Master Global Sourcing of Stud Shoes for Superior Quality

Guide to Stud Shoe

- Introduction: Navigating the Global Market for stud shoe

- Understanding stud shoe Types and Variations

- Key Industrial Applications of stud shoe

- Strategic Material Selection Guide for stud shoe

- In-depth Look: Manufacturing Processes and Quality Assurance for stud shoe

- Comprehensive Cost and Pricing Analysis for stud shoe Sourcing

- Spotlight on Potential stud shoe Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for stud shoe

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the stud shoe Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of stud shoe

- Strategic Sourcing Conclusion and Outlook for stud shoe

Introduction: Navigating the Global Market for stud shoe

In today’s highly interconnected global marketplace, the stud shoe has emerged as a critical component across various industries, including sports, fashion, and industrial applications. For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing high-quality stud shoes is essential to maintaining competitive advantage, ensuring product durability, and meeting diverse market demands. The stakes are high: choosing the right supplier, material, and manufacturing process directly impacts product performance and profitability.

This comprehensive guide offers an in-depth exploration of the stud shoe supply chain, covering key aspects such as types, materials, manufacturing standards, quality control, sourcing strategies, and cost considerations. It also provides actionable insights into navigating different supplier markets—from established manufacturers in Asia to emerging suppliers in Africa and South America—empowering buyers to make informed, strategic decisions.

Whether you are sourcing for retail, industrial, or specialized markets, this guide aims to equip you with the knowledge needed to optimize your procurement process, mitigate risks, and leverage global opportunities. By understanding the intricacies of the stud shoe industry, regional market dynamics, and best practices, international B2B buyers—particularly from regions like Saudi Arabia, UAE, and beyond—can confidently establish resilient supply chains that meet both quality standards and cost targets.

Understanding stud shoe Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fixed Stud Shoe | Permanently attached studs; non-removable | Heavy machinery, construction equipment | Pros: Durable, reliable; Cons: Less flexibility for customization |

| Removable Stud Shoe | Studs designed for easy attachment and removal | Mining, agriculture, temporary setups | Pros: Flexibility, ease of maintenance; Cons: Potential for loosening |

| Adjustable Stud Shoe | Features adjustable components for height or position | Precision machinery, versatile applications | Pros: Customizable fit; Cons: Slightly higher cost, complexity in assembly |

| Heavy-Duty Stud Shoe | Reinforced construction with high-strength materials | Heavy load-bearing equipment, industrial use | Pros: Exceptional strength; Cons: Heavier, higher initial investment |

| Light-Duty Stud Shoe | Lighter materials, simplified design | Light machinery, portable equipment | Pros: Cost-effective, easy to install; Cons: Less durable under heavy stress |

Fixed Stud Shoe

Fixed stud shoes are designed with permanently attached studs, offering a robust and maintenance-free solution. They are ideal for applications where stability and durability are paramount, such as in heavy machinery or construction equipment operating under continuous load. For B2B buyers, these shoes are advantageous due to their longevity and minimal upkeep requirements. However, their lack of flexibility can be a drawback if modifications or replacements are needed, potentially leading to higher long-term replacement costs.

Removable Stud Shoe

Removable stud shoes feature studs that can be easily attached or detached, providing significant flexibility for varied operational needs. They are especially suitable for industries like mining or agriculture, where equipment may need frequent adjustments or maintenance. From a procurement perspective, these shoes offer cost savings by enabling quick repairs or replacements without replacing the entire shoe assembly. Nonetheless, buyers should consider the risk of studs loosening over time and ensure proper fastening mechanisms are in place to maintain operational integrity.

Adjustable Stud Shoe

These shoes incorporate adjustable components that allow for modifications in height, angle, or positioning of the studs. They are highly versatile and suitable for applications requiring precise alignment, such as in manufacturing or specialized machinery. For B2B buyers, adjustable stud shoes facilitate customization to match specific operational parameters, potentially reducing downtime. However, their increased complexity and manufacturing cost may influence initial procurement expenses, and proper installation is critical to ensure optimal performance.

Heavy-Duty Stud Shoe

Constructed with reinforced materials like high-grade steel or composites, heavy-duty stud shoes are designed to withstand extreme loads and harsh environments. They are essential in industries like industrial equipment, cranes, or heavy transport where maximum strength and durability are required. Buyers benefit from their extended service life and reliability, though they tend to be heavier and involve higher upfront costs. Proper handling and installation are vital to maximize their benefits and prevent premature wear.

Light-Duty Stud Shoe

Light-duty stud shoes are made from lighter materials such as aluminum or composites, featuring simplified designs for ease of installation and cost efficiency. They are well-suited for portable or low-stress applications, such as small machinery or temporary setups. For B2B purchasers, these shoes offer affordability and quick deployment, but they may not be suitable for heavy or prolonged use, requiring careful assessment of operational demands to avoid premature failure.

Key Industrial Applications of stud shoe

| Industry/Sector | Specific Application of stud shoe | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Wellhead and flange support in high-pressure environments | Ensures secure load distribution, reduces equipment wear, enhances safety | Material resistance to corrosive media, compliance with API standards |

| Mining & Heavy Industry | Conveyor belt tensioning and support systems | Improves operational stability, minimizes downtime, prolongs equipment life | Heavy-duty durability, ease of installation, availability of custom sizes |

| Construction & Infrastructure | Foundation and structural support in heavy machinery | Provides reliable load transfer, prevents structural deformation | Compatibility with construction materials, resistance to environmental conditions |

| Power Generation | Turbine and generator support in thermal and hydro plants | Ensures stability, reduces vibration, enhances equipment longevity | High-temperature resistance, precision manufacturing, certification needs |

| Marine & Offshore | Support for offshore platforms and ship components | Corrosion resistance, reliable load support in harsh maritime environments | Marine-grade materials, adherence to international standards, sourcing logistics |

Oil & Gas

Stud shoes are critical in oil and gas applications, especially for wellhead and flange support in high-pressure, high-temperature environments. They distribute stress evenly across flanged connections, preventing leaks and equipment failure. For international B2B buyers from regions like the Middle East or West Africa, sourcing stud shoes with corrosion-resistant materials such as stainless steel or alloy steels that meet API standards is essential. Ensuring compatibility with aggressive media and high-pressure conditions minimizes maintenance costs and enhances operational safety.

Mining & Heavy Industry

In mining and heavy industry, stud shoes are used to support conveyor belts, crushers, and heavy machinery. They provide stability and absorb vibrations, which reduces wear and prolongs equipment lifespan. Buyers from South America or Africa should prioritize sourcing stud shoes with high durability, capable of withstanding abrasive environments and heavy loads. Ease of installation and availability of customized sizes are crucial for minimizing downtime and optimizing operational efficiency in remote or rugged sites.

Construction & Infrastructure

Within construction projects, stud shoes support heavy structural components and machinery foundations. They facilitate load transfer and help prevent structural deformation under heavy loads. For European or Middle Eastern buyers, selecting stud shoes made from materials resistant to environmental factors such as moisture, chemicals, or temperature fluctuations is vital. Reliable sourcing ensures compliance with construction standards and reduces the risk of structural failures, especially in large-scale infrastructure projects.

Power Generation

Stud shoes are employed in thermal and hydroelectric power plants to support turbines and generators. They help stabilize equipment, reduce vibrations, and improve overall operational longevity. International buyers from regions like Europe or the Middle East should focus on sourcing stud shoes with high-temperature resistance and precision manufacturing. Certification for safety and performance, along with availability of custom solutions, are key to ensuring seamless integration into critical power infrastructure.

Illustrative Image (Source: Google Search)

Marine & Offshore

Offshore platforms and ships rely on stud shoes for supporting heavy equipment exposed to harsh maritime conditions. These components must resist corrosion from saltwater and extreme weather while maintaining load-bearing capacity. Buyers from the Middle East or South America should prioritize marine-grade materials, such as specialized stainless steels or corrosion-resistant alloys. Sourcing from suppliers adhering to international standards ensures durability, safety, and compliance with maritime regulations, reducing long-term maintenance costs.

Strategic Material Selection Guide for stud shoe

Material Analysis for Stud Shoe Components

Selecting the appropriate material for stud shoes is critical for ensuring durability, performance, and cost-efficiency across diverse international markets. Different materials offer distinct advantages and limitations, which must be carefully weighed by B2B buyers from regions such as Africa, South America, the Middle East, and Europe. Here, we analyze four common materials used in stud shoe manufacturing, emphasizing their properties, pros and cons, and considerations relevant to international trade.

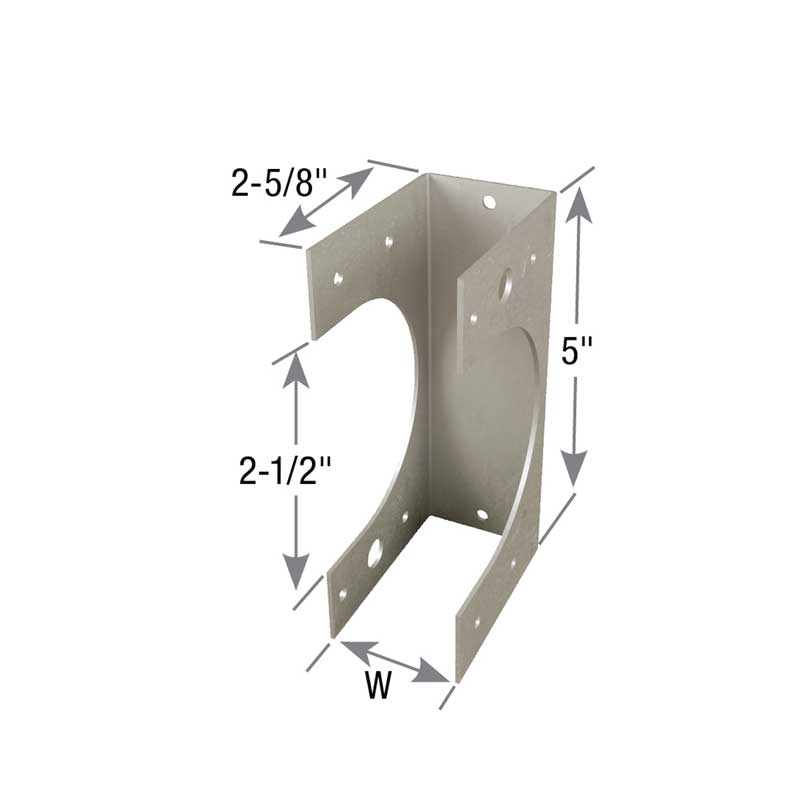

Illustrative Image (Source: Google Search)

1. Carbon Steel (e.g., A216 WCB)

Key Properties:

Carbon steel is known for its high strength, toughness, and moderate corrosion resistance when properly coated. It withstands high pressure and temperature environments, making it suitable for heavy-duty applications. Its machinability allows for precise shaping, which is essential for stud shoes that require tight tolerances.

Pros & Cons:

* Pros:*

– Cost-effective and widely available globally.

– Excellent mechanical properties, including high tensile strength.

– Ease of manufacturing and repair.

- Cons:*

- Susceptible to corrosion if not protected with coatings or galvanization.

- Requires maintenance and protective coatings, especially in humid or saline environments.

- Not suitable for prolonged exposure to corrosive media without additional treatment.

Impact on Application:

Ideal for environments where corrosion is manageable through coatings or where cost is a primary concern. Suitable for general industrial applications but less so for highly corrosive media.

International Buyer Considerations:

Buyers from regions like the Middle East or Africa, where humidity and salinity are high, should prioritize suppliers offering galvanized or coated carbon steel. Compliance with standards such as ASTM A216 ensures quality consistency. European markets may demand additional certifications like EN standards, influencing procurement decisions.

2. Stainless Steel (e.g., 304, 316 grades)

Key Properties:

Stainless steel offers excellent corrosion resistance, especially grades like 316, which resist chlorides and saline environments. It maintains strength at elevated temperatures and is highly durable.

Pros & Cons:

* Pros:*

– Superior corrosion resistance, reducing maintenance needs.

– Good mechanical strength and ductility.

– Suitable for aggressive media and outdoor applications.

- Cons:*

- Higher material cost compared to carbon steel.

- Manufacturing complexity is increased due to its hardness, requiring specialized tools.

- Heavier than alternatives, which may impact transportation costs.

Impact on Application:

Perfect for applications exposed to harsh environments, such as marine or chemical industries. Its corrosion resistance makes it suitable for regions with high humidity or saline conditions, common in Middle Eastern coastal areas.

International Buyer Considerations:

Buyers should verify compliance with international standards like ASTM A240 or DIN 1.4301/1.4404. In markets like Europe, adherence to REACH and RoHS directives is essential. For African and South American buyers, sourcing from reputable suppliers ensures material authenticity, especially given the premium cost.

3. Aluminum Alloys (e.g., 6061, 7075)

Key Properties:

Aluminum alloys are lightweight, corrosion-resistant, and possess good strength-to-weight ratios. They perform well under moderate pressure and temperature conditions, with excellent machinability.

Pros & Cons:

* Pros:*

– Significantly lighter than steel, reducing transportation and handling costs.

– Good corrosion resistance, especially when anodized.

– Easier to machine and shape.

- Cons:*

- Lower strength compared to steel, limiting use in high-stress applications.

- More susceptible to wear and deformation under extreme loads.

- Cost varies depending on alloy grade and processing.

Impact on Application:

Suitable for lightweight, portable applications or where weight reduction is critical. In regions with high transportation costs, aluminum can offer logistical advantages.

International Buyer Considerations:

Buyers should specify alloy grades conforming to standards like ASTM B209 or EN AW-6061. Anodized aluminum is preferred for enhanced corrosion resistance, especially in humid or saline environments. Cost considerations are vital for buyers in emerging markets, where balancing performance and affordability is key.

4. Polymer Composites (e.g., Reinforced Nylon, Polyetheretherketone – PEEK)

Key Properties:

Polymer composites are lightweight, corrosion-resistant, and can be engineered for specific mechanical properties. Reinforced nylons are suitable for moderate loads, while high-performance polymers like PEEK withstand high temperatures and aggressive media.

Pros & Cons:

* Pros:*

– Excellent corrosion and chemical resistance.

– Lightweight, reducing overall product weight.

– Easier to mold into complex shapes.

- Cons:*

- Generally lower mechanical strength compared to metals.

- Higher raw material costs, especially for high-performance variants.

- Limited high-temperature applications unless specially formulated.

Impact on Application:

Ideal for specialized or niche applications where corrosion resistance and weight are more critical than extreme strength. Suitable for environments with aggressive chemicals or where metal contamination must be avoided.

International Buyer Considerations:

Buyers should ensure materials meet industry standards like ISO 10993 or ASTM F2026 for medical or chemical applications. Sourcing from certified suppliers ensures quality consistency, especially important in markets with strict regulatory environments like Europe or the Middle East.

Summary Table

| Material | Typical Use Case for stud shoe | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel (e.g., A216 WCB) | Heavy-duty industrial applications, general service | Cost-effective, high strength | Susceptible to corrosion without protection | Low |

| Stainless Steel (e.g., 304, 316) | Marine, chemical, outdoor environments | Excellent corrosion resistance | Higher cost, heavier weight | High |

| Aluminum Alloys (e.g., 6061, 7075) | Lightweight applications, transport-heavy regions | Lightweight, corrosion-resistant | Lower strength, susceptible to wear | Med |

| Polymer Composites (e.g., Reinforced Nylon, PEEK) | Chemical, high-corrosion environments | Corrosion-resistant, lightweight | Limited strength, higher material cost | High |

This comprehensive analysis equips international B2B buyers with critical insights into material selection for stud shoes, enabling informed procurement decisions tailored to regional environmental conditions, standards compliance, and cost considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for stud shoe

Manufacturing Processes of Stud Shoes

The production of stud shoes involves a series of carefully orchestrated stages, each critical to ensuring product integrity and compliance with international standards. Understanding these processes enables B2B buyers from regions such as Africa, South America, the Middle East, and Europe to better evaluate supplier capabilities and quality consistency.

Material Preparation

The foundation of a durable stud shoe begins with sourcing high-quality raw materials. Typically, this includes:

– Upper Material: Leather, synthetic leather, or textiles, selected based on intended application and market preferences.

– Sole Material: Rubber, thermoplastic elastomers, or polyurethane compounds, chosen for durability and slip resistance.

– Stud Components: Usually metal (steel, brass) or high-strength plastics, designed to withstand wear and environmental exposure.

Suppliers should ensure raw materials are certified according to international standards like ISO 9001, which emphasizes quality management systems. Traceability of materials—through batch numbers and certificates of conformity—is vital for B2B buyers seeking transparency.

Forming and Assembly

The manufacturing process proceeds through:

– Cutting: Precise cutting of upper materials using automated or manual cutting tables, often with CAD/CAM technology to optimize material use.

– Stitching and Bonding: Assembling the upper parts via industrial sewing machines or adhesive bonding, depending on material and design specifications.

– Stud Attachment: Incorporating the studs into the shoe, either by embedding during the sole molding process or attaching post-assembly through mechanical fastening or adhesives.

– Lasting and Molding: Shaping the upper around a mold (last) to achieve the desired form, often using heat and pressure in specialized machines.

Advanced manufacturers utilize automation and CNC machinery to enhance precision and consistency, critical for meeting international standards and reducing defects.

Finishing

The final steps include:

– Trimming and Surface Treatment: Removing excess material, applying coatings, or surface treatments to improve aesthetics and weather resistance.

– Quality Checks: Visual inspections and dimensional verifications to ensure conformity to design specifications.

– Packaging: Proper packaging with protective materials, labels, and barcodes for traceability and branding.

Manufacturers adhering to industry best practices will employ controlled environments for finishing, minimizing contamination and ensuring consistent product quality.

Quality Control (QC) Practices

Robust QC systems are essential for international B2B transactions, especially when dealing with diverse markets with varying regulatory requirements.

International Standards & Industry Certifications

- ISO 9001: The most globally recognized standard for quality management systems. Suppliers with ISO 9001 certification demonstrate consistent process control, customer satisfaction focus, and continual improvement.

- CE Marking: Mandatory for products sold within the European Economic Area (EEA), indicating compliance with safety, health, and environmental protection standards.

- Other Industry-Specific Certifications: For specialized markets, certifications such as API (American Petroleum Institute) for certain industrial applications or ASTM standards for material testing may be relevant.

B2B buyers should verify these certifications through official documentation and supplier audits, ensuring they align with their specific market requirements.

QC Checkpoints

- Incoming Quality Control (IQC): Inspection of raw materials upon receipt, including visual assessment, dimensional verification, and testing for contaminants or defects.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing, including process audits, measurement checks, and functional testing of critical parameters such as stud attachment strength and sole adhesion.

- Final Quality Control (FQC): Comprehensive inspection before shipment, covering visual defects, dimensional accuracy, functionality (e.g., stud retention), and packaging integrity.

Each checkpoint should be documented with detailed reports, including non-conformance reports (NCRs) and corrective action records.

Testing Methods

- Mechanical Testing: Tensile strength tests for studs, adhesion tests for soles, and flexural tests for upper materials.

- Environmental Testing: Resistance to UV, moisture, and temperature variations, critical for products exported to diverse climates.

- Dimensional and Visual Inspection: Ensuring uniformity in size, shape, and surface quality.

Third-party laboratories accredited under ISO/IEC 17025 are often used for independent testing, providing an impartial verification of compliance.

Verifying Supplier QC for International Buyers

B2B buyers should adopt rigorous verification protocols to ensure supplier quality standards are met consistently:

– Supplier Audits: Conduct on-site audits focusing on manufacturing processes, QC systems, personnel training, and documentation practices. Engaging third-party inspection agencies like SGS or Bureau Veritas adds objectivity.

– Review of Quality Reports: Regularly request and analyze QC reports, test certificates, and audit results. Suppliers with digitalized quality management systems provide easier access to real-time data.

– Sample Testing and Pre-shipment Inspections: Request pre-shipment inspection (PSI) reports, including random sampling and testing, to validate ongoing quality.

– Certifications Verification: Confirm authenticity of certifications through issuing bodies and ensure they are current and applicable to the specific product and market.

Special Considerations for B2B Buyers from Africa, South America, the Middle East, and Europe

In regions like Saudi Arabia, UAE, or other Middle Eastern markets, adherence to strict standards such as CE marking and local regulatory requirements is mandatory. Buyers should prioritize suppliers with proven compliance histories and experience exporting to these markets.

For African and South American markets, where regulatory enforcement may vary, establishing a clear quality assurance framework and insisting on third-party testing can mitigate risks. European buyers, in particular, should verify compliance with REACH regulations, ensuring chemical safety and environmental standards are met.

Furthermore, establishing long-term partnerships with transparent suppliers who can provide comprehensive documentation and are open to regular audits will enhance reliability. Engaging local inspection agencies or consultants familiar with regional standards can facilitate smoother import processes and compliance.

Summary

For B2B buyers, understanding the manufacturing and QC landscape of stud shoes is crucial to making informed procurement decisions. Emphasizing supplier certifications, rigorous QC checkpoints, and independent verification processes ensures product quality and compliance across diverse international markets. By integrating these insights into their sourcing strategies, buyers can mitigate risks, foster supplier accountability, and secure high-quality products tailored to their regional requirements.

Comprehensive Cost and Pricing Analysis for stud shoe Sourcing

Cost Structure Breakdown for Stud Shoe Sourcing

Understanding the comprehensive cost framework for stud shoes is essential for effective pricing negotiations and procurement strategies. The primary cost components include:

-

Materials: The core material typically involves high-strength rubber, thermoplastic elastomers, or metal components for the studs. Material costs fluctuate based on quality, sourcing region, and specifications. Premium materials with certifications (e.g., ISO, REACH) will command higher prices but may offer better durability and safety compliance.

-

Labor: Manufacturing labor costs vary significantly across regions. Countries like China, Vietnam, and India offer competitive labor rates, whereas sourcing from Europe or the Middle East may involve higher wages but potentially higher craftsmanship standards. Consider labor compliance standards, especially for countries with strict labor regulations.

-

Manufacturing Overheads: This includes factory utilities, machinery depreciation, and administrative costs. Efficient factories with high automation levels tend to reduce per-unit costs, but initial investments in automation can impact early pricing.

-

Tooling & Setup Costs: For customized designs or molds, tooling costs can be substantial upfront but are amortized over large production runs. Buyers should negotiate tooling fees carefully, especially for low-volume orders.

-

Quality Control & Certifications: Ensuring product consistency and safety requires rigorous QC processes, which add to costs. Certifications such as ISO 9001, CE, or specific regional standards (e.g., SABS in South Africa) may be necessary depending on the target market.

-

Logistics & Shipping: International freight, customs duties, and insurance significantly influence the final landed cost. Shipping mode (sea, air, rail) impacts cost and lead times, with sea freight being more economical for bulk orders.

-

Margins & Markups: Suppliers typically add a markup to cover their risks, profit, and overheads. Markups vary but generally range from 15% to 35%, influenced by order volume, relationship strength, and market competitiveness.

Key Price Influencers for Stud Shoe B2B Purchases

Several factors directly impact the final pricing:

-

Order Volume & MOQ: Larger orders benefit from economies of scale, reducing per-unit costs. Many suppliers offer tiered pricing, with significant discounts for bulk purchases exceeding certain thresholds (e.g., 10,000 pairs).

-

Customization & Specifications: Custom designs, branding, or specialized materials increase costs due to longer lead times and bespoke tooling. Clear specifications upfront help in obtaining accurate quotes.

-

Material Choices: Opting for premium or eco-friendly materials can elevate costs but may also open access to higher-end markets or certifications.

-

Quality & Certification Requirements: Higher quality standards and regional certifications (e.g., CE for Europe, SASO for Saudi Arabia) often entail additional testing and documentation costs, which should be factored into pricing negotiations.

-

Supplier Location & Capabilities: Suppliers in regions with lower operational costs (e.g., Southeast Asia, parts of South America) can offer more competitive pricing. However, proximity to your market can reduce logistics costs and lead times.

-

Incoterms & Delivery Terms: FOB (Free On Board), CIF (Cost, Insurance, Freight), or DDP (Delivered Duty Paid) terms significantly influence pricing. Buyers should evaluate the total landed cost, including duties and taxes, especially when sourcing from regions with high tariffs.

Strategic Tips for International B2B Buyers

-

Negotiate Total Cost of Ownership (TCO): Focus not only on unit price but also on shipping, customs, lead times, and after-sales support. A cheaper unit price might be offset by higher logistics or compliance costs.

-

Leverage Volume & Long-term Relationships: Larger orders and consistent partnerships often unlock discounts and priority production slots. Building trust can also facilitate better payment terms and customization options.

-

Understand Pricing Nuances: Be aware of potential hidden costs such as inspection fees, packaging, or special handling charges. Clarify all cost components upfront.

-

Consider Quality & Certifications: Cheaper options might compromise safety or durability, impacting brand reputation and compliance in your target markets. Invest in suppliers who meet relevant regional standards.

-

Regional Market Dynamics: Prices tend to be higher in regions with strict labor or environmental regulations (e.g., Europe, Middle East) but often include higher quality assurance. Conversely, sourcing from regions with lower costs can be advantageous but requires rigorous vetting for quality and compliance.

Disclaimer

Indicative prices for standard stud shoes, depending on order volume, quality, and customization, typically range from $2.50 to $5.50 per pair for large-volume orders (e.g., over 10,000 pairs). Smaller or customized orders may see prices from $4.00 to $8.00 per pair. These figures are subject to fluctuations based on raw material costs, supplier negotiations, and logistical variables. Buyers should conduct detailed quotations tailored to their specific needs and market conditions.

Spotlight on Potential stud shoe Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for stud shoe.)*

Essential Technical Properties and Trade Terminology for stud shoe

Critical Technical Properties for Stud Shoe

Understanding the technical specifications of stud shoes is essential for making informed procurement decisions and ensuring product suitability across different markets.

1. Material Grade and Composition

The primary material used in stud shoes—typically rubber, polyurethane, or specialized plastics—directly impacts durability, flexibility, and resistance to environmental factors. High-grade materials (e.g., industrial-grade rubber or thermoplastic elastomers) are preferred for heavy-duty applications, ensuring longevity and reducing maintenance costs. Buyers should verify material certifications to confirm compliance with industry standards and regional safety regulations.

2. Tolerance and Dimensional Accuracy

Tolerance refers to the permissible deviation from specified dimensions during manufacturing. Precise tolerances (e.g., ±0.2mm) are critical for ensuring proper fit and performance, especially when integrating stud shoes into existing equipment or machinery. Tight tolerances reduce issues such as misalignment, uneven wear, or operational inefficiencies, which can be costly in industrial or construction settings.

3. Load Capacity and Mechanical Strength

Stud shoes must withstand specific loads depending on their application—be it for supporting machinery, vehicles, or structural elements. Technical datasheets often specify maximum load capacities, which should align with operational demands. Choosing a product with appropriate mechanical strength minimizes risks of failure, accidents, and associated liabilities.

4. Resistance Properties (Environmental & Chemical)

Operational environments vary widely; hence, resistance to chemicals, moisture, extreme temperatures, and abrasion is crucial. For example, in coastal regions or industrial zones, corrosion resistance becomes vital. Selecting stud shoes with the right resistance properties ensures consistent performance and reduces replacement frequency.

5. Surface Finish and Texture

The surface quality affects grip, wear, and ease of installation. A uniform, smooth finish minimizes the risk of material fatigue, while textured surfaces can enhance grip or friction where needed. Proper surface specifications help maintain safety standards and prolong product lifespan.

Common Industry and Trade Terms

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce components or products to be incorporated into another company’s finished goods. When sourcing stud shoes, understanding whether a supplier offers OEM services can influence customization options and pricing, especially if buyers need tailored specifications for specific machinery.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to accept for an order. MOQs impact procurement planning and inventory management, especially for buyers in emerging markets where demand volume may be lower. Negotiating MOQs can help optimize cash flow and reduce excess stock.

3. RFQ (Request for Quotation)

A formal document sent by buyers to suppliers requesting price, lead times, and terms for a specific product. Efficient RFQ processes enable quick comparison of suppliers, ensuring competitive pricing and reliable delivery schedules. Clear RFQs with detailed specifications lead to more accurate quotes.

4. Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce (ICC) defining responsibilities in international shipments. Common Incoterms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) specify who bears costs and risks at different transit stages. Familiarity with Incoterms ensures clarity and reduces disputes during international trade.

5. Lead Time

The period from order placement to product delivery. Understanding lead times is vital for planning inventory and avoiding delays, especially when dealing with remote regions such as Africa, South America, or the Middle East. Negotiating shorter lead times can be advantageous in just-in-time supply chains.

6. Quality Certification (e.g., ISO, CE)

Certificates indicating compliance with international quality and safety standards. For buyers in regulated markets, verifying certifications helps ensure that stud shoes meet necessary standards, facilitating smoother customs clearance and reducing compliance risks.

By mastering these technical properties and trade terms, international B2B buyers can streamline procurement processes, negotiate effectively, and ensure the quality and performance of stud shoes across diverse operational environments.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the stud shoe Sector

Market Overview & Key Trends

The stud shoe sector is experiencing dynamic shifts driven by global economic trends, technological advancements, and evolving consumer preferences. For international B2B buyers from Africa, South America, the Middle East, and Europe, understanding these drivers is crucial to optimize sourcing strategies and capitalize on emerging opportunities.

Global Drivers: Rising disposable incomes and a growing youth demographic, especially in emerging markets, are fueling demand for fashionable, affordable footwear. The increasing influence of social media and celebrity endorsements boosts the popularity of stud shoes, especially in urban markets. Additionally, the expansion of e-commerce platforms facilitates direct-to-consumer sales, enabling brands to reach diverse markets more efficiently.

Emerging Sourcing Trends: Technological integration, such as 3D printing and automation, is transforming manufacturing processes, reducing lead times, and lowering costs. Modular and flexible production lines allow for rapid customization, which appeals to markets seeking personalized footwear. Sustainable sourcing is also gaining momentum, with buyers increasingly prioritizing eco-friendly materials and ethical labor practices.

Market Dynamics for B2B Buyers: For buyers from regions like Africa and South America, establishing resilient supply chains amidst geopolitical uncertainties and fluctuating raw material costs is vital. Leveraging regional manufacturing hubs can mitigate risks and reduce logistics costs. European and Middle Eastern buyers are exploring nearshoring options or diversified sourcing to ensure supply continuity and adapt to rapid market changes. Digital platforms and trade facilitation tools further streamline procurement, offering transparency and real-time insights into production statuses and compliance.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone of responsible sourcing in the stud shoe industry. Environmental concerns surrounding traditional leather and synthetic materials have prompted brands to adopt greener alternatives. For B2B buyers, integrating sustainability into procurement not only aligns with global trends but also enhances brand reputation and consumer trust.

Eco-conscious sourcing involves selecting materials with certifications such as Global Organic Textile Standard (GOTS), Leather Working Group (LWG), or recycled content labels. For instance, using recycled plastics or plant-based alternatives reduces the carbon footprint of production. Ethical labor practices, verified through audits and certifications like SA8000 or Fair Trade, are equally critical, especially for buyers from regions emphasizing corporate social responsibility.

Implementing sustainable practices can also offer economic benefits, such as access to green funding or preferential trade terms. Establishing transparent supply chains ensures traceability from raw material to finished product, fostering trust among end consumers and regulatory bodies. As sustainability standards become more stringent globally, proactive engagement with certified suppliers will be essential for future-proofing sourcing strategies.

Brief Evolution/History

The stud shoe market has evolved significantly over recent decades, transitioning from simple fashion accessories to essential elements of contemporary footwear design. Initially driven by youth culture and streetwear trends, the sector has expanded through technological innovations and globalized supply chains. For B2B buyers, understanding this evolution highlights the importance of agility, quality standards, and sustainability in maintaining competitive advantages. Recognizing historical shifts also aids in predicting future market trajectories, allowing for strategic positioning in sourcing and product development.

Frequently Asked Questions (FAQs) for B2B Buyers of stud shoe

1. How can I verify the credibility and reliability of a stud shoe supplier?

To ensure supplier credibility, start with comprehensive background checks, including business licenses, certifications, and references from previous clients. Request samples to assess product quality firsthand. Verify their production capacity and compliance with international standards such as ISO or CE, especially if exporting to regions with strict regulations like Europe or the Middle East. Conduct virtual factory audits or visit in person when feasible. Additionally, review their trade history on platforms like Alibaba, Global Sources, or local trade chambers. A transparent communication process and prompt responses are also good indicators of a reliable partner.

2. What customization options are typically available for stud shoes, and how do they impact lead times and costs?

Most manufacturers offer customization in design, branding, color, size, and specific stud configurations. Advanced customizations, such as unique sole patterns or logo embossing, may require longer lead times and higher minimum order quantities (MOQs). Clearly communicate your specifications upfront to get accurate quotes and timelines. Customization often increases costs proportionally to complexity and volume; therefore, negotiate for bulk discounts or phased deliveries if possible. Be aware that high customization may extend lead times by several weeks, so plan accordingly for your supply chain and inventory management.

3. What are typical MOQs, lead times, and payment terms for international stud shoe orders?

MOQs for stud shoes generally range from 500 to 5,000 pairs, depending on the manufacturer and complexity. Lead times typically span 4 to 12 weeks, accounting for production, quality checks, and logistics. Payment terms often include a 30% deposit upfront with the balance payable before shipment, or letters of credit for larger orders. Some suppliers may offer flexible terms for established buyers or large-volume contracts. Always negotiate terms that suit your cash flow, and consider using escrow or trade assurance platforms to mitigate payment risks when dealing across borders.

4. What quality assurance certifications and testing should I look for in a stud shoe supplier?

Reliable suppliers should provide certifications such as ISO 9001 (quality management), ISO 14001 (environmental management), or specific safety standards relevant to your target market. Request laboratory test reports for durability, slip resistance, and material safety—especially important for regions with strict safety regulations like Europe or the Middle East. Ensure the supplier conducts in-house QC inspections and offers third-party testing if necessary. Establish clear quality benchmarks in your contract, and consider conducting pre-shipment inspections or third-party audits to prevent quality issues upon arrival.

5. How can I manage international logistics effectively for stud shoe shipments?

Effective logistics management involves selecting reliable freight forwarders experienced in international trade, especially to your region. Understand the Incoterms (e.g., FOB, CIF, DDP) to clarify responsibilities and costs. For Africa and South America, consider maritime shipping for bulk orders due to cost efficiency, while air freight might suit urgent needs. Be aware of regional customs procedures, import duties, and VAT. Maintain open communication with your supplier and logistics providers, and track shipments diligently. Incorporate contingency plans for delays or customs issues, and ensure all documentation (invoice, packing list, certificates) is accurate and complete to facilitate smooth clearance.

6. What common disputes arise in international stud shoe trade, and how can I prevent or resolve them?

Disputes often involve quality discrepancies, delayed shipments, or payment issues. To prevent these, establish clear contractual terms covering specifications, inspection rights, delivery schedules, and payment conditions. Use detailed purchase agreements and include clauses for dispute resolution, such as arbitration under recognized rules like ICC or local arbitration bodies. Maintain transparent communication and document all correspondence. If a dispute occurs, engage in amicable negotiations first; if unresolved, escalate to arbitration or legal channels. Working with suppliers who have a solid reputation and positive reviews reduces the likelihood of disputes and facilitates quicker resolution.

7. How do regional trade agreements and tariffs affect the import of stud shoes into Africa, South America, and the Middle East?

Regional trade agreements can significantly reduce tariffs and streamline customs procedures. For example, the African Continental Free Trade Area (AfCFTA) aims to facilitate intra-African trade, potentially lowering tariffs for member countries. Similarly, the Gulf Cooperation Council (GCC) agreements may offer preferential tariffs for Middle Eastern countries like Saudi Arabia and the UAE. South American countries often have Mercosur trade agreements that impact tariffs. Always verify the current trade agreements applicable to your country and ensure proper tariff classification and documentation to avoid unexpected costs. Partnering with local customs brokers can optimize clearance processes and reduce delays.

8. What are best practices for establishing long-term relationships with stud shoe suppliers?

Building long-term partnerships requires consistent quality, reliable delivery, and transparent communication. Start with smaller pilot orders to evaluate supplier performance. Maintain regular contact and provide feedback to foster mutual understanding. Negotiate flexible terms that accommodate your growth and seasonal fluctuations. Consider supplier development programs or joint planning to align production schedules. Establish clear performance metrics and conduct periodic reviews. A trustworthy supplier will prioritize your account, offer competitive pricing, and adapt to your evolving needs—ultimately enabling a stable supply chain and better negotiation leverage over time.

This structured approach ensures that international B2B buyers from diverse regions can confidently navigate the complexities of sourcing stud shoes, fostering successful and sustainable trade relationships.

Strategic Sourcing Conclusion and Outlook for stud shoe

Conclusion and Future Outlook

Effective strategic sourcing is vital for B2B buyers seeking to capitalize on the growing demand for stud shoes across diverse markets. By focusing on reliable suppliers, ensuring quality standards, and leveraging cost efficiencies, buyers from Africa, South America, the Middle East, and Europe can secure a competitive advantage. Emphasizing supplier diversity and sustainable sourcing practices further enhances resilience and brand reputation in an increasingly conscious global marketplace.

Looking ahead, the stud shoe industry is poised for innovation, driven by technological advancements and evolving consumer preferences. International buyers should prioritize building strong, transparent supplier relationships and stay informed about emerging sourcing regions and materials. This proactive approach will enable you to adapt swiftly to market changes and seize new growth opportunities.

Illustrative Image (Source: Google Search)

Actionable takeaway: Begin evaluating and diversifying your sourcing portfolio today to mitigate risks and maximize value. Embrace sustainable and ethical sourcing standards to meet increasing demand for responsible products. By doing so, you position your business not only for current success but also for sustainable growth in the dynamic stud shoe industry.