Master Sourcing Air Conditioned Shoes for Global Markets

Guide to Air Conditioned Shoes

- Introduction: Navigating the Global Market for air conditioned shoes

- Understanding air conditioned shoes Types and Variations

- Key Industrial Applications of air conditioned shoes

- Strategic Material Selection Guide for air conditioned shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for air conditioned shoes

- Comprehensive Cost and Pricing Analysis for air conditioned shoes Sourcing

- Spotlight on Potential air conditioned shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for air conditioned shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the air conditioned shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of air conditioned shoes

- Strategic Sourcing Conclusion and Outlook for air conditioned shoes

Introduction: Navigating the Global Market for air conditioned shoes

In today’s competitive global footwear industry, innovation is key to meeting evolving consumer demands, and air conditioned shoes represent a groundbreaking advancement in comfort and functionality. For international B2B buyers across Africa, South America, the Middle East, and Europe—particularly from dynamic markets such as Turkey and Thailand—understanding this niche product is essential for gaining a competitive edge. These specialized shoes address the growing need for temperature regulation, enhancing user experience in diverse climates and lifestyle settings.

This comprehensive guide is designed to equip you with the critical insights necessary for effective sourcing, from identifying the different types of air conditioned shoes to understanding the materials, manufacturing processes, and quality control standards involved. It also explores key supplier landscapes, cost considerations, and market trends shaping demand across regions. Additionally, the guide offers practical answers to common FAQs, helping you navigate regulatory, logistical, and quality assurance challenges.

By providing a detailed overview of the supply chain and market dynamics, this resource empowers B2B buyers to make informed, strategic decisions. Whether you are sourcing for retail, wholesale, or private label brands, understanding the nuances of this innovative footwear segment will enable you to identify reliable partners, optimize costs, and meet the specific needs of your target markets. Ultimately, this guide aims to facilitate smarter sourcing practices in the expanding realm of air conditioned shoes, helping you capitalize on a high-growth niche with confidence.

Understanding air conditioned shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Active Cooling Shoes | Incorporate built-in fans or ventilation systems to circulate air | Sportswear, healthcare, hospitality sectors | Pros: Enhanced comfort, high-tech appeal. Cons: Higher manufacturing costs, maintenance requirements. |

| Gel-Enhanced Air Shoes | Use gel inserts with micro-ventilation channels for cooling | Workwear for hot environments, retail | Pros: Cost-effective, easy to source. Cons: Limited longevity, less advanced cooling. |

| Evaporative Cooling Shoes | Utilize moisture-wicking materials and evaporative cooling pads | Outdoor labor, agricultural sectors | Pros: Low-tech, affordable. Cons: Less effective in humid climates, requires frequent replacement. |

| Phase-Change Material Shoes | Embedded phase-change materials that absorb and release heat | High-performance footwear, medical sectors | Pros: Precise temperature regulation, durable. Cons: Higher initial investment, complex manufacturing. |

| Modular Ventilated Shoes | Customizable ventilation modules that can be added or removed | Industrial safety, custom branding | Pros: Flexibility, tailored cooling. Cons: Potential for component loss, higher logistics complexity. |

Active Cooling Shoes

Active cooling shoes feature integrated fans, micro-ventilation systems, or battery-powered airflow mechanisms that actively circulate air within the shoe. These are suitable for industries demanding high-performance comfort, such as sports, healthcare, and hospitality. B2B buyers should consider factors like power source logistics, maintenance needs, and initial cost. While they offer superior cooling and user satisfaction, their complexity can increase manufacturing costs and after-sales service requirements, making them more suitable for premium or specialized markets.

Gel-Enhanced Air Shoes

Gel-enhanced air shoes combine traditional footwear with gel inserts that facilitate passive cooling through micro-ventilation channels. These shoes are ideal for work environments in hot climates, retail, and casual markets where affordability and ease of procurement are priorities. For buyers, the key considerations include sourcing reliable gel materials, ensuring consistent quality, and evaluating the longevity of the cooling effect. They are generally cost-effective but may require periodic replacement of gel inserts or ventilation components, impacting long-term operational costs.

Evaporative Cooling Shoes

Utilizing moisture-wicking fabrics and evaporative pads, these shoes provide cooling through natural evaporation. They are well-suited for outdoor labor, agriculture, and sectors where low-cost solutions are essential. B2B buyers should assess climate compatibility, as evaporative cooling is less effective in humid environments. These shoes are inexpensive to produce and maintain but may need frequent replacement of cooling pads or fabrics, affecting inventory planning and supply chain logistics.

Phase-Change Material Shoes

Embedded with phase-change materials (PCMs), these shoes regulate temperature by absorbing excess heat and releasing it gradually. They are highly suitable for high-performance applications, medical sectors, and environments with fluctuating temperatures. Buyers should evaluate the durability of PCMs, initial cost implications, and supply chain reliability for specialized materials. While offering precise temperature control and durability, their higher manufacturing complexity and cost make them more appropriate for premium markets or bulk orders targeting specific industries.

Modular Ventilated Shoes

These shoes feature customizable ventilation modules that can be added or removed based on user needs. They are versatile for industrial safety, promotional branding, or sectors requiring adaptable cooling solutions. B2B buyers should consider the logistics of component inventory, compatibility across product lines, and potential loss or theft of modules. Their flexibility allows tailored cooling solutions, but increased complexity in assembly and distribution should be factored into procurement strategies.

Key Industrial Applications of air conditioned shoes

| Industry/Sector | Specific Application of air conditioned shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare & Medical | Staff footwear in high-temperature hospital environments | Enhances staff comfort, reduces fatigue, and improves hygiene standards | Certification for medical use, antimicrobial materials, reliable cooling technology |

| Food Processing | Workers in hot, humid food production facilities | Maintains worker comfort, supports hygiene, and reduces heat-related fatigue | Food-grade materials, ease of cleaning, compliance with safety standards |

| Construction & Heavy Industry | Workers operating in outdoor or poorly ventilated sites | Improves safety by reducing heat stress, boosts productivity, and minimizes heat-related health issues | Durability, slip resistance, thermal regulation performance |

| Hospitality & Tourism | Staff in tropical or desert climates (hotels, resorts) | Ensures employee comfort, enhances customer service, and reduces absenteeism | Comfort fit, lightweight design, climate adaptability |

| Logistics & Warehousing | Staff working in large, temperature-variable storage facilities | Increases worker endurance, reduces heat exhaustion, and supports long shifts | Robust construction, ventilation features, long battery life (if powered) |

Healthcare & Medical

In healthcare settings, especially in hot climates or poorly ventilated hospitals, staff often endure long shifts in high temperatures. Air conditioned shoes provide a critical solution by maintaining a comfortable foot temperature, reducing fatigue, and supporting hygiene standards. For B2B buyers in regions such as Africa or the Middle East, sourcing shoes with antimicrobial linings and reliable cooling systems is essential. Certification for medical-grade safety and hygiene compliance ensures these shoes meet regulatory standards, making them suitable for hospital procurement.

Food Processing

Workers in food processing plants are frequently exposed to high humidity and heat, which can lead to discomfort and health risks. Air conditioned shoes help regulate foot temperature, reducing heat stress and associated fatigue. For international buyers, especially in South America and Southeast Asia, sourcing shoes made from food-grade, easy-to-clean materials with effective cooling technology is vital. Ensuring compliance with food safety standards guarantees product acceptance and reduces liability.

Construction & Heavy Industry

Construction workers and heavy industry personnel often operate outdoors or in poorly ventilated environments, exposing them to extreme heat. Air conditioned shoes can significantly lower heat-related health issues such as heat exhaustion and dehydration. For B2B buyers in Europe or Turkey, selecting durable, slip-resistant shoes with robust thermal regulation features is critical. These shoes should withstand rough conditions while providing consistent cooling, thus supporting worker safety and productivity.

Hospitality & Tourism

In tropical or desert climates, hospitality staff—such as hotel personnel and resort workers—face intense heat during long shifts. Air conditioned shoes enhance comfort, reduce fatigue, and improve overall service quality. For international buyers from regions like Thailand or the Middle East, sourcing lightweight, climate-adaptive footwear with reliable cooling systems can lead to better employee retention and guest satisfaction. Emphasizing comfort and durability is key for scalability across multiple locations.

Logistics & Warehousing

Warehouse staff working in large, temperature-variable environments often experience prolonged exposure to heat, especially during summer or in poorly ventilated spaces. Air conditioned shoes help sustain worker endurance, prevent heat exhaustion, and support longer shifts without compromising safety. For B2B buyers in Africa or South America, prioritizing shoes with high durability, ventilation features, and long-lasting cooling performance ensures operational efficiency and worker well-being, reducing downtime and health-related costs.

Strategic Material Selection Guide for air conditioned shoes

Analysis of Common Materials for Air Conditioned Shoes

1. Aluminum Alloys

Aluminum alloys are widely used in air conditioned shoe components due to their excellent thermal conductivity, lightweight nature, and ease of fabrication. Their high thermal conductivity allows rapid heat dissipation, making them ideal for cooling elements within the shoe system. Additionally, aluminum alloys exhibit good corrosion resistance, especially when treated or coated, which extends product lifespan in humid or saline environments.

-

Pros & Cons:* Aluminum alloys are relatively cost-effective compared to other metals, especially when produced in bulk, and are easy to machine, reducing manufacturing complexity. However, they can be prone to fatigue and deformation under repeated mechanical stress, which may limit their durability in high-usage scenarios. The need for protective coatings to prevent corrosion in aggressive environments (e.g., coastal or industrial regions) adds to manufacturing considerations.

-

Impact on Application:* Aluminum’s compatibility with various media is high; it can be anodized or coated to enhance corrosion resistance, making it suitable for humid climates common in Africa, South America, and parts of the Middle East. For European markets, compliance with standards like ASTM B209 (aluminum alloys) is essential.

-

International Considerations:* Buyers should verify regional standards and ensure suppliers adhere to quality certifications such as ISO 9001. Aluminum’s recyclability aligns with sustainability trends favored in Europe and increasingly in emerging markets.

2. Thermoplastic Polymers (e.g., Polycarbonate, ABS)

Thermoplastics like polycarbonate and ABS are popular for their moldability, lightweight nature, and cost-effectiveness. They are often used in the structural components of air conditioned shoes, such as casing or housing for cooling modules.

-

Pros & Cons:* These materials are highly resistant to impact and can withstand a range of temperatures, making them suitable for various climates. They are also easy to process with injection molding, which reduces manufacturing costs. However, their thermal conductivity is low, which may limit their direct use in heat dissipation unless combined with other materials or design features. Additionally, UV exposure can degrade some plastics over time, especially in sunny regions like the Middle East.

-

Impact on Application:* Suitable for media that require chemical resistance and durability, such as saline or sweat exposure. For markets with high UV exposure, UV-stabilized grades are recommended. Compliance with JIS or DIN standards is common in Asian and European markets, respectively.

-

International Considerations:* Cost and ease of manufacturing make thermoplastics attractive for emerging markets. Buyers should specify grade requirements for UV stability and chemical resistance, and confirm supplier certifications for safety and environmental standards.

3. Copper and Copper Alloys

Copper and its alloys (e.g., brass, bronze) are valued for their superior thermal and electrical conductivity, making them ideal for heat exchange components within air conditioned shoes. Their antimicrobial properties also add value in hygiene-sensitive applications.

-

Pros & Cons:* Copper alloys offer excellent corrosion resistance, especially in saline or humid environments, which is advantageous for tropical and coastal regions. They are durable and maintain structural integrity over time. However, copper is more expensive than aluminum or plastics, and manufacturing processes are more complex, often requiring specialized tooling.

-

Impact on Application:* Copper’s high thermal conductivity enhances cooling efficiency, especially in systems that rely on phase change or active cooling. For international markets, compliance with standards such as ASTM B128 (brass) or JIS H3300 (copper) is relevant.

-

International Considerations:* Due to cost, copper components are often used selectively in critical areas. Buyers should evaluate total cost of ownership and consider local tariffs or import duties. Copper’s recyclability aligns with sustainability goals, beneficial for European and environmentally conscious markets.

4. Elastomers (e.g., Silicone, EPDM)

Elastomers like silicone and EPDM are used for sealing, insulation, and flexible components within air conditioned shoes. Their ability to withstand temperature extremes and environmental exposure makes them versatile.

-

Pros & Cons:* Silicone elastomers exhibit excellent temperature stability, from -60°C to +230°C, and maintain flexibility over time. They are resistant to UV, ozone, and many chemicals, suitable for outdoor or high-UV environments. EPDM offers good weather resistance and is more cost-effective but has slightly lower temperature tolerance.

-

Impact on Application:* Elastomers are critical for ensuring airtight seals and preventing moisture ingress, which is vital for the efficiency of cooling systems. Compatibility with various media, including sweat and environmental contaminants, is high. Standards like ASTM D2000 or JIS K 6253 are relevant for quality assurance.

-

International Considerations:* Buyers should specify the required temperature range and chemical resistance based on regional environmental conditions. Certification for medical or food contact (if applicable) may be necessary in certain markets.

Summary Table

| Material | Typical Use Case for air conditioned shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Heat exchangers, cooling modules | Excellent thermal conductivity, lightweight, corrosion resistant | Susceptible to fatigue, needs protective coatings | Med |

| Thermoplastic Polymers | Housing, casing, structural components | Impact resistant, lightweight, cost-effective | Low thermal conductivity, UV degradation risk | Low |

| Copper and Alloys | Heat exchange components, antimicrobial surfaces | Superior thermal/electrical conductivity, corrosion resistant | Higher cost, complex manufacturing | High |

| Elastomers (Silicone, EPDM) | Seals, insulation, flexible components | Temperature stability, UV/ozone resistant | Cost varies, lower structural strength | Low/Med depending on grade |

This comprehensive analysis provides B2B buyers with critical insights into material selection, enabling strategic decisions tailored to regional climates, standards, and cost considerations. Proper material choice directly impacts product performance, durability, and compliance, ensuring competitiveness in diverse international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for air conditioned shoes

Manufacturing Processes for Air Conditioned Shoes

The production of air conditioned shoes involves a series of meticulously coordinated stages, each critical to ensuring product functionality, durability, and safety. Understanding these stages allows B2B buyers to evaluate supplier capabilities effectively.

1. Material Preparation

The process begins with sourcing high-quality, breathable, and moisture-wicking materials such as advanced mesh fabrics, specialized insoles with integrated cooling channels, and durable outsoles. Suppliers often use eco-friendly or innovative materials to meet sustainability standards and consumer expectations. Critical to quality assurance is verifying material certifications, such as OEKO-TEX or REACH compliance, which ensure safety and environmental standards are met.

2. Forming and Component Manufacturing

This stage involves shaping components through processes like injection molding for insoles and outsoles, cutting fabric panels, and assembling cooling elements. Precision tooling ensures consistent dimensions, which is vital for fit and comfort. For air conditioned shoes, the integration of cooling systems—such as micro-perforated insoles or embedded fans—requires advanced manufacturing techniques like ultrasonic welding or laser cutting to ensure airtight seals and precise assembly.

3. Assembly

During assembly, components are combined under controlled conditions. This includes attaching cooling modules, inserting moisture-wicking insoles, and securing upper fabrics. Automation is often employed for consistency, but manual quality checks are essential, especially for complex integrations. B2B buyers should inquire whether assembly lines are certified under international standards, which reflects adherence to quality protocols.

4. Finishing and Packaging

Final steps include quality inspections, cleaning, branding, and packaging. Finishing processes ensure that seams are smooth, no defects are present, and the cooling systems are functioning correctly. Packaging must protect the product during international shipping, often requiring custom solutions for sensitive components. Suppliers adhering to environmental standards often utilize recyclable packaging materials.

Quality Control (QC) Framework for Air Conditioned Shoes

Robust QC protocols are essential to ensure consistent product quality, safety, and compliance with international standards. For B2B buyers, understanding these controls helps in assessing supplier reliability and product legitimacy.

1. International Standards and Certifications

- ISO 9001: The cornerstone for quality management systems, ISO 9001 certification indicates that a manufacturer has systematic processes for quality assurance, including documentation, process control, and continual improvement.

- CE Marking: Mandatory for shoes sold within the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

- Industry-specific Certifications: For innovative cooling systems, certifications like UL (for electrical safety) or API (for specific functional standards) may be relevant, especially if the shoes incorporate electrical components or advanced cooling technology.

2. QC Checkpoints

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival, including testing for material properties, certifications, and batch consistency.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing, focusing on critical control points such as bonding integrity, cooling system integration, and dimensional accuracy.

- Final Quality Control (FQC): Final inspection before shipment, emphasizing visual defects, functional testing of cooling features, and overall durability assessment.

3. Testing Methods

- Physical Testing: Includes tensile strength, adhesion tests, and flexibility assessments to ensure structural integrity.

- Functional Testing: Verifying cooling performance, airflow, and battery safety if applicable. This may involve thermal imaging, airflow measurement, and electrical safety tests.

- Environmental Testing: Simulating conditions like humidity, temperature extremes, and mechanical stress to assess product resilience.

4. Verification and Auditing

B2B buyers should perform or commission third-party audits to verify QC reports, manufacturing practices, and compliance status. Regular on-site inspections, process audits, and review of quality documentation strengthen confidence in supplier capabilities.

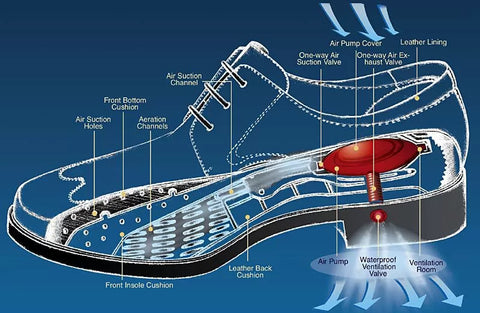

Illustrative Image (Source: Google Search)

Special Considerations for International B2B Buyers

1. Supplier Certifications and Documentation

Buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers with recognized certifications such as ISO 9001, ISO 14001 (environmental management), and industry-specific standards. Request detailed quality manuals, test reports, and certification copies to validate claims.

2. Factory Audits and Third-Party Inspections

Engaging reputable third-party inspection agencies (e.g., SGS, Bureau Veritas) provides independent verification of manufacturing processes and QC adherence. For buyers in regions with complex import regulations, such audits can preempt customs delays and compliance issues.

3. Communication and Traceability

Effective communication channels and transparent traceability systems are crucial. Suppliers should maintain detailed batch records, QC logs, and testing results accessible to buyers. This transparency is particularly vital for technologically complex products like air conditioned shoes, where component origin and assembly details impact quality.

4. Cultural and Regional Standards

Manufacturers in Turkey, Thailand, or other manufacturing hubs often adhere to local standards, which may differ from international norms. B2B buyers should ensure that suppliers understand and meet their specific regulatory requirements, including safety standards, environmental regulations, and import/export documentation.

Final Recommendations for B2B Buyers

- Establish clear quality specifications early in the procurement process, including performance benchmarks for cooling features and durability.

- Require comprehensive documentation—test reports, certifications, inspection certificates—to substantiate quality claims.

- Conduct or commission regular audits and factory visits, especially for long-term partnerships.

- Leverage third-party inspection services to validate supplier QC processes before shipment.

- Prioritize suppliers with proven experience in manufacturing technologically advanced footwear and those who demonstrate continuous improvement in quality management.

By understanding and scrutinizing the manufacturing and QC processes, international B2B buyers from Africa, South America, the Middle East, and Europe can mitigate risks, ensure product reliability, and establish resilient supply chains for air conditioned shoes.

Comprehensive Cost and Pricing Analysis for air conditioned shoes Sourcing

Cost Structure Overview for Air Conditioned Shoes

Understanding the comprehensive cost structure is vital for international B2B buyers to negotiate effectively and optimize procurement strategies. The primary cost components include:

-

Materials: High-quality, breathable fabrics, integrated cooling technology components (e.g., microfans, thermoelectric modules), and durable soles contribute significantly to material costs. Premium materials and advanced cooling features can elevate costs by 20-30% compared to conventional footwear.

-

Labor: Manufacturing costs vary widely based on the sourcing country. For instance, factories in Turkey or Thailand often offer competitive labor rates, whereas some African or South American producers may have higher wages or limited automation, influencing overall costs.

-

Manufacturing Overheads: These include factory utilities, equipment depreciation, and quality assurance processes. Factories with advanced automation and efficient processes tend to have lower overheads, impacting the final price.

-

Tooling and Molds: Custom molds for unique shoe designs or cooling components require upfront investment, typically amortized over large production runs. For small MOQ (Minimum Order Quantity), tooling costs can significantly inflate unit prices.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability, especially for tech-integrated shoes. Higher QC standards, including certifications for safety and durability, can add 5-10% to manufacturing costs.

-

Logistics and Shipping: Shipping costs depend on order volume, destination country, and chosen Incoterms. For Africa and South America, freight costs are often higher due to longer transit routes and limited direct shipping options. Air freight offers speed but at a premium, whereas sea freight reduces costs but extends lead times.

-

Profit Margin: Suppliers typically aim for a margin of 15-30%, influenced by competitive landscape, order volume, and customization complexity.

Price Influencers and Their Impact

Several factors influence the final pricing of air conditioned shoes:

-

Order Volume and MOQ: Larger orders often unlock volume discounts, reducing unit costs. Buyers should negotiate for favorable MOQs, especially when dealing with new suppliers or for testing market acceptance.

-

Specifications and Customization: Customized designs, branding, or specific cooling technology integrations increase costs. Precise specifications require detailed negotiations to balance features with budget constraints.

-

Material Choices: Opting for advanced, lightweight, or eco-friendly materials can elevate costs but may also justify premium pricing or appeal to specific markets.

-

Quality Certifications: International standards such as ISO, CE, or local safety certifications add to costs but enhance product credibility, especially in European markets.

-

Supplier Factors: Supplier experience, reputation, and production capacity influence pricing. Established suppliers with proven quality records may command higher prices but reduce risk.

-

Incoterms and Shipping Arrangements: FOB (Free on Board) pricing might be lower but shifts shipping responsibilities to the buyer. CIF (Cost, Insurance, Freight) includes shipping costs, simplifying logistics but increasing total cost.

Strategic Tips for International B2B Buyers

-

Negotiate for Volume Discounts: Larger orders or long-term partnerships often unlock better pricing and terms. Clarify MOQ requirements upfront to avoid surprises.

-

Focus on Total Cost of Ownership (TCO): Consider not just unit price but also shipping, customs duties, taxes, and after-sales support. For example, importing to Africa or South America may involve higher customs duties, impacting overall cost.

-

Leverage Multiple Suppliers: Diversify sourcing to mitigate risks, especially if certain regions face logistical or political challenges. Multiple sources can also foster competitive pricing.

-

Understand Pricing Nuances: Be aware that lower upfront prices may come with longer lead times or less reliable quality. Conversely, premium pricing may include faster delivery and higher quality assurance.

-

Be Mindful of Incoterms: Choose terms that align with your logistics capabilities. FOB terms might be preferable if you have reliable freight partners, while CIF can simplify customs clearance.

Price Range and Indicative Costs

As a guideline, the unit price for air conditioned shoes from established manufacturers ranges approximately from $25 to $60 per pair, depending on specifications, order volume, and supplier region. Higher-end, customized, or technologically advanced variants can exceed $70. Importantly, prices from Asian suppliers (e.g., Thailand, China) tend to be more competitive, whereas European or Turkish manufacturers may offer higher quality but at increased costs.

Disclaimer: These prices are indicative and subject to fluctuation based on market conditions, currency exchange rates, and specific supplier negotiations. Engaging directly with multiple suppliers and requesting detailed quotations is essential for accurate budgeting.

By understanding these cost dynamics and influencing factors, B2B buyers from Africa, South America, the Middle East, and Europe can develop informed sourcing strategies, optimize procurement costs, and build resilient supply chains for innovative air conditioned footwear.

Spotlight on Potential air conditioned shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for air conditioned shoes.)*

Essential Technical Properties and Trade Terminology for air conditioned shoes

Critical Technical Properties for Air Conditioned Shoes

1. Material Grade and Composition

The choice of materials—such as breathable fabrics, moisture-wicking insoles, and lightweight plastics—is vital. High-grade materials ensure durability, comfort, and effective cooling performance. For B2B buyers, verifying material specifications helps assess product quality and compliance with regional standards, especially important for markets with strict regulations like Europe and the Middle East.

2. Thermal Regulation Technology

This property refers to the integrated cooling mechanisms, such as micro-ventilation channels, phase-change materials, or embedded fans. The efficacy of these systems directly impacts customer satisfaction and brand reputation. Suppliers should provide technical data on cooling duration, airflow rates, and energy consumption to facilitate comparative evaluation.

3. Tolerance Levels and Manufacturing Precision

Tolerance specifications define permissible deviations in dimensions (e.g., sole thickness, shoe width). Tight tolerances (e.g., ±0.5mm) reflect higher manufacturing quality, reducing post-production issues like fitment problems or premature wear. For international buyers, understanding tolerance levels ensures product consistency across large orders and reduces returns.

4. Power Source and Energy Efficiency

Most air-conditioned shoes rely on rechargeable batteries or USB-powered systems. Key specs include battery capacity (mAh), charging time, and operational duration per charge. Energy-efficient designs lower operational costs and appeal to eco-conscious markets, especially in regions emphasizing sustainable products.

5. Weight and Ergonomics

The overall weight impacts comfort, especially for prolonged wear. Lightweight, ergonomically designed shoes are preferred in active or professional settings. Specifications should detail weight per shoe and ergonomic features that enhance user experience, crucial for competitive differentiation.

6. Durability and Water Resistance

Given diverse climates—humid in Africa and Southeast Asia or dry in the Middle East—durability and water resistance ratings (e.g., IPX4) are critical. These properties influence product lifespan and suitability for different environments, affecting after-sales service and warranty considerations.

Common Industry and Trade Terms

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce shoes based on a buyer’s specifications and branding. Understanding OEM capabilities allows buyers to customize designs, features, and technology integrations, enabling tailored solutions for different markets.

2. MOQ (Minimum Order Quantity)

The smallest number of units a manufacturer is willing to produce per order. Knowing MOQ helps buyers plan procurement budgets and inventory levels. Larger MOQs often lead to lower unit costs but require more upfront investment.

3. RFQ (Request for Quotation)

A formal document submitted by buyers requesting price, lead times, and technical details from suppliers. Properly structured RFQs facilitate clear communication and enable accurate comparisons among potential partners, especially when sourcing across continents.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and tariffs between buyers and sellers (e.g., FOB, CIF, DDP). Mastery of Incoterms ensures clarity on cost-sharing and risk management, which is essential for smooth international transactions.

5. Certification and Compliance Terms

Includes standards like CE (Europe), UL (US), or ISO certifications. These assure product safety, quality, and environmental compliance, which are often mandatory in regulated markets such as Europe and the Middle East.

6. Lead Time

The period from order placement to product delivery. Accurate knowledge of lead times helps in supply chain planning, especially in regions with logistical challenges or customs delays. B2B buyers should negotiate realistic lead times aligned with their inventory cycles.

Understanding these technical properties and trade terms empowers international buyers to make informed decisions, negotiate effectively, and establish reliable supply chains for air-conditioned shoes across diverse markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the air conditioned shoes Sector

Market Overview & Key Trends

The air conditioned shoes sector is experiencing rapid growth driven by technological innovation, changing consumer preferences, and increasing health consciousness globally. Key drivers include the rising demand for comfortable, climate-controlled footwear suitable for diverse climates—particularly in regions with high temperatures like the Middle East, parts of Africa, and South America. For international B2B buyers, especially from these regions, sourcing opportunities are expanding as manufacturers develop more advanced, energy-efficient cooling systems integrated into footwear.

Emerging sourcing trends emphasize localized manufacturing and supply chain diversification. Countries such as Turkey, Thailand, and Vietnam are becoming pivotal hubs due to their robust footwear industries, cost advantages, and improving technological capabilities. Buyers from Africa and South America benefit from regional sourcing to minimize logistical costs and lead times, while European buyers often focus on integrating high-quality, innovative features with sustainable production practices.

Digital transformation is reshaping the market, with e-commerce platforms, B2B marketplaces, and supply chain analytics facilitating better sourcing decisions. Additionally, the adoption of Industry 4.0 technologies—such as automation, IoT sensors, and data-driven quality control—enhances production efficiency and product customization. This evolving landscape demands that international buyers stay informed about regional manufacturing strengths, technological advancements, and evolving consumer preferences to secure competitive advantages.

Market dynamics also show a trend toward premium, feature-rich products targeting niche segments like outdoor enthusiasts, healthcare markets, and corporate wellness initiatives. As the sector matures, collaborations with tech firms and startups are fostering innovative cooling mechanisms, making the sector more competitive and diverse.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical criterion for international B2B buyers in the air conditioned shoes sector. The environmental impact of manufacturing processes—including energy consumption, waste generation, and material sourcing—directly influences purchasing decisions. Buyers from Africa, South America, the Middle East, and Europe are increasingly prioritizing suppliers that demonstrate strong environmental stewardship through transparent supply chains and sustainable practices.

Ethical sourcing encompasses fair labor practices, responsible material procurement, and adherence to international labor standards. Certifications such as Fair Trade, SA8000, and ISO 14001 are gaining prominence, serving as benchmarks for responsible manufacturing. These credentials not only mitigate reputational risks but also appeal to environmentally conscious consumers and corporate clients.

The adoption of ‘green’ materials is vital—biodegradable, recycled, or low-impact alternatives are gaining traction. For example, using recycled PET plastics for cushioning or natural, sustainably sourced textiles reduces ecological footprints. Energy-efficient manufacturing processes, such as solar-powered facilities or waste heat recovery systems, further align with sustainability goals.

For B2B buyers, establishing partnerships with suppliers committed to environmental and social responsibility enhances brand integrity and long-term viability. Engaging with suppliers that hold sustainability certifications, participate in environmental audits, and promote fair labor practices ensures compliance with evolving global standards and consumer expectations.

Brief Evolution/History (Optional)

The concept of cooling footwear emerged from the broader innovation wave in comfort and health-oriented footwear. Initially, air conditioned shoes were experimental, featuring basic ventilation systems. Over the past decade, technological advancements—such as microclimate control, phase change materials, and smart textiles—have transformed them into sophisticated products.

Manufacturers have shifted from niche markets to mainstream segments, driven by consumer demand for comfort and health benefits. This evolution is supported by advancements in lightweight materials, miniaturized cooling systems, and integration with wearable technology. For B2B buyers, understanding this trajectory offers insight into future innovations, enabling strategic sourcing and product development aligned with emerging trends.

Frequently Asked Questions (FAQs) for B2B Buyers of air conditioned shoes

-

How can I verify the credibility and reliability of an air conditioned shoe supplier?

To ensure supplier credibility, conduct thorough due diligence by requesting industry certifications, such as ISO or CE marks, which indicate compliance with international safety and quality standards. Review their business licenses, client references, and online reputation through trade platforms like Alibaba, Global Sources, or industry-specific directories. Consider requesting sample products to assess quality firsthand. Additionally, evaluate their communication responsiveness, transparency in pricing, and willingness to provide detailed product documentation. Engaging with suppliers who have a proven track record in international markets minimizes risks and builds a trustworthy foundation for your B2B partnership. -

What customization options are typically available, and how can I ensure they meet my market needs?

Most manufacturers offer customization in aspects such as branding, color schemes, design features, and even cooling technology specifications. To align products with your target market, communicate your specific requirements early, including any regional preferences or ergonomic standards. Request detailed customization proposals and prototypes before bulk production. Establish clear specifications, including materials, sizing, and cooling system integration, to avoid misunderstandings. Working with suppliers experienced in international markets ensures they understand regional trends and compliance, helping you deliver a product that appeals to your customers and stands out competitively. -

What are common MOQ, lead times, and payment terms I should expect when sourcing air conditioned shoes?

MOQ (Minimum Order Quantity) can vary widely—often ranging from 500 to 5,000 pairs—depending on the supplier’s production capacity and customization level. Lead times typically span 4 to 12 weeks, influenced by order complexity, production capacity, and logistics considerations. Payment terms usually include a 30% deposit upfront, with the balance payable before shipment, though flexible terms may be negotiated based on your order volume and relationship. Establish clear agreements upfront, and consider requesting FOB or CIF terms to better manage logistics and costs, especially when dealing with international suppliers. -

What quality assurance (QA) standards and certifications should I look for in suppliers?

Seek suppliers certified under recognized standards such as ISO 9001 (Quality Management), ISO 13485 (Medical Devices, if applicable), or specific safety standards relevant to your market (e.g., CE marking for Europe). Request detailed QA processes, including material testing, durability assessments, and cooling system safety checks. Suppliers should provide test reports and compliance certificates for each batch. Implementing a pre-shipment inspection or engaging third-party QC services ensures products meet specified standards before delivery, reducing the risk of returns, complaints, or regulatory issues in your target markets.

Illustrative Image (Source: Google Search)

- How can I effectively manage international logistics and customs clearance for air conditioned shoes?

Partner with experienced freight forwarders familiar with your target regions—Africa, South America, the Middle East, or Europe—to optimize shipping routes, costs, and transit times. Ensure all export documentation, such as commercial invoices, packing lists, and certificates of origin, are accurate and comply with local customs requirements. Consider incoterms like FOB or CIF to clarify responsibilities and costs. Stay updated on import tariffs, VAT, and regulatory restrictions in your destination countries. Establish clear communication channels with logistics providers to track shipments and handle delays proactively, ensuring timely delivery to your customers.

Illustrative Image (Source: Google Search)

-

What strategies can I use to resolve disputes or quality issues with international suppliers?

Start by establishing clear contractual terms, including quality standards, inspection procedures, and dispute resolution clauses (preferably arbitration or mediation). Maintain detailed records of communications, inspections, and product samples to support your case if issues arise. Engage local legal counsel familiar with international trade laws to advise on enforcement options. Foster open, ongoing dialogue with your supplier to address concerns promptly, aiming for collaborative solutions. Building strong relationships and setting transparent expectations upfront significantly reduces the likelihood of disputes and facilitates smoother resolution processes when issues occur. -

How do I evaluate the total cost of sourcing air conditioned shoes from international suppliers?

Assess all cost components: unit price, MOQ, shipping, customs duties, taxes, currency exchange fees, and potential tariffs. Factor in lead times and potential storage costs to avoid stockouts or overstocking. Consider quality-related costs, including inspection and potential rework or returns. Negotiating favorable payment terms and bulk discounts can also reduce overall expenses. Conduct a comprehensive cost analysis periodically, comparing local sourcing options versus international suppliers, to ensure your procurement remains cost-effective and aligned with your profit margins and market pricing strategies. -

What are key considerations for building long-term partnerships with international suppliers of air conditioned shoes?

Focus on establishing trust through consistent communication, timely payments, and collaborative problem-solving. Prioritize suppliers with proven compliance to quality standards and strong logistics networks. Invest in supplier development by sharing market insights and providing feedback, which can lead to better product innovation and service. Regular audits, site visits, and performance reviews help maintain high standards. Building strategic relationships often results in better pricing, priority production scheduling, and tailored solutions, giving you a competitive edge in your target markets. Cultivating mutual growth ensures sustainability and resilience in your supply chain.

Strategic Sourcing Conclusion and Outlook for air conditioned shoes

Strategic Sourcing Outlook for Air Conditioned Shoes

Effective strategic sourcing is crucial for international buyers seeking to capitalize on the growing demand for air conditioned shoes. By establishing strong relationships with reliable manufacturers—particularly in emerging manufacturing hubs like Turkey, Thailand, and key suppliers in South America and Africa—buyers can secure high-quality products at competitive prices. Diversifying supply chains and conducting thorough due diligence will mitigate risks related to quality, lead times, and geopolitical uncertainties.

Investing in supplier development and fostering long-term partnerships can lead to better innovation, customization, and cost efficiencies, enabling buyers to differentiate their offerings in competitive markets. As consumer preferences evolve toward comfort and health-conscious footwear, sourcing strategies should prioritize sustainable and technologically advanced manufacturing practices.

Looking ahead, international B2B buyers should leverage market intelligence and emerging sourcing hubs to stay ahead of industry trends. Embracing digital procurement tools and fostering collaborative relationships will enhance agility and resilience. Now is the opportune moment to refine sourcing strategies, capitalize on regional manufacturing strengths, and position your business as a leader in the innovative air conditioned footwear market.