Master Global Sourcing of Michael Jackson Shoes for B2B

Guide to Michael Jackson Shoes

- Introduction: Navigating the Global Market for michael jackson shoes

- Understanding michael jackson shoes Types and Variations

- Key Industrial Applications of michael jackson shoes

- Strategic Material Selection Guide for michael jackson shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for michael jackson shoes

- Comprehensive Cost and Pricing Analysis for michael jackson shoes Sourcing

- Spotlight on Potential michael jackson shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for michael jackson shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the michael jackson shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of michael jackson shoes

- Strategic Sourcing Conclusion and Outlook for michael jackson shoes

Introduction: Navigating the Global Market for michael jackson shoes

In the dynamic landscape of global footwear trade, michael jackson shoes have emerged as a unique niche with significant commercial potential. Their iconic association with pop culture, coupled with increasing consumer demand for themed and collectible footwear, makes them a compelling product for B2B buyers seeking differentiation and market appeal. For importers and distributors across Africa, South America, the Middle East, and Europe—such as Brazil and Kenya—sourcing high-quality michael jackson shoes can open avenues for niche branding, exclusive collections, and increased profitability.

This comprehensive guide provides critical insights into the entire supply chain—from understanding the various types of michael jackson shoes (including replicas, licensed merchandise, and custom designs) to evaluating materials, manufacturing processes, and quality control standards. It also covers sourcing strategies, supplier selection, cost considerations, and market trends, empowering you to make informed purchasing decisions. Additionally, the guide addresses frequently asked questions and offers practical tips tailored to international buyers navigating diverse regulatory environments and logistical challenges.

Equipped with this knowledge, B2B buyers can confidently identify reliable suppliers, negotiate favorable terms, and optimize their product offerings for local markets. Whether you are expanding an existing footwear portfolio or entering a new niche, this guide aims to serve as an essential resource for strategic sourcing and sustainable growth in the global michael jackson shoes market.

Understanding michael jackson shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Loafers | Smooth leather, slip-on design, iconic silhouette | Fashion retail, costume manufacturing | Pros: Timeless appeal, high brand recognition; Cons: Limited style variation, potential stock oversupply risk |

| Custom-Design Sneakers | High-top or low-top, customizable with unique embellishments | Entertainment merchandise, promotional items | Pros: High demand for exclusivity, strong branding opportunities; Cons: Higher manufacturing costs, longer lead times |

| Stage Performance Boots | Tall, sturdy, often with platform soles, embellished details | Concert costumes, theatrical productions | Pros: Durable for stage use, high visual impact; Cons: Bulkier, higher logistics costs |

| Replica Icon Shoes | Exact replicas of Jackson’s stage shoes, authentic materials | Collectibles, licensing agreements | Pros: High resale value, strong market demand; Cons: Licensing complexities, counterfeit risks |

| Limited Edition Collectibles | Unique designs, often numbered or signed, limited quantities | Collector markets, premium partnerships | Pros: High profit margins, brand prestige; Cons: Niche market, inventory risk |

Classic Loafers

Classic loafers are a staple in Michael Jackson’s footwear repertoire, characterized by sleek leather construction and slip-on convenience. They are ideal for costume manufacturers and fashion retailers seeking authentic, timeless styles. B2B buyers should consider sourcing from reputable suppliers to ensure authenticity and quality control, as counterfeit loafers flood the market. These shoes suit mass production but require careful inventory management to avoid overstocking.

Custom-Design Sneakers

Custom sneakers reflect Jackson’s innovative style, often featuring unique embellishments, vibrant colors, and personalized touches. These shoes are highly sought after in entertainment merchandise and promotional campaigns, offering brands a chance to leverage Jackson’s legacy. B2B buyers must prioritize suppliers with flexible manufacturing capabilities and reliable lead times. While customization commands higher prices, it demands larger minimum orders and longer production cycles.

Stage Performance Boots

Jackson’s stage boots are notable for their height, durability, and elaborate embellishments, designed to withstand rigorous performances. They are primarily used in theatrical productions and concert costumes. For bulk orders, buyers should focus on suppliers with experience in stage footwear, ensuring durability and comfort. The higher production costs are offset by the premium pricing these boots can command in theatrical markets.

Replica Icon Shoes

Exact replicas of Jackson’s stage and performance shoes are popular among collectors and licensing partners. These shoes require strict adherence to authenticity, often involving licensed manufacturers. B2B buyers interested in licensing or resale should verify supplier credentials and legal compliance to avoid counterfeit issues. These shoes typically fetch premium prices but involve complex negotiations and quality assurance processes.

Limited Edition Collectibles

Limited edition shoes are designed as exclusive collectibles, often numbered or signed by designers or artists. They appeal to high-end collectors and brand collaborations. Buyers should evaluate the supplier’s reputation for exclusivity and craftsmanship, as these shoes carry high profit margins but also inventory risks due to their niche appeal. Establishing partnerships with trusted manufacturers ensures product authenticity and brand integrity.

By understanding these variations, international B2B buyers can better tailor their sourcing strategies, negotiate effectively, and meet specific market demands across Africa, South America, the Middle East, and Europe.

Key Industrial Applications of michael jackson shoes

| Industry/Sector | Specific Application of michael jackson shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Entertainment & Performing Arts | Stage costumes and dancewear for high-profile performances | Enhances visual appeal, authenticity, and brand differentiation | Quality assurance, authenticity verification, bulk procurement options |

| Fashion & Retail | Specialty footwear for themed collections or limited editions | Differentiates product lines, appeals to niche markets | Design customization capabilities, reliable supply chain |

| Film & Media Production | Prop footwear for movies, music videos, and commercials | Ensures realism and iconic visual impact | Certification for safety standards, consistent availability |

| Collectibles & Memorabilia | Limited-edition collector shoes for fans and collectors | Drives premium pricing, brand loyalty | Authenticity certification, packaging standards |

| Event & Exhibition Design | Themed displays and interactive exhibits | Creates immersive experiences, attracts visitors | Customization options, logistical support for international shipping |

Entertainment & Performing Arts

In the entertainment industry, especially in stage performances and music videos, michael jackson shoes serve as iconic costume elements that elevate the authenticity and visual impact of a performer’s look. B2B buyers such as costume designers and production houses seek high-quality, authentic footwear that withstands rigorous stage use. For international buyers from regions like Africa or South America, sourcing authentic shoes can be challenging but essential for maintaining brand reputation. Ensuring product authenticity, durability, and bulk supply options are critical for large productions aiming for consistent quality.

Fashion & Retail

Fashion brands and retail outlets often incorporate michael jackson shoes into themed collections or limited editions to attract niche markets and collectors. These shoes help differentiate product offerings, increase perceived value, and enhance brand identity. B2B buyers in Europe or the Middle East should focus on sourcing customizable options and reliable supply chains to meet seasonal demand spikes. Authenticity verification and quality consistency are vital to prevent counterfeits and protect brand integrity, especially when exporting to regions with high counterfeit risks.

Film & Media Production

In film and media, especially in music videos or biopic movies, michael jackson shoes are used as essential props to recreate iconic moments accurately. They contribute to the realism and visual storytelling, making scenes more compelling. B2B buyers such as production companies need footwear that meets safety standards and is available in sufficient quantities for large-scale shoots. International buyers should prioritize suppliers with certification for safety and quality, as well as logistical flexibility to meet tight production schedules across continents.

Collectibles & Memorabilia

Limited-edition michael jackson shoes are highly sought after by collectors and fans worldwide, often commanding premium prices. B2B buyers in this sector should focus on sourcing authentic, certified shoes with premium packaging to enhance collectible value. Ensuring provenance and authenticity certification is crucial, especially for international buyers from regions like Europe and South America, where counterfeit memorabilia can undermine trust. Proper packaging and secure shipping are essential to preserve the product’s integrity.

Event & Exhibition Design

Themed exhibitions and immersive event experiences utilize michael jackson shoes to create engaging displays that attract visitors and enhance storytelling. These shoes can serve as centerpiece artifacts or interactive elements that evoke nostalgia and cultural significance. B2B buyers should consider options for customization and logistical support for international shipping, ensuring seamless integration into exhibits across diverse regions. High-quality replicas or authentic items should be chosen based on the event’s purpose and audience expectations.

Strategic Material Selection Guide for michael jackson shoes

Material Analysis for michael jackson shoes

Selecting the appropriate materials for michael jackson shoes is critical for ensuring product quality, durability, and compliance with international standards. Each material offers unique properties that influence manufacturing processes, cost, and end-user satisfaction. For B2B buyers from Africa, South America, the Middle East, and Europe, understanding these nuances helps optimize procurement strategies and meet regional market demands.

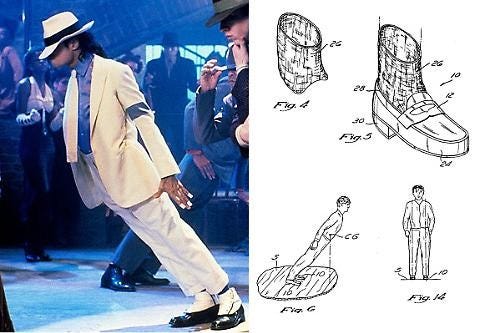

Illustrative Image (Source: Google Search)

Leather and Synthetic Leather

Key Properties:

Leather, especially high-quality full-grain or top-grain, provides excellent durability, breathability, and aesthetic appeal. Synthetic leather, made from PU or PVC, mimics genuine leather but offers more uniformity and lower costs. Both materials are flexible and suitable for fashion-oriented footwear like michael jackson shoes.

Pros & Cons:

– Leather: Highly durable, breathable, and develops a unique patina over time. However, it requires careful tanning and finishing, increasing manufacturing complexity and cost. It also demands proper maintenance to prevent cracking.

– Synthetic Leather: Cost-effective, easier to produce, and resistant to water and stains. Yet, it tends to be less breathable and may degrade faster under harsh conditions.

Impact on Application:

Leather’s breathability and comfort make it ideal for performance shoes, while synthetic options are suitable for costume or fashion shoes where cost and manufacturing efficiency are prioritized.

International Considerations:

For regions like Africa and South America, sourcing genuine leather involves compliance with local environmental and labor standards, such as the Leather Working Group certifications. Synthetic leather must meet safety standards regarding chemical emissions (e.g., REACH in Europe). Buyers should verify supplier certifications to ensure compliance with regional regulations.

Rubber and EVA Soles

Key Properties:

Rubber offers excellent slip resistance, shock absorption, and weather resistance, making it a popular choice for soles. EVA (ethylene-vinyl acetate) is lightweight, flexible, and provides good cushioning, often used in mid-soles or entire sole units.

Pros & Cons:

– Rubber: Highly durable and resistant to wear, but can be heavier and more expensive depending on formulation. Manufacturing complexity varies based on whether natural or synthetic rubber is used.

– EVA: Cost-effective, lightweight, and easy to mold, but less resistant to UV degradation and may compress over time.

Impact on Application:

Rubber soles are preferred for outdoor or performance shoes due to their durability. EVA is ideal for lightweight fashion shoes or costume footwear, where comfort and cost are priorities.

International Considerations:

Buyers should ensure that rubber and EVA materials comply with environmental standards, such as restricted use of hazardous chemicals (e.g., phthalates). In regions like Europe, adherence to REACH regulations is essential, while in Africa and South America, compliance with local chemical safety standards is equally important.

Textile and Mesh Fabrics

Key Properties:

Textile materials, including mesh fabrics, are used for lining, uppers, or decorative elements. They are lightweight, breathable, and versatile, allowing for intricate designs and color customization.

Pros & Cons:

– Textile: Cost-effective and easy to produce, with good flexibility. However, they may have lower durability and be susceptible to moisture and staining.

– Mesh fabrics: Enhance breathability, suitable for performance shoes, but require careful finishing to prevent fraying.

Impact on Application:

Textile and mesh are ideal for performance-oriented shoes or costumes requiring ventilation and aesthetic flexibility. They are less suitable for heavy-duty or outdoor applications unless reinforced.

International Considerations:

Manufacturers should ensure textiles meet safety standards like Oeko-Tex certifications to guarantee low chemical emissions. Buyers from regions with strict import regulations (e.g., Europe) should verify textile compliance and consider local availability to reduce import costs.

Summary Table

| Material | Typical Use Case for michael jackson shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather and Synthetic Leather | Uppers and decorative elements | Leather: durability, breathability; Synthetic: cost-efficiency | Leather: higher cost, maintenance; Synthetic: less breathable | Leather: High; Synthetic: Med |

| Rubber and EVA Soles | Outsoles, mid-soles | Rubber: durability, slip resistance; EVA: lightweight, cushioning | Rubber: heavier, more expensive; EVA: less durable over time | Rubber: Med; EVA: Low |

| Textile and Mesh Fabrics | Uppers, lining, decorative elements | Lightweight, breathable, versatile | Lower durability, moisture susceptibility | Low |

This comprehensive understanding of material properties and regional compliance considerations enables B2B buyers to make informed procurement decisions, optimize costs, and ensure product quality across diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for michael jackson shoes

Manufacturing Processes for Michael Jackson Shoes

The production of Michael Jackson shoes involves a series of meticulously planned stages designed to ensure high quality, durability, and aesthetic appeal. For international B2B buyers, understanding these stages helps in assessing supplier capabilities and compliance with quality standards.

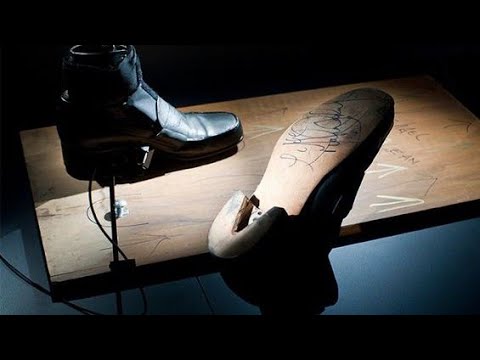

Illustrative Image (Source: Google Search)

1. Material Preparation

The process begins with sourcing premium materials such as genuine leather, synthetic textiles, and specialized embellishments like sequins or rhinestones. Suppliers often select materials based on the specific design and performance requirements, ensuring they meet safety and environmental standards (e.g., REACH compliance in Europe). Material inspection at this stage involves visual examination, dimensional checks, and testing for colorfastness and durability.

2. Forming and Component Manufacturing

In this stage, components such as the upper, sole, and lining are formed using techniques like cutting, molding, and stamping. Advanced machinery like CNC cutters and automated molding equipment ensure precision and consistency. For custom designs, especially those inspired by Michael Jackson’s iconic style, bespoke molds and patterns are used. This stage emphasizes minimizing waste and optimizing material utilization.

3. Assembly and Construction

Assembly involves stitching, bonding, and attaching components—upper to sole, embellishments to fabric, and securing fastenings. Techniques such as high-frequency welding, ultrasonic sealing, and industrial stitching are employed for durability and aesthetic finesse. Attention to detail during assembly is critical, as it directly impacts the shoe’s performance and visual appeal.

4. Finishing and Quality Checks

Final touches include polishing, surface treatment, and the addition of branding elements. Automated and manual inspections verify the alignment, stitching quality, and overall appearance. Packaging is also executed during this phase, ensuring the product is ready for shipment while adhering to safety standards.

Quality Assurance (QA) and Control (QC) Protocols

Robust QC systems are vital for maintaining consistency, safety, and compliance, especially when catering to international markets with diverse regulatory requirements.

1. International Standards Compliance

Most reputable manufacturers adhere to standards such as ISO 9001 for quality management systems, ensuring a structured approach to process control and continuous improvement. For specific markets, additional certifications like CE (European conformity), ASTM, or API (for certain performance criteria) may be required.

2. QC Checkpoints and Processes

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival for defects, compliance, and safety parameters. Suppliers should provide test reports for critical components like leather and synthetic fabrics.

– In-Process Quality Control (IPQC): Monitoring during manufacturing involves routine checks on dimensions, stitching quality, and assembly accuracy. This ensures early detection of deviations.

– Final Quality Control (FQC): Before shipment, finished shoes undergo comprehensive inspections, including visual checks, functional tests (e.g., sole adhesion, fastening strength), and consistency assessments.

3. Testing Methods

Effective QC relies on standardized testing, including:

– Durability Tests: Abrasion resistance, flex testing, and impact resistance.

– Safety Tests: Non-toxicity, chemical safety (e.g., lead, phthalates), and slip resistance.

– Appearance Tests: Colorfastness, surface smoothness, and embellishment security.

4. Verification and Supplier Audits

B2B buyers should perform or commission regular audits—either through third-party inspectors or in-house teams—to verify supplier QC processes. Request detailed inspection reports, test certificates, and audit summaries. For high-value or custom orders, consider engaging independent testing labs accredited under ISO/IEC 17025 standards.

Considerations for International B2B Buyers from Africa, South America, the Middle East, and Europe

1. Regulatory and Certification Requirements

Buyers in regions like Brazil, Kenya, or Middle Eastern countries often face specific import regulations. Ensure suppliers provide compliance documentation such as REACH certificates for Europe, SAFETY certifications for South America, or local customs certifications. Certifications like ISO 9001 are often a baseline, but additional industry-specific standards may be necessary.

2. Supplier Qualification and Due Diligence

Given the variability in manufacturing quality across regions, it’s crucial to vet suppliers thoroughly. Conduct on-site audits, review quality management systems, and verify their adherence to international standards. For regions with less mature manufacturing sectors, partnering with suppliers who have third-party certification and transparent QC documentation reduces risk.

3. Sampling and Pilot Orders

Before large-scale procurement, request samples that undergo rigorous testing aligned with your market’s safety and performance standards. Pilot orders allow you to assess the manufacturer’s consistency, responsiveness, and ability to meet deadlines.

4. Building Long-term Quality Partnerships

Establish clear quality agreements, including detailed specifications, inspection criteria, and corrective action protocols. Regular communication and periodic audits foster trust and ensure ongoing compliance.

Final Recommendations for B2B Buyers

- Leverage Third-party Inspection Services: Employ globally recognized inspection companies (e.g., SGS, Bureau Veritas, Intertek) for independent QC verification.

- Request Comprehensive Documentation: Certificates of compliance, test reports, and detailed QC reports should be mandatory for every batch.

- Implement a Robust Incoming Inspection Protocol: Verify raw materials and components upon receipt to prevent downstream issues.

- Develop Clear Quality Agreements: Define quality standards, inspection procedures, and corrective measures explicitly within supplier contracts.

- Prioritize Suppliers with Proven International Certification: This minimizes compliance risks and facilitates smoother customs clearance.

By understanding and actively managing manufacturing and quality assurance processes, international B2B buyers from Africa, South America, the Middle East, and Europe can secure reliable partnerships, ensure product safety, and meet market-specific standards for Michael Jackson shoes.

Comprehensive Cost and Pricing Analysis for michael jackson shoes Sourcing

Understanding Cost Components in Michael Jackson Shoes Sourcing

For international B2B buyers, grasping the detailed cost structure of Michael Jackson shoes is essential to negotiate effectively and optimize procurement. The primary cost components include:

-

Materials: The choice of materials significantly impacts the base cost. Authentic or high-quality synthetic materials can range from $3 to $10 per pair, depending on the supplier and material quality. Customization, such as special prints or embellishments, will add to material costs.

-

Labor: Manufacturing costs vary based on country and factory standards. In regions like China or Vietnam, labor costs might range from $1 to $4 per pair. Buyers from Africa or South America should consider local labor cost differences, factoring in potential wage variations and skill levels.

-

Manufacturing Overhead: This includes equipment, utilities, and factory expenses, typically adding 10-20% to the direct labor and material costs. Efficient factories with high throughput can reduce overhead per unit.

-

Tooling and Setup: Initial tooling costs for molds or custom designs can range from $500 to $2,000, amortized over large orders. For small-volume runs, these costs significantly influence unit pricing.

-

Quality Control (QC): Rigorous QC ensures compliance with safety and quality standards, especially for certified or branded products. QC costs may add $0.50 to $2 per pair, depending on complexity.

-

Logistics and Shipping: Shipping costs depend on order volume, destination, and chosen Incoterms. FOB (Free on Board) terms generally make the supplier responsible until shipment, with freight costs potentially ranging from $0.50 to $3 per pair for sea freight, which is common for bulk imports.

-

Profit Margin: Suppliers typically add a margin of 10-30%, influenced by order volume, exclusivity, and relationship strength.

Price Influencers and Their Impact

Several factors influence the final pricing of Michael Jackson shoes in international markets:

-

Order Volume & MOQ: Larger orders benefit from economies of scale, reducing per-unit costs. Minimum order quantities (MOQs) can start at 500 pairs but are negotiable, especially for established buyers.

-

Specifications & Customization: Unique designs, special materials, or branding increase costs. Custom packaging or special certifications (e.g., safety standards) also add to the price.

-

Material Choices: Premium or imported materials command higher prices, impacting overall cost. Buyers should weigh material costs against perceived value and branding goals.

-

Quality & Certifications: Meeting international safety and quality standards (e.g., ISO, CE) may involve additional testing fees but can open access to premium markets, justifying higher prices.

-

Supplier Factors: Factory reputation, compliance with labor laws, and production capacity influence pricing. Reliable suppliers with certifications may charge a premium but offer greater assurance of quality and delivery.

-

Incoterms & Delivery Terms: FOB terms shift logistics responsibility to buyers, often lowering initial costs but requiring import handling. CIF (Cost, Insurance, Freight) includes these costs but increases the landed price.

Strategic Tips for International Buyers

-

Negotiate for Better Terms: Leverage order volume, long-term relationships, or bulk commitments to negotiate lower unit prices or better payment terms.

-

Focus on Total Cost of Ownership (TCO): Consider all costs—shipping, customs, taxes, and potential rework—beyond the unit price to accurately assess affordability.

-

Understand Pricing Nuances: Prices are often indicative; actual costs depend on supplier negotiations, order specifics, and current market conditions. Always request detailed quotations and clarify inclusions.

-

Leverage Local Market Insights: Buyers from Africa, South America, the Middle East, and Europe should consider regional trade agreements, tariffs, and import duties that impact final landed costs. For example, free trade zones or preferential tariffs can reduce overall expenses.

Final Considerations

While indicative prices for Michael Jackson shoes can range from $10 to $25 per pair wholesale, actual costs vary widely based on specifications, order volume, and logistics. Establishing clear communication, understanding the full cost structure, and negotiating effectively are crucial steps for international B2B buyers aiming to maximize value and ensure consistent supply. Always conduct due diligence on suppliers’ certifications and compliance to mitigate risks and secure quality standards.

Spotlight on Potential michael jackson shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for michael jackson shoes.)*

Essential Technical Properties and Trade Terminology for michael jackson shoes

Critical Technical Properties

1. Material Grade and Composition

The quality and durability of Michael Jackson shoes heavily depend on the materials used. High-grade leather, synthetic alternatives, and specialized fabrics are common, each with specific industry standards (e.g., full-grain leather vs. bonded leather). For B2B buyers, understanding material grade ensures the product’s longevity, comfort, and authenticity, which directly impact customer satisfaction and brand reputation.

2. Manufacturing Tolerance

Tolerance levels define the permissible deviations in shoe dimensions such as length, width, and heel height. Precise tolerances (e.g., ±1mm) are crucial for consistent sizing, especially when mass-producing for international markets. Tight tolerances reduce returns and exchanges, ensuring a reliable supply chain.

3. Sole and Heel Specifications

The composition and durability of soles and heels—such as rubber, leather, or synthetic compounds—affect performance and safety. Specifications include slip resistance ratings, tread patterns, and shock absorption features. For B2B buyers, selecting shoes with appropriate sole specifications aligns with regional safety standards and consumer preferences.

4. Finish and Detailing Quality

This includes stitching precision, surface coating, and decorative elements. High-quality finishes prevent premature wear and enhance visual appeal, which is vital for branded or celebrity-inspired shoes. Consistent finishing across batches indicates reliable manufacturing processes, reducing quality control issues.

5. Compliance with International Standards

Shoes must meet specific safety and quality standards relevant to target markets (e.g., CE marking in Europe, ASTM standards in the US). Ensuring compliance minimizes legal barriers, customs delays, and potential product recalls in export regions.

Industry and Trade Terminology

1. OEM (Original Equipment Manufacturer)

Refers to manufacturers producing shoes under a different brand name, often for wholesale or licensing. Understanding OEM relationships helps B2B buyers negotiate cost-effective sourcing, especially when customizing designs inspired by Michael Jackson.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce or sell in a single order. For international buyers, knowing MOQ helps in planning inventory, managing cash flow, and negotiating better terms, especially when testing new markets.

3. RFQ (Request for Quotation)

A formal request sent to manufacturers for pricing, lead times, and terms on specific shoe designs. An RFQ process ensures transparency and competitive pricing, enabling buyers from regions like Africa or South America to compare multiple suppliers efficiently.

4. Incoterms (International Commercial Terms)

Standardized trade terms (e.g., FOB, CIF, DDP) that define responsibilities for shipping, insurance, and customs duties. Familiarity with Incoterms helps buyers manage logistics costs, reduce risks, and clarify responsibilities during international transactions.

5. CMT (Cut, Make, Trim)

A manufacturing service where the supplier handles cutting, assembly, and finishing, but not raw materials. This term is relevant when buyers source materials separately, allowing flexibility in design and cost management.

6. Quality Assurance (QA) & Quality Control (QC)

Processes ensuring the shoes meet specified standards before shipment. B2B buyers should establish clear QA/QC protocols to maintain product consistency, particularly when sourcing from different regions with varying manufacturing practices.

Understanding these technical properties and trade terms equips international buyers with the knowledge to evaluate suppliers effectively, negotiate favorable terms, and ensure product quality. This strategic insight is essential for successful market entry and sustainable partnerships in the global distribution of Michael Jackson shoes.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the michael jackson shoes Sector

Market Overview & Key Trends

The global market for niche footwear, including specialized products like Michael Jackson shoes, is experiencing significant shifts driven by technological advancements, consumer preferences, and supply chain innovations. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding these dynamics is critical to sourcing effectively and competitively.

Emerging trends include the integration of digital tools—such as 3D design, virtual prototyping, and AI-driven supply chain management—that streamline production and reduce time-to-market. E-commerce platforms and online B2B marketplaces are expanding access to international suppliers, offering transparency and ease of transaction, especially vital for buyers in emerging markets seeking reliable sources.

Current market drivers include the global demand for collectible and performance footwear, fueled by pop culture, nostalgia, and entertainment collaborations. For instance, licensed Michael Jackson-themed shoes are increasingly sought after, creating opportunities for brands and manufacturers to expand their offerings. Market dynamics also reflect shifting consumer preferences toward customization and limited editions, which require agile sourcing and production capabilities.

Illustrative Image (Source: Google Search)

For B2B buyers, especially from regions like Kenya or Brazil, sourcing trends emphasize the importance of flexible manufacturing partners capable of small-batch production and rapid turnaround. The rise of nearshoring and regional hubs in Europe and South America also offers advantages in reducing shipping costs and lead times. Additionally, geopolitical factors and trade agreements influence import tariffs and logistics, necessitating continuous market monitoring.

In summary, success hinges on leveraging digital sourcing platforms, establishing strong supplier relationships, and staying attuned to consumer trends. Diversification of sourcing channels and embracing innovative technologies will be vital for navigating these evolving market conditions.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a core consideration in the footwear industry, impacting sourcing decisions and brand reputation. For Michael Jackson shoes, which often attract a niche but dedicated customer base, integrating environmentally responsible practices offers a competitive advantage in global markets.

Environmental impacts associated with footwear production include water consumption, chemical usage, and waste generation. B2B buyers should prioritize suppliers with verifiable eco-friendly practices, such as using sustainable materials, water-efficient manufacturing processes, and waste recycling systems. Certifications like ISO 14001, Fair Trade, or Leather Working Group (LWG) ratings serve as credible indicators of a supplier’s commitment to sustainability.

Ethical sourcing is equally vital. This encompasses fair labor practices, transparent supply chains, and anti-child labor policies. Buyers from regions like Africa or South America should seek suppliers who adhere to internationally recognized standards and can demonstrate traceability from raw material to finished product. Engaging with suppliers holding green certifications and social compliance audits minimizes reputational risks and aligns with global consumer expectations.

The adoption of ‘green’ materials—such as recycled plastics, organic textiles, or plant-based leathers—resonates with environmentally conscious consumers. Additionally, developing long-term partnerships with suppliers committed to continuous improvement in sustainability metrics can foster innovation and resilience in supply chains.

For international buyers, fostering collaboration with suppliers on sustainability initiatives can unlock benefits like reduced costs through efficiency gains, improved brand positioning, and access to growing markets that prioritize eco-friendly products. Ensuring transparency and adherence to ethical standards will be crucial as global regulations tighten and consumer awareness continues to grow.

Brief Evolution/History (Optional)

While niche footwear like Michael Jackson shoes may not have a long historical evolution comparable to mass-market footwear, their development reflects a broader trend in entertainment-inspired fashion and collectible footwear. Initially driven by fan demand and licensing agreements, the market has matured to include limited editions, collaborations, and bespoke designs. For B2B buyers, understanding this evolution underscores the importance of licensing rights, intellectual property management, and aligning with reputable manufacturers capable of producing high-quality, officially licensed products. Recognizing the cultural significance and collectible nature of these shoes can also inform sourcing strategies aimed at premium segments.

Frequently Asked Questions (FAQs) for B2B Buyers of michael jackson shoes

1. How can I verify the credibility and reliability of a supplier offering Michael Jackson shoes?

To ensure supplier credibility, prioritize suppliers with verifiable certifications, such as ISO or industry-specific quality standards. Request references from previous B2B clients, especially from your region, to confirm their track record. Conduct virtual audits or request detailed product samples to assess quality firsthand. Additionally, review online platforms like Alibaba, Global Sources, or industry directories for supplier ratings and reviews. Establish clear communication channels and negotiate payment terms that include escrow or letter of credit options to mitigate risks. Partnering with suppliers who have a transparent supply chain and positive reputation is crucial for consistent quality and reliable delivery.

2. What customization options are typically available for Michael Jackson shoes in B2B transactions?

Many suppliers offer customization to meet branding or design preferences, including logo placement, color schemes, and packaging. Some may provide options for limited design modifications, such as adding special embellishments or adjusting sizing specifications. It’s essential to clarify upfront whether customization incurs additional costs, lead times, or minimum order quantities (MOQs). Establish detailed specifications in your purchase agreement and request prototypes before mass production. For regional markets, consider cultural preferences and regional sizing standards to enhance product appeal. Working with suppliers experienced in custom manufacturing can streamline the process and ensure your brand’s unique requirements are met effectively.

3. What are typical minimum order quantities (MOQs), lead times, and payment terms for bulk orders of Michael Jackson shoes?

MOQs for branded or licensed footwear like Michael Jackson shoes often range from 500 to 5,000 pairs, depending on the supplier and customization level. Lead times generally span from 4 to 12 weeks, influenced by production complexity, customization, and logistics. Payment terms commonly include a 30-50% upfront deposit, with the balance payable before shipment or upon delivery. Some suppliers may accept letters of credit or bank guarantees, especially for large orders. To optimize cash flow, negotiate flexible terms or staged payments aligned with production milestones. Early planning and clear communication with suppliers help ensure timely delivery aligned with your sales cycles.

4. What quality assurance (QA) certifications and product testing should I look for when sourcing Michael Jackson shoes?

Ensure products meet safety and quality standards relevant to your target markets. Look for suppliers with QA certifications like ISO 9001, or compliance with regional standards such as CE marking (Europe), ASTM, or CPSIA (U.S.). Request detailed product testing reports covering durability, colorfastness, and safety, especially if the shoes are intended for children or high-traffic use. Consider third-party inspection services for pre-shipment quality checks. Additionally, verify the authenticity of licensing agreements if the shoes are officially branded, to avoid counterfeit risks. These measures safeguard your reputation and ensure compliance with import regulations.

5. How can I manage logistics efficiently when importing Michael Jackson shoes from overseas suppliers?

Effective logistics management begins with selecting suppliers who can provide clear shipping options, including FOB, CIF, or DDP terms. Work with freight forwarders experienced in international trade, especially in your region, to navigate customs procedures and tariffs efficiently. Consolidate shipments where possible to reduce costs and lead times. Ensure all necessary documentation, such as commercial invoices, packing lists, and certificates of origin, are complete and accurate. Consider warehousing options in regional hubs to facilitate faster distribution within Africa, South America, or Europe. Regular communication with your logistics partners and proactive customs clearance planning are essential for smooth delivery.

6. What are common dispute resolution mechanisms in international B2B transactions for footwear?

Disputes may arise over quality, delivery delays, or payment issues. Establish clear contractual terms specifying dispute resolution methods, preferably favoring arbitration under internationally recognized rules (e.g., ICC or UNCITRAL). This approach provides neutrality and enforceability across jurisdictions. Incorporate detailed clauses on quality inspections, inspection rights, and penalty provisions for non-compliance. Maintain detailed records of all communications, contracts, and shipment documentation to support claims. Engaging local legal counsel familiar with international trade laws can help navigate regional regulations. Proactive communication and transparent negotiation are key to resolving disputes efficiently and maintaining long-term supplier relationships.

7. How do currency fluctuations and regional payment preferences impact international transactions for Michael Jackson shoes?

Currency volatility can significantly affect pricing and profit margins. Consider using hedging instruments or quoting in stable currencies like USD or EUR to mitigate risks. Understand regional payment preferences—many regions favor bank transfers, letters of credit, or escrow services over open accounts. Negotiating flexible payment terms, such as 30-50% upfront with balance upon delivery, can balance risk. For regions with limited banking infrastructure, explore alternative methods like mobile money or local escrow providers. Establishing consistent, transparent payment procedures and keeping abreast of currency trends helps manage financial exposure and fosters trust with international suppliers.

8. What are best practices for handling product recalls or quality issues post-shipment?

Develop a clear post-shipment quality assurance process, including warranties and return policies. Maintain open communication channels with suppliers for quick resolution of quality concerns. When issues arise, document discrepancies thoroughly and request immediate corrective actions, such as replacements or refunds. Incorporate contractual clauses that specify liability limits and procedures for product recalls or defect rectifications. Consider establishing regional inspection points or third-party quality checks upon receipt to identify issues early. Building strong, transparent relationships with suppliers facilitates prompt resolution, minimizing financial and reputational risks across markets in Africa, South America, the Middle East, and Europe.

Strategic Sourcing Conclusion and Outlook for michael jackson shoes

Conclusion and Future Outlook

Effective strategic sourcing of Michael Jackson shoes offers international B2B buyers a competitive advantage by ensuring product authenticity, quality, and cost-efficiency. Emphasizing relationships with reputable suppliers, leveraging regional trade agreements, and adopting comprehensive due diligence are critical steps to mitigate risks and optimize supply chains. For buyers in Africa, South America, the Middle East, and Europe, understanding local market dynamics and import regulations enhances sourcing success and fosters sustainable partnerships.

Looking ahead, the increasing demand for iconic merchandise presents significant growth opportunities, especially with the rising influence of e-commerce and digital marketplaces. Buyers should prioritize building resilient, transparent supply networks that adapt to evolving market trends and consumer preferences.

Actionable Takeaway: Engage with verified suppliers, explore regional manufacturing hubs, and leverage strategic alliances to secure reliable sourcing channels. By doing so, international buyers can capitalize on the enduring legacy of Michael Jackson and meet global consumer demand with confidence. Proactive, well-informed sourcing strategies will be key to maintaining a competitive edge in this dynamic market landscape.