized markets such as healthcare or outdoor footwear. Clear specifications help ensure the product performs as intended in diverse environmental conditions.

4. Tolerance for Manufacturing Variations

Tolerance levels refer to permissible deviations in size, shape, and construction parameters during manufacturing. Tight tolerances (e.g., ±1mm) reflect higher quality standards and are essential for international markets where sizing accuracy influences consumer trust and brand reputation.

5. Compliance with Regional Standards

Different markets have specific safety and quality standards—such as CE marking in Europe or ISO certifications globally. Ensuring that wide toe shoes meet these standards is critical for smooth customs clearance and market acceptance, reducing delays and additional costs.

Essential Industry and Trade Terminology

1. OEM (Original Equipment Manufacturer)

An OEM produces footwear based on a buyer’s specifications and branding. Understanding OEM capabilities helps B2B buyers negotiate customization, quality, and lead times. It is especially relevant when importing branded or private-label wide toe shoes.

2. MOQ (Minimum Order Quantity)

This defines the smallest quantity a manufacturer or supplier will accept per production run. Knowing the MOQ helps buyers plan their inventory and manage cash flow, particularly when entering new markets or testing new product lines.

3. RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers to obtain detailed pricing, lead times, and terms for specific product specifications. Preparing clear RFQs ensures accurate and competitive bids, streamlining procurement processes.

4. Incoterms (International Commercial Terms)

These standardized trade terms (e.g., FOB, CIF, DDP) specify the responsibilities and liabilities of buyers and sellers during shipping and delivery. Familiarity with Incoterms allows B2B buyers to negotiate favorable shipping terms, control costs, and mitigate risks during international trade.

5. Lead Time

The period between placing an order and receiving the finished product. Accurate knowledge of lead times is critical for supply chain planning, especially for seasonal markets or urgent demand.

6. Quality Certification

Certifications such as ISO 9001 or environmental standards (REACH, RoHS) validate manufacturing quality and compliance. They are essential for gaining trust in international markets, reducing the risk of product rejection at customs.

In Summary:

A thorough understanding of these technical properties ensures that B2B buyers can specify precise product requirements, evaluate supplier capabilities, and navigate international trade effectively. Mastery of trade terminology facilitates smoother negotiations, transparent transactions, and successful market entry across diverse regions such as Africa, South America, the Middle East, and Europe.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the wide toe shoes Sector

Market Overview & Key Trends

The global market for wide toe shoes is experiencing steady growth driven by increasing consumer awareness around foot health, comfort, and inclusive fashion. Emerging demographic segments, notably older adults and individuals with foot deformities, are expanding demand across North America, Europe, and parts of Asia. B2B buyers from Africa, South America, the Middle East, and Europe—especially countries like Vietnam and Germany—are capitalizing on this trend by sourcing from innovative manufacturers offering customizable, ergonomic designs.

Technological advancements are transforming sourcing dynamics. Digital platforms now enable real-time supplier vetting, order tracking, and quality assurance, reducing lead times and enhancing transparency. Additive manufacturing and automation are also beginning to influence production, allowing for more flexible, localized manufacturing—particularly beneficial for regions seeking to mitigate supply chain disruptions.

Market dynamics are shaped by shifting consumer preferences for sustainability and ethical production, compelling suppliers to adopt greener practices. Trade policies and tariffs continue to influence sourcing costs, prompting buyers to diversify supplier bases to mitigate risks. Notably, the rise of regional trade agreements and free trade zones simplifies cross-border transactions, especially within the European Union and between emerging markets.

For international B2B buyers, understanding regional manufacturing capabilities, currency fluctuations, and logistics infrastructure is crucial. Partnering with suppliers committed to innovation, quality, and compliance can provide a competitive edge. Moreover, leveraging data analytics and market intelligence tools helps anticipate demand shifts, optimize inventory, and adapt sourcing strategies proactively.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal factor in sourcing wide toe shoes, influencing brand reputation and consumer trust across global markets. Environmentally conscious buyers prioritize suppliers with transparent supply chains that minimize ecological impact, such as those utilizing eco-friendly materials, renewable energy, and waste reduction practices.

Certifications like Global Organic Textile Standard (GOTS), Fair Trade, and Forest Stewardship Council (FSC) are increasingly demanded by B2B clients aiming for compliance with international standards. For wide toe shoes, sourcing from suppliers using sustainable leathers, recycled textiles, or biodegradable materials not only aligns with eco goals but also appeals to eco-conscious markets in Europe, South America, and parts of Africa.

Ethical sourcing extends beyond environmental concerns to social responsibility. Ensuring fair wages, safe working conditions, and community engagement are critical components. B2B buyers should conduct rigorous supplier audits and seek transparency reports to verify compliance with labor standards.

Investing in ‘green’ certifications and sustainable materials can also lead to cost efficiencies in the long term—such as reduced waste disposal and energy savings. Additionally, integrating sustainability into product design, such as using biodegradable packaging and low-impact dyes, enhances brand differentiation and market positioning. Building long-term partnerships with responsible suppliers is essential to maintaining supply chain resilience and meeting evolving regulatory requirements.

Brief Evolution/History

While the concept of wide toe shoes has historical roots linked to foot health and orthopedic needs, the modern commercial focus has shifted significantly over the past two decades. Initially driven by medical necessity, the market has expanded into mainstream fashion, driven by increased awareness of foot health and ergonomic comfort.

This evolution has led manufacturers to innovate in design, sourcing, and materials to meet both health and style demands. The integration of sustainable practices and ethical sourcing has gained momentum as consumers and regulators alike demand greater accountability. For B2B buyers, understanding this trajectory highlights opportunities for early engagement with emerging brands and suppliers committed to innovation and sustainability, ensuring competitiveness in a rapidly evolving market.

Frequently Asked Questions (FAQs) for B2B Buyers of wide toe shoes

-

How can I effectively vet and verify the credibility of wide toe shoe suppliers internationally?

International B2B buyers should conduct comprehensive due diligence by requesting verified business licenses, certifications (such as ISO, CE), and third-party audits. Review supplier websites, customer testimonials, and online marketplaces like Alibaba or Global Sources. Engage in video calls or factory visits when possible to assess production capacity and quality control processes. Request sample products to evaluate craftsmanship. Additionally, check references from other international clients to confirm reliability. Using escrow payment services or trade assurance platforms can also mitigate risks during initial transactions, ensuring supplier credibility before large orders. -

What customization options are typically available for wide toe shoes, and how do I communicate my specifications effectively?

Suppliers often offer customization in sizing, material selection, color, and design details like branding or sole type. Clearly specify your requirements through detailed technical drawings, material samples, and written specifications. Use visual aids such as sketches or 3D models to minimize misunderstandings. Establish clear communication channels, preferably via email or dedicated project management tools, to ensure ongoing dialogue. Confirm lead times for customization, and request prototypes before mass production to verify alignment with your standards, reducing costly errors and ensuring product-market fit. -

What are typical MOQ (Minimum Order Quantities), lead times, and payment terms I should expect when sourcing wide toe shoes internationally?

Most suppliers set MOQs ranging from 300 to 1,000 pairs, but this varies based on customization complexity and supplier size. Lead times usually range from 4 to 12 weeks, depending on order size and production capacity. Common payment terms include 30% deposit upfront with the balance paid before shipment, or letters of credit for larger orders. Negotiate flexible terms if possible, especially for first orders, and consider establishing long-term relationships to access better terms and priority production. Always clarify these details upfront to align expectations and avoid delays. -

What certifications and quality assurance measures should I look for in international suppliers of wide toe shoes?

Ensure suppliers hold relevant certifications such as ISO 9001 (quality management), CE (European safety standards), or other region-specific standards like ASTM or SGS testing reports. Request factory quality control protocols, test reports for durability, and materials used. Verify if they follow internationally recognized standards for footwear safety and comfort, especially if targeting specific markets like Europe or the Middle East. Conduct or commission third-party inspections during production and prior to shipment. This diligence helps ensure product consistency, compliance, and reduces the risk of defective goods entering your supply chain. -

How do I manage logistics and shipping when importing wide toe shoes from overseas suppliers?

Coordinate with suppliers to choose reliable freight forwarders experienced in handling footwear shipments. Consider multimodal options—sea freight for cost efficiency, air freight for faster delivery. Clarify Incoterms (e.g., FOB, CIF) to delineate responsibilities and costs. Factor in customs clearance, import duties, and taxes based on your destination country’s regulations. Using trackable shipping methods and comprehensive documentation (commercial invoice, packing list, certificates) ensures transparency. Establish clear communication with logistics providers and plan inventory buffers to accommodate potential delays, ensuring a smooth supply chain flow. -

What strategies should I use to resolve disputes or quality issues with overseas suppliers?

Maintain detailed records of all communications, agreements, and inspection reports. If issues arise, address them promptly through direct communication, clearly outlining the defect or concern with supporting evidence. Engage in collaborative problem-solving, requesting corrective actions or replacements. If unresolved, consider mediation through trade associations or international trade dispute resolution platforms. Having arbitration clauses in contracts and proper documentation minimizes risks. Building strong supplier relationships based on transparency and mutual respect also facilitates smoother resolutions and long-term cooperation. -

What are best practices for ensuring product quality during manufacturing and before shipment?

Implement a comprehensive quality control plan that includes pre-production samples, in-line inspections during manufacturing, and final pre-shipment inspections. Engage third-party inspection agencies if possible, to verify adherence to specifications, craftsmanship, and safety standards. Use detailed checklists covering materials, sizing, finishing, and packaging. Establish clear acceptance criteria and communicate them to your supplier. Regularly monitor production progress through photos, videos, or factory visits. This proactive approach minimizes defective products, reduces returns, and ensures your wide toe shoes meet your quality expectations. -

How can I build strong, long-term relationships with international suppliers of wide toe shoes?

Foster open, transparent communication and respect cultural differences to build trust. Start with smaller initial orders to evaluate performance before scaling up. Offer timely payments and constructive feedback to demonstrate reliability. Share market insights and collaborate on product development to meet evolving demands. Consider visiting suppliers periodically to strengthen relationships and better understand their operations. Consistently honoring contractual commitments and resolving issues amicably encourages loyalty. Over time, this approach can lead to preferential pricing, priority production slots, and collaborative innovation, boosting your competitive edge in the global market.

Strategic Sourcing Conclusion and Outlook for wide toe shoes

Final Considerations and Future Outlook

Effective strategic sourcing for wide toe shoes offers significant competitive advantages, including cost optimization, quality assurance, and supply chain resilience. By establishing strong relationships with reliable manufacturers—particularly in key sourcing hubs like Vietnam, Germany, and regional suppliers across Africa, South America, and the Middle East—B2B buyers can ensure product consistency and meet the growing demand for comfortable footwear.

Looking ahead, the global emphasis on ergonomic and health-conscious footwear is set to accelerate. Buyers who proactively diversify their sourcing portfolios and leverage technology-driven supply chain management will be better positioned to adapt to market fluctuations and consumer preferences. Embracing sustainable sourcing practices and fostering transparency will also enhance brand reputation and consumer trust.

Illustrative Image (Source: Google Search)

For international buyers, especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe, a strategic approach to sourcing wide toe shoes is crucial. By building resilient, adaptable, and ethically aligned supply chains today, you can capitalize on future growth opportunities and establish a competitive edge in this expanding segment. Stay proactive, innovative, and committed to quality to secure long-term success in the global footwear market.