Master International Sourcing for Golf Shoe Bags:

Guide to Golf Shoe Bag

- Introduction: Navigating the Global Market for golf shoe bag

- Understanding golf shoe bag Types and Variations

- Key Industrial Applications of golf shoe bag

- Strategic Material Selection Guide for golf shoe bag

- In-depth Look: Manufacturing Processes and Quality Assurance for golf shoe bag

- Comprehensive Cost and Pricing Analysis for golf shoe bag Sourcing

- Spotlight on Potential golf shoe bag Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for golf shoe bag

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the golf shoe bag Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of golf shoe bag

- Strategic Sourcing Conclusion and Outlook for golf shoe bag

Introduction: Navigating the Global Market for golf shoe bag

In the competitive landscape of golf accessories, the golf shoe bag has emerged as a vital product for retailers, distributors, and OEMs seeking to meet the evolving demands of golf enthusiasts worldwide. Its significance extends beyond mere functionality, serving as a branding opportunity and a key differentiator in a saturated market. For international B2B buyers, understanding the nuances of sourcing high-quality golf shoe bags—spanning material choices, manufacturing standards, and cost considerations—is essential to gaining a competitive edge.

This comprehensive guide offers a strategic overview of the global golf shoe bag market, tailored specifically for buyers from Africa, South America, the Middle East, and Europe—including key markets like Spain and Indonesia. It covers critical aspects such as product types, material innovations, manufacturing and quality control processes, supplier landscape, and cost dynamics. Additionally, it addresses frequently asked questions to clarify common sourcing challenges.

By providing actionable insights and data-driven guidance, this resource empowers B2B buyers to make informed sourcing decisions, optimize supplier relationships, and navigate international trade complexities confidently. Whether you are establishing new supplier partnerships or expanding existing supply chains, this guide aims to streamline your procurement process and ensure you capitalize on emerging market opportunities with confidence and strategic foresight.

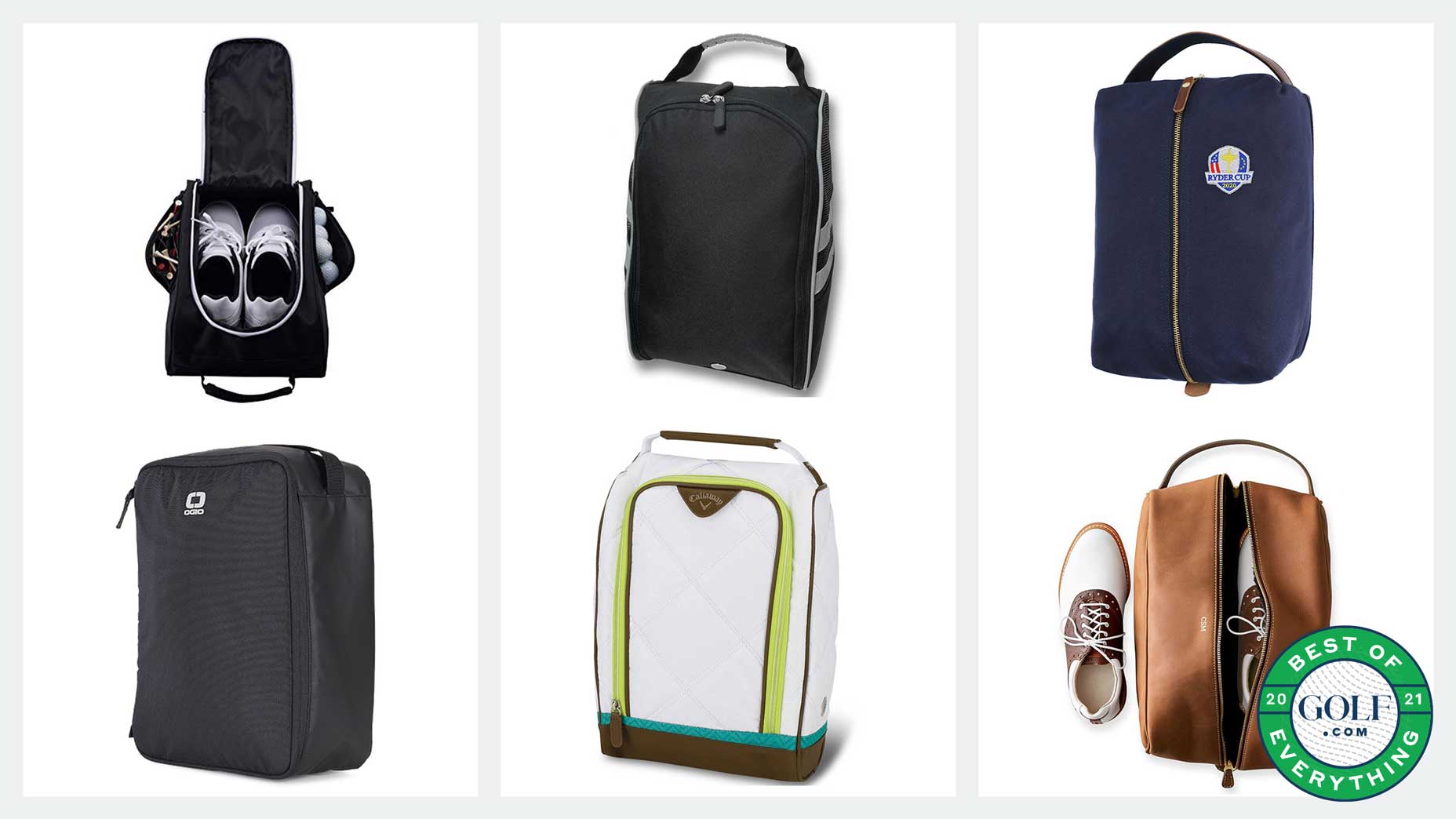

Illustrative Image (Source: Google Search)

Understanding golf shoe bag Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hard-shell Golf Shoe Bag | Rigid, impact-resistant exterior; often with reinforced structure | High-end retail, premium golf equipment suppliers | Pros: Durable, excellent protection for shoes; enhances brand perception. Cons: Higher manufacturing costs, heavier, less flexible for bulk shipping. |

| Soft-sided Golf Shoe Bag | Lightweight, flexible fabric; often with additional compartments | Wholesale distributors, promotional giveaways | Pros: Cost-effective, easy to store and transport; customizable. Cons: Less protection against impact, may wear faster over time. |

| Travel/Carry Golf Shoe Bag | Compact, designed for portability; often includes handles or straps | Travel gear suppliers, golf resorts, corporate gifting | Pros: Convenient for travel, versatile. Cons: Limited space, less protective for long-distance shipping. |

| Double-compartment Golf Shoe Bag | Separate sections for each shoe, often with ventilation features | Golf clubs, sports retailers, B2B gifting programs | Pros: Keeps shoes organized and ventilated, ideal for premium markets. Cons: Slightly more expensive, bulkier for storage. |

| Customizable/Branded Golf Shoe Bag | Fully customizable with logos, colors, and branding elements | Corporate branding, promotional campaigns | Pros: Enhances brand visibility, tailored to client needs. Cons: Higher initial costs, longer lead times for production. |

Hard-shell Golf Shoe Bags

Hard-shell golf shoe bags are characterized by their rigid, impact-resistant exteriors, often made from durable plastics or composites. They provide superior protection against shocks, moisture, and rough handling, making them ideal for high-end retail or corporate gifting where product integrity is crucial. B2B buyers should consider the higher manufacturing costs and weight, which can impact shipping and logistics. These bags are suitable for premium brands seeking to reinforce quality and durability, especially when shipping to regions with less controlled handling environments.

Soft-sided Golf Shoe Bags

Soft-sided golf shoe bags are constructed from lightweight fabrics like nylon or polyester, offering flexibility and ease of customization. They are favored by wholesale distributors and promotional companies due to their cost-effectiveness and adaptability for branding. While they are less protective against impacts and weather, their lower price point and ease of transport make them attractive for bulk orders and promotional campaigns. Buyers should evaluate the balance between cost savings and the level of protection needed based on their distribution channels.

Illustrative Image (Source: Google Search)

Travel/Carry Golf Shoe Bags

Designed with portability in mind, travel/carry golf shoe bags are compact and often include handles, straps, or shoulder slings. They are suitable for travel gear suppliers, golf resorts, and corporate gifting programs targeting travelers. These bags prioritize convenience over extensive protection, making them ideal for short-distance transport or as supplementary accessories. B2B buyers should consider their target customer’s usage patterns and whether the focus on portability aligns with their product positioning.

Double-compartment Golf Shoe Bags

These bags feature separate compartments for each shoe, often with ventilation panels to prevent odor buildup. They are typically made from durable fabrics with added features like zippers and mesh panels. Double-compartment bags appeal to premium markets, golf clubs, and sports retailers aiming to offer organized and ventilated storage solutions. Their increased complexity and manufacturing costs should be weighed against the benefits of enhanced organization and hygiene, particularly for clients emphasizing quality and presentation.

Customizable/Branded Golf Shoe Bags

Fully customizable golf shoe bags allow for branding with logos, colors, and personalized design elements. They are highly suitable for corporate branding, promotional campaigns, and sponsorship events. These bags can significantly enhance brand visibility and loyalty but come with higher initial costs and longer lead times due to customization processes. B2B buyers should plan for these factors and consider their marketing objectives to maximize ROI from branded products.

In summary, understanding these variations enables B2B buyers to select golf shoe bags aligned with their target markets, logistical needs, and brand positioning. Whether prioritizing protection, cost, portability, or branding opportunities, each type offers distinct advantages that can be leveraged to optimize distribution, customer satisfaction, and brand recognition across diverse regions.

Key Industrial Applications of golf shoe bag

| Industry/Sector | Specific Application of golf shoe bag | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports & Recreation | Custom-branded golf shoe bags for golf courses and clubs | Enhances brand visibility, customer loyalty, and provides a premium experience | Customization options, durability, material quality, branding flexibility |

| Hospitality & Tourism | Golf resorts and luxury hotels offering branded shoe bags | Adds value to guest amenities, promotes brand recognition, and encourages repeat visits | High-end materials, design aesthetics, bulk order capabilities |

| Retail & Wholesale | Wholesale supply to sporting goods retailers and distributors | Expands market reach, offers diverse product lines, and increases sales volume | Cost-effective manufacturing, variety in design, reliable supply chain |

| Corporate Gifts & Events | Promotional golf shoe bags for corporate tournaments | Strengthens corporate branding, improves client relationships, and enhances event prestige | Customization options, quality standards, timely delivery |

| Manufacturing & OEM | OEM production for international brands | Enables brand differentiation, meets international quality standards, and reduces lead times | Compliance with international standards, flexible MOQ, quality assurance |

Sports & Recreation

Golf shoe bags are widely used within the sports industry, especially by golf courses, clubs, and academies. These organizations often seek custom-branded bags to enhance their branding and offer a premium experience to members and visitors. For international B2B buyers from Africa, South America, the Middle East, and Europe, sourcing durable, high-quality, and customizable golf shoe bags can boost their competitive edge. Emphasizing materials that resist wear and environmental factors (e.g., humidity, salt air) ensures longevity and customer satisfaction.

Hospitality & Tourism

Luxury hotels and golf resorts frequently provide branded golf shoe bags as part of their guest amenities. These bags serve as a memorable takeaway, reinforcing brand loyalty and elevating the guest experience. For buyers in regions like Spain, Indonesia, or Middle Eastern luxury markets, sourcing aesthetically appealing, high-end materials with customization options is essential. Ensuring reliable supply chains and quality consistency across bulk orders is vital to meet the expectations of high-end clientele.

Retail & Wholesale

Retailers specializing in sporting goods and golf accessories often source golf shoe bags in bulk for distribution across various markets. Offering a range of designs, sizes, and price points allows for broader market penetration. International B2B buyers should prioritize manufacturers with scalable production capabilities, competitive pricing, and adherence to safety and quality standards. This approach supports building a diverse product portfolio that appeals to different customer segments.

Corporate Gifts & Events

Golf shoe bags are popular promotional items at corporate tournaments and events. They serve as functional, stylish gifts that reinforce brand visibility and foster client relationships. For international buyers, especially those organizing events in diverse markets, sourcing customizable, high-quality bags with quick turnaround times is critical. Suppliers offering flexible branding options and reliable logistics can significantly enhance event success.

Manufacturing & OEM

OEM partnerships enable brands to incorporate golf shoe bags into their product lines, often under private labels. For international manufacturers, collaborating with reliable OEM suppliers ensures compliance with global standards, cost efficiency, and timely delivery. Buyers should focus on manufacturers with proven quality control processes, flexible MOQ, and experience in international markets, particularly in regions like Europe, Africa, and Southeast Asia.

Strategic Material Selection Guide for golf shoe bag

Material Analysis for Golf Shoe Bags

Selecting the appropriate materials for golf shoe bags is critical for ensuring durability, functionality, and cost-effectiveness across diverse international markets. Each material offers unique properties that influence manufacturing processes, product performance, and compliance with regional standards. Below is an in-depth analysis of common materials used in golf shoe bags, tailored for B2B buyers from Africa, South America, the Middle East, and Europe.

1. Polyester (Polyester Fabric or Synthetic Leather)

Key Properties:

Polyester is a versatile synthetic polymer known for its high tensile strength, resistance to shrinking, and good color retention. It performs well under various temperature ranges and is resistant to moisture, making it suitable for outdoor use. When coated or treated, polyester can also exhibit water-resistant or waterproof qualities.

Pros & Cons:

– Pros: Cost-effective, lightweight, easy to print or embroider branding, resistant to fading, and relatively simple to manufacture at scale.

– Cons: Less durable than natural leather, susceptible to tearing if not thick enough, and can degrade under prolonged UV exposure unless UV-stabilized.

Impact on Application:

Polyester’s water resistance makes it ideal for protecting shoes from rain and humidity, especially relevant in regions with high rainfall like parts of South America and Southeast Asia. Its compatibility with various dyes and coatings allows customization to meet branding and aesthetic preferences.

International Considerations:

Polyester complies with many international standards, including ASTM and ISO certifications for textiles. For markets like Europe and the Middle East, ensuring the polyester is free from harmful chemicals (e.g., REACH compliance) is essential. In Africa and South America, cost considerations often favor polyester, but durability under local environmental conditions should be verified.

2. Leather (Full-Grain, Genuine, or Faux Leather)

Key Properties:

Leather offers excellent durability, natural breathability, and a premium aesthetic. Full-grain leather is highly resistant to wear and tear, while faux leather provides a similar look at a lower cost. Leather performs well across a broad temperature range and can resist moderate moisture if properly treated.

Pros & Cons:

– Pros: Highly durable, premium appearance, excellent aging characteristics, and good for branding with embossing.

– Cons: Higher cost, heavier weight, requires maintenance to prevent cracking or drying, and manufacturing complexity is higher due to tanning processes.

Impact on Application:

Leather’s natural properties make it suitable for high-end golf accessories, appealing to markets with a preference for luxury goods, such as Europe and the Middle East. Its breathability helps prevent odor buildup in humid climates but may require additional water-resistant coatings in rainy regions.

International Considerations:

Leather products must adhere to environmental and animal welfare standards, especially in Europe (e.g., REACH, EU Leather Regulation). For African and South American markets, cost and supply chain stability are key factors. Faux leather can be a cost-effective alternative but may not meet the same durability standards.

3. Nylon (Ripstop or Cordura)

Key Properties:

Nylon is a synthetic polymer known for its high strength-to-weight ratio, excellent abrasion resistance, and flexibility. Ripstop variants incorporate reinforcement threads to prevent tearing, making them highly durable. Nylon also offers good water resistance, especially when coated.

Pros & Cons:

– Pros: Very durable, lightweight, resistant to tearing, and relatively affordable.

– Cons: Can degrade under prolonged UV exposure, may absorb dyes unevenly, and requires specific manufacturing processes for water resistance.

Impact on Application:

Nylon’s robustness makes it suitable for rugged environments, such as outdoor golf courses in Africa and South America. Its lightweight nature benefits shipping costs and ease of transport, and it can be easily customized with prints or patches.

International Considerations:

Nylon complies with many global standards, but buyers should verify UV stability and water-resistant treatments for specific climates. For markets with strict environmental regulations, sourcing nylon with eco-friendly manufacturing processes (e.g., recycled nylon) can be advantageous.

4. PVC (Polyvinyl Chloride) or Vinyl

Key Properties:

PVC is a synthetic plastic material characterized by its rigidity or flexibility depending on formulation. It offers excellent water resistance, chemical resistance, and ease of cleaning. PVC can be produced in various finishes, from matte to glossy.

Pros & Cons:

– Pros: Very cost-effective, waterproof, easy to mold and print, and highly resistant to environmental elements.

– Cons: Less breathable, can crack or become brittle over time, and environmental concerns regarding production and disposal.

Impact on Application:

PVC is suitable for budget-conscious markets or where waterproofing is a priority. Its rigidity can be advantageous for maintaining shape, but it may not appeal to premium segments seeking natural or high-end materials.

International Considerations:

PVC’s environmental footprint is under scrutiny globally. Buyers should seek compliant formulations that meet local regulations regarding chemical emissions (e.g., RoHS, REACH). In regions like Europe, eco-friendly PVC options are increasingly preferred.

Summary Table

| Material | Typical Use Case for golf shoe bag | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Lightweight, water-resistant bags for general outdoor use | Cost-effective, customizable, moisture resistant | Less durable than leather, UV degradation possible | Low |

| Leather | Premium, durable bags for high-end markets | Natural durability, premium aesthetic | High cost, weight, maintenance required | High |

| Nylon (Ripstop) | Rugged, lightweight bags for outdoor or travel-focused applications | High strength, abrasion resistance | UV sensitivity, dyeing issues | Medium |

| PVC (Vinyl) | Budget-friendly, waterproof bags for mass-market or utilitarian needs | Waterproof, easy to clean, moldable | Environmental concerns, less breathable | Low |

This comprehensive analysis provides B2B buyers with clear insights into material selection, considering regional environmental conditions, compliance standards, and market preferences. Carefully aligning material choice with target markets ensures optimal product performance, customer satisfaction, and regulatory adherence across diverse international regions.

In-depth Look: Manufacturing Processes and Quality Assurance for golf shoe bag

Manufacturing Processes for Golf Shoe Bags

The production of golf shoe bags involves a series of carefully orchestrated stages, each critical to ensuring product quality, durability, and aesthetic appeal. For international B2B buyers, understanding these stages aids in assessing supplier capabilities and ensuring compliance with industry standards.

Material Preparation

The manufacturing process begins with sourcing high-quality raw materials, primarily durable fabrics such as nylon, polyester, or leather, and sturdy zippers, straps, and reinforcement materials. Suppliers often select materials based on the target market—e.g., water-resistant fabrics for humid regions like Southeast Asia or abrasion-resistant textiles for rugged environments in Africa and South America. Material certification (e.g., OEKO-TEX, REACH compliance) is vital for verifying safety and environmental standards, especially when exporting to Europe and the Middle East.

Forming and Cutting

Once raw materials are procured, they undergo precise cutting, often using computer-controlled cutting machines (CCM) for consistency and waste minimization. High-volume producers leverage CAD (Computer-Aided Design) to optimize fabric utilization. Cutting accuracy directly impacts the fit and finish of the final product, so B2B buyers should inquire about equipment and quality controls during this stage.

Assembly and Sewing

The assembly stage involves stitching components—main body, zippers, handles, and reinforcement patches—using industrial sewing machines. Automated and semi-automated sewing lines improve efficiency and uniformity. For added strength, suppliers may use reinforced stitching techniques like double-stitched seams or bar-tacking, especially in stress-prone areas such as zippers and handles.

Finishing and Quality Checks

Post-assembly, the bags undergo finishing processes such as trimming excess threads, applying water-repellent coatings, and attaching branding labels. Final inspections ensure that all components are correctly assembled and meet specified quality standards. Some manufacturers employ heat sealing or bonding techniques for waterproof features, which should be verified during quality audits.

Quality Assurance Practices

Robust quality assurance (QA) is essential for international B2B transactions, especially given the diverse regulatory landscapes of Africa, South America, the Middle East, and Europe. Suppliers adhering to international standards demonstrate a commitment to consistent quality and compliance.

International Standards and Certifications

- ISO 9001: Most reputable manufacturers operate under ISO 9001 certification, ensuring an effective quality management system that covers design, production, and customer satisfaction.

- Environmental & Safety Certifications: For European markets, compliance with REACH, OEKO-TEX, and ISO 14001 (environment management) is often required. For Middle Eastern and African markets, certifications may vary but are increasingly important for market access.

Additional industry-specific certifications, such as CE marking for products with electrical components or water-resistant tests, may be relevant depending on product features.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Incoming raw materials are inspected for defects, dimensional accuracy, and compliance with specifications. Suppliers should provide material test reports and certificates.

- In-Process Quality Control (IPQC): Continuous inspection during manufacturing, including sewing quality, seam strength, and component placement, helps detect issues early. Use of statistical process control (SPC) techniques is common.

- Final Quality Control (FQC): Before packaging, finished products are subjected to comprehensive inspections—visual assessments for defects, measurement checks, and functional tests (e.g., zipper operation, water resistance).

Testing Methods

- Dimensional and Visual Inspection: Ensures size accuracy and defect-free appearance.

- Strength Tests: Tensile testing for seams and handle attachments.

- Water Resistance: Spray tests or immersion tests to verify waterproof features.

- Durability Testing: Simulated wear tests to assess product lifespan.

- Color Fastness: Testing for color stability under various conditions.

How B2B Buyers Can Verify Supplier Quality

- Supplier Audits: Conduct on-site audits to assess manufacturing facilities, equipment, and quality management systems. This provides firsthand validation of claims and processes.

- Third-Party Inspections: Engage independent inspection agencies (e.g., SGS, Bureau Veritas) to perform pre-shipment quality checks, especially for high-volume orders.

- Quality Documentation: Request detailed QC reports, test certificates, and compliance documentation to verify adherence to standards.

- Sample Testing: Obtain samples for independent testing aligned with your market’s regulatory requirements, especially for specialized features like waterproofing or eco-labels.

- Ongoing Monitoring: Establish a quality management relationship that includes periodic audits, feedback loops, and corrective action procedures.

Nuances for International B2B Transactions

For buyers from regions like Africa, South America, the Middle East, and Europe, understanding local regulatory and industry nuances is critical. European buyers, for example, must prioritize compliance with REACH and CE standards, while Middle Eastern markets may require certifications related to safety and water resistance. African and South American buyers should focus on durability and environmental certifications suitable for local conditions.

Additionally, language barriers and differing inspection standards necessitate clear communication of quality expectations. Establishing transparent quality agreements, detailed inspection criteria, and regular supplier evaluations can mitigate risks. Working with suppliers experienced in international exports and familiar with specific regional standards enhances the likelihood of compliance and product success.

In summary, B2B buyers should adopt a comprehensive approach to understanding manufacturing processes and implementing rigorous quality assurance practices. By demanding transparency, certifications, and thorough testing, buyers can ensure the golf shoe bags supplied meet their market needs and uphold brand reputation across diverse regions.

Comprehensive Cost and Pricing Analysis for golf shoe bag Sourcing

Understanding Cost Structure for Golf Shoe Bags

A comprehensive grasp of the cost components involved in manufacturing golf shoe bags is essential for effective sourcing. The primary cost drivers include raw materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margins. Material costs typically account for 40-50% of the total, influenced heavily by the choice of fabric (nylon, PU leather, polyester), zippers, and hardware. Labor costs vary significantly based on the manufacturing country—generally lower in regions like Southeast Asia and higher in Europe or the Middle East. Manufacturing overhead encompasses factory expenses, machinery depreciation, and energy costs, which can fluctuate based on location and scale.

Tooling and setup costs are mostly incurred upfront, especially for customized designs or molds, and may be amortized over large orders. Quality assurance costs are vital to meet international standards and certifications, impacting both cost and marketability. Logistics expenses depend on shipment volume, destination, and chosen Incoterms, with FOB (Free on Board) and CIF (Cost, Insurance, and Freight) being common options. Finally, a typical profit margin for suppliers ranges from 10-20%, influenced by order size and relationship strength.

Illustrative Image (Source: Google Search)

Price Influencers and Variability

Several factors shape the final pricing of golf shoe bags:

-

Order Volume & MOQ: Larger orders typically reduce unit costs due to economies of scale. Buyers should aim to negotiate favorable terms for higher volumes, especially when planning long-term partnerships.

-

Customization & Specifications: Custom features—such as branding, unique materials, or specific dimensions—can increase costs due to additional tooling, design work, and quality checks. Standard models are generally more cost-effective.

-

Material Selection: Premium materials like genuine leather or high-end fabrics elevate costs but may command higher retail prices. Budget options like polyester or coated nylon are more economical.

-

Certifications & Quality Standards: Suppliers compliant with ISO, REACH, or other international standards often incur higher costs but can access premium markets requiring such certifications.

-

Supplier Location & Capabilities: Manufacturers in regions with lower wages and production costs (e.g., Indonesia, Vietnam) tend to offer more competitive pricing, whereas European or Middle Eastern suppliers may command premium prices due to higher operational costs.

-

Incoterms & Logistics: The choice of shipping terms influences costs significantly. FOB prices are typically lower, but buyers assume responsibility for freight and insurance. CIF prices include these costs, offering simplicity but often at a premium.

Buyer Tips for Cost Optimization

-

Negotiate Volume Discounts: Leverage larger or repeat orders to secure better unit prices. Establish long-term partnerships to benefit from preferential rates.

-

Focus on Total Cost of Ownership (TCO): Consider not just unit price but also shipping, customs duties, taxes, and potential rework or quality issues. Sometimes, sourcing slightly higher-priced but more reliable suppliers reduces overall TCO.

-

Specify Clear Requirements: Precise specifications and quality standards reduce rework and ensure consistent product quality, which minimizes hidden costs.

-

Understand Pricing Nuances: Be aware of currency fluctuations, import tariffs, and regional taxes that impact landed costs, especially for buyers in Africa, South America, the Middle East, and Europe.

-

Engage in Strategic Negotiation: Use market insights to negotiate better payment terms, lead times, and after-sales support, which can influence overall costs.

Indicative Pricing Range (Disclaimers Included)

Based on recent market data, the unit price for standard golf shoe bags typically ranges from $3 to $8 USD for bulk orders (over 1,000 units). Custom or premium models may range from $8 to $15 USD or higher. These estimates serve as a baseline; actual prices vary widely depending on the factors discussed.

In summary, understanding the detailed cost structure and influencing factors enables international buyers from diverse regions to negotiate effectively, optimize procurement strategies, and reduce total costs. Careful consideration of order volume, specifications, supplier location, and logistics arrangements is vital for securing the best value in golf shoe bag sourcing.

Spotlight on Potential golf shoe bag Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for golf shoe bag.)*

Essential Technical Properties and Trade Terminology for golf shoe bag

Critical Technical Properties for Golf Shoe Bags

1. Material Grade and Composition

The choice of material significantly influences durability, weight, and aesthetic appeal. Common materials include synthetic leather, nylon, or polyester, with higher-grade options offering enhanced abrasion resistance and water repellency. For international buyers, understanding the material grade ensures compatibility with regional climate conditions and usage expectations, reducing the risk of product failure or customer dissatisfaction.

2. Water Resistance and Waterproofing

Golf shoe bags are often exposed to outdoor elements. Technical specifications such as water resistance ratings (e.g., IPX ratings) or waterproof membrane features are crucial. A higher water resistance grade ensures shoes remain dry during transport or in rainy conditions, which adds value for end-users and supports premium pricing strategies.

3. Size Tolerance and Capacity

Precise measurements and tolerance levels (e.g., ±1 cm) are vital for consistent production quality. Buyers should verify size specifications to ensure the bag fits standard golf shoes and additional accessories. Consistent sizing reduces returns and enhances brand reputation across different markets.

4. Ventilation Features

Effective airflow design, such as mesh panels or vent holes, helps prevent odor and moisture buildup. Technical specifications should include airflow rates or ventilation area percentages. Good ventilation is a key selling point, especially in humid regions like Southeast Asia or parts of Africa.

5. Weight and Portability

Lightweight yet sturdy materials improve portability, an essential factor for traveling golfers. Technical data on the overall weight and maximum load capacity helps buyers assess suitability for airline restrictions and ease of handling, especially in regions with high travel activity.

6. Manufacturing Tolerance and Quality Standards

Adherence to industry standards (e.g., ISO, ASTM) and tolerance levels in stitching, seams, and fittings ensure consistent quality. Suppliers who meet these standards are more reliable, reducing defect rates and warranty claims, which is critical for international distribution.

Common Trade Terminology for Golf Shoe Bags

1. OEM (Original Equipment Manufacturer)

Refers to manufacturers producing products branded by another company. Understanding OEM relationships helps buyers negotiate pricing, customization options, and production lead times, especially when sourcing from regions with established manufacturing hubs like China or Indonesia.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce or sell per order. MOQs impact initial investment and inventory planning. Buyers from Africa or South America should clarify MOQs early to align production with local demand and avoid excess stock.

3. RFQ (Request for Quotation)

A formal document sent to suppliers requesting price quotes and terms. An RFQ allows buyers to compare multiple suppliers based on price, quality, and lead times, which is essential for making cost-effective purchasing decisions in competitive markets.

4. Incoterms (International Commercial Terms)

Standardized trade definitions published by the ICC that clarify responsibilities for shipping, insurance, and tariffs. Familiarity with Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) ensures clear agreement on cost distribution and risk management during international transactions.

5. Lead Time

The period from order placement to product delivery. Understanding lead times helps buyers coordinate inventory and marketing schedules, especially important in regions with logistical challenges such as some parts of Africa or South America.

6. Quality Certification (e.g., ISO, SGS)

Third-party certifications validate product quality and safety standards. For international buyers, especially those entering new markets, insisting on certified suppliers reduces compliance risks and facilitates smoother customs clearance.

In summary, grasping these technical properties and trade terms empowers B2B buyers to make informed, strategic decisions. It ensures product quality aligns with regional market needs, enhances negotiation leverage, and mitigates supply chain risks across diverse international markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the golf shoe bag Sector

Market Overview & Key Trends

The global golf accessory market, including golf shoe bags, is experiencing steady growth driven by increasing participation in golf across diverse regions. Key drivers include rising disposable incomes, expanding middle classes in emerging markets, and a surge in golf tourism, especially in regions like Southeast Asia, the Middle East, and parts of South America. For international B2B buyers from Africa, Europe, and the Middle East, sourcing opportunities are expanding as brands seek innovative, durable, and stylish solutions that cater to evolving consumer preferences.

Emerging trends are notably shaped by advancements in technology and supply chain digitization. E-commerce platforms and B2B marketplaces like Alibaba, Global Sources, and dedicated trade portals facilitate easier sourcing and real-time communication. Additionally, innovations in materials—such as lightweight, water-resistant, and eco-friendly fabrics—are becoming standard expectations, especially in premium segments.

Market dynamics are also influenced by geopolitical factors, trade agreements, and regional manufacturing capacities. Europe, with its focus on quality and sustainability, is increasingly demanding eco-conscious products, while regions like Indonesia and Spain are becoming key manufacturing hubs due to their established supply chains and competitive costs. For African and South American buyers, diversifying sourcing channels beyond traditional markets is vital to mitigate risks and capitalize on emerging suppliers with specialized craftsmanship.

Furthermore, customization and branding capabilities are crucial, with many brands seeking private-label solutions that enhance their market differentiation. Keeping abreast of these trends enables B2B buyers to negotiate better, select innovative suppliers, and align their procurement strategies with global market shifts.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a core consideration in the golf shoe bag sector, driven by increasing consumer awareness and stricter regulatory standards. Environmentally conscious buyers prioritize suppliers with transparent supply chains and eco-friendly practices, which reduces risks related to reputational damage and non-compliance.

Eco-friendly materials such as recycled polyester, organic cotton, and biodegradable synthetics are gaining prominence. Certifications like Global Organic Textile Standard (GOTS), OEKO-TEX, and Forest Stewardship Council (FSC) are often prerequisites for buyers aiming to demonstrate environmental responsibility. These certifications ensure that raw materials are sourced responsibly, with minimal environmental impact.

Ethical sourcing extends beyond materials to encompass fair labor practices, safe working conditions, and fair wages. Buyers should verify suppliers’ adherence to international labor standards through audits or third-party certifications such as SA8000 or WRAP. Incorporating social responsibility into sourcing strategies not only aligns with global ESG initiatives but also appeals to increasingly conscientious consumers.

For African, South American, Middle Eastern, and European buyers, establishing long-term partnerships with suppliers committed to sustainability can lead to competitive advantages. It fosters brand loyalty, reduces supply chain risks, and meets the rising demand for ethically produced products. Emphasizing transparency, traceability, and ongoing supplier audits are practical steps to embed sustainability into procurement processes.

Brief Evolution/History (Optional)

The golf shoe bag sector has evolved significantly over the past two decades, transitioning from simple, utilitarian designs to highly functional, stylish accessories. Initially driven by basic needs for protection and portability, the market has shifted toward innovation in materials, branding, and sustainability. The rise of eco-conscious consumerism has prompted manufacturers to incorporate sustainable materials and transparent supply chains. For B2B buyers, understanding this evolution helps in selecting suppliers capable of meeting modern standards for quality, innovation, and environmental responsibility, ensuring products remain competitive in a dynamic global market.

Frequently Asked Questions (FAQs) for B2B Buyers of golf shoe bag

1. How can I verify the credibility and reliability of a golf shoe bag supplier internationally?

To ensure supplier credibility, start by reviewing their business credentials, including business licenses, export certificates, and third-party audits. Request references from previous international clients, especially from Africa, South America, the Middle East, or Europe, to gauge their performance and reliability. Additionally, verify their manufacturing capabilities, quality control processes, and certifications such as ISO or environmental standards. Engaging with suppliers who have a strong online presence, transparent communication, and positive reviews on B2B platforms like Alibaba or Global Sources can also provide reassurance. Consider visiting their facilities or hiring third-party inspection services for on-site verification when feasible.

2. What customization options are typically available for golf shoe bags, and how can I ensure they meet my market needs?

Most suppliers offer customization in branding (logo embroidery or printing), color schemes, material choices, and size specifications. To align with your target market—whether in Europe, Africa, or the Middle East—discuss regional preferences, such as eco-friendly materials or specific color trends. Provide clear design files and detailed specifications upfront to avoid miscommunication. Confirm minimum order quantities (MOQs) for customized products, as they can vary widely. Also, request samples before full production to verify that the customization aligns with your expectations, ensuring your branding is accurately represented and the product appeals to your customers.

3. What are typical minimum order quantities, lead times, and payment terms for international golf shoe bag sourcing?

MOQs for golf shoe bags generally range from 500 to 2000 units, but some suppliers offer lower MOQs for initial trials or smaller markets. Lead times usually span 4-8 weeks, depending on order complexity, customization, and supplier location. Standard payment terms include 30% upfront deposit with the balance payable before shipment, but negotiable terms like letter of credit or escrow payments may be available for larger orders. To optimize cash flow and production schedules, establish clear timelines and payment milestones early in negotiations, and consider supplier reliability and their capacity to meet your delivery deadlines.

4. What quality assurance procedures and certifications should I look for in a golf shoe bag supplier?

Reliable suppliers should adhere to strict quality control protocols, including in-line inspections, pre-shipment audits, and testing for durability, water resistance, and colorfastness. Certifications such as ISO 9001 (quality management), environmental standards like ISO 14001, or specific product safety certifications (e.g., REACH compliance for Europe) are indicators of compliance with international standards. Request detailed QA reports, sample testing results, and proof of certifications before placing large orders. Establish clear quality standards in your contract and consider third-party inspection services at production and before shipment to prevent defects and ensure compliance with your market requirements.

5. How do I manage logistics and shipping for international golf shoe bag orders, especially to remote markets?

Effective logistics management begins with selecting reliable freight forwarders experienced in international trade, especially to Africa, South America, the Middle East, or Europe. Consider shipping options like sea freight for bulk orders to reduce costs, or air freight for urgent deliveries. Clarify Incoterms (e.g., FOB, CIF) to define responsibilities and costs clearly. Work with suppliers who can assist with customs clearance, documentation, and insurance. For remote or less accessible markets, partnering with local distributors or freight consolidators can streamline delivery. Always plan for lead times, customs duties, and potential delays to ensure timely market entry.

6. How should I handle disputes or quality issues with international suppliers?

Establish clear contractual terms covering quality standards, inspection rights, and dispute resolution mechanisms upfront. In case of disputes, gather comprehensive evidence such as photos, inspection reports, and correspondence to support your claim. Engage in direct communication with the supplier to seek amicable solutions, such as replacements or refunds. If unresolved, consider arbitration through international bodies like the ICC or local trade chambers. Building strong relationships and maintaining open communication channels can prevent misunderstandings. Having a contingency plan, including backup suppliers, can mitigate risks associated with quality issues or delivery delays.

7. What are the key factors influencing pricing for golf shoe bags in international trade?

Pricing is influenced by raw material costs, manufacturing complexity, customization level, order volume, and supplier location. Suppliers in countries with lower labor costs, such as parts of Asia, often offer more competitive prices, but shipping costs and lead times must be considered. Higher customization and quality standards typically increase costs. Negotiating bulk discounts, long-term partnerships, or flexible payment terms can improve pricing. Always request detailed quotations that include FOB or CIF prices, shipping, taxes, and potential hidden costs. Balancing cost with quality and delivery reliability is critical to ensure profitability in your target markets.

8. How can I ensure compliance with regional regulations and standards when importing golf shoe bags?

Research and understand the specific import regulations, safety standards, and labeling requirements of your target market—be it in Europe, Africa, South America, or the Middle East. For example, European markets require CE marking and REACH compliance, while Middle Eastern markets may have specific packaging and safety standards. Collaborate with suppliers familiar with these regulations or hire compliance consultants. Ensure that product labels include necessary information such as origin, materials, and care instructions in the local language. Proper documentation, including certificates of conformity and test reports, will facilitate smooth customs clearance and reduce the risk of penalties or shipment delays.

Strategic Sourcing Conclusion and Outlook for golf shoe bag

Conclusion and Future Outlook

Effective strategic sourcing is critical for international B2B buyers seeking to optimize quality, cost-efficiency, and supply chain resilience in the golf shoe bag market. Prioritizing reliable supplier relationships, rigorous quality assurance, and flexible sourcing strategies will ensure competitiveness across diverse markets such as Africa, South America, the Middle East, and Europe. Understanding regional manufacturing strengths and logistical nuances enables buyers to make informed decisions that align with their growth objectives.

Looking ahead, the golf accessory industry is poised for innovation driven by sustainable materials and technological integration, offering new opportunities for differentiation. Buyers should proactively engage with emerging suppliers and leverage trade platforms to access diverse manufacturing hubs, reducing dependency on traditional sources and mitigating risks.

Actionable Insight: Develop a comprehensive sourcing strategy that incorporates supplier diversification, quality standards, and sustainability considerations. Stay attuned to regional market shifts and technological advancements to maintain a competitive edge. By doing so, international B2B buyers can secure a resilient supply chain that supports long-term growth and market expansion in the global golf accessory industry.