Your Ultimate Guide to Sourcing Shoes Newspaper

Guide to Shoes Newspaper

- Introduction: Navigating the Global Market for shoes newspaper

- Understanding shoes newspaper Types and Variations

- Key Industrial Applications of shoes newspaper

- Strategic Material Selection Guide for shoes newspaper

- In-depth Look: Manufacturing Processes and Quality Assurance for shoes newspaper

- Comprehensive Cost and Pricing Analysis for shoes newspaper Sourcing

- Spotlight on Potential shoes newspaper Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for shoes newspaper

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the shoes newspaper Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of shoes newspaper

- Strategic Sourcing Conclusion and Outlook for shoes newspaper

Introduction: Navigating the Global Market for shoes newspaper

In the dynamic landscape of global footwear trade, the role of a comprehensive and reliable source like shoes newspaper cannot be overstated. For B2B buyers across Africa, South America, the Middle East, and Europe, understanding market trends, supplier networks, and product innovations is vital to maintaining a competitive edge. Shoes newspaper serves as an essential industry intelligence platform, offering up-to-date insights that enable informed sourcing decisions and strategic planning.

This guide provides a detailed exploration of the shoes industry, covering key areas such as product types, materials, manufacturing processes, quality control standards, and supplier evaluations. It also delves into cost considerations, market dynamics, and frequently asked questions to address common buyer concerns. By equipping you with actionable insights, this resource empowers international buyers to navigate complex supply chains, identify trustworthy partners, and optimize procurement strategies.

Whether sourcing for retail, wholesale, or OEM production, understanding the nuances of the global shoes market is crucial. This guide aims to enhance your knowledge base, mitigate risks, and unlock new opportunities for growth. As markets evolve rapidly, staying informed through authoritative sources like shoes newspaper ensures your sourcing decisions are grounded in the latest industry intelligence, helping you succeed in a highly competitive global environment.

Understanding shoes newspaper Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Shoes Newspaper | Basic, single-layered paper with minimal coatings | General distribution, retail displays | Cost-effective and widely available; limited durability and print quality |

| Laminated Shoes Newspaper | Coated with plastic or polymer layers for moisture resistance | Outdoor advertising, high-traffic areas | Durable and weather-resistant; higher cost and more complex printing process |

| Recycled Shoes Newspaper | Made from recycled paper fibers, often with eco-friendly inks | Eco-conscious branding, sustainability campaigns | Environmentally appealing; variable print quality and strength |

| Glossy Shoes Newspaper | Coated with gloss finish, high visual impact | Premium branding, high-end promotions | Attractive visuals and sharp images; more expensive and prone to glare |

| Digital-Printed Shoes Newspaper | Customizable with digital printing technology | Targeted marketing, limited editions | High customization and quick turnaround; higher per-unit cost |

Characteristics and Suitability of Shoes Newspaper Types

Standard Shoes Newspaper: This traditional format is characterized by its simple, uncoated paper construction. It is highly cost-effective, making it suitable for mass distribution in retail outlets or promotional giveaways. Its primary advantage is affordability, but it offers limited durability and print fidelity, which can be a drawback for brands seeking high-quality visuals. B2B buyers should consider volume discounts and the environmental impact when choosing this type.

Laminated Shoes Newspaper: Featuring a plastic or polymer coating, this variation offers enhanced moisture and tear resistance. It’s ideal for outdoor use or in environments with high humidity, such as markets in tropical regions or open-air events. However, the added durability comes with increased production costs and complexity. For B2B buyers, it’s essential to balance the need for durability against budget constraints, especially in large-scale campaigns.

Recycled Shoes Newspaper: Manufactured from recycled fibers, this type appeals to eco-conscious markets and brands promoting sustainability. It often uses eco-friendly inks and processes, aligning with corporate social responsibility goals. The trade-off is that recycled paper can sometimes compromise print quality and strength, requiring careful supplier selection. B2B buyers should verify supplier certifications and test samples before large orders to ensure quality standards.

Glossy Shoes Newspaper: Coated with a glossy finish, this newspaper provides vibrant, sharp images that enhance visual appeal. It’s suitable for premium branding, product launches, or high-end promotional events. The glossy surface, however, increases production costs and can cause glare under certain lighting conditions, which might affect readability. For luxury brands or high-impact campaigns, this type offers a compelling visual advantage.

Digital-Printed Shoes Newspaper: Utilizing advanced digital printing technology, this variation allows for high levels of customization, including limited editions or targeted messaging. It supports shorter runs and rapid turnaround times, making it attractive for time-sensitive campaigns. The per-unit cost is higher compared to traditional printing, so B2B buyers should evaluate the volume and frequency of campaigns to maximize ROI. It’s particularly effective for personalized marketing or regional promotions.

In summary, B2B buyers should align their choice of shoes newspaper type with campaign goals, environmental considerations, and logistical needs. Cost, durability, visual impact, and customization capabilities are key factors influencing procurement decisions across diverse markets in Africa, South America, the Middle East, and Europe. Selecting the appropriate variation can significantly enhance brand visibility and campaign effectiveness in targeted regions.

Key Industrial Applications of shoes newspaper

| Industry/Sector | Specific Application of shoes newspaper | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Civil Engineering | Temporary safety barriers and signage coverage | Enhances visibility and safety compliance, reduces risk of accidents | Durability under harsh conditions, weather resistance, ease of installation |

| Manufacturing & Warehousing | Protective flooring overlays and conveyor covers | Protects surfaces, reduces wear and tear, and minimizes downtime | High tensile strength, chemical resistance, ease of cleaning |

| Transportation & Logistics | Packaging and wrapping for fragile goods | Provides cushioning, prevents damage during transit | Flexibility, tear resistance, compatibility with packaging machinery |

| Agriculture & Food Processing | Coverings for machinery and storage areas | Maintains cleanliness, prevents contamination, shields equipment from dust | Food-grade materials, chemical resistance, ease of handling |

| Oil & Gas / Petrochemical | Insulation covers for pipes and valves | Ensures thermal insulation, protects against corrosion and environmental factors | Heat resistance, chemical stability, compatibility with existing infrastructure |

Construction & Civil Engineering

In construction environments, shoes newspaper is used as temporary safety barriers, signage coverage, or protective sheeting on-site. Its flexibility and durability make it ideal for quick setup and removal, providing a cost-effective solution for site safety and visibility. International buyers from Africa and the Middle East, where construction projects often face variable weather conditions, should prioritize sourcing products with high weather resistance and UV stability. For European and South American markets, durability and compliance with safety standards are key, ensuring the material withstands prolonged exposure without degradation.

Manufacturing & Warehousing

Within manufacturing plants and warehouses, shoes newspaper functions as protective overlays for floors or conveyor belts. It helps prevent surface damage, reduces maintenance costs, and minimizes operational downtime. For B2B buyers across Europe, Australia, and South America, sourcing options should emphasize tensile strength and chemical resistance, especially in environments with exposure to oils, solvents, or cleaning agents. African and Middle Eastern buyers benefit from products that are easy to handle and install, reducing labor costs and ensuring swift deployment in busy industrial settings.

Transportation & Logistics

In logistics, shoes newspaper is often used as packaging material for fragile or sensitive goods. Its cushioning properties help absorb shocks during transit, preventing product damage and reducing return rates. International B2B buyers should focus on sourcing flexible, tear-resistant materials that are compatible with automated packaging systems. For regions with high transportation volumes like South Africa or South America, reliable supply chains and consistent quality are crucial to maintain packaging efficiency and protect brand reputation.

Agriculture & Food Processing

In agricultural and food processing sectors, shoes newspaper is used as coverings for machinery, storage areas, or transport containers. It maintains hygiene standards by shielding equipment from dust, moisture, and contaminants. Buyers from regions like the Middle East or Africa must prioritize food-grade, chemical-resistant options that meet safety regulations. European and South American buyers should look for environmentally friendly and biodegradable variants to align with sustainability goals and regulatory compliance.

Oil & Gas / Petrochemical

In the oil and gas industry, shoes newspaper is utilized for insulation covers on pipes, valves, and equipment. It provides thermal insulation, protects against corrosion, and withstands harsh environmental conditions. Sourcing considerations include heat resistance, chemical stability, and compatibility with existing infrastructure to ensure long-term performance. Buyers in the Middle East or Africa, where extreme temperatures are common, should focus on products designed for high thermal endurance, while European buyers may seek materials with proven corrosion resistance and compliance with industry standards.

Strategic Material Selection Guide for shoes newspaper

Analysis of Common Materials for Shoes Newspaper

Selecting the appropriate materials for shoes newspaper production requires a thorough understanding of their physical properties, manufacturing implications, and suitability for various applications. For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, considerations extend beyond technical specifications to include compliance with regional standards, cost-effectiveness, and supply chain reliability.

Paper-based Materials (Standard Newsprint & Specialty Papers)

Key Properties:

Traditional shoes newspapers are predominantly made from recycled or virgin paper, such as newsprint or specialty coated papers. These materials are lightweight, easily printable, and flexible. They typically have a smooth surface for high-quality image reproduction and moderate tear resistance.

Pros & Cons:

Advantages include low cost, ease of printing, and recyclability. However, they often lack durability under moisture or heavy handling, which can limit their lifespan in certain applications. Manufacturing is straightforward, making them accessible globally, but they may require lamination or coating for enhanced water resistance.

Impact on Application:

Paper-based media are suitable for short-term advertising or informational inserts within shoes packaging. They are compatible with most printing technologies, including offset and digital printing.

International Considerations:

Buyers must verify compliance with regional environmental standards, such as FSC or PEFC certifications, especially in Europe and Australia. Additionally, moisture resistance treatments might be necessary in humid climates prevalent in South America and parts of Africa.

Polypropylene (PP) Films

Key Properties:

Polypropylene films are semi-rigid, clear, and resistant to moisture, chemicals, and tearing. They offer excellent dimensional stability and can be produced in various thicknesses, from thin films to thicker overlays.

Pros & Cons:

PP films provide superior durability compared to paper, making them ideal for long-term or high-exposure applications. They are relatively cost-effective and easy to process with heat sealing or adhesive bonding. However, their manufacturing involves plastic processing equipment, which may increase initial setup costs.

Impact on Application:

Suitable for waterproof overlays, protective covers, or inserts that require durability and moisture resistance. They also support holographic or metallic finishes, enhancing visual appeal.

International Considerations:

Regulatory compliance regarding plastic use varies; some regions enforce strict regulations on plastic waste (e.g., EU’s plastic directive). Buyers should consider recyclable PP options and ensure compatibility with regional waste management practices. Certification standards such as ASTM D6400 for compostability or ISO 17088 should be checked.

Vinyl (PVC) Materials

Key Properties:

Vinyl, or PVC, is a versatile plastic with high durability, chemical resistance, and flexibility. It can be formulated as rigid or flexible, depending on the application, and can be printed or embossed.

Pros & Cons:

PVC offers excellent longevity and resistance to environmental factors, making it suitable for outdoor or high-traffic applications. It is relatively inexpensive and widely available. Conversely, PVC production involves chlorine, raising environmental concerns, and some regions impose restrictions on its use due to health and sustainability issues.

Impact on Application:

Ideal for long-lasting signage, overlays, or inserts that need to withstand harsh conditions. It supports various finishing options, including embossing, lamination, and printing.

International Considerations:

Buyers from regions with strict environmental standards (e.g., Europe, Middle East) should evaluate regulations on PVC use and disposal. Certifications such as RoHS or REACH compliance are critical. Additionally, sourcing from suppliers with environmentally responsible manufacturing processes is advisable.

Summary Table

| Material | Typical Use Case for shoes newspaper | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Paper-based materials (newsprint, specialty papers) | Short-term advertising inserts, informational media | Low cost, easy to print, recyclable | Limited durability, moisture sensitivity | Low |

| Polypropylene (PP) films | Waterproof overlays, protective covers | Moisture resistant, durable, cost-effective | Environmental concerns, requires plastic processing | Med |

| Vinyl (PVC) | Long-lasting signage, outdoor inserts | High durability, chemical resistance | Environmental impact, regulatory restrictions | Med |

| Metal (e.g., Aluminum foil) | Specialty inserts, decorative elements | Excellent durability, premium appearance | Higher cost, complex manufacturing | High |

Final Insights for International B2B Buyers

When selecting materials for shoes newspaper production, buyers should balance cost, durability, environmental impact, and regional standards. In regions like Europe and Australia, sustainability certifications and recyclability are critical. In Africa, South America, and the Middle East, considerations include climate resilience—particularly moisture and heat resistance—and supply chain reliability. Establishing partnerships with suppliers who adhere to regional standards and can provide documentation for compliance will facilitate smoother international trade and ensure product acceptance across markets.

In-depth Look: Manufacturing Processes and Quality Assurance for shoes newspaper

Manufacturing Processes for Shoes

The manufacturing of shoes involves a series of complex, highly coordinated stages designed to ensure durability, comfort, and aesthetic appeal. For B2B buyers, understanding these stages helps in assessing supplier capabilities and ensuring product quality.

1. Material Preparation:

This initial phase involves sourcing and preparing raw materials such as leather, synthetic fabrics, rubber, foam, and adhesives. Suppliers often customize material blends based on shoe type—sports, formal, casual—and target markets. Key considerations include material consistency, source traceability, and compliance with regional standards (e.g., REACH in Europe).

2. Forming and Cutting:

Materials are cut into patterns using manual or automated cutting tables. Advanced manufacturers utilize computer-aided design (CAD) and computer-aided manufacturing (CAM) systems for precision. For high-volume production, automated cutting reduces waste and variability, ensuring consistent sizing and pattern accuracy.

3. Assembly and Construction:

This stage involves stitching, bonding, and assembling components. Techniques vary from traditional hand-stitching to modern automated sewing and adhesive bonding, depending on the shoe type and quality requirements. Key processes include lasting (attaching the upper to the sole), heel attachment, and reinforcement. Precision in assembly impacts fit, comfort, and longevity.

4. Finishing:

Final steps include trimming excess materials, polishing, adding decorative elements, and applying protective coatings or waterproofing agents. Quality finishing enhances visual appeal and product durability. Some manufacturers incorporate eco-friendly finishing techniques, appealing to environmentally conscious markets.

Quality Control (QC) in Shoe Manufacturing

Ensuring consistent quality in shoe production demands rigorous QC protocols aligned with international standards and industry-specific certifications.

1. International Standards Compliance:

– ISO 9001: Most reputable manufacturers adhere to ISO 9001 standards for quality management systems, emphasizing process consistency and continuous improvement.

– ISO 14001: Environmental management standards are increasingly relevant, especially for suppliers targeting European and Australian markets.

2. Industry-Specific Certifications:

– CE Marking (Europe): Indicates compliance with EU safety, health, and environmental requirements.

– API (American Petroleum Institute): Relevant for manufacturers producing components like soles from rubber compounds that meet specific safety standards.

3. QC Checkpoints and Techniques:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival for defects, weight, and compliance with specifications.

– In-Process Quality Control (IPQC): Continuous monitoring during manufacturing—sewing tension, bonding strength, dimensional accuracy.

– Final Quality Control (FQC): Comprehensive inspection of finished shoes, including visual checks, measurement verification, and functional testing.

4. Testing Methods:

– Visual Inspection: Checking for defects, color consistency, and finishing quality.

– Dimensional Testing: Ensuring size accuracy and uniformity across batches.

– Durability Tests: Wear, flex, and abrasion testing simulate long-term use.

– Comfort and Fit Tests: Assessments involving pressure mapping and ergonomic evaluation.

– Environmental Testing: Resistance to water, UV exposure, and temperature variations, especially for outdoor or specialized footwear.

Verifying Supplier QC for International Buyers

For B2B buyers, especially from Africa, South America, the Middle East, and Europe, verifying a supplier’s QC practices is crucial to mitigate risks and ensure product compliance.

1. Factory Audits:

Engage third-party inspection agencies (e.g., SGS, Bureau Veritas) to conduct comprehensive audits covering production facilities, quality systems, and worker conditions. Audits should evaluate adherence to ISO standards, safety protocols, and environmental practices.

2. Inspection Reports and Documentation:

Request detailed QC reports, test certificates, and batch sampling results. Suppliers should provide traceability documentation, including raw material certificates and process control records.

3. Third-Party Testing:

Utilize independent laboratories for product testing, especially for certifications like CE, ASTM, or specific regional standards. This is particularly important for buyers concerned about imports into strict regulatory environments.

4. Ongoing Monitoring:

Establish continuous quality monitoring through periodic audits, pre-shipment inspections, and sample testing. Digital platforms and real-time reporting tools can facilitate ongoing oversight.

Considerations for International B2B Buyers

Regional Standards and Market Expectations:

European buyers often prioritize ISO 9001, CE compliance, and eco-labels such as OEKO-TEX. South American and African markets may have less stringent standards but increasingly demand certifications like ISO 9001 or local standards. Middle Eastern buyers often require compliance with Gulf Standards (GSO) and specific safety certifications.

Cultural and Market-Specific Quality Expectations:

Manufacturers must adapt to regional preferences, such as aesthetic styles, sizing standards, and durability expectations. B2B buyers should specify these requirements clearly and verify supplier adherence through samples and audits.

Supply Chain Transparency and Ethical Practices:

Buyers are increasingly scrutinizing supply chain transparency, especially regarding labor conditions and environmental impact. Suppliers with transparent, certified practices (e.g., Fair Trade, Leather Working Group) can offer a competitive edge.

Final Recommendations for B2B Buyers:

– Conduct comprehensive supplier assessments before engagement.

– Specify detailed quality requirements and testing protocols in contracts.

– Leverage third-party inspection agencies for impartial verification.

– Request and review certification documents regularly.

– Foster long-term relationships with suppliers committed to continuous improvement and compliance.

By understanding and rigorously evaluating manufacturing and QC processes, international B2B buyers from diverse regions can ensure they source high-quality shoes that meet regional standards, reduce risks, and enhance their market reputation.

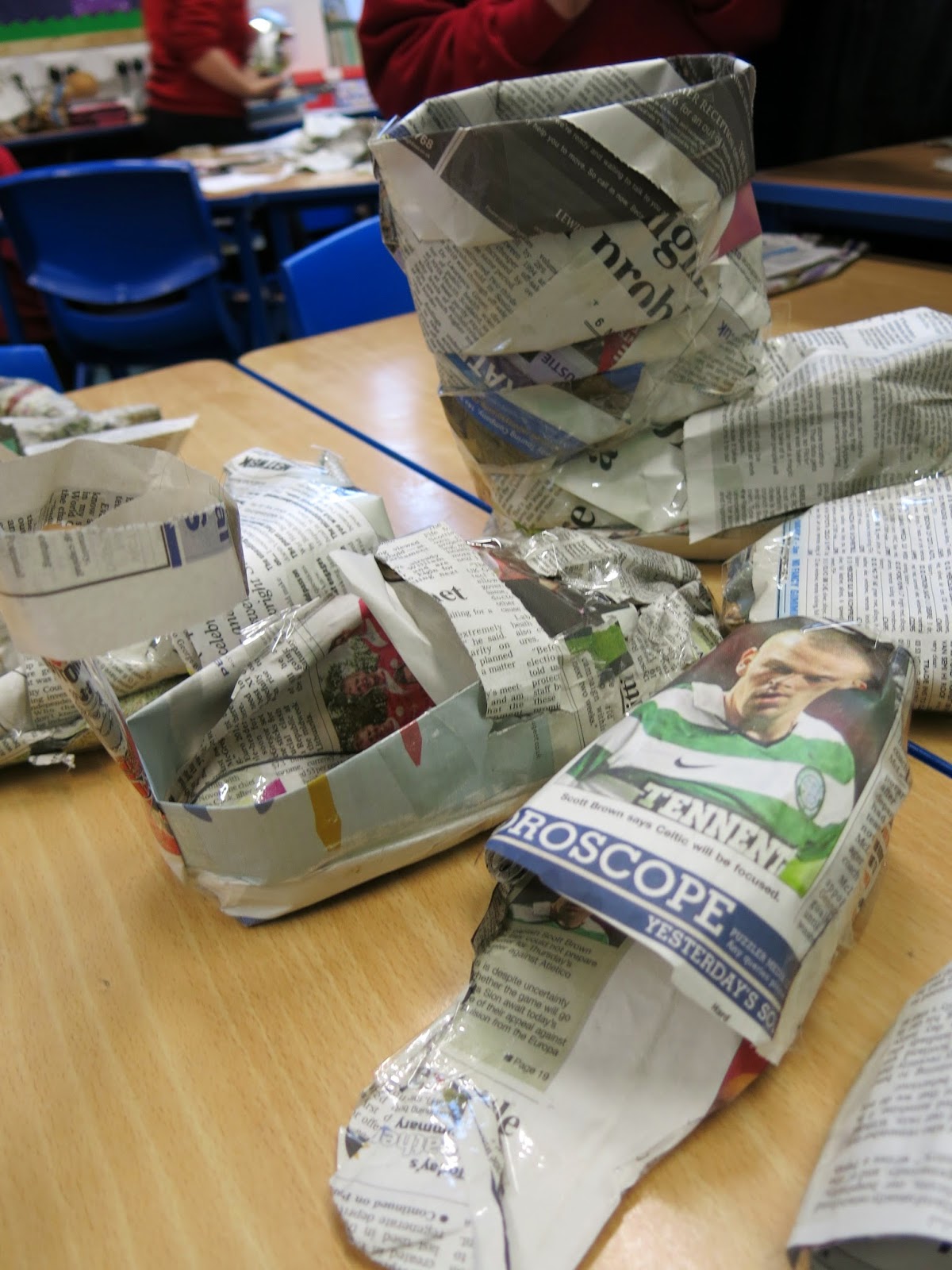

Illustrative Image (Source: Google Search)

Comprehensive Cost and Pricing Analysis for shoes newspaper Sourcing

Understanding Cost Components in Shoes Newspaper Sourcing

A thorough grasp of the cost structure is essential for international buyers aiming to optimize their sourcing strategies. The primary cost components include:

-

Materials: The core of shoes newspaper production involves paper quality, ink, and binding materials. Premium papers or specialized inks for durability and print clarity can significantly elevate costs, especially if sourcing eco-friendly or recycled materials.

-

Labor: Manufacturing labor costs vary widely depending on the country of production. Countries like China and India tend to offer lower labor rates, while European or North American manufacturers may charge premium rates due to higher wages and stringent labor standards.

-

Manufacturing Overhead: This encompasses factory utilities, machinery maintenance, and administrative expenses. Overhead costs tend to be higher in developed regions with stricter environmental and safety regulations.

-

Tooling and Setup: Initial setup costs include mold creation, printing plates, and other tooling. These are often fixed costs amortized over the order volume, making larger volumes more cost-effective.

-

Quality Control (QC): Ensuring print quality, paper integrity, and adherence to specifications adds to the overall cost, especially when seeking certifications such as FSC, PEFC, or ISO standards.

-

Logistics: Shipping expenses are influenced by destination, weight, volume, and chosen Incoterms. International freight costs can fluctuate due to fuel prices, carrier availability, and geopolitical factors.

-

Profit Margin: Suppliers embed a margin to ensure profitability, which varies based on market competition, order volume, and relationship dynamics.

Price Influencers for Shoes Newspaper Procurement

Several factors can sway the final pricing beyond basic costs:

-

Order Volume and Minimum Order Quantities (MOQs): Larger orders typically reduce per-unit costs due to economies of scale. Buyers should negotiate for favorable MOQs that align with their market needs without overcommitting.

-

Specifications and Customization: Custom designs, specific paper qualities, or unique formats increase costs. Standardized products tend to be more economical but may limit branding opportunities.

-

Materials and Certifications: Eco-friendly or recycled materials, along with certifications like FSC or PEFC, often come at a premium. These are increasingly valued in markets with sustainability mandates, such as Europe.

-

Quality and Certifications: Higher quality standards, including print durability and paper longevity, can influence cost. Certification costs may also be passed down, especially if suppliers need to meet international standards.

-

Supplier Factors: Supplier reputation, reliability, and proximity influence pricing. Established suppliers with extensive quality assurance processes may charge higher but offer better consistency.

-

Incoterms and Logistics: The choice of Incoterms (e.g., FOB, CIF, DDP) impacts logistics costs and responsibilities. Buyers should evaluate these terms carefully to optimize total landed costs.

Strategic Tips for International Buyers

-

Negotiate Effectively: Leverage volume commitments and long-term relationships to negotiate better pricing and favorable terms. Clarify cost components upfront to identify potential savings.

-

Focus on Total Cost of Ownership (TCO): Beyond unit price, consider logistics, customs duties, taxes, and lead times. An apparent low-cost supplier might incur higher TCO due to freight or compliance costs.

-

Understand Pricing Nuances: Be aware that pricing structures can vary based on currency fluctuations, import tariffs, and regional market conditions. Request detailed quotes breaking down all cost elements.

-

Leverage Local Sourcing Opportunities: In regions like Africa or South America, local suppliers may offer more competitive rates due to lower transportation costs and regional incentives.

-

Plan for Certification and Quality Standards: Investing in suppliers with recognized certifications can mitigate risks, reduce rework, and appeal to quality-conscious markets like Europe and Australia.

Disclaimer on Price Estimates

Indicative prices for shoes newspapers can vary significantly based on specifications, order size, and supplier location. As a rough guide, costs might range from $0.50 to $2.00 per unit for standard quantities in Asia, with European or North American options potentially higher. Always request customized quotes and conduct due diligence to confirm current market rates.

By understanding these cost structures and influencing factors, international B2B buyers from Africa, South America, the Middle East, and Europe can make informed decisions, optimize procurement strategies, and foster mutually beneficial supplier relationships.

Spotlight on Potential shoes newspaper Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for shoes newspaper.)*

Essential Technical Properties and Trade Terminology for shoes newspaper

Critical Technical Properties for Shoes Newspaper

1. Material Grade and Composition

The quality of raw materials used in shoes newspaper production—such as paper type, ink, and binding adhesives—directly impacts durability, print clarity, and environmental compliance. Higher-grade materials typically ensure better print resolution and longer shelf life, which are vital for brand reputation. B2B buyers should specify preferred grades (e.g., FSC-certified paper) to align with sustainability goals and quality standards.

2. Thickness (GSM – Grams per Square Meter)

GSM indicates the paper’s weight and thickness, affecting the newspaper’s rigidity and durability. For shoes newspaper, a typical GSM range is 70-120, balancing print quality with handling ease. Thicker paper (higher GSM) offers better tear resistance and premium feel, while lower GSM reduces costs. Precise GSM specifications help ensure consistency across production batches.

3. Tolerance and Dimensional Accuracy

Tolerance refers to acceptable deviations in size and weight during manufacturing. Tight tolerances are critical to ensure that the newspaper fits standard shoe boxes and packaging lines without issues. Suppliers must meet agreed tolerances (e.g., ±0.5mm) to avoid costly reworks or delays in the supply chain.

4. Print Compatibility and Ink Absorption

The paper must be compatible with various printing inks, especially high-resolution digital or offset printing. Proper ink absorption ensures sharp images and text, which enhance branding and product information clarity. B2B buyers should verify that suppliers use papers with proven print performance for their specific design needs.

5. Environmental and Safety Certifications

Certifications such as FSC, PEFC, or ISO 14001 indicate environmentally sustainable sourcing and manufacturing practices. These are increasingly important in global markets, especially for buyers in Europe and Australia with strict eco-regulations. Choosing certified materials can also facilitate compliance with import standards.

6. Moisture Resistance and Storage Stability

Shoes newspaper often faces varying storage conditions. Materials with moisture resistance properties prevent warping or mold growth, maintaining print quality over time. B2B buyers should specify moisture resistance levels based on logistics and storage environments to ensure product integrity.

Essential Industry and Trade Terms

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce shoes or components based on a buyer’s specifications and branding. When sourcing shoes newspaper, understanding OEM relationships helps clarify whether the supplier can customize print designs or adapt to specific branding requirements, which is essential for differentiated packaging.

2. MOQ (Minimum Order Quantity)

The smallest quantity of shoes newspaper a supplier agrees to produce per order. MOQs influence purchasing strategies, especially for buyers with limited initial demand or testing needs. Negotiating flexible MOQs can reduce financial risk and improve supply chain agility.

3. RFQ (Request for Quotation)

A formal document sent by buyers to suppliers requesting price, lead times, and terms for a specific order. An RFQ helps compare multiple suppliers and ensures transparency. B2B buyers should prepare detailed RFQs, including technical specifications and quantities, to obtain accurate and competitive quotes.

4. Incoterms (International Commercial Terms)

Standardized trade terms published by the ICC that define responsibilities for shipping, insurance, and tariffs. Common Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) clarify cost-sharing and risk points during transit. Understanding Incoterms ensures clear contractual obligations and helps manage logistics costs effectively.

5. Lead Time

The period between order confirmation and delivery. For shoes newspaper, lead times can vary based on material availability and production capacity. Accurate understanding of lead times allows buyers to plan inventory and avoid stockouts, especially in seasonal markets.

6. Quality Assurance (QA) and Inspection

Processes and standards applied during production to ensure the product meets specified criteria. B2B buyers should establish QA protocols and specify inspection stages to prevent defects, ensuring the shoes newspaper maintains consistent quality and supports brand integrity.

This comprehensive grasp of technical properties and trade terminology equips international buyers with the knowledge to optimize sourcing strategies, negotiate effectively, and ensure seamless supply chain operations across diverse markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the shoes newspaper Sector

Market Overview & Key Trends

The global shoes newspaper sector operates within a dynamic landscape influenced by technological advancements, shifting consumer preferences, and evolving supply chain complexities. For international B2B buyers from regions like Africa, South America, the Middle East, and Europe, understanding these drivers is crucial for strategic sourcing and market positioning.

Emerging trends include the integration of digital printing technologies, which enhance customization capabilities and reduce waste, aligning with sustainability goals. Additionally, automation and Industry 4.0 practices are streamlining production, improving quality control, and lowering costs—beneficial for buyers seeking reliable and scalable supply options.

Market dynamics are increasingly shaped by geopolitical factors, trade agreements, and tariffs, which can impact sourcing costs and lead times. Buyers from emerging markets such as Africa and South America should leverage regional trade blocs and local partnerships to mitigate risks and access competitive pricing. Meanwhile, European and Middle Eastern buyers often focus on premium quality and innovative designs, driven by sophisticated consumer markets.

Sourcing trends are also shifting towards diversified supply chains. Many buyers are exploring alternative sourcing regions to reduce dependency on traditional hubs like Asia, thus enhancing supply chain resilience. The adoption of digital platforms for real-time order tracking and supplier communication is now commonplace, enabling more agile procurement processes.

In this landscape, sustainability is becoming a key differentiator. Buyers are increasingly demanding transparency and traceability, prompting suppliers to adopt more responsible practices. Emphasizing agility, technological adoption, and regional collaboration will be critical for navigating the evolving market landscape effectively.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a central concern in the shoes newspaper sector, driven by environmental impacts and consumer demand for ethically produced products. The sourcing of raw materials, such as recycled paper and eco-friendly inks, directly influences the environmental footprint of shoes newspapers, which are often used for promotional and informational purposes within the footwear industry.

For B2B buyers, prioritizing suppliers committed to sustainable practices is essential. This includes verifying certifications such as FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification), which ensure responsible forest management. Additionally, suppliers utilizing vegetable-based inks and biodegradable coatings contribute to reducing chemical pollution and waste.

Implementing strict supplier audits and transparency measures can help buyers establish ethical supply chains. This is particularly vital for regions like Africa and South America, where supply chain oversight may be more challenging but equally critical for maintaining brand integrity. Collaborating with suppliers who embrace green certifications and sustainable sourcing standards not only mitigates environmental risks but also aligns with corporate social responsibility (CSR) goals.

Illustrative Image (Source: Google Search)

Furthermore, investing in innovative materials—such as recycled paper or post-consumer waste—can reduce reliance on virgin resources. Green procurement strategies often lead to cost savings over time, as eco-friendly materials and processes become more cost-competitive. For buyers, integrating sustainability criteria into supplier selection and contractual agreements will foster long-term partnerships rooted in ethical practices.

Brief Evolution/History (Optional)

The shoes newspaper sector has evolved from traditional print-based promotional materials to a more sophisticated, digitally integrated medium. Initially, shoe brands relied heavily on paper advertisements and catalogs, but the advent of digital printing and online marketing has transformed the landscape. Today, the sector emphasizes eco-conscious production and innovative designs, reflecting broader industry shifts towards sustainability and customization.

This evolution underscores the importance for B2B buyers to stay informed about technological innovations and market standards. Early adoption of sustainable printing practices and digital solutions can provide a competitive edge, enabling brands to meet consumer expectations and regulatory requirements more effectively. As the sector continues to adapt, collaboration with forward-thinking suppliers will be key to ensuring resilience and sustainability in sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of shoes newspaper

1. How can I effectively vet international suppliers for shoes newspapers to ensure reliability and quality?

To vet suppliers effectively, start with comprehensive due diligence. Check their business licenses, certifications, and references from existing clients. Request samples to evaluate print quality, paper durability, and design accuracy. Use online platforms like Alibaba, Global Sources, or industry-specific directories to review ratings and feedback. Conduct virtual or in-person audits where feasible, and verify their manufacturing capabilities and compliance with international standards such as ISO. Establish clear communication channels to gauge responsiveness and professionalism. A well-vetted supplier reduces risks of delays, quality issues, and counterfeit products, ensuring a smooth procurement process.

2. What are the main customization options available for shoes newspapers, and how do I communicate my requirements effectively?

Customization options typically include size, design layout, color schemes, branding, and content focus (e.g., industry news, market trends). To communicate effectively, prepare detailed specifications, including dimensions, preferred paper quality, and design preferences. Use visual mock-ups or prototypes to clarify your vision. Engage with suppliers who offer design support or in-house graphic services to ensure alignment. Clearly specify deadlines and revision policies upfront. This proactive approach minimizes misunderstandings and ensures the final product meets your branding and informational needs, enhancing your market positioning.

3. What are typical MOQs, lead times, and payment terms for international orders of shoes newspapers?

MOQ (Minimum Order Quantity) varies depending on the supplier but generally ranges from 500 to 5,000 copies for newspapers, with larger runs often offering better unit prices. Lead times typically span 2 to 6 weeks, accounting for printing, quality checks, and logistics. Payment terms commonly include 30% upfront deposit with the balance payable before shipment or upon delivery, especially for new suppliers. Some suppliers may offer letters of credit or bank guarantees for larger orders. Negotiating flexible payment terms and early planning can optimize cash flow and ensure timely delivery, especially for recurring or large-volume orders.

4. What certifications and quality assurance measures should I look for when sourcing shoes newspapers internationally?

Look for suppliers with ISO 9001 certification for quality management systems, ensuring consistent production standards. Additionally, certifications like FSC for paper sourcing or environmental standards demonstrate sustainability commitments. Request quality assurance reports, sample testing results, and third-party inspection reports if available. Establish clear quality benchmarks in your contract, including print clarity, paper durability, and color accuracy. Regular audits and ongoing communication are vital to maintain standards. Suppliers with robust QA processes minimize defects, reduce reprints, and ensure your newspapers uphold your brand reputation.

5. How can I manage logistics effectively when importing shoes newspapers from overseas?

Effective logistics management involves selecting reliable freight forwarders experienced in handling print materials. Consider shipping options—air freight offers faster delivery but at higher costs, ideal for urgent needs, while sea freight is more economical for bulk orders. Work with suppliers who can provide detailed shipping schedules and tracking. Ensure compliance with import regulations and customs documentation specific to your country, including tariffs, duties, and import licenses. Collaborate closely with your logistics partners to optimize packaging for protection and efficiency. Planning ahead and maintaining clear communication reduces delays, damages, and unexpected costs.

6. What steps should I take to resolve disputes with international suppliers regarding quality, delivery, or payment issues?

Begin with clear contractual terms covering quality standards, delivery timelines, and payment conditions. If issues arise, communicate promptly with documented evidence (photos, correspondence). Engage in direct negotiation, aiming for amicable resolution; many disputes are resolved through mediation or arbitration. If unresolved, escalate to international trade dispute mechanisms or seek legal counsel familiar with cross-border trade laws. Maintaining detailed records of all communications and agreements is crucial. Proactive relationship management and transparency foster trust, reducing the likelihood of disputes and facilitating swift resolution when they occur.

7. How can I ensure compliance with local import regulations and standards for shoes newspapers in my country?

Research your country’s import regulations, including tariffs, import licenses, and labeling requirements for printed materials. Consult with customs brokers or trade consultants familiar with your jurisdiction to ensure all documentation (commercial invoices, bill of lading, certificates of origin) is accurate and complete. Verify that the newspapers meet local content or language requirements and adhere to intellectual property laws. Staying updated on regulatory changes through government portals or trade associations helps prevent delays or penalties. Proper compliance not only smooths customs clearance but also enhances your reputation with local authorities and partners.

8. What strategies can I employ to build long-term relationships with reliable international shoes newspaper suppliers?

Focus on consistent communication, timely payments, and constructive feedback to foster trust. Develop mutually beneficial agreements, such as volume discounts or flexible payment terms for repeat orders. Invest in supplier development by sharing market insights and collaborating on new formats or content ideas. Regularly review supplier performance through KPIs related to quality, delivery, and responsiveness, and provide recognition for excellent service. Building personal relationships through virtual visits or industry events can deepen trust. Long-term partnerships reduce sourcing risks, improve pricing stability, and enable collaborative innovation, ultimately strengthening your competitive position in the market.

This comprehensive FAQ aims to empower international B2B buyers from diverse regions with practical, strategic insights into sourcing, managing, and maintaining high-quality shoes newspapers, ensuring successful and sustainable procurement operations.

Strategic Sourcing Conclusion and Outlook for shoes newspaper

Final Insights and Future Directions

Effective strategic sourcing remains a cornerstone for international B2B buyers aiming to capitalize on the global footwear market. By prioritizing supplier diversification, leveraging technological advancements, and fostering sustainable practices, buyers can mitigate risks and enhance competitiveness. Emphasizing quality, innovation, and compliance ensures long-term partnerships that drive growth and resilience.

Illustrative Image (Source: Google Search)

For buyers from Africa, South America, the Middle East, and Europe, adopting a proactive sourcing approach can unlock new opportunities amid evolving market dynamics. Building strong relationships with reliable suppliers, exploring emerging manufacturing hubs, and integrating digital tools for procurement transparency are critical steps forward.

Looking ahead, the footwear industry will continue to be shaped by sustainability demands, technological innovations, and shifting consumer preferences. B2B buyers who stay agile, informed, and strategic will be well-positioned to navigate these changes successfully. Now is the time to invest in robust sourcing strategies that align with your long-term business goals—seizing opportunities for growth in the dynamic global footwear landscape.