Master Global Sourcing of Guys Oxford Shoes for Strategic

Guide to Guys Oxford Shoes

- Introduction: Navigating the Global Market for guys oxford shoes

- Understanding guys oxford shoes Types and Variations

- Key Industrial Applications of guys oxford shoes

- Strategic Material Selection Guide for guys oxford shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for guys oxford shoes

- Comprehensive Cost and Pricing Analysis for guys oxford shoes Sourcing

- Spotlight on Potential guys oxford shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for guys oxford shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the guys oxford shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of guys oxford shoes

- Strategic Sourcing Conclusion and Outlook for guys oxford shoes

Introduction: Navigating the Global Market for guys oxford shoes

In the competitive landscape of global footwear, Guys Oxford shoes stand out as a timeless symbol of style, professionalism, and craftsmanship. For B2B buyers across Africa, South America, the Middle East, and Europe, sourcing high-quality Oxford shoes is more than a procurement task—it’s a strategic opportunity to meet evolving market demands and consumer preferences. As these regions experience rising disposable incomes and a growing appetite for premium footwear, understanding the nuances of the supply chain becomes essential.

This comprehensive guide offers actionable insights into every critical aspect of sourcing Guys Oxford shoes—from various styles and materials to manufacturing processes, quality control standards, and reliable supplier networks. It also delves into cost considerations, market trends, and common FAQs, equipping buyers with the knowledge needed to make informed, strategic decisions. Whether you’re seeking affordable bulk production or premium craftsmanship, this resource aims to streamline your sourcing process and mitigate risks.

By mastering the intricacies of the global Oxford shoe market, international B2B buyers can capitalize on emerging opportunities, negotiate better terms, and establish long-term supplier relationships. This guide empowers you to navigate complexities confidently, ensuring your procurement aligns with quality standards, market trends, and your business goals—ultimately enhancing your competitive edge in the global footwear industry.

Understanding guys oxford shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Oxford | Closed lacing system, sleek silhouette, minimal embellishments | Formalwear, corporate uniforms | Pros: Timeless appeal, versatile across markets. Cons: Slightly higher manufacturing complexity, potentially higher cost. |

| Cap Toe Oxford | Features an additional layer of leather over the toe box | Business attire, luxury shoe lines | Pros: Enhanced style, perceived quality. Cons: Slightly more expensive, limited casual versatility. |

| Wholecut Oxford | Made from a single piece of leather, seamless appearance | Premium fashion, executive footwear | Pros: Elegant, high-end look, fewer seams reduce manufacturing steps. Cons: Higher material costs, more delicate. |

| Balmoral Oxford | An open lacing system with a more relaxed, less formal design | Business casual, semi-formal events | Pros: Comfort, easier to manufacture, appealing for less formal markets. Cons: Less traditional for ultra-formal settings. |

| Oxford Brogue | Classic Oxford shape with decorative brogue perforations | Fashion-forward markets, casual business | Pros: Unique aesthetic, appeals to diverse styles. Cons: May be considered less formal, limited in conservative sectors. |

Classic Oxford

The Classic Oxford is characterized by its closed lacing system, where the eyelet tabs are stitched underneath the vamp. It offers a sleek, minimalistic silhouette suitable for formal occasions and professional environments. For B2B buyers, especially those supplying corporate or luxury brands, this style’s timeless appeal ensures consistent demand across markets such as Europe and South America. When sourcing, consider high-quality leather and precise craftsmanship to meet premium standards, and evaluate manufacturing costs relative to market pricing expectations.

Cap Toe Oxford

The Cap Toe Oxford features an extra piece of leather stitched over the toe box, adding a subtle design detail that elevates its visual appeal. It is widely favored in business settings and luxury segments, making it a versatile choice for B2B suppliers targeting executive markets. Buyers should prioritize sourcing durable, high-grade leather and consider the added manufacturing complexity, which could influence unit costs. The style’s perceived sophistication often justifies a higher price point, appealing to premium clients globally.

Wholecut Oxford

Constructed from a single piece of leather, the Wholecut Oxford boasts a seamless, refined appearance that exudes luxury. Its minimal seams reduce potential points of weakness, aligning with high-end fashion demands. For B2B buyers, this style appeals to upscale retailers and bespoke shoemakers in Europe and affluent markets in the Middle East. However, sourcing high-quality, consistent leather and ensuring skilled craftsmanship are critical, as manufacturing is more complex and costly. This style commands premium pricing, suitable for exclusive collections.

Balmoral Oxford

The Balmoral Oxford features an open lacing system, offering a slightly more relaxed yet still polished look. It is well-suited for semi-formal and business casual markets, especially in regions with evolving dress codes like parts of Africa and South America. B2B buyers should focus on sourcing comfortable, durable leathers and consider market preferences for less formal footwear. Its manufacturing process is simpler than closed-lacing styles, potentially reducing costs and lead times, making it attractive for volume orders.

Oxford Brogue

This variation combines the classic Oxford shape with decorative brogue perforations, creating a more distinctive and fashionable appearance. It appeals to markets seeking stylish, versatile footwear that blends formal and casual elements, such as fashion-forward retailers in Europe and emerging markets in South America. Buyers should evaluate leather quality and perforation craftsmanship, as these details influence durability and aesthetic appeal. The Oxford Brogue’s unique look can command higher margins, but its less formal nature may limit appeal in strictly conservative sectors.

Key Industrial Applications of guys oxford shoes

| Industry/Sector | Specific Application of guys oxford shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Corporate & Business Attire | Executive and office staff footwear | Enhances professional appearance, promotes brand image | Quality craftsmanship, consistent sizing, reliable supply chain |

| Hospitality & Service | Staff uniforms in hotels, restaurants, and events | Projects a polished, uniform look; improves guest perception | Durability for daily use, comfort, and easy maintenance |

| Retail & Fashion | Wholesale supply to retail outlets and boutiques | Meets demand for stylish, formal footwear; brand differentiation | Trend alignment, customizable options, competitive pricing |

| Manufacturing & Logistics | Employee uniform footwear in factories and warehouses | Ensures safety compliance, comfort during long shifts | Safety standards (e.g., slip resistance), bulk availability, cost efficiency |

| Education & Government | Staff and faculty uniforms in schools, government offices | Conveys authority and professionalism, uniformity | Consistent quality, size range, compliance with local standards |

Corporate & Business Attire

In the corporate sector, especially among executives and office staff, guys oxford shoes are essential for projecting professionalism and credibility. These shoes are often used in formal business environments, including multinational corporations and government agencies. B2B buyers from regions like Europe and the Middle East prioritize high-quality materials, refined craftsmanship, and consistent sizing to ensure a polished appearance. Reliable sourcing ensures minimal delays and maintains brand standards across international offices.

Hospitality & Service

In the hospitality industry, staff uniforms in hotels, restaurants, and event venues often feature guys oxford shoes to promote a consistent and upscale image. These shoes must balance style with durability, as they endure daily wear and frequent cleaning. For international buyers, especially in regions like South America and Africa, sourcing shoes with high durability, comfort, and ease of maintenance is critical to reduce replacement costs and uphold service standards.

Retail & Fashion

Wholesale distribution of guys oxford shoes to retail outlets and boutiques is a significant application. Retailers in markets such as Brazil and Thailand seek trendy yet classic designs that appeal to diverse customer bases. B2B buyers should focus on suppliers offering customizable options, seasonal styles, and competitive pricing. Ensuring consistent quality and timely deliveries helps retailers maintain stock levels and meet consumer demand effectively.

Manufacturing & Logistics

In manufacturing and logistics sectors, employees often wear guys oxford shoes as part of uniform policies, especially in factories and warehouses where safety and comfort are paramount. These shoes should meet safety standards such as slip resistance, steel toes, or anti-static features. For international B2B buyers, sourcing shoes in bulk at competitive prices while maintaining compliance with regional safety regulations is vital to ensure operational efficiency and employee well-being.

Education & Government

Educational institutions and government offices require formal, uniform footwear for staff and faculty, with guys oxford shoes being a preferred choice for their professional look. B2B buyers from regions like Europe and the Middle East should prioritize consistent quality, a wide size range, and adherence to local standards. Establishing reliable supply chains ensures timely procurement, helping institutions maintain a cohesive and authoritative appearance.

Strategic Material Selection Guide for guys oxford shoes

When selecting materials for men’s Oxford shoes, B2B buyers must consider a range of factors including durability, cost, manufacturing complexity, and suitability for various climatic and regulatory environments. The choice of material directly impacts product performance, compliance with international standards, and market acceptance across regions such as Africa, South America, the Middle East, and Europe. Below is an in-depth analysis of three common materials used in Oxford shoe manufacturing, along with strategic insights tailored for international procurement.

Leather

Leather remains the most traditional and preferred material for high-quality Oxford shoes. It offers excellent breathability, flexibility, and aesthetic appeal, making it suitable for formal and business settings worldwide. From a performance perspective, leather performs well across a broad temperature range and resists tearing, but it requires proper treatment to enhance water resistance and longevity.

Pros:

– Superior comfort and aesthetic appeal

– Good durability when properly maintained

– Biodegradable and environmentally friendly if sourced sustainably

Cons:

– Higher cost, especially for premium grades like full-grain leather

– Manufacturing complexity involves skilled craftsmanship and longer processing times

– Sensitive to moisture, requiring water-resistant treatments for humid or rainy environments

Impact on Application:

Leather’s breathability makes it suitable for moderate climates but less ideal for extremely humid or rainy conditions unless treated. It is highly compatible with European standards (e.g., REACH compliance), and many African and Middle Eastern markets prefer genuine leather for luxury and durability.

International Considerations:

Buyers should verify leather sourcing certifications (e.g., LWG, ISO 14001) to ensure sustainability and compliance. For regions with stringent import standards, such as the EU, adherence to chemical regulations like REACH is critical. Additionally, sourcing from reputable tanneries can mitigate risks of counterfeit or substandard materials.

Synthetic Materials (Polyurethane and Microfiber)

Synthetic materials, particularly polyurethane (PU) and microfiber, have gained popularity due to their cost-effectiveness and ease of manufacturing. These materials are engineered to mimic leather’s appearance and feel, offering a consistent quality at lower prices.

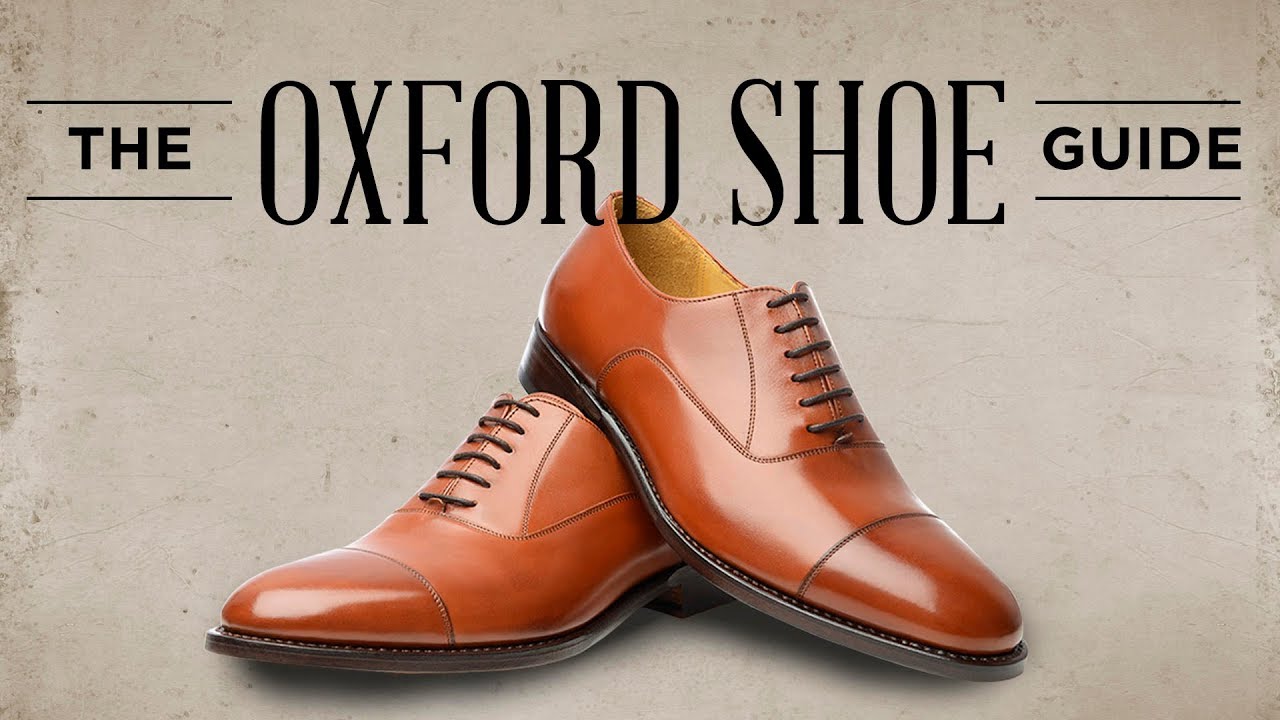

Illustrative Image (Source: Google Search)

Pros:

– Lower manufacturing costs and shorter production cycles

– Water-resistant and less prone to environmental damage

– Lightweight and easy to maintain

Cons:

– Generally less breathable, which can affect comfort in hot climates

– Reduced durability compared to genuine leather, especially under heavy use

– Environmental concerns related to non-biodegradability and chemical processing

Impact on Application:

Synthetic materials are well-suited for mass-market shoes, especially in regions with high humidity like parts of Brazil and Southeast Asia. They meet many international standards for safety and chemical content, making them compliant for export to various markets. However, they may not satisfy premium market segments seeking luxury or heritage aesthetics.

International Considerations:

Buyers should verify compliance with chemical safety standards such as JIS, ASTM, or REACH, especially for markets with strict regulations. Sourcing from certified suppliers ensures product safety and reduces the risk of import restrictions. Additionally, environmental regulations in Europe may favor eco-friendly or recycled synthetics.

Rubber and Synthetic Soles

While primarily used for shoe soles rather than upper materials, rubber and synthetic compounds are crucial for overall product performance. They influence slip resistance, shock absorption, and weather resistance.

Pros:

– Excellent wear resistance and grip

– Cost-effective and widely available

– Suitable for various climatic conditions, including wet environments

Cons:

– Can be heavy and less flexible

– Aesthetic limitations for formal shoes

– Environmental concerns regarding non-biodegradable waste

Impact on Application:

Rubber soles are particularly advantageous in regions with high rainfall or rugged terrains, such as parts of Africa and South America. They are compatible with both leather and synthetic uppers, providing versatility in design and function.

International Considerations:

Buyers should ensure that rubber compounds meet local safety standards, such as ASTM or DIN, and are free from harmful chemicals like phthalates or heavy metals. For export markets, sourcing from environmentally certified suppliers can enhance brand reputation and compliance.

Summary Table

| Material | Typical Use Case for guys oxford shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Formal, luxury, high-end business shoes | Superior comfort, aesthetic appeal, durability when maintained | Higher cost, sensitive to moisture, requires skilled craftsmanship | High |

| Synthetic (PU, Microfiber) | Mass-market, casual, mid-range shoes | Cost-effective, water-resistant, lightweight | Less breathable, lower durability, environmental concerns | Low |

| Rubber and Synthetic Soles | Outsoles for all-weather, rugged use | Slip-resistant, durable, weatherproof | Heavy, less aesthetic for formal shoes, environmental impact | Low |

This strategic material analysis enables international buyers to align their sourcing decisions with regional market preferences, regulatory requirements, and end-user expectations. By understanding each material’s properties and limitations, buyers can optimize product quality, compliance, and cost-efficiency across diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for guys oxford shoes

Manufacturing Processes of Guys Oxford Shoes

The production of high-quality guys Oxford shoes involves a series of meticulously coordinated stages, each critical to ensuring product durability, comfort, and aesthetic appeal. For B2B buyers, understanding these processes helps in assessing supplier capabilities and aligning expectations.

1. Material Preparation

The process begins with sourcing premium raw materials such as full-grain or top-grain leather, synthetic leathers, and textiles. Suppliers often source leather from tanneries adhering to environmental and safety standards, especially important for buyers from regions like Europe and South America where sustainability certifications (e.g., LWG, ISO 14001) are valued. Leather is processed through conditioning, dyeing, and finishing, often involving techniques like chrome tanning or vegetable tanning, depending on the desired look and environmental considerations.

2. Pattern Cutting and Upper Formation

Cutting is performed using either manual templates or automated CNC cutting machines, ensuring precise piece dimensions. Advanced manufacturers employ computer-aided design (CAD) systems to optimize patterns, reduce waste, and ensure consistency. The upper components—quarter, vamp, tongue, and lining—are then stitched or glued together, often using industry-standard techniques such as Blake stitching, Goodyear welt, or cementing, which influence the shoe’s durability and repairability.

3. Lasting and Shaping

The upper is pulled over a last—a mold shaped like a foot—using mechanical or manual lasting techniques. This step defines the shoe’s final shape and fit. For quality assurance, suppliers should employ automated last-fitting machines for consistency and use lasts made from durable materials like wood, plastic, or metal, tailored to different shoe sizes and styles.

4. Assembly and Sole Attachment

The outsole is attached through various methods: direct attachment, welt construction, or cementing. The choice impacts the shoe’s longevity and water resistance. Vibram and other premium outsole manufacturers are often involved for high-end models. Heel components are assembled separately and attached securely, with attention to alignment and finish.

5. Finishing and Quality Control

Final finishing involves polishing, edge trimming, and adding decorative elements such as broguing. Quality checks are integrated at this stage to ensure aesthetic standards and functional integrity. Manufacturing plants often incorporate automation for consistency but rely heavily on skilled artisans for detailed finishing touches.

Quality Assurance Protocols and Industry Standards

Robust quality assurance (QA) is vital for B2B buyers to mitigate risks associated with supplier variability and to meet international standards. Here’s an overview of typical QA practices and standards relevant to guys Oxford shoes:

1. International Quality Standards

– ISO 9001: Most reputable manufacturers align their quality management systems with ISO 9001, ensuring consistent product quality, process improvement, and customer satisfaction.

– Environmental Standards: Compliance with ISO 14001 and OEKO-TEX certifications demonstrates environmental responsibility, increasingly demanded in Europe and by eco-conscious buyers in South America and Africa.

– Product-specific Certifications: CE marking (Europe) for footwear that meets safety and health requirements; ASTM standards for durability testing; and other regional certifications like Brazil’s INMETRO or Middle Eastern safety standards.

2. Key QC Checkpoints

– Incoming Quality Control (IQC): Raw materials, especially leather and adhesives, are inspected for defects, color consistency, and compliance with specifications. Suppliers should provide material test reports and certifications upon request.

– In-Process Quality Control (IPQC): During manufacturing, checkpoints include stitching integrity, dimensional accuracy, bonding quality, and adherence to pattern specifications. Automated inspection systems can detect deviations in real-time, reducing defect rates.

– Final Quality Control (FQC): Before shipment, finished shoes undergo thorough inspection for visual defects, finishing quality, sole attachment strength, and overall conformity to specifications. Random sampling and detailed reports are standard practice.

3. Testing Methods and Inspection Techniques

– Durability Testing: Flex tests, abrasion resistance, and heel stability tests assess the shoe’s longevity under typical usage conditions.

– Comfort and Fit Testing: Pressure mapping and ergonomic assessments ensure shoes meet comfort standards, vital for export markets with high customer expectations.

– Environmental and Safety Tests: VOC emissions, waterproofing, and slip resistance tests ensure compliance with regional safety standards.

How B2B Buyers Can Verify Supplier Quality

To ensure suppliers adhere to quality standards, B2B buyers from Africa, South America, the Middle East, and Europe should adopt rigorous verification processes:

- Supplier Audits: Conduct comprehensive on-site audits focusing on production processes, quality management systems, and compliance with certifications like ISO 9001. Consider engaging third-party inspection agencies with regional expertise for audits in Thailand, Brazil, or other manufacturing hubs.

- Inspection Reports and Certifications: Request detailed inspection reports, test certificates, and certification documents. Cross-verify authenticity through issuing bodies or certification databases.

- Sample Testing: Before large orders, commission independent testing of samples based on regional standards or specific buyer requirements. This helps verify material quality, durability, and compliance.

- Third-party Inspection Services: Engage reputable inspection firms (e.g., SGS, Bureau Veritas, Intertek) to perform pre-shipment inspections, especially for bulk shipments to regions with strict import standards.

- Long-term Supplier Relationships: Establish partnerships with suppliers committed to continuous improvement, transparency, and compliance. Regular audits and quality reviews foster mutual trust and consistent product quality.

Special Considerations for International Buyers

Buyers from diverse regions should tailor their QC approach to regional standards and expectations:

- Africa and South America: Emphasize certifications related to environmental sustainability, fair labor practices, and durability testing to meet local consumer expectations and regulations.

- Middle East: Focus on heat resistance, waterproofing, and slip resistance testing, given the climate conditions.

- Europe (e.g., Thailand, Brazil): Prioritize compliance with EU directives, eco-labels, and ergonomic standards, alongside rigorous durability and safety testing.

In summary, a comprehensive understanding of manufacturing stages and quality assurance practices enables B2B buyers to select reliable suppliers, ensure product conformity, and mitigate risks associated with international trade. Leveraging certifications, audits, and third-party inspections fosters transparency and builds confidence across diverse markets.

Comprehensive Cost and Pricing Analysis for guys oxford shoes Sourcing

Cost Structure Breakdown for Guys Oxford Shoes

Understanding the comprehensive cost components involved in sourcing guys Oxford shoes is essential for international buyers aiming to optimize their procurement strategies. The primary cost elements include:

- Materials: High-quality leather remains the standard for premium Oxford shoes, with prices varying based on origin and grade. Faux or synthetic alternatives can reduce costs but may impact perceived value. Additional components like insoles, lining, and outsole materials also contribute to overall costs.

- Labor: Manufacturing costs fluctuate significantly by region. For instance, suppliers in Southeast Asia (e.g., Vietnam, Thailand) often offer competitive labor rates, whereas European factories may command higher wages but offer superior craftsmanship.

- Manufacturing Overheads: These encompass factory utilities, machinery depreciation, and administrative expenses. Overhead costs tend to be higher in regions with stringent labor and environmental regulations.

- Tooling & Development: Initial mold creation and design setup are upfront costs that can be amortized over larger production volumes, reducing per-unit costs.

- Quality Control & Certifications: Ensuring consistent quality through rigorous QC processes and obtaining certifications (e.g., ISO, REACH compliance) can influence costs but are vital for market acceptance, especially in Europe and North America.

- Logistics & Shipping: FOB (Free on Board) or CIF (Cost, Insurance, and Freight) terms significantly affect landed costs. Shipping modes, customs duties, tariffs, and import taxes vary by destination and influence overall pricing.

Price Influencers and Their Impact

Several factors directly impact the final pricing of Oxford shoes in the international B2B market:

- Order Volume & MOQ: Higher order volumes typically lead to lower unit costs due to economies of scale. Many suppliers offer discounts for large MOQ orders, which is crucial for buyers aiming for competitive pricing.

- Specifications & Customization: Custom features—such as branded packaging, specific colors, or bespoke designs—can increase costs. Standard models tend to be more economical.

- Material Selection: Premium leathers or eco-friendly materials usually command higher prices, affecting the overall cost structure.

- Quality Standards & Certifications: Meeting international standards, especially in Europe and North America, often entails additional testing and certification costs, influencing final pricing.

- Supplier Location & Capabilities: Suppliers in regions like China, Vietnam, or Brazil have different cost structures and lead times, which should be factored into negotiations and planning.

- Incoterms & Delivery Terms: FOB terms typically lower the initial cost but transfer logistics responsibility to the buyer. CIF includes shipping and insurance, often simplifying procurement but adding to the cost.

Strategic Tips for International Buyers

- Negotiate for Volume Discounts: Leverage larger orders to secure better unit prices, especially when working with suppliers in Asia or South America.

- Focus on Total Cost of Ownership: Consider all costs—production, shipping, customs, and after-sales service—to avoid surprises and optimize procurement budgets.

- Assess Supplier Reliability & Certifications: Prioritize suppliers with proven quality records and certifications to minimize risks and ensure compliance with destination market standards.

- Leverage Flexible Incoterms: Negotiate terms that balance cost savings with control over logistics and customs clearance, aligning with your supply chain capabilities.

- Request Detailed Cost Breakdowns: Always seek transparent pricing to identify potential cost-saving areas and avoid hidden fees.

Price Range Estimates (Indicative Only)

While actual prices vary widely based on specifications and supplier relationships, typical FOB unit prices for standard men’s Oxford shoes range approximately from $10 to $25 per pair for bulk orders. Premium or customized options can range from $30 to $50 or more per pair. Landed costs, including shipping, duties, and taxes, often add 20–50% to the FOB price, depending on destination and import tariffs.

Disclaimer: These figures are indicative and subject to fluctuations based on raw material costs, currency exchange rates, and market demand. Buyers should conduct due diligence and obtain multiple quotes to ensure competitive pricing.

In summary, a strategic approach combining volume leverage, quality assessment, and detailed cost analysis enables international B2B buyers—particularly from Africa, South America, the Middle East, and Europe—to optimize their sourcing of guys Oxford shoes, ensuring cost efficiency without compromising quality.

Spotlight on Potential guys oxford shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for guys oxford shoes.)*

Essential Technical Properties and Trade Terminology for guys oxford shoes

Critical Technical Properties for Guys Oxford Shoes

Understanding key technical specifications is essential for international B2B buyers to ensure product quality, consistency, and suitability for target markets. Below are the most vital properties:

1. Material Grade and Composition

The quality of materials used directly impacts durability, comfort, and aesthetic appeal. Common upper materials include full-grain leather, genuine calfskin, or high-quality synthetic leathers, each with varying grades. For wholesale purposes, specifying the material grade ensures consistent product standards and aligns with market expectations, especially in regions demanding premium craftsmanship like Europe or the Middle East.

2. Last Type and Fit Tolerance

The last refers to the mold shaping the shoe’s form. Different lasts influence fit, style, and comfort. Precise tolerance levels (e.g., ±1mm) are critical for uniformity across production batches, reducing returns and dissatisfaction. Buyers should specify last dimensions compatible with regional foot shapes, especially when exporting to Africa or South America where sizing standards may vary.

3. Sole Composition and Thickness

Soles can be made from leather, rubber, or synthetic compounds. The choice affects slip resistance, durability, and weight. Specifying sole thickness (commonly 2-4mm for dress shoes) ensures appropriate balance between comfort and formal appearance. For markets prioritizing longevity, thicker or reinforced soles may be preferred.

4. Stitching and Finish Quality

High-quality stitching (e.g., double or reinforced stitches) enhances durability and aesthetic appeal. Tolerance in stitch spacing (e.g., ±0.2mm) impacts overall finish and defect rates. Clear standards on stitching quality reduce defects, especially important for bulk orders to retail outlets in emerging markets.

5. Colorfastness and Finish Durability

Colorfastness measures how well the shoe’s color resists fading or bleeding during wear and cleaning. A standardized testing method (e.g., ISO 105) ensures products withstand regional climate conditions, such as high humidity in South America or Middle Eastern heat. Finish durability also covers resistance to scratches and scuffs.

6. Compliance with Regional Standards

Certain markets require compliance with safety, environmental, or quality standards (e.g., REACH in Europe, ASTM in the US). Buyers should verify certifications and testing reports, especially when importing to regions with strict import regulations or eco-conscious consumers.

Common Trade Terms for Guys Oxford Shoes

A clear understanding of trade jargon helps streamline procurement processes and negotiations:

1. OEM (Original Equipment Manufacturer)

Refers to factories producing shoes under a buyer’s brand name. OEM agreements allow buyers to customize designs, materials, and packaging, crucial for private-label brands targeting diverse markets.

2. MOQ (Minimum Order Quantity)

The smallest quantity a manufacturer is willing to produce per order. MOQs vary widely, often ranging from 500 to 5,000 pairs for footwear. Knowing MOQs helps B2B buyers plan inventory and negotiate prices effectively, especially when entering new markets or testing demand.

3. RFQ (Request for Quotation)

A formal document sent by buyers requesting price, lead time, and terms for specific shoe styles or specifications. RFQs are essential for initial sourcing and comparison across multiple suppliers, particularly for bulk orders.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs duties. Common Incoterms include FOB (Free on Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid). Selecting the appropriate Incoterm influences cost control and risk management, especially when exporting to regions with complex customs procedures like Africa or South America.

5. Lead Time

The period from order confirmation to shipment readiness. Accurate lead time estimation ensures timely delivery, crucial for retail planning in competitive markets.

6. Quality Inspection and Certification

Refers to the process of verifying that shoes meet specified standards before shipment. Certifications such as ISO, REACH, or CE compliance can be mandatory for certain markets, ensuring adherence to safety and environmental regulations.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions, foster stronger supplier relationships, and optimize their supply chain for success across diverse markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the guys oxford shoes Sector

Market Overview & Key Trends

The global market for men’s oxford shoes, particularly the “guys oxford shoes” segment, is experiencing dynamic shifts driven by evolving consumer preferences, technological advancements, and supply chain innovations. Key drivers include increased demand from emerging markets such as Africa, South America, and the Middle East, where rising disposable incomes and a growing middle class are expanding the customer base. In Europe and Thailand, established markets are increasingly focusing on premium and sustainable offerings, reflecting a broader shift toward quality and ethical consumption.

B2B buyers should note the rising influence of digital sourcing platforms and e-commerce tools that streamline procurement processes, enhance transparency, and facilitate real-time communication with suppliers. Innovations in manufacturing—such as 3D printing and automation—are reducing lead times and costs, enabling buyers to respond swiftly to market trends. Additionally, customization and niche branding are gaining prominence, with brands seeking to differentiate in crowded markets through unique designs, materials, and storytelling.

For international buyers, understanding regional sourcing nuances is crucial. For instance, Africa and South America offer cost advantages through local tannery and leather production, but may pose logistical challenges. Conversely, European and Asian suppliers often provide higher standards of quality and compliance, which can be pivotal for premium segments. Navigating these market dynamics requires a strategic balance of cost, quality, and sustainability considerations to meet diverse consumer demands across markets.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a central pillar in sourcing men’s oxford shoes, driven by increasing consumer awareness and regulatory pressures. Environmental impacts associated with leather production—such as water consumption, chemical use, and greenhouse gas emissions—are prompting brands to seek greener alternatives and transparent supply chains. Ethical sourcing practices, including fair labor conditions and responsible animal welfare standards, are now non-negotiable for many buyers, especially in Europe and developed markets.

Implementing sustainable sourcing involves prioritizing suppliers with recognized environmental certifications like ISO 14001, Leather Working Group (LWG) ratings, or Global Organic Textile Standard (GOTS) for alternative materials. The use of eco-friendly materials, such as vegetable-tanned leather, recycled synthetics, or plant-based dyes, is gaining traction. These materials not only reduce environmental footprints but also appeal to eco-conscious consumers.

B2B buyers should foster supplier partnerships committed to continuous improvement in sustainability metrics. This can involve audits, capacity building, and integrating sustainability criteria into procurement policies. Emphasizing traceability and transparent reporting helps mitigate reputational risks and aligns sourcing strategies with global sustainability goals. Ultimately, adopting sustainable practices can lead to cost efficiencies, enhanced brand loyalty, and compliance with international standards, positioning buyers advantageously in competitive markets.

Brief Evolution/History (Optional)

The evolution of oxford shoes as a staple in men’s formal wear dates back to the 19th century, originating from Scottish and Irish shoemaking traditions. Initially designed as practical, durable footwear for students and professionals, they gained popularity across Europe and North America, symbolizing sophistication and professionalism. Over time, manufacturing innovations and fashion shifts introduced variations in design, materials, and construction techniques.

Illustrative Image (Source: Google Search)

In recent decades, globalization and technological advances have transformed sourcing and production, allowing for wider accessibility and customization options. The rise of sustainable fashion movements has further influenced the sector, prompting brands to innovate with eco-friendly materials and ethical supply chains. For B2B buyers, understanding this historical context underscores the importance of quality, craftsmanship, and ethical standards in sourcing oxford shoes, which continue to evolve in response to market and societal demands.

Frequently Asked Questions (FAQs) for B2B Buyers of guys oxford shoes

1. How can I effectively vet Oxford shoe suppliers to ensure quality and reliability?

To vet suppliers effectively, start with comprehensive background checks, including business licenses, certifications (such as ISO), and production capabilities. Request samples to assess craftsmanship, materials, and finishing quality firsthand. Review their references and client testimonials, especially from other international buyers in your region. Evaluate their communication responsiveness and willingness to share detailed product info. Consider visiting their factories if feasible or engaging third-party inspection services for audits. Establish clear quality standards upfront and include quality assurance clauses in contracts to mitigate risks.

Illustrative Image (Source: Google Search)

2. What customization options are typically available for Oxford shoes, and how do I communicate my specific needs?

Most reputable suppliers offer customization in design, materials, color, sole type, and branding (like logos or labels). To communicate your needs effectively, provide detailed specifications, including sketches or reference images. Discuss material preferences (leather type, finish), sizing standards, and packaging requirements. Clarify minimum order quantities (MOQs) for customized options, lead times, and associated costs. Maintain clear, written communication and request prototypes before mass production to ensure alignment with your brand standards and market preferences.

3. What are typical MOQs, lead times, and payment terms for international B2B orders of Oxford shoes?

MOQs vary depending on the supplier, generally ranging from 300 to 1,000 pairs for custom orders. Lead times typically range from 4 to 12 weeks, depending on order complexity and supplier capacity. Payment terms often include a deposit (30-50%) upfront with the balance payable before shipment or upon delivery. Some suppliers accept letters of credit or bank guarantees for added security. Negotiate flexible payment options and clear schedules upfront, especially for large or ongoing orders, to ensure smooth cash flow management.

4. What quality assurance and certification standards should I look for when sourcing Oxford shoes internationally?

Look for suppliers adhering to recognized quality standards such as ISO 9001, ensuring consistent quality management. Certifications related to ethical sourcing, such as Fair Trade or Leather Working Group (LWG) certification, add credibility. Ask for detailed QA processes, including inspection reports, laboratory testing (for durability, colorfastness, and chemical safety), and compliance with import regulations in your country. Ensuring suppliers have robust QA systems minimizes risks of defects, delays, and non-compliance with your regional standards.

5. How do I manage logistics and shipping for international orders to ensure timely delivery and cost efficiency?

Partner with experienced freight forwarders familiar with your target regions—Africa, South America, the Middle East, or Europe. Opt for Incoterms like FOB or CIF to clearly define responsibility points. Consolidate shipments where possible to reduce costs and consider sea freight for large volumes or air freight for urgent needs. Track shipments in real-time and maintain open communication with logistics providers to anticipate delays. Additionally, understand customs procedures, duties, and taxes in your country to avoid unexpected costs or delays upon arrival.

6. What should I do in case of disputes or quality issues with my Oxford shoe orders?

Establish a clear dispute resolution process in your contracts, including escalation procedures and timelines. If quality issues arise, document defects with photos and detailed descriptions, then communicate promptly with the supplier. Negotiate corrective actions such as replacements, refunds, or discounts. Engage third-party inspectors or mediators if necessary. Building strong supplier relationships and setting clear quality benchmarks from the start can prevent disputes. Always retain detailed records of communications, inspections, and agreements for reference.

7. How can I ensure compliance with regional import regulations and standards when importing Oxford shoes?

Research specific import regulations, tariffs, and standards applicable in your country—whether it’s Brazil, Nigeria, the UAE, or Europe. Verify that your supplier provides necessary documentation such as commercial invoices, packing lists, certificates of origin, and any required safety or compliance certificates. Work with customs brokers or legal advisors familiar with local regulations to streamline clearance. Ensuring compliance from the outset reduces delays, penalties, and potential product recalls, safeguarding your investment and market reputation.

8. What are best practices for building long-term relationships with Oxford shoe suppliers internationally?

Focus on transparent communication, timely payments, and consistent quality to build trust. Regularly review supplier performance, provide constructive feedback, and discuss future needs openly. Consider visiting suppliers periodically to strengthen relationships and verify operations. Negotiate long-term agreements with favorable terms, including volume discounts or exclusivity clauses where appropriate. Stay updated on market trends and share insights to help suppliers innovate. Cultivating mutual respect and collaboration ensures reliable supply chains and competitive advantages in your target markets.

Strategic Sourcing Conclusion and Outlook for guys oxford shoes

Key Takeaways for Strategic Sourcing

Effective sourcing of guys’ Oxford shoes requires a comprehensive understanding of global manufacturing hubs, supplier reliability, and quality standards. Prioritizing supplier diversity and establishing long-term partnerships can mitigate risks and ensure consistent product quality. Leveraging technological tools such as supply chain management platforms and quality assurance systems enhances transparency and efficiency.

The Value of Strategic Sourcing

A strategic approach to sourcing not only reduces costs but also improves lead times, product customization, and compliance with regional standards. For B2B buyers from Africa, South America, the Middle East, and Europe, this means gaining a competitive edge in local markets while maintaining global quality benchmarks. Emphasizing sustainability and ethical sourcing can also strengthen brand reputation and meet increasingly strict regulatory requirements.

Future Outlook and Call to Action

As global demand for premium footwear continues to grow, proactive sourcing strategies will become even more critical. International buyers should actively explore emerging manufacturing regions and foster collaborative supplier relationships to adapt to market shifts. Moving forward, embracing innovation, sustainability, and agility will be essential to capitalizing on new opportunities in the guys’ Oxford shoe segment. Engage with trusted suppliers today to secure a resilient supply chain and achieve long-term success in this dynamic industry.