Master Global Sourcing with the Ultimate Shawn Kemp Shoes

Guide to Shawn Kemp Shoes

- Introduction: Navigating the Global Market for shawn kemp shoes

- Understanding shawn kemp shoes Types and Variations

- Key Industrial Applications of shawn kemp shoes

- Strategic Material Selection Guide for shawn kemp shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for shawn kemp shoes

- Comprehensive Cost and Pricing Analysis for shawn kemp shoes Sourcing

- Spotlight on Potential shawn kemp shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for shawn kemp shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the shawn kemp shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of shawn kemp shoes

- Strategic Sourcing Conclusion and Outlook for shawn kemp shoes

Introduction: Navigating the Global Market for shawn kemp shoes

In the fiercely competitive landscape of international footwear sourcing, Shawn Kemp shoes have emerged as a compelling product category for B2B buyers seeking quality, innovation, and brand recognition. Their growing global demand underscores the importance of understanding the nuances of sourcing, manufacturing, and distribution—especially for buyers in Africa, South America, the Middle East, and Europe. These regions present unique opportunities and challenges, from navigating diverse regulatory environments to identifying reliable suppliers that meet quality and cost expectations.

This comprehensive guide equips you with critical insights into all facets of Shawn Kemp shoes, including the various types and materials used, manufacturing and quality control standards, supplier landscapes, and cost considerations. It also explores market trends and provides practical answers to frequently asked questions, enabling you to make informed, strategic sourcing decisions. Whether you are looking to expand your product portfolio, negotiate better deals, or establish long-term supplier relationships, this resource offers actionable intelligence tailored to your regional and business needs.

By leveraging this guide, international B2B buyers can confidently navigate the complexities of the global Shawn Kemp shoe market, ensuring procurement processes that are efficient, compliant, and aligned with your growth objectives. Ultimately, it empowers you to capitalize on emerging opportunities and secure a competitive edge in the dynamic footwear industry.

Understanding shawn kemp shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Shawn Kemp Model | Retro design, high-top silhouette, signature colorways | Retail, sports apparel, sneaker boutiques | Pros: Recognizable brand appeal, high resale value. Cons: Limited innovation, higher procurement costs due to brand premium |

| Performance Edition | Enhanced cushioning, lightweight materials, advanced sole tech | Sports teams, athletic footwear suppliers | Pros: Superior comfort and durability, appeals to performance markets. Cons: Higher manufacturing costs, longer lead times |

| Custom/Collaborative Series | Unique designs, limited editions, artist collaborations | Specialty boutiques, collector markets | Pros: High exclusivity, premium pricing. Cons: Limited stock, unpredictable demand, higher MOQ requirements |

| Lifestyle/Casual Variants | Trendy, versatile, lower profile, often with modern materials | Fashion retailers, casual footwear markets | Pros: Broader consumer appeal, easier inventory turnover. Cons: Marginally lower margins compared to performance models |

| OEM/Private Label Models | Custom branding, tailored specifications for bulk buyers | Distributors, private label brands | Pros: High volume sales, customizable options. Cons: Less brand differentiation, dependency on OEM quality control |

Classic Shawn Kemp Model

The classic Shawn Kemp shoes are characterized by their iconic high-top silhouette and nostalgic appeal rooted in the original basketball sneaker design. These models typically feature vibrant colorways and signature branding, making them highly recognizable. They are suitable for retail outlets focusing on retro or vintage sports apparel, especially in markets like Europe and the Middle East where vintage sneaker culture is growing. B2B buyers should consider the premium pricing and limited production runs, which can impact inventory planning and margins. Sourcing authentic models ensures brand integrity but may involve higher procurement costs due to licensing and exclusivity.

Performance Edition

Designed for athletic performance, these shoes incorporate advanced cushioning technologies, lightweight materials, and durable soles tailored for high-impact sports. They are ideal for suppliers targeting sports teams, athletic stores, or markets demanding high-performance footwear, such as South America and Africa. B2B buyers should evaluate the technical specifications for durability and comfort, as these influence customer satisfaction and repeat sales. While offering higher margins due to their technical superiority, these models often come with longer lead times and higher manufacturing costs, necessitating careful planning and supplier vetting.

Custom/Collaborative Series

Limited edition and artist collaborations give these models a unique edge, often featuring exclusive designs and branding elements. They appeal to sneaker collectors, fashion-forward consumers, and specialty boutiques across regions like Europe and the Middle East. B2B buyers should focus on inventory management and demand forecasting, as these products tend to have unpredictable demand and limited stock. The high price point and exclusivity can lead to significant profit margins but require strong relationships with suppliers or licensors to ensure timely delivery and authenticity.

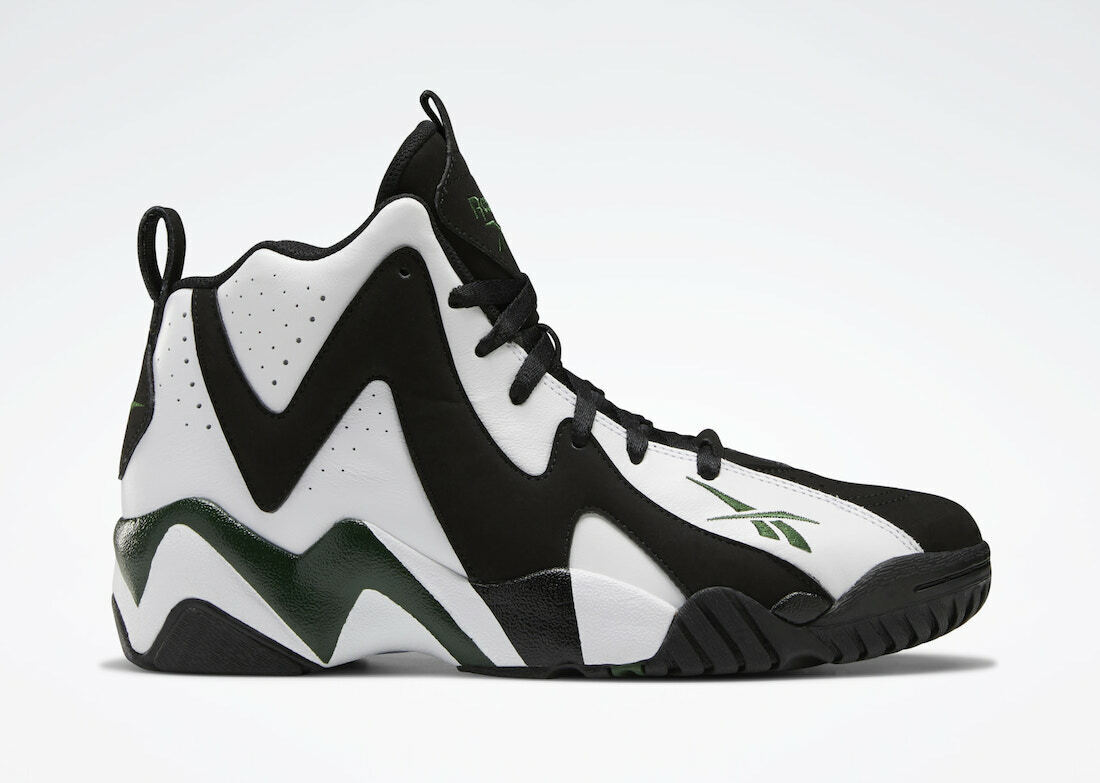

Illustrative Image (Source: Google Search)

Lifestyle/Casual Variants

These models prioritize versatility, comfort, and modern aesthetics, often using contemporary materials and design cues. They are well-suited for fashion retailers and casual footwear markets across Africa and Indonesia, where sneaker culture intersects with everyday fashion. Buyers should consider the broader consumer appeal and quicker inventory turnover, which reduces financial risk. Margins may be slightly lower compared to performance or limited editions, but the increased volume potential can compensate for this, making them a strategic choice for expanding market share.

OEM/Private Label Models

Manufactured to specifications for bulk buyers, these models enable distributors and private label brands to offer Shawn Kemp shoes under their own branding. They are highly customizable in terms of design, materials, and packaging, suitable for large-scale distribution in diverse markets. B2B buyers should prioritize quality control and consistent supply chain management, as OEM models depend heavily on manufacturer reliability. This approach offers high-volume sales opportunities but requires careful negotiation on MOQ, lead times, and intellectual property rights to maximize profitability.

Key Industrial Applications of shawn kemp shoes

| Industry/Sector | Specific Application of shawn kemp shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Heavy Industry | Heavy-duty safety footwear for construction sites and industrial plants | Enhances worker safety, reduces injury risk, and ensures compliance with safety standards | Durability, slip resistance, certification standards (e.g., EN, ANSI) |

| Logistics & Warehousing | Durable shoes for warehouse staff handling heavy loads and equipment | Improves worker comfort and safety, minimizes downtime due to injuries | Comfort for extended wear, slip resistance, availability in bulk orders |

| Mining & Extractive Industries | Robust footwear designed for underground and surface mining operations | Protects against rough terrains, falling objects, and hazardous environments | Resistance to abrasions, waterproofing, thermal insulation |

| Oil & Gas | Specialized shoes for offshore and onshore oil field workers | Ensures safety in high-risk environments, compliance with industry regulations | Oil-resistant soles, chemical resistance, anti-slip features |

| Agriculture & Farming | Heavy-duty shoes for fieldwork, livestock handling, and farm operations | Provides protection against uneven terrain, mud, and potential injuries | Weather resistance, comfort, durability in rugged outdoor conditions |

Construction & Heavy Industry

Shawn Kemp shoes are widely used in construction and heavy industry sectors due to their exceptional durability and safety features. They are designed to withstand harsh environments, offering slip resistance, impact protection, and compliance with safety standards such as EN and ANSI. For international buyers in regions like Africa and the Middle East, sourcing shoes that meet local safety certifications is crucial. These shoes help minimize workplace injuries, ensure regulatory compliance, and reduce long-term costs associated with worker accidents.

Logistics & Warehousing

In logistics and warehousing, workers often operate in environments with heavy machinery, pallets, and uneven surfaces. Shawn Kemp shoes provide the necessary durability and comfort for extended shifts, reducing fatigue and injury risks. Their slip-resistant soles are vital for preventing accidents on slick warehouse floors. B2B buyers should prioritize sourcing shoes that can be supplied in bulk, meet safety standards, and offer consistent quality to ensure operational efficiency across regions like South America and Europe.

Mining & Extractive Industries

Mining operations demand footwear that can withstand extreme conditions, including rough terrains, exposure to dust, and potential impacts from falling debris. Shawn Kemp shoes excel in providing robust protection, with features such as abrasion resistance, waterproofing, and thermal insulation. For buyers in Africa, South America, and the Middle East, sourcing footwear with certifications like ISO or ASTM can ensure safety compliance. These shoes help reduce downtime and injuries, supporting sustainable mining operations.

Oil & Gas

Offshore and onshore oil field workers face high-risk environments requiring specialized footwear. Shawn Kemp shoes designed for this sector offer chemical and oil resistance, anti-slip soles, and thermal insulation. For B2B buyers in regions like the UAE or Indonesia, sourcing shoes that meet industry-specific safety standards and environmental conditions is essential. Proper footwear enhances safety, reduces liability, and ensures operational continuity in demanding environments.

Illustrative Image (Source: Google Search)

Agriculture & Farming

Agricultural workers encounter diverse outdoor conditions, including mud, uneven terrain, and exposure to chemicals. Shawn Kemp shoes for this sector are rugged, weather-resistant, and provide excellent foot protection. They help prevent injuries from slips, trips, and impacts, which are common in farming activities. International buyers should focus on sourcing shoes that combine durability with comfort, suited to the climatic conditions of their regions, ensuring long-term value and worker safety.

Strategic Material Selection Guide for shawn kemp shoes

Material Analysis for Shawn Kemp Shoes

Selecting the appropriate materials for Shawn Kemp shoes requires a comprehensive understanding of their properties, manufacturing implications, and suitability for various markets. For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, considerations extend beyond technical performance to include regional standards, import regulations, and consumer preferences.

Leather

Leather remains a traditional and highly favored material in athletic and casual footwear, including Shawn Kemp shoes. It offers excellent durability, breathability, and a premium aesthetic, making it suitable for high-end markets. Key properties include natural flexibility, moisture-wicking capabilities, and resistance to wear over time. However, leather production involves complex tanning processes that can vary significantly in environmental impact and compliance standards, especially relevant for European markets with stringent regulations like REACH and ECHA.

Pros:

– High durability and comfort

– Natural breathability and aesthetic appeal

– Good aging characteristics

Cons:

– Higher cost due to processing and raw material quality

– Environmental concerns and compliance issues in certain regions

– Sensitive to water damage unless treated

Impact on Application:

Leather’s breathability and comfort make it ideal for casual and lifestyle shoes. Its resistance to wear enhances product longevity, appealing to consumers seeking value.

International Considerations:

European buyers often prefer leather that complies with eco-label standards; thus, sourcing from suppliers with certified tanning processes is advantageous. In Africa and South America, raw leather costs are lower, but quality control is essential to meet international standards.

Synthetic Materials (e.g., PU, TPU)

Synthetic materials like Polyurethane (PU) and Thermoplastic Polyurethane (TPU) are increasingly popular in Shawn Kemp shoes due to their versatility and cost-effectiveness. These materials can be engineered for specific properties such as flexibility, abrasion resistance, and lightweight performance. They are also easier to manufacture at scale, making them attractive for mass production.

Pros:

– Cost-effective and scalable manufacturing

– Consistent quality and performance

– Lightweight and customizable properties

Cons:

– Generally less breathable than natural leather

– Environmental concerns related to plastic production and disposal

– Potential degradation under UV exposure

Impact on Application:

Ideal for sports and performance-oriented shoes where durability and lightweight features are prioritized. Suitable for markets with price sensitivity, such as parts of Africa and South America.

International Considerations:

European and Middle Eastern markets increasingly favor eco-friendly synthetic options with low VOC emissions. Buyers should verify compliance with standards like OEKO-TEX or ISO certifications. In regions with less stringent regulations, synthetic materials can be sourced more freely but should still meet basic safety standards.

Rubber and EVA (Ethylene Vinyl Acetate)

Rubber and EVA are common for outsoles and midsoles in Shawn Kemp shoes, providing essential cushioning and traction. Rubber offers excellent wear resistance and grip, while EVA contributes to lightweight shock absorption.

Pros:

– High durability and slip resistance

– Good shock absorption (EVA)

– Cost-effective for large-volume production

Cons:

– Rubber can be heavy and less flexible

– EVA may degrade with prolonged exposure to UV and heat

– Environmental concerns with synthetic rubber disposal

Impact on Application:

Critical for outsole performance, especially in outdoor or high-traction environments. Suitable for sports shoes in regions with varied terrains, such as parts of Africa and South America.

International Considerations:

Buyers should prioritize natural or recycled rubber options to align with sustainability trends. Compliance with environmental standards like REACH or ASTM D2047 is recommended for European markets.

Summary Table

| Material | Typical Use Case for Shawn Kemp Shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Upper material, premium casual or lifestyle shoes | Durable, breathable, premium appearance | Higher cost, environmental concerns, water sensitivity | High |

| Synthetic (PU, TPU) | Upper, midsole, and reinforcement components | Cost-effective, customizable, lightweight | Less breathable, environmental impact, UV degradation | Med |

| Rubber/EVA | Outsoles and midsoles | Durable, slip-resistant, shock absorption | Heavy (rubber), UV/heat degradation of EVA | Low |

This strategic material selection approach ensures international B2B buyers can optimize product performance, cost, and compliance, aligning with regional market preferences and regulatory standards.

In-depth Look: Manufacturing Processes and Quality Assurance for shawn kemp shoes

Manufacturing Processes of Shawn Kemp Shoes

The manufacturing of Shawn Kemp shoes typically follows a multi-stage process designed to ensure durability, comfort, and aesthetic appeal, aligned with international standards. For B2B buyers, understanding these stages is crucial to evaluating supplier capabilities and ensuring product consistency.

1. Material Preparation

The process begins with sourcing high-quality raw materials, including leather, synthetic fabrics, rubber, and foam padding. Suppliers often collaborate with certified material vendors to guarantee compliance with safety and environmental standards such as ISO 14001. Material inspection at this stage involves checking for defects, weight consistency, and material integrity through visual and tactile assessments, often supported by laboratory testing for chemical composition and durability.

2. Forming and Cutting

Once materials are approved, they are cut into specific patterns using automated cutting machines, which ensure precision and reduce waste. Advanced CAD/CAM systems are often employed to optimize material usage and maintain consistency across batches. For higher-end or custom models, manual cutting may be involved, requiring meticulous quality checks.

3. Assembly and Stitching

The cut components are assembled through a combination of stitching, adhesive bonding, and sometimes heat welding, depending on the shoe design. Automated sewing machines with programmable stitches are standard, but skilled manual assembly is often employed for complex designs. This stage includes attaching the sole, lining, and upper, with precise adherence to specifications to ensure product integrity.

4. Finishing and Quality Checks

Final finishing involves polishing, embossing, and applying branding elements. The shoes are then subjected to finishing inspections, including cleaning, polishing, and quality touch-ups. This stage ensures that aesthetic standards are met before proceeding to testing.

Quality Assurance (QA) and Control Measures

Maintaining high-quality standards is critical, especially for international B2B transactions. Manufacturers typically implement comprehensive QC systems aligned with global standards like ISO 9001, which emphasizes process consistency, customer satisfaction, and continuous improvement.

1. International and Industry-Specific Certifications

- ISO 9001: Demonstrates a quality management system that ensures consistent production quality.

- CE Marking: Indicates compliance with European safety, health, and environmental requirements, essential for export to European markets.

- Other Certifications: Depending on the destination, certifications such as ASTM for safety standards or specific regional standards (e.g., Dubai’s DCL or South American certifications) may be relevant.

2. Inspection Points and QC Stages

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival, including visual checks, chemical testing, and physical property assessments.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing, focusing on stitch quality, dimensional accuracy, and assembly integrity. Techniques include statistical process control (SPC) and visual inspections.

- Final Quality Control (FQC): Comprehensive inspection of finished shoes, including visual assessment for defects, measurement verification, and functional testing like flexibility and adhesion tests.

3. Testing Methods

- Durability Tests: Bend, flex, and wear tests simulate real-world usage.

- Adhesion Tests: Ensuring sole attachment withstands stress.

- Color Fastness: Testing for fading or bleeding after washing or exposure to light.

- Environmental Tests: Resistance to water, temperature variations, and UV exposure, especially for outdoor or sports models.

Verifying Supplier QC Capabilities for International Buyers

For B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying the integrity of manufacturing and QC processes is vital to mitigate risks and ensure compliance.

1. Conducting Factory Audits

- Engage third-party inspection agencies (e.g., SGS, Bureau Veritas) to conduct comprehensive audits covering production facilities, QC processes, and workforce conditions.

- Focus on the supplier’s adherence to documented procedures, equipment calibration, and traceability systems.

2. Reviewing Quality Reports and Certifications

- Request recent quality inspection reports, test certificates, and certifications such as ISO 9001, CE, or regional standards.

- Cross-verify documentation with issuing authorities or certification bodies to confirm authenticity.

3. Sample Testing and Pre-shipment Inspection

- Arrange for pre-shipment inspections, including random sampling, to verify product conformity.

- Utilize third-party inspection services to perform detailed testing on sample batches, ensuring they meet specified standards before shipment.

4. Ongoing Quality Monitoring

- Establish clear quality agreements that specify inspection criteria and corrective actions for non-conformance.

- Implement periodic audits and request production monitoring reports to maintain ongoing quality oversight.

Special Considerations for International B2B Buyers

International B2B buyers from diverse regions should be aware of regional standards and compliance nuances:

- Africa & South America: Buyers should prioritize suppliers with ISO 9001 certification and regional compliance for safety and environmental standards. Be aware of customs regulations and import tariffs that may require specific certifications.

- Middle East (e.g., UAE): Emphasize CE marking and compliance with Gulf Cooperation Council (GCC) standards. Audits should verify adherence to local environmental and safety regulations.

- Europe (e.g., Indonesia, UAE): Strict compliance with EU standards, including REACH and CE, is essential. Suppliers with ISO 9001 and ISO 14001 certifications are preferred, and independent third-party testing is often required.

Summary and Actionable Insights

- Assess manufacturing capabilities by understanding each stage of the process, from material sourcing to finishing, and ensure suppliers employ advanced techniques and automation where appropriate.

- Verify quality systems through certifications, documented QC procedures, and third-party audits. Prioritize suppliers with ISO 9001 and industry-specific standards like CE.

- Implement rigorous inspection protocols at IQC, IPQC, and FQC stages, and demand detailed testing reports.

- Leverage third-party inspectors to validate supplier claims, especially when dealing with overseas manufacturers unfamiliar with regional standards.

- Maintain ongoing communication with suppliers to ensure continuous compliance, especially for customized or high-value orders.

By thoroughly understanding manufacturing processes and implementing robust QC verification strategies, international B2B buyers can confidently source Shawn Kemp shoes that meet their quality expectations and regulatory requirements, fostering long-term, mutually beneficial partnerships.

Comprehensive Cost and Pricing Analysis for shawn kemp shoes Sourcing

Cost Structure Breakdown for Shawn Kemp Shoes Sourcing

Understanding the cost components involved in sourcing Shawn Kemp shoes is essential for international buyers aiming to optimize their procurement strategies. The primary cost elements include raw materials, manufacturing labor, overhead expenses, tooling, quality control, logistics, and profit margins.

Materials:

The choice of materials—such as synthetic leather, mesh fabrics, rubber soles, and specialized cushioning—significantly impacts the unit price. High-performance or customized materials tend to elevate costs, especially if they meet specific certifications or sustainability standards. Buyers should evaluate whether suppliers offer cost-effective alternatives without compromising quality.

Labor Costs:

Labor expenses vary widely based on the manufacturing country. For instance, sourcing from Asian manufacturers (e.g., China, Vietnam) often offers lower labor costs compared to European or Middle Eastern suppliers. However, higher labor costs might be justified by superior craftsmanship, stricter quality standards, or faster lead times.

Manufacturing Overhead:

Overheads include factory utilities, machinery depreciation, and administrative expenses. Efficient factories with advanced automation can reduce overhead costs, which could translate into more competitive pricing for buyers.

Tooling and Setup Fees:

Custom designs or significant modifications require initial tooling investments, which can range from a few hundred to several thousand dollars. These are typically amortized over large order volumes but can be a barrier for small or trial orders.

Quality Control and Certifications:

Ensuring compliance with international standards (e.g., ISO, SGS testing) may add to the cost but is crucial for market acceptance, especially in Europe and the Middle East. Suppliers with established quality assurance processes tend to command higher prices but offer reduced risk.

Logistics and Incoterms:

Shipping costs depend on factors like order volume, destination port, and chosen Incoterms (e.g., FOB, CIF, DDP). Buyers in remote regions or countries with complex customs procedures should anticipate higher logistics expenses, which can significantly influence the total landed cost.

Profit Margins:

Suppliers typically include a margin to ensure profitability. Negotiation can influence this component, especially for large-volume orders or long-term partnerships.

Price Influencers and Variations

Several factors influence the final unit price of Shawn Kemp shoes in international markets:

-

Order Volume & MOQ:

Higher volumes generally lead to lower per-unit costs due to economies of scale. Many suppliers set minimum order quantities (MOQs) that can range from 500 to 5,000 pairs, impacting entry costs for smaller buyers. -

Customization & Specifications:

Customized designs, branding, or special features (e.g., eco-friendly materials, specific cushioning) increase costs. Standard models are more price-competitive but may limit differentiation. -

Material Selection:

Premium or imported materials command higher prices. Local sourcing options may reduce costs but could affect quality or compliance. -

Certifications & Standards:

Meeting regional safety, environmental, or quality certifications can add to costs but are often necessary for market entry, particularly in Europe and the Middle East. -

Supplier Factors:

Established manufacturers with higher reputations or those offering quicker lead times and better after-sales support tend to have premium pricing. Conversely, emerging suppliers may offer lower prices but with increased risk. -

Incoterms & Logistics Arrangements:

Choosing FOB (Free on Board) prices shifts shipping costs to the buyer, providing more control, while CIF (Cost, Insurance, Freight) includes these costs in the quoted price. DDP (Delivered Duty Paid) offers maximum convenience but at a higher cost.

Buyer Tips for Cost Optimization

-

Negotiate Volume Discounts:

Leverage larger orders to negotiate better unit prices or reduced setup fees. Establishing long-term relationships often results in more favorable terms. -

Assess Total Cost of Ownership (TCO):

Focus not only on the initial purchase price but also on shipping, customs duties, taxes, and potential quality costs. For example, opting for slightly higher-priced suppliers with better quality control can reduce returns and rework. -

Understand Pricing Nuances:

Prices can vary based on currency fluctuations, regional tariffs, and seasonal demand. Stay informed about market trends that may affect costs. -

Customize for Local Markets:

Adapting products to meet regional preferences or standards can open new markets but may increase costs. Balance customization with cost-efficiency to maximize profit margins. -

Leverage Strategic Sourcing:

Identify suppliers with proven reliability and certifications, especially those familiar with export procedures to Africa, South America, the Middle East, and Europe. This reduces delays and unforeseen costs.

Indicative Price Range (Disclaimer)

While actual prices fluctuate based on order specifics, typical FOB prices for Shawn Kemp shoes range from $20 to $50 per pair for standard models in bulk. Customization, premium materials, or smaller order volumes may push prices upward. Buyers should engage directly with suppliers for precise quotations tailored to their specific requirements.

In summary, a thorough understanding of cost components, pricing influencers, and strategic negotiation can significantly enhance procurement efficiency. By carefully analyzing these factors, international buyers from diverse regions can secure competitive deals while ensuring product quality and compliance.

Spotlight on Potential shawn kemp shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for shawn kemp shoes.)*

Essential Technical Properties and Trade Terminology for shawn kemp shoes

Key Technical Properties for Shawn Kemp Shoes

Understanding the technical specifications of Shawn Kemp shoes is essential for international B2B buyers to ensure product quality, compatibility, and compliance with market standards.

-

Material Grade:

The quality of materials used—such as leather, synthetic fibers, or rubber—directly impacts durability, comfort, and brand reputation. Higher-grade materials typically command a premium price but offer better longevity and performance, making them critical for premium markets in regions like Europe and the Middle East. -

Sole Composition and Tread Pattern:

The sole material (e.g., rubber, EVA foam) influences grip, cushioning, and overall wear resistance. Tread pattern design affects slip resistance and suitability for various terrains, which is vital for markets in Africa and South America where diverse surfaces are common. -

Manufacturing Tolerance:

This refers to the acceptable variation in dimensions during production. Tight tolerances (e.g., ±0.5 mm) ensure consistency, which is crucial for bulk orders and ensuring that shoes fit as expected across different regions. -

Weight and Flexibility:

Lightweight shoes with high flexibility appeal to athletes and casual users alike. These properties influence comfort, especially in markets where long walking or standing hours are typical. -

Colorfastness and Finish:

Resistance to fading and quality of surface finishing are important for maintaining aesthetic appeal over time, especially in humid or sun-intensive climates common in the Middle East and tropical regions. -

Environmental Compliance:

Materials and manufacturing processes should meet regional standards such as REACH (Europe) or local safety regulations. This ensures smoother customs clearance and market acceptance.

Essential Industry and Trade Terms

Familiarity with common trade terminology enhances communication and negotiation efficiency in international markets.

-

OEM (Original Equipment Manufacturer):

Refers to factories producing Shawn Kemp shoes under the buyer’s brand. Understanding OEM capabilities helps buyers evaluate manufacturing flexibility, customization options, and lead times. -

MOQ (Minimum Order Quantity):

The smallest number of units a supplier is willing to produce per order. Knowing MOQ helps buyers plan procurement volumes, manage inventory, and negotiate better terms, especially when entering new markets. -

RFQ (Request for Quotation):

A formal request sent to suppliers asking for pricing, lead times, and terms for specific shoe models. An RFQ is essential for comparing suppliers and securing competitive deals in diverse regions. -

Incoterms (International Commercial Terms):

Standardized trade terms defining responsibilities for shipping, insurance, and customs duties (e.g., FOB, CIF). Mastery of Incoterms ensures clarity on costs and liabilities, crucial for smooth cross-border transactions. -

Lead Time:

The duration from order confirmation to delivery. Recognizing lead times helps buyers align production schedules, especially for seasonal or promotional launches in different markets. -

Quality Certification:

Documentation such as ISO standards or regional safety certificates. Ensuring compliance with certifications facilitates market entry and reduces customs delays.

Strategic Implications for International Buyers

By understanding these technical properties and trade terms, B2B buyers from Africa, South America, the Middle East, and Europe can make informed decisions, negotiate effectively, and establish reliable supply chains. Prioritize clear communication of specifications and contractual terms to mitigate risks, optimize costs, and ensure product suitability for targeted markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the shawn kemp shoes Sector

Market Overview & Key Trends

The global market for Shawn Kemp shoes, like many niche athletic footwear segments, is experiencing rapid evolution driven by technological advancements, shifting consumer preferences, and geopolitical factors. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including key markets like Indonesia and the UAE, are increasingly seeking innovative sourcing options that balance quality, cost-efficiency, and sustainability.

Emerging trends include the integration of smart manufacturing processes—such as 3D printing and AI-driven quality control—that reduce lead times and enhance customization capabilities. Digital platforms and e-commerce marketplaces have also revolutionized sourcing, enabling buyers to connect directly with manufacturers or authorized distributors worldwide, thereby reducing intermediaries and costs.

Market dynamics are influenced by fluctuating raw material costs, tariffs, and trade policies. For instance, tariffs on imported footwear in certain Middle Eastern and European markets can impact pricing strategies, necessitating proactive sourcing diversification. Additionally, regional demand for premium, limited-edition, or customized Shawn Kemp shoes is growing, prompting manufacturers to adopt agile production techniques.

For B2B buyers, understanding regional supply chain intricacies is crucial. Countries like Indonesia are becoming hubs for footwear manufacturing due to their established infrastructure and skilled labor, while emerging markets in Africa and South America offer cost advantages. Navigating these dynamics requires ongoing monitoring of geopolitical shifts, trade agreements, and technological innovations to optimize sourcing and maintain competitive edge.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly central to sourcing decisions in the Shawn Kemp shoes sector, driven by both consumer demand and regulatory pressures. Buyers in Africa, South America, the Middle East, and Europe are prioritizing suppliers that demonstrate strong environmental stewardship and ethical labor practices. This shift aligns with global efforts to reduce carbon footprints and eliminate unethical labor practices within supply chains.

Environmental impacts of footwear manufacturing—such as water consumption, waste generation, and chemical use—are under scrutiny. Sourcing from suppliers with verified green certifications (e.g., ISO 14001, Bluesign, OEKO-TEX) can significantly mitigate these concerns. These certifications ensure environmentally responsible processes, from raw material extraction to manufacturing and packaging.

Ethical sourcing also involves ensuring fair wages, safe working conditions, and transparent supply chains. B2B buyers should seek partners with robust audits, traceability systems, and adherence to international labor standards (e.g., SA8000). Incorporating eco-friendly materials—such as recycled plastics, organic cotton, or plant-based leathers—can enhance the sustainability profile of Shawn Kemp shoes, appealing to environmentally conscious markets like Europe and the Middle East.

Furthermore, adopting a circular economy approach—encouraging product recycling, refurbishing, or biodegradable components—can provide a competitive advantage. Transparency and certification are key; they not only meet regulatory requirements but also build trust with end consumers, especially in regions with stringent sustainability expectations.

Brief Evolution/History (Optional)

While specific historical details about Shawn Kemp shoes are limited, understanding the brand’s evolution offers valuable context for B2B buyers. Originating as a niche or signature sneaker line associated with the athlete Shawn Kemp, the brand has grown through collaborations, limited editions, and embracing streetwear culture. This evolution has shifted the focus toward premium quality, exclusivity, and innovative design—factors that influence sourcing strategies.

For international buyers, recognizing these brand dynamics is essential for positioning in premium or collector markets. The emphasis on authenticity and high-quality craftsmanship has driven demand for specialized manufacturing processes and materials. As the brand continues to evolve, aligning sourcing practices with its heritage and innovation trajectory will be key to maintaining market relevance and consumer loyalty globally.

This comprehensive understanding of market dynamics, sourcing trends, and sustainability considerations equips B2B buyers with actionable insights to optimize their procurement strategies for Shawn Kemp shoes across diverse international markets.

Frequently Asked Questions (FAQs) for B2B Buyers of shawn kemp shoes

1. How can I effectively vet Shawn Kemp shoes suppliers to ensure product quality and reliability?

To vet suppliers effectively, start by requesting comprehensive company profiles, including business licenses, export licenses, and relevant certifications (e.g., ISO, CE). Review their product catalogs and ask for samples to assess craftsmanship, materials, and comfort. Check references or customer testimonials, especially from international buyers in your region. Conduct virtual or in-person audits when possible, focusing on manufacturing processes, quality control measures, and compliance standards. Additionally, verify their production capacity and lead times to ensure they can meet your demand volumes consistently. A reliable supplier will provide transparent documentation and demonstrate a proactive approach to quality assurance.

2. What customization options are typically available for Shawn Kemp shoes, and how do they impact MOQ and lead times?

Most Shawn Kemp shoe suppliers offer customization options such as colorways, branding (logos, labels), material choices, and packaging. Customization usually requires a higher minimum order quantity (MOQ) compared to standard products, often ranging from 500 to 1,000 pairs or more, depending on complexity. Lead times for customized orders are generally longer—typically 4-8 weeks—due to additional production steps. To optimize costs and timelines, clearly define your specifications upfront and work closely with suppliers to understand any constraints. Establishing a detailed design brief and confirming all options before placing an order minimizes delays and additional costs.

3. What are typical MOQ, lead times, and payment terms for international B2B orders of Shawn Kemp shoes?

MOQ for Shawn Kemp shoes varies depending on the supplier, but generally ranges from 300 to 1,000 pairs for standard models. Lead times are usually between 4 to 8 weeks after order confirmation, with faster delivery possible for stock items. Common payment terms include 30% upfront deposit with the balance paid before shipment, or letters of credit for larger orders. Some suppliers may offer flexible terms for repeat buyers or large-volume orders. To mitigate risks, negotiate clear payment schedules, request detailed invoices, and consider escrow services or trade assurance platforms when dealing across borders.

4. What certifications and quality assurance measures should I look for when sourcing Shawn Kemp shoes internationally?

Ensure your supplier provides relevant certifications such as ISO 9001 (quality management), environmental standards (e.g., REACH, RoHS), and footwear-specific certifications like CE marking for European markets. Ask for third-party testing reports on materials, durability, and safety standards. Implement a strict quality control process, including pre-shipment inspections by third-party inspectors or your representatives, to verify adherence to agreed specifications. Request detailed product testing reports, especially for regions with strict import regulations like the EU or Middle East. Confirm that suppliers maintain traceability of materials and have documented QA procedures to prevent defects and non-compliance.

5. How can I manage logistics and shipping effectively when importing Shawn Kemp shoes to regions like Africa, South America, or the Middle East?

Start by selecting suppliers experienced in international shipping and familiar with your target region’s import regulations. Opt for FOB (Free on Board) or CIF (Cost, Insurance, Freight) terms to balance control and risk. Work with reliable freight forwarders who can consolidate shipments, optimize routes, and handle customs clearance efficiently. Consider warehousing options near major ports or regional hubs to reduce transit times. Be aware of regional tariffs, taxes, and import duties—factor these costs into your pricing strategy. Establish clear communication channels with logistics providers and include tracking and insurance to mitigate losses or delays.

6. What are best practices for resolving disputes or handling quality issues with Shawn Kemp shoes suppliers?

Establish clear contractual agreements outlining quality standards, inspection procedures, and dispute resolution processes before placing orders. Maintain thorough documentation, including photos, inspection reports, and correspondence, to support claims. When issues arise, communicate promptly with the supplier, providing detailed evidence of the defect or discrepancy. Negotiate amicably for corrective actions, such as replacements, refunds, or discounts. If resolution stalls, consider involving third-party arbitration or mediation services familiar with international trade laws. Building strong, transparent relationships with suppliers fosters trust and minimizes disputes, while a well-structured contract offers legal protection.

7. How do I ensure compliance with regional import regulations and standards for Shawn Kemp shoes?

Research specific import regulations, safety standards, and labeling requirements in your country or region—such as the EU’s CE marking, the Middle East’s Gulf Standards, or African import certifications. Request suppliers provide compliance documentation and test reports aligned with your target market’s standards. Work with local customs brokers or trade consultants to navigate tariffs, taxes, and documentation procedures. Ensure products meet environmental and safety regulations to avoid delays or penalties. Incorporate compliance checks into your quality control process and request periodic audits or certifications to maintain adherence as regulations evolve.

8. What strategies can help me build long-term, mutually beneficial relationships with Shawn Kemp shoes suppliers?

Focus on transparent communication, timely payments, and consistent order volumes to foster trust. Provide clear feedback on product quality and delivery performance to help suppliers improve. Consider establishing long-term agreements or volume-based discounts to incentivize loyalty. Visit suppliers when possible to assess operations and build rapport. Share market insights and collaborate on new designs or customization to align offerings with regional preferences. Maintaining professionalism and reliability in all transactions encourages suppliers to prioritize your orders and offer better terms, ultimately leading to a stable supply chain and competitive advantage in your market.

Strategic Sourcing Conclusion and Outlook for shawn kemp shoes

Conclusion and Future Outlook

Effective strategic sourcing is essential for international buyers seeking to optimize their supply chains and gain competitive advantages in the Shawn Kemp shoes market. By prioritizing supplier diversification, rigorous quality assurance, and sustainable sourcing practices, buyers from Africa, South America, the Middle East, and Europe can mitigate risks, reduce costs, and enhance product reliability.

Illustrative Image (Source: Google Search)

As the market evolves, leveraging technological advancements such as digital procurement platforms and data analytics will be crucial for making informed sourcing decisions. Building strong relationships with reputable manufacturers and staying attuned to emerging trends will position buyers to capitalize on new opportunities and navigate potential disruptions.

Looking ahead, proactive engagement with suppliers and a focus on ethical sourcing will not only strengthen supply chain resilience but also align with global consumer expectations for sustainability. International buyers are encouraged to continually refine their sourcing strategies, explore innovative partnerships, and embrace a future-oriented mindset. Doing so will ensure they remain competitive in the dynamic Shawn Kemp shoes market and unlock long-term growth opportunities across diverse regions.