Master Global Sourcing for Ballet Shoes: Essential

Guide to Ballet Shoes

- Introduction: Navigating the Global Market for ballet shoes

- Understanding ballet shoes Types and Variations

- Key Industrial Applications of ballet shoes

- Strategic Material Selection Guide for ballet shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for ballet shoes

- Comprehensive Cost and Pricing Analysis for ballet shoes Sourcing

- Spotlight on Potential ballet shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for ballet shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ballet shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of ballet shoes

- Strategic Sourcing Conclusion and Outlook for ballet shoes

Introduction: Navigating the Global Market for ballet shoes

In the highly specialized world of ballet footwear, precision, quality, and reliability are paramount. For international B2B buyers—from distributors and wholesalers across Africa, South America, the Middle East, and Europe—understanding the intricacies of the global ballet shoe market is essential to making informed sourcing decisions. These shoes are not merely performance accessories; they are vital tools that influence a dancer’s technique, safety, and stage presence. As demand for authentic, durable, and ethically produced ballet shoes grows worldwide, so does the need for strategic sourcing that balances quality, cost, and compliance.

This comprehensive guide offers an in-depth exploration of the ballet shoe industry, covering key topics such as different types of shoes (e.g., slippers, pointe shoes), materials used (canvas, satin, leather), manufacturing processes, quality control standards, and sourcing options from leading suppliers. It also provides critical insights into cost structures, global market trends, and frequently asked questions that help buyers navigate complex supply chains. Equipped with this knowledge, B2B buyers can optimize their sourcing strategies, mitigate risks, and establish long-term partnerships with trusted manufacturers.

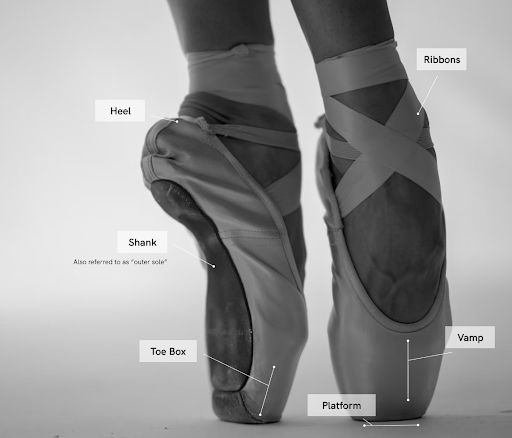

Illustrative Image (Source: Google Search)

By leveraging these insights, buyers from emerging markets and established regions alike will be empowered to select suppliers that meet their unique needs—whether for high-end performance shoes or cost-effective production. This guide aims to be your authoritative resource for navigating the dynamic, global ballet shoe market with confidence and clarity.

Understanding ballet shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Canvas Ballet Shoes | Lightweight, flexible, breathable, with elastic or drawstring closure | Wholesale, dance schools, costume supply | Pros: Cost-effective, versatile, easy to customize. Cons: Less durable, prone to wear in heavy use. |

| Satin Pointe Shoes | Luxurious satin exterior, reinforced toe box, shank for support | Premium dance companies, boutiques | Pros: High-end appeal, excellent aesthetic, supportive for advanced dancers. Cons: Higher cost, delicate. |

| Leather Ballet Shoes | Durable, moldable, offers good support, often used for rehearsals | Bulk orders, training academies | Pros: Long-lasting, good support, suitable for various foot shapes. Cons: Heavier, less breathable. |

| Split-sole Ballet Shoes | Separate sole from the upper, flexible sole for enhanced movement | Specialty studios, performance groups | Pros: Increased flexibility, lightweight, better arch support. Cons: Higher price, less protective. |

| Pointe Shoes | Rigid toe box, shank, satin exterior, designed for en pointe work | Professional companies, advanced students | Pros: Essential for pointe work, customizable fit. Cons: Expensive, requires careful fitting and maintenance. |

Canvas Ballet Shoes

Canvas ballet shoes are the most common entry-level option, favored for their affordability and flexibility. They are lightweight, breathable, and easy to sew or customize, making them ideal for dance schools and costume suppliers. However, their durability can be limited under heavy or prolonged use, which is a key consideration for bulk purchasing. B2B buyers should focus on sourcing high-quality canvas and reliable manufacturing partners to ensure consistent product quality, especially when catering to training academies or retail outlets.

Satin Pointe Shoes

Satin pointe shoes are a staple for professional performances and high-end dance boutiques. Their luxurious appearance and supportive construction—featuring reinforced toe boxes and supportive shanks—make them suitable for advanced dancers. For B2B buyers, sourcing these shoes involves careful attention to craftsmanship, material quality, and customization options. While they command higher prices, their demand in premium markets justifies investment. Buyers should consider establishing relationships with reputable manufacturers capable of consistent quality and timely delivery.

Leather Ballet Shoes

Leather shoes are valued for their durability and ability to mold to a dancer’s foot over time. They are often used for rehearsals and training, especially where support and longevity are prioritized. For international buyers, sourcing high-quality leather from trusted suppliers is crucial, as material consistency impacts product performance and customer satisfaction. Although heavier and less breathable than fabric options, leather shoes appeal to buyers seeking a balance of durability and comfort, particularly in markets with rigorous training programs.

Split-sole Ballet Shoes

Split-sole shoes feature a sole that is separate from the upper, providing enhanced flexibility and arch support. They are popular among performers and advanced students who require greater freedom of movement. B2B buyers should consider the higher manufacturing costs associated with these shoes, balanced against their appeal to high-end dance studios and performance groups. Ensuring access to reliable suppliers capable of producing high-quality split soles with durable materials is essential to meet market expectations.

Pointe Shoes

Pointe shoes are specialized footwear critical for ballet companies and professional dancers performing en pointe. They are highly customizable, with options for different shank stiffness and box shapes, and often require precise fitting. For B2B buyers, establishing partnerships with experienced manufacturers who can produce consistent, high-quality pointe shoes is vital. Due to their complexity and cost, buyers should also consider offering a range of options to cater to various skill levels and foot shapes, ensuring customer satisfaction and repeat business.

Related Video: How to Choose Your First Pair of Ballet Flats

Key Industrial Applications of ballet shoes

| Industry/Sector | Specific Application of ballet shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Performing Arts & Entertainment | Custom-designed ballet shoes for professional dance companies and theaters | Enhances performance quality, supports brand reputation, and ensures precision | Material quality, customization options, compliance with safety standards |

| Sports & Fitness | Ballet-inspired fitness programs and dancewear lines | Attracts niche markets, offers innovative product differentiation | Material durability, comfort, flexibility, and cost-effectiveness |

| Retail & Wholesale | Bulk supply of ballet shoes for dance schools, retailers, and distributors | Facilitates large volume sales, ensures consistent quality, reduces costs | Volume pricing, reliable supply chain, adherence to international standards |

| Manufacturing & OEM | Private label ballet shoes for global brands | Enables brand differentiation, scalability, and quality control | Consistent material sourcing, compliance with manufacturing standards, flexibility in design |

| Cultural & Educational Institutions | Educational kits and training equipment including ballet shoes for academies | Supports youth engagement, promotes cultural exchange, and educational outreach | Cost efficiency, durability, and ease of procurement logistics |

Performing Arts & Entertainment

Ballet shoes are integral to professional dance companies, theaters, and performance arts institutions. These entities require shoes that offer superior craftsmanship, precise fit, and aesthetic appeal, often custom-made to meet specific choreography needs. For international B2B buyers, sourcing high-quality ballet shoes ensures the preservation of artistic integrity and enhances the overall performance experience. The emphasis is on premium materials, adherence to safety standards, and customization capabilities to meet diverse production demands. Reliable supply chains and compliance with international safety and quality standards are critical considerations, especially for buyers from regions like Europe and the Middle East where performance standards are high.

Sports & Fitness

The growing popularity of ballet-inspired fitness classes and dance-based workouts has created a new application for ballet shoes outside traditional performance settings. Fitness brands and gyms seek lightweight, durable, and flexible shoes that can withstand frequent use while maintaining comfort. B2B buyers in this sector should focus on sourcing materials that balance durability with breathability, such as synthetic fabrics or treated canvas. Cost efficiency and scalability are also vital, especially for large-scale distribution to fitness chains or retail outlets across Africa, South America, and Europe. Ensuring consistent quality and timely delivery supports brand reputation and customer satisfaction.

Retail & Wholesale

Dance schools, retail chains, and wholesale distributors constitute a significant market for ballet shoes. These buyers require a steady supply of standardized, high-quality shoes in bulk, often with options for customization such as different sizes, colors, and designs. Sourcing from reliable manufacturers with proven quality control processes minimizes returns and enhances customer loyalty. Cost competitiveness and compliance with international manufacturing standards are crucial, especially for buyers in Turkey, Poland, and other European markets where quality expectations are high. Establishing long-term supplier relationships ensures consistent availability and enables scalable growth.

Manufacturing & OEM

Private label manufacturing presents an opportunity for global brands to expand their product lines with ballet shoes tailored to specific market needs. OEM partners must deliver consistent quality, adhere to safety and labor standards, and offer flexibility in design and material selection. For international B2B buyers, especially from emerging markets, sourcing ballet shoes with scalable production capabilities and transparent supply chains is essential. This approach allows brands to differentiate through branding, packaging, and specialized features while maintaining cost efficiency and compliance with local regulations.

Cultural & Educational Institutions

Educational institutions, dance academies, and cultural organizations often purchase ballet shoes for training, youth programs, and cultural exchanges. These buyers prioritize durability, ease of procurement, and affordability, especially when outfitting large student groups. Sourcing ballet shoes that meet safety standards and are suitable for repeated use helps institutions maintain operational efficiency. For international buyers, especially from regions with logistical challenges, establishing reliable supply channels and ensuring consistent product quality are vital to support ongoing training programs and cultural initiatives.

Related Video: Uses and Gratifications Theory

Strategic Material Selection Guide for ballet shoes

When selecting materials for ballet shoes, especially from a B2B perspective, understanding the key properties, advantages, limitations, and regional considerations of each material is crucial. The choice impacts not only the performance and durability of the final product but also compliance with international standards and market preferences. Below is an in-depth analysis of four common materials used in ballet shoe manufacturing: leather, canvas, satin, and synthetic composites.

Leather

Leather has historically been the primary material for ballet shoes, particularly for the upper part and the sole of certain models. It offers excellent durability, moldability, and natural breathability, which are highly valued in professional dance environments. Leather’s temperature and pressure resistance make it suitable for rigorous performances, and its natural properties provide good moisture absorption, reducing foot discomfort.

Pros:

– High durability and longevity

– Excellent moldability to fit the dancer’s foot over time

– Natural breathability and moisture management

Cons:

– Higher cost compared to synthetic alternatives

– Manufacturing complexity due to the need for specialized tanning and finishing processes

– Less flexible initially, requiring break-in time

Impact on Application:

Leather’s natural properties make it compatible with a wide range of cleaning and maintenance products. However, it may require specific care to prevent cracking or degradation, especially in humid or variable climates.

Regional Considerations:

For buyers in Africa, South America, the Middle East, and Europe, sourcing high-quality leather must align with regional standards such as ASTM, DIN, or JIS. Compliance with environmental and social standards (e.g., leather tanned with eco-friendly processes) is increasingly important. Leather imports may face tariffs or import restrictions depending on the country, so establishing reliable supply chains is essential.

Canvas

Canvas is a popular choice for ballet slippers due to its lightweight, flexible, and breathable nature. It is often used in beginner and intermediate shoes, offering a cost-effective alternative to leather. Canvas shoes are easy to customize with different colors and patterns, making them appealing for various performance styles.

Pros:

– Cost-effective and widely available

– Highly breathable and lightweight

– Easy to produce and customize

Cons:

– Lower durability compared to leather, especially under intense use

– Less moldable, which may affect fit over time

– Susceptible to wear and tear in humid or wet conditions

Impact on Application:

Canvas’s compatibility with dyes and paints allows for aesthetic flexibility. However, moisture absorption can lead to faster deterioration if not properly treated or maintained.

Regional Considerations:

For markets in Africa and South America, local availability of quality canvas can reduce costs and lead times. European and Middle Eastern buyers should verify that imported canvas complies with regional safety and environmental standards, such as REACH in Europe. Additionally, sourcing from suppliers with sustainable practices aligns with increasing consumer demand for eco-friendly products.

Satin

Satin is predominantly used in pointe shoes, especially for the toe box, due to its smooth, glossy appearance and lightweight qualities. Satin provides an elegant aesthetic suitable for performance and stage presentation but requires careful handling to maintain its finish.

Pros:

– Elegant, stage-ready appearance

– Lightweight, facilitating dancer mobility

– Good for aesthetic customization

Cons:

– Less durable, prone to snags and tears

– Requires delicate handling and maintenance

– Higher cost compared to canvas

Impact on Application:

Satin’s compatibility with dyes and embellishments makes it ideal for custom designs. However, its sensitivity to abrasion and moisture necessitates careful supply chain management to ensure quality and consistency.

Regional Considerations:

European and Middle Eastern markets often favor satin for high-end productions, demanding high-quality, compliant fabrics. Buyers should ensure that satin sourced meets regional standards such as OEKO-TEX or GOTS for organic and chemical safety. For African and South American markets, sourcing satin locally or regionally can reduce costs and lead times, provided quality standards are maintained.

Synthetic Composites

Modern synthetic materials, such as microfiber or engineered fabrics, are increasingly used in ballet shoes for their performance benefits. These materials can be engineered for specific properties like enhanced flexibility, moisture-wicking, and increased durability.

Pros:

– Customizable properties tailored to performance needs

– Generally lower cost and easier to manufacture at scale

– Resistant to moisture, mold, and environmental degradation

Cons:

– May lack the natural feel of leather or satin

– Environmental concerns related to synthetic production and disposal

– Variability in quality depending on manufacturer

Impact on Application:

Synthetic composites are compatible with modern manufacturing techniques, allowing for innovative designs and performance enhancements. They are suitable for mass production, especially in markets emphasizing cost efficiency.

Regional Considerations:

Buyers in regions with strict environmental regulations, such as Europe, should verify that synthetic materials comply with chemical safety standards like REACH. In Africa, South America, and the Middle East, availability and cost advantages make synthetics attractive, but due diligence on supplier certifications and environmental impact is essential.

Summary Table

| Material | Typical Use Case for ballet shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Upper and sole of professional ballet shoes | High durability, excellent moldability, breathability | Higher cost, complex manufacturing, less flexible initially | High |

| Canvas | Beginner and intermediate ballet slippers | Cost-effective, lightweight, breathable | Lower durability, less moldable, wear in humid conditions | Low |

| Satin | Toe box of pointe shoes, stage performance aesthetic | Elegant appearance, lightweight, customizable | Less durable, prone to snags, higher cost | High |

| Synthetic Composites | Modern performance-oriented ballet shoes | Customizable, resistant to moisture and environmental factors | Environmental concerns, variable quality | Med |

By understanding these materials’ properties and regional considerations, international B2B buyers can make informed sourcing decisions that align with their quality standards, cost targets, and compliance requirements. Establishing relationships with reputable suppliers who adhere to international standards and sustainability practices will ensure consistent product quality and market competitiveness.

In-depth Look: Manufacturing Processes and Quality Assurance for ballet shoes

Manufacturing Stages for Ballet Shoes

The production of ballet shoes is a highly meticulous process that combines traditional craftsmanship with modern manufacturing techniques, ensuring consistent quality and performance. The main stages include material preparation, forming, assembly, and finishing, each with specific techniques and quality controls.

Material Preparation

This initial phase involves sourcing and processing raw materials such as leather, canvas, satin, cotton linings, elastic, and ribbons. Suppliers must meet international standards like ISO 9001 for quality management systems, ensuring raw materials are free from defects and meet specifications. For B2B buyers, verifying supplier certifications and material test reports (e.g., tensile strength, colorfastness) is essential to ensure durability and compliance.

Forming

During forming, raw materials are cut into precise patterns using die-cutting machines or laser cutters to minimize waste and ensure accuracy. For leather or satin components, forming involves shaping the upper and toe box through specialized molds or handcrafting techniques. This stage demands strict control over dimensions and tolerances, often validated through in-process quality checks (IPQC). For pointe shoes, shaping the toe box and shank requires skilled craftsmanship to achieve optimal support.

Assembly

In the assembly phase, components are stitched together using industrial sewing machines or hand-sewing for intricate parts like the sole attachments and elastic bands. Reinforced stitching techniques such as double-stitched seams or bar tacking enhance durability, especially in high-stress areas. Adhesives may be used in conjunction with stitching, particularly for the sole attachment, adhering to industry standards for bonding strength. Proper alignment and tension are critical to prevent deformation and ensure consistent fit.

Finishing

Final touches include trimming excess threads, applying edge treatments, attaching ribbons and elastic, and performing quality inspections. The shoes are shaped, pressed, and sometimes hand-finished to ensure a smooth appearance and proper fit. Quality assurance at this stage ensures that aesthetic standards are met and that the shoes can withstand rigorous dance movements.

Quality Assurance and Industry Standards

Quality assurance (QA) in ballet shoe manufacturing is integral to delivering reliable products that meet international safety, performance, and durability standards. B2B buyers must understand both general manufacturing standards and industry-specific protocols to effectively evaluate suppliers.

International Standards & Certifications

– ISO 9001: The cornerstone for quality management, ensuring continuous process improvement and customer satisfaction. Suppliers compliant with ISO 9001 demonstrate systematic control over production and QC processes.

– CE Marking (European Market): Indicates conformity with EU safety, health, and environmental requirements, crucial for products sold within Europe.

– ASTM and EN Standards: Relevant for materials testing, including tensile, tear, and abrasion resistance.

– Specific Industry Certifications: Some manufacturers may pursue additional certifications like the Ethical Trading Initiative (ETI) or Fair Trade, which are increasingly valued globally.

QC Checkpoints and Procedures

– Incoming Quality Control (IQC): Inspection of raw materials upon receipt, verifying specifications, visual defects, and compliance certificates.

– In-Process Quality Control (IPQC): Continuous monitoring during manufacturing, including dimensional checks, stitch integrity, and bonding strength.

– Final Quality Control (FQC): Comprehensive inspection of finished shoes for appearance, structural integrity, and functionality. This includes tests for sole adhesion, elasticity, and overall craftsmanship.

Testing Methods

– Mechanical Testing: Tensile, tear, and flex tests to simulate dance movements and ensure longevity.

– Visual Inspection: Checking for defects, color consistency, and finishing quality.

– Fit and Comfort Testing: Verifying that the shoes meet ergonomic standards, especially important for pointe shoes which require precise support.

– Durability Testing: Simulating wear and tear through repeated flexing and abrasion tests.

How B2B Buyers Can Verify Supplier Quality

For international buyers from Africa, South America, the Middle East, and Europe, establishing confidence in supplier quality is critical. Several strategies can be employed:

- Audits and Factory Visits: Conduct on-site audits or third-party inspections to assess manufacturing practices, working conditions, and QC procedures. Many certification bodies provide detailed reports aligned with ISO 9001 or industry standards.

- Request for Quality Documentation: Review detailed QC reports, test certificates, and compliance documents. These should include raw material certifications, test results, and process audits.

- Third-Party Inspection Services: Engage independent inspection companies (e.g., SGS, Bureau Veritas) for pre-shipment quality checks, ensuring products meet specifications before shipment.

- Sample Testing: Purchase samples for independent laboratory testing, verifying material properties, and manufacturing quality.

- Supplier Certifications: Prioritize suppliers with recognized certifications, transparent quality management systems, and proven track records with international clients.

Nuances for International B2B Buyers

Buyers from different regions should be aware of specific considerations:

- Regional Standards and Regulations: European buyers often require CE marking and compliance with REACH regulations, while Middle Eastern markets may have specific standards for safety and materials.

- Language and Documentation: Ensure all QC reports, certificates, and compliance documents are available in accessible languages or are certified translations.

- Lead Times and Flexibility: Suppliers with robust QC processes can adapt to urgent orders without compromising quality, vital for dynamic markets.

- Traceability: Demand detailed traceability records for raw materials and production batches, ensuring accountability and ease of defect resolution.

In conclusion, robust manufacturing and QC protocols are essential for delivering high-quality ballet shoes that meet diverse international standards. B2B buyers must adopt a comprehensive approach—combining supplier audits, certifications, testing, and ongoing monitoring—to secure reliable supply chains. This proactive engagement not only mitigates risks but also ensures that the products uphold the performance and aesthetic standards critical to the dance industry worldwide.

Related Video: Interesting! Shoes Mass Production Process. Korea’s Old Shoe Factory

Comprehensive Cost and Pricing Analysis for ballet shoes Sourcing

Cost Structure Breakdown

When sourcing ballet shoes internationally, understanding the detailed cost components is essential for accurate pricing and negotiation. The primary costs include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and desired profit margin.

Materials constitute a significant portion, typically 30-50% of the final price. High-quality fabrics like satin, canvas, or leather, along with supportive components such as ribbons, elastics, and lining, influence costs directly. Premium materials, especially those with certifications for sustainability or safety, tend to elevate the price but can add value and appeal to specific markets.

Labor costs vary widely depending on the sourcing country. For instance, manufacturers in Turkey or Poland often offer competitive rates due to lower labor costs compared to Western Europe, while factories in South America or Africa might provide even more cost-efficient options. Skilled craftsmanship, especially for pointe shoes requiring intricate stitching, will increase labor expenses.

Manufacturing overhead includes factory operational costs, machinery depreciation, and compliance expenses. This typically accounts for 10-20% of the production cost but can be higher for factories adhering to strict social or environmental standards.

Tooling and setup costs are generally fixed and amortized over large order volumes. Initial mold creation or pattern development can range from a few hundred to several thousand dollars, which should be factored into larger purchase agreements.

Quality assurance (QC) and testing, especially for internationally exported products, add to costs but are crucial to meet safety and performance standards. Certifications such as ISO or specific safety standards for children’s products can also impact expenses.

Logistics costs depend on shipment volume, destination, and chosen Incoterms. FOB (Free On Board) terms shift transportation costs to the buyer, while CIF (Cost, Insurance, Freight) includes these costs in the price. Shipping from Asian or Eastern European factories to Africa, South America, or Europe typically accounts for 10-20% of the total landed cost, influenced by fuel prices, customs duties, and freight rates.

Finally, margin is determined by the supplier’s pricing strategy, market positioning, and buyer relationship. A typical markup ranges from 15-30%, but premium or bespoke shoes may command higher margins.

Price Influencers

Several factors impact the final unit price of ballet shoes in B2B transactions:

- Order volume & MOQ: Larger quantities usually attract discounts, with MOQ reductions sometimes leading to 10-15% savings. Buyers should aim for volume commitments to leverage better pricing.

- Specifications & customization: Custom designs, specific sizing, or specialized materials increase costs. Complex stitching, reinforced toe boxes, or bespoke branding add further premiums.

- Material selection: High-grade satin or certified eco-friendly textiles elevate costs but can differentiate products in premium markets.

- Quality & certifications: Meeting international safety, environmental, or social compliance standards (e.g., Fair Trade, ISO) can add to costs but improve market access, especially in Europe and North America.

- Supplier factors: Factory reputation, location, and capacity influence price stability and reliability. European and Turkish manufacturers often offer high-quality standards, sometimes at a premium, while Asian or Latin American suppliers might be more cost-effective but require rigorous vetting.

- Incoterms & logistics: FOB terms reduce upfront costs but shift transportation and customs responsibilities to the buyer. DDP (Delivered Duty Paid) provides convenience at higher cost.

Buyer Tips for Cost Optimization

For international B2B buyers, especially from regions like Africa, South America, the Middle East, or Europe, strategic negotiation is vital. Establish long-term relationships to access volume discounts and prioritize factories with proven compliance and quality records. Consider consolidating shipments and planning for larger orders to reduce per-unit logistics costs.

A comprehensive approach involves evaluating the Total Cost of Ownership (TCO) — factoring in customs duties, taxes, storage, and potential rework costs. Price negotiations should also include clauses for quality assurance, lead times, and after-sales support.

Understanding pricing nuances—such as the difference between FOB and CIF—can prevent unexpected expenses. Buyers should also be aware of market fluctuations in raw material costs, which directly affect shoe pricing. Engaging with multiple suppliers, requesting detailed quotes, and conducting factory audits are recommended practices to ensure competitive pricing without compromising quality.

Indicative Price Range (Disclaimers)

While prices vary based on specifications, order volume, and supplier location, typical FOB prices for standard ballet slippers can range from $2.50 to $5.50 per pair for bulk orders. For high-end pointe shoes with custom features, prices may escalate to $8.00 or more per pair. Buyers should consider additional costs such as shipping, duties, and customs clearance when calculating the landed cost.

In conclusion, a thorough understanding of these cost components and influencing factors enables better negotiation and sourcing strategies, ensuring competitive pricing and sustainable supply chains across diverse international markets.

Spotlight on Potential ballet shoes Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘ballet shoes’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for ballet shoes

Critical Technical Properties for Ballet Shoes

Material Grade

The quality of raw materials—such as leather, satin, or canvas—directly impacts the durability, flexibility, and comfort of ballet shoes. Buyers should specify minimum grade standards to ensure consistent performance, especially when sourcing large quantities. Higher-grade materials typically undergo stricter quality control, reducing defects and enhancing the shoe’s lifespan.

Tolerances

Manufacturing tolerances define the acceptable deviations in dimensions (e.g., length, width, heel height). Precise tolerances are vital for ensuring a consistent fit across bulk orders, minimizing returns or adjustments. For international sourcing, suppliers with tight tolerance controls often indicate better quality management, which is essential for maintaining brand standards.

Sole Thickness and Flexibility

The sole’s thickness and flexibility influence a dancer’s movement and support. Thinner, more flexible soles allow for greater foot articulation and a more authentic ballet experience. Buyers should specify minimum flexibility standards aligned with the intended performance level, ensuring shoes meet professional or beginner needs.

Stitching Strength and Seam Quality

Durable stitching prevents seam splitting during rigorous use. High-quality, reinforced stitches—often double-stitched—are a hallmark of reliable production. When importing, verify that suppliers adhere to strict stitching standards through quality certifications or sample inspections to avoid performance issues.

Breathability and Moisture Management

Materials that promote airflow and moisture absorption (like cotton linings) enhance comfort and reduce foot odor. For high-performance applications, specify breathability standards to ensure the shoes can withstand extended use without degrading. This property is particularly critical for suppliers targeting markets with warmer climates.

Colorfastness and Finish Quality

For shoes made of satin or dyed canvas, colorfastness ensures that the footwear maintains its appearance after cleaning or prolonged use. Suppliers should provide evidence of colorfastness testing, especially when sourcing for premium brands or stage performances, to guarantee visual consistency.

Common Trade and Industry Terms

OEM (Original Equipment Manufacturer)

Refers to manufacturers producing ballet shoes according to a buyer’s specifications and branding. Understanding OEM relationships helps buyers negotiate custom designs, materials, and branding, which is essential for private-label or exclusive product lines.

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce or sell. Clarifying MOQ upfront helps manage procurement budgets and production planning, particularly for buyers in emerging markets or those testing new designs.

RFQ (Request for Quotation)

A formal request sent to suppliers to obtain detailed pricing, lead times, and terms for a specific order. Using RFQs enables B2B buyers to compare offers objectively, ensuring transparency and cost competitiveness across international suppliers.

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and delivery (e.g., FOB, CIF). Mastery of Incoterms allows buyers to negotiate optimal logistics arrangements, minimizing risks and controlling costs in cross-border transactions.

Factory Certification and Compliance Standards

Certificates such as ISO, SA8000, or social compliance audits assure buyers of ethical manufacturing practices and quality management. For international buyers, verifying certifications is crucial to mitigate risks related to social responsibility and product safety.

Sample Lead Time

The duration from order placement to sample delivery. Understanding lead times helps plan production schedules and market launches, especially when entering new markets or coordinating seasonal launches.

Conclusion:

A comprehensive grasp of these technical properties and trade terms empowers international B2B buyers from regions like Africa, South America, the Middle East, and Europe to make informed sourcing decisions. Ensuring clarity on material standards, manufacturing tolerances, and contractual terms reduces risks, enhances product quality, and fosters long-term supplier relationships.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ballet shoes Sector

Market Overview & Key Trends

The global ballet shoe market is experiencing dynamic shifts driven by evolving consumer preferences, technological advancements, and supply chain innovations. Key drivers include increased demand for high-performance, durable, and aesthetically refined footwear tailored to diverse dance styles. Emerging trends such as 3D printing, automation in manufacturing, and digital design tools are transforming how ballet shoes are produced, enabling more precise customization and faster turnaround times.

For international B2B buyers from regions like Africa, South America, the Middle East, and Europe, understanding regional market nuances is vital. Europe, especially countries like Poland and Turkey, remains a major sourcing hub due to established manufacturing infrastructure, skilled craftsmanship, and proximity to major markets. Meanwhile, Africa and South America are gaining prominence as cost-effective manufacturing centers, driven by lower labor costs and expanding industrial capabilities.

Market dynamics are also influenced by a rising emphasis on sustainability and ethical sourcing, with buyers increasingly seeking suppliers committed to environmentally responsible practices. Digital platforms and global trade agreements facilitate easier access to diverse sourcing options, but buyers must remain vigilant about quality standards and compliance issues. Staying ahead involves leveraging data-driven insights on material costs, production capacities, and compliance trends, which are crucial for optimizing sourcing strategies in this competitive landscape.

Sourcing Trends & Opportunities

B2B buyers should focus on diversifying their sourcing portfolios to mitigate risks associated with regional disruptions or supply chain bottlenecks. The adoption of nearshoring and regional manufacturing alliances is gaining momentum, particularly within Europe and Turkey, enabling faster delivery and reduced logistics costs. Additionally, the rise of direct-to-manufacturer platforms and online sourcing marketplaces simplifies supplier identification and negotiation processes.

Innovation in materials—such as eco-friendly satin, recycled canvas, and biodegradable adhesives—offers new avenues for sustainable product offerings. Buyers should prioritize suppliers who utilize advanced production techniques like CNC cutting and automated stitching, which enhance quality consistency and reduce waste.

Furthermore, establishing strong relationships with suppliers that adhere to recognized social and environmental standards—such as Fair Trade or ISO certifications—can provide a competitive edge. Transparency in sourcing, coupled with real-time supply chain tracking, is increasingly critical, especially for buyers from regions with stringent import regulations or sustainability mandates.

Sustainability & Ethical Sourcing

Environmental concerns are reshaping the ballet shoe supply chain. Traditional materials like leather and synthetic fabrics pose significant ecological footprints, prompting a shift toward greener alternatives. Recycled and biodegradable materials—such as organic cotton, recycled polyester, and natural rubber—are gaining traction among conscientious manufacturers and buyers.

Ethical sourcing is paramount, with a focus on ensuring fair labor practices, safe working conditions, and compliance with international labor standards. Buyers should seek suppliers with verifiable social compliance certifications, such as SA8000 or Fair Trade, to mitigate risks related to labor exploitation or supply chain disruptions. Implementing traceability systems and conducting regular audits enhances supply chain transparency, fostering trust and brand integrity.

Incorporating sustainability into procurement strategies not only aligns with global environmental goals but also appeals to a growing segment of consumers and performers who prioritize ethical and eco-friendly products. Certifications like GOTS (Global Organic Textile Standard) and OEKO-TEX can serve as benchmarks for verifying environmentally responsible practices and material safety.

Brief Evolution/History

The evolution of ballet shoes from simple leather slippers to sophisticated, performance-enhancing footwear reflects broader technological and cultural shifts. Historically, shoes were crafted with traditional materials, emphasizing durability and basic support. As ballet evolved into a highly technical art form, so did the footwear, leading to innovations like pointe shoes with reinforced toe boxes and specialized arch support.

For B2B buyers, understanding this evolution underscores the importance of sourcing from suppliers who combine artisanal craftsmanship with modern manufacturing techniques. The integration of sustainable materials and ethical practices has become a defining aspect of modern production, influencing procurement decisions and market positioning. Recognizing these historical trends helps buyers anticipate future innovations and align their sourcing strategies with industry standards and consumer expectations.

This comprehensive understanding of market dynamics, sourcing innovations, and sustainability practices equips international B2B buyers to navigate the complex ballet shoe industry effectively. Emphasizing regional strengths, technological integration, and ethical standards will support sustainable growth and competitive advantage in this specialized sector.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of ballet shoes

1. How can I verify the reliability and quality standards of a ballet shoe supplier?

To ensure supplier reliability, prioritize those with proven track records, transparent manufacturing processes, and verifiable certifications such as ISO 9001 or social compliance standards like SA8000. Request detailed product samples, factory audits, and references from previous clients in similar markets. Additionally, review their quality control protocols, including testing for durability, comfort, and adherence to international safety standards. Engaging third-party inspection services before shipment can further mitigate risks. Building strong communication channels and establishing clear quality expectations upfront are vital for long-term, dependable partnerships.

2. What customization options are typically available for ballet shoes, and how do they impact lead times and costs?

Ballet shoes can be customized in several ways, including materials (canvas, satin, leather), color, sole type, stitching, embellishments, and sizing adjustments. Advanced customization, like branding or specialized padding, may incur additional costs. Custom orders usually extend lead times by 2-4 weeks, depending on complexity and supplier capacity. It’s essential to communicate your specifications early and request detailed quotations, including setup fees and minimum order quantities (MOQs). Working with experienced manufacturers familiar with international markets helps optimize turnaround times and ensures your branding and design preferences are accurately executed.

3. What are typical minimum order quantities (MOQs), lead times, and payment terms for international ballet shoe sourcing?

MOQs for ballet shoes generally range from 500 to 2,000 pairs, depending on the manufacturer and customization level. Lead times typically span 4 to 8 weeks from order confirmation to shipment, influenced by design complexity and factory capacity. Payment terms vary but often include a 30% deposit upfront with the balance payable before shipment or upon receipt of documents. Some suppliers offer flexible arrangements for repeat orders or larger volumes. Negotiating payment terms and lead times early in the sourcing process can help align production schedules with your market demands.

4. What certifications and quality assurance measures should I look for when importing ballet shoes?

Essential certifications include ISO quality management standards, social compliance certifications (e.g., SA8000, BSCI), and safety standards relevant to footwear, such as EN or ASTM standards. Quality assurance measures should involve pre-shipment inspections, third-party testing for durability, colorfastness, and materials safety, as well as detailed product documentation. Suppliers should provide test reports, factory audit reports, and compliance certificates. Ensuring adherence to these standards mitigates risks related to product recalls, customs issues, and brand reputation, especially when sourcing from regions with varying manufacturing regulations.

Illustrative Image (Source: Google Search)

5. How do I manage logistics and customs procedures when importing ballet shoes from overseas suppliers?

Begin by selecting suppliers experienced in international freight and familiar with your import country’s customs regulations. Work with reputable freight forwarders who can handle shipping, customs clearance, and delivery logistics efficiently. Ensure all documentation—commercial invoices, packing lists, certificates of origin, and compliance certificates—is accurate and complete to avoid delays. Understand import duties, VAT, and tariffs applicable in your country (e.g., Turkey, Poland, or African nations). Establish clear delivery timelines and contingency plans for customs holds or delays, and consider incoterms like FOB or CIF to clarify responsibilities and costs.

6. What should I include in a supplier agreement to prevent disputes over product quality, delivery, or payment?

A comprehensive agreement should specify product specifications, quality standards, and inspection procedures. Include clear terms on MOQs, lead times, and penalties for late delivery or non-conforming products. Payment terms, including currency, method, and schedule, must be explicitly detailed. Incorporate clauses on intellectual property rights, confidentiality, and dispute resolution mechanisms—preferably arbitration or local courts familiar with international trade. Defining responsibilities for customs clearance and logistics helps prevent misunderstandings. Regular communication and documentation throughout the process foster transparency and reduce potential conflicts.

7. How can I ensure compliance with social and environmental standards in my ballet shoe supply chain?

Partner with suppliers that demonstrate compliance with internationally recognized standards such as SA8000, BSCI, or WRAP. Request detailed social audits, factory certifications, and sustainability reports. Incorporate clauses in contracts requiring ongoing compliance and periodic audits. Collaborate with third-party inspection agencies for on-site assessments before and after order placement. Promoting transparency and encouraging suppliers to improve social and environmental practices can be supported through supplier development programs and clear ethical guidelines, reducing risks of supply chain disruptions and reputational damage.

8. What are common dispute resolution methods in international ballet shoe trade, and how can I protect my interests?

Disputes often arise from quality issues, delayed shipments, or payment disagreements. Preferred resolution methods include negotiation, mediation, or arbitration, with arbitration being the most common in international trade due to enforceability. Specify dispute resolution clauses in your contracts, including the choice of jurisdiction and arbitration institutions (e.g., ICC or local arbitration bodies). Using a legal advisor familiar with international trade laws can help craft enforceable agreements. Maintaining detailed records, clear communication, and adhering to contractual terms are vital for protecting your interests and resolving disputes efficiently.

Strategic Sourcing Conclusion and Outlook for ballet shoes

Strategic Sourcing Conclusion and Outlook for ballet shoes

Effective strategic sourcing remains vital for international B2B buyers aiming to deliver high-quality ballet shoes that meet both performance standards and market expectations. Prioritizing reliable supplier relationships, ensuring compliance with social and environmental standards, and leveraging global material sourcing can significantly optimize cost-efficiency and product consistency. Given the complexity of materials and craftsmanship involved, a well-structured supply chain approach reduces risks and enhances competitiveness.

Looking ahead, emerging markets in Africa, South America, and regions like Turkey and Poland present promising opportunities for diversified sourcing. These areas offer a combination of cost advantages, skilled craftsmanship, and increasing manufacturing capabilities. To capitalize on these trends, buyers should foster long-term partnerships, invest in supplier development, and stay informed on evolving compliance standards and material innovations.

Illustrative Image (Source: Google Search)

For international buyers, a proactive, strategic approach to sourcing will be essential in maintaining supply chain resilience and meeting the rising demand for premium ballet footwear. Embracing a forward-looking, flexible sourcing strategy will enable you to stay ahead in a competitive global market and deliver excellence on stage and beyond.