Master Sourcing and Quality Control for Foam Inside Shoes

Guide to Foam Inside Shoes

- Introduction: Navigating the Global Market for foam inside shoes

- Understanding foam inside shoes Types and Variations

- Key Industrial Applications of foam inside shoes

- Strategic Material Selection Guide for foam inside shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for foam inside shoes

- Comprehensive Cost and Pricing Analysis for foam inside shoes Sourcing

- Spotlight on Potential foam inside shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for foam inside shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the foam inside shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of foam inside shoes

- Strategic Sourcing Conclusion and Outlook for foam inside shoes

Introduction: Navigating the Global Market for foam inside shoes

In the competitive landscape of footwear manufacturing, the choice of foam inside shoes is a critical factor influencing comfort, durability, and overall product quality. For international B2B buyers—from manufacturers in Africa, South America, the Middle East, and Europe—understanding the nuances of foam materials and sourcing options is essential to maintain a competitive edge. This guide offers a comprehensive overview of the key elements shaping the foam inside shoe market, including types, materials, manufacturing processes, quality control, and sourcing strategies.

By equipping you with detailed insights into global suppliers, cost considerations, and market trends, this resource empowers you to make informed, strategic sourcing decisions. Whether you’re seeking cost-effective solutions or premium materials, understanding the intricacies of foam selection and supplier capabilities can optimize your supply chain and product performance.

Illustrative Image (Source: Google Search)

Furthermore, the guide addresses frequently asked questions and provides actionable recommendations tailored to diverse regional needs. For buyers operating in dynamic markets like Egypt, Spain, or other emerging and established manufacturing hubs, this knowledge ensures you can navigate the complexities of global sourcing confidently. Ultimately, mastering the essentials of foam inside shoes enhances your ability to deliver high-quality products while optimizing costs and establishing reliable supplier partnerships across continents.

Illustrative Image (Source: Google Search)

Understanding foam inside shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| EVA (Ethylene Vinyl Acetate) | Lightweight, flexible, good shock absorption, closed-cell foam | Athletic shoes, casual footwear, insoles | Pros: Cost-effective, versatile, easy to mold. Cons: Lower durability under heavy use. |

| PU (Polyurethane) | Dense, resilient, high rebound, good compression set resistance | Work boots, orthopedic insoles, luxury shoes | Pros: Long-lasting, supportive, high comfort. Cons: Heavier, higher cost. |

| Memory Foam | Viscoelastic, conforms to foot shape, slow recovery | Premium sneakers, orthopedics, insoles | Pros: Superior comfort, pressure relief. Cons: Can retain heat, higher price. |

| EVA Blends | Hybrid formulations combining EVA with other polymers | Sports footwear, fashion shoes | Pros: Enhanced durability and flexibility, customizable properties. Cons: Slightly more expensive. |

| Latex Foam | Natural or synthetic, highly elastic, excellent cushioning | Specialized sports, luxury footwear | Pros: Superior cushioning, elasticity. Cons: Less resistant to compression over time. |

EVA (Ethylene Vinyl Acetate)

EVA foam is renowned for its lightweight and flexible properties, making it a popular choice across various footwear segments. Its excellent shock absorption and ease of molding allow manufacturers to produce cost-effective insoles and midsoles that cater to casual and athletic shoes. For B2B buyers, EVA’s affordability and versatility are key advantages, especially when sourcing large quantities for mass-market footwear. However, its lower resilience under prolonged heavy stress may necessitate frequent replacement, which is a critical consideration for durability-focused applications in work or orthopedics footwear.

PU (Polyurethane)

Polyurethane foam offers a dense, resilient profile with high rebound characteristics, making it ideal for footwear requiring sustained support and longevity. Its resistance to compression set ensures that insoles retain their shape over time, which is vital for premium and orthopedic footwear markets. B2B buyers should consider PU’s higher cost and weight, balanced against its durability and comfort benefits. For applications in work boots or high-end shoes, PU provides a value proposition through its long-term performance, although initial procurement costs are higher.

Memory Foam

Memory foam is distinguished by its viscoelastic properties, conforming closely to foot contours and providing pressure relief. Its premium feel and comfort make it suitable for orthopedics, luxury sneakers, and high-performance insoles. B2B buyers targeting niche markets or premium segments should evaluate the higher price point against consumer demand for enhanced comfort. Memory foam’s tendency to retain heat can be a drawback in hot climates, requiring consideration of ventilation solutions. Its slow recovery time also influences the overall footwear design and manufacturing process.

EVA Blends

Blended foams combining EVA with other polymers offer tailored performance characteristics, balancing cost, durability, and flexibility. These formulations are increasingly popular in sports and fashion footwear, where customization of properties like hardness and rebound is essential. For B2B buyers, sourcing EVA blends allows for differentiation and adaptation to specific market needs, but it requires close collaboration with suppliers to ensure consistency and quality. Slightly higher costs compared to pure EVA are offset by enhanced performance and product differentiation.

Latex Foam

Latex foam, whether natural or synthetic, provides exceptional cushioning and elasticity, making it suitable for luxury and high-performance footwear. Its natural resilience supports active lifestyles and specialized sports shoes. B2B buyers should weigh latex’s superior comfort against its susceptibility to compression over extended use, which can impact long-term durability. Sourcing high-quality latex foam often involves considerations of sustainability and supply chain stability, especially for natural variants, influencing procurement strategies in different regions.

Key Industrial Applications of foam inside shoes

| Industry/Sector | Specific Application of foam inside shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Footwear Manufacturing | Cushioning in insoles for athletic and casual shoes | Enhances product comfort, boosts customer satisfaction, and reduces return rates | Consistent foam density, biocompatibility, and compliance with safety standards |

| Sports & Performance Gear | Shock absorption layers in high-performance sports shoes | Improves athlete performance and reduces injury risk, adding value to premium products | High resilience, lightweight properties, and durability under repeated impact |

| Medical & Orthopedic | Custom orthotic insoles with foam for therapeutic purposes | Provides tailored support, aiding in patient recovery and comfort | Medical-grade foam, moldability, and certification for healthcare compliance |

| Safety & Workwear | Impact-absorbing insoles in safety shoes for industrial workers | Reduces fatigue and injury, ensuring worker safety and compliance with occupational standards | Flame retardant, slip-resistant, and resistant to oils and chemicals |

| E-commerce & Customization | Modular foam inserts for personalized footwear solutions | Enables customization, enhances value proposition, and caters to niche markets | Versatile, easy to cut or shape, and stable under various environmental conditions |

Footwear Manufacturing

Foam inside shoes is primarily used as cushioning in insoles, serving as the backbone of comfort in athletic, casual, and formal footwear. For international B2B buyers, sourcing high-quality foam with consistent density and resilience is critical to ensure product durability and customer satisfaction. Suppliers must adhere to safety and biocompatibility standards, especially for markets with strict regulations like Europe and North America. Reliable supply chains and certifications (e.g., ISO, OEKO-TEX) are essential for seamless integration into manufacturing processes across regions such as Egypt, Spain, and South America.

Sports & Performance Gear

In high-performance sports shoes, foam layers are integral to shock absorption, energy return, and lightweight design. These applications demand foams with high resilience and durability to withstand repeated impacts during rigorous activities. For B2B buyers in regions with active sports markets—such as parts of Europe and Latin America—sourcing advanced foams that meet performance standards enhances product differentiation. Emphasizing properties like moisture resistance and long-term resilience ensures the footwear maintains performance over time, appealing to premium sports brands globally.

Medical & Orthopedic

Foam inside shoes is vital for custom orthotic insoles used in medical and therapeutic contexts. These foams must be moldable, hypoallergenic, and compliant with healthcare regulations. Buyers from regions with growing healthcare markets—such as Egypt and South America—must prioritize medical-grade certifications and consistent quality to meet regulatory standards. Sourcing from suppliers with proven expertise in medical applications ensures the insoles provide effective support, aid recovery, and foster trust among healthcare providers and patients.

Safety & Workwear

Industrial safety footwear relies on impact-absorbing foam insoles to protect workers in hazardous environments. These foams reduce fatigue, prevent injuries, and help companies comply with occupational health standards. For buyers in regions with extensive industrial sectors like the Middle East and parts of Europe, sourcing fire-retardant, chemical-resistant, and slip-resistant foams is essential. Suppliers should demonstrate compliance with safety certifications such as EN standards and OSHA requirements, ensuring the insoles perform reliably under tough conditions.

E-commerce & Customization

Modular foam inserts enable personalized footwear solutions, appealing to niche markets and consumers seeking tailored comfort. These applications require versatile foams that are easy to cut, shape, and assemble, providing flexibility for customization. For B2B buyers targeting online retailers or bespoke footwear brands in Africa, South America, and Europe, sourcing stable, environmentally resistant, and easy-to-process foams supports scalable customization. Reliable supply of such materials can open new revenue streams and strengthen brand differentiation through bespoke offerings.

Strategic Material Selection Guide for foam inside shoes

Analysis of Common Foam Materials for Inside Shoes

Selecting the appropriate foam material for inside shoes requires careful consideration of performance, manufacturing complexity, cost, and compliance with international standards. Here, we analyze four prevalent foam materials—Polyurethane (PU), Ethylene Vinyl Acetate (EVA), Memory Foam (Viscoelastic Polyurethane), and Cross-linked Polyethylene (XLPE)—from a B2B perspective, emphasizing their suitability for global markets, especially Africa, South America, the Middle East, and Europe.

Polyurethane (PU) Foam

Key Properties:

PU foam is highly versatile, offering a broad range of densities and firmness levels. It exhibits excellent shock absorption, resilience, and durability, making it a popular choice for insoles. It performs well across a wide temperature range and has good chemical resistance, although it can be susceptible to hydrolysis over time.

Pros & Cons:

PU foam’s advantages include high durability, customizable properties, and ease of manufacturing. However, it tends to be more expensive than EVA and requires more complex processing, which can impact lead times. Its chemical composition can raise concerns regarding VOC emissions, especially in regions with strict environmental standards.

Impact on Application:

PU foam is compatible with various adhesives and can be molded or cut to fit different shoe designs. Its resilience makes it suitable for high-impact footwear, and it generally performs well in humid or variable climates, provided proper sealing is employed.

International Buyer Considerations:

For buyers in Europe and the Middle East, compliance with VOC emission standards (e.g., REACH, CARB) is critical. In Africa and South America, cost sensitivity may favor lower-density variants, but durability remains essential. Manufacturers should verify local standards and ensure suppliers provide certifications such as ISO or ASTM compliance.

Ethylene Vinyl Acetate (EVA)

Key Properties:

EVA foam is lightweight, flexible, and exhibits excellent shock absorption. It has good chemical resistance and performs reliably across a range of temperatures, though it can soften in high heat. Its open-cell structure provides breathability, beneficial for moisture management inside shoes.

Pros & Cons:

EVA is cost-effective, easy to process, and suitable for mass production, making it attractive for large-scale manufacturing. Its primary limitation is lower durability compared to PU, especially under prolonged stress or heavy use. EVA can also degrade over time when exposed to UV or extreme heat, which can be a concern in hot climates.

Impact on Application:

Ideal for casual and athletic footwear, EVA’s flexibility and lightness improve comfort. It is compatible with various bonding agents and can be molded into complex shapes, but its lower resilience necessitates reinforcement in high-wear zones.

International Buyer Considerations:

EVA’s low cost and ease of processing make it popular in emerging markets. Buyers should ensure suppliers adhere to environmental standards, as some EVA formulations may contain phthalates or other additives restricted in certain regions. Certification to standards like ASTM D3574 is advisable.

Memory Foam (Viscoelastic Polyurethane)

Key Properties:

Memory foam offers superior cushioning by conforming to the foot’s shape, providing excellent pressure distribution. It has moderate resilience, with slow recovery times, and performs well in temperature-sensitive environments. It is generally resistant to moisture but can retain heat, which may affect comfort.

Pros & Cons:

The main advantage is enhanced comfort and support, making it suitable for premium footwear. Its drawbacks include higher cost, potential for heat retention, and lower durability under repeated compression. Manufacturing complexity is higher due to specialized processing requirements.

Impact on Application:

Memory foam is often used in orthotic insoles or high-end athletic shoes. Its temperature sensitivity requires consideration in hot climates, as it can lead to discomfort. Proper ventilation and moisture management are essential for optimal performance.

International Buyer Considerations:

Buyers should verify that memory foam complies with health and safety standards, especially regarding off-gassing and VOC emissions. In regions like Europe, adherence to REACH regulations is vital. Cost considerations may limit its use to premium segments in Africa and South America.

Cross-linked Polyethylene (XLPE)

Key Properties:

XLPE foam is known for its excellent chemical resistance, low water absorption, and high resilience. It maintains its properties over a wide temperature range and offers good impact absorption. Its cross-linked structure provides superior dimensional stability and durability.

Pros & Cons:

While highly durable and resistant to environmental factors, XLPE is more expensive and requires specialized manufacturing processes, such as extrusion and cross-linking. It is less flexible than EVA or PU, which can limit its use in certain shoe designs.

Impact on Application:

XLPE is suitable for insoles in work or safety shoes where durability and chemical resistance are priorities. It performs well in harsh environments, including exposure to oils, solvents, and moisture.

International Buyer Considerations:

For buyers in regions with strict environmental or safety standards, ensuring that XLPE formulations are free from hazardous additives is essential. Certification to standards like ASTM or DIN can facilitate acceptance in global markets.

Summary Table

| Material | Typical Use Case for foam inside shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane (PU) | High-impact athletic and orthotic insoles | Highly durable, customizable | Higher cost, complex manufacturing | High |

| Ethylene Vinyl Acetate (EVA) | Casual, athletic, lightweight footwear | Cost-effective, lightweight | Lower durability, heat softening | Low |

| Memory Foam (Viscoelastic PU) | Premium orthotics, high-end athletic shoes | Superior comfort, pressure distribution | Expensive, heat retention | Med |

| Cross-linked Polyethylene (XLPE) | Work, safety, and outdoor footwear | Excellent chemical resistance, durability | Higher cost, less flexible | High |

This comprehensive analysis aims to guide international B2B buyers in selecting the most suitable foam materials based on application needs, environmental considerations, and regional standards. Ensuring compliance and understanding the trade-offs associated with each material will optimize product performance and market acceptance across diverse regions.

In-depth Look: Manufacturing Processes and Quality Assurance for foam inside shoes

Manufacturing Processes for Foam Inside Shoes

The production of foam inserts for footwear involves a series of carefully controlled stages to ensure product consistency, performance, and safety. Understanding these stages enables B2B buyers to better evaluate supplier capabilities and compliance with international standards.

Material Preparation

The process begins with selecting high-quality raw materials, primarily polyurethane (PU), ethylene-vinyl acetate (EVA), or memory foam, depending on the desired properties such as cushioning, durability, and flexibility. Suppliers often source these materials from reputable chemical companies with certifications like ISO 9001 and ISO 14001 to ensure environmental compliance and quality management.

Material preparation involves precise mixing and compounding. Additives such as flame retardants, anti-microbial agents, or anti-odor substances are incorporated at this stage. Proper storage conditions and handling are critical to prevent contamination or degradation that could compromise foam integrity.

Forming and Molding

Foam formation typically employs techniques like extrusion, compression molding, or casting. In extrusion, raw foam sheets are pushed through dies to achieve specific dimensions. Compression molding involves placing pre-measured foam blocks into molds and applying heat and pressure to shape them into the desired form.

Innovative manufacturing facilities utilize advanced automation and precision molds to produce consistent foam shapes, such as insoles or cushioning pads. Proper temperature control and curing times are vital to prevent defects like porosity, warping, or incomplete curing.

Assembly and Integration

Once formed, foam components undergo trimming, shaping, and surface finishing. Automated cutting machines ensure dimensional accuracy, while surface treatments can improve adhesion with other shoe components or enhance aesthetic appeal.

Assembly involves attaching foam inserts to the shoe’s upper or midsole using adhesives, heat bonding, or mechanical fasteners. The choice of method depends on the shoe design, foam material, and intended use. High-quality adhesives compliant with international safety standards are crucial to ensure durability and safety.

Finishing and Packaging

Final inspection includes surface cleaning, defect removal, and packing. Some manufacturers apply protective coatings or anti-microbial treatments at this stage. The foam inserts are then packaged in moisture-proof, recyclable materials suitable for export.

Quality Control (QC) in Foam Shoe Manufacturing

Effective quality assurance is essential for meeting international standards and satisfying B2B buyers’ expectations. Manufacturers typically implement multi-tiered QC processes aligned with recognized standards such as ISO 9001, ISO 14001, and industry-specific certifications like CE (European conformity) or API standards (for industrial applications, where relevant).

QC Checkpoints

-

Incoming Quality Control (IQC): Raw materials are tested upon receipt for parameters such as density, cell structure, tensile strength, and chemical composition. Suppliers should provide test reports and certifications from accredited laboratories.

-

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring ensures parameters like temperature, pressure, and curing time are within specified ranges. Dimensional checks, surface inspection, and adhesion tests are conducted regularly.

-

Final Quality Control (FQC): Finished foam components undergo comprehensive testing, including:

- Physical Tests: Compression set, resilience, tear strength, and elongation.

- Chemical Tests: Off-gassing, VOC emissions, and allergen presence.

- Performance Tests: Shock absorption, durability under cyclic loading, and aging tests.

Common Testing Methods

- ASTM and ISO Standards: These provide standardized procedures for foam testing, such as ASTM D3574 for flexible cellular materials.

- Accelerated Aging: Simulates long-term use conditions to verify foam stability.

- Adhesion and Compatibility Tests: Ensuring foam bonds securely with adhesives and other shoe components.

- Environmental Tests: Humidity, temperature cycling, and UV exposure to assess environmental resilience.

Verifying Supplier Quality for International B2B Buyers

Given the importance of consistent quality, international buyers should adopt rigorous verification methods:

- Supplier Audits: Conduct on-site audits focusing on manufacturing facilities, QC processes, and workforce qualifications. For buyers from regions like Egypt or Spain, local agents or third-party inspection firms can facilitate audits efficiently.

- Review of Certification Documents: Request ISO 9001 certificates, test reports, and compliance certificates such as CE marking or REACH registration for chemical substances.

- Third-Party Inspection and Testing: Engage independent inspection agencies (e.g., SGS, Bureau Veritas) to verify sample conformity, production consistency, and QC adherence before shipment.

- Sample Testing: Perform independent testing on samples received to validate specifications and compliance with international standards.

Industry-Specific and Regional QC Nuances

Different regions impose specific requirements that B2B buyers must consider:

- Africa and South America: There may be less stringent local regulations, but international standards (ISO, ASTM) are critical for export compliance. Buyers should verify supplier adherence through third-party audits and certification reviews.

- Middle East: Emphasizes compliance with safety and fire-retardant standards (e.g., NFPA, local fire codes). Suppliers should demonstrate testing for flammability and VOC emissions.

- Europe (e.g., Spain): Strict enforcement of chemical safety (REACH), eco-labeling, and environmental standards. Suppliers must provide comprehensive documentation and testing reports aligned with these regulations.

Actionable Recommendations for B2B Buyers

- Establish Clear Specifications: Define material properties, performance standards, and testing requirements upfront.

- Demand Certification and Traceability: Require suppliers to provide traceability data, test certificates, and compliance documentation.

- Implement Regular Audits and Inspections: Schedule periodic audits, either in person or via trusted third-party inspectors, to ensure ongoing compliance.

- Leverage Technology: Use digital platforms for document verification, real-time QC reporting, and supply chain transparency.

- Build Long-Term Partnerships: Collaborate with suppliers committed to continuous improvement and adherence to international standards, fostering trust and consistent quality.

By understanding these manufacturing and QC processes, B2B buyers from Africa, South America, the Middle East, and Europe can make informed sourcing decisions, mitigate risks, and ensure the procurement of high-quality foam components that meet their market and regulatory requirements.

Comprehensive Cost and Pricing Analysis for foam inside shoes Sourcing

Cost Structure Breakdown for Foam Inside Shoes

Understanding the detailed cost components involved in sourcing foam for inside shoes is essential for effective negotiation and procurement planning. The primary cost elements include:

-

Materials: The type of foam (e.g., EVA, PU, memory foam) significantly influences cost. Premium, high-density, or specialized foams with enhanced durability or cushioning tend to be more expensive. Material costs can vary widely depending on quality standards, certifications (like REACH or OEKO-TEX), and regional supply chain factors.

-

Labor: Manufacturing labor costs depend on the sourcing country. For instance, factories in Egypt or Eastern Europe may have lower labor rates compared to Western Europe, but quality standards and labor laws influence overall expenses.

-

Manufacturing Overhead: This includes factory utilities, machinery depreciation, and administrative expenses. Overhead costs are often embedded in unit prices but can fluctuate based on factory efficiency, scale, and automation levels.

-

Tooling and Molds: Custom molds or specific cutting tools for foam shaping can incur significant upfront costs, especially for tailored designs or high-volume production. These costs are amortized over the production run, impacting unit pricing.

-

Quality Control (QC): Rigorous QC processes, including testing for foam density, elasticity, and safety certifications, add to the overall cost. Higher QC standards often correlate with higher costs but reduce the risk of defective shipments.

-

Logistics and Shipping: Freight costs depend on shipment volume, destination, and mode (sea, air, or land). For African, South American, or Middle Eastern buyers, inland transportation and customs clearance can significantly influence total landed costs.

-

Profit Margin: Suppliers typically add a margin to cover business risks and ensure sustainability. Margins vary based on supplier reputation, order volume, and negotiation outcomes.

Key Price Influencers

Several factors directly impact foam pricing and should be carefully evaluated:

-

Order Volume and Minimum Order Quantities (MOQs): Larger orders usually attract better per-unit prices due to economies of scale. For buyers from regions like Africa or South America, establishing consistent order volumes can lead to substantial cost savings.

-

Specifications and Customization: Tailored foam properties—such as specific densities, thicknesses, or branding—may increase costs. Standardized products are cheaper but may lack the desired performance features.

-

Material Choice: Premium foams with enhanced features (e.g., anti-microbial, eco-friendly) command higher prices. Material certifications and origin also influence pricing, especially when sourcing from regions with stricter environmental standards.

-

Quality Certifications: Suppliers with ISO, OEKO-TEX, or other industry certifications often charge a premium due to compliance costs but provide assurance of safety and durability.

-

Supplier Factors: Supplier reputation, manufacturing capacity, and experience can affect pricing. Established suppliers in Europe or Asia often have higher costs but may offer better consistency and quality.

-

Incoterms and Shipping Terms: FOB (Free On Board) prices are common, but buyers should consider additional costs such as freight, insurance, and customs fees, especially when sourcing from distant regions.

Strategic Tips for International B2B Buyers

-

Negotiate for Volume Discounts: Leverage larger, consistent orders to negotiate better prices, especially if you can commit to long-term partnerships.

-

Focus on Total Cost of Ownership (TCO): Consider not just the unit price but also costs related to quality issues, rework, returns, and logistics. Sometimes paying slightly more upfront reduces downstream expenses.

-

Explore Multiple Suppliers: Diversify sourcing to mitigate risks and compare pricing structures. Regional suppliers in Egypt or Spain might offer competitive rates with shorter lead times.

-

Understand Pricing Nuances: Be aware that initial quotations may exclude additional costs such as customs duties or inland transportation. Clarify all costs upfront to avoid surprises.

-

Customization vs. Standardization: Balance the need for product-specific features with cost-efficiency. Standard foam solutions can significantly reduce costs, but may require compromises on performance.

-

Timing and Lead Times: Manufacturing costs can fluctuate based on seasonal demand and raw material availability. Early planning and forecasting can lock in better rates.

Disclaimer on Price Indicators

Indicative prices for foam inside shoes can range from approximately $1.50 to $4.00 per pair, depending on foam type, volume, and region. Premium or specialized foams may cost more, and logistical costs can further influence the final landed price. Always conduct direct supplier inquiries for tailored quotations aligned with your specific requirements and market conditions.

By thoroughly analyzing these cost and pricing factors, B2B buyers from Africa, South America, the Middle East, and Europe can develop strategic sourcing plans, negotiate effectively, and optimize their total cost of ownership in the competitive foam-inside-shoes market.

Spotlight on Potential foam inside shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for foam inside shoes.)*

Essential Technical Properties and Trade Terminology for foam inside shoes

Key Technical Properties of Foam Inside Shoes

Understanding the technical specifications of foam materials is vital for making informed purchasing decisions and ensuring product quality. Here are the critical properties to evaluate:

-

Material Grade

This refers to the quality level of the foam, often categorized by standards such as density, firmness, and durability. Higher-grade foams typically offer better resilience and longevity, which are crucial for premium footwear markets. B2B buyers should specify desired grades based on target product positioning and end-user expectations. -

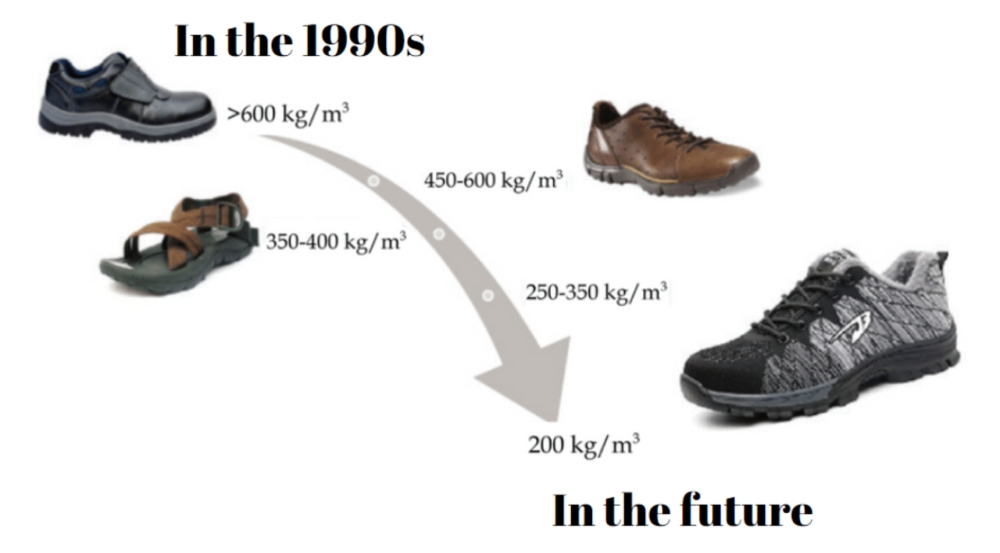

Density

Density, measured in kilograms per cubic meter (kg/m³), indicates the weight and compactness of the foam. Denser foams usually provide superior support and durability but may be heavier. Balancing density with comfort and performance is essential, especially for high-performance or orthopedic shoes. -

Compression Set

This property measures the foam’s ability to recover after compression. A low compression set (typically below 10%) means the foam retains its shape over time, which is critical for maintaining shoe cushioning and comfort during prolonged wear. -

Tensile and Tear Strength

These properties reflect the foam’s resistance to breaking under tension or tearing. High tensile and tear strengths are desirable for shoes subjected to frequent flexing and stress, ensuring the foam maintains its integrity throughout product life. -

Hardness (Shore A or D)

Hardness indicates the foam’s firmness, measured by Shore scales. Softer foams (lower Shore A) offer cushioning, while firmer foams (higher Shore D) provide support. Selecting the appropriate hardness level depends on the shoe’s purpose and target consumer preferences. -

Thermal and Water Resistance

Foam used inside shoes should withstand temperature variations and moisture exposure. Properties like water absorption rate and thermal insulation influence comfort, especially in diverse climates across Africa, South America, the Middle East, and Europe.

Essential Industry and Trade Terms

Clear understanding of industry jargon streamlines communication and negotiations. Here are key terms every B2B buyer should know:

-

OEM (Original Equipment Manufacturer)

Refers to companies that produce foam components or shoes based on specifications provided by brand owners. Recognizing OEM relationships helps buyers understand production capabilities and potential customization options. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce or sell. Knowing MOQs helps buyers plan procurement volumes, negotiate better terms, and avoid overstocking or shortages. -

RFQ (Request for Quotation)

A formal document issued by buyers to suppliers requesting price, lead times, and terms for specific foam products. RFQs are essential for comparing supplier offerings and ensuring competitive pricing. -

Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce, defining responsibilities for shipping, insurance, and tariffs. Familiarity with Incoterms (e.g., FOB, CIF) ensures clarity in delivery obligations and cost-sharing. -

Lead Time

The period from placing an order to receiving the foam products. Understanding lead times helps in planning production schedules and inventory management, especially in regions with logistical challenges. -

Certifications (e.g., REACH, ISO)

Industry certifications verify compliance with safety, environmental, and quality standards. Ensuring foam materials meet relevant certifications is critical for market access, particularly in Europe and the Middle East.

Strategic Insights for B2B Buyers

By thoroughly evaluating these properties and understanding trade terminology, buyers from Africa, South America, the Middle East, and Europe can make more confident procurement decisions. Emphasizing quality specifications aligned with regional climatic conditions and end-use requirements ensures product performance and customer satisfaction. Additionally, mastering trade terms facilitates smoother negotiations, clearer contracts, and efficient supply chain management across diverse international markets.

Illustrative Image (Source: Google Search)

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the foam inside shoes Sector

Market Overview & Key Trends

The global foam inside shoes market is driven by increasing consumer demand for comfort, lightweight footwear, and innovative design. Major manufacturing hubs in Asia, particularly China and Vietnam, continue to dominate supply chains due to cost efficiencies and advanced production capabilities. However, emerging markets in Africa, South America, the Middle East, and Europe are witnessing significant shifts driven by regional growth, consumer preferences, and sustainability commitments.

For international B2B buyers from regions like Egypt, Spain, and South American countries, understanding regional sourcing trends is crucial. In Europe, there is a strong push toward high-performance, eco-friendly foams, with buyers favoring suppliers offering sustainable certifications. Middle Eastern markets often prioritize premium quality and innovative cushioning solutions, aligning with luxury and sports footwear segments. Conversely, African and South American buyers increasingly seek cost-effective, reliable sources without compromising quality, often turning to regional manufacturers or diversified global suppliers.

Technological innovations such as bio-based foams, recycled materials, and advanced manufacturing processes like extrusion and mold-injection are transforming the market. Digital sourcing platforms and supply chain transparency tools are becoming essential for B2B buyers aiming to reduce lead times and ensure quality consistency. Additionally, customization capabilities—such as tailored foam densities and specific damping properties—are gaining importance for brands seeking differentiation.

Market dynamics are also influenced by fluctuating raw material costs, geopolitical stability, and trade policies. For example, tariffs and import-export regulations can impact sourcing decisions, prompting buyers to explore regional diversification or local production partnerships. As sustainability becomes a core criterion, the demand for ‘green’ foam materials that meet environmental standards is expected to grow, shaping future procurement strategies.

Sustainability & Ethical Sourcing in B2B

Sustainability in the foam inside shoes sector has transitioned from a niche consideration to a primary purchasing criterion. Environmental impacts of traditional foam production—such as high energy consumption, volatile petrochemical use, and waste generation—are prompting brands and suppliers to adopt greener practices. B2B buyers across Africa, South America, the Middle East, and Europe are increasingly scrutinizing supply chains for environmental responsibility, seeking suppliers that demonstrate transparency and sustainability credentials.

Certifications like ISO 14001, Global Recycled Standard (GRS), and OEKO-TEX Standard 100 are becoming essential benchmarks. These certifications ensure that foam materials are produced with minimal environmental impact, utilizing recycled or bio-based inputs and adhering to strict manufacturing standards. For instance, bio-foams made from renewable resources such as algae or cornstarch offer eco-friendly alternatives to traditional polyurethane foams, reducing reliance on fossil fuels.

Ethical sourcing also encompasses fair labor practices, safe working conditions, and supply chain transparency. Many brands now require suppliers to adhere to ethical codes aligned with international labor standards, often verified through third-party audits. Developing strong partnerships with certified suppliers not only mitigates reputational risks but also aligns procurement with global sustainability goals.

Investing in sustainable materials and ethical supply chains can also provide competitive advantages—such as access to eco-conscious markets and compliance with stricter regulations—making it a strategic imperative for B2B buyers aiming for long-term resilience and brand integrity.

Brief Evolution/History (Optional)

The foam inside shoes sector has evolved significantly over the past few decades, transitioning from basic cushioning materials to highly engineered, sustainable solutions. Initially dominated by petrochemical-based polyurethane foams, the industry has seen a shift toward bio-based and recycled materials driven by environmental concerns and regulatory pressures. Advances in polymer science have enabled the development of lightweight, durable, and customizable foams that enhance comfort and performance.

This evolution has been supported by innovations in manufacturing technology, which have improved quality control, reduced waste, and lowered costs. Additionally, increasing consumer awareness and demand for sustainable products have prompted brands to incorporate eco-friendly foams into their offerings, influencing sourcing strategies globally. For B2B buyers, staying abreast of these developments is essential to leverage new materials, meet regulatory standards, and satisfy evolving market expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of foam inside shoes

1. How can I verify the reliability and quality standards of foam inside shoe suppliers?

To ensure supplier credibility, start with comprehensive due diligence. Request industry certifications such as ISO 9001 for quality management and environmental standards like REACH or OEKO-TEX. Examine their product testing reports, including foam durability, elasticity, and safety compliance relevant to your target markets. Additionally, review references or seek samples for physical inspection. Engaging with suppliers who have a proven track record in international markets and positive customer reviews minimizes risks. Consider visiting manufacturing sites or hiring third-party inspectors for on-site audits, especially if large volume orders are involved.

2. What are the typical customization options available for foam inside shoes, and how do they impact lead times?

Suppliers often offer customization in foam density, thickness, shape, and color to meet specific brand or comfort requirements. Advanced options include adding antimicrobial properties or specific cushioning profiles. Customization may extend lead times by 2-6 weeks depending on complexity, tooling, and supplier capacity. To streamline production, clearly communicate your specifications upfront and request detailed prototypes or samples before bulk manufacturing. Establishing a strong relationship with suppliers who have flexible R&D teams can accelerate customization processes, especially for urgent orders or market-specific adaptations.

3. What are the common MOQ (Minimum Order Quantity), lead times, and payment terms for international foam inside shoe sourcing?

MOQ varies significantly based on supplier size and production capacity, typically ranging from 1,000 to 10,000 pairs or equivalent weight/volume of foam. Lead times generally span 4-12 weeks, influenced by order complexity, customization, and logistics. Payment terms often include 30% upfront payment with the balance paid before shipment or upon delivery. Negotiating flexible terms is possible, especially for repeat business or larger orders. Building strong relationships and demonstrating reliable payment history can unlock better terms, while clear contracts reduce risks associated with currency fluctuations and delayed payments.

4. What certifications and quality assurance processes should I look for in foam suppliers?

Key certifications include ISO 9001 for quality management, ISO 14001 for environmental responsibility, and industry-specific safety standards like REACH or OEKO-TEX. Suppliers should provide comprehensive QA documentation, including incoming raw material inspection, in-process controls, and final product testing. Request certificates of compliance and third-party testing reports for foam safety, durability, and non-toxicity. Establishing strict quality assurance protocols, such as random sampling and third-party audits, ensures consistent product standards and reduces the risk of non-compliance in your target markets.

5. How can I manage logistics and shipping when importing foam inside shoes from overseas suppliers?

Effective logistics management involves selecting reliable freight forwarders experienced in handling lightweight, bulky materials like foam. Consider shipping options—sea freight for cost efficiency on large volumes, air freight for urgent orders. Clarify incoterms (e.g., FOB, CIF) with your supplier to define responsibilities. Ensure proper packaging to prevent deformation during transit. Additionally, account for customs clearance procedures, tariffs, and import regulations specific to your country (e.g., Egypt, Spain). Building strong communication channels with logistics providers and maintaining transparent documentation simplifies customs processes and minimizes delays.

6. What are common dispute resolution mechanisms in international foam supplier agreements?

Disputes often arise over quality issues, delivery delays, or payment disagreements. To mitigate risks, include clear contractual clauses specifying dispute resolution methods—preferably arbitration under recognized rules (e.g., ICC, LCIA)—located in neutral jurisdictions. Define detailed quality standards and inspection rights, and specify remedies such as refunds, replacements, or penalties. Maintain comprehensive documentation of all communications, inspections, and transactions. Engaging legal counsel familiar with international trade laws ensures your agreements are enforceable and aligned with local regulations, safeguarding your interests in cross-border transactions.

7. How do I ensure compliance with environmental and safety standards in foam production for different markets?

Research and adapt to regional regulations—EU’s REACH and EUROPOL standards, Middle Eastern safety regulations, or South American environmental laws. Choose suppliers committed to sustainable practices, such as using non-toxic, biodegradable raw materials, and minimizing waste. Request environmental compliance certificates and sustainability reports. Incorporate clauses in your contracts requiring suppliers to adhere to evolving standards. Regular audits and third-party certifications can verify ongoing compliance. This proactive approach not only mitigates legal risks but also appeals to environmentally conscious consumers and enhances your brand reputation.

8. What are best practices for handling potential disputes or quality issues post-shipment?

Establish clear communication channels with your supplier for rapid issue escalation. Use detailed inspection reports and photographs to document quality concerns immediately upon receipt. Implement a structured claim process outlined in your contract, including timelines for reporting issues and resolution expectations. Engage third-party inspectors or testing labs for unbiased assessments if needed. Consider including arbitration clauses or alternative dispute resolution mechanisms to resolve disagreements efficiently. Maintaining professional, transparent dialogue and fostering collaborative problem-solving helps preserve supplier relationships and ensures swift resolution, minimizing supply chain disruptions.

Strategic Sourcing Conclusion and Outlook for foam inside shoes

Conclusion and Future Outlook

Effective strategic sourcing of foam inside shoes is essential for international B2B buyers aiming to optimize quality, cost, and sustainability. By prioritizing reliable supply chains, diversifying sourcing regions, and engaging with innovative manufacturers, buyers can mitigate risks and adapt swiftly to market fluctuations. Emphasizing transparency and compliance with regional standards further enhances competitiveness and brand reputation.

As the footwear industry continues to evolve—with increasing demand for eco-friendly materials and technological advancements—future sourcing strategies must incorporate sustainable practices and digital procurement solutions. Embracing these trends will unlock new opportunities for cost savings, product differentiation, and market expansion.

For buyers across Africa, South America, the Middle East, and Europe, establishing long-term partnerships with reputable foam suppliers is crucial. Proactively exploring emerging markets and fostering collaborative relationships will position you ahead of the curve. Moving forward, a strategic, adaptable approach to sourcing will be key to capturing growth and maintaining resilience in a dynamic global footwear landscape.