Master Global Sourcing of Artificial Turf Baseball Shoes

Guide to Artificial Turf Baseball Shoes

- Introduction: Navigating the Global Market for artificial turf baseball shoes

- Understanding artificial turf baseball shoes Types and Variations

- Key Industrial Applications of artificial turf baseball shoes

- Strategic Material Selection Guide for artificial turf baseball shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for artificial turf baseball shoes

- Comprehensive Cost and Pricing Analysis for artificial turf baseball shoes Sourcing

- Spotlight on Potential artificial turf baseball shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for artificial turf baseball shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the artificial turf baseball shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of artificial turf baseball shoes

- Strategic Sourcing Conclusion and Outlook for artificial turf baseball shoes

Introduction: Navigating the Global Market for artificial turf baseball shoes

In the rapidly evolving landscape of baseball equipment, artificial turf baseball shoes have become a critical component for athletes and teams worldwide. Their importance extends beyond performance, influencing player safety, durability, and overall game strategy. For international B2B buyers, understanding the nuances of this specialized footwear is essential to making informed procurement decisions that align with market demands and quality standards.

This comprehensive guide covers every vital aspect of the artificial turf baseball shoe industry—from the different types and high-performance materials to manufacturing processes and quality assurance protocols. It also explores key suppliers across regions such as Africa, South America, the Middle East, and Europe—including manufacturing hubs like Vietnam and Spain—helping buyers identify reliable partners. Additionally, the guide delves into cost considerations, market trends, and frequently asked questions, equipping buyers with actionable insights to optimize sourcing strategies.

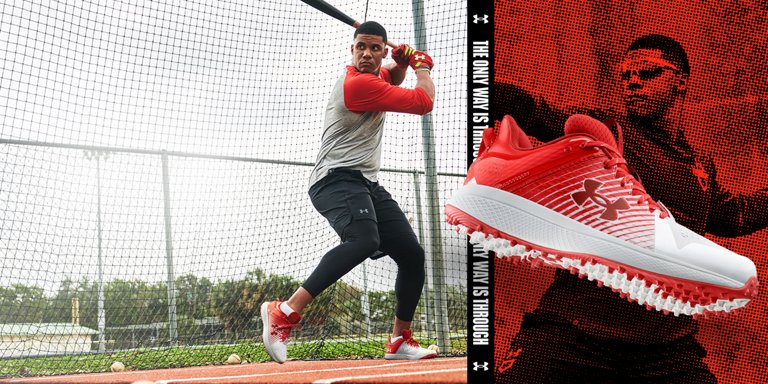

Illustrative Image (Source: Google Search)

By leveraging this resource, international B2B buyers can navigate complex global markets with confidence, ensuring they select products that meet their quality, price, and logistical requirements. Whether sourcing for retail, wholesale distribution, or private labeling, this guide aims to empower buyers with the knowledge necessary to make strategic, value-driven decisions in the competitive world of artificial turf baseball shoes.

Understanding artificial turf baseball shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Firm Ground (FG) Shoes | Multi-directional rubber studs designed for natural grass and turf surfaces | Training facilities, multi-use sports centers | Pros: Versatile, widely available; Cons: Not optimized for artificial turf, may wear quickly |

| Turf Shoes (TR) | Short, rubber cleats or textured soles with minimal stud height | Dedicated artificial turf fields, indoor training | Pros: Enhanced grip on turf, lightweight; Cons: Limited use outside turf environments |

| Hybrid Shoes (HY) | Combination sole with both rubber studs and cleats | Clubs with varied field types, multi-surface venues | Pros: Flexibility across surfaces; Cons: Slightly higher cost, complex manufacturing |

| Indoor/Artificial Shoes (IN) | Flat, non-marking soles with grip-enhancing patterns | Indoor training, multi-purpose sports facilities | Pros: Excellent grip indoors, non-marking; Cons: Not suitable for outdoor use |

| Specialized Turf Cleats (ST) | Low-profile, textured soles with strategically placed cleats for maximum traction | Professional training, high-performance teams | Pros: Superior traction, durability; Cons: Higher price point, less versatile for other surfaces |

Characteristics and Suitability of Major Artificial Turf Baseball Shoe Types

Firm Ground (FG) Shoes

FG shoes are traditionally designed with multi-directional rubber studs suitable for natural grass and hybrid fields. While they are highly durable and widely available, their design makes them less ideal for pure artificial turf, where longer studs can cause uneven traction or wear quickly. B2B buyers should consider procurement costs versus lifespan, especially when supplying clubs or academies that primarily play on turf. Bulk purchasing of FG shoes may benefit organizations seeking versatile footwear but may require replacement or supplementary turf-specific shoes over time.

Turf Shoes (TR)

Designed explicitly for artificial turf, these shoes feature short, rubber cleats or textured soles that provide excellent grip without damaging the surface. They are lightweight, making them suitable for training sessions and casual play. For buyers, the focus should be on sourcing models with durable rubber compounds and non-slip tread patterns to withstand frequent use. They are ideal for clubs and schools looking for cost-effective, high-performance footwear tailored to turf environments, with considerations for size variety and manufacturing lead times.

Hybrid Shoes (HY)

Hybrid shoes combine elements of FG and turf designs, offering flexible traction options for venues with mixed surface types. These shoes are suitable for organizations that require multi-surface functionality, such as sports academies or multi-purpose facilities. B2B buyers should evaluate the manufacturing quality, as hybrids often involve complex sole designs, impacting cost and lead times. Bulk orders should emphasize consistent quality to ensure performance across different environments.

Indoor/Artificial Shoes (IN)

These shoes feature flat, non-marking soles with specialized grip patterns, making them perfect for indoor training facilities or multi-use sports centers. They are less suitable for outdoor artificial turf but excel in controlled environments. For international buyers, especially in regions with climate variability, sourcing high-quality non-marking shoes can reduce surface damage and prolong shoe life. Volume discounts and reliable supply chains are critical considerations to meet demand for indoor sports programs.

Specialized Turf Cleats (ST)

Designed for high-performance play, these shoes have low-profile soles with strategically placed cleats for maximum traction on artificial turf. They are often used by professional or semi-professional teams. For B2B buyers, investing in durable, high-quality models can provide long-term value, especially when catering to elite teams or training academies. However, the higher price point necessitates careful supplier vetting to ensure consistent quality and supply reliability across large orders.

Key Industrial Applications of artificial turf baseball shoes

| Industry/Sector | Specific Application of artificial turf baseball shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports & Recreation | Providing durable footwear for baseball training facilities, youth leagues, and amateur clubs operating on artificial turf fields | Enhances athlete performance, reduces injury risk, and extends shoe lifespan in high-traction environments | Material durability, slip resistance, comfort, and compliance with international sports standards |

| Manufacturing & Wholesale | Supplying artificial turf baseball shoes to sports retailers, gyms, and equipment distributors | Facilitates bulk sales, brand differentiation, and access to emerging markets; supports customization options | Consistent quality, scalable manufacturing, competitive pricing, and reliable logistics |

| Corporate & Event Sponsorship | Custom-branded shoes for sports events, corporate teams, and promotional activities on artificial turf | Increases brand visibility, fosters partnerships, and boosts customer engagement | Customization capabilities, lead times, branding quality, and compliance with event-specific regulations |

| Education & Training | Supplying specialized shoes for sports academies, training centers, and educational institutions | Improves training outcomes, ensures athlete safety, and promotes brand loyalty | Fit and comfort, safety features, availability in various sizes, and adherence to safety standards |

| Infrastructure & Facility Maintenance | Shoes designed for maintenance crews working on artificial turf fields | Provides grip and protection during field upkeep, reducing injury and fatigue | Slip resistance, durability, ergonomic design, and compatibility with work environments |

Sports & Recreation

Artificial turf baseball shoes are crucial in sports and recreational sectors, especially for training facilities, youth leagues, and amateur clubs that operate on synthetic turf surfaces. These shoes are engineered to provide superior grip, stability, and shock absorption, which are vital for safe and effective play. International B2B buyers from regions like Africa, South America, and the Middle East should prioritize sourcing shoes that meet global sports standards, ensuring durability against abrasive turf materials and varying climatic conditions. Reliable supply chains and customizable designs can also differentiate offerings in competitive markets.

Manufacturing & Wholesale

The manufacturing and wholesale sectors benefit from bulk procurement of artificial turf baseball shoes to supply retail outlets, gyms, and sports equipment distributors across emerging and developed markets. These shoes serve as a key product line for brands aiming to establish a foothold in regions with expanding sports infrastructure, such as Spain or Vietnam. Key considerations include consistent quality control, scalable production capacity, and competitive pricing structures. Additionally, suppliers offering customization—such as branding or color options—can better serve diverse client needs, fostering long-term partnerships.

Corporate & Event Sponsorship

Custom-branded artificial turf baseball shoes are highly effective for corporate sponsorships, sporting events, and promotional campaigns. These shoes enhance brand visibility when worn by athletes or event participants on synthetic turf fields. B2B buyers should focus on sourcing suppliers capable of delivering high-quality customization, rapid turnaround times, and adherence to event-specific safety and branding standards. This approach not only boosts brand recognition but also creates memorable engagement opportunities in markets like Europe or the Middle East.

Education & Training

Educational institutions and sports academies require specialized footwear to support training programs on artificial turf. These shoes must combine comfort, safety, and performance, helping athletes develop skills while minimizing injury risks. For international buyers, sourcing shoes with ergonomic design, proper fit, and durability is essential, especially in regions with diverse climatic conditions that influence material performance. Establishing relationships with suppliers offering tailored solutions can ensure consistent supply and foster loyalty among training centers.

Infrastructure & Facility Maintenance

Maintenance crews working on artificial turf fields need durable, slip-resistant shoes to perform their tasks safely and efficiently. These shoes are designed to provide excellent grip, reduce fatigue, and withstand harsh environmental conditions, which are common in outdoor maintenance scenarios. B2B buyers in regions like Africa or South America should look for shoes with high durability, ergonomic comfort, and compatibility with work environments. Reliable sourcing ensures field maintenance is carried out efficiently, minimizing downtime and prolonging turf lifespan.

Strategic Material Selection Guide for artificial turf baseball shoes

Material Analysis for Artificial Turf Baseball Shoes

Selecting the appropriate materials for artificial turf baseball shoes is critical for ensuring product durability, performance, and compliance with international standards. For B2B buyers across Africa, South America, the Middle East, and Europe, understanding the key properties, advantages, and limitations of common materials can facilitate better sourcing decisions and product customization.

Illustrative Image (Source: Google Search)

1. Thermoplastic Polyurethane (TPU)

Key Properties:

TPU is a versatile polymer known for its excellent abrasion resistance, flexibility, and weatherability. It maintains performance across a broad temperature range (-40°C to +80°C) and exhibits high impact absorption, making it suitable for shoe outsoles.

Pros & Cons:

TPU’s advantages include high durability, resistance to cracking and tearing, and ease of manufacturing via injection molding. It also offers good chemical resistance, including to oils and greases. However, TPU can be more expensive than traditional rubber and may require specialized equipment for processing, increasing initial manufacturing costs.

Impact on Application:

TPU’s flexibility and resilience make it ideal for outsole components that endure repeated impacts and friction on artificial turf surfaces. Its chemical resistance ensures longevity even in humid or chemically aggressive environments.

International Considerations:

For buyers in regions like Africa and South America, TPU complies well with ASTM standards for footwear components. European markets often require compliance with REACH regulations, which TPU generally meets. Manufacturers should verify supplier certifications to ensure adherence to local safety and environmental standards.

2. Ethylene Vinyl Acetate (EVA)

Key Properties:

EVA is a lightweight, flexible foam material with excellent shock absorption properties. It performs well in a wide temperature range (-30°C to +70°C) and provides cushioning, which is essential for comfort during play.

Pros & Cons:

EVA is cost-effective, easy to process, and offers good flexibility, making it a popular choice for midsoles and cushioning layers. Its main drawbacks include lower abrasion resistance compared to TPU, leading to faster wear on high-friction surfaces like artificial turf. Additionally, EVA can degrade under prolonged UV exposure unless treated with stabilizers.

Impact on Application:

EVA’s cushioning benefits enhance player comfort, reducing fatigue. However, for outsole applications, EVA’s wear resistance may be insufficient unless combined with tougher materials, which could increase costs.

International Considerations:

EVA materials often meet global standards such as DIN and JIS, making them suitable for export to Europe and Asia. Buyers should specify UV stabilizers and anti-oxidants in contracts to ensure material longevity in sunny climates like the Middle East and parts of Africa.

3. Rubber Compounds (Natural and Synthetic)

Key Properties:

Rubber remains a staple in outsole manufacturing due to its excellent grip, elasticity, and impact resistance. Natural rubber offers superior resilience, while synthetic variants like styrene-butadiene rubber (SBR) provide better aging and weather resistance.

Pros & Cons:

Rubber compounds are highly durable and cost-effective, especially in large-volume production. They excel in providing traction on artificial turf surfaces. However, natural rubber can be susceptible to environmental degradation (ozone, UV), and synthetic rubbers may involve complex manufacturing processes, increasing initial costs.

Impact on Application:

Rubber outsoles are critical for traction and stability, directly affecting player safety and performance. The choice between natural and synthetic rubber depends on environmental exposure and cost considerations.

International Considerations:

Rubber materials are globally standardized, with compliance to ASTM D2000 and DIN standards common. For markets like Europe, eco-labeling and sustainable sourcing (e.g., FSC-certified rubber) may be important. Buyers should verify supplier certifications for environmental compliance.

4. Composite Materials (Fiber Reinforced Polymers)

Key Properties:

Composite materials, such as fiber-reinforced plastics, combine polymers with fibers like fiberglass or carbon fiber to enhance strength-to-weight ratios. They are resistant to corrosion, lightweight, and customizable in terms of stiffness and impact resistance.

Pros & Cons:

These materials provide high structural integrity, ideal for specialized components or reinforcements. However, they involve complex manufacturing processes, leading to higher costs and longer lead times. They are less common for general outsole use but valuable for high-performance or niche applications.

Impact on Application:

Use in critical load-bearing parts can significantly extend product lifespan and performance, especially in demanding environments.

International Considerations:

Compliance with standards like ASTM F3040 or ISO 9001 is essential. Buyers should ensure suppliers adhere to environmental regulations, especially in regions with strict chemical use policies like Europe.

Summary Table

| Material | Typical Use Case for artificial turf baseball shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic Polyurethane (TPU) | Outsole components, impact-resistant parts | High durability, chemical resistance, flexibility | Higher cost, processing complexity | High |

| Ethylene Vinyl Acetate (EVA) | Midsoles, cushioning layers | Lightweight, excellent shock absorption | Lower wear resistance, UV sensitivity | Low |

| Rubber Compounds (Natural/Synthetic) | Outsoles, traction elements | Superior grip, impact resistance | Environmental degradation (natural rubber), manufacturing complexity (synthetic) | Med |

| Composite Materials | Reinforcements, specialized structural parts | High strength-to-weight ratio, corrosion resistance | Costly, complex manufacturing | High |

This detailed understanding of material properties and regional considerations equips international B2B buyers with the insights needed to select optimal materials for artificial turf baseball shoes, balancing performance, cost, and compliance across diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for artificial turf baseball shoes

Manufacturing Processes for Artificial Turf Baseball Shoes

The manufacturing of artificial turf baseball shoes is a complex, multi-stage process that demands precision, consistency, and adherence to international standards. For B2B buyers, understanding these stages helps in evaluating supplier capabilities and ensuring product reliability.

1. Material Preparation and Procurement

The process begins with sourcing high-quality raw materials, including synthetic fibers, rubber soles, foam insoles, and adhesives. Suppliers often select materials based on durability, flexibility, and resistance to wear—key attributes for artificial turf performance. International suppliers typically adhere to standards like ISO 9001 for quality management, ensuring raw materials meet specified criteria. Buyers should verify supplier certifications and request material test reports (e.g., tensile strength, elongation, and chemical safety) during initial qualification.

2. Forming and Component Manufacturing

In this stage, components such as the upper, midsole, and outsole are manufactured separately. Techniques include injection molding for midsoles, thermoforming for the upper, and vulcanization or molding for outsoles. Precision molds and advanced machinery ensure dimensional accuracy and surface finish quality. For artificial turf shoes, particular attention is paid to the outsole design—often featuring specialized cleats or textured patterns—produced via CNC machining or mold injection.

3. Assembly and Integration

The assembled shoe undergoes multiple assembly steps: attaching the upper to the midsole, embedding the outsole, and installing insoles and laces. Automated stitching, adhesive bonding, and ultrasonic welding are common techniques to ensure durability and consistency. For artificial turf shoes, the focus is on securing the outsole firmly to withstand lateral movements on synthetic surfaces. B2B buyers should inquire about the use of eco-friendly adhesives and assembly automation levels, as these impact both quality and sustainability.

4. Finishing and Quality Checks

Final finishing includes trimming excess material, applying branding, and performing surface treatments such as water-resistant coatings. Visual inspections are complemented by functional tests like flexibility, grip, and shock absorption assessments. Advanced manufacturers employ CNC laser marking for branding and RFID tagging for traceability.

Quality Assurance Protocols and Industry Standards

Quality assurance (QA) is integral to manufacturing, especially when catering to international markets with diverse regulatory requirements. B2B buyers must understand the QA frameworks and testing procedures that suppliers employ.

1. International Standards and Certifications

– ISO 9001: Most reputable manufacturers operate under ISO 9001, which emphasizes quality management systems, continuous improvement, and customer satisfaction. Verification involves reviewing certification documents and audit reports.

– CE Marking (Europe): For products sold within the European Union, CE marking indicates compliance with safety, health, and environmental protection standards. Suppliers must conduct conformity assessments, including testing for mechanical safety and chemical emissions.

– API Standards (Middle East and other regions): Some markets require compliance with regional standards like API specifications for materials and safety. Buyers should request documentation demonstrating adherence.

2. QC Checkpoints Throughout Production

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival for conformity to specifications, including physical, chemical, and mechanical properties. Testing methods include tensile testing, chemical composition analysis, and visual inspections.

– In-Process Quality Control (IPQC): During manufacturing, checkpoints monitor dimensional accuracy, bonding strength, and assembly precision. Techniques such as ultrasonic testing and in-line visual inspection ensure defects are caught early.

– Final Quality Control (FQC): Before shipment, products undergo comprehensive inspections—visual, functional, and mechanical testing—to verify durability, comfort, and safety. Standard tests include abrasion resistance, slip resistance, and shock absorption measurements.

3. Testing Methods and Validation

– Mechanical Testing: Assess flexibility, tensile strength, and impact resistance using standardized equipment like universal testing machines.

– Environmental Testing: Simulate exposure to moisture, UV light, and temperature variations to evaluate product resilience.

– Performance Testing: Field tests on artificial turf surfaces assess grip, stability, and wear over simulated playing conditions.

How B2B Buyers Can Verify Supplier Quality

Given the importance of consistent quality, international buyers should adopt rigorous supplier evaluation practices:

- Supplier Audits: Conduct on-site audits focusing on manufacturing facilities, quality management systems, and worker safety. Audits can be performed by internal teams or accredited third-party inspectors familiar with regional manufacturing practices.

- Request Detailed Quality Reports: Require comprehensive QC documentation, including test reports, inspection records, and certification copies. Transparent suppliers will readily provide these documents.

- Third-Party Inspection Services: Engage independent inspection companies (e.g., SGS, Bureau Veritas) for pre-shipment inspections. These inspectors verify product conformity against specifications and standards before shipment.

- Sample Testing and Certification: Obtain samples for independent testing in accredited laboratories, especially when entering new supplier relationships or launching new product lines.

QC and Certification Nuances for Specific Regions

Africa and South America:

Manufacturers may face less stringent enforcement of standards but should still adhere to internationally recognized certifications like ISO 9001. Buyers should prioritize suppliers with traceable quality documentation and consider third-party audits to mitigate risks.

Middle East:

Markets such as the Gulf Cooperation Council (GCC) often require CE marking or regional certifications like SASO. Suppliers must demonstrate compliance through certified testing reports, which buyers should verify via official channels.

Europe (e.g., Spain):

European buyers are highly diligent about CE conformity, chemical safety (REACH compliance), and environmental standards. Buyers should perform or commission detailed audits and insist on comprehensive technical documentation.

Vietnam and Asia-Pacific:

While some manufacturers may claim compliance, buyers should verify through independent testing and ensure supplier certifications are valid and up-to-date. Establishing long-term partnerships with suppliers holding recognized certifications reduces compliance risks.

Final Recommendations for International B2B Buyers

- Develop a clear supplier qualification process emphasizing quality management systems and certifications.

- Incorporate regular audits and inspections into procurement cycles.

- Leverage third-party testing and inspection services, especially for first-time suppliers.

- Maintain detailed documentation for all QC activities to facilitate compliance verification.

- Foster transparent communication channels with suppliers to address quality concerns proactively.

By understanding the manufacturing nuances and implementing rigorous quality assurance measures, international B2B buyers from Africa, South America, the Middle East, and Europe can mitigate risks, ensure product consistency, and build resilient supply chains for artificial turf baseball shoes.

Comprehensive Cost and Pricing Analysis for artificial turf baseball shoes Sourcing

Cost Structure Breakdown for Artificial Turf Baseball Shoes

Understanding the comprehensive cost structure is crucial for international B2B buyers sourcing artificial turf baseball shoes. The primary cost components include:

-

Materials: High-quality synthetic fibers, rubber soles, insoles, and reinforcement materials form the core. Material costs vary based on quality, sourcing region, and specifications. Premium materials for durability and performance command higher prices but can justify premium retail pricing.

-

Labor: Manufacturing labor costs differ significantly across regions. For example, Vietnam and parts of Southeast Asia typically offer lower labor costs compared to Europe or Spain, impacting overall production costs. Quality control and skilled craftsmanship can increase labor expenses but are essential for product consistency.

-

Manufacturing Overheads: These include equipment depreciation, factory utilities, and maintenance. Overheads are often proportional to production volume, emphasizing the importance of order size.

-

Tooling and Development: Initial tooling costs can be substantial but are amortized over large production runs. Custom designs, unique logos, or specific features increase tooling expenses.

-

Quality Control and Certifications: Rigorous QC processes and certifications (e.g., ISO, ASTM) add to costs but are vital for international markets, especially in Europe and the Middle East where compliance standards are strict.

-

Logistics and Shipping: Incoterms, shipping method (air vs. sea), and destination influence costs. Bulk shipping reduces per-unit logistics costs, but buyers must account for customs, tariffs, and duties, which vary by country.

-

Profit Margin: Suppliers typically target margins of 10-30%, depending on market competitiveness, product differentiation, and order volume.

Key Price Influencers in Sourcing Artificial Turf Baseball Shoes

Several factors significantly influence the final pricing:

-

Order Volume and MOQ: Larger orders generally reduce per-unit costs due to economies of scale. Suppliers may impose minimum order quantities, often ranging from 500 to 5,000 pairs, impacting initial investment.

-

Product Specifications and Customization: Higher customization levels—such as bespoke colors, logos, or specific performance features—escalate costs. Standard models are more economical, while customized products command premium prices.

-

Materials Quality: Using advanced synthetic fibers, eco-friendly materials, or specialized soles increases material costs but can be leveraged for premium positioning.

-

Quality Certifications and Standards: Meeting international standards (e.g., CE, ASTM) adds costs but enhances market access, especially in Europe and the Middle East.

-

Supplier Factors: Manufacturer reputation, production capacity, and lead times influence pricing. Established suppliers with reliable quality may charge higher but offer better consistency.

-

Incoterms and Delivery Terms: FOB (Free on Board) prices are common, but buyers should consider additional costs for freight, insurance, and customs clearance.

Strategic Tips for International B2B Buyers

-

Negotiate for Volume Discounts: Leverage larger orders to secure better unit prices. Establish long-term relationships to negotiate favorable terms.

-

Focus on Total Cost of Ownership (TCO): Beyond unit price, consider logistics, customs duties, and potential rework costs. Sometimes, sourcing closer to your market (e.g., Spain from European suppliers) reduces TCO despite higher unit prices.

-

Evaluate Pricing Nuances: Be aware of currency fluctuations, payment terms, and hidden costs such as packaging or compliance testing fees. Clarify all cost components upfront.

-

Request Detailed Quotations: Obtain comprehensive quotes that specify all costs—material, tooling, QC, logistics—to facilitate accurate comparison.

-

Prioritize Quality and Certifications: Cheaper options may save costs initially but could incur penalties or reputational damage if standards are not met.

Indicative Price Range (Disclaimers Applied)

For a baseline, unit prices for standard artificial turf baseball shoes typically range from $10 to $25 per pair at large production volumes. Premium, customized, or certified products can range from $25 to $50 or more per pair. Prices are highly variable based on sourcing region, order size, and specifications.

This analysis aims to equip international buyers from Africa, South America, the Middle East, and Europe with actionable insights. Conduct thorough supplier assessments, negotiate strategically, and consider the full spectrum of costs to optimize sourcing outcomes.

Spotlight on Potential artificial turf baseball shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for artificial turf baseball shoes.)*

Essential Technical Properties and Trade Terminology for artificial turf baseball shoes

Critical Technical Properties for Artificial Turf Baseball Shoes

1. Material Grade and Composition

The quality of materials used in artificial turf baseball shoes significantly impacts durability, performance, and comfort. High-grade synthetic fibers, such as polyethylene or nylon, are preferred for their resilience and lightweight properties. For B2B buyers, understanding the material grade ensures the product meets the expected lifespan and withstands rigorous use, especially in diverse climatic conditions across regions like Africa, South America, the Middle East, and Europe.

2. Traction Pattern and Sole Configuration

The outsole design, including stud or cleat placement and pattern, directly influences grip and stability on artificial turf surfaces. A well-engineered traction pattern minimizes slipping and enhances player performance. When sourcing, verify that the sole configuration aligns with the specific turf type used in your target markets to avoid mismatched grip issues.

3. Tolerance and Precision Manufacturing

Manufacturing tolerance refers to the allowable variation in shoe dimensions, such as width, length, and sole thickness. Tight tolerances ensure consistent quality and fit across batches, reducing returns and dissatisfaction. For international B2B transactions, clear specifications regarding tolerances are vital to maintain product uniformity, especially when scaling production or customizing for different markets.

4. Weight and Flexibility

Lightweight shoes improve player agility and reduce fatigue, critical factors for competitive play. Flexibility in the shoe’s upper and sole enhances comfort and natural movement. B2B buyers should specify weight ranges and flexibility standards to ensure the shoes meet performance expectations across different player profiles.

5. Breathability and Moisture Management

Artificial turf can generate significant heat and moisture. Materials with breathable uppers and moisture-wicking linings prevent overheating and blisters. When evaluating suppliers, prioritize products with proven moisture control features to enhance player comfort and reduce injury risks.

6. Durability and Wear Resistance

Shoes must withstand frequent, intense use without significant degradation. Key indicators include abrasion resistance of the outsole and upper, as well as the resilience of glued or stitched components. For international markets, selecting products with certified durability standards minimizes logistics costs related to replacements or repairs.

Industry and Trade Terminology for Artificial Turf Baseball Shoes

1. OEM (Original Equipment Manufacturer)

Refers to manufacturers producing shoes under a client’s brand name. Understanding OEM capabilities helps B2B buyers assess whether a supplier can customize designs, branding, or specifications to meet regional preferences or branding strategies.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce per order. Knowledge of MOQ assists buyers in planning inventory and negotiating pricing, especially when entering new markets with uncertain demand, such as emerging markets in Africa or the Middle East.

3. RFQ (Request for Quotation)

A formal process where buyers solicit price and technical details from multiple suppliers. Efficient RFQ processes enable comparative analysis of costs, lead times, and quality, ensuring better decision-making in competitive international markets.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and delivery between buyers and sellers. Familiarity with Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, Freight) ensures clarity in logistics costs and risk management across regions such as Europe or South America.

5. Lead Time

The duration from order placement to product delivery. Understanding lead times is crucial for inventory planning, especially in markets with fluctuating demand or logistical challenges, such as remote regions in Africa or the Middle East.

6. Certification Standards

References to safety, quality, or environmental standards (e.g., ISO, CE, or local certifications). Ensuring compliance with regional standards facilitates smoother customs clearance and market acceptance, vital for international B2B transactions.

By mastering these technical properties and trade terms, B2B buyers from diverse regions can make informed decisions, streamline procurement processes, and foster successful supplier relationships in the artificial turf baseball shoes market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the artificial turf baseball shoes Sector

Market Overview & Key Trends

The global market for artificial turf baseball shoes is experiencing robust growth driven by increasing participation in baseball and softball across diverse regions. Emerging markets in Africa, South America, and the Middle East are becoming significant players, often seeking affordable yet durable footwear solutions to support local leagues and youth development programs. Meanwhile, European markets, particularly countries like Spain and Germany, are witnessing a shift toward high-performance, technologically advanced footwear that enhances player safety and comfort.

B2B buyers from these regions are influenced by several key trends. First, there is a rising demand for customizable and lightweight shoes that cater to specific playing surfaces, especially artificial turf. Second, advancements in manufacturing technology—such as 3D printing and improved synthetic materials—are enabling manufacturers to offer more innovative, high-quality products at competitive prices. Third, digital sourcing platforms and supplier transparency are gaining importance, allowing buyers to vet manufacturers more effectively and ensure compliance with quality standards.

Furthermore, supply chain resilience has become a focal point, especially amidst global disruptions. Buyers from Vietnam, Europe, and the Middle East are increasingly diversifying their sourcing channels, balancing cost efficiency with reliability. Sustainability considerations are also influencing procurement decisions, prompting a shift toward suppliers that can demonstrate environmentally responsible practices. Overall, navigating these market dynamics requires a strategic approach that balances cost, quality, technological innovation, and sustainability.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal factor for international B2B buyers in the artificial turf baseball shoe sector. The environmental impact of synthetic materials—primarily plastics and rubber—raises concerns about waste management and carbon footprint. Buyers are now prioritizing suppliers that utilize recycled or biodegradable materials, which can significantly reduce environmental harm.

Ethical sourcing practices are equally critical. Buyers are increasingly scrutinizing supply chains to ensure fair labor practices, safe working conditions, and compliance with international labor standards. Certifications such as Fair Trade, ISO 14001, and SA8000 serve as benchmarks for ethical compliance and environmental responsibility. Engaging with suppliers that hold these certifications not only mitigates reputational risks but also aligns with the growing consumer demand for ethically produced sporting goods.

In addition, transparency throughout the supply chain is vital. B2B buyers are leveraging blockchain technology and third-party audits to verify sourcing claims. Incorporating ‘green’ certifications and sustainable materials into product specifications can also serve as a competitive differentiator, especially in markets where environmental consciousness is rising rapidly, such as Europe and parts of South America. Ultimately, integrating sustainability into sourcing strategies is not only ethically responsible but also increasingly demanded by end-users and regulatory bodies globally.

Illustrative Image (Source: Google Search)

Brief Evolution/History

The evolution of artificial turf baseball shoes reflects broader advances in sports footwear technology. Initially, players relied on traditional cleats designed for natural grass surfaces, which posed safety and performance challenges on artificial surfaces. As artificial turf became more prevalent, footwear manufacturers adapted by developing shoes with specialized traction patterns, softer outsoles, and enhanced grip suited for synthetic surfaces.

Over the past decade, innovations such as lightweight materials, enhanced cushioning, and improved durability have transformed these shoes into high-performance gear suitable for competitive play. The integration of eco-friendly materials and sustainable manufacturing practices is a recent trend driven by global environmental initiatives. For B2B buyers, understanding this evolution underscores the importance of sourcing from manufacturers who stay ahead of technological and sustainability trends, ensuring that their products remain competitive and compliant with emerging standards.

Frequently Asked Questions (FAQs) for B2B Buyers of artificial turf baseball shoes

1. How can I effectively vet suppliers of artificial turf baseball shoes to ensure product quality and reliability?

To vet suppliers effectively, start by requesting comprehensive company credentials, including business licenses and manufacturing certifications (ISO, SGS, etc.). Review their product catalogs and request samples to assess material quality, durability, and comfort. Check references or seek feedback from previous international buyers, especially from your region. Conduct virtual factory audits or visit if feasible, focusing on production capacity and quality control processes. Additionally, evaluate their communication responsiveness and transparency, which are critical for building trust in international trade relationships.

2. What customization options are typically available for artificial turf baseball shoes, and how can I communicate my specific needs?

Most manufacturers offer customization in areas such as color, logo placement, packaging, and sometimes design features like cleat patterns or sole types. Clearly specify your branding requirements, including logo size, placement, and color schemes. Provide detailed technical drawings or samples to ensure alignment. Engage with suppliers early to discuss feasible modifications, lead times, and associated costs. Establish a formal agreement on customization specifications and quality standards to prevent misunderstandings and ensure your products meet regional preferences and regulations.

3. What are typical minimum order quantities (MOQs) and lead times for importing artificial turf baseball shoes, and how can I plan accordingly?

MOQs for artificial turf baseball shoes generally range from 500 to 2,000 pairs, depending on the manufacturer’s capacity and customization level. Lead times vary from 4 to 12 weeks, influenced by order complexity, factory workload, and shipping logistics. To plan effectively, communicate your desired delivery schedule upfront, and negotiate flexible MOQs if necessary, especially for initial orders. Building strong supplier relationships can also facilitate priority production and shorter lead times. Always factor in customs clearance and shipping duration to avoid delays in your supply chain.

4. What payment terms are standard in international B2B transactions for artificial turf baseball shoes?

Common payment terms include a 30% deposit upfront with the remaining 70% paid before shipment, or letters of credit for larger orders, which provide security for both parties. Some suppliers may accept T/T (telegraphic transfer), PayPal, or Alibaba Trade Assurance, depending on the transaction size. For new suppliers, negotiate milestones tied to production stages, quality inspections, or partial shipments. Establish clear payment schedules and ensure agreements are documented to mitigate risks such as non-delivery or quality disputes, especially when dealing with overseas suppliers.

5. What quality assurance measures and certifications should I look for when sourcing artificial turf baseball shoes?

Prioritize suppliers with relevant certifications such as ISO 9001 (quality management), SGS testing reports, and compliance with regional standards like CE (Europe) or ASTM (North America). Request detailed product testing reports covering durability, slip resistance, and safety standards. Conduct or commission third-party inspections during production and before shipment. Establish quality control protocols, including sampling procedures and acceptance criteria. Having transparent QA processes reduces the risk of receiving defective products and ensures compliance with your market’s regulatory requirements.

6. How can I manage logistics and shipping effectively when importing artificial turf baseball shoes to regions like Africa, South America, or Europe?

Partner with experienced freight forwarders familiar with your destination region to optimize shipping routes and costs. Consider sea freight for large volumes due to cost efficiency, and air freight for urgent needs. Ensure all shipping documentation (commercial invoices, packing lists, certificates of origin) are accurate to avoid customs delays. Stay informed about import duties, taxes, and regional regulations. Use tracking systems to monitor shipments in real-time, and plan for potential customs clearance times. Establish clear communication channels with your supplier and logistics providers to handle any issues promptly.

7. What common disputes arise in international B2B transactions for artificial turf baseball shoes, and how can I prevent or resolve them?

Disputes often involve quality issues, late deliveries, or payment disagreements. To prevent them, clearly define product specifications, quality standards, and delivery timelines in contracts. Use detailed purchase agreements and include dispute resolution clauses such as arbitration or mediation, preferably under neutral jurisdictions. Maintain open communication and document all exchanges and agreements. In case of disagreements, gather evidence (photos, inspection reports), and attempt amicable resolution before escalating. Employ third-party inspection agencies and escrow payment services to mitigate risks.

8. How do I ensure compliance with regional regulations and standards when importing artificial turf baseball shoes into my country?

Research your country’s import regulations, safety standards, and labeling requirements specific to sports footwear. Ensure your supplier provides necessary certifications and test reports aligned with these standards. Consider engaging local customs brokers or regulatory consultants to navigate complex procedures. Verify that product labels include compliance marks, country of origin, and safety instructions as required. Staying proactive about regulatory changes and maintaining thorough documentation will facilitate smooth customs clearance and reduce the risk of product recalls or penalties.

This comprehensive FAQ provides actionable insights tailored for international B2B buyers from diverse regions, enabling informed sourcing decisions and fostering successful global trade partnerships in artificial turf baseball shoes.

Strategic Sourcing Conclusion and Outlook for artificial turf baseball shoes

Conclusion and Future Outlook for Strategic Sourcing of Artificial Turf Baseball Shoes

Effective strategic sourcing is vital for international B2B buyers aiming to capitalize on the growing demand for artificial turf baseball shoes. By prioritizing supplier diversification, quality assurance, and cost optimization, buyers can mitigate risks and secure competitive advantages in this dynamic market. Emphasizing partnerships with reputable manufacturers across regions such as Vietnam, Spain, and other key manufacturing hubs ensures product consistency and innovation.

Looking ahead, technological advancements in materials and manufacturing processes will continue to elevate product standards, offering new opportunities for differentiation. Buyers should remain vigilant to global supply chain shifts and emerging sustainability standards, which are increasingly influencing procurement decisions.

For buyers in Africa, South America, the Middle East, and Europe, establishing long-term relationships with reliable suppliers will be crucial for maintaining supply stability and meeting evolving market demands. Proactive sourcing strategies—combined with comprehensive market analysis—will position your organization to capitalize on growth opportunities and foster competitive resilience.

In conclusion, embracing a strategic, forward-looking approach to sourcing will enable international buyers to navigate market complexities and secure high-quality, innovative artificial turf baseball shoes that meet global standards and customer expectations.